When the most hazardous part of the emergency can be getting to the scene, you need a vehicle that is safe by design. Utilizing a cab built with heavy-duty perimeter roof extrusions supported by twin vertical columns, the E-ONE Quest is designed to keep occupants safe in the event of a roll-over. And while in route, have added confidence with G4, our exclusive electronic stability control system. Also available are our new tethered seats with integrated seat belts and roll-over protection system. Get behind the wheel of the Quest and experience the protection of an industry benchmark.

at

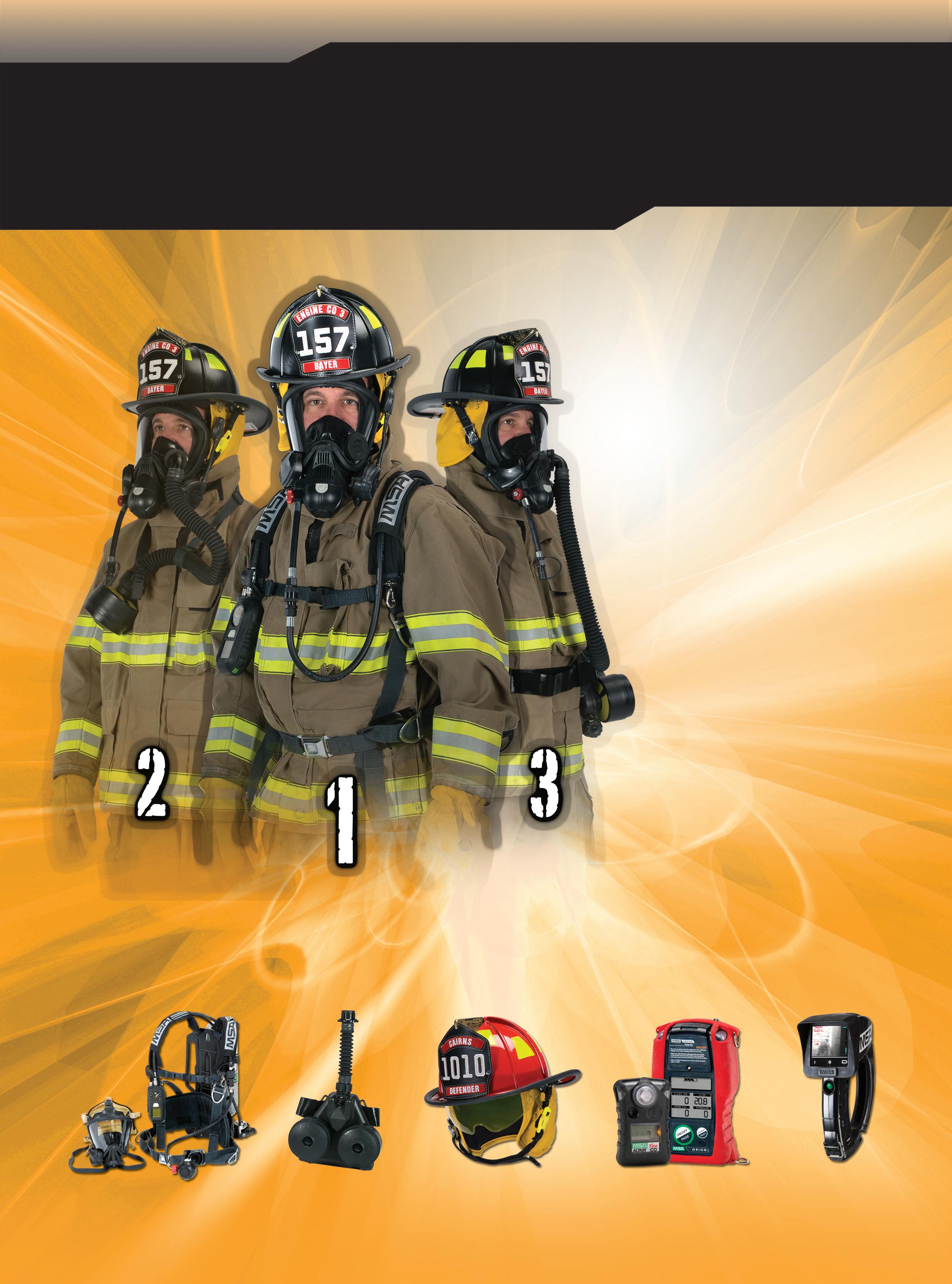

1 Use Firehawk M7 CBRN SCBA for firefighting and rescue

2 Switch to Firehawk CBRN Gas Mask (air-purifying respirator) for scene management, after low hazard level is assessed

3 Convert to Firehawk CBRN PAPR (powered air-purifying respirator) for long-term comfort and use

Each model meets/exceeds the latest requirements of NFPA & NIOSH standards

14

UP TO STANDARD

With 2009 on the horizon, Canadian fire departments need to ensure that they are current with the latest National Fire Protection Association (NFPA) standards. As James Careless reports, there are four areas to be aware of: bunker gear, apparatus, PASS and SCBA.

22

Q-AND-A WITH CHIEF TREMBLAY

Serge Tremblay was appointed chief of the Service de sécurité incendie de Montreal in 2004, after spending 28 years working his way up the ranks from firefighter in various jurisdictions. As chief in one of Canada’s largest cities, he runs a department in which firefighting challenges are numerous and varied.

BY LAURA KING Editor

lking@annexweb.com

t the risk of preaching to the converted, the next few weeks have to be among the scariest on the calendar for Canada’s fire services. You all know it’s stupid and dangerous for people to take the batteries out of their smoke detectors or come home after a few too many pops and turn on the deep fryer for some late night fries and then fall asleep. Or sit around a camp fire that never gets properly extinguished with the resulting bush fire triggering an evacuation.

But add to that the seasonal ritual of putting a fir tree in the house for two or three weeks, stringing it with electrical wires, lighting candles and enjoying some holiday spirits. Like I said, I’m singing to the choir.

A new report by the United States Fire Administration identifies the benefits of residential sprinklers in containing the heat release from Christmas trees. (It’s cleverly titled Impact of a Residential Sprinkler on the Heat Release Rate of a Christmas Tree Fire.)

significant impact on a fire.”

The study landed in my e-mail in box a couple of weeks ago along with the barrage of daily press releases but caught my eye because I was in the middle of editing a story on residential sprinklers. It’s cricual that we get the message out. It’s that time of year. Dry trees, electrical wires, paper and gift wrap, candles, fireplaces . . . it’s a wonder the trucks aren’t rolling 24/7. So, here’s a wish for good luck and smart ratepayers this holiday season. Not every tragedy is inevitable. Fire education makes a difference.

The study found that even a single sprinkler was able to prevent a flashover and, in many instances, put out a fire before the firefighters arrived. And, while you’re making the pre-Christmas fire safety education speeches don’t forget to point out the importance of watering the tree. The study also found that high moisture content in the needles goes a long way to slow or even stop the spread of fire.

Dan Madrzykowski, a fire protection engineer with the National Institute of Standards and Technology, laid out a primary and seemingly obvious conclusion. “This project’s experiments demonstrate that a small amount of water can have a

May.

As I sign off on the final editorial of 2008, I want to thank the writers, photographers and others who have helped build the content of our magazines and website. I know from your calls and e-mails that these pages serve as an industry gathering place.

We’re proud of that.

Thanks also to the many people who took time to share their stories and concerns, to educate me on the challenges and priorites and the successes and failures of the Canadian fire services. It means a great deal to me to have your time and trust.

To everyone else, thanks for reading. We appreciate it.

Here’s a wish to everyone for a happy, healthy, prosperous and safe 2009. Happy holidays and Merry Christmas.

One other quick note, Steve Kraft’s Your Call column will return in February.

ESTABLISHED 1957 December 2008 VOL. 52 NO. 8

EDITOR LAURA KING lking@annexweb.com 289-259-8077

EDITOR EMERITUS DON GLENDINNING ADVERTISING MANAGER HOPE WILLIAMSON hwilliamson@annexweb.com 800-265-2827 ext. 253

PUBLISHER MARTIN MCANULTY fire@annexweb.com 1-519-429-5178 800-265-2827 ext. 252

PRODUCTION ARTIST KRISTA MISENER kmisener@annexweb.com

VP/GROUP PUBLISHER DIANE KLEER dkleer@annexweb.com

PRESIDENT MIKE FREDERICKS mfredericks@annexweb.com

PUBLICATION MAIL AGREEMENT #40065710

PAP Registration #8885

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT.

P.O. Box 530, SIMCOE, ON N3Y 4N5 email: sbrady@annexweb.com

Periodical Postage Paid at Buffalo NY. USPS 007-276, ISSN 0015-2595. Published eight times per year (Feb., March, May, June, Aug., Sep., Nov., Dec.) by Annex Publishing & Printing Inc.

