Shim It Once and Done. SAVE

Shim It Once and Done. SAVE

Grove Products, Inc. has the perfect shim for every job every time.

Grove Products, Inc. has the perfect shim for all your shimming needs. With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money.

Need help? Just ask! We’re here to help.

1-800-72-GROVE

Visit us online to see all of our available solid 3x4 Shims.

www.groveproductsinc.com

Free Samples are Available Upon Request.

Grove Products, Inc. is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

18 Challenge meets opportunity

Building science experts George Torok and Yvon Chiasson take a look at the evolution of window wall in Canada and where the standards are now.

22 Lighter gets stronger

The Glass Canada feature interview with Richard Collins, technology analyst at IDTechEx, on the promise of new lightweight building materials.

26 Home run, CGA

The Canadian Glass Association hosts a successful Glass Connections event in Burnaby, B.C.

30 Fabrication machinery

Benders, IG lines, edgers, coaters and more...

Undeterred by an oppressive regime in communist Poland, Ted Redlarski pursued his entrepreneurial dreams. Ultimately, they brought him all the way to southern Ontario, where he’s built Noram Glass, a leading building envelope fabricator.

Anyone can send you an email from anywhere in the world. But how do you know they are a supplier commited to serving you locally? Easy. Check the Glass Canada Buyer’s Guide, your comprehensive listing of Canada’s most trusted architectural glazing suppliers. Organized into popular product categories, the online Buyers Guide is your fastest way to find the right supplier for the products you need.

You do good work, you take pride in your work and you want to be able to make a decent living doing it. So it’s infuriating when some jerk swoops in to a project with a bid you know to be incomplete, priced at a level you know to be unsustainable. You know what lies in the client’s future. Cost overruns that will bring the price close to or above your own. Shoddy, hurried workmanship with inferior materials that will produce costly defects down the road. The quick insolvency of the rival contractor, possibly before the project is even completed. Or some combination of all three.

The question for glaziers committed to their craft is how to ensure quality in our industry in an environment where building owners and general contractors seem unable or unwilling to assess it themselves. I’ve been following some lively conversations on social media recently that revisit a lot of the familiar remedies to this problem. They fall into three main categories: government control; improved training and certification of glaziers; and doing nothing – letting market forces weed out the ignorant and unscrupulous.

• Codes update

• Grey PIB

• IGMA Fall Conference

Market forces are certainly effective and have the advantage of being incorruptible. But they lose effectiveness when there is a seemingly endless supply of the ignorant and unscrupulous to take the place of those who are weeded out. And then the public has to live with the results in the built environment.

Ensuring architectural glaziers are trained and competent would surely help. But the devil of how to do this is in the details. Taking a course and passing an exam is no guarantee of work ethic or expertise. No one has, to date, figured out the problem of how to get business owners to invest in training apprentices when journeypersons can leave and become the competition the minute they get their tickets. And control over certification regimes falls prey to competing interests and agenda.

All of this, of course, could be mooted if governments were able to tightly control building standards. A rigorous inspection regime that effectively prevented low-quality construction fairly and consistently would force everyone to step up their game and prevent the aforementioned ignorant and unscrupulous from hanging around and making everyone’s lives miserable. So all we have to do is figure out how to get governments to do the right thing. I’ll get back to you on that.

I’d like to suggest a fourth potential solution that doesn’t get talked about nearly as much: communication of quality. The difference between you and the jerk bidding against you is your quality. You know that – but does your client? Communicating commitment to quality and a value proposition is something glaziers often don’t do well. It’s called a brand, and building one requires some thought and investment. Your clients don’t want to deal with the ignorant and unscrupulous. They just may not understand the difference between them and you because you haven’t told them. •

August 2017

Volume 29 • Number 4

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexweb.com 226.931.0545

SALES MANAGER | Danielle LABRIE dlabrie@annexweb.com 519.429.5187

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexweb.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Alison KEBA

DIRECTOR OF SALES/GROUP

PUBLISHER | Martin McANULTY mmcanulty@annexweb.com

COO | Ted MARKLE tmarkle@annexweb.com

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710

Printed in Canada ISSN 0843-7041

CIRCULATION

email: asingh@annexbizmedia.com Tel: 416-510-5189

Fax: 416-510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST) ($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbizmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2017 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

With luck comparable to that of the 2017 Blue Jays, the Ontario Glass and Metal Association’s scheduled day for its spring golf tournament landed on a day of continuous driving rain, forcing the first cancellation of the golf round in living memory. Instead, staff at Piper’s Heath Golf Club in Milton, Ont., moved with impressive flexibility to start the steak dinner early at 2 p.m. and give the approximately 50 members in attendance an enjoyable afternoon of discussion and laughter. Attendees received a rain check. OGMA president Angelo Cairo of Stouffville Glass gave members an update on association activities. He reported on the status of the OGMA’s efforts with Prompt Payment Ontario to craft recommendations for new Ontario legislation governing payment terms for the construction industry. The review has been completed and recommendations delivered to the Ministry, but the association continues to have some concerns. For comprehensive reaction to the

CORRECTIONS

recommendations, see Frank Fulton’s You Bet Your Glass column on page 34. Cairo reminded the group of its affiliation with the Canadian Glass Association, where Cairo is treasurer. Before the dinner, Cairo requested a moment of silence in the room to remember some recently departed friends of the industry. Dennis Haatvedt, executive director of the AGMCA, passed away from brain cancer in March. Also, Al Jones of Parkway Glass lost both his wife, Barbara, and daughter-in-law, Sandra Beaudette. Steve Ringler of Oakville Glass presented the $500 OGMA spring bursary award to Josh Williams, an apprentice glazier training at the Ontario Industrial and Finishing Skill Centre. Ringler read out a testimonial from Williams’ instructor, Steve Laird, which said his marks have been “almost perfect” and described him as having a talent for “making it right” and projecting a positive attitude. Williams works at Regional Glass and Mirror in Welland, Ont.

In our story in June Glass Canada “A window on learning” profiling the Lazaridis Hall project at Laurier University we mistakenly listed Arcop and Fournier Gersovitz Moss Drolet Architects as joint architects on the project. In fact, Diamond Schmitt Architects were the sole architects. Also in June Glass Canada, a photo of Alumicor’s Mario Lemay was mistakenly identified as Mario Savoie, also of Alumicor. Glass Canada regrets the errors.

Aug. 17

PGAA Golf Lacombe, Alta. pgaa.ca

Aug. 24

CSC Golf Tournament Richmond Hill, Ont. toronto.csc-dcc.ca

Sept. 12 - 14

GlassBuild Atlanta, Ga. glassbuildamerica.com

Sept. 21

OGMA Fall Golf Woodbridge, Ont. ogma.ca

Oct. 26

Fenestration West Surrey, B.C. fen-bc.org

2018

Jan. 31 - Feb. 2

IGMA Winter Conference Tucson, Ariz. igmaonline.org

March 21 - 24

Fensterbau Frontale Nuremburg, Germany frontale.de

April 17

Top Glass Mississauga, Ont. topglasscanada.com

June 21 - 23

AIA Conference New York, N.Y. conferenceonarchitecture.com

TheCGA’s annual Glass Connections conference took place June 7 and 8 in Burnaby, B.C. The event, which drew 85 registrants, featured 15 tabletop exhibits from a wide array of suppliers to the industry. These exhibitors were also key sponsors of the event. The conference began with its membership meeting, at which the board of directors for the 2017-2018 term were elected. The individuals serving CGA in the coming year are:

• President: David Langton of Competition Glass, Kelowna, B.C.

• Vice-president: Keith Wallace of Metro Glass Products, Edmonton, Alta.

• Treasurer: Angelo Cairo of Stouffville Glass, Stouffville, Ont.

