performance under pressure

INTRODUCING 1630 SS IR CURTAIN WALL – ELITE IMPACT RESISTANCE FROM KAWNEER

High Performance. Larger Spans. Increased Impact Resistance. Kawneer’s new 1630 ss Ir curtain Wall – an impact resistant 3" sightline curtain wall system – offers an additional line of defense against high winds, heavy rains and hurricanes. Having undergone rigorous testing, our new curtain wall meets increasing design pressure requirements in impact zones and can deliver larger spans. and, screw-spline architecture with both dry and wet glazing options makes the 1630 ss Ir easy and fast to install. Kawneer knows how to protect buildings and occupants. 1630 SS IR Curtain Wall is performance under pressure.

Aluminum Systems

+ Framing

In

20 GlassBuild preview

North America’s big showcase for the glass industry is back in Atlanta in September.

22 Window and door hardware showcase

If it locks or swings, you’ll find it here.

DEPARTMENTS

14 Innovations

RPM Rollforming is pushing the boundaries of what can be done by bending metal.

18 Under the Glass Ferguson-Neudorf looks at installers as customers – and finds great success.

ASSOCIATIONS

Greening our reputation

A lot of people think manufacturing is always bad for the environment. It is time for us to educate them.

There was a commercial on TV recently for Kijiji, which is an online marketplace where people can post classified ads to sell their used stuff. The commercial is listing all the reasons why the frumpy-looking guy who just bought a washer and drier on Kijiji is a “hero.” One of these reasons is that, because he bought a used item, no new washer and dryer had to be manufactured, which is good for the environment.

Is this what we have come to: not manufacturing things seen as so socially positive it can be used as a marketing benefit? Does anyone beside me see a problem with this?

NEXT ISSUE

• Win-door preview • IG components

We wonder why young people are not interested in getting into the trades. We wonder why our domestic industry takes flight overseas. We wonder why efforts to turn these destructive trends around never seem to get off the ground. Here is part of the answer. There are some people who simply do not see any benefit to having a manufacturing sector in our economy. In fact, if the makers of Kijiji’s marketing campaign have their numbers right, there are significant numbers of people who see manufacturing enterprise as downright detrimental. In such a political climate, it comes as little surprise that our capability as a nation to make things declines bit by bit every year.

The whole attitude is owed, in my opinion, to people who have little idea about and less interest in where the things they buy come from. They are not people who make things with their hands, and probably do not even know anyone who does. They have no idea what role manufacturing plays in the economy, or even the direct role it plays in their day-to-day well-being. Instead, it is just something dirty and distasteful that other people do. Oh, and someone told them it is bad for the environment.

Our industry needs tools to combat this kind of thinking, and this issue’s cover story is about one of those tools. Environmental Product Declarations give manufacturers a chance to show their customers proof of where their products come from and exactly what impact their production has in a number of different environmental categories. The declarations are certified and updated by third-party auditors, so there are no questions about “greenwashing” and everyone is on a level playing field. One of the article’s sources, Mike Silverberg of Technoform Bautec, described them as nutrition labels for manufactured products, and I agree they play an analogous role. Getting third-party certifiers to support industry standards is how North American manufacturers have proven product quality for years, so it makes sense to apply the same regime to environmental concerns. Another plus: EPDs are about giving the customer information, not about telling manufacturers how to make products or run their businesses. •

August 2013 Volume 25 • Number 4

Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexweb.com 226.931.0545

SALES MANAGER | Danielle LABRIE dlabrie@annexweb.com 519.429.5187

SALES ASSISTANT | Jarah STEFEK jstefek@annexweb.com 519.429.5183 | 888.599.2228 ext. 219

MEDIA DESIGNER | Alison KEBA

GROUP PUBLISHER | Martin MCANULTY mmcanulty@annexweb.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: subscribe@glasscanadamag.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

e-mail: subscribe@glasscanadamag.com Tel: 866.790.6070 ext. 208 Fax: 877.624.1940 Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST)

($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.glasscanadamag.com

INdUSTry NEWS

Triple Seal acquires Guardian Rexdale

TripleSeal, which includes Independent Mirror Industries, has announced the acquisition of the Guardian rexdale facility from Guardian Industries Canada, whose parent company is Guardian Industries, headquartered in Auburn Hills, Mi. The acquisition will add laminated glass to Triple Seal’s fabrication product line as well as increased capacity for tempering, fabricating and IG units. Plans are already under way to add new technologies to the rexdale plant with the installation of a heat soak oven used to test tempered glass for applications such as balcony railings. The Guardian rexdale facility will now be named Triple Seal rexdale and orders will be honoured going forward.

Mark Franklin, president of Triple Seal, says that the company had been researching and preparing for this acquisition for many months, and the combined strength of both companies is a great opportunity for Triple Seal to deliver greater value to customers through increased capacity and broader product offering.

“This is a very exciting time for Triple Seal,” he said. “We see huge business potential as we are acquiring solid production capabilities with great people, leading edge equipment and a strong customer base.”

The extra capacity that the rexdale facility affords, as well as laminated glass, strengthens the ability of the Triple Seal Group to offer a full glass solution to existing customers such as oEM furniture manufacturers, contract glazers, installers and all other glass consumers. Triple Seal is a regional glass fabricator and flat glass distributor headquartered in Toronto, with branches in London and ottawa. It specializes in IGUs, but also offers a range of other product types. Triple Seal serves contract glazers working on commercial and residential projects, as well as glass shops and window manufacturers.

Founded in 1976 as a manufacturer of IGUs, Triple Seal began serving the residential market working out of a modest 2,000-squarefoot facility in Toronto. Its first major expansion came in 1988, when distribution of glass products was added to the product offering. rapid expansion followed throughout the 1990s, with branches established in ottawa and London. Today, those branches account for approximately 300,000 square feet of manufacturing space. Each branch is fully self-sufficient, able to take on commercial glass fabrication, but working in close collaboration with its sister branches, ensuring consistency in quality and distribution processes.

PPGIndustries has named bradley P. boone market manager of the residential segment, PPG flat glass. A 33-year PPG veteran, boone brings vast experience in the production of glass and in the technical support and marketing of glass products. For the past 12 years, he has been a senior account manager serving residential, architectural and solar glass customers in the northeastern U.S. during his career, boone has provided technical and customer support for well-known PPG brands such as Solarban and Sungate low-emissivity (loweglasses and Intercept insulating spacers.

Patrick J. Kenny, PPG director of marketing, flat glass, said, “New building codes and consumer concerns are increasing the demand for more energyefficient homes, and in turn driving innovation in the residential window and door market. brad has the experience and technical knowledge to help window and door makers meet the performance and costmanagement challenges they face. His background also will enable him to help PPG more effectively translate the needs of consumers and window makers into customer-driven solutions.”

CGA Newsletter

CANADIAN GLASS ASSOCIATION

TheCanadian Glass Association held its Annual General Meeting on June 27 via webinar. A new board of directors was elected at the AGM and they are:

• Mike Higgins of Economy Glass in Moncton, N.b (APGA)

• richard Verdon of rSVP Agency in ottawa, ont. (APGA)

• Alain Langis of Gamma Industries in L’Ange Gardien, Que. (AIPVFQ)

• Angelo Cairo of Stouffville Glass and Mirror in Stouffville, ont. (oGMA)

• Fred Fulton of FI Glazing Solutions in Etobicoke, ont. (oGMA)

• dennis Haatvedt of AGC Flat Glass North America in Vaughan, ont. (AGMCA)

• Jim brady of desa Glass in Calgary, Alta. (PGAA)

• Chris Johnson of oldcastle building Envelope in Calgary, Alta. (PGAA)

The CGA then held its first board meeting on July 4 where a new executive was voted in. They are:

• Jim brady, president

• Alain Langis, vice-president

• dennis Haatvedt, treasurer

The new board has set aside the first Tuesday of every month at 10:00 a.m. PST, 1:00 p.m. EST for its monthly board meetings. It is the hope of the new board that consistent meetings will help to move the association forward. The primary focus of the new board will be the Glass Connections show to be held

in Calgary on october 10 at the Acclaim Hotel. More details will be provided, please save the date.