U.S. Office of Publication c/of DDM Direct.com, 1223 William St. Buffalo NY 14240. U.S. Postmaster send address change to P.O. Box Niagara Falls Ny 14304.

Printed in Canada ISSN 0015–2595

CIRCULATION

e-mail: sbrady@annexweb.com

Tel: 866-790-6070 ext. 206

Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Canada – 1 Year - $25.44

(includes GST - #867172652RT0001)

USA – 1 Year $50.00

We acknowledge the financial support of the Government of Canada, through the Publications Assistance Program and the Canada Magazine Fund, toward our mailing and editorial cost. Nous reconnaissons l’aide financiere accordee par le gouvernement du Canada pour nos coults d’envoie postal et nos coutl redactionnels par l’entremise du Programme d’aide aux publications et du Fonds du Canda pour les magazines.

From time to time, we at Fire Fighting In Canada make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission @2008 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.firefightingincanada.com

■ ONTARIO

Thunder Bay – Rescue equipment, supplies, personnel, and search and rescue dogs were airlifted via a Canadian Forces transport airplane to Thunder Bay from Toronto as part of the largest emergency response exercise held in recent Canadian history.

Exercise Trillium Response, which was held Nov. 17-23, was a multi-jurisdictional disaster response exercise that simulated the consequences of a massive ice storm in northwestern Ontario, similar to the one that devastated eastern Ontario and Quebec in 1998. Emergency Management Ontario and the Canadian Forces jointly led the exercise. It involved more than 1,500 participants from 40 different organizations including provincial ministries, federal departments, municipalities, First Nations, non-governmental organizations and the private sector.

The air movement to Thunder Bay International

Airport from Toronto Pearson International Airport tested the rapid response capability of Toronto’s Heavy Urban Search and Rescue (HUSAR) team following the staged collapse of local buildings with more than 100 people fictionally trapped inside.

A fleet of specialized equipment and tactical teams was deployed in the exercise including:

• The Emergency Medical Assistance Team (EMAT)

• Emergency Management Ontario (EMO)’s Mobile Emergency Operations Centre or Mobile 1

• 1,000 members of the Canadian Forces, dozens of specialized army vehicles, naval craft and a Boeing CC-177, the military’s newest heavy transport aircraft.

The Ministry of Health and Long-Term Care’s EMAT is a mobile 56-bed medical field unit that can be driven anywhere in Ontario within 24 hours.

Promotions & appointments

KEITH BOSWELL has been a member Surrey Fire Service in B.C. since 1977. He steadily progressed through the ranks including positions of lieutenant, captain, training officer, acting battalion chief and, presently, one of two assistant fire chiefs in charge of operations. Boswell’s passion for the fire service and desire to learn led him to the Justice

Institute of British Columbia Fire Academy in 1985 where he began instructing and developing a wide variety of fire service programs. He played an integral role in the development of

Shuniah volunteer firefighter John Ayearst comforts a victim of a simulated bus accident Saturday as part of the Trillium Response large-scale mock emergency exercise.

many critical programs for the JIBC including obtaining IFSAC accreditation, development of the NFPA 1001 recruit training program and the development of an officer program meeting the NFPA 1021 standard. He also worked with IFSTA in Oklahoma in the development of the incident safety officer manual.

JOE DELUCA has been a member of the City of Surrey Fire Service since 1980. He has steadily progressed through

the ranks including positions of lieutenant, captain and acting battalion chief, to his new position as one of two assistant fire chiefs in charge of operations. He has an extensive

■ ONTARIO

Toronto – Four firefighters and are the recipients of Ontario’s top honours for bravery.

Lieutenant-Governor David C. Onley invested the recipients with medals at a Queen’s Park ceremony on Nov. 21 as Minister of Community Safety and Correctional Services Rick Bartolucci read out each name and spoke of the act of bravery. These medals are the province’s highest award in recognition of firefighters and police officers whose actions demonstrate outstanding courage and bravery in the line of duty.

The recipients of the Ontario Medal for Firefighter Bravery are Lieutenant John Chatterton of the Ottawa Fire Services, firefighter Les O’Neill of the North Middlesex Fire Department, firefighter Steven Reynolds of the Milton Fire Department and firefighter Michael Sophocleous of the

London Fire Department.

“The medals for bravery remind us of the courage and dedication of those who serve in police and fire services across the province, that every day, these brave men and women face extraordinary dangers, to keep our communities safe,” said Lieut.Gov. Onley.

“It’s a great honour to celebrate the bravery and courage of firefighters and police officers who risk their lives to protect us,” said Minister Bartolucci. “Ontario is one of the safest jurisdictions in the world, thanks to the selfless dedication and outstanding heroism of our firefighters and police officers.”

A total of 179 Ontario Medals for Firefighter Bravery have been awarded since 1976.

An independent body of citizens representing all regions of Ontario determines medal recipients.

■ CANADA

A report for the the Canadian Centre for Emergency Preparedness on its inaugural national survey concludes that Canadians are not well versed in emergency preparedness.

“The overwhelming majority of respondents feel that people just do not think about emergency preparedness (81%) . . ., ” the report says. “The second most common reason is that people just expect the government, police, hospitals and fire departments to make the necessary preparations (39%).”

In the preface to the report, Dr. James Young, one-time commissioner of Emergency Management for Ontario and Ontario’s first Commissioner for Public Security, acknowledges that some of the findings are not surprising.

“Both the low public profile of Emergency Awareness Week and the finding that individuals and small companies are not

■ SASKATCHEWAN

Regina – A Saskatchewan traffic law under which a volunteer firefighter was ticketed while speeding to an emergency call is being changed.

The provincial government is amending the Traffic Safety

Act so that municipalities can designate volunteer firefighters and first responders’ cars as emergency vehicles.

The change, which takes effect in April, would allow volunteer firefighters to use red flashing lights and sirens and

drive contrary to the rules of the road.

Provincial law currently requires volunteer firefighters to obey all traffic laws while responding to emergency calls.

The issue came to light after a volunteer firefighter in

prepared could be predicted,” he says.

The survey acknowledges that fewer people are getting news and information from newspapers and TV but are using the internet.

“The use of the internet to provide ongoing timely information in an emergency has barely begun. The idea in the COMPAS/CCEP report of governments’ pooling resources to create big, fast and robust portals is a very good one. Pointing people in the correct direction through advertisements, links and press conferences is also solid.

The final analysis? “The central, unavoidable conclusion is the low level of preparedness among Canadians and their low, diffuse level of awareness of where to turn in the event of an emergency.

The report is available online at http://www.ccep.ca/ survey/srvyadd.asp

background in operations, as he has served for many years at some of Surrey’s high-call volume stations. For more than 17 years, he has been an active member of the Critical Incident Stress Team and Family Assistance Program and his contribution has been invaluable. In addition, DeLuca has served as an adjunct faculty member of the Justice Institute of B.C.-Fire Academy since 1994.

MARC LEDUC is the new fire chief of the Greater Sudbury Fire Service. Prior to this appointment, he was the deputy fire chief with the Greater Sudbury Fire Service and has been in an acting fire chief capacity since May upon the retirement of Donald Donaldson.

Effective Oct. 30, GEOFF HAYMAN became the first Deputy Fire Chief for the County of Brant. His duties include emergency planning for the

county and training volunteer firefighters. Hayman has 24 years with the Mount Pleasant Volunteer Fire Department, most recently as fire prevention and inspection officer for the County of Brant.

After 33 years of service, as of Dec. 31, 2008, Fire Chief KENT MACCARL will be retiring from Whitby Fire and Emergency Services in Ontario.

Estevan went through a red light and was given a $220 ticket, which a judge later bumped down to $70.

Manitoba and Ontario already let volunteer firefighters carry flashing lights.

– The Canadian Press

A retired 30 year veteran of the St. John’s Regional Fire Department was laid to rest Oct. 25. Capt. JOHN “JACK” SIMMONS died at the Health Sciences Complex. Simmons joined the city’s fire department in 1953 and retired in 1983.

JACK ROBINSON, age 90, passed away Nov. 7. He served 37 years with the Paris Volunteer Fire Department in Ontario.

THE MOUNT LORNE FIRE DEPARTMENT in Yukon took delivery on May 15 of a Fort Garry Fire Trucks built MXV three-man Crown CAFS pumper on a Sterling Acterra chassis with a Caterpillar C7, 300-hp engine, a Waterous CDC10 1250 pump, a Pneumax 150P CAFS with FoamPro 1600 foam system and a co-poly 1000-gallon tank.

THE SASKATOON FIRE DEPARTMENT took delivery in August of a Rosenbauer America rescue-pumper on a Spartan Diamond chassis with a Cummins ISL-365 motor, a Waterous CSUY pump rated at 1,750 gpm, a 600-gallon UPF water tank and a FoamPro 2002 system supported by two 30-gallon foam cells.