• Secretary: Garry Parsons of Desa Glass, Edmonton, Alta.

• Director: Wes Penteliuk of Penwest Sales, Saskatoon, Sask.

• Director: Brent Wihlidal of Glacier Glass Service, Regina, Sask.

• Director: Mike Higgins of Northfield Glass Group, Moncton, N.B.

• Director: Zana Gordon of the Fenestration Association of B.C., Langley, B.C.

• Past President: Jim Brady, Cal-Tech Glass Services, Calgary, Alta.

A lively reception followed the meeting and kept attendees engaged in conversation well into the evening.

The second day featured six diverse presentations that

included important updates to standing topics of discussion, such as sealants and fire-rated glazing as well as new information on glazing and certification matters.

Many thanks again to our sponsors and exhibitors. We look forward to seeing the industry again next year at the next Glass Connections conference. More information on dates and location will be provided in the future.

Thanks to our sponsors

• Safti First

• Tremco

• Cascade Aqua-Tech

• Alumicor

• Bezdan Geo

• CRL-US Aluminum

• Grant Metal Products/C Jay Supply

• Guardian Glass

• Kuraray America

• Lenmak Exterior Innovations

• Mainstreet Computers

• Metro Glass Products

• Sage Glass

• Sika Canada

• Vitrum Glass

CGA TECHNICAL COMMITTEE

The CGA technical committee provides technical assistance to the Canadian Glass Association’s board of directors. While the technical committee formally meets a few times a year, most issues are dealt with by email correspondence in the interim periods. Over the years, the technical committee has worked with the CGA directors on some of their publications, advisories, glazing manuals and conferences. The committee is also active in participation on industry glass committees and the Glazing Industry Codes Committee, acting as a technical resource and assisting with other technical information.

The technical committee is currently drafting a wired glass advisory based on recent code changes. Look for that update to be available on the website in the near future.

The committee’s goal is to have representation from the majority of the provincial glass associations that are part of the national CGA. Below is the current roster; we are always looking for additional volunteers to sit on the committee.

• Chair: Brent Harder of Ferguson Corporation, Calgary, Alta.

• Rob Botman of Glassopolis Specialty Glass, Toronto, Ont.

• David Vadocz of Berkeley Vadocz Engineering, Surrey, B.C.

• Andrew Crosby of Read Jones Christoffersen, Kitchener, Ont.

Contact Brent Harder today if you are interested in getting involved: brenth@ferguson.ca.

ThePGAA board met for our 2017 AGM and board meeting in March in Red Deer, Alta., and again in May in Edmonton for our board meeting ahead of Skills Canada.

The Calgary Construction Association Career Expo in Calgary and Skills Canada in Edmonton were both very successful with about 3,000 students through both venues.

The Master Glazier Program’s second course, Doors and Related Hardware, is now being offered and development is underway on two more courses – Specialty Glazing

and Structural Glazing – to be added to the curriculum in 2017. This will leave us with five more to develop in late 2017 and 2018. We are in the planning stages for our 2017 golf tournament, looking for a strong event to help build our war chest as we move towards the end of development of the MGP. It is hoped that the program will be fully offered by the end of 2018.

The PGAA is actively seeking a new secretary.

CLA UPDATE: We’ve been duped. For where things stand please check out Frank Fulton’s You Bet Your Glass column in this issue.

FISHING DERBY: Scheduled for August 10, this years’ derby has unfortunately been cancelled for this year due to the unusually high water conditions on Lake Ontario.

FALL GOLF: The OGMA will once again hold our fall tournament at the prestigious Country Club in Woodbridge on Thursday, Sept. 21. Mark your calendar now. Details will follow as the date approaches.

For the past four years, the OGMA has worked with Workplace Safety Protection Services to create a health and safety plan designed specifically for glass shops and glazing contractors. They are offering their plan to OGMA members for about half what they usually charge for similar plans. Contact the OGMA and we’ll arrange the contacts.

The American Architectural Manufacturers Association recently released a new white paper created by the AAMA Aluminum Material Council that discusses the use of aluminum in high-performing building enclosures. AMC-2-26, “Aluminum in High-Performing Building Enclosures,” is now available in the AAMA online store as a complimentary download.

“This white paper was needed in order to educate and inform the marketplace about the energy advantages of using aluminum fenestration,” said Elizabeth Cotton of Kawneer, chair of the AMC Marketing Committee. “With today’s technology, these products can achieve current and foreseeable stringent codes requirements in an efficient and innovative manner, as well as achieving credits through green building certification programs.”

AMC-2-16, unlike most other AAMA documents which are available for purchase, may be downloaded at no cost from AAMA’s online store at its new website, which is intended to increase ease of usability for members and other visitors. The site’s address has not changed, and can still be located at aamanet.org. Updates to the site were based upon usability testing, which identified several strategic improvements,

Apogee Enterprises has announced it has entered into an agreement to acquire 100 per cent of the stock of privately-held EFCO Corporation from Pella Corporation for approximately $195 million. EFCO is a leading U.S. manufacturer of architectural aluminum window, curtainwall, storefront and entrance systems for commercial construction projects. Apogee, which provides distinctive value-added glass and metal solutions for the architectural and picture-framing industries, expects to close on the purchase of EFCO in the first half of fiscal 2018, pending regulatory approval.

“Our acquisition of EFCO will accelerate our growth strategies, and expand our presence in mid-size commercial buildings, broaden our product offerings and increase our geographic presence across the United States,” said Joseph F. Puishys, Apogee CEO. “EFCO operates in a space we know and structurally has similar operations to those across the Apogee businesses. In addition, with its broad range of high-performance window, curtainwall and storefront products, it rounds out the Apogee product offering. We also see significant margin enhancement opportunities as we leverage Apogee’s scale, operational excellence, expertise and supply chain synergies that build on initiatives already being implemented by EFCO’s strong management team.

“EFCO is a growing and profitable company, with annual revenues of more than $250 million that are largely generated from less cyclical mid-size and small commercial projects, a target Apogee growth sector,” he said. “We expect this acquisition to generate cash and be accretive to Apogee’s EBITDA and earnings per share, excluding transaction costs, this fiscal year. We expect to generate $10 million to $15 million in annual synergies and operational efficiencies by fiscal 2020.”

EFCO’s management team will continue to lead the business following the acquisition close. “A leader in commercial construction products, Apogee is an ideal parent company for EFCO,” said Cameron McGinley, EFCO president. “We are pleased to be joining the Apogee family and look forward to working with Apogee to capitalize on product, market and operational opportunities for EFCO.”

including creating a seamless experience for members, updating the look and feel to be consistent with current branding and providing for responsive design, making the site easily accessible on all devices. The site also features a stronger search function, which was how most users accessed information on the site, according to usability testing conducted at the beginning of the project.

The development of the Architectural Glass and Metal Technician Certification Program has reached a milestone with the formation of a 27-member steering committee that met for the first time in a two-hour teleconference on June 15. The program, a third-party, personnel certification initiative, is being developed by Administrative Management Systems and is sponsored by the Finishing Trades Institute International. The committee is comprised of a balanced representation of industry experts from three major stakeholder segments: glaziers, glazing contractors and the user community consisting of manufacturers, suppliers, architects, consultants and spec writers. Assigned to five sub-committees, each handling separate facets of the program’s design, the members will jointly oversee the foundational stages of the program’s development. At the meeting, they listened to a presentation that focused on a design concept and development steps necessary for a world-class program that would meet the criteria for gaining ANSI accreditation in accordance with ISO/IEC 17024. Among many of the committee’s immediate responsibilities will be to provide comprehensive feedback that will help establish the necessary fundamental knowledge- and performance-based competencies required of an architectural glass and metal technician, as well as help shape the program’s foundation. Development of the fundamental certification phase is estimated to be an 18- to 24-month project, with advanced certification endorsements in specific product categories and specialized skill requirements to follow.