The board will also be reviewing the direction of the association and once a consensus has been made, the findings will be forwarded to the provincial/ regional associations.

The CGA wishes to thank the past president, david Langton, and the previous board of directors for all of their efforts and hard work over the years. We have completed our programming for the Glass Connections Calgary 2013 Conference at the Acclaim Hotel in Calgary on october 10, 2013. Here is the speaker lineup:

1. building Codes in Canada. Are you ready?

Jeff baker, Fenestration Canada technical consultant

2. building Envelope Commissioning as Part of the design and Construction Process Mark Van dalen, bVdA Engineering

3. dynamic Photochromatic John Carpenter, president of Clearstream International Products / Schott okalux Architectural Glass

4. Looking beyond Today’s Glass systems: New and

Innovative Products and System designs for the building Envelope

Mike Harpell, read Jones Christoffersen

5. designing Glass railings and designing overhead Glazing Units

robin Czyzewicz, dupont

The program will include a breakfast, lunch and table top opportunities. Thanks again to our great technical committee for arranging these presentations: Leonard Pianalto (rJC), Steve Gusterson (Alumicor), and brent Harder (Ferguson).

ONTARIO GLASS AND METAL ASSOCIATION

Atour spring golf tournament at Glen Eagle GC in bolton, ont., president Steve ringler presented the inaugural winner of the oGMA’s Award of Excellence bursary to brad bida from Thunder bay, ont. brad recently successfully completed the glaziers apprentice program at the ontario Indus-

trial Finishing Trades School. read more in Frank Fulton’s column.

Mark Thursday, Sept. 19 on your calendar and plan to attend the renowned oGMA Fall Golf Tournament once again being held at the Carrying Place Golf Club. The weather is always good, the food is great, and we will be presenting our second oGMA Award of Excellence to a deserving glaziers apprentice student.

The oGMA fall seminar is being planned. details to be announced later.

Now that the NHL is prepared to play a full season again, we have booked a block of 20 seats to a detroit red Wings game in detroit. details will be firmed up once the official 2013 – 14 schedule has been released.

PROVINCIAL GLAzIERS ASSOCIATION OF ALBERTA

ThePGAA will be holding its third annual golf tournament at Alberta Springs in red deer. We have 144 golfers registered. All proceeds will go towards education initiatives with the primary focus on the Master Glazier Program.

The Master Glazier Program is currently being developed with subject matter experts and with SAIT. There are nine courses in the MGP, which is gearing towards continuing education for certified journeyman glaziers. We anticipate that this tournament will raise in excess of $50,000 toward the MGP. over the three years, the tournaments have raised in excess of $95,000, all of which is going towards education initiatives. Ray Wakefield of Trulite was presented with the OGMA Lifetime Achievement Award at the spring golf tournament. For a full report, search “wakefield” at www.glasscanadamag.com.

Loewens back in Loewen

Loewen of Steinbach, Man., has been acquired by a group of investors including Charles Loewen, Clyde Loewen, Al babiuk, president and CEo, members of management, and other

Hanam retires

MorganHanam, head of Enermodal Engineering’s window division, has announced his retirement at the end of July. He leaves the Kitchener, ont.,-based consulting firm after a 35-year career in the fenestration industry. Hanam is 60. Hanam’s career in the window industry started at Golden Windows in 1977, moving to Enermodal in 1999. He has been continuously active

private investors. Loewen is a manufacturer and distributor of custom-made wood and clad wood windows and doors for the residential and light commercial markets.

The company was established in 1905 and sells through a network of Loewen window centers and authorized Loewen dealers in the United States and corporate retail stores and independent dealers in Canada. Charles Loewen will assume the role of chairman of the board, and Clyde Loewen will be rejoining the executive management group. In addition to investment by the shareholders, royal bank of Canada continues to provide banking facilities for Loewen

and financing for capital investments has been provided through the Manitoba Industrial opportunities Program through the province of Manitoba.

Loewen will continue with its strategic focus of providing premium quality, innovative products for the window and door market, while expanding its product portfolio, implementing lean processes, and developing its employees. The company was owned by the Loewen family until July 2010 when it was acquired by VKr Holding A/S of denmark. A review by VKr of its portfolio strategy for North America led to a decision to divest of Loewen, as well as Gienow Windows and doors of Calgary.

in industry associations, including a term as president of the Canadian Window and door Association in 1997 and 1998. Hanam has participated on technical committees for the Canadian Standards Association, the Canadian General Standards board, the Insulating Glass Manufacturers Association of Canada, and the National Fenestration rating Council. He was inducted as a Fenestration Canada Pioneer last year, and won the C.P. Loewen award for lifetime achievement in 2000. Hanam was also honoured by the CSA for 25 years of

service in 2010.

Hanam says he has welcomed the opportunity to improve products in the industry and thus contribute to the overall improvement of society. He is proud of the level of service to clients he has been able to give throughout his career. He says he worked make Fenestration Canada a more open association and less of an old boys’ club.

Hanam says he will continue to work a bit, but take longer winter breaks with his wife, Gail. Micheal barclay will take over his responsibilities at Enermodal.

Fenestration Manitoba holds inaugural AGM

Fenestration Manitoba held its firstever Annual General Meeting June 11. It was a combination educational day and golf event, including an informative presentation by Fenestration Canada technical directory, J.F. Kogovsek of Maxam Marketing. About 50 attendees took in the morning presentations. The seminars were followed by golf, a short

official program in the early evening and then a dinner at the rossmere Golf and country club.

Acrylon, Cardinal, PPG and Veka sponsored the AGM event. Amesbury, Anatoli Glass and Mirror, Crystal Glass, rehau, Screenco, Sika, Truth Hardware, Windowmaker and Zobel sponsored the golf.

by SKIP MACLEAN

Skip Maclean is president of Fenestration Canada. He is business development manager for Tru-Tech Doors and has over 40 years’ experience in the window and door industry.

A call to action

There is a growing perception that a fundamental group of window and door fabricator owners is underrepresented at industry events, meetings and discussion forums. Fabricator involvement and visible participation at the table in helping this association deal with emerging issues of concern, particularly in the areas of code compliance and implications for product conformance, is critical. To address this shortfall, Fenestration Canada is launching a Fabricators’ Council spearheaded by a leading fenestration manufacturer. Lisa Bergeron, government relations manager for Jeld-Wen of Canada, has accepted our invitation to chair this council. The group will be comprised of member window and door fabricators only with the proviso that the council would seek the assistance of experienced experts and regional input as required.

In our view, this bedrock group of fabricators will benefit greatly from the opportunity for companies to meet and discuss a variety of key interests, including the processes for development and implementation of codes. The objective of this council will be to obtain a broader and deeper participation by window and door fabricators at all Fenestration Canada events. It is through the collaborative efforts of those who are directly involved that we can be assured that this group and other committees can work together and maintain perspective on the development of policy and initiatives to protect and promote the long term health of fenestration manufacturing. An effective Fabricators Council will be a long term asset to the practical, effective implementation of initiatives promulgated by Fenestration Canada.