THE CORNWALL FIRE SERVICE in Ontario, under the command of Fire Chief Vic Leroux, took delivery in June of a Spartan Metro Star ( LFD ) rescue pumper with a six-person cab, a Hale QFLO, 5,000 litre/minute pump, a Hale Foam Master foam proportioner and an Allison transmission, driven by a Diesel Cummins ISC 330 engine.

Check in daily for news from across Canada.

Help us take the pulse of the Canadian fire services with our online polls. Recently, 81.8 per cent of respondents said they agreed with the installation of “black boxes” or data recorders in fire apparatus; 14.3 per cent said they disagreed; and 3.9 per cent were undecided. The data recorders can tell if all firefighters in the apparatus have fastened their seatbelts, and how fast the truck was going while it responded to a call, among other things.

Exclusively online in December, David Hodgins, managing director of the Alberta Emergency Management Agency, says the fire service needs leaders with hands-on experience to assume responsibility for the safety of team members who are operating in dangerous situations. Visit Leadership Forum in December.

Also exclusively online in December, Lyle Quan, the deputy chief in Guelph, Ont., looks at change in the fire hall and how to make it work. In his CornerStone column, Quan says leaders have to first embrace change before it is accepted by others in the workplace.

And Brad Patton, the chief in Centre Wellington, Ont., ponders the pros and cons of the word “volunteer” in his Volunteer Vision column.

BY SEAN TRACEY Canadian Regional Manager NFPA International, Ottawa, Ont.

he high cost of gasoline and concern over dependence on foreign oil has spurred a number of new developments in the petroleum industry. Two items of concern to fire services are the increased use of ethanol and the production of biodiesel. Both of these will result in increased risks to the fire service as production of both increases.

In the case of biodiesel, there is the potential for smaller backyard stills to be more prevalent. These increased risks have not been presented to the Canadian fire service – a result of not having a national fire advisor bureau.

In 2002, there were five plants in Canada producing ethanol at approximately 175 million litres a year. Presently, the industry is reporting that there are 10 plants in operation with a further six under construction. Once these plants come online, the production capacity will be 1,620 million litres a year – almost a tenfold increase in six years.

This is still well below the production capacity of the U.S. but as fuel prices soar there will be more pressure on these alternatives. Such increases in production will result in greater risk as ethanol in its pure form is shipped across the country by rail or road. In the U.S., studies have shown that ethanol has now gone from No. 5 to No. 1 in its hazmat ranking based on volume of product being transported.

The risk posed by ethanol is unlike gasoline; a traditional fire department response to a hydrocarbon fire will not be effective. Gasoline will sit upon water while ethanol is water soluble. Conventional foams will likely not work. Instead, alcohol-resistant foams are necessary and the fire service needs to be made aware of the potential hazards and appropriate response.

include the response to ethanol, but also many other production chemicals and the explosive hazards due to processing combustible agriculture dusts.

Biodiesel is a means of cutting the cost of diesel fuel. A number of Canadian plants have started up operations. There are similar concerns with these plants because of the risks of using large quantities of methanol – a fuel that burns invisible. What is of greater concern is that biodiesel operations can be small-scale backyard-type operations. They scrounge or purchase waste oils from restaurants and then convert this through the addition of chemicals and refining into fuel that can be burned in a diesel engine without need for modification.

The worry is that these operations probably never apply for a permit but they store large quantities of methanol and other dangerous materials and there may be improper disposal. The fire service needs to be aware of the potential threat when responding to suspicious incidents. The U.S. Fire Administration published an infogram on Sept. 4 on the item.

Both of the above issues highlight an interesting point. Not one source in Canada has been alerting or engaging the fire ser-

The risk posed by ethanol is unlike gasoline; a traditional fire department response to a hydrocarbon fire will not be effective. ‘‘ ’’

To this end, the USFA and IAFC have produced a downloadable training package entitled Responding to Ethanol Incidents, available at www.iafc.org. This includes downloadable instructor and student workbooks and a full set of presentation materials.

The ethanol plants pale in comparison to larger refineries for their throughput and so are less costly to start up. The smallerscale nature of the facilities will likely mean that there would be no industrial fire brigade response present and instead response would be from outside municipal departments. This would expose the responders to unique threats that would require special preincident planning, unique tactics and additional resources. These

Sean Tracey, P.Eng., MIFireE, is the Canadian regional manager of the National Fire Protection Association International and formerly the Canadian Armed Forces fire marshal. Contact him at stracey@nfpa.org

vice on these issues (except one AFSOA e-mail to its members on biodiesel). We have the same potential risks in Canada on these issues as the U.S.. The Canadian Renewable Fuels Association should be engaged to assist in seeing materials distributed to the fire service – but by whom? Having a national fire advisor would help to ensure that Canadian fire service personnel are given and made aware of such materials.

The nature of risks faced by the fire service is constantly evolving. No one department can keep abreast of every change.

We need a central body that can be the go-to source for information for the Canadian fire services. We need a national resource to gather best practices, lessons learned, resource materials and the latest research. We need a body that can fund needed research and disseminate it. We need a means to help fund the fire services to achieve the public’s expectations. We need a national fire advisor bureau.

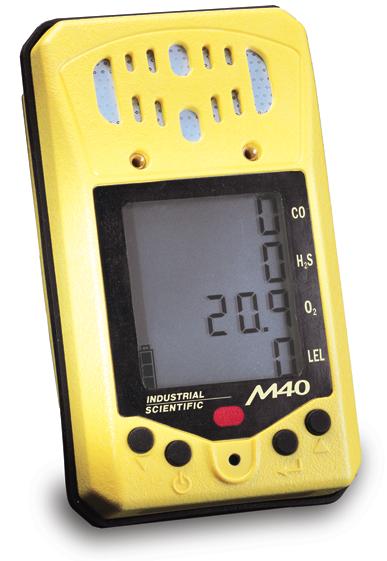

M40 Multi-Gas Monitor

• Continuous monitoring of O2, H2S, CO and combustible gases with discrete sensors

• 18 hour runtime with lithium-ion battery

• Standard vibrating, 90 dB audible, and LED visual alarms

• Up to 75 hour datalogging capacity

• Optional compact parasitic sampling pump

• 2-year, all inclusive warranty

M•Cal™ Calibration Station

• Simple, push-button operation

• Function (bump) testing

• Calibration

• Battery recharging

• Stand-alone operation No PC is required

• Automatic documentation via PC or printer interface

By JAMES CARELESS

New rules mean bunker gear needs to be replaced every 10 years, no matter how well it’s taken care of, due to wear and tear on the fabric that can result in deterioration of the protective materials.

With 2009 on the horizon, departments must ensure that they are current with National Fire Protection Association (NFPA) standards. There are four areas to be aware of: bunker gear; apparatus; PASS; and SCBA. Here’s an outline of each, with explanations from NFPA Canadian regional director Sean Tracey and FFIC Truck Checks columnist Don Henry, who is also the chair of the IAFC’s apparatus maintenance section and a principal member of the NFPA 1071 emergency vehicle technician professional qualifications standard committee.

■

Issued in 2007 and due for revision in 2010, NFPA 1971: Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting details requirements for bunker wear. This standard is derived from investigations into why firefighters have been injured or killed in the line of duty. In the present standard, “there is now an option that specifies what is required for a suit to be deemed ‘CBRN-compliant’,” says Sean Tracey. “This is a response to the threat of terrorist-created CBRN incidents. I do not expect many Canadian departments to select this option. But for those operating in major cities and/or industrial areas, knowing what it takes for bunker gear to be CBRN-compliant is extremely useful.”

All bunker gear built to meet NFPA 1971 will come with a handle/strap attached to the back exterior of each coat to allow rescuers to drag the wearer to safety should he lose consciousness on the job. “We have also seen the standard revised to require improved reflective trim and increased protection against scalding,” says Tracey. “NFPA 1971-compliant bunker gear must also provide better protection against heat on elbows, knees and harness points, where fabric compression can effectively thin the distance between the skin and the heat.”

Worth noting: NFPA 1851: Standard on Selection, Care and Maintenance of Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting has tightened the lifespan rules for bunker gear. Under the new standard, suits must be retired after 10 years of service no matter how well they have been maintained. The reason: even the best-kept suits deteriorate over time as their protective materials degrade due to aging and exposure to heat.

NFPA 1901: Standard for Automotive Fire Apparatus (issued for 2009, revision due in 2013) deals with the biggest ticket items, as far as departments are concerned. (Note: Canadian departments can order apparatus based on either NFPA or ULC standards. The new NFPA 1901 is different in some areas from the ULC S515 standard, so be sure to check both before ordering.)

