10:00am

Top Glass Show Floor Opens

10:30am

Grading On The Curve: A practical approach to evaluating bent glass insulating units

Speaker: Elie Alkhoury, P.Eng., M.Eng., founder, president and CEO of Can-Best

12:15pm

Building Green in Toronto: TGSV3-compliant glazed assemblies

Speaker: Hamid Vossoughi, P.Eng., is a project principal at WSP Canada.

2:00pm

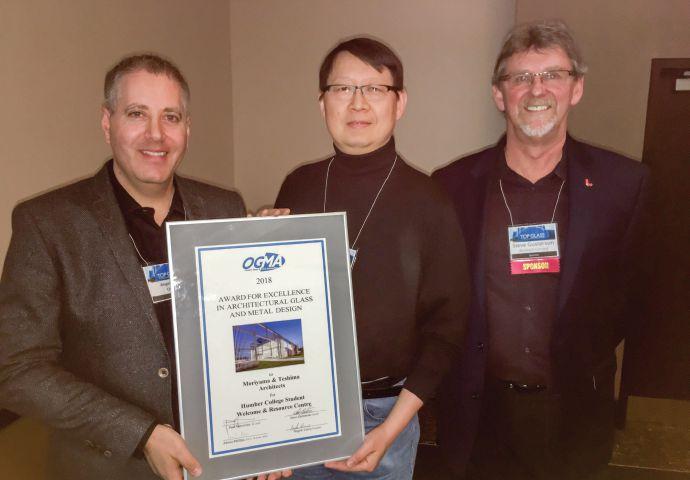

OGMA Awards for Excellence Presentation

Join the Ontario Glass and Metal Association as we celebrate Ontario’s top glass projects.

2:45pm

The Gold Standard: Contractor and glazier certification to enhance the bid process

Speakers:

Jeff Dalaba, program manager, North American Contractor Certification Program

Ben Beeler, co-developer, Architectural Glass and Metal Technician Certification program

4:30pm

Through A Glass Sideways: New efforts to measure and mitigate anisotropy

Speaker: Louis Moreau, head of technology and innovation, AGNORA

5:00pm

Networking Hour - Join us for refreshments and conversation as we wrap up Top Glass

6:00pm

Exhibits Close

· EARN continuing education credits · NETWORK with industry professionals · BROWSE the latest technology

· Architects and building engineers

· Glazing contractors

Architectural glass and facade fabricators Book your booth today, contact: 1-888-599-2228 ext. 245 I dlabrie@annexbusinessmedia.com

Browse the latest trends and technology. Meet Canada’s top commercial glazing contractors and their suppliers.

AGC Glass Company

AGNORA

Alcurv

Alectra Utilities

Alumicor Limited

Ameri-Can Machinery

Artistic Skylight Domes Ltd.

Can-Best

Canadian Consulting Engineer

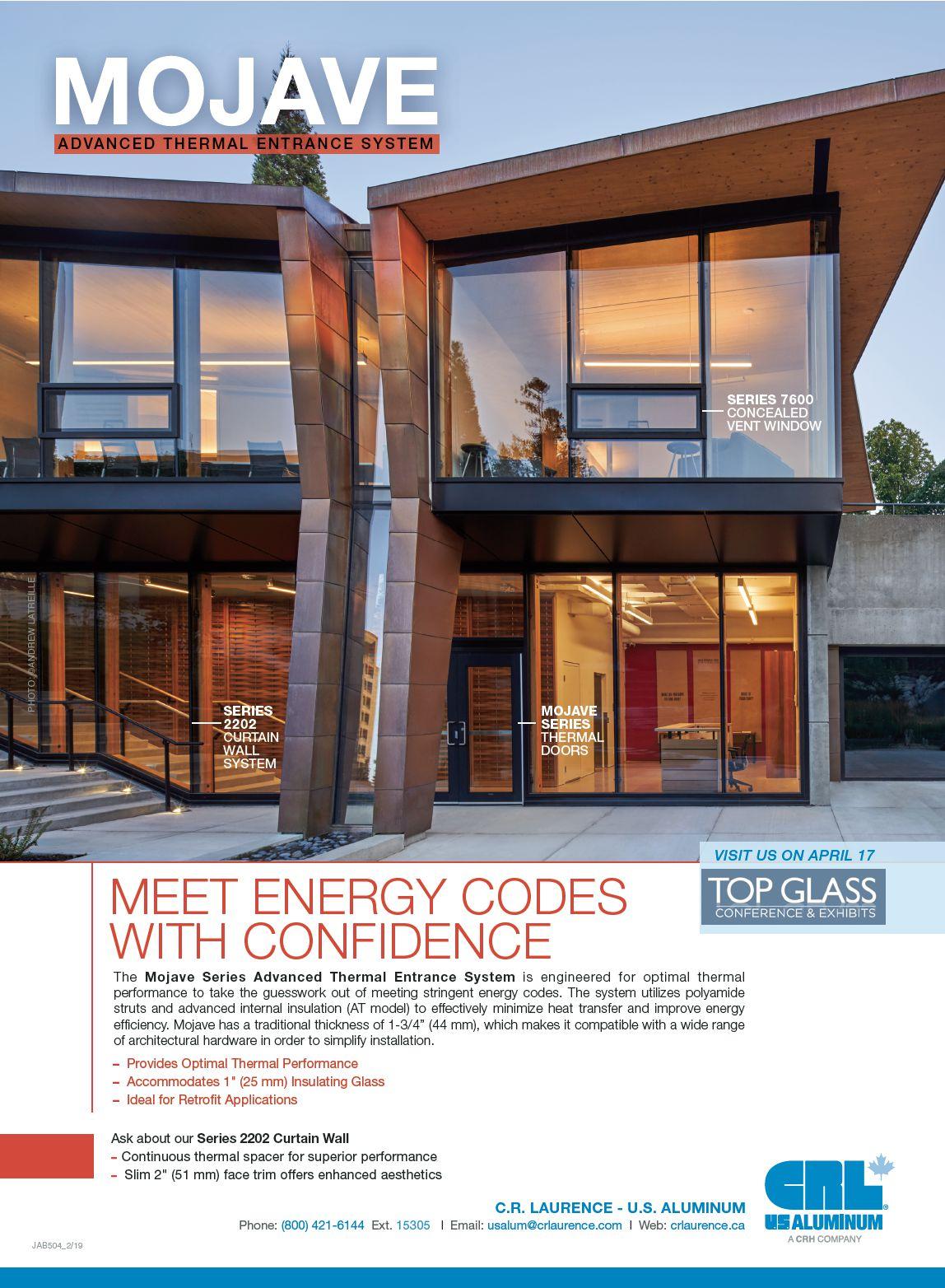

C.R. Laurence

Clearview Industries Ltd.

Clearstream Architectural Products

CMS

Commdoor Aluminum

Dow Silicones Corporation

Elton Manufacturing

Erdman Automation Corporation

Ergo Robotic Solutions

Everlast Group of Companies

Exova Canada Inc.

Fenestration Canada

Fenzi North America

GlasCurtain Inc.

GlassCan

Glassopolis

Gridline Design Drafting

Imagic Glass

Inline Fiberglass

INT Machinery

Kawneer

Kear Fabrication Inc.

Klaas Swaving Ltd.

Klaes

Laser Template Inc.

Litezone Glass Inc.

Lothar’s Industrial Sales

NACC

OGMA

RegaLead

RIMAC Metal Curving Specialists

RPM Rollformed Metal Products

Sika Canada Inc.

Steve Brown Machinery Solutions

TAG Railings Inc.

Tri-Temp Glass Inc.

Trosifol

Trulite

Veka Canada

Velux

Ventex

Vicone Rubber

Windowmaker Software Ltd.

Windspec Inc.

*current at time of publication and subject to change.

Shim It Once and Done. SAVE

Grove Products, Inc. has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Grove Products, Inc. has the perfect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 1-800-72-GROVE

Visit us online to see all of our available solid 3x4 Shims. www.groveproductsinc.com Free Samples are Available Upon Request.

Grove Products, Inc. is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Imagic Glass is distinguishing itself with some of the most ambitious colour, etching and carving work being done in Canada today.

You’re familiar with the Glass Canada e-news roundup appearing every other Thursday with links to recent top stories. From time to time we will put a special focus on one topic area with news, features and technical content both old and new. Look for our focus on specialty glass, coming soon!