Don’t just wait for things to happen; become part of the solution.

“Window and door fabricators are uniquely challenged as they bring a finished product to market,” Bergeron says. “This council was set up to provide a forum for fabricators to address issues that are inherently specific to commercializing products. Our objective is to engage more fabricators in their association and Industry. We are at a very crucial time in the building industry where the codes and regulations are changing the landscape on what seems like a daily basis. It’s exciting to see Fenestration Canada initiate such a group giving fabricators the opportunity to become more involved in their Industry. I am honoured that the Fenestration Canada executive board has asked me to chair this new council and look forward to working with Industry colleagues on the challenges ahead.”

Fenestration Canada is a membership-driven organization with a mandate to represent and support all aspects of the window and door manufacturing industry across the country. This includes involvement and promotion of high quality standards in manufacturing, design, marketing, distribution, sales and application of all types of window and door products. The association operates through an elected board of industry representatives and members are encouraged to get involved in various committees and working groups to address specific issues of interest to those involved in the fenestration sector. The primary committees are: Technical Services; Government Relations; Edcation; Win-Door Show; Finance; Governance and Editorial/Media Relations.

We invite all interested Fenestration Canada fabricator members to consider getting involved with this collaborative effort which will lead to better understanding and solutions to the challenges that lie ahead for all. Don’t just wait for things to happen, become part of the solution –your business profitability and viability will depend on it.

Please call or contact Robert Rivard at the Fenestration Canada office if you wish to support this initiative and participate in this very worthwhile council. Robert can be reached at 1-613423-7239 or via email at rrivard@fenestrationcanada.ca. As always, we invite members and potential members alike to visit our website regularly for important updates on activities and availability of information and resource materials. The website link is www.fenestrationcanada.ca.

FENESTrATIoN CANAdA

GREEN FOR LIFE

Environmental Product Declarations level the play

by PATRICK FLANNERY

Think of them as nutritional labels for manufactured products. Environmental Product Declarations (sometimes called Type III Ecolabels) are third-party monitored certifications that tell your customers exactly what impact on the environment your products have. To do so, they refer to a commonly agreed set of industry measures called Product Category Rules that set out the way environmental impact is assessed and presented for fenestration and building envelope components. Once the PCR regime is established for an industry, customers can compare apples to apples when looking at a product’s green credentials because each company measures and reports on the same environmental impact factors in the same way. Things like carbon footprint, contribution to acidification, energy efficiency in production and recyclability are measured, looking at the product’s entire life cycle from raw materials to destruction. Critically, manufacturers are not told what they have to produce or how to produce it. They are just told how to measure and report the environmental impact of their product. Customers can still choose to buy a less earth-friendly product, but with an EPD attached they know exactly what they are getting.

For fenestration fabricators, attaching an EPD to your product gives you a chance to answer all your customers’ questions about a product’s life cycle and environmental impact with one clear and mutually understood document. If your company has worked hard to save energy, reduce waste, recycle and source local materials to meet LEED standards and other such demanding builder specifications, an EPD gives you a chance to leverage that investment into new sales to environmentally conscious buyers. “Sign me up,” you may be saying. Well, there is a snag. No PCR yet exists for windows, doors and other architectural glazing components. But after years of effort, a multi-association task force may be closing in on developing these valuable certification tools for North American glaziers.

This is the image many people have when someone mentions manufacturing. If the glass industry is to counter this perception, we need an accurate, standarized measure of our environmental impact.

ing field for green product claims.

An EPD is a document that lists as comprehensively as possible the environmental impact that your product represents. For instance, an EPD posted by Cormo, an Italian wood window fabricator, lists all the material that go into its windows by percentage of the finished window. It details the kinds of wood, paint, fasteners, sealants, glass and other materials used. It outlines the expected lifecycle of the window. Then it lists measures of the following environmental impacts arising from sourcing the materials, fabricating, shipping, installing and disposing of its windows. Global warming, ozone layer depletion, photochemical oxidation, eutrophication and acidification are all tracked and given numbers. (If you are wondering what any of those are, check out the sidebar.) Importantly, the way these numbers are obtained and reported is all covered in the Product Category Rule, which is agreed on and filed with the governing agency.

Mark Silverberg, president of Technoform Bautec North America, co-chairs the American Architectural Manufacturers Association task group that reports to members on the efforts to develop an industry-wide, North American PCR for fenestration products. Those efforts are occurring inside a cross-association task group with members from AAMA, the Glass Association of North America, the Insulating Glass Manufacturers Alliance and the U.S. Window and Door Manufacturers Association, with participation from Rita Schenck, executive director of the Institute for Environmental Research and Education. “What you

are going to have is a PCR for windows,” Silverberg explains. “That is going to include windows, skylights, residential, commercial and full-view patio doors. One PCR includes a scope that theoretically could have included entrance doors, but we felt that was too complex given the ingress concerns. So we have stuck to windows and patio doors, but windows in a commercial application gets you into storefront.”

The official EPD name and logo is trademarked by the European Union, and companies must be registered with the governing body, Sweden’s Environmental Management Council, in order to use it. The whole registration and certification process is underpinned by ISO 14025. Centralized control of use of the logo, registration standards and the certification list is intended to keep the system credible and independent - critical aspects if it hopes to gain the support of builders and their suppliers. According to the official website at environdec.com, almost 200 organizations in 19 countries have registered 400 EPDs covering hundreds of products. Given that the system is applicable to just about every kind of manufactured product as well as services, it is safe to say the program is in its infancy as far as market penetration.

Tom Gloria, a life cycle assessment consultant based in Boston, Mass., recently updated the American Architectural Manufacturers Association on EPDs at its conference in Rosemont, Ill., in June. Gloria sees a number of factors converging that could make use of EPDs take off in North America.

Global Warming: Changes in the surface-to-air temperature, referred to as the global temperature, brought about by the greenhouse effect caused by the emission of greenhouse gases.

Ozone layer depletion: The layer of atmospheric ozone that protects the earth from the sun’s ultraviolet radiation is damaged by the release of chemicals called chlorofluorocarbons and halons which are used in refrigeration, cleaning and aerosols.

Photochemical oxidation: A combination of fog and chemicals from automobile and factory emissions that reacts with the sun to cause smog.

Eutrophication: Excessive enrichment of water with nutrients causing destructive algae blooms and other adverse biological effects.

Acidification: Changes to the natural environmental chemical balance from increased concentration of acids. Contributes to acid rain.

The first is frustration with the absence of any internationally accepted standard for quoting product life cycle information. “The kind of Wal-Mart effort that has occurred added a market driver to the sustainability consortium,” he explains. “They [the U.S. Green Building Council that administers LEED] were going down a different path that was outside the ISO umbrella, so it really didn’t catch on. They had the market, but they were not playing by the same international rules so it did not have that mass proliferation.” When manufacturers and builders have a Chinese menu of different certifications to choose from for each component, it tends to weaken the value of the entire certification process and open the door for funny business. Demand from architects and high-end homeowners for green fenestra-

tion components has not waned, but fatigue from dealing with overlapping and contradictory certification regimes has shot up. “Sustainability professionals have had a challenging situation with all sorts of entities claiming environmental performance,” Gloria says. “EPDs are a way to ameliorate that issue of apples and oranges and get everyone on an even playing field.”