ASTM International’s committee on glass and glass products is creating a standard that will define requirements for cleaning and restoring glass windows, doors and other architectural glass used in modern buildings. People involved in related industries including glass manufacturing, glazing companies and maintenance/restoration contractors are invited to participate in the development of the proposed standard (WK58123, Practice for Cleaning Architectural Flat Glass).

“Glass is a major component used in both residential and commercial architectural buildings today,” says ASTM International member Paul West of the International Window Cleaning Association. “The beauty and integrity of architectural glass products can be maintained for decades by adhering to a proper schedule of routine cleaning.”

According to West, the IWCA is supporting the development of the new standard to help educate and enhance professionalism in its industry. He says that the proposed standard will explore proper techniques for professional contractors to follow. In addition, the standard will address how to identify, minimize and/or eliminate problems associated with scratched glass. The standard will also explore advanced restoration techniques for glass surfaces damaged by stains or scratching.

AGC Asahi Glass has announced that it will invest approximately $210 million to relocate a float furnace and mirror manufacturing facility run by its subsidiary, AMG, from its plant in Jakarta, Indonesia, to the Cikampek Plant of PT Asahimas Flat Glass, also in Indonesia. Mass production is scheduled to commence in the first quarter of 2019. The new float furnace and mirror manufacturing facility will increase production capacity by 40 and 30 per cent respectively, which will significantly enhance AMG’s architectural glass production.

The

boards of directors for the Glass Association of North America and the National Glass Association will jointly announce the outcome of their association combination talks during the GlassBuild America Opening Session on Sept. 12 at 8:00 a.m. The Opening Session, open to all attendees, features keynote speaker Cam Marston and includes a continental breakfast.

GANA is bringing its Fall Conference to GlassBuild America in Atlanta for a firsttime integration of its important committee work and presentations with the annual trade show where the industry gathers to meet and buy. The GANA Fall Conference

runs concurrently with GlassBuild, Sept. 12 to 14 at the Georgia World Congress Center in Atlanta. The combination of the two events provides a larger audience and opportunities for new participation to address technical and advocacy priorities on behalf of members and the industry at large.

“We encourage our peers to attend our joint Express Learning sessions and other Fall Conference opportunities,” said Doug Schilling, GANA president. “The agenda includes ample time for our volunteer activities, plus time to visit exhibiting companies on the trade show floor to take advantage of all that GlassBuild America offers.”

WSP Canada has announced two changes to the senior executive leadership of its Canadian Buildings team. Armin von Eppinghoven will assume the role of senior vice-president of key client strategy and engagement for Buildings, following his successful tenure as a senior executive on the team. Von Eppinghoven’s over 30 years of experience will be applied in this strategic, externally focused role where he will direct and develop innovative approaches to leading key client engagement and business development activities, as well as growth in new market sectors.

WSP also welcomes Terry Tommason as the new national business line executive for Buildings. Terry is an executive-level major program, project and development executive with more than 24 years’ industry experience. Prior to joining WSP, Tommason held several leading roles, including managing director and operations director for two leading multi-disciplinary consultancy firms and was directly responsible for pursuing, converting and delivering major projects, including the Kingdom Tower (the world’s tallest building) in Saudi Arabia and the FIFA World Cup 2022 stadium in Qatar, UAE.

Both executives will be located in WSP’s Markham, Ont., office.

AMG’s Jakarta Plant has been manufacturing flat glass since 1973. Under the Jakarta City master plan, the plant is facing re-location

as the land category of the plant premises will be changed from industrial to commercial use. One of the two float furnaces at the plant has already been transferred to the Cikampek Plant and started operation in December 2016. In anticipation of continued growth in Indonesia and southeast Asia, the new furnace will be relocated with increased production capacity as well as excellent productivity for high-quality glass. Following the relocation, AMG’s Jakarta Plant will cease all production activities, and the property will be sold.

The

by MARGARET

Let’s take a look at some of the great work our Emerging Technology and Innovation Committee has been doing.

The committee is chaired by Helen Sanders of Technoform Glass Insulation.

The Advanced Testing Fenestration task group, chaired by Aaron Ryan of Pella, has reviewed data results from two test methodologies (the Intertek Variable Environment Chamber and the modified ASTM E 2190 test developed by H.B. Fuller) with a view to choosing a recommended method for accelerated testing of IGU durability. It has been agreed that more data is required before making a decision of which direction to pursue.

John Kent of the Insulating Glass Certification Council has reported on the preliminary results from the data collected under the Insulating Glass Certification Council’s Provisional Certification Pilot Program. The two groups have now met and reviewed the data from the pilot IGCC program. The group has agreed to move forward with a modification of the variable environmental cycling chamber. This has the potential to dramatically reduce the amount of time in testing and promote faster development of new technologies.

The Vacuum Insulating Glass task group, chaired by David Cooper of Guardian Industries, is monitoring the development of the ISO standard for VIG. Dave actively participated in developing the draft of the Part 1 durability standard and has continued work on the next phase, which covers temperature-induced effects. The ISO standard is currently out for ballot to the various

Technology and Innovation Committee seeks to assist fabricators to integrate new technology and methods.

countries that have representation on the committee. The remaining task group objectives have been deferred pending publication of the ISO standard. Once the ISO standard has been published, the task group will develop certification program procedures to qualify VIG units for code compliance, including Energy Star.

Dave is also chair of the National Fenestration Rating Council VIG task group, which is validating the Lawrence Berkeley National Laboratory window and thermal simulation programs against various VIG window constructions. Testing will be commencing soon.

The Gas Measurement and Validation task group, chaired by Randi Ernst of FDR Design, has reported on the current activities at ASTM. As reported in December 2016, there have been some issues with the spark emission spectrometer that may be related to the desiccant (nitrogen-to-oxygen ratios). It was agreed to reconvene the Desiccant task group to develop a standard specification for testing desiccant.

The first draft of a standard to assess Thermal Stress for insulating glass units was reviewed by the ASTM E 1300 task group at their Seattle, Wash., task group meeting. The research to develop this standard was funded by IGMA under the Emerging Technology and Innovation Committee. Consideration is being given to develop a software program to run the simulations. This program will be the property of IGMA and will be available to IGMA members at no charge. There will be discussion of offering this program at no charge to the industry at large.

That’s just one of the four committees our active and engaged members are running. We encourage all members to attend our conferences to find out more about their important work.The 2017 Summer Conference is happening as this goes to print, July 31 to Aug. 2 at the Sheraton Centre Montreal. After that is the 2018 Winter Conference, Jan. 31 to Feb. 2 at the Loews Ventana Canyon in Tucson, Ariz. •

Perfect for different glass thicknesses, without changing gaskets, our multi-directional adjustment allows pivot point, flush, and zero position adjustment—even after installation.

Visit dormakaba at GlassBuild America

Booth 909

Atlanta, GA—Sept 12–14

The clean precision of MUNDUS patch fittings offers smooth transitions between glass panels for greater transparency. MUNDUS fittings support glass thicknesses up to 7/8", tempered laminates, and glass doors weighing up to 440 pounds. So simple to install, the fittings can be mounted and fixed in place as delivered to provide a secure hold. Post installation, multidirectional adjustability ensures a perfect fit. It’s easy to see why MUNDUS is the clear choice for creating contemporary glass environments. Are we clear?

Visit dormakaba.us

JACK KOHANE

Noram’s 150,000-square-foot fabrication plant houses the latest technology because owner Ted Redlarski believes innovation drives business.