EDITORIAL

Thanks to our sister publication, Plant magazine, for sharing its Outlook 2019 study of confidence levels among Canadian manufacturers (see page 22). The overall picture is one of cooling activity in the short term demanding a renewed focus on productivity and innovation to control costs. In general, I’d say the overall results match closely what a similar study restricted to glass fabricators would find.

April 2019

Volume 31 • Number 2

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

• Canada’s top glazing projects

• Metal cutting

U.S. protectionism is on the minds of many CEOs, and I know façade fabricators are no exception. It can hurt us on the demand side, if we want to export to the U.S., and on the supply side when we buy materials and machinery if the Canadian government retaliates. Most Canadian architectural glass manufacturers still rely mostly on the Canadian market for their daily bread, but our economies are just too entangled for us to be completely insulated from anything the U.S. does. More concerning than the direct effects on our businesses is the overall depressive effect on the economy from reductions in trade. When automotive and energy catch a cold, the rest of us come down with the flu, to adapt a common cliché. Both sectors are laid up with the sniffles right now; automotive because of uncertainty about the long-term viability of its cross-border supply chains and ongoing taxpayer-funded perks for auto makers in American jurisdictions; and energy because of competition from American fracking and the failure of pipeline projects like Trans-Mountain that have been scuttled by protectionist lobbies wearing a fig leaf of environmentalism.

Back to the study. Three-quarters of respondents said machinery was their top investment priority in the next three years and 63 per cent said training. Good. Investment in things that will help you meet an upsurge in demand when things are temporarily slow will help you take full advantage of opportunities when they emerge. Recoveries from market slowdowns can be more dangerous to small companies than the slowdowns themselves.

About half of respondents reported concern with cyber attacks and this number is probably too low. I’ve been bumping into more and more people lately who have been hit with ransomware attacks and the effects are devastating. Imagine having to throw out your corporate server with all the data on it and start fresh with a new one – or pay tens of thousands of dollars to a criminal with no assurance that you won’t simply be targeted again. Don’t think you are too small and poor to become a target. This has happened to smaller shops only pulling down a few million per year.

As you can see from our special cover, we are focused on Top Glass in this issue. Our annual trade conference is the place where you can find the technology and education that will prepare you to meet all the challenges discussed above. See you April 17 at the International Centre in Mississauga, Ont.•

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Curtis MARTIN

DIRECTOR OF SALES/GROUP

PUBLISHER | Martin McANULTY mmcanulty@annexbusinessmedia.com

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710

Printed in Canada ISSN 0843-7041

CIRCULATION

email: asingh@annexbusinessmedia.com

Tel: 416-510-5189

Fax: 416-510-6875 (main) 416-510-5133

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $37.00 (plus tax) U.S.A. - 1 Year $65.50 (in US dollars)

Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com

Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2019 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

Glaston has signed an agreement to acquire the Bystronic glass group from Swiss industrial holding company Conzzeta. Bystronic glass has a comprehensive range of products for the architectural, automotive and display markets. Glaston provides glass processing technologies and services for the architectural, solar, appliance and automotive industries globally.

Through the combination Glaston seeks to become a significant player in the glass machinery business providing a comprehensive product range offering from tempering, bending and laminating through insulating glass manufacturing and glass handling to automotive and display glass pre-processing as well as services.

Arto Metsänen, president and CEO of Glaston, commented, “I am very pleased to welcome Bystronic glass’s highly professional team to Glaston.We have followed the company for years and we are very impressed by the quality of its products and its transformation when it comes to both operational and financial performance.Together we will become a leading player in the glass processing technology market for the benefit of our customers.With our combined capabilities and expertise, we will be able to offer customers equipment, services and solutions from one supplier optimizing customer operations and driving customer value.”

Burghard Schneider, CEO of Bystronic, added, “We are proud of our employees for delivering significant improvements over recent

years.The transaction will open a new chapter to the benefit of all stakeholders.With an enhanced systems-thinking and strengthened R&D capabilities we will shape the industry trends towards energy-efficient solutions and digital integration, jointly with our new colleagues from Glaston.Together we can serve our broad, global client base even better and we remain committed to deliver flat glass processing at its best in terms of productivity, quality and cost.”

In other Glaston news, Bavelloni has signed an agreement for the acquisition of 100 per cent of the shares of Glaston Tools with Glaston Corporation. Glaston Tools, based in Bregnano, Italy, is specialized in the production and sale of tools for glass and natural stone processing. Glaston Tools, already the official supplier of tools for all Bavelloni machines, has a staff of 39 people and in 2017 achieved a turnover of about five million Euros.The company name has been changed to Bavelloni Tools.

“The acquisition of Glaston Tools represents a milestone in the completion of Bavelloni’s product range,” says Roberto Califano, marketing director and partner at Bavelloni. “This is an important goal allowing us to return to offer our customers the complete machine-tool synergy in which the Bavelloni brand has always believed since the beginning of its activity.”

Glaston and Bavelloni will also continue their partnership in the tools business, through distribution agreements with the Glaston branches in Mexico, Singapore and Brazil.

April 12

OGMA Spring Seminar Richmond Hill, Ont. ogma.ca

April 17

Top Glass Mississauga, Ont. topglasscanada.com

May 16

FenBC Golf Tournament Surrey, B.C. fen-bc.org

May 30

OGMA Spring Golf Milton, Ont. ogma.ca

June 6 - 8

AIA Conference Las Vegas, Nev. conferencearchitecture.com

June 16 - 28

Glass Performance Days Tampere, Finland gpd.fi

June 17 – 20

IGMA Summer Conference Victoria, B.C. igmaonline.org

Sept. 17 – 19

GlassBuild America Atlanta, Ga. glassbuildamerica.com

Oct. 23

FenBC Industry Conference Surrey, B.C. fen-bc.org

Nov. 12 – 14

IG Fabricator Workshop Plano, Texas igmaonline.org

National activities of the Canadian Glass Association are on hiatus pending discussions of a new direction for the association. To help chart a course forward, please contact David Langton at dlangton@compglass.com. The CGA website at canadianglassassociation.com has been taken down for now. Information about the association is on the FenBC website at fen-bc.org.

held its Technical conference and AGM on Feb 28. The conference was well attended and packed with information. At the AGM the current chairperson David Langton of Competition Glass gave the president’s report on the activities of FENBC over the past year. We are working on a “Coles Notes” version of many fenestration topics that continue to create some confusion or discussion. Once these documents are completed, they will be available for members only. However, we will encourage members to share them. Our website is going to get a few minor changes. Mainly a more accessible “members only” page. We have worked with the Ministry of Energy and the ICE Funds to promote and encourage the development of window systems that meet either Energy Star Most Efficient or Passive House standards. As of today we have given out awards to three companies for completion of either new

Canadian Glass Association

3759 York Durham Line, Stouffvillle, Ont. L4A 7X4

Tel: 250.258.0578

canadianglassassociation.com

Passive House or energyefficient window systems. We also worked with the Ministry of Energy and the ICE Funds to partner with RDH to develop a Canadian methodology for window U-values in Passive House buildings. This project is due to be completed very soon. FenBC has engaged Morrison Hershfield to update our Glazing Systems Specification Manual to reflect the 2015 National Building Code. This project is due to be completed soon. FenBC held a very successful conference in October 2018. FenBC videotaped all the sessions and they are now available for membersonly viewing. This is another initiative to increase member benefits. FenBC is also taping the sessions from our Feb 28 conference and they will also be posted for members only. FenBC has continued working on establishing relationships with associations with members in the fenestration industry. Last year FenBC became a member of the American Façade Tectonic Institute, the Building Officials Association of BC, and the BC Building Envelope Council. We have continued to grow our relationships with the Vancouver Regional Construction Association, Fenestration Canada and the BC Manufacturers Alliance. We are currently working on membership with the Certified Energy Advisors Association. FenBC held its annual elections and the following persons comprise the new board of directors: James Bates, (JTB Installations and Consulting), Mark Frampton (Excalabor Glass), Murray Frank (Constructive Home Solutions), Dave Goldsmith (Plygem), David Langton (Competition Glass) Cam Leslie (All West Glass), Jason Loutet (Intertek), Peter Kuschnir (Starline Windows),

Calvin Marshall (Retrotech Windows), Carlos Mueller (Atlas Meridian), Rich Porayko (Construction Creative), and Amy Roberts (PFG Glass). FenBC chair David Langton would like the thank the following resigning board members for their time and service: Frank Hua (Frank Hua Engineering), and Jean-Francois (J.R.) Robert, (Blackcomb Glass)