Because the EPD system is tied right into the EU Environmental Directorate - a body roughly equivalent to the U.S. Environmental Protection Agency in terms of its ability to regulate and enforce environmental rules - Gloria sees the day coming sooner rather than later when EPDs could become a matter of law. “It could go from voluntary to compulsory pretty quickly,” he predicts. “It has all the mechanisms to do so and the infrastructure to do so. It has the ISO stamp on it. It has the government stamp on it. It has the western European market, with is as large as the U.S. market but with that sense of the various nations within the EU involved. So it has many different Developing an EPD for your products will probably entail hiring a consultant or investing in some software that is capable of crunching your numbers and spitting out the correct measurements. What is the contribution to global warming of producing a pound of aluminum? What if that aluminum was made in China instead of Canada? These are the kinds of questions most companies do not easily know the answer to. However, there are databases with the accepted answers, and consultants and software companies know how to use those databases. Gloria emphasizes that gathering the information itself is not as onerous as it may appear. “Companies are usually tracking this stuff already,” he points out. “They are purchasing electricity and they know how much money they are spending on electricity because they are trying to reduce the cost. They know how much material they are buying because they are trying to be more efficient. To find out the carbon footprint for that material, I just plug it in to a data suite and we have a cottage industry of software to calculate it.”

Silverberg sees EPDs as potentially carrying strong benefits for the glass industry. “I think to establish accurate standardization of the environmental aspect of our products reinforces their legitimate marketability,” he says. “Consumers can know that the product claims match and that performance matches the claims. That is what AAMA’s technical standards have represented for over 75 years - to ensure consumers get what manufacturers claim is in the product.”

It is a green and greening world out there with builders and architects pushing ever harder for more energy-efficient and environmentally friendly products. They have the ear of governments and institutional owners, who will not build anything any more unless it meets some high standard of green construction. Regulators and activists would be only too happy to tell you not only what standard to build to, but specifically how to build and what materials to use. You need only look at the fight over window-to-wall ratios to see how that debate could turn out very badly for our industry. EPDs offer the chance for the industry to go down a different regulatory path. If fenestration fabricators can satisfy regulators that consumers have all the information they need to make environmentally conscious choices, then the onus shifts to consumers to choose those products. •

Rockin’ rollforming

rPM rollforming is taking an old fabrication technology in new directions.

AT RIGHT: An extensive library of dies gives RPM the ability to quickly come up with rollforming processes to meet custom demands. Because creating new dies is one of the biggest costs in rollforming, this huge inventory can help keep costs down.

Rollforming is a process normally associated with fast mass production of relatively simple, linear shapes in metal. Coil aluminum or steel is fed into a series of dies, rollers, punches, notchers, presses, welders and saws and strips of cut-to-length product are continuously discharged at the other end of the line. In the fenestration industry, rollforming processes have provided such commodity items as C-channel, muntin, grille and pencil bar, sash reinforcements and patio door track for decades. If you ask most people, little has changed in this field of metal fabrication in living memory. But RPM Rollforming in Concord, Ont., and its executive team of vice-president Yousif Abachi and sales manager Vince Porcelli, think they can offer more. Having already pioneered a thermally broken aluminum spacer – the well-known Climatech product – the RPM team is looking for more challenges from the glass industry to create new channel profiles with custom contours, special bending characteristics and exotic materials. Abachi says their combination of experienced staff, long exposure to the industry and engineering expertise gives them the flexibility to take on the kinds of unique custom projects other rollformers have long shied away from.

RPM’s journey to innovations started

with previous owner Gunter Berdan’s invention of Climatech three years ago. Climatech IG spacer bar incorporated plastic into the rollformed aluminum or stainless steel profile, creating a thermal break and allowing IG manufacturers to achieve a warm edge with the structural integrity of metal. Finding the right resin to integrate into the spacer bar was challenging, but the real innovation was in the process design. “The key piece is doing operations that would otherwise be done as a secondary operation,” Abachi explains. “You don’t really impact the speed of the line in feet per minute, but you get more processes done. In this case, the metal is bonded to the plastic in-line. All the prepunching and holds are done as an in-line process. So it is very cost effective and eliminates secondary operations as much as we can.” Porcelli reports that window fabricators have found the Climatech spacer easier to bend than some other products, which makes the assembly process more efficient. The combination of function and low-cost, high-speed production has made Climatech RPM’s flagship fenestration product. But Porcelli and Abachi are sure there is more out there.

Much of the rollforming that now takes place in the fenestration industry is by companies who are primarily fabricators

and invested in a machine to satisfy their own needs. RPM’s difference is the company is a rollforming specialist first, serving a wide variety of industries from storage to automotive. Berdan recently sold the company to a larger group that includes tool and die, hydraulics, mould-making, precision grinding and automation shops. So RPM has a wealth of metalworking experience to draw from, and not just in aluminum. Yet the company’s experience with the fenestration industry is now so extensive, it is seeing some significant advantages when designing new processes for new products. “With the vast library we have amassed of punching and rollforming and tooling, we have noticed that a lot of guys will use similar components,” Porcelli says. “Window guys tend to use similar lineals, and because we have created a library we can now go out there and say we may very well have all the tooling and punching requirements in-house. So that helps keep the costs down for the market.” Creating new tooling for a specific shape in a rollforming process is probably the single most expensive element of setting up a new line, and a major reason why most rollformers dedicate one line to one product and never change it. With a stock of established, fenestration-related tooling to choose from, RPM has put itself in a better position to serve the industry. If making tooling is the single most expensive element of changing over a rollforming process, the various elements involved in setting up and commissioning a line for a job probably add up to the greatest chunk of the overall cost. For a rollforming line to function correctly, dozens of separate tools, guides, switches, sensors, and materials need to operate in tandem with perfect timing and minute positioning accuracy. Every adjustment affects several other settings up and down the line. Even with modern computer controls, calibrating a rollforming line is more of an art than a science. In a shop with inexperienced operators, or operators for whom running the rollform line is not their primary occupation, changing the setup on a rollforming line is something to be avoided at all costs. Days of labour are often involved, and weeks if something goes wrong. This is where RPM’s identity as a rollforming shop first really pays dividends and puts it in position to try some new things. “Over the years, RPM has developed a very strongly skilled setup staff,” Abachi says. “Not only do we have 14 lines here with the 15th coming, but within those 15 lines none of them are dedicated. Some of these lines see changeovers two or three times per week. We are very flexible and agile and have a very strong team on the backs of our setup personnel rather than operators only.” One area where ex-

perience gives RPM a distinct advantage is in prepunching. “The process of pre-punching involves several feeders, like stamping,” Abachi explains. “You need to add a pre-punch press and then integrate the whole line together. So it is not just about putting the line in place. It is about having people who can set up these lines, achieve a stable process and get a repeatable accuracy from hole to hole.” Abachi uses the example of changing coil thicknesses, a common challenge in the industry. “If the next master coil has a thickness variation, that will drive changing the settings from A to Z – from the prepunching, through several feeders, the pressures, the rollformers and the clearances as well. The ability to do that quickly is not something that came over night. That is something we have developed over the years.”

It is difficult to see how the tool could have made such a fold without. The ability to work with steel – even heavy steel up to seven gauge – opens on prepunching thicker steel and heavier gauge material,” Abachi admits.

HERE COMES THE SUN

rPM sees great potential for rollforming processes in making solar energy components. Photovoltaic panels tend to be larger and heavier, making steel channels and brackets more desirable. Solar energy collectors often need channels and framework for wiring and electronic panels, as well as punched pieces for mounting and attaching external equipment. rPM has picked up work on some large projects of this kind both in Canada and the U.S., and hopes to expand its portfolio in this area.