At the tender age of 12, Ted Redlarski ran his first business: a small shop repairing bikes. It was a first money-maker. Later, while still in college (age 19), he became one of the youngest company presidents in his native Poland to helm a construction company. And, remarkably, he did it at a time when that country was under communist rule, discouraging attempts at private enterprise. Undeterred, he unleashed his entrepreneurial spirit.

It’s that same drive that has powered his vision to make Noram Glass, the company he founded in Canada almost three decades ago, to be among the leaders in Canadian architectural glass, aluminum curtainwall systems and structural glazing. He’s doing it one client at a time.

Word-of-mouth is a great marketing tool, says Redlarski, admitting he’s the company’s one-man sales team. “The glass industry in Canada is not a huge sector, so if you leave a good impression, word gets around. We get questions from clients about the projects we’ve

done. The quality of work tends to speak for itself.”

That work speaks volumes in the newly opened, $15 million Vaughan Civic Centre Resource Library, sited on Toronto’s northern outskirts. Noram won the 2017 Ontario Glass and Metal Association award for the project’s unique and complex glazing design and execution. The curvilinear form of the building’s plan coupled with the vertical cant in two axes of the curtainwall system required significant design detailing and coordination, generating construction challenges which were, according to the OGMA, all successfully met. The judges deemed this building a dynamic and excellent example of the application of standard curtainwall technology to create a visually distinct façade.

It’s Noram’s signature achievement. “The Vaughan Civic Centre Resource Library is a shining example of one of the most challenging glazing jobs we’ve ever done,” Redlarski beams. “Certain elevations of the building proved the most tricky. Glass was used to build a wall of sweeping curves tilting sideways 15

Founded: 1989

Owner: Ted Redlarski

Employees: 150 Facility: 150,000 square feet

Serves:

Mainly Ontario, with projects in Quebec, New York, Miami, and Florida

Focus:

Institutional, commercial, and industrial projects

degrees and leaning forwards from zero to 15 degrees, substantially twisting the infill glass and aluminum panels, creating an extraordinary illusion appearing to defy the laws of physics.” Complex tilted panels were installed to create an illusion of movement as the sun hits the Vaughan Civic Centre library from different angles through the day. The design was inspired by the curves of a nearby roller coaster at Canada’s Wonderland.

In order to craft such a sophisticated shape, the design had to be first produced in a complex 3D model. Notes Redlarski, “From this model, we extracted and refined the exact sizes and

Top: Having been in business for himself since the age of 12, Redlarski is well-equipped to act as his own salesperson. Bottom: Noram Glass has come a long way from its beginnings in a 400-square-foot shop. The company now employs 150.

angles to achieve each infill panel and frame components’ unique and perfect fit.” Throughout the installation process, further intricate steps were taken to ensure its success. The installation of the anchor points required complex laser triangulation in order to place the anchors in their precise positions. Due to the twisted shape of the frame, multiple pieces of glass and panels were subject to substantial cold bending during installation. With the masterful relationships between glass and aluminum, and the visual relationship of pushing the boundaries of physics in architecture, the gradient frit pattern creates a seamless transition from vision glass to solid panel that adds more depth and artistry to the look of the library. “Our entire team was proud to be part of this great accomplishment,” Redlarski enthuses.

Winning the award was a crowning moment for Redlarski, who emigrated to Canada as a 25-year-old budding capitalist hankering to escape the economic and political shackles of communism. Articulate, intelligent, and today sporting a salt-and-pepper beard and close-cropped pate, he describes the rules of enterprise back in Poland in the 1970s as stifling, and non-compliance being downright dangerous. Despite the massive amount of red tape, and countless systemic challenges of living in a communist country, Redlarski thrived. His construction company, which grew to over 400 employees within a span of five years after its founding, specialized in flat roofs, industrial painting and specialty services (including underwater photography for inspection of submerged structures, industrial high altitude services such as renovations for oil refinery structures, steel bridges, radio antenna, and servicing industrial steel towers).

As his business grew ever more prosperous in communist Poland, a country where at the time the idea of private enterprise had no place, his father advised him to join the Communist Party and not to rock the collective boat. “Or things could get pretty rough for

me, he warned me, but I wouldn’t have it,” Redlarski recalls. He, along with his wife Maggie, chose to leave Poland in 1987, seeking political refugee status in Turkey. They remained there for almost two years when they decided to “give it all up to come to Canada.” Arriving in Moncton, N.B., Redlarski immediately went to work in a quarry and later as a supervisor on a vegetable farm. Later, they moved to Waterloo, Ont., where he landed work as an electrician. But he was again bitten by the entrepreneurial bug. “Within four months, I jumped in starting my own business again,” he says. Noram Enterprises was born. “A necessity as my family was growing.” Today, the Redlarksi’s daughter, Jessica, 24, spearheads Noram’s quality assurance/

Despite the massive amount of red tape, and countless systemic challenges of living in a communist country, Redlarski thrived.

quality control and marketing initiatives, also acting as the staff photographer. His son, Kevin, 22, has a keen interest in virtual technologies and animation.

After involvement in several house renovations, Redlarski decided to take Noram to the next level: erection of building envelopes in 1990 and manufacturing building envelopes in 1995. The company’s first fabrication facility (it was just 400 square feet) opened in Innisfil north of Toronto in 1997 and relocated a year later to a 2,300-squarefoot plant in Toronto. “We’ve experienced steady growth ever since,” says Redlarski. “We moved to this facility in 2012, offering all the services and staff required to get the job done.” The modern 150,000-square-foot plant houses a workhorse AXYZ full CNC industrial router, two Ermak Speed Bend synchronized hydraulic press brakes equipped with 3D capability, a welding station, and a sophisticated glass components testing site that blasts panes for leakage and breakage with powerful hurricaneforce fans.

Redlarski was presented with the Ontario Glass and Metal Association’s Award of Excellence for Execution in architectural glazing at Top Glass in April. The association recognized his work on the Vaughan Centre Library as “requiring significant design detailing and coordination, which generates significant construction challenges which are all successfully met.”

Having everything managed under one roof allows the Noram team to control all aspects of its projects from start to finish, maintaining quality control and high levels of operational efficiency, in tandem with in-house capabilities that include professional project managers, fabricators, and installers. “To put it simply,” says Chad Hall, the company’s plant manager, “we believe that providing the complete package for glass and aluminum services is the only way to do business.”

It’s a can-do approach that’s hallmarked in Noram’s other recent high-

profile projects: St Michaels Hospital, the new 18-story patient care tower in downtown Toronto, where the team created a fully unitized high-performance curtain wall, custom glass sun shades, louvers, structural glass, a specialty interior fit-up including switchable glass, lead glass and specialty glazing products for the mental health wards; and the Westbury, an eight-story, state-of-the-art office facility located in Mississauga, Ont., for which Noram supplied and installed the entire building facade, including curtainwall, revolving doors, custom sun shades, metal panels

• Make a plan

• Work hard, listen to logic and follow your gut instinct in your decisions

• Learn from the experts around you; seek out new possibilities

• Always keep an outlook for new challenges and industry developments. I like to jump in and execute difficult architectural visions

• Lead the way in solving project challenges in bringing solutions to the design intent

including extensive stainless steel features and glass canopies.

As for Noram’s path moving forward, Redlarski believes innovation will drive its march. “To stay in the game, you must be on top of trends,” he insists. “Seek out innovations and embrace new technologies if you want to stay ahead of the curve.”

Next on Noram’s action plan: the mental health security sector. Redlarski has designed in-house a prototype sullsash (a specialty operable window installed on the interior of an existing window in order to protect that window from access of unauthorized people) with integrated blinds that open and close via an integrated non-ligature knob, and multi-point locks for custodial keyed entry. “We see a need in this market and are now testing a product: glass that’s high-security laminated, including optional ballistic glass. And we must ensure that our windows will meet the unique structural and safety requirements (high impact, forced entry resistance) to which a mental health security facility must comply,” explains Redlarski. “Whether it’s in designing a new facility, or upgrading a hospital to meet psychiatric security needs, we work with clients to ensure all performance, safety and esthetic requirements are met.”