Here’s what you need to know: Enhanced firefighter safety has driven changes to NFPA 1901. This is why apparatus sold after Jan. 1 must carry vehicle data recorders, which will track operational data over the equipment’s last 48 hours of use. Data recorded includes rate of acceleration or deceleration, engine speed, seats occupied and seatbelt status (worn or not). There’s good reason for this:

Continued on page 33

By DON HENRY

What are emergency vehicle technicians? They are people of many skills – small engine mechanic, automotive and heavy duty technician, plumber with a dash of auto body artist throw in. They are people who are willing to accept the tremendous responsibility for the results of their work. Simply put, unless you walk to the fire, you need these people.

It is very important that we encourage and support the training and recognition of this group of skilled people. The Emergency Vehicle Technician Certification Commission is a group that works to accomplish this outcome. It has numerous exams that can be taken to prove your level of knowledge. Exams on fire apparatus, ARFF law enforcement and ambulance are available. Theses exams are fair but tough. The cost is reasonable. There are two test dates each year, one in October and the other in June. For more information go to www.evtcc.org.

Technicians are sometimes a bit hesitant to attempt these exams. I produced an assessment exam on fire apparatus for those people who would like to get a feel for what these exams are about. I made up 20 questions in each area and then divided the question further into

two groups, 10 general knowledge questions about the nuts and bolts and 10 that deal with the NFPA standards used to make and maintain the fire truck. You will need to get your nose into to both the NFPA 1901 and the 1911 if you want to pass these exams.

Give these questions a try. The answers will be posted at www. granitefleet.com/answers.

While you are at the Granite site, look at the fleet maintenance software. If you do well on my questions then sign up for the Emergency Vehicle Technician Certification Commission exams, study hard and good luck.

Meantime, I would like to recognize and congratulate the following people for recently achieving their Master Level EVT status: Dayle Coghlin, Kitchener Fire Department, Ont.; Doug Cox, Vancouver Fire and Rescue Services; Lynn Deacon, London Fire Services, Ont; Barry Dollmaier, Town of Caledon Fire & Emergency Services, Ont; Tom Hooker, Richmond Fire-Rescue, B.C.; Glenn Jones, City of Victoria Fire Department; David Kennedy, Halifax Regional Fire & Emergency Service; Dennis McCarthy, Toronto Fire Services; Gale Myers, Rocky Mountain Phoenix; Terry Santink, Strathmore Fire Department, Alta.; Roger Zanettin, Windsor Fire & Rescue Services; D.W. Scott Urquhart, District of North Vancouver Fire & Rescue Service; Daniel Vieno, St. Catharines Fire and Emergency Services Department, Ont.

■ THESE FIRST 20 QUESTIONS DEAL WITH DESIGN AND PERFORMANCE OBJECTIVES.

1. Fill in the blanks: Apparatus that can flow water under pressure while moving is referred to as _________________________ and _________________________.

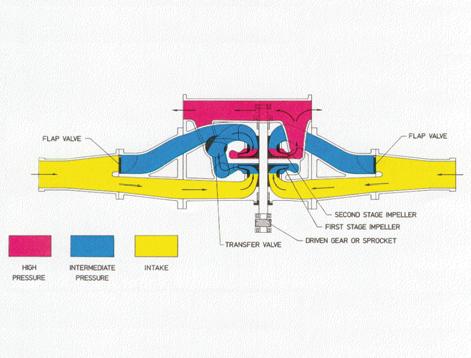

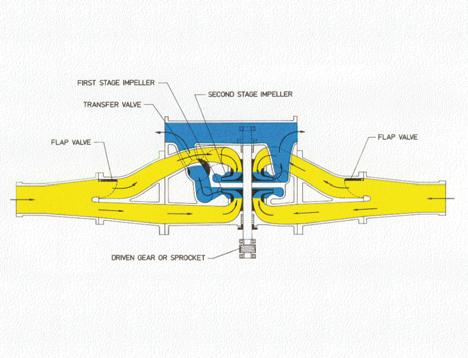

QUESTION 30

Identify the pump.

ALTERNATOR

Electrical section starts with question 41

TRUCK CHECKS

Apparatus at the fire.etc training school at Lakeland College enjoy regular maintenance.

2. Define the term “draft” as it applies to fire apparatus.

3. Define the term “residual” water pressure as it applies to fire apparatus and fire hydrants.

4. Define the term “static” water pressure as it applies to fire apparatus.

5. GVWR stands for:

6. GAWR stands for:

7. GCWR stands for:

8. A soft suction hose can be used to supply a fire pumper directly from a lake or pond.

a. True

b. False

9. A gauge located on the pump panel that can read both a vacuum and a pressure is called:

a. Twin gauge

b. Double gauge

c. Vacuum gauge

d. Compound gauge

10. The term “maximum governed speed” refers to the:

a. Maximum engine r.p.m.

b. Engine high idle

c. Maximum fire pump

shaft speed

d. Fastest forward speed

e. Both a and b

■ QUESTIONS 11 TO 20 REFER TO NFPA 1901, 2009 EDITION

11. Service brakes must be able to stop a fully loaded apparatus at a speed of 32 kph (20 mph) in a distance not to exceed:

a. 10.7 metres (35 feet)

b. 15 metres (49.2 feet)

c. 20 metres (65.2 feet)

d. Four times the length of the truck

12. To be considered an initial attack pumper, a pumper must have a pump size of at least:

a. 750 litres (198 gallons)

b. 1,000 litres ( 250 gallons)

c. 1,250 litres (330 gallons)

d. 2,000 litres (528 gallons)

13. The apparatus shall be able to maintain a speed of at least 32 kph (20 mph) on a grade of up to _________ per cent.

14. Who determines the maximum engine operating temperature?

a. Fire department

b. Engine manufacturer

c. Apparatus manufacturer

15. The pump to tank fill line on pumps of more than 3785 litres (1,000 gallons) shall be of at least:

a. 300 mm (12 inches)

b. 200 mm (8 inches)

c. 100 mm (4 inches)

d. 50 mm (2 inches)

16. Non-driving steering axles must be capable of a minimum angle of how many degrees?

a. 15

b. 20

c. 25

d. 30

17. Pump water intake valves (excluding tank to pump) must be gated with slow moving valves if they are of what size or larger?

a. 76 mm (3 inches)

b. 65 mm (2.5 inches)

c. 100 mm (4 inches)

d. any intake valve

18. The engine’s fuel tank must hold enough fuel for:

a. 2.5 hours of pumping @ 1035 kPa (150 p.s.i.)

b. 3 hours of pumping

@ 1400 kPa (200 p.s.i.)

c. 1 hour of pumping @ 1035 kPa (150 p.s.i.)

d. 3 hours of pumping @ 1035 kPa (150 p.s.i.)

19. By design the braking system must hold a fully loaded vehicle on a grade per cent of at least:

a. 7 per cent

b. 10 per cent

c. 20 per cent

d. 25 per cent

20. All fully loaded apparatus shall be able to attain a minimum top speed on a level road of at least:

a. 80 kph (50 mph)

b. 105 kph (65 mph)

c. 88 kph (55 mph)

d. 72 kph (45 mph)

■ THESE QUESTIONS RELATE TO THE OBJECTIVES OF THE FIRE PUMPS

21. When operating the fire pump in the “series/pressure”

operation of a two-stage pump, the pump will deliver:

a. Double the pressure, half the volume of water

b. Half the pressure, double the volume of water

c. Double the pressure, double the volume of water

d. Half the volume, half the pressure of water

22. When operating the fire pump in the “volume/parallel” operation of a two-stage pump, the pump will deliver:

a. Double the pressure, half the volume of water

b. Half the pressure, double the volume of water

c. Double the pressure, double the volume of water

d. Half the volume, half the pressure of water

23. A pumper has to be subjected to a strong water hammer. The master pump gauge will not return to zero but reads 100 kPa. (14.5 psi) You should:

a. Recalibrate the gauge

b. Replace the gauge

c. Advise the operators to just subtract 100 kPa (14.5 psi) from all readings

d. Water hammers the fire pump with a reverse flow of water to re-centre the gauge

24. Technician A wants to adjust a fire pump packing when operating under pressure and flow until no water drips from the packing. Technician B says that pump packing can be adjusted with only static water pressure from the truck’s water tanks. Who is correct?

a. Technician A

b. Technician B

c. Both technicians

d. Neither technician

25. The most common reason for failing a fire pump service test during the high pressure, low flow is:

a. Engine low on power

b. Excessive wear (clearance) between the impeller hub and wear ring

c. Transmission slipping in low gear

d. Transmission oil overheating

e. Pump losing prime

26. A pitot gauge is used to measure what?

a. Engine oil pressure

b. Water pump flow during a flow test

c. Air-flow rates

d. Small pilots

27. The dry vacuum test is performed the first time with:

a. Intake suction hose in the water source (pond, lake) and open

b. Discharge valves open but capped

c. Discharge valves closed but capped on tight as possible

d. Intake ports capped, but intake valves open

e. Intake suction hose connected but not capped

28. A mechanical r.p.m. counter on the fire pump transfer case reads excessively different than the engine r.p.m. on the pump panel during pumping. This is:

a. This is normal, you often have to multiply by a factor of ten times.

b. Caused because the slippage in the transmission

c. Caused because one of the gauges is defective

d. Because the transmission is in overdrive when pumping

e. Both b and c

29. The picture above shows the pump in:

a. Parallel/volume

b. Series/pressure

30. The picture above shows the pump in:

a. Parallel/volume

b. Series/pressure

■ THE

QUESTIONS REFER TO NFPA 1901, 2009

EDITION:

31. At less than 2,000 feet above sea level, a priming device must be able to reach a maximum of how many inches of mercury during the vacuum test

a. 18 inches

b. 20 inches

c. 22 inches

d. 25 inches

Continued on page 24

Shesuredoesn’tthinkso. Over-engineered?