Abachi is eager to help fabricators develop new products or improve old ones. “We have gotten involved in the development phase when the customer has a theoretical sketch of a more complex channel and they pass it by us so we can give them feedback,” he says. “We can tell them what changes would take that project that requires $100,000 in tooling down to a project that requires $2,000 or zero tooling. We have found that is very much appreciated for two reasons. One, it eliminates costs. The second thing is lead time because if we do have standard tooling that can achieve a certain shape we could be up and running within three days if we have a slot available on the machine.”

rollforming processes are especially suited for the following components and processes:

• Z purlins

• C channels

• U channels

• punching

• notching

• cut-to-length

by bILL LINGNELL

Bill Lingnell has over 46 years of experience in the technical field of glass and architectural products. He holds three Masters of Science degrees in engineering: civil, mechanical and engineering science. Lingnell is the technical consultant for the Insulating Glass Manufacturers Alliance.

Shadow conditions

In the June 2013 publication of Glass Canada, Margaret Webb gave an overview of a Technical Services bulletin developed by the Insulating Glass Manufacturers Association to assist the industry in providing a proper technical understanding for thermal stress. The bulletin, TB 1300-13, is titled Guidelines for Thermal Stress Considerations. IGMA has recognized the demand for an understanding of this subject matter and has addressed this issue by the guidelines presented in the document that are intended to assist those who design, specify, manufacture and install insulating glass units.

The June article expresses an outline of the many elements that contribute to the condition of thermal stresses that occur in insulating glass units. Here, I will highlight some of the conditions that contribute to thermal stress when shadows occur on the glass in a commercial or residential building. The IGMA bulletin that is intended to be released this fall after the final review by the IGMA technical policy committee and board of directors has addressed this item in the Building Design section of the bulletin.

The architect or building designer will create a building façade or residence with specific architectural features that include overhangs, extended vertical and horizontal framing members, punched openings, special shade devices and other items that will cast shadows on the glass at certain times of day on certain elevations of the building. These must be considered in the thermal stress review. One of the most common examples of thermal stress breakage can occur

One of the most common examples of thermal stress breakage can occur from conditions arising from a clear, cold winter night.

IGMA

from conditions arising from a clear, cold winter night when the glass cools to an ambient condition overnight and then is exposed to solar exposure in the morning with shading conditions that allow portions of the glass to stay cold while other portions of the glass are being heated by the sun. The heated areas of the glass tend to expand, being forced into a state of compression, while the cool zones that are encapsulated by the framing system and/or shaded are forced into a state of tension.

The phenomenon resulting from the heated area entering a state of compression and the cooler areas maintaining a tension state can lead to a thermal stress condition that is in excess of the strength of the glass. This is especially important for annealed glass and will be dependent on the solar properties of the glass with regard to the solar absorbance, reflectance, and transmittance. The edge tension in combination with inherent edge flaws, damage and cutting conditions may create a situation where the glass fracture is initiated at the edge of the glass. Edge flaws and conditions are found to be more predominant for thermal stress breakage than surface conditions. Surface conditions resulting from scratches and surface damage in critical stress regions have been found to cause fractures, but this is not as frequent as the edge condition.

Experience and examination of fracture origins has verified that the conditions described can and will occur from thermally induced glass fracture and can occur in summer or winter conditions. This is because the thermal gradient between the heated area of the glass and cooler edges is the critical condition to evaluate. The shadowing of the glass enhances the thermal stress issue and certain types of shadows have more of an impact than others. The shadows that cast an angular shadow or a V shape on the glass have been demonstrated to develop larger thermal stresses that linear shadows.

Fenestration Buyers Guide

ANNUAL OCTOBER 2013

∆ Reaching 4,500 qualified window and door fabricators and installers

∆ Comprehensive Buyers Guide with the industry’s top suppliers

∆ Receive full coverage of Win-door North America

∆ Regularly updated website and e-newsletter offering industry information year round

For more information on advertising or to participate in the Buyers Guide please contact: d anielle Labrie, national advertising manager dlabrie@annexweb.com

New product & industry information can be sent to: Patrick Flannery, editor pflannery@annexweb.com

GLASS

Vision and execution

At Ferguson-Neudorf, the installer is the customer.

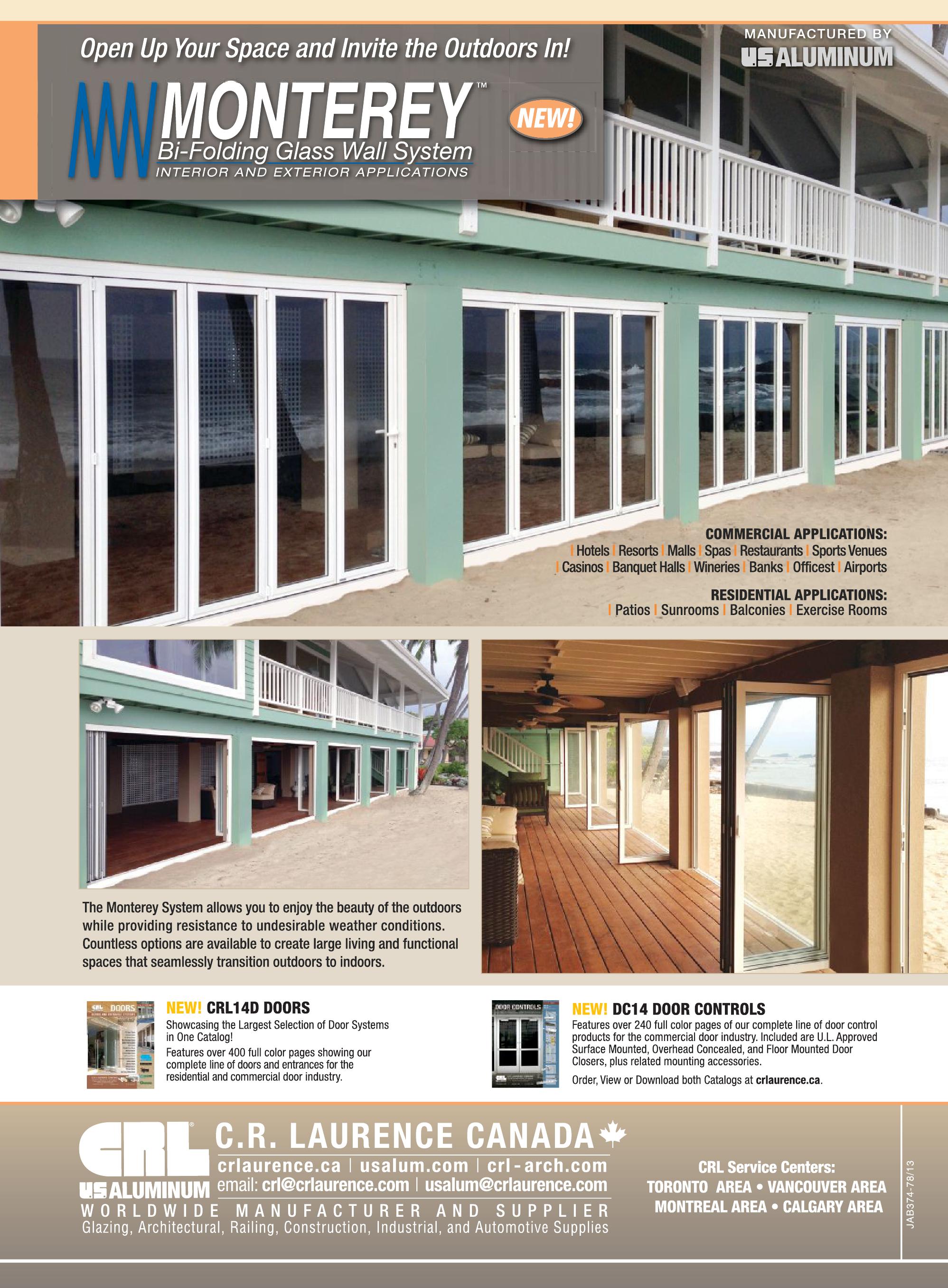

Ferguson-Neudorf runs four 200-foot glazing lines permanently, but is not reluctant to set up more lines or even whole remote plants as necessary. On one project for Manitoba Hydro, the company set up an entire assembly facility in Winnipeg to minimize the distance the finished modules would have to travel.