Redlarksi likes to laud the talents of the Noram team. “I’m proud that our designers, fabricators and installers work together to create and build markets that don’t exist or are just in their infancy,” he says. “We see the benefit of jumping in early to capture the market in a more dynamic way.” •

by BRIAN BURTON

Brian is a construction writer from Ottawa Ontario who served on the CSA’s Fenestration Installation Technician Certification Program Personnel Committee.

You can contact Brian at Blueblade49@gmail.com or learn more by visiting Burton’s-Pen.com

Your showroom is the public face of your company. Too often in our industry, these areas take on the appearance of secondary storerooms for the unsold remnants of yesteryear, complete with dusty, out-of-date products haphazardly scattered amid poor lighting, flat decor, yesterday’s lunch garbage and a stack of boxes awaiting shipping. When properly thought out and designed, an attractive well-lit and colourful showroom can enhance the customer buying experience for both homeowners and commercial customers.

Your goals in designing your showroom only start with creating an opportunity to showcase your product lines in the best possible light. Some companies use their showroom space to illustrate their corporate history and background. A great showroom helps you demonstrate to potential clients your on-going leadership in the industry, establishing your credibility. Instead of just showing off the product, assist customers to visualize it installed in their home or business. Doing all this helps you stand out clearly and distinctly from your competitors.

When designing a showroom, three or four traditional rules of thumb apply. Keep it simple. While it might be tempting to jam everything you carry into your showroom, less can be more in terms of focusing customer attention. Rather than put in everything, feature only the latest and greatest and update the products frequently to prevent the look from getting stale. Above all, avoid clutter and using the area for storage or stock. Experts suggest the aisles be wide enough to accommodate two people to encourage easy circulation.

In recent years, interior designers have begun to incorporate virtual or interactive elements

A good showroom actually has a lot in common with an effective window display.

to keep product showrooms lively and this is something you can consider along with bringing in outside design help if you think it might help augment your efforts. Professional designers often make a point to use bold colours, and frequently recommend investing in complementary light fixtures and contemporary wallcoverings. Your showroom investment can also be a multipurpose space if designed correctly, becoming useful for staff meetings, training sessions, product launches, media events and lunch-and-learns. Take your time and test it out to make sure it works well in all its various functions. It also helps if your showroom space has easy access to your offices and lobby spaces. Consider making room for a few desks where you can lay out paperwork to expedite the sales process.

While planning your layout, keep in mind that at some point you might expand or add product lines. You also need to consider design features and amenities. Think about convenient parking with plenty of space, immaculate washrooms and proper signage.

Ensuring your showroom has a spacious look and incorporating room for circulation and movement from one product area to the other helps create a welcoming space and can be an important key to helping customers feel at home. The same applies to waiting areas where you provide refreshments. Providing reading material and WiFi in these areas is not a bad idea.

A good showroom actually has a lot in common with an effective window display. The best ones manage to tell a story, or at least demonstrate your brand and commitment to quality. Although your showroom is a business space, you also need to incorporate areas or spaces that encourage informality. For example, access to the outdoors and comfortable and informal furnishings. These are especially effective if your client is thinking about improving their residential environment.

We’re not always as comfortable showing off what we do as we are just doing it. But don’t let that lead to neglect of your showroom. Your customers won’t buy what they can’t see. •

The evolution of Canadian window wall ranged from punched windows in mass masonry walls through vertical strips of floor-toceiling windows and brick veneer or precast concrete walls to the complete enclosure of the entire building.

One of the defining characteristics of modern high-rise residential apartment building design in Canada today is window wall. Most systems in use today evolved from punched windows in double-wythe mass-masonry walls in the 1960s, beginning in the Greater Toronto Area. The original punched windows incorporated thermally broken, open-back, extruded aluminum frames. Fixed glazing was usually double-glazed in the form of sealed, insulating glass units or a fixed exterior pane of single glass with a removable interior panel of single glass. Both types were typically face-sealed to the surrounding frames. Sliding sashes were single glazed in double run configuration with some provisions for drainage. Glass was clear and uncoated. Performance varied. Windows sometimes leaked in the rain. Condensation on glass and frames was a common problem in the winter, and sealed units often fogged after only a few years of service.

The advent of reinforced concrete structural frame construction employing flying form technology enabled a rapid increase in building height in the ‘60s and ‘70s. Masonry wall construction changed, with the exterior wythe of brick becoming a veneer separated from the inner wythe, supported off the slab on shelf angles with through-wall flashings and drainage holes to improve rainwater leakage resistance. The introduction of roll-crimp clamping of aluminum extrusions to plastic thermal breaks and deepening the exterior extrusion to form an integral brick mould allowed window frames to span the larger gap between veneer and inner wythe. Roll-crimp formed frames were also capable of withstanding higher wind loads acting on taller buildings. Windows grew in size along with increasing height of buildings, extending to the floor slab to create vertical bands of windows from top to bottom of the building, separated by masonry veneer or precast concrete clad walls. Slab edges were

concealed, yet expressed, with simple sheet metal covers. In the 1980s, the first true window wall systems appeared with the sheet metal slab cover replaced by extending the frame outboard of the thermal break from the top of the floor slab to the head of the window below, concealing the slab edge. This slab by-pass design has become a defining feature of modern Canadian window wall systems from coast to coast.

As buildings grew taller, opaque wall and window system performance had to evolve to address higher climatic loads and increasing resident expectations. Wet-sealed frame joints and rainscreen installation methods for fixed glazing as well as operable glazing were introduced to control water leakage. Window to opaque wall joints are now also rainscreen design to prevent leakage from window assemblies to wall assemblies and vice versa. The PVC thermal break has given way to polyamide and insulating glass units now routinely include low-E coated glass, warm-edge spacers and argon gas fill to reduce heat loss and improve condensation resistance. Sealant materials and methods for assembly of insulating glass have greatly improved durability. These improvements were sometimes ahead of, and sometimes pushed along by material and assembly standards such as CSA-A440 Windows, CGSB-12.8 Insulating Glass Units and by general requirements for building enclosure design in Canadian building codes although in general, standards and codes address punched windows. Window wall as a fenestration product type is not specifically addressed in product standards, including the so-called harmonized North American Fenestration Standard. Following local performance failures in the late ‘90s and early ‘00s, municipal building regulations such as the City of Vancouver Building Bylaw 10908 and insurance industry requirements such as the Ontario Association of Architects/ Pro-Demnity Insurance Company’s Window Wall Endorsement and Tarion Warranty Corporation’s Builder Bulletin 19 imposed additional design, testing and construction inspection rules. The National Building Code of Canada followed suit in 2015 with the designation of a new category of building envelope enclosure, Other Fenestration Assemblies, which includes window wall. Subsection 5.9.3 sets out required design, performance and testing requirements and the accom-

panying appendix describes additional recommended actions. Work is also in progress on an installation standard for high-rise residential window system under the aegis of the Canadian Standards Association. The new 2015 NBC requirements and recommendations will take some time to be adopted and enforced by authorities having jurisdiction but in the author’s opinion, they represent current state-of-the-art and good practice that should be followed.

The NBC 2015 performance and testing requirements for “other fenestration systems” are set out in Division B, Part 5 Environmental Separation, Subsection 5.9.3. The following is a summary of requirements, together with commentary to identify changes from past practice for design, construction and installation of window wall systems in Canada.