Allsheknowsisherdadcamehomesafeandsound. That’sgoodenoughforher.Andthat’sthedriving forcebehindDräger.Wheresafetyiseverythingand exceptionalengineeringisstandard.

That’swhyournewPSS®7000SCBAdoesn’tjust meetNFPAstandards,it exceeds them.Infact,after aseriesofrigorouscomparisontestsconductedby thePhoenixArizonaFireDepartment,theDräger PSS7000wasjudgedthebestofallSCBAsonthe market.Thecompetitionwasn’tevenclose.

ToseethedetailsofthePhoenixtest,visit www.draeger.com/scbaChallenge. Formore information,contactyourlocalDrägerfireservicerepresentativeorcall 1-800-615-5503.

ThePSS7000– Re-engineeredfromthegroundup,wetookno shortcutsindevelopingthemostergonomicallydesigned,easiest-touseandeasiest-to-maintainSCBAever.Itfeaturesafullyadjustable back-platedesign,durablerubberharness(500%moreabrasionresistantthancloth),five-secondcylinderchangeout,activeCBRN protectionwith360°second-stagerotation,waterproofinternal Heads-UPDisplayanddualvoiceamps,aswellasthereliabilityof Sentinel7000–Dräger’sthird-generationPASStechnologywith morethanadecadeofprovenperformance.

By JAMES CARELESS

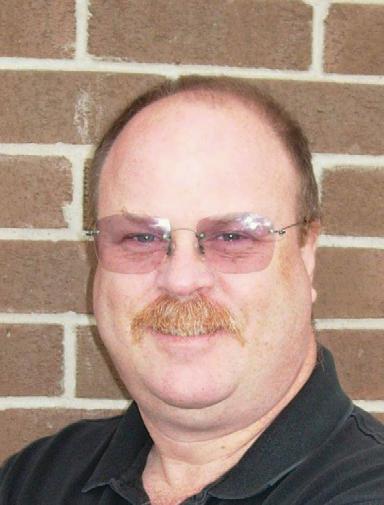

Serge Tremblay was appointed chief of the Service de sécurité incendie de Montreal in 2004, after spending 28 years working his way up the ranks from firefighter in various jurisdictions. As chief in one of Canada’s largest cities, he runs a department in which firefighting challenges are numerous and varied. Chief Tremblay took time to speak with Fire Fighting in Canada in late October.

FFIC: What are the biggest challenges in fighting fires in Montreal?

Chief Tremblay: There are many challenges. One is the age of our city.

Some of our oldest residences are connected to each other, with wooden sheds attached or close to the back. What this means is that, if a fire starts in one of these sheds, it can spread to the house and from there to other houses connected to it. Such buildings tend to be rental units, which means they may not be up to modern code.

Then there’s our underground city, which runs almost 30 kilometres under the downtown core. This is the largest such complex in the world, and it represents some unusual challenges. For instance, if a fire breaks out in one of the shopping areas, the smoke can spread into the office buildings that are connected to it. This can force some rather large evacuations, which is a real problem during the business day when so many people are working here.

FFIC: How about your resources? Do you have enough to do the job?

Chief Tremblay: That’s an interesting question. Back in 2002, 22 fire departments were brought together under amalgamation. These were 22 departments with their own ways of doing things. As well, the bylaws that they worked under, like those governing smoke detectors, also varied from jurisdiction to jurisdiction.

Since that time, we have been working diligently to integrate these 22 units into one seamless Montreal Fire Department. Collectively, we protect a population of 1.8 million over an area of almost 500 square kilometres. To do the job, we have about 2,300 firefighters plus 400 civilians, equipped with over 400 vehicles, of which 142 are fire apparatus. We are currently renewing our fleet; by 2011, we will have spent $80 million in new equipment.

So do we have enough resources to do the job? Yes, but we need more, based on the Fire Safety Risk Cover Plan that we drew up on the behest of the province. This plan specifies what fire risks we have to deal with, and what our strategy is for doing so. As a result, the Montreal Fire Department will be hiring 209 new people over the

next five years starting in 2009, of which 137 will be firefighters. We will be building more fire stations and acquiring new pieces of equipment.

FFIC: I understand that smoke detectors are a primary concern of yours?

Chief Tremblay: Yes, It’s very sad: Every year we have deaths that can be traced back either to a lack of smoke detectors, or detectors that aren’t working because their batteries are dead or missing. We have managed to reduce the death rate through increased public awareness to nine in 2007. In previous years, it has run between 15 to 18 deaths annually.

Under our Fire Safety Risk Cover Plan, we are trying to have one bylaw governing smoke detectors created to cover all of Montreal, rather than the 22 bylaws that exist now. We want to have a tough law, and improve it by requiring people to use 10 year lithium batteries in their detectors. This will improve the odds that the detectors will work when they are needed.

These are deaths that just shouldn’t be happening. Too many people are living without proper smoke detectors.

FFIC: Are you concerned about CBRN threats? If so, what actions have you taken to prepare for them?

Offering: A 2 course certificate in incident command for experienced incident commanders. Please contact our office for more information.

Are you looking to take on more responsibility in your Department? Trying to round out your technical ability with leadership skills? Preparing to advance your career?

At Dalhousie University we offer a three course program, the “Certificate in Fire Service Leadership” to career and volunteer fire officers.The 3 courses Station Officer: Dealing with People,Station Officer:Dealing with New Operations and The Environment of the Fire Station are all offered in each of our 3 terms, September, January and April. The program can be completed in one year.

For more information and a program brochure please contact:

Gwen Doary,Program Manager

Dalhousie University Fire Management Certificate Programs 201-1535 Dresden Row,Halifax,Nova Scotia B3J 3T1 Tel:(902) 494-8838 • Fax:(902) 494-2598 • E-mail:Gwen.Doar y@Dal.Ca

You will also find the information in our brochures or at the following internet address:Web site:http://collegeofcontinuinged.dal.ca

Continued from page 19

32. The priming vacuum must be held for a minimum of how many minutes?

a. Two minutes

For more information, call your local Globe dealer or Safedesign.

more information, call your Glb dl Sfdi FootGear

BRITISH COLUMBIA AND ALBERTA

Coquitlam, British Columbia 800-667-3362

Calgary, Alberta 800-661-9227

Edmonton, Alberta 800-222-6473

Kamloops, British Columbia 250-374-0044

Nanaimo, British Columbia 250-758-3362

Prince George, British Columbia 250-960-4300

QUEBEC

LaSalle, Quebec 800-905-0821

ATLANTIC PROVINCES

St. John's, Newfoundland 800-563-9595

Dartmouth, Nova Scotia 800-567-1955

Saint John, New Brunswick 800-567-1955

MANITOBA AND SASKATCHEWAN

Thompson, Manitoba 204-778-7123

877-253-9122

www.safedesign.com

b. Three minutes

c. Five minutes

d. No time is referred to in the standard

33. During the vacuum test, it is permissible to lose some vacuum. What is the maximum allowable amount?

a. Five inches

b. 10 inches

c. 14.7 inches

d. All of the vacuum

34. Priming devices on new fire pumps must now to able to operate with what type of lubrication?

a. No lubrication

b. Biodegradable nontoxic lubricant

c. 10-weight motor oil

d. Synthetic motor oil

e. A or B

35. For pumps of 4732 L/min. (1250 gpm) or less, the time to prime from draft shall not exceed:

a. 15 seconds

b. 30 seconds

c. 45 seconds

d. 60 seconds

36. For pumps larger than 6000 L/min. (1500 gpm), the time to prime is extended by:

a. 10 seconds

b. 15 seconds

c. 30 seconds

d. 45 seconds

37. All pumps must have a working pressure control system. This system must not allow the pressure to rise by more than what amount when a discharge valve is closed no more rapidly than in 3 seconds and not more slowly than in 10 seconds?

a. 30 p.s.i.

b. 10 p.s.i.

c. 45 p.s.i.

d. 12 p.s.i.