From time to time the AGMCA will use this space to turn the spotlight on its volunteer directors or its member companies. This month, we salute John Bastedo of National Contract Glazing in Ottawa, Ont. National Contract Glazing (NCG), was founded in May of 2000 by John Bastedo, and Jean Guy Tremblay. John and Jean Guy first met while the pair worked at St Lawrence Glass, and a strong relationship was developed that would last many years, and is still strong today. From humble beginnings as a two-man team in a 1,200-square-foot shop on Lancaster Street, John and Jean Guy have today assembled a team of dedicated professionals who are committed to the success of NCG, operating out of an 8,000-square-foot facility on Industrial Ave. NCG specializes in the design, fabrication and installation of aluminum curtainwall, windows, skylights, storefront and glazing in both the private and public sector market in eastern Ontario. John began his career in the industry in 1982 when he answered an ad for a sales position with Ford Glass. After some time

with Ford, John moved on to Preston and Leiff, then to St Lawrence Glass, back to Ford (by then AFG) as manager, then on to LBL where Jean Guy was a site superintendent. John became a director of the AGMCA in 2013, and is currently our vice-president. John has been involved in many committees but perhaps his most important role is on our negotiating committee. With 2019 being a contract year, John will be busy again. John has done a lot of tireless volunteer work on behalf our association, and is dedicated to the health of our industry. He can be reached at john @ncg.ca.

For more information on our association, please contact us by email or through our website at agmca.ca.

TheOGMAvoted in its new board for 2019 at our meeting on Feb. 28. Here are your leaders for the next year: Andrew Dolphin, president (BV Glazing); Jeff Makimoto, vicepresident (TAGG Industries); Brian Wiles, treasurer (Walker Glass); and Lee Baker, secretary. The Spring Seminar takes place April 12 at the Richmond Hill Golf and Country Club. Golf season is just around the corner – mark May 30, in your calendar now and plan on being out at Pipers Heath Golf Club in time for lunch that day. While you’re at Top Glass, don’t miss our Awards for Excellence presentation. The Awards for Excellence are annual awards that recognize excellence in the design and execution of a building that incorporates the use of architectural glass and metal.

Oldcastle BuildingEnvelope has announced that it has completed the divestment of Toronto-based Antamex International, its fenestration subcontracting business, to New York City-based private investment company O3 Industries.

“We are continuously evaluating our portfolio to align with our vision of being the leading supplier of glazing-focused interior and exterior products and services,” said Nathan Creech, president of Oldcastle BuildingEnvelope. “This decision is another step in executing our strategy as we focus on our core business: manufacturing, fabricating and distributing high quality architectural glass, metal, engineered systems, and glazing hardware and supplies.”

Antamex installs high-performance customized façade solutions and provides engineering design services for commercial, institutional, high-end residential and mixed-use projects across North America.

“Antamex has a great reputation in the façade solutions industry. The opportunity to leverage this history with the experienced team in place is very exciting,” said Daniel Ozen, president of O3 Industries. “Antamex is a perfect fit for our strategy of acquiring best-in-class businesses with top-tier

Vmanagement. Between our entrepreneurial ownership style and Antamex’s world class team, we are looking forward to driving the business forward and partnering with customers for further future success.”

“We are confident that O3 Industries is the right home for the Antamex business, its employees and customers,” added Creech.

itrum Glass Group has announced that Tara Brummet has been appointed business development manager for U.S. markets. Brummet will be responsible for the overall implementation of growth strategies for Vitrum’s continued expansion into various U.S. markets. She has more than 20 years of experience working in the architectural glass industry and her experience and in-depth knowledge of the industry is broad and comprehensive. She has been a critical team member on various significant projects and has led teams in multiple capacities. Over the past four years, Brummet has successfully developed and grown the U.S. market for Vitrum Glass Group. She has also held various board positions for North American glass associations and continues to dedicate her time to several committees.

Thomas Martini, president of Vitrum Glass Group, commented, “Tara has proven that her focus and determination is unrivaled, and we are confident that growth in these markets will be consistent and that service levels will remain exemplary under her sales leadership. I congratulate her on this well-earned promotion.”

Jennifer Conrad has joined Vitrum Glass Group as its newest sales representative. Conrad has nearly a decade of glass industry experience within the region of Washington State and has demonstrated a great understanding of architectural glass. She will focus on sales growth for Vitrum in Washington, Oregon and Alaska. Vitrum Glass Group has cultivated deep client relationships in the Washington area from its head office in Langley, B.C. With Conrad joining the team and remaining based in Seattle, Vitrum seeks to ensure these clients continue to receive the care and attention they deserve while also broadening an important market.

“I am really pleased that Jennifer has joined our team. She will be a real asset to us as we grow within these regions.” said Martini. “I have great trust in her ability to further develop our brand and our customer relationships.”

Integrated Solutions welcomed over 30 employees in 2018 as the company continues to grow.To keep pace with sales growth, it has added several new individuals in key management positions.Trevor Kropf has been hired as a regional sales manager representing GED’s Canadian territory to promote and sell all product offerings and serve Canadian customers. Kropf has 20 years of industrial sales experience, and resides outside of Toronto. Bradly Duguay has been hired as director of customer service to plan, direct, and manage the operations of GED’s service department. Duties and responsibilities include formulating policies, managing daily operations, and planning the use of materials and human resources to serve our customers.

“GED is pleased to have Bradly on board to develop customer service strategies to continually improve our customers’ experiences with our brand,” said Bill Weaver, president and CEO of GED. “I’m confident the addition of Bradly to the GED service department will grow our service capabilities as well as strengthen the service team as a whole.”

The American Architectural Manufacturers Association (AAMA) has updated two documents for evaluating window wall, curtainwall and storefront systems when it comes to seismic drift.

AAMA 501.4-18, “Recommended Static Test Method for Evaluating Window Wall, Curtain Wall and Storefront Systems Subjected to Seismic and Wind-Induced Inter-Story Drift,” and AAMA 501.6-18,” Recommended Dynamic Test Method for Determining the Seismic Drift Causing Glass Fallout from Window Wall, Curtain Wall and Storefront Systems,” were first released in 2001 and were last updated in 2009. The two are now available as separate documents for the first time. AAMA 501.4 provides a means of evaluating the performance of windows, window wall, curtainwall and storefront systems when subjected to specified horizontal displacements in the plane of the wall. AAMA 501.6 focuses on determining the horizontal racking displacement amplitude of exterior wall system framing members that would cause fallout of representative architectural glass panels under controlled laboratory conditions.

“The test methods described in both documents are important to the industry,” said Tanya Dolby of Kawneer, chair of the AAMA 501.4 and 501.6 seismic test update task group. “Now, for the first time, those who need one or the other can conveniently access each individually through the AAMA Online Store.”

The AAMA has also updated a document providing guidelines for describing colour measurement requirements for inclusion in AAMA documents. AAMA CMR-1-18 “Guidelines for Development of Color Measurement Requirements,” was first released in 2016. This is its first update, which was made to accommodate changes made to measurement averaging and colour difference equations.

“The CMR document is an excellent resource for identifying the six parameters that need to be called out or specified to properly and clearly measure and compare colour,” said Doug Holmberg of Wausau Window and Wall Systems, co-chair of the AAMA Finishes Steering Committee.

“This is important for both matching colours and measuring the amount of colour change over time. Although the document was originally published in 2016, once in use and after additional research, the Finishes Steering Committee felt it was a good time to update the document.”

In addition to changes made to the document, a note was added to reference a visual correlation study conducted in 2016, the data from which did not provide a compelling reason to change from the Hunter colour space in the documents referencing it.

Understanding and correctly stating the parameters related to colour measurements may allow for a more complete and correct measurement and interpretation of results. Per the standard, when colour measurements are required, refer to ASTM E805 for the procedures to perform the measurements and ASTM D2244 for the equations to calculate colour differences.

The Architectural Glass and Metal Technician (AGMT) Certification program has completed its final phase of development and announced it is now accepting applications for live testing. The program provides third-party, ANSI-accredited certification of an experienced glazier’s fundamental knowledge and skills. In development since early 2017, the certification program was created with the help of numerous professionals (subject matter experts) from within the glass and glazing community, including glazing technicians and contractors, architects, engineers, general contractors, construction managers, industry consultants, manufacturers, suppliers, and professional exam developers to produce an impartial, effective test. With the goal of minimizing installation-related defects and failures within the industry, the program provides an independent assessment of an experienced glazier’s fundamental knowledge skills and abilities. To become AGMT-certified, candidates must meet program prerequisites and pass both a knowledge-based and performance-based test. While testing location dates and times are still being lined up, first stops are scheduled for Philadelphia, Baltimore, and the California Bay area, with more locations to be scheduled in the coming months. To allow interested glaziers across North America an opportunity to sign up for the certification, the program will run testing in the coming months and will begin issuing certifications to those who qualify on an initial “sunrise” date later this year.