Structural and Environmental Loads (5.9.3.2) – Compliance is required to Article 5.1.4.1, which sets out generic requirements for all building envelope materials, components and assemblies. Appendix A to article 5.9.3.2 also identifies ASTM E330 as the applicable test

method, which is the same test method required for punched windows. Appendix A also identifies AAMA 501, AAMA 501.4 and AAMA 501.6, which are commonly used for curtainwall assemblies, as applicable test methods. This recognizes the broader range of potential movements that a window wall assembly can be expected to accommodate (wind induced interstorey drift, seismic movement), depending on building location, climate, seismic activity, building height, etc.

Heat Transfer (Article 5.9.3.3) –Compliance is required to Section 5.3, which sets out generic requirements for heat transfer for all building envelope materials, components and assemblies. Metal-framed fenestration assemblies are required to incorporate a thermal break to minimize condensation. Appendix A recommends compliance to National Standard of Canada CSA-A440.2, which in turn references procedures developed by the National Fenestration Rating Council for simulation or physical testing to determine U-factor (NFRC 100 and NFRC 200). Two physical test methods are identified for assessing condensation resistance: the temperature index method in CSA-A440.2, which is used for

A Canadian window wall system during installation. Left, story high panels installed with the other half of the frame extended to cover the floor slab. Right, close-up at slab edge showing slab by-pass with projection of window frame beyond the slab edge, aluminum extrusions at jambs outboard of the thermal break are extended downward to allow the spandrel panel to cover the slab face, with self-adhesive membrane and metal flashings to shed water.

punched windows, or measuring roomside surface temperatures by extending one of the cold cycles of the AAMA 501.5 thermal cycling test, which is often used for assessing condensation resistance in curtainwall. The latter option recognizes that existing guarded hot-box test facilities are unlikely to be suitable for installation of a complex window wall system. The default temperature range and placement of measurement devices during the AAMA 501.5 test may need to be adjusted to provide results suitable for evaluating performance to determine if compliance to the 2015 NBC Article 5.3.1.2 requirement to “minimize surface condensation on the warm side of the component” has been met (Sentence 5.3.1.2.(1).(a)).

Air Leakage (Article 5.9.3.4) – Compliance is required to Section 5.4 for generic requirements that apply to all building envelope materials, components and assemblies. Testing to ASTM E 283 is required. Specific air maximum air leakage rates for fixed glazing and opaque/ spandrel areas and vents are set out, consistent with air leakage performance required for punch windows in the Canadian Supplement NAFS, CSA-A440S1.

Water Penetration (Article 5.9.3.5)

– Compliance is required to Section 5.6 for generic requirements applicable to all envelope systems of buildings. For “other fenestration assemblies,” lab testing is required to ASTM E331 or to ASTM E547. Testing to ASTM E331 is the norm for curtainwall systems whereas testing to ASTM E547 is the norm for punched windows. Test pressure is determined in accordance with CSA-A440S1 using the Driving Rain Wind Pressure, the same as for punched windows, consistent with the approach in Canada for determining wind-load rain resistance test pressure separately from structural test pressure.

Appendix A also identifies AAMA 501.1 as an applicable test method. This recognizes that window wall systems are similar to unitized curtainwall systems, often installed at similar building heights and therefore subjected to variable and gusting winds. Testing to static pressure differentials (ASTM E331 and E547) may not adequately duplicate service conditions when installed on very tall buildings.

Discerning readers may notice a certain

ambiguity in the 2015 NBC requirements. For example, for water penetration resistance, testing to ASTM E331 or E547 are required in the body of the code, consistent with requirement for punched window systems, while more stringent test methods suitable for high-rise construction such as AAMA 501 “can be used” to evaluate performance in Appendix A. The authors of these requirements are constrained by rules for Canadian building codes to reference standards that are developed following a consensus approval model. AAMA standards are not considered to be so, with the exception of NAFS, which is a joint standard with CSA and thus must follow rules for the development of consensus-based standards. It is important to understand this because some window wall manufacturers may not have performance test documentation available that meets all of the strictly mandatory requirements. Also, as of March 1, only the Yukon, Northwest Territories and P.E.I. have adopted building regulations based on the 2015 NBC, so compliance is not yet required in most jurisdictions where window wall systems are likely to be used. However, in our experience, window wall manufacturers that supply product for U.S.A. construction projects have tested to the AAMA standards identified in Appendix A because such performance is expected in that market. Therefore, in Canada today it is possible to obtain window wall systems consistent with 2015 NBC mandatory and Appendix A supplementary performance requirements and test methods. The assistance of a knowledgeable building enclosure consultant is invaluable to ensure such state-of-the-art design guidelines are used, to avoid future performance problems, costly litigation and repair.

The authors extend their appreciation to Martin Cash, president and CEO, and Jody Cash, vice-president, of Quest Window Systems, and Peter Kuschnir, technical manager of Starline Windows, for comments regarding the development of Canadian window wall systems and discussions regarding past, current and future trends. The authors also wish to acknowledge the assistance of members of the façade engineering team at Morrison Hershfield in offices across North America for commentary on window wall design, construction and installation techniques in Canada. •

by Patrick Flannery

Carbon fibre composite remains too expensive and slow to process for widespread use as a building material. But trends both on the supply and demand side are perhaps bringing it closer to feasibility. The material’s strength-toweight ratio, corrosion-resistance and low thermal conductivity make it an intriguing possibility for very high-end projects demanding low sight lines, big glass and good thermal performance. Meanwhile, processing innovations are making the raw material cheaper and the fabrication process quicker. We discussed the far-out possibilities of carbon fibre composites with Richard Collins, technology analyst for IDTechEx.

GC: In general, how do carbon fibre composites compare to other common materials used for framing and architectural glazing?

Collins: The general rule of composite materials, and particularly carbon fibre, is that they can be viewed as a metal replacement. So they have the best strength and stiffness-to-weight ratio in comparison to it. You do see examples of carbon fibre being used for some very bespoke structural building and construction. Same for glass fibre as well, but glass fibre is not the same quality in terms of strength and stiffness to weight. So that’s kind of the payoff that you’re taking there.

GC: In general, how do carbon fibre composites compare to other common materials used for framing and architectural glazing?

Collins: The general rule of composite materials, and particularly carbon fibre, is that they can be viewed as a lightweight metal replacement. They have the best strength and stiffness-to-weight ratio in comparison to steel, aluminium, and titanium.

In terms of the role it could play, if you compare composites versus aluminum versus vinyl, composites and aluminum are much more on the same page.

GC: What makes carbon fibre composites an interesting material for building construction?

Collins: A composite material it is basically a fibre embedded in a matrix. When people say carbon fibre, what they usually mean is carbon fibre-reinforced polymer. That’s a carbon fibre embedded in a polymer matrix. One of the main interests for building construction is the strength-to-weight ratio of these composite parts.

Left: The top seven metres of a sliding telescopic crane – designed by Riba Composites. This CFRP part provides a 20 per cent increase in lifting load for the same stiffness and 40 per cent weight reduction compared to metal solution.

Right: A structural beam for a bridge. CFRP with a concrete core designed by Marstrom.

Now, what you’ve got is that the fibre has got a fantastic tensile strength. However, as tensile strength is only relevant in one direction this does not necessarily make it suitable for compressive and lateral forces. There are ways around that. You can stack them in different ways so that you can have layers of fibres going in X direction, Y direction, and other angles and you can build them up like that. Alternatively, there are lots of options in weaving and braiding.

So when you say strength-to-weight ratio, you really have to ask what do you mean by that. When designed properly, they are more competitive in terms of strength-to-weight, but there are these extra considerations because they are a fibre.

GC: Why have carbon fibre composites become such popular materials in other industries, such as automotive and aerospace?