38. During the above test, the pump pressure must

a. 70 psi to 300 psi net pump pressure

b. 90 psi to 320 psi net pump pressure

c. 100 psi to 350 psi

d. Makes no difference

39. The overload pump test shall be conducted for:

a. 1,138 kPa (165 p.s.i.) for 10 minutes

b. 1,035 kPa (150 p.s.i.) for 15 minutes

c. 1,380 kPa (200 p.s.i.) for 10 minutes

d. there is no such test, overload test is for springs

40. During the annual service test, is it

permissible to remove engine covers, raise hoods, or remove panels from the truck?

a. Yes

b. No

c. Only if you need to keep the engine from overheating

■ THE FOLLOWING QUESTIONS DEAL WITH THE ELECTRICAL OBJECTIVES

41. The normal open cell voltage (OCV) for a six cell battery after the surface charge has been removed is:

a. 12.0 to 13.8 volts

b. 12.4 to 12.8 volts

c. 13.0 to 14.4 volts

d. never lower than 9.6 volts

42. Define cold cranking amps (CCA) in regard to batteries.

43. Define reserve capacity (RC) in regard to batteries.

44. Why is RC more important to a fire truck than CCA?

a. Because fire trucks start in warm fire halls

b. Because if the alternator fails at a fire, you want to know how long you can operate with only the batteries

c. Because fire trucks are easy to boost

d. Both A and B

e. Both A and C

45. Define voltage drop.

46. What is the purpose of a load-shed device?

a. To shut off excessive loads as battery voltage increases

b. To shut off excessive loads as battery voltage decreases

c. To turn on loads as battery voltage decreases

47. An alternator has a lower than normal amperage output. The technician suspects a defective diode. If one defective diode was open, the alternator output would be:

a. 10 per cent less

b. 30 per cent less

c. 60 per cent less

d. No effect

The second part of the test will appear in the February issue of Fire Fighting in Canada.

Don Henry teaches in the Automotive Services Technician and Heavy Equipment Technician programs at Lakeland College in Vermilion, Alta. He can be reached at don. henry@lakelandcollege.ca

:

NFPA 1971 (Structural Fire Fighting) and NFPA 1992 (Liquid Splash) compliant. Also available in a 12” Zipper/Speed Lace.

SAY GOODBYE TO HEAVY, STIFF, MILITARY-CONSTRUCTION BOOTS FOREVER – GLOBE FOOTGEAR IS HERE. REMARKABLY FLEXIBLE WITH A UNIQUE CUSHIONED AND CONTOURED SOLE AND CUSTOM FIT

SYSTEM, GLOBE FOOTGEAR FITS BETTER, GRIPS BETTER, AND FEELS BROKEN IN RIGHT OUT OF THE BOX. GLOBE FOOTGEAR COMES IN A RANGE OF STRUCTURAL, TECHNICAL AND EMERGENCY NFPA COMPLIANT STYLES. FIND THE GLOBE SOLUTION TO ALL YOUR PPE PROBLEMS AT:

Unique cement construction combines contoured outsole, 3D lasting board with built-in flex zone, and multilayer composite puncture protection. Without stiff welts, ribbed midsoles, or steel plates, this attachment process is far more flexible than traditional welt construction. Globe FootGear has been tested

flexes with no compromise in performance.

By ED BROUWER

Most fires start in the contents of a structure. That contents fire, if not quickly extinguished, spreads further into the building, through the walls, common roof and or attic spaces, and even from one structure to an adjacent building.

In a recent series of full-scale laboratory experiments at the National Institute of Standards and Technology (NIST), it took fewer than five minutes for flames from a simulated house with combustible exterior walls to ignite a similar “house” two metres away. In fewer than five minutes, flames shattered the window of the home with the original fire, spread across the gap and ignited the exterior of the second structure.

In a structure fire the concealed flames must be located and cut off, in addition to extinguishing the original contents fire. To do this effectively, incident commanders must know the different ways fire can spread in a structure.

If the fire grows, it spreads by four principal means: convection; conduction; radiation; and direct flame impingement (sometimes actually considered a form of radiation). Just as water and electricity seek the route of least resistance, so does fire.

Fire and smoke spread by convection is the most dangerous and causes a large proportion of injuries and deaths. When fire starts in an enclosed space such as a building, the smoke and heat rising from the fire becomes trapped by the ceiling and then spreads in all directions to an ever-deepening layer in the entire space. This ever-increasing superheated thermal layer will eventually cause everything in that compartment to burst into flame (flashover). Do not be fooled into thinking this is a long, drawn-out process. Flashover can happen within three minutes.

Some materials, such as metal, can readily absorb heat and transmit it to other rooms by conduction, where it can set fire to combustible items that are in contact with the heated material. Radiation transfers heat in the air in the same way that an electric base board heater heats

All buildings in Canada can be associated with one of five basic types of construction, identified by Roman numerals in building codes and by engineering schools throughout the nation:

• Type I, fire-resistive

• Type II, non-combustible

• Type III, ordinary construction

• Type IV, heavy-timber;

• Type V, wood-frame. The five basic construction types are arranged in a scale based on the amount of combustible material used in their construction. For example, a Type I fireresistive building has the least amount of combustible material while a Type V wood-frame has the most.

BY

a room. Material close to a fire will absorb the heat, and, if it’s not extinguished, will begin to smolder and then burn.

If incident commanders know the basic construction types in their communities, they have a better chance of determining how a fire may spread in those particular structures.

When the hydroelectric station in Kemano (a company town built by Alcan in northwestern B.C.) was automated, the town became obsolete. It was donated to B.C.’s fire services for fire research and training. The 40 abandoned houses filled with donated furniture and props made an ideal, full-scale experimental fire research site. It was in one of those houses, a two-story Type V building, that I discovered the “white room”. The entire second floor (three bedrooms and a bathroom) had heavy fire damage – it was fire charred and blackened. The door of the third bedroom had extensive fire damage but was closed. When I opened the door I was shocked to find an almost pristine baby’s room. The white walls and white baby crib were untouched by the fire. There wasn’t even any smoke damage. A closed door restricted the fire spread enough that it could very well have saved a life.

Some construction types burn much more readily than others. Size-up must not only consider the construction type, but also the building’s contents; both add fuel to a fire. Far too often when there is a line-of-duty-death we hear reports that the firefighters didn’t know where the fire was or that the fire spread more quickly than expected. (See sidebar.) Each construction type has its own fire-spread problems.

Type I fire-resistive construction was originally designed to contain fire inside the building to one floor. However, there are two avenues by which fire and smoke can spread throughout a modern fire-resistive building; the central air conditioning ducts and auto-exposure, (flames extending vertically from window to window).

Air ducts of a central air conditioning system penetrate every fire barrier in the modern Type I building.

One of the IC’s first actions at a fire inside a fire-resistive building should be to order the air system shut down.

Auto-exposure is when flames erupt out of a heat-shattered window and melt and break the glass window directly above. Once the window above is broken and falls away, flames can enter and ignite ceiling tile, curtains or furnishings. Even if the windows do not melt or break from heat, a small-concealed space between the exterior wall and the end of the floor slab can allow vertical spread of fire and smoke from floor to floor above and near a window. To combat fire spread by auto-exposure, the IC should order an aerial master stream into operation.

A water stream directed against the exterior wall between the top of one window opening and the bottom of the window above can slow down fire spread.

■

When a fire occurs inside a Type II building, flames rising to the underside of the steel roof deck may conduct heat through the metal and ignite the roof covering above. After a fire has been extinguished inside a Type II building, the IC should go to the roof and examine the roof covering directly above for extension.

■

The major recurring fire spread problem of Type III construction is concealed spaces and poke-through holes. Concealed spaces are created by wood studs, floor joists and suspended ceilings. Poke-through holes are created by small openings for utilities. These small openings around pipes and wires allow fire to spread into concealed spaces. Flames can spread vertically several storeys or horizontally to adjoining spaces. When firefighters search for hidden fire in this type of building they should try to cut off the rising fire. For example, if they discover fire in a floor, open up the wall above it. If they discover fire in a wall, open up the ceiling. If they discover fire in a ceiling, open up the baseboards on the floor above. By doing this, convection currents of flame and heat can be cut off and revealed so they can be extinguished.

■

One difference between a heavy-timber building and ordinary construction is that a heavy-timber building does not have plaster

walls and ceilings covering the interior wood framework. The exposed wood timber girders, columns, floor beams and decks, if ignited in a fire, create large radiated heat waves after the windows break during a blaze. Flames coming out of the windows may spread fire to adjoining buildings by radiated heat. As the fire grows, apparatus will have to be repositioned away from the radiated heat waves. Large water supply sources must be located and master streams set up to protect nearby buildings.