The total value of building permits rose 4.7 per cent in 2018 to $99.7 billion, the fifth consecutive annual increase, according to Statistics Canada. Higher construction intentions for multi-family dwellings and commercial buildings were the main factors behind the increase. Four provinces reported gains, led by British Columbia and Quebec. The largest decline was in Ontario, where the value of permits was down 2.2 per cent to $38.2 billion. Construction intentions in the non-residential sector rose 3.7 per cent in 2018 to $36.9 billion. Increases in the commercial component ( up 18.4 per cent to $21.6 billion) more than offset the decline for institutional buildings ( down 22.1 per cent to $8 billion). The decrease in institutional building permits may be due, in part, to the end of the Post-Secondary Institutions Strategic Investment Fund, as applications to the program closed in February 2018. Meanwhile, permits for industrial buildings rose 3.6 per cent to $7.3 billion. Five provinces reported gains in the non-residential sector, led by British Columbia (up $1.5 billion) and Quebec (up $1.2 billion). The largest decline was in Ontario, where the value of non-residential building permits declined by $1.3 billion.

by DAVID HESKA

David Heska, P.Eng. is a Director with WSP’s Building Sciences team in Southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows in commercial and residential buildings. He can be reached at David. Heska@wsp.com

With the shortest day of the year behind us, it only gets brighter from now until the summer. Today I would like to address a topic that directly impacts our glass industr y but rarely gets the attention it needs. Intrinsically, we all know that increased daylight results in increased happiness and comfort. We also know that people exposed to daylight are more productive, more efficient, miss less work due to illness and will be more creative. An American study found that a store’s sales index increased by an average of 40 per cent simply by adding skylights. For example, if a non-daylit store had average sales of $20 per square meter, sales would be $26 to $30 if skylights were added. Additionally, students in classrooms with the highest levels of daylight performed seven to 18 per cent higher on standardized tests.

The introduction of daylighting strategies can also considerably reduce a building’s electricity consumption. Consider the office I’m sitting in as I write this article. Ten years ago, WSP’s LEED platinum office in Kitchener, Ont., was constructed and named “A Grander View.” The energy intensity of the building is less than 70 kilowatt-hours per meter squared. Our designers recognized that one of the largest consumers of energy in a typical office is lighting. So, in addition to installing triple glazed, low-E, argon filled, fiberglass windows, the following three design features were also implemented:

Effective daylighting is not just about increasing the size of windows.

1. A long, skinny building was designed with a 12-meter-wide footprint enabling most interior spaces to benefit from windows on at least one external wall.

2. A large skylight that provides natural light was placed in the central atrium and stairway.

3. Meeting rooms have interior glass walls that allow light to pass through in order to brighten corridor spaces.

But effective daylighting is not just about increasing the size of windows. The quantity of glass is not always a direct measure of quality daylighting. We’ve all experienced poor lighting conditions when either direct beams of sunlight shine in our eyes or there is glare on our computer monitors. In these cases, daylighting is more of a hindrance than a help and people draw the blinds or cover the windows.

Previously I have written about the need to have reasonable window-to-wall ratios around 40 to 50 per cent. There are other design considerations that can help maximize daylighting. We should minimize the window area on the east and especially on the west elevation of buildings. Architects should consider the building orientation (if possible) and specifications should not restrict the design to one glazing type for all elevations. We can remove glass that extends below eye level since it provides little benefit to light levels. And we should increase the use of skylights, light tubes and clerestory windows, which are great design features anyways.

Many of the manufacturers listed in Glass Canada’s Buyers Guide have excellent products and unique coatings, films and frit patterns that can control glare and reduce solar heat gain. I encourage you to get to know them. As the days get longer I hope you enjoy the warmer weather and the productivity boost that comes with it. •

by MARGARET WEBB

The Insulating Glass Manufacturers Alliance held its Winter Conference in Austin, Texas, Feb. 4 through 7. As always, there is a great deal of progress to report.

The Certification Committee chaired by Roland Rossman of Garibaldi Glass heard from the Quality Management System task group that Tier I, II, III and IV of the “IGMA Quality Management System for the Fabrication of Insulating Glass Units to the ISO 9001:2008 Standard,” encompassing the quality manual, the procedures, the work instructions and the forms, are now available from the IGMA Publication Store after a successful ballot at the Certification Committee. The task group will now revise the quality manual to the ISO 9001:2015 standard. It is anticipated that this work will be complete by mid-year. This document is a template for a complete ISO-certified quality system tailored for the insulating glass manufacturing industry.

The Emerging Technologies and Innovation Committee chaired by Helen Sanders of Technoform Glass Insulation and David Cooper of Guardian Industries heard that the Material Transparency (formerly the Life Cycle Assessment) task group has redefined its scope to include other activities such as development of Environmental Product Declarations, Health Product Declarations, LEED requirements and other material transparency programs. Discussions during the conference were related to the California Buy Clean Act (AB 262), which will require structural steel, rebar, mineral wool and flat glass to report their Global Warming Potential for government and other construction projects. Vik Ahuja of Thinkstep gave a presentation on AB 262 noting that California’s Department of General Services would be considering including processed glass. A survey will be sent to the members of

Membership heard reports of progress from all committees.

IGMA and the National Glass Association to determine interest in developing an industry-wide EPD for processed glass. On the window Product Category Rules front, a different survey has been developed by a pan-association group to determine whether the group will work on a new window PCR to replace the existing one.

The Technical Services Committee chaired by Jeff Haberer of Trulite heard from the IG Cavity Compensation task group that the document “TM-3200-XX” is close to completion and is expected to be balloted to the IGMA Technical Services Committee this year. This technical manual includes generic design alternatives for cavity compensation for insulating glass units and defines conditions that impact the pressure in the IGU cavity. Items included in the document are capillary and breather tubes, one-way valves, desiccant adsorption/desorption, pre‐inflating/pre‐deflating the unit, temperature manipulation during fabrication and the use of bladders.

The PIB Migration task group working jointly with the former GANA Insulating Division (now NGA) reported that “TB-1250, PIB Primary Sealant” has successfully passed all levels of approval and will be forwarded for publication.

The Visual Quality task group reported that, working jointly with the AAMA Glass Materials Council, it has published “A Consumers’ Guide to Understanding Glass Standards” to both the IGMA and American Architectural Manufacturers Association websites.

The Education and Safety Committee chaired by Bill Briese of GED Integrated Solutions decided to schedule a IG Fabricator Workshop workshop Nov. 12 to 14 at Intertek’s Plano, Texas, facilities. Registration will be launched early. The next series in the Leadership Development Program will be launched this spring with three orientation sessions for those who did not register for the first series. An announcement will be made in the next month regarding the program.

IGMA Leadership Development Program webinar series: April 2019

IGMA 2019 Summer Conference: June 17 to 20, Victoria, B.C. (joint with AAMA)