Collins: One of the things that people don’t always necessarily realize about carbon fibre is that strength-to-weight ratio is one thing, but actually it’s stiffness-to-weight that is special. That’s what makes it a potential automotive replacement in structural parts; that’s what makes it so liked by the aerospace industry in all those roles. And if it that’s key for your particular large glass product, that stiffness, then, yes, it would be very useful again.

GC: Do you see it as theoretically possible to design, say, a window frame made of carbon fibre composite that would structurally stronger and be able to bear larger glass panels with fewer mullions or other supports?

Collins: Yes. If we consider the specific strength or specific modulus, carbon fibre is about five to six times better than aluminum alloys as a ballpark figure. But again, that is in one direction.

I’m sure with a frame you could design that appropriately. One of the problems that they have for moving parts, like a suspension upright, is when you suddenly get a force from a different direction than what you designed for it could be devastating to your part. But, for a big window, you’re not really going to have too many unexpected forces. So you should be able to design it appropriately, would be my guess.

GC: How are carbon fibre composite items made?

Collins: Making composite parts is one of the biggest problems, particularly making them with a good degree of automation and a good degree of speed. That’s where there are a lot of innovations going on. What you effectively have to do is buy carbon fibre from some of the big chemical manufacturers. Toray are the market leaders. What you get is something that they call a “tow” wound on a bobbin – that’s thousands of individual carbon fibre strands. It looks almost like a thin black tape. And you lay all these down and usually stitch, weave, or braid them together to give a fabric or mat of just carbon fibre. Dedicated companies or the fibre manufacturers themselves usually provide these fabrics or mats. And then you have to infuse that with the polymer. So, you can infuse that in a variety of ways. In the most basic traditional way, you pretty much do it with a paintbrush. So you can just get your resin, paint it on there, wait for your resin to cure, and you’ve got a part.

Now, there’s a lot more sophisticated stuff. A more common technique is where you’ve got almost like an injection moulding process called resin transfer moulding. And then you got different types of compression technologies as well as progressing into more robotic layups and things like that. It’s a really complicated process.

GC: Can you imagine how a manufacturer might go about producing something like aluminum lineal out of carbon fibre?

Collins: What they typically do is make what they call a preform. So you would cut your fabric into shape in advance of then injecting it with the resin. Alternatively, there’s something called a pre-preg. This is where you have a fabric that already has the resin in place, but the resin’s not cured yet. So then you cut that fabric into your shape and then all you have to do is heat it and you’ve got your part. So, your milling process that you would traditionally do in a metal scenario isn’t quite the same. It’s more literally cutting a fabric and getting it in the right shape before you turn it into a solid part.

GC: You mentioned things are happening to make production of carbon fibre composite parts more efficient. What things are those?

Collins: It’s in the actual processing. Because of the automotive industry and others getting involved, they’re obviously so keen on speed. So, there’s lots of innovation around getting that processing time really fast and getting that turnover because, as you know, in automotive you’re looking at maximum three minutes a part – any more and you’re wasting money and time. So, there are lots of examples of that and that’s a step they are taking in that direction. But then you’ve got the associated industries. So if you go all the way back to making your carbon fibre then you might be turning it into a fabric. You might be weaving it, you might be pre-impregnating it. There are several steps, but then to make the actual final part they do try to make it as fast as they can.

GC: What are some of the hurdles to using carbon fibre composite as a building material?

Collins: Really the thing holding it back in a lot of industries and particularly in a lot of, let’s say, main industries, such as building and construction – what keeps it in the realms of premium vehicles and aerospace – is the cost of the pure fibre is expensive. To make the carbon fibre itself is pricey. So, when you’re buying that off a chemical company, you’re already spending a lot. It depends what brand you buy, there’s almost a high-quality and a lowquality one, something they call a light tow and a heavy tow. So, the heavy tow is a slightly lower quality. I mean, it’s still very good. And that, at the moment, is in the order of about $13-14 dollars a kilogram. So, quite a lot higher than aluminum.

And that’s just the fibre. That’s the thing that’s limiting it.

Now, what they say, typically, in the industry is there’s this magical price of $5 a pound. That’s about $11 dollars a kilogram. And they say when you hit that point, you will be accessing much more widespread industries. And there is hope and there is a lot of research going on to making that happen. So one way you can reduce the overall cost is in the processing. The way that you make carbon fibre is very energy-intensive and very slow. So, you can switch the process there. Alternatively, you can use a new precursor. So, the actual initial polymer that you use to make that carbon fibre, if you switch that precursor to something else that is, say, easier to come across, then you’ve really reduced the cost, as well, on that front.

So these do give it options. It’s not going to be quick. I forecast the cost of the heavy tow to be coming down to around the $12 dollars per kilogram mark within the next decade. But for the higher quality one it will only be coming down to around $16 a kilogram within the next decade, unless there is a big stepwise change in the use of precursors that could bring it closer to that magical $11 per kilogram level. Even then the lower the better. But even when I say magical, there are lots of limitations that come with this, holding it back.

GC: That certainly makes for a very expensive building material. Are there any benefits that could make up for such a high cost?

Collins: One point I should mention about carbon fibre, that maybe doesn’t get mentioned enough, is that one of the best things about it is its corrosion resistance. Because that’s a huge problem with metals. Even if we take the most fundamental steel-reinforced concrete, you’ve got a lifetime on that because your steel will corrode over time. And, of course, there’s lots of good chromium platings for steel –and many aluminum corrosion resistance solutions. But fundamentally you save all that by switching to carbon fibre. Corrosion resistance just basically stops being an issue. Now, there’s a lot of other issues, but that is something that is in its favour and perhaps doesn’t get the nod it deserves.

Other potential benefits are related to the coefficient of thermal expansion and the ease with which a lightweight material can be transported and installed.

GC: How thermally conductive are carbon fibre composites?

Collins: They are not thermally insulating, but they’re not very conductive. They’re definitely lower than a metal. So I think they are perfect, because they have some conductive transmitability, but they are lower than a metal. It’d be a lot closer to vinyl, a lot further away from the metal and give you some advantage on that front.

GC: Would you be able to make carbon fibre lineal with a thermal break cavity inside it, similar to a vinyl part?

Collins: It’s a good question. You can make hollow composite parts but, again, it’s more complicated because what you have to do is you have to have use a specific mould (what the industry call tool) that can be removed after the curing process.

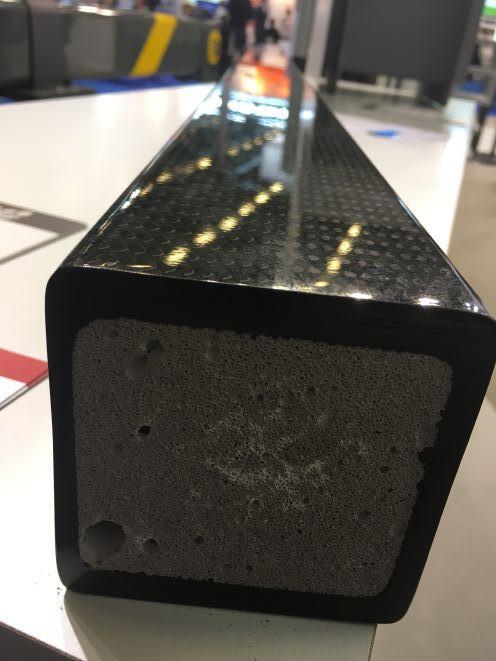

So there are examples of this but they, again, add different complications and factors. The best being dissolvable tools, and 3D printing actually plays a role in this. But I think the most likely solution for your world would be making what they would call a sandwich part where maybe it wouldn’t be hollow but it would have a foam or honeycomb structure in the middle. So you could have it with a variety of different types, like a PET foam or something in the middle that could both add extra stiffness and also give you some properties, like vibration dampening, sound dampening, thermal, electrical and maybe some moisture resistance. •

Dr. Richard Collins is a technology analyst for IDTechEx, a U.K.-based technology consultancy with offices in the U.S., Germany, Japan and Korea. He has a background in polymer science and leads IDTechEx’s research into lightweight materials.

by RICH PORAYKO

The Canadian Glass Association’s Glass Connections conference hit a home run when it returned to Burnaby, B.C., in June, offering high caliber educational and networking opportunities with local, national and U.S. glazing leaders. The welcome reception on June 7 was a success with many sticking around until late singing everything from “Sweet Caroline” to “Sweet Child o’ Mine” at the casino’s dueling piano bar.