Although heavy-timber construction is often called slow burning, a better term is long burning. These buildings may have self releasing floors lightly tied to columns so the floors will fall without pulling down adjacent floor sections. This is good for the building, but bad for firefighters. A collapse danger zone must be designated to protect against a building collapse. Expect the floors to collapse first and then the walls to push outward falling into the street. Note: Water curtains are of little use in stopping radiant heat. In order to protect an exposure the water must be applied to the exposure to reduce the temperature of the exposure itself.

■

Wood-frame (Type V) construction is the most combustible of the five building types. When sizing up a fire in a wood-frame building, the outside walls must be considered for the fire spread. Flames can spread out a window and then along the outside wood walls (in addition to the interior fire spread). To combat fire this type of fire the IC must position a hose line or master stream outside the structure in addition to the attack line inside the structure. Outside streams must stand by or extinguish exterior siding fire from spreading to adjoining structures.

In our next issue we will look at advancing the attack line.

Until then stay safe and remember to train like their lives depend on it, because they do.

(Special thanks to retired Deupty Chief Vincent Dun of the FDNY, who has so graciously given me access to his training materials.)

Ed Brouwer is the chief instructor for Canwest Fire in Osoyoos, B.C., and the training officer for West Boundary Highway Rescue. The 19-year veteran of the fire service is also a fire warden with the B.C. Ministry of Forests, a wildland interface fire suppression instructor/evaluator and a fire-service chaplain. Contact Ed at ed@thefire.ca

The durability of our CROSSTECH® 3-Layer Moisture Barrier makes it the right choice for today’s challenging environments. And thanks to its rugged 3-layer construction, this moisture barrier addresses the increased emphasis NFPA 1851 places on long-lasting turnout gear service. For the best combination of durability, heat stress reduction, thermal protective performance, and liquid penetration, there’s no other product like it.

For every challenge you encounter, rely on the most rugged moisture barrier on the market today— CROSSTECH 3-Layer Moisture Barrier.

BY MARK VAN DER FEYST

Advancing hose is an important part of our jobs when we are implementing an aggressive fire attack. As mentioned in November, there is a saying in the fire service, “as the first line goes, so goes the fire”. Getting that first line off the engine and into position is vital to the outcome of our fire attack. To aid us in getting our lines in place, we have different hose loads that we can configure on our engines. One such load is the minuteman hose load. This hose load is designed to help firefighters get the initial attack line in place with ease for any type of operation – residential, commercial or high rise.

Whether you are packing a 1.75-inch or a 2.5-inch hose line, the minuteman hose load takes no time to load. As with any project, set up is the most important part of the operation. With the set up properly done, the rest of the operation will flow easily. The minuteman needs to be loaded correctly and set up correctly in order for it to work effectively and efficiently. See photo 1.

To load a minuteman hose load, you will need to first determine if you want to load 150-foot or 200-foot preconnect. For the 150-foot preconnect, you will need three sections of hose; for the 200-foot preconnect, you will need four sections of hose. The first section of hose will be loaded as you would normally for any flat load. The added step is to not attach the male coupling to the next section of hose, but rather leave it hanging on the opposite side of the load. This male coupling will be attached to the female coupling at the very end of the load. (See photo 1-A).

Next, you will need to attach your nozzle to the second section of hose and start to feed the line by placing the nozzle at the edge of the hose load and start to underfeed the line to the other edge of the load. (See photo 1-B).

Once you have underfed the first lay of the second section, you will then wrap the line around the nozzle and continue to flat load the rest of the line. (See photo 1-C).

If you are double stacking the load, you will need to create an identical loop next to the nozzle. This will give you a handle to pull on to advance the line. From this point, the rest of the load will be a simple flat load.

Continue to load the hose until all sections are loaded. At the end of your last section, you will attach the female coupling to the first male coupling that was left hanging on the opposite side of the hose load. You are now wrapping the back of the hose load with the first section of hose. (See Photo 1-D).

The best method for loading the minuteman hoseload is to double stack it rather than single stacking. A double stack hose load will be easier to handle by one firefighter than a single-stack load. If you are loading 150 feet of preconnect, then you will have 100 feet of hose on your shoulders; not bad if you have a single stack, but it will tend to fall over if you don’t have a firm grasp on it. If you are loading 200 feet of preconnect , then you will have 150 feet of hose on your shoulder. You will definitely want to have a double stack load for this.

Continued on page 34

Continued from page 15

Two-thirds of volunteer firefighters killed in apparatus incidents were not wearing seatbelts. NFPA 1901-compliant apparatus must have an audible seatbelt warning alarm plus visual alerts for driver/officer positions.

That’s not all: NFPA 1901 requires new apparatus to undergo more rigorous stability testing, or have a stability system installed. New maximum speeds will also be automatically enforced by the truck’s operating system based on its maximum vehicle weight and whether it is a water/foam apparatus.

Standardized reflective markers are now the norm on apparatus, with at least half or more of the truck’s rear being covered in reflective material. NFPA 1901 also requires each new truck to have one reflective traffic vest for each seating position, five fluorescent orange traffic cones, five illuminated warning devices and one automatic external defibrillator.

“For many years, rural Canadian departments did not follow NFPA 1901 for cost reasons,” says Don Henry. “Thankfully, this has changed, a fact helped by the Canadian ULC S515 standard becoming much tougher in recent years.”

Even though the new NFPA 1901 does diverge from ULC S515 in some respects, the overall trend is for Canadian departments to pay attention to the safety requirements that each outlines and work to meet them, he adds. “When it comes to electrical, building or plumbing standards fire departments fall over themselves to meet the standards,” says Henry. “When it comes to how to build the truck it’s still a bit of a fight, but it is getting better.”

■

NFPA 1982: Standard on Personal Alert Safety Systems (PASS), (issued 2007; due for revision 2011) addresses a very serious problem with PASS equipment, namely that PASS units that passed rigorous laboratory testing were failing in service due to heat and/or water. “At least 15 firefighter fatalities have been traced to PASS failures,” Tracey says. “As it turns out, the problem is that the laboratory testing conditions did not encompass the full range of extremes found in a fire situation. To respond to this, NFPA 1982 toughens up PASS testing procedures so these units meet realistic fire scene conditions.”

NFPA 1981: Standard on Open-Circuit SelfContained Breathing Apparatus (SCBA) for Emergency Services was issued in 2007 and is due for revision in 2011. In its current form, NFPA 1981 calls for SCBA wearers

to have access to a second air-pressure indicator in addition to the one shown in their heads-up display. “Basically, the fire services that helped us write NFPA 1981 were not comfortable with having such data solely displayed on the SCBA facemask,” Tracey says. “They wanted an element of redundancy, which is why a second air-pressure indicator – such as a handheld gauge visible to the wearer – has been mandated.”

New SCBA gear will also have to meet National Institute for Occupational Safety and Health standards, even in Canada. In fact, NFPA and NIOSH are jointly certifying SCBA gear as suitable for CBRN

environments. “This adds an extra level of complexity to the testing system, but ensures that NFPA 1981-compliant SCBA will work in CBRN situations,” Tracey says. “The result is a better level for protection for firefighters wearing SCBA equipment.”

When your jurisdiction is buying new equipment, study the NFPA standards carefully. Moreover, demand that the vendors who approach you provide detailed proof that they are NFPA compliant. For more information on NFPA standards, visit www.nfpa.org.

Now you can get strength and comfort under fire. With Lock-Fit Ankle Support System™, PierceProtect Arch Protection System™ and Vibram ® Fire & Ice outsoles, the STC fire boot brings you the science of fire protective footwear.

Over 75 Years of Excellence In Fire Service

Aluminum & Fiberglass Fire Service Ladders

Featuring Welded & Expanded Rungs

Welded Expanded

This two step process makes the strongest rung to rail connection.

Duo-Safety Ladder Corporation

513 W 9th Avenue, PO Box 497

Oshkosh, WI 54903-0497

Toll Free: 877-386-5377 Fax: 920-231-2460 www.duosafety.com mail@duosafety.com

Continued from page 32

One firefighter can pull the mintueman hose load and advance the line. It is designed to unload itself as you advance toward the fire. The top part of the hose load will start to flake off because it is actually the bottom first section of hose that is connected to the discharge. This unique design allows us to deploy the hose while we are advancing to the structure.

Notice in photo 2, as the firefighter is advancing the hose line, the top part of the line starts to flake off as he is advancing. Eventually the hose load will be flaked out, leaving the nozzle in the firefighter’s hand ready for attack. This method of advancing a hose line allows for one firefighter to advance the line, the officer to conduct size up, the driver to get the pump in gear and the other firefighter (if there is a fourth) to aid in any other way.

The majority of our fire attacks are residential fires. The minuteman hose load is perfect for residential fires. It is also perfect for highrise operations. If you don’t pack a highrise hose pack on your engine, then the minuteman hose load becomes your highrise kit. As you can see in photo 2, the last coupling of the first 50 feet of hose becomes exposed. The firefighter is now able to uncouple the hose line from the initial 50-foot section and ends up with a 100-foot to 150-foot high-rise kit. (See photo 3 and 4.)