IG Fabricator Workshop: Nov. 12 to 14, Intertek, Plano, Texas •

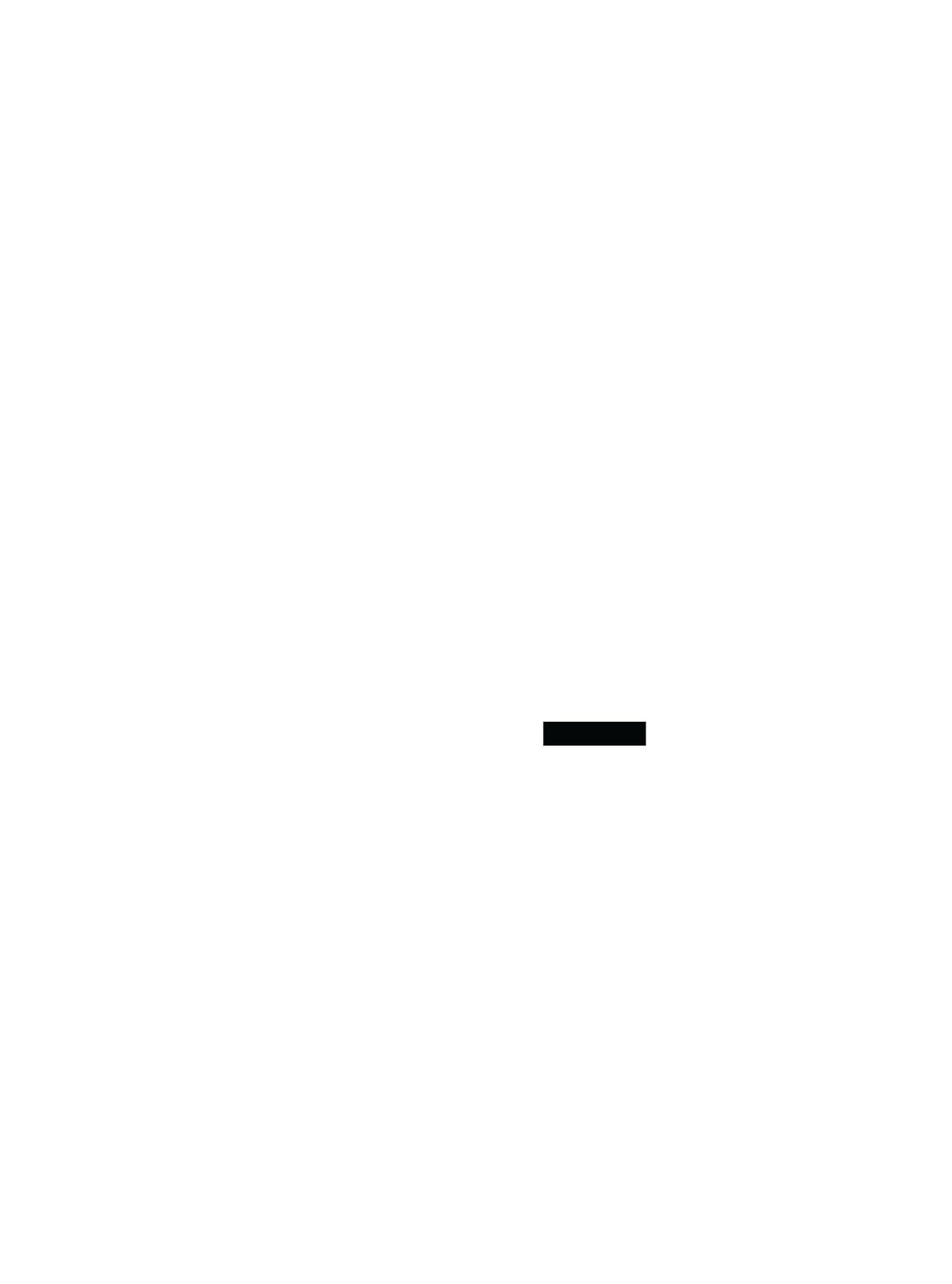

Imagic carved this watch face feature glass for Richard Mille’s New York flagship storefront. The finished feature glass weighs over 37,000 pounds. The largest of several pieces spent over 160 hours in the carving line.

Lots of people talk the talk about fenestration innovation, but Imagic Glass walks the walk. “We thrive on complex glass fabrication and love to figure things out,” says Adam Shearer, president of Imagic Glass. He speaks from his 30,000-square-foot plant in Vaughan Ont., north of Toronto. It’s a cutting-edge facility that has both drive-in and multiple dock level access for streamlined shipping and receiving, a custom built multi-bridge crane system and racking systems which allow for safe and efficient glass-handling. There’s a separate clean room for digital printing and glass lamination assembly so that these functions are isolated from glass processing.

And in just six years, Imagic’s capabilities have expanded quickly to cover a breadth of products and technologies, including digitally printed glass, back painted glass, switchable glass, with a particular specialty in exquisitely etched and carved glass.

“Our focus has been on innovation, it’s in our DNA,” enthuses Shearer. Launched in 2012, the company is con-

stantly on the search for new techniques that can be incorporated into its production capabilities that include high resolution digital printing, CNC machining, multi glass polishing lines, large format glass washing, two automatic etching and sandblasting lines, high capacity lamination oven and a technologically advanced high capacity paint line that includes in-feed and out-feed conveyors, panel pre-heating, multi-head spray cabin and a high temperature curing oven.

One outstanding example of Imagic’s frontispiece finesse is the custom-carved feature glass etched on the new Manhattan flagship store of the famed ultraupscale Swiss watchmaker Richard Mille. “We have carved glass for multiple store locations for this client over the years,” says Shearer. “Because we had successfully completed multiple locations previously, we were invited to be a part of the team working on this New York project.” The feature glass, depicting the intricately detailed internal workings of a Richard Mille wristwatch, is comprised of a surface 30-feet high and over 20 feet wide. The largest piece is over 1.5 inches thick, 15

Location: Vaughan, Ont

Founded: 2012

President: Adam Shearer

Employees: 45

Regions: Primarily North America, some overseas Markets: Commercial, high-end residential, institutional, hospitality, retail, gaming, health care, education

feet tall by 10 feet wide and weighs in at about two tonnes. It was a very complex project to say the least. Shearer points out it necessitated breaking up the feature glass area into sections. This meant carving the artwork in such a way that it transitioned seamlessly from piece to piece. And, because of the scale, the glass had to be specially engineered to ensure it met safety and load requirements. The client had very specific artwork that required tremendous precision in carving. Only annealed glass can be carved, which meant engineering a glass that would accept carving while also providing strength. In addition to the complex engineering, there were huge challenges in handling such

Capture clarity with new Acuity ™ Low-Iron Glass. Meet the aesthetic demands of architects and the performance demands of owners, all for a modest investment. Developed to withstand value-engineering, new Acuity Glass by Vitro Architectural Glass (formerly PPG Glass) joins Starphire Ultra-Clear ® Glass in the Vitro family of low-iron brands. An affordable low-iron option available with Solarban ® solar control low-e coatings, Acuity™ glass offers vivid views with no green cast.

Request samples and learn more at vitroglazings.com/acuity

gargantuan slabs of glass during fabrication. Imagic had to commission a custom carving line for this project in order to handle the massive pieces. Imagic’s own custom crane system includes a five-ton bridge which allowed safe loading and unloading of the glass on to the carving line and then into huge custom crates for shipping (direct from the company’s Toronto location to New York). Not one piece of glass was damaged over three months of fabrication in the Imagic Glass facility. Many of the pieces spent over 160 hours on the carving lines to achieve the desired esthetic. “There were to be three layers of feature glass physically separated and carved on five of the six surfaces,” he explains. “Customers will literally walk through the feature glass upon entering the store. And all of the feature glass was to be illuminated with custom LED fixtures. It is visually stunning.” It will also, literally, stand the test of time as an iconic location along the posh Park Avenue district known as Billionaires’ Row.

Shearer credits Imagic’s ingenious carving technology for etching the company into the minds of its growing roster of A-list clients. Some of the high-profile projects in Imagic’s portfolio:

• The UP Express office at Toronto’s Union Station. Custom-printed gradient laminated glass was installed to hide cement bulkheads. The gradient transitioned from 500 per cent opacity to zero per cent to clear and back again

• Princeton University, using custom sandblasted and laminated glass

• Casino Niagara, employing customprinted laminated glass, custom artwork and multiple opacities

Imagic’s technology can produce lightly shaded glass, surface etchings, and deep carving. “This results in crisp, distinct artwork reproduction which provides tremendous visual depth and allows us to meet the client’s strict requirements,” notes Shearer.

Printed and mirrored glass is a point of pride for Imagic. It holds a patent for one of its printed glass applications. The company can achieve one of the highest resolutions in the industry for digital images at 1,500 dots per inch. Unlike traditional ceramic ink glass printing, the Imagic technology offer outstanding colour reproduction across the entire colour spectrum. Imagic can print in multiple

Designed for spectacular year-round enjoyment. Connect your outdoor oasis with the indoors: private residences, restaurants, cottages, patios, event centres, and entertainment complexes. Experience the full potential of your space today.

CONTINUED FROM PAGE 16

layers, which means its achieves opacity levels from zero to 500 per cent or more on the same piece of glass. It can print gradients with no banding or “lawnmower” effect. Because Imagic doesn’t use traditional ceramic ink methods, it can print on annealed, heat strengthened or tempered glass as well as mirror. It can print directly to the glass or to film and laminate producing exceptional resolution, vivid colours and outstanding artwork reproduction. Print capacity is up to 200 by 98 inches and on glass thicknesses of three to 19 millimeters. Because of the outstanding clarity and colour reproduction, Imagic has seen increased demand for reproducing artists work onto glass for public art

Imagic’s sandblaster can create novel textured sufaces, like this interior wall at Northwestern University.

projects. The result is beautiful large format art reproduction that is visually breathtaking.