Glazing restoration was a major theme of the conference with Tremco’s senior building envelope specialist, Bill Cardott, kicking off the full-day program. “Upgrading glazing systems for energy performance is probably one of the

first things people are looking for nowadays in a glazing restoration,” said Cardott. “Just upgrading to wet seals to reduce air leakage improves energy performance. But there are all of the other typical reasons for a restoration: fixing something that was done wrong in the first place, solving leaks, improving the esthetic or changing a system that has simply worn out.”

There are a lot of potential causes of glazing failures. Some of them are readily recognizable while others are not as obvious. “When someone says ‘my windows are leaking,’ it’s very important to look at the interconnections,” said Cardott. “When you look at the interconnections, a lot of times it’s not related to the window. It’s the connections.

“With all the differences in glazing and potential remedies, it’s really important that every single glazing restoration project begin with a licensed professional who’s properly equipped and trained to survey the conditions and find out what’s really wrong and find out what can be achieved with the window system in terms of performance,” he went on.

With the advent of fire-resistive products, there are many

more options at your disposal from a design standpoint compared to just a few years ago. Tim Nass of Safti First emphasized that natural daylight is an important consideration. “The system looks like a standard interior storefront, but in fact is a two-hour fire barrier. Glass and frame work in concert together to control the visual elements as well as the energy generated. You see the flexibility in design.”

Nass told attendees that codes are evolving to where he sees demand for these products on the exterior of the building.

“When you incorporate a soft coat low-E, you can be assured you are going to be getting impressive solar heat coefficients, Uvalues and condensation-resistance factors,” said Nass. “There is no degradation in performance when these products are incorporated into the building envelope. They have been tested statically as well as dynamically. These products enhance from a code perspective as well as from an overall performance and esthetic perspective.”

Canada is going through a big code transition. Wired glass has lost its safety designation in the National Building Code.

ABOVE: By travelling around the country, Glass Connections gives architectural glaziers a rare opportunity to mingle. Richard Verdon, Jim Brady, Wei Chen and Christine Jaynes appreciate the chance.

“Does fire-rated mean that it’s safety rated? The answer is ‘No.’,” said Nass. “They are mutually exclusive. Just because a product is fire-rated, doesn’t mean that it is safety rated. However, products in the market today are tested for both. Wired glass has been used across Canada. It was given an exemption for a safety rating because it was the only rated product on the market.”

Wired mesh products give the illusion of security, durability and strength. According to Nass, it actually weakens the glass by half. “The issue is that not only does the glass break, it remains in the opening,” says Nass. “An individual who penetrates that opening can cause serious damage to themselves because of the wire mesh. It’s very gruesome. I read that the Ontario School Board insurance exchange incurred $6 million from 2001 to 2015. It’s one of the most heavily litigated aspects of fenestration. They go after the glazier. You’re the glazing professional. You’re the expert in their eyes.”

Nass said wired glass that does not comply with safety standards is illegal. “They are coming to look for you if you

Jim Brady, past president, (right) took time out to thank Richard Verdon of RSVP, who has been a strong proponent of the CGA.

put that piece of glass in and something happens. Be aware of that. There are better options than the wired product.”

“When someone calls me and says ‘I have a problem with my glazing,’ it usually breaks down into a couple of issues,” said Brian Hubbs of RDH Building Science.

“Condensation on the interior when it gets cold out. That’s a very common one. Sliding patio doors tend to go pretty quickly. That’s very indicative of the IGU losing its edge seal. Condensation on the exterior is common but it’s not an actual defect. I get calls on it all the time. That’s

just high-performance glass.”

Hubbs believes that the durability of the glazing units is the single biggest aspect of an IGU. “It has to be airtight. It has to be moisture-resistant. It has to have a good vapour barrier.”

“Corrosion of low-E coatings often correlates well with high dew points,” Hubbs went on. “If there is a low-E coating on it and you look carefully and see fingerprint marks and roller marks, you can often tell that it has condensed. It has corroded that low-E coating and it just isn’t full of water right now.”

Hubbs feels that in-situ repairs of IGUs are rarely practical. “I have never found one that is really good unless someone forgot to seal a capillary tube, it is really early on and hasn’t failed the unit yet.”

With Canada moving towards the Passive House standard, Hubbs told the audience that the industry is going to be throwing everything we can at our glazing systems to be as energy efficient as possible. “Argon will be a critical part of this process to get to the levels that we need to get for Passive House. So you’re really going to want to make sure that

argon is actually in your units. I provide a quality assurance role that things are as specified. When it comes to air, water and thermal, I can sign a letter of assurance that this building meets the requirements that we set. So I want to make sure that there’s argon there.”

Being a clear, colourless and odorless gas, the presence of argon is pretty difficult to confirm. “A nice way to make sure is to go to the plant and check that they are doing it properly,” said Hubbs. “There are some plants where the IGU assembly is an argon-filled room where it is very hard to make a mistake. Other plants drill two holes and fill the gas until a buzzer goes off. There are a lot of ways to do it. Unlike past years, it didn’t really matter because no one would ever know if the argon was there. In the future years, two or three years from now, it will matter and people will know if it’s not there.”

RDH tested 100 random units in the field for argon. Hubbs told attendees all IGUs were manufactured within one to four months previously so there was no argument that the argon diffused through the spacer. “If the argon wasn’t there, it wasn’t put in or it escaped

before it was sealed. Three percent had concentrations above 90 per cent argon fill. Twenty-five per cent had concentrations between 75 and 90 per cent, and 11 per cent had concentrations between 50 and 75 per cent. Sixty-one percent had no measurable argon. Some of the initial studies out of IGMA say you can easily expect argon to last the life of the unit if it is built properly.”

So what is Passive House and why is making sure argon is actually inside your IGUs so important? According to Monte Paulsen, also of RDH Building Science, a simple way of thinking about Passive House is that it is a building with a sweater around it that is so thick that you wouldn’t need and could not install a furnace.

“We super-insulate the building with very thick walls, ceilings and floors,” said Paulsen. “In the residential scale, we are typically talking walls in the R50 to R60 range. If we move to an apartment building where we have better form backer, the walls are in the R30 to R40 range. They have much more stringent air tightness in the range of 0.6 air changes per hour.”

Thermal bridges are being eliminated.

“We’re designing out those places where concrete and metal window frames transmit energy through the building enclosure,” said Paulsen. “Triple-pane glazing in every instance until we start talking about northern Canada, where we are looking at quadruple-pane glazing. Mechanical ventilation with a minimum of 75 per cent heat recovery, although we are always looking for heat recovery in the 90 to 95 per cent range.”

And finally, just a little bit of heat. Paulsen said a typical passive house will only need a few BTUs of heat in December and in January and you won’t even see the meter run the rest of the year. In a recent Passive House project in Langley, B.C., a family of five went through the winter and didn’t notice that the heating system wasn’t connected. You could literally heat it with a hair dryer, if you needed to.

“The ticket item that is the sticker shock for every developer is windows because they are automatically tossing out the double pane window option and looking at high-performance triple-pane windows,” said Paulsen. “If there is a sector in the industry poised to do very well on the move to Passive House, its glazing.”