Amid the vineyards in Beamsville, Ont., between Hamilton and St. Catharines, about an hour south of Toronto, sits one of the great success stories in Canadian glazing. Growing from the merger of two iconic glaziers of the 1960s and ’70s, Ferguson Glass and Ontario Glass Craftsmen, Keith Ferguson and Peter Neudorf built a custom architectural glazing company with the capabilities to take on any project, and to push the envelope of what is possible in building envelope construction. Their enterprise stands today as a model of organized technical expertise, with each element meshing precisely to address every detail and let nothing slip. Built on a first-hand understanding of how to execute the highest standards in glazing, Ferguson-Neudorf is turning away business in favour of taking only the most challenging, spectacular and lucrative projects in North America.

The company was born in 1986 of the synergy between two very different personalities. Ferguson, a business graduate from the University of Western Ontario, began his career in 1953. He was recruited by Canadian Pittsburgh Industries (CPI) and worked out of its Windsor branch and was known for his

AT A GLANCE | Ferguson-Neudorf Glass

methodical approach to solving problems at other branches. In 1967, he founded Ferguson Glass.

Neudorf, self-educated, humble and hardworking, born in the village of Neuanlage in the German Mennonite community of Hague, Sask., began his career at Niagara Glass Ltd. in St. Catharines, Ont. In 1956, he started Ontario Glass Craftsmen, which became one of the largest glazing contractors in Ontario. In 1984 he founded Neudorf Glass Industries.

The two met while bidding against each other on the National Art Gallery project in Ottawa, and instead chose to join forces on the project as Ferguson Neudorf Glass Inc.

Today, Ferguson-Neudorf would like to concentrate on custom unitized building envelopes. “Almost everything we do is unitized,” says Doug Liljah, director of sales and pre-construction services, who has been with the company three years, after an 18-year career with Fulton/ Oldcastle. “It gives us the flexibility and the control over the build process that we need.” Liljah says all the projects the company is involved with in the U.S. and those they’re just finishing in Canada –many of which entail high standards for thermal, condensation and U-value – are

Location: beamsville, ontario with engineering office in Toronto No. of staff: 205

Plant: 88,000 sq. ft. in beamsville Products: design, fabrication and installation of aluminum curtainwall, skylights and building envelope systems

Founded: 1986

Ferguson-Neudorf is a custom architectural glazing company that specializes in design-assist projects, unitized curtainwall, punched windows, structural glass walls, terracotta, and other technologies.

design-assists. The company takes on the most technically challenging projects without hesitation. It recently designed and built from scratch an adjustable photovoltaic sun shade that attaches to the module mullion so there is no break in the envelope. The shade had to meet tough standards for snow and wind load due to its location in Halifax.

To work this way, you need a good track record and it’s a “somewhat open book,” says Liljah. “You’ve got to have a level of trust and good faith in each other and you’ve got to be committed.”

Labelling and tracking are something of an obsession at Ferguson Neudorf. Quality inspectors have the power to pull any part out of production and delay shipment until issues are resolved.

REMOTE POSSIBILITIES

Ferguson-Neudorf is possibly unique in the glazing industry in its willingness to set up semi-temporary remote locations for its operations, sometimes even just to address a specific project. “Part of what makes it feasible to set up a remote plant is we’re a unitizer,” says Liljah. We ship our extrusions to Winnipeg and we can turn more on a dime because we’re there. We have a dedicated crew who’s working on that project and it makes sense and we’re not losing three and four days in trucking. We can be more responsive and therefore we can do it with less people.”

In the case of jobs that require fast turnaround, being remote helps because they are shortening a lot of the timelines of moving materials. As long as they keep the stock and do the engineering and paperwork at the main office, he says, the process is effective.

KEEPING IT IN THE HOUSE

The company, which has many highly experienced, longtime employees, has a policy of severely limiting the use of subcontractors.

“We believe that at the end of the day, we own our commitments and the execution,” says Liljah, “and whether we do it ourselves or we can do it through a third party, it falls on us and we’ve learned through all the different experiences that when it falls on us, the best way to get it done is do it yourself. And it allows us to say that we’re selfperforming.

“Depending on jurisdiction and union requirements or just our manpower availability, we may blend crews but we will never have a crew that’s not led by our team,” he notes.

EXECUTION, EXECUTION, EXECUTION

Moving through the Ferguson-Neudorf plant, it is easy to see that all elements in the production process are carefully organized, thought-out and monitored. Lifters are in convenient positions, the four 200-foot glazing lines are well spaced and supplied with up-to-date equipment. Everything is bar coded, with the codes

relating back to all the relevant production data including machine programs. If an order has too few of a certain piece, the CNC operator can scan one of the pieces to call up the right program, load up a blank and make a new one without ever going back to drawings. That said, there is not much problem with going to drawings because Ferguson Neudorf probably has the most drawings on the production floor of any fabricator in the business. Each supervisor’s station in the plant has a full set of documentation for each project and for several that are not there yet. Glazing line stations have elevation drawings of the complete building with the part the glaziers are working on marked off so they can see how their work will fit into the finished whole. Once the untized modules are complete, they are carefully palleted,

Ferguson-Neudorf does all its own machining on a variety of CNC equipment.

labelled, shrink-wrapped and stored in the copious yard sometimes weeks before shipping.

What becomes clear in all this careful attention to process detail is that everything at Ferguson Neudorf is done in order to make sure the final installation of its modules proceeds swiftly and on time with no disappointments related to performance or appearance. Liljah credits Peter’s origins as an installer with the company’s culture of making sure everything is about the final experience at the job site. “It’s a family business,” says Liljah. There’s pride involved. And it’s hands on. You know, Peter Sr., he started as a glazier. He was cutting steel windows in the cold 70 years ago. He’s been through good and bad and then he’s brought people in here and they’ve always been a company that was doing bigger projects because they’re very good at execution and really, really good field people. With lots of work in the pipeline, including a couple of really big jobs that won’t start until 2015, Ferguson Neudorf can afford to cherry-pick. Part of being successful is being able to say “No.” •

INDUSTRYEVENT

GET READY FOR GLASSBUILD

Now in its 11th year, GlassBuild America is the gathering place for the entire glass, window and door industry in North America. Organized by the National Glass Association, which has produced meetings and trade shows for over 50 years, GlassBuild America offers a comprehensive and united audience. NGA has secured show partnerships with the American Architectural Manufacturers Association, the Glass Association of North America, the Insulating Glass Manufactures Alliance and the Bath Enclosures Manufacturers Association to attract a variety of

industry segments.