Imagic Glass has metamorphosed from a brash startup to a world class producer and supplier of custom architectural glass and patent-pending high resolution direct-to-glass digital printing. It’s currently an international supplier of upscale glass products with clients across North America and as far as Hong Kong and Dubai, servicing multiple industries including hospitality, gaming, high rise residential, commercial office, retail, residential, institutional, health care, professional sports and more.

How’s it grown so fast? Shearer likes to echo Steve Forbes: “The most wildly successful start-ups are led by people who follow their dreams, and who understand and undertake the measured risks associated with launching a business.” An apt description of the entrepreneurial architects at Imagic Glass.

Co-founder and managing partner, Vilius Garsva, who hails from Lithuania, began his apprenticeship in a glass shop on arriving in Canada, eventually getting promoted to plant manager. “One of the key goals of the company from the start was to ensure we fabricate the highest quality glass in the industry. To achieve that, we invested heavily in state-of-the-art equipment, processes and safety training to ensure we could accomplish our quality goals and stay ahead of the curve. We’re focused on R&D as evidenced by a patent we own for glass and mirror fabrication techniques.”

Breadth of product offerings is what co-founder and business development leader, Colin Sless, believes raises Imagic above the herd. “We can do simpler solutions (for instance, single tempered, painted, laminated) and we do them very well. But we really get energized when asked to problem-solve complex glass challenges involving multiple techniques, like multi-lite, printed and painted and laminated. We make sure that Imagic Glass is among the easiest shops our clients will ever deal with.”

Bringing a wealth of deal-making savvy to the management team, chairman Steve Rogers, who formerly built a global $1.5 billion franchise enterprise from the ground up, is Imagic’s notable business strategist and brand visionary. He’s been instrumental in providing guidance when establishing partnerships with important vendors and suppliers, for example Intermac, Bottero, Kurary (SentryGlas), ICD (Opaci-Coat-300), Vitro and many others. “We are very selective when deciding who we partner with,” Rogers says, emphasizing that Imagic’s philosophy is to put quality and service ahead of lowest cost.

“You can have great products, great marketing, great equipment, and great processes, but if you don’t have great people, it doesn’t matter,” asserts Shearer, who joined the company in 2016 with a background in branding and customer service that includes stints as president of California Closets and as director of sales for Lucent Technologies/Bell Labs. “We made the decision to hire the best people we could and ensure we were aligned on values first. We value our employees as they bring vast experience and skills to the table. We communicate openly, coach and develop our team – factors we believe are the successful blueprints in forging a winning corporate culture. We’ve seen rapid growth at a pace of over 50 per cent per year since 2013 and we expect that trend to continue over the next few years.” It’s a tribute to Imagic finding new ways to stretch it’s ability to etch. •

Making a statement in the Toronto skyline.

See what’s possible™ with Guardian SunGuard® Advanced Architectural Glass for your next project.

with SunGuard® AG 50 and SunGuard® SuperNeutral® 68

by PATRICK FLANNERY

Top Glass 2019 will mark the seventh edition of the event and we can say with confidence (and not a little pride) that it is now Canada’s premier gathering for the architectural glass industry. Top decision-makers and thought leaders from the contracting, fabrication and design communities tell me they mark their calendars for each show and find great value in attending – on the show floor, where they find the latest technology; in the lecture room, where they get great advice from top experts; and in the aisles and sitting areas where they have stimulating conversations with peers and business contacts. The concept has been simple but powerful: provide a quick, one-day opportunity for everyone to come together to renew bonds and work on the business rather than in the business.

Most of all, Top Glass is a chance to get together.

To that end, we’ll be adding some opportunities at this years’ show for everyone to gather and chat. It always seems to me that no matter how good an education program is or how many vendors are exhibiting, the real opportunity at a trade event is in the chance to meet someone new and hear what they have to say.

That’s the reason Top Glass always includes some generous breaks in the day to give you a chance to wander the show floor and interact with the exhibitors. They are the ones who make the whole thing possible, after all. And

when it comes to the latest technical knowledge and business gossip, there’s no one better than a salesperson. In my view, anyone attending Top Glass just to sit in the presentations is missing half the fun.

But it’s easy to see how that can happen, given the excellent agenda we’ve assembled again. I’m gratified every year by the strong response to my call for papers and the

compelling experts we attract. There really is no program like it in Canada for the commercial side of the glass construction industry. Most people have never even heard of anisotropy. At Top Glass, you’ll get an hour presentation with time for questions from someone who is leading international efforts to develop a standard for measuring it. Sick of trying to figure out if a glazing contractor knows what they are doing and will finish the job? Sick of bidding against those who don’t and won’t? Come hear about a certification program that could help establish a glazier’s credentials to high standards of quality and practice. And where else can you learn about testing bent IG units and building to Toronto’s TGSV3 standard all in one place?

To the above add the chance to help celebrate some of Ontario’s top achievements in the architectural glass field at the Ontario Glass and Metal Association’s Awards of Excellence presentation. It might help your business to know who is doing the great work that goes on in this industry and get a chance to shake their hands.

Are you an architect or building engineer looking for continuing education credits? Top Glass is your chance to qualify for four one-hour structured learning credits in for free in one day. The presentations are recognized by most Canadian archtiecture and professional engineering associations, and all attendees receive certificates of attendance when they fill our the online feedback survey. Sometimes the presentations also qualify for AIA credits – contact us if you need to know in advance if a particular seminar qualifies.

See you at Top Glass! •

10:30

TOPIC / Testing bent glass IGUs

PRESENTER / Elie Alkhoury, P.Eng., M.Eng., founder, president and CEO of Can-Best

Elie Alkhoury will explain how Can-Best is testing the curved glass for the Crown Sydney Barangaroo at Top Glass 2019. It requires some scaling and new approaches that have never been tried before

Advances in bent glass are inspiring architects to ever-bolder heights of design, but methods for testing and certifying these complex components are still in their infancy. In this presentation, Elie Alkhoury of Can-Best describes his groundbreaking work to assess the design of an overseas landmark building with cur ved insulating glass units, including assessment of seal durability on full-scale mock-ups. ASTM E2188 was adopted as the basis of evaluation with some bells and whistles added.

The presentation describes the testing of full-scale two-by-four-meter IG panels in all phases of high humidity and weather cycling with dew point measurements taken periodically. In addition to the standard weather cycling parameters of ASTM E2188, wind load pressures were superimposed on the typical cycle and applied in both positive and negative directions. The challenges did not stop there; the test panel was subjected to prescribed bending prior to cycling and assessed in the bent configuration. The complicated setup to test four panels simultaneously will be described.

Elie Alkhoury has been involved on the technical side of the window industry since 1983. He is the founder, president and CEO of Can-Best, but prefers to be known as director of research and testing services for its laboratories. Elie has been actively serving on the CSA A440 Technical Committee for more than 27 years. •

12:15

TOPIC / TGSV3 green building standards

PRESENTER

/

Hamid Vossoughi, M.Sc.Eng., P.E., P.Eng, project principal, WSP Canada

It’s Canada’s largest real estate market, and it has rules all its own. Toronto codes and standards are finally acknowledging the importance of building envelope in overall energy conservation measures. Yet highly glazed buildings continue to be in demand and have to respond to the more stringent requirements.

The Toronto Green Standard is Toronto’s sustainable design requirements for new private and city-owned developments. The standard consists of tiers of performance measures with supporting guidelines that promote sustainable site and building design. Tier 1 of the Toronto Green Standard is required through the planning approval process. Tiers 2 to 4 are higher level voluntary standards associated with financial incentives and verified post construction. The standard addresses the city of Toronto’s environmental priorities to improve air quality and reduce the urban heat island effect; reduce energy use and greenhouse gas emissions from new buildings while making buildings more resilient to power disruptions and encourage the use of renewable and district energy; protect and enhance ecological functions, integrate landscapes and habitats and decrease building-related bird collisions and mortalities; and divert household and construction waste from going to landfill sites.

This presentation will focus on Toronto’s TGSV3 requirements, explaining what facade designers have to do to meet both mandatory and stretch targets. It will also look at proposed changes to the Ontario Building Code and evaluate systems, assemblies, and components for highly glazed buildings and what it takes to achieve higher performance targets.