From here, this firefighter is able to walk up to any floor in a highrise and connect to a standpipe system. The firefighter must not forget to grab a spanner wrench and a 2.5-inch gated wye so that another attack line can be added.

A firefighter is also able to advance a minuteman into a structure and up stairs to the second or third storey. If you wanted to advance a dry line to an upper floor, then the minuteman will allow you

to accomplish this. The same can be done for advancing a line down a set of stairs.

In order for this hose load to become effective, firefighters must be trained on a consistent basis for both loading and advancing. The more familiar you become with this hose load, the better it will work for you.

Mark van der Feyst began his career in the fire service in 1998 with the Cranberry Township Volunteer Fire Company, Station 21, in Pennsylvania. He served as a firefighter and training officer for four years. From there, he joined the Mississauga Fire & Emergency Services, where he served for three years as a firefighter and shift medical instructor. Presently, he works for the City of Woodstock Fire Department.

Continued from page 22

Chief Tremblay: Since 9-11 occurred, large cities like Montreal have become more concerned about being prepared for CBRN incidents. This is why we have formed a joint anti-terrorism committee in the city, with all relevant agencies working together to plan strategies.

In 2005, we held a major multi-agency simulated incident downtown. It was called Metropole 2005, and it modelled a VX nerve gas attack in a Metro station. We learned a lot from it.

We have also upgraded our CAD at a cost of $15 million, and we are in the middle of a three-year plan to bring the entire department up to first responder status. This means that all of the fire stations and personnel will be operating at the highest level by 2009. It is a huge challenge.

FFIC: Finally, what is your biggest goal as chief?

Chief Tremblay: Besides the items I have listed so far, I am concerned about the department’s historical relationship with our union. For too many years, there has been confrontation between both sides, as if we were not dedicated to the same goals and

Old Montreal is a tourist attraction but the age of the buildings and the fact that some residences are connected to each other pose a threat for firefighters, says Chief Serge Tremblay.

public service.

This is something I want to change. I want to tone down the conflict and get us working together. After all, we have achieved much as a team; especially since the amalgamation in 2002 and all the adapting we all have done.

I am very proud of my department and everyone who belongs to it. We are all members of the Montreal Fire Department at the end of the day; whether firefighter or chief. We are all on the same side.

Over 40,000 in use. We’ve been in business for over sixty years, so you can depend on us. That’s why Newton Kwik-Dump Valves can be trusted to get your tanker emptied and on its way FAST. Standard length, Mild Steel and Stainless Steel are in-stock. Need special length valves? Call us and it’s as good as done! Don’t accept look-alikes. Ask for us by name. For prompt, timely delivery, call us today.

CUSTOM TRAINING PROGRAMS: MESC will provide custom design training programs. Other courses available include: Building standards, Rescue program, Emergency Medical, Management Program, Fire Prevention, Public Safety and Hazardous Material. Manitoba Emergency Services College, Brandon, Manitoba, phone: (204) 726-6855.

LIVE FIRE FIGHTING EXPERIENCE: Short and long term courses available, Municipal and Industrial fire fighting. Incident Command System, Emergency Response/HazMat, three year Fire Science Technology Diploma program. Lambton College, Sarnia, Ontario, call 1-800-791-7887 or www.lambton.on. ca/p_c/technology/fire_emerg_resp.htm. Enroll today!

BY PETER SELLS District Chief

When we look at the history of our services we often dwell on the tragedies. This is natural and appropriate; it connects us with our heritage. But to learn from the mistakes of the past is to truly honour our forbearers.

At 1:16 a.m. on May 17, 1947, Toronto Fire Department pumper 5 was responding eastbound when it t-boned the northbound pumper 4 in the intersection at Queen and Parliament streets. All eight firefighters were thrown from their open-cab apparatus, either off the tailboard or over the windshield. The fire those men were racing to was inside a public school that had been broken into and trashed. This callous and immature act of vandalism was, in fact, the murder of three brave firefighters.

Firefighters Melville Kerfoot, Charles Leslie and Joseph Walker died that morning. All three were riding on the tailboard – Kerfoot on pumper 5, the other two on pumper 4. Albert Creighton was on the back of pumper 5 with Kerfoot. He sustained a fractured skull and severe internal injuries but survived.

Two weeks later, the Municipal Act was amended to repeal the right of local councils to pass bylaws that gave absolute right-ofway to fire apparatus. To this day, we are required to adhere to the Highway Traffic Act, which grants us the right to go through red lights only after stopping first to ensure the way is clear, even at 1:16 in the morning.

It wasn’t until 50 years later that the law of the land, at least in this part of the country, finally and explicitly took us off of the tailboard. The photos of those pumpers after the crash, along with the descriptions of the event that have been written over the years by witnesses and survivors, are graphic and detailed.

St. Louis has a total quint fleet, so the vehicles involved were much larger, heavier apparatus. The laws of physics are such that occupants of a heavy vehicle will tend to fare better in a collision, even with another heavy vehicle. Obviously, the firefighters were not riding on the tailboard. Today’s apparatus feature enclosed cabs for all personnel, reducing BUT NOT ELIMINATING the chance of firefighters being thrown into the street. Why did I emphasize those words? Because modern apparatus also feature seatbelts, which work even better when firefighters are buckled up. None of the St. Louis firefighters was thrown from the rigs because they were wearing their seatbelts. This incredibly simple fact prevented a mistake from becoming a tragedy.

If today was the first time you watched that video, it certainly will not be the last. The news stories of this incident mention that it is being used to train recruits and remind veteran firefighters of the necessity to buckle up and to reinforce safe emergency response driving behaviours. I have a feeling that we will all be seeing this clip or, in fact, using it in our own lessons for years to come. In that way, it will become as well known in the fire service as the video documentation of the 1988 fire in Hackensack, N.J., in which the collapsing

None of the St. Louis firefighters was thrown from the rigs because they were wearing their seatbelts. ‘‘ ’’

Fast forward to 2008 and we have red-light cameras, rapid electronic mass media and streaming video over the internet. If you haven’t seen this one already, take a break from reading this, go to YouTube and search for “St Louis fire truck crash”. Go ahead, I’ll wait here . . .

. . . Did you see it? Essentially, it was the same incident. Both apparatus were responding to the same fire on separate routes. One entered the intersection without stopping and was struck by the other, spun around and overturned. In this case, no firefighters were killed, although all eight were injured. Let’s examine the differences:

District Chief Peter Sells writes, speaks and consults on fire service management and professional development across North America and internationally. He holds a B.Sc. from the University of Toronto and an MBA from the University of Windsor. He sits on the advisory councils of the Ontario Fire College and the Institution of Fire Engineers Canada Branch.

roof of an auto dealership took the lives of five firefighters.

My hat is off to the St. Louis fire chief for responding quickly and appropriately to the problem rather than sweeping it under the rug. I only hope that it is not seen as exclusively a training issue and then forgotten until the next accident. The city administration, however, is reportedly miffed that the clip got onto the internet. It’s not like you can trash a couple million dollars worth of fire equipment in broad daylight and keep it a secret, so I’m with the chief on this one. You can’t correct an invisible problem.

Incredibly, statements were made after the Hackensack fire to the effect that “I wouldn’t have done anything differently” even after exhaustive review showed breakdowns in incident management and communications.

Failure to recognize and react to our mistakes with positive change does a disservice to our fallen comrades.

KERMEL® has developed HEROSKIN™, an exclusive range of fabrics intended to be worn by Emergency Responders, Wildland Fire Fighters, and Station Wear Apparel. Permanently flame-resistant, HEROSKIN™ products guarantee a high degree of protection, comfort and resilience.

The KERMEL® fiber used in HEROSKIN™ is a Polyamide-Imide fiber; meaning it is non-flammable. It provides excellent thermal insulation, and has great mechanical strength with a high degree of resistance to chemicals. KERMEL® has an almost rounded circular cross section and its low modulus give it a soft and silky touch.

One of the main assets to KERMEL® compared with other fibers lies in the fact that it is solution-dyed during the

manufacturing process. This distinctive feature makes it possible to achieve the best results for color fastness. Additionally, KERMEL® does not pill. Thus enabling garments made from HEROSKIN™ fabrics and knits to maintain a faultless appearance that is everlasting.

For more than 30 years, KERMEL® has been at the forefront of innovation, developing many technical solutions offering protection in outer fabrics, membrane supports, thermal barriers and comfort linings. These many fabrics are used to make lasting uniforms for fire and police services; for all types of special clothing subjected to extreme conditions, including wildland firefighting, special flying suits, military tank and crew uniforms; and for garments in high risk industries.

The KERMEL® new generation of HEROSKIN™ fabrics used in emergency interventions meet the most stringent standards of safety complying with the NFPA 1975, NFPA 1977, and NFPA 2112.