The show floor at GlassBuild America covers over 110,000 net square feet of exhibit space. This show floor is the central showcase for glass processing equipment, window and door manufacturing equipment, and the latest technologies for all types of glass and fenestration products. In addition, the show floor is home to the Innovations Pavilion which showcases cutting-edge technologies from across the glass industry, ranging from energy conservation devices to design innovations and the latest green products. World class seminars and educational

Azon Saves Energy

Daylighting systems produced with Azon structural thermal barrier technologies—the MLP™ or Dual Cavity—for aluminum windows and Warm-Light® warm-edge spacer for insulating glass, will yield a fenestration system capable of upholding the highest efficiency and sustainability standards

programs are offered daily, addressing the unique concerns of the glass and window and door industries and providing insight into emerging technologies, industry trends and market updates. Action-packed show floor demonstrations simulate the effect of hurricane debris on non-impact- and impact-resistant glass. Exhibiting companies cover the broad spectrum of manufacturing, distributing, fabricating, retailing and dealing flat glass and residential windows and doors.

GlassBuild America attracts participants from all facets of the glass, window, and door industries. Fortyeight percent of registered attendees hold CEO, president or other executive management positions. Seventy-six percent of attendees recommend or make the final decision about their company’s purchase of products.

FOCUS ON INNOVATION

GlassBuild America has seen continued growth in the Innovative Product Promotion program featured once again at the 2013 trade show. The program is on track to exceed 2012’s sold-out pavilion area and record-setting participation. “It is clear our industry values innovation and we are excited to provide the only trade show in North America that will display such industry innovation,” commented Denise Sheehan vice-president of NGA Industry Events.

Nearly 20 per cent of exhibiting companies at GlassBuild America 2013 have been accepted into the Innovative Product Promotion program. Many of these exhibitors are showcasing products and services for both the commercial and residential segments of the glass, window and door industry. The Innovative Product Pavilion includes a designated area on the show floor for this expanding segment. The pavilion is 80

Continued on page 23

PRODUCTSHOWCASE

Heavy lifting balances High performance hinge

www.aribell.ca

New Ab-Q-LW683 Low Wick weatherstrip from Aribell has two significant improvements. The thicker profile generates more contact with the door for a tighter seal, and the Low Wick foam ensures better performance. Ab-Q-LW683 replaces the previous PE650 weatherstrip, and seals better. The new design almost eliminates air and water infiltration, even when subjected to high air pressure. The Low Wick foam formulation uses a combination of closed-cell and open-cell structure to absorb 50 per cent less water. As moisture wicks into foam, its travel and subsequent volume is limited once it contacts the closed cells. This is especially important in cold Canadian climates where the weatherstripping can freeze when saturated.

www.truth.com

building on the popularity of Truth’s award-winning Fusion System, Truth has now embarked on the next generation of combination lock and tilt-latch systems named Harmony. The name illustrates how this system beautifully integrates the check rail lock and tilt latch together in a manner which creates a new level of installation ease. Manufacturers will appreciate how easy it is to just snap the tilt latch, screw down the lock you are good to go.

www.amesbury.com

Amesbury Window Hardware is proud to introduce Spiral, Lite-Lift and Super-Lift balances. The 3/8-inch heavy-duty Spiral can achieve weights up to 52 pounds per pair or up to 104 pounds when used in tandem making it a powerful Class 4 balance in a small package. The Lite-Lift and Super-Lift Class 5 balances can attain weights up to 130 pounds, while leading the market in overall travel and balance length availability.

www.aribell.ca

The new agricultural door sills from Aribell feature all solid plastic construction and low profile design.These economical sills have a durable extruded finish with no caps to break off. The tough plastic provides maximum holding power for screws and staples. door hangers will appreciate the full bottom for better sealing with more area to attach jambs.They come in a dark bronze colour, 10 to a box. Sills are available in three- or six-inch sizes.

www.truth.com

New energy specifications and requirements for increased window performance have necessitated sashes that contain triple-pane and/or laminated glass. This combined with the move towards larger windows has pushed the envelope on what standard-duty concealed casement hinges can handle. Truth Hardware has responded to this issue with our new High Performance Hinge which produces impressive performance and weight-carrying capabilities and allows window manufacturers to meet these demanding new requirements. The new hinge is capable of supporting a 140-pound sash which allows manufacturers to use triple-pane and laminated glass packages in larger windows. This is made possible by the innovative patented shoe design with a built-in roller to reduce friction during operation, providing smoother travel even under maximum load.

www.amesbury.com

Amesbury door

Hardware has introduced its new patented P3000 multipoint lock system. This new lock incorporates an American Style look with the thumbturn oriented above the handle and the deadbolt operation is independent of the satellite locking points. Available with a multitude of locking options, this system is a premium solution in today’s multi-point locking technology.

per cent occupied with room to expand and is on track to be the largest Innovative Product Pavilion ever at GlassBuild America. Of the pavilion exhibitors, seven are first-time participants at GlassBuild and more than 40 per cent are repeating companies providing new products and using this program to promote their innovations. To be accepted into the Innovative Product Promotion program, exhibitors must apply and be approved with a product or service introduced to the glass, window and door industry within the last three years. Many choose to launch new products and services in the categories of High Performance/ Efficiency, Green/Sustainability, Dynamic Products, New Technology, Design Innovation, or Solar Integration.

NATIONAL RECOGNITION

GlassBuild America came in at No. 184 on the Trade Show News Network’s list, which is based on net square footage data supplied by show management to TSNN. GlassBuild America has been listed as a top U.S. trade show since 2003. “Once again, we are honoured to be on this list and it

really goes to show that despite challenging times, GlassBuild America and the industry it serves can rise above,” said Sheehan. “We are very excited about our 2013 event as we’ve lined up an incredible and innovative floor that will allow our attendees to gain knowledge, network and ultimately grow their businesses.”

CONVENIENT TRAVEL

Attendees and exhibitors can now make housing reservations for GlassBuild. “We are very excited about the hotel options this year. With so many choices, there really is something for everyone from luxury hotels to classic Atlanta properties, and, of course, options for those traveling on a budget. The hotel rates are very competitive and we are pleased to offer such great city accommodations to GlassBuild America attendees and exhibitors,” Sheehan said.

Atlanta Marriott Marquis is the headquarters hotel for GlassBuild and is only a few short blocks from the Georgia World Congress Center. The Marriott Marquis is offering rates as low as $175 per night. The additional official hotels are:

• Omni CNN Center ($179)

Next Generation Lock & Tilt Latch System

Designed for Ease of Installation and Operation.

HARMONY™ LOCK AND TILT LATCH SYSTEM WORKS ON A WIDE VARIETY OF PROFILES.

The next generation combination lock and tilt latch system named the Harmony™ System — integrates the check rail lock and tilt latch together in a manner which creates a new level of installation ease. This integrated system has been designed to allow the homeowner to activate the lock and tilt latches from the same device.

scan this Qr code with your smart phone to learn more about the Harmony™ system.

• Westin Peachtree Plaza ($159)

• The Glenn (Marriott Autograph Collection) ($179)

• Embassy Suites Hotel ($179.00)

• Hilton Garden Inn ($159)

• Holiday Inn Express Hotel & Suites ($135)

Quoted rates are minimums and do not include taxes and fees and are subject to limited availability. Reservations can be made online at www.GlassBuildAmerica.com/accommodations or by calling EventSphere, the official housing bureau, at 1-855-201-2606. As the official housing provider for GlassBuild America 2013, EventSphere is the only company authorized to sell rooms in the official hotel blocks. Attendees and exhibitors are encouraged not to use other companies to secure hotel rooms.