About the speaker

Hamid Vossoughi is a project principal at WSP Canada. Hamid is driven by delivering unique solutions to complex and challenging problems. He is the leader of WSP Canada’s Facade Centre of Excellence. He has a bachelor’s degree from Northeastern University and Master of Science from Cornell University. •

2:45

TOPIC / Contractor and glazier certification

PRESENTERS / Jeff Dalaba, program manager

Ben Beeler, co-developer

Building designers and glazing contractors are holding opposite ends of the same problem. Designers need a reliable method to evaluate contractors to ensure their technical expertise and good business practices. Reputable contractors need a trusted way to prove their bona fides to designers, separating themselves from those who cut corners and cut and run on contracts. This presentation takes a look at one existing solution to this problem: third-party certification of contractors and glaziers through the Architectural Glass and Metal Certification Council, a not-for-profit industry organization operating throughout North America. Through voluntary compliance with its best practices, monitored by rigorous testing and reporting, the AGMCC seeks to create a standard that will lift the fog on bid processes and raise the bar of professionalism across the industry.

Jeff Dalaba is program manager for the North American Contractor Certification Program (NACC) and program developer for the Architectural Glass and Metal Technician Certifica tion Program (AGMT) with Administrative Management Systems (AMS, Inc.) in Sackets Harbor, N.Y.

Ben Beeler is co-developer of the Architectural Glass and Metal Technician (AGMT) Certifica tion program and the director of development for the physical based portion of the program’s exam. For over 35 years he has worked in the glass industr y in estimating, project management, sales, and manufacturing, and as executive vice-president of a regional U.S. glass fabrication company. Ben is now an architectural glass and metal industry consultant who has been working with Administrative Management Systems Inc., for the past two years on the development of the industry’s first personnel certification program. •

4:30

TOPIC / Measuring anisotropy

Anisotropy, as opposed to isotropy, means that a material exhibits properties with different values when measured in different directions. In architectural glass, anisotropy relates to a visual effect caused by the presence of polarized light, the birefringent property of the glass and the mechanical stresses in the glass due to heat treatment. Louis Moreau believes the industry can improve on those aspects, with the long-term goal of aesthetic improvements for glass panels. This presentation will explain the fundamentals of anisotropy, when buildings are more susceptible to it, how to quantify it, and ultimately how to minimize it.

With over 25 years of experience in the glass industry, Louis brings an eclectic mix of international experience from float manufacturing, high performance vacuum coatings, large building glazing, and high-end glass fabrication.

As its Head of Technology and Innovation, Louis has played an instrumental role in the development and success of AGNORA. Louis likes to explore the limits of materials and processes to come up with innovative solutions. His most ambitious projects include More London Plot 1 and Plot 6; Mid City Place, London UK; Tour Granite, Paris FR; Sperone Westwater Gallery, New York USA, O’Hare Air Traffic Control Tower, QMA and the Onassis Center all-glass staircase. Most recently, Louis was named Task Group Chair for a new ASTM standard test method for retardation measurement on glass. •

Join the OGMA as it recognizes outstanding achievement

Each year Top Glass is proud to host the Ontario Glass and Metal Association’s Awards for Excellence. The Awards for Excellence are annual awards that recognize excellence in the design and execution of a building that incorporates the use of architectural glass and metal. There are two awards, one for Excellence in Architectural Glass and Metal Design and one for Excellence in Architectural Glass and Metal Execution. •

The Ontario Glass & Metal Association is committed to its mandate to promote the glass and metal industry and to encourage an image of responsibility and integrity. Founded in 1990, the association’s mandate is:

• To promote and assist to develop an image of a responsible and valuable Canadian industry.

• To provide educational, social and collaborative events relative to the glass and metal industry.

• To promote the interests and conserve the rights of those engaged in the manufacture, sale and installation of flat glass, architectural metal and related products.

• To promote co-operation between its members and other groups within related industries

• To gather information related to the industry and to communicate such information to members of the Association and other interested parties

Booth: 49 glassopolis.com

Glassopolis, a premier Canadian source for fire-rated glass, will show two fire-rated glass options for Canada. First, Schott Pyran Platinum, a premium choice for fire-rated glass, is now available in a large glass ceramic sheet size at 51 by 101 inches. It is a fire-rated glass ceramic that is floated, not rolled, and as a result it does not require polishing like other glass ceramics. Its naturally good-looking for better quality and better value. Secondly, Protect3 Safety Glass is a low-cost fully buildingcode-compliant fire-rated glazing available in Canada. Based on a surface-laminated wired glass, each piece comes UL-certified for fire and meets the most stringent impact safety requirements. Glassopolis also will present an array of lead x-ray glass and other specialty glass products.

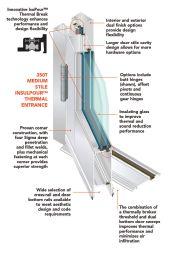

Booth: 64 kawneer.com

Kawneer has redefined thermal technology with the introduction of its new Insulpour Thermal Entrances featuring the advanced IsoPour thermal break technology. Ideal for high-end commercial and multifamily facilities, Insulpour Thermal Entrances offer high thermal performance, strength,

and interior and exterior dual-finish options for increased design flexibility. The new IsoPour technology merges the industry-proven pour and de-bridge thermal break with polymer isolator technologies. Both the door and the frame employ it to create assemblies with higher structural performance, enhanced energy efficiency and greater design flexibility. With sightlines that match non-thermal doors, the entrance is available in 250T narrow, 350T medium and 500T widestile options. The unique thermal break design allows for a wider selection of locking hardware than previous thermal entrance designs. Additionally, multiple cross-rail sizes and bottom rail heights are available, giving architects, designers and building owners more opportunities to bring their vision to life. Insulpour Thermal Entrances have undergone shock tube testing for blast mitigation and meet ASTM E1996 hurricane impact resistant requirements up to Zone 4 and Level D.

Booth: 59

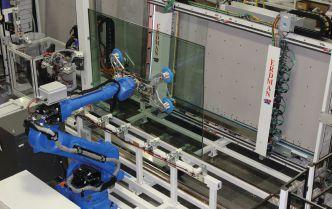

erdmanautomation.com

The Erdman unmanned robotic IG work cell produces large-size insulating glass (up to five-by-12 feet) with no direct labour.The use of three robots not only minimizes labour but also reduces needed floor space by roughly half. The target cycle times are one five-by12-foot IG unit every minute with no gas fill and every 90 seconds with gas fill.The needed floor space is only approximately 20 by 75 feet. Non-gas filled IG units can be produced

one per minute and the robots don’t need to take lunch or breaks.With the robotic work cell users can produce 480 units in one eight-hour shift. Running around the clock and at 100 per cent efficiency, 1,440 units can be produced in only 1,500 square feet whereas a traditional line would require roughly 3,000 square feet of machinery and 12 to 18 people. This solves the labour problem in this time of very low unemployment. Fabricators can reduce labour by four to six operators down to less than one and shift labour into areas of more critical thinking. Less direct labour means more safety because all the heavy lifting is performed by robots. Erdman robotic lines also produce cleaner IG because of reduced conveying and material handling.

LET THE LIGHT IN artisticskylight.com

Booth: 43

The model G-FF-Butted skylight from Artistic Skylight is a sloped modular glass skylight that can be fabricated to any desired length. This model is extremely versatile and can be adapted to any residential or commercial application. Its modular design results in an almost infinite amount of possibilities of lengths and makes for simplified logistics. This design has been laboratory-tested to the highest standards of NAFS-17 (North American Fenestration Standards) to meet and exceed all water and air penetration standards. This testing categorizes it among the most elite glazing categories. Its options include any custom colour exterior and interior finish combinations, high-performance glazing including reflective, tinted, or laminated glass, and an upgraded option for Self-Supporting Rafters (model G-FF-ButtedSTR). The model G-FF-Butted skylight is a perfect complement to any luxury home

project to bring in that much-needed daylight into the living area. Its price-point is moderate, with a wow-factor that far exceeds its price tag. For commercial-style buildings these skylights are recommended for areas with large atriums, over large office spaces or in dark hallways to provide the staff inside with natural daylighting and warmth as well as extended energy and cost savings.