Shuttle service will be provided September 10 - 12 between the Georgia World Congress Center and selected official hotels. These hotels include Marriott Marquis, Westin Peachtree Plaza, The Glenn, and Holiday Inn Express Hotel & Suites. Shuttle schedules will be posted in the lobby of each hotel and at the GWCC. •

by brIAN bUrToN

Brian Burton is a business development consultant and is serving on the Personnel Committee for the CSA’s Certification Program for Fenestration Installation Technicians. His current interests include adaptive reuse of buildings, overcladding technologies, maintenance of the building envelope and the rapidly growing use of computers in construction. You can contact him at brianburton@live.ca or visit his new website at http:// burtons-pen.com

Keeping up the facade

Facade engineering is a specialized building science discipline that focuses primarily on documentation, assessment and/or resolution of aesthetic, environmental and structural issues related to the building envelope. The ultimate goal is to achieve acceptable levels of environmenatal enclosure of occupied space while ensuring the health, safety and comfort of the occupants. The activity also serves to maximize building service life and energy performance. In today’s construction environment effective moisture management or mitigation are considered vital. The need for moisture mitigation results from the fact that most defects in new buildings are related to water penetration or accumulation in or near the building envelope components. It’s also a fact of life that when buildings fail to perform as intended addressing defects or deficiencies can be extremly expensive. In new buildings, the total construction cost of the façade may often be very close to that of the building structure. As a result independent advice from façade engineers assits owners and developers in balancing the commercial and technical risks involved.

Building enclosure systems also have to meet a long list of performance requirements. They must maintain the desired separation of interior and exterior environments with an acceptable degree of control. It is also essential that they are accessible for cleaning, maintenance and repairs. Durability, sustainability, occupant safety as well as aesthetics and economic considerations are part of façade design strategies. Fortunately the building envelope is rarely required to meet all of these requirements at the same time.

In today’s modern buildings the interaction between the many disciplines involved has become increasingly complex.

To enable buildings to achieve high energy efficiency and create a comfortable indoor environment for occupants in Canada’s ever-changing climate, façade engineers must also consider performance criteria that may include building physics, thermal characteristics, ventilation, lighting, solar control, acoustics and safety. Facade engineers are also called on to assess and plan for the loads that result from seismic activity, wind, temperature, construction, maintenance and more recently the impact of climate change. In today’s modern buildings the interaction between the many disciplines involved in the design, supply, installation, testing and operation of building facades has become increasingly complex. There is no doubt that we are indeed pushing the envelope (pardon the pun).

Facade engineers concern themselves with all aspects of the building’s envelope components design and performance above ground level, including cladding, curtainwalls, stonework, masonry, mortar and roofing as well as fenestration components, glazing, sealed units, sealants, gaskets and weatherstripping. On occssion they also evaluate railing systems and access/egress systems. Facade engineers also evaluate the performance of systems and materials with regard to sustainability and environmental impact for both new and existing buildings. For new buildings they may be involved in both design and design review, working in close coordination with the architect, structural, and HVAC engineers.

Facade engineering services often include design development for new construction as well as review of materials, acoustics and environmental issues.They are frequently called upon to undertake structural analysis of cladding and glazing and may be involved with development of specifications and construction documentation. Typically they will also undertake in-situ quality control inspections that may be supported by mock-up testing and evaluation. In the case of existing buildings, they often complete facade condition assessments that typically involve determining the mechanism(s) of failure or completion of defects surveys.

Facade engineers have to maintain a broad set of skills and knowledge, and can be valuable partners in the construction process. •

FENESTrATIoN

by FrANK FULToN

Frank Fulton is president of Fultech Fenestration Consulting. He has been in the industry for 30 years and can be reached via e-mail at fultech.fc@gmail.com

A worthy winner

For as long as the Ontario Glass and Metal Association and its predecessor, the Metro Toronto Glass Association have been in existence, making charitable donations to the benefit of childrens’ needs has been an ongoing top priority. The funding for donations comes from proceeds from events and from members’ dues.

This year, in addition to childrens’ charities, in order to further support the development of our industry, the OGMA introduced a bursary award to benefit students in the architectural metal and glazing trade. The OGMA approached the Ontario Industrial and Finishing Skills Centre and together worked out the details for the bursary. The award will be given twice per year to the glazier apprentice student who fulfills the criteria as set out by the school, those being initiative, attitude, helping others and volunteerism. The course instructors are solely responsible for determining the winner of the award.

The winner of the inaugural OGMA Award of Excellence bursary is a fine young gentleman by the name of Brad Bida from Thunder Bay, Ont. Brad proudly received the award and a commemorative plaque from the OGMA at its spring golf tournament in May. I had the pleasure of playing golf with and getting to know Brad that day. It became obvious quite quickly that Brad had spent more time handling glazing tools than golf tools during the past few years.

The glazing trade is actually a new start in life for Bida. Brad had started his working career with a diploma in Environmental Engineering Technology and pursued that career for nine years.

It became obvious quite quickly that Brad had spent more time handling glazing tools than golf tools during the past few years.

yoU bET yoUr GLASS

He held a number of positions in that field including government contracts, highway construction, and mining. Unfortunately however, the mining company he was working with became insolvent and Brad suddenly found himself looking for work.

In November 2008, Frontier Glass in Thunder Bay needed an extra set of hands for a few weeks to help fabricate a curtainwall project. Brad jumped at the opportunity and started by drilling hundreds of countersunk holes. It didn’t take long for him to discover that he loved the tools and the variety of work in the glazing trade. So impressed by his work ethic, Frontier found a way to keep Brad on and he now has four and a half years experience in the glass trade and is set to become a journeyman this summer. Says Bida, “The switch in trades had a steep learning curve – work anywhere, anytime, in any weather, and get the job done. I’ve enjoyed the challenges at all the positions I’ve held, but feel that the glass trade is the place to invest my time for the future.”

Brad completed his third and final level of apprenticeship training in April, and his trainers at the Ontario Industrial Finishing Skills Centre had high praise for the first-time bursary winner. Steve Laird, glazing health and safety instructor, stated “I consider Brad Bida to be a very wellrounded tradesperson. He has proven his knowledge, has experience in and shows interest in all aspects of the glazing profession including curtainwall, store fronts, and mirrors. Brad has the attitude that he was here to learn and if he did not understand something he would not hesitate to ask, but if he did know the material he would help others to understand. Brad stayed after school to help tutor other students and came in on Fridays to assist the instructors in preparing the shop for student instruction. All in all Brad has been a pleasure to work with and I wish him well in the future.”

Working in the architectural metal and glazing field, while difficult at times, is challenging, rewarding, and never dull. The OGMA is grateful to the OIFSC for selecting such a deserving recipient for the bursary in Brad Bida and we look forward to supporting future students for years to come. •

Stop Worrying About Quality!

The LiSEC HWM horizontal washing machine is perfect for applications where washing quality is crucial. Designed especially for float glass with all types of sensitive coatings as well as laminated and tempered glass, the LiSEC HWM is the perfect fit for your most sensitive washing needs.

n Residue-free cleaning and fast drying of glass sheets

n Ideal for washing glass sheets with highly sensitive coatings

n Ideal for glass sheets which will be coated after the washing process

n Intelligent design for easy maintenance, noise reduction and energy savings

Please call us at +1-866-547-3226 or send us an email to sales@lisecamerica.com

www.lisec.com/HWM