Booth: 50 everlast.altitudewindows.com

The Everlast Altitude Plus window series sets a higher standard for aluminum windows. This window features extruded aluminum

profiles interior and exterior connected to a thermal insulation system called the Performance Core, representing the core of the window. The Performance Core is a new proprietary engineered material. It is designed for this specific task, offering improved dimensional stability and higher deflection temperatures resulting in increased strength – the perfect combination for any market. The Altitude Plus line also features mitred corners assembled with gaskets and corner keys all crimped together. This window series has achieved Energy Star certification. Low profiles make it an ideal window for today’s modern homes. Altitude Plus also meets the CW classification, making it suitable for midrise buildings with institutional application. It provides the possibility of multiple assembly and opening configurations, including casement, awning or fixed window configurations. Combination windows are achieved using either structural mullions with continuous frames or modular construction. The frame depth is 114 millimeters. The standard sash depth is 73 millimeters with a height of 44 millimeters. It is designed for 31-millimeter glazed units in dual- or triple-pane configura-

tion. Cardinal glass in various low-E combinations is available to achieve the desired performance. Mullions are 116 millimeters deep. Installation clips make for quick and easy installs as well.

Booth: 53 trosifol.com

Kuraray’s Trosifol business is a leading global specialist in the development, manufacture and supply of PVB and ionoplast interlayers for laminated safety glass in architectural applications. With the acquisition of the DuPont Glass Laminating Solutions business in 2014, Trosifol PVB and SentryGlas ionoplast provide the broadest range of interlayer solutions in the market. The Trosifol portfolio’s innovative glass-laminating solutions include structural and functional interlayers for safety, security, impact resistance, sound insulation, and UV protection. In structural applications, SentryGlas is the premier interlayer for glass guards and railings as its post-glass breakage performance is unsurpassed. Trosifol SC can improve STC and OITC by three points in applications where acoustic performance is critical. For decorative applications, Trosifol offers coloured interlayers for interior design projects and shower enclosures. Trosifol UltraClear and SentryGlas exhibit the lowest yellowness index (YID) in the industry for low-iron glass applications.

If you are planning a new project with glass – we have the right solutions. We are the leading global specialist in structural and functional interlayers for safety and security applications, sound insulation and UV control. For further information about our SentryGlas® ionoplast and Trosifol® PVB interlayers, please visit us at www.trosifol.com . trosifol@kuraray.com

Booth: 35 metalcurving.com

For 35 years, Rimac has built a reputation of quality and trust in the Canadian and North American metal curving market. The

company provides a wide variety of services, including metal curving, press brake forming, sheet metal shearing and machining. Rimac employs various methods for curving, including stretch forming, roll forming and rotary draw bending. Each method of curving provides unique advantages and disadvantages. By providing various methods for curving, it provides the best quality of parts, with minimal distortion at the best price. Rimac recently acquired a sheet metal shear and press brake, each measuring 13 feet three inches long. This added service allows it to provide custom brake formed profiles to compliment its curved parts. The full-service machine shop augments services by allowing Rimac to drill, tap, notch and contour parts. This allows the company to provide customers with complete parts, ready for assembly. This also helps it to build custom tooling, quickly, in house and at a fraction of the cost. Rimac truly is a one-stop-shop for custom curved components. The team of experts is dedicated to delivering first-rate customer service with their expertise in the industry. Rimac prepares a competitive and comprehensive quotation, outlining all necessary details for the job. The company maintains an inclusive social media presence, showcasing some of its best work.

Booth: 21

alectraconservation.com

Your next glass tempering furnace will save you money. By upgrading to a new high-efficiency glass tempering furnace with a

variable frequency drive or simply upgrading controls on your exhaust system, you will lower your energy consumption and increase productivity – meaning higher margins and lower bills. Alectra Utilities specializes in upgrading small and large manufacturers to maximize their energy efficiency with equipment retrofits, monitoring and targeting solutions, process and systems analysis, construction audits and consulting.

Booth: 28

alcurvcanada.com

Alcurv Canada is a metal curving company dedicated to excellence in continuous service to the residential and commercial glazing industry. Located in Brampton, Ont., – just minutes from the airport and the technology triangle – Alcurv has been providing outstanding quality service to all customers with the highest possible level of quality while ensuring that turnaround time is kept to a minimum. Using state of the art machinery and techniques the company provides stretch forming, roll forming and more. Alcurv Canada can curve it all from small angles and channels to large sections for skyscrapers. Whether the project demands one curve or 10,000, Alcurv is here to help and add a unique look and feel to every project. The team of knowledgeable staff will make sure each project is a complete success. From the introductory phone call or email, right through to completion, Alcurv prides itself on expert customer service.

by FRANK FULTON

Fulton is a former principal of Fulton Windows and former president of the OGMA.

I’m sick and tired of being gouged. Administration fees, facility fees, set up fees, convenience charges, baggage fees, event service fees…call them what you will, they’re all just a means of digging into your pocket in an underhanded and unethical way. Personally, I consider all unjustified charges of this nature to be devious and deceitful and the companies that levy them to be sniveling weasels. Where this type of behavior would have been limited to only the sleaziest of organizations in the past, the practice has become commonplace in today’s business culture, totally lacking in ethics and integrity.

There have been numerous studies done proving that fees cause widespread public displeasure, frustration, outrage and a sense of betrayal, particularly in cases where companies have unbundled their service offerings by introducing numerous fees for services that were previously provided as “free.” All of which results in increased complaints, an angry relationship with the service provider and negative word-of-mouth. The worst charges that are viewed as the most unfair and taking advantage actually breed hatred towards the provider.

The most spoken-about fees in mainstream media and most reviled by the general public are baggage and seat fees levied by the airlines. Both of these “conveniences” used to be included in your ticket price. Bringing luggage when you travel is still considered a necessity, so passengers view these as unjustified. The services cost the airlines little or nothing to provide in incremental terms, so they are simply taking advantage of travelers with no choice. In 2018, Air Canada took in $1 billion from these payments while the world’s top 10 airlines collected US$29.7 billion in ancillary fees. Profits are soaring as practically all of this goes straight to the bottom line.

Corporate entities are a lot like governments when they impose a tax.

This brings us around to the glass industry where the Energy Surcharge (ESC) has been a major source of angst and frustration for the past 15 years. Initially, the surcharge was introduced as the glass producers’ temporary solution to skyrocketing natural gas costs which peaked in the fall of 2005 and again in 2008. Natural gas makes up about 21 per cent of the cost of making glass. The industry didn’t react totally negatively at the time as the reason for the surcharge was understandable and it was to be only a temporary measure.

Unfortunately, corporate entities are a lot like governments when they impose a tax, even a temporary or revenue-neutral one. They fall in love with the added cash flow and revenue-neutral becomes a coffer filler. Look up B.C.’s carbon tax as an example and what began as temporary becomes permanent and institutionalized. Not only has the glass ESC become a standard practice, soon after it was introduced it was expanded to add freight to the equation. The cost of natural gas has since fallen to 25 per cent of its 2005 peak. Hands up if you’ve seen a 25-per cent reduction in your ESC.

If the objective of glass producers and glass fabricators was to instigate distrust in its clients, it couldn’t have found a better way than how they have mishandled and abused the ESC. If the charge was truly a reflection of real costs, one would expect it to be similar from all suppliers. However, the rates vary wildly from company to company and between primary producers and fabricators. The ESC added by producers ranges from around one to 6.4 per cent. This is the sector that actually incurs the bulk of the added input costs. Fabricators on the other hand have recently increased their ESC to over 10 per cent in some cases, without seemingly having to bear the incremental costs to support their charges. If there is an explanation I’m not aware of, I’d sure like to be updated so I could relay the information in the next edition of this publication.

So, why does our industry simply sit back and quietly take it? For one, everyone’s busy running their business and trying to make sense of the amounts and discrepancies in the charges from the various suppliers seems hopeless considering they don’t have enough data to reference to make an objective assessment. Secondly, the surcharges are a lot like the HST. You add it into your price and pass it on so the consumer at the end of the supply chain is really the one footing the bill. It is easy to simply pass the costs on to customers but then we end up in the same boat of mistrust and dislike. •

Some glass companies offer the obligatory handful of decorative glass products. Others none. But the world’s largest glass maker always gives you more. Take LACOBEL® and MATELAC™ – a gorgeous duo of back-painted designer glass products. Accentuate the high gloss of glass with LACOBEL. Or, go soft and satiny with expertly acid-etched MATELAC. Combined with unlimited colors, amazing new possibilities for interior design await you with AGC.

Learn about these and other Amazing AGC products at agcglass.com