DURABLE AND LOW-MAINTENANCE VINYL AND HYBRID CONSTRUCTION

AVAILABLE IN PREMIUM FINISHIELD LAMINATE COLOURS

SLEEK, LOW-PROFILE HARDWARE DESIGN

ENERGY-EFFICIENT DUAL-PANE AND TRI-PANE LOW-E GLASS OPTIONS

26% LOWER PROFILE FRAME INCREASES GLASS AREA

UP TO 22% BETTER ENERGY EFFICIENCY

JELD-WEN® of Canada is proud to continue to be a trusted household name in Canada, coast to coast. JELD-WEN of Canada does not just manufacture its windows and doors in Canada; we create beauty while providing home and energy saving solutions in the spaces where Canadian families live their lives. As climate change brings more extreme weather across Canada, the demand for energy-efficient products that can stand up to the elements is higher than ever.

JELD-WEN of Canada proudly introduces the groundbreaking JWC8500 hybrid window—a perfect blend of style, performance, and energy savings, meticulously engineered to exceed expectations. While 2030-rated to meet Canada’s U-Factor 0.14 (U.S./I-P) / 0.82 (Metric/SI) or ER 44 building codes, these windows are designed to significantly reduce energy costs while ensuring year-round comfort in your home.

Tailored to meet design flexibility needs, our windows are the perfect fit for homeowners planning a renovation or new home build, seamlessly blending functionality and style to suit any project.

Discover the JWC8500 hybrid series window from JELD-WEN of Canada—and experience the future of home comfort.

Fenestration Review 2025

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Rep.

Tel: (416) 510-5113 • Fax: (416) 510-6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

BRAND SALES

MANAGER | Leslie OSBORNE losborne@annexbusinessmedia.com 647.280.5885

ACCOUNT

COORDINATOR | Barb COMER bcomer@annexbusinessmedia.com 519.429.5171

MEDIA DESIGNER | Emily SUN

AUDIENCE DEVELOPMENT

MANAGER | Shawn ARUL sarul@annexbusinessmedia.com 416.510.5181

GROUP PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 226.931.0375

CEO | Scott JAMIESON sjamieson@annexbusinessmedia.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

SUBSCRIPTION RATES Canada - 1 Year $22.44 (plus applicable taxes)

U.S.A. - 1 Year $51.51 (in CDN dollars) Foreign – 1 Year $59.16 (in CDN dollars)

ANNEX PRIVACY OFFICER Privacy@annexbusinessmedia.com Tel: 800.668.2374

Occasionally, Fenestration Review will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. www.fenestrationreview.com

4 EDITORIAL Imagining a post-free trade world.

6 INDUSTRY NEWS Tariff pushback...Lolex in Ontario...A440 help from CSA...

6 22 16

16 BEWARE OF GREENWASHING Canadian competition law makes exaggerating your performance claims a dangerous business.

7 SIDING AND WINDOW DEALERS ASSOCIATION

22 2025 FENESTRATION CANADA MEMBERS DIRECTORY

10 HINTS OF EUROPE Berdick Windows and Doors brings tilt-and-turn and other European innovations to Winkler, Man.

34 PHILIBUSTER What happens when you put windows designed for houses in high-rises?

14 FENESTRATION AND GLAZING INDUSTRY ALLIANCE

FENESTRATION CANADA

A mixed bag for our industry.

Iturned 18 in 1988 and voted for the first time. The big issue was whether to give Brian Mulroney a mandate to negotiate a free trade agreement with the United States. Remembering those days helps us understand these days. Even at that time, Canadian sovereignty and identity was on the table. Should we allow the Americans to have a say in what industries we protected? Were we a weak and vulnerable economy that couldn’t survive without protectionist intervention, or could our companies go toe-to-toe with Americans in our own markets and theirs? Did committing ourselves to free trade mean we were limply giving away our rights to the American behemoth, or fearlessly meeting it on its own terms, confident we could succeed as equal partners? The existential dread meeting Trump’s current tariff threat shows just how decisively that question has been answered in the minds of Canadians in the decades since. Free trade with the U.S. and Mexico is broadly acknowledged here to have been a massive benefit, and the maximal entanglement of our economies something we have taken for granted.

Now we might have to do without it. What does that look like?

First of all, the imposition of the kind of sweeping across-the-board tariff regime Trump has been talking about would cause a general recession both here and in the U.S. It would be a few points worse here than it is there, as always – maybe five percent to their two percent. Some companies with too much debt (just built an addition), very high expenses (located downtown) or too focused on markets that are particularly sensitive to economic fluctuations (neighbourhoods near oil fields) would go out

by Patrick Flannery

of business. So we’d say goodbye to some friends and competitors, then the industry would find a new equilibrium with lower levels of investment and employment meeting the lower levels of demand.

Fenestration companies exporting to the United States would have to take a hard look at things. Already some Ontario companies have started to refocus on the West. Higher-end products with larger margins allow more play in pricing to both absorb and recover the cost of tariffs. Maybe Canada becomes known in the U.S. for its top-of-the-line, high-performing fenestration the way Europe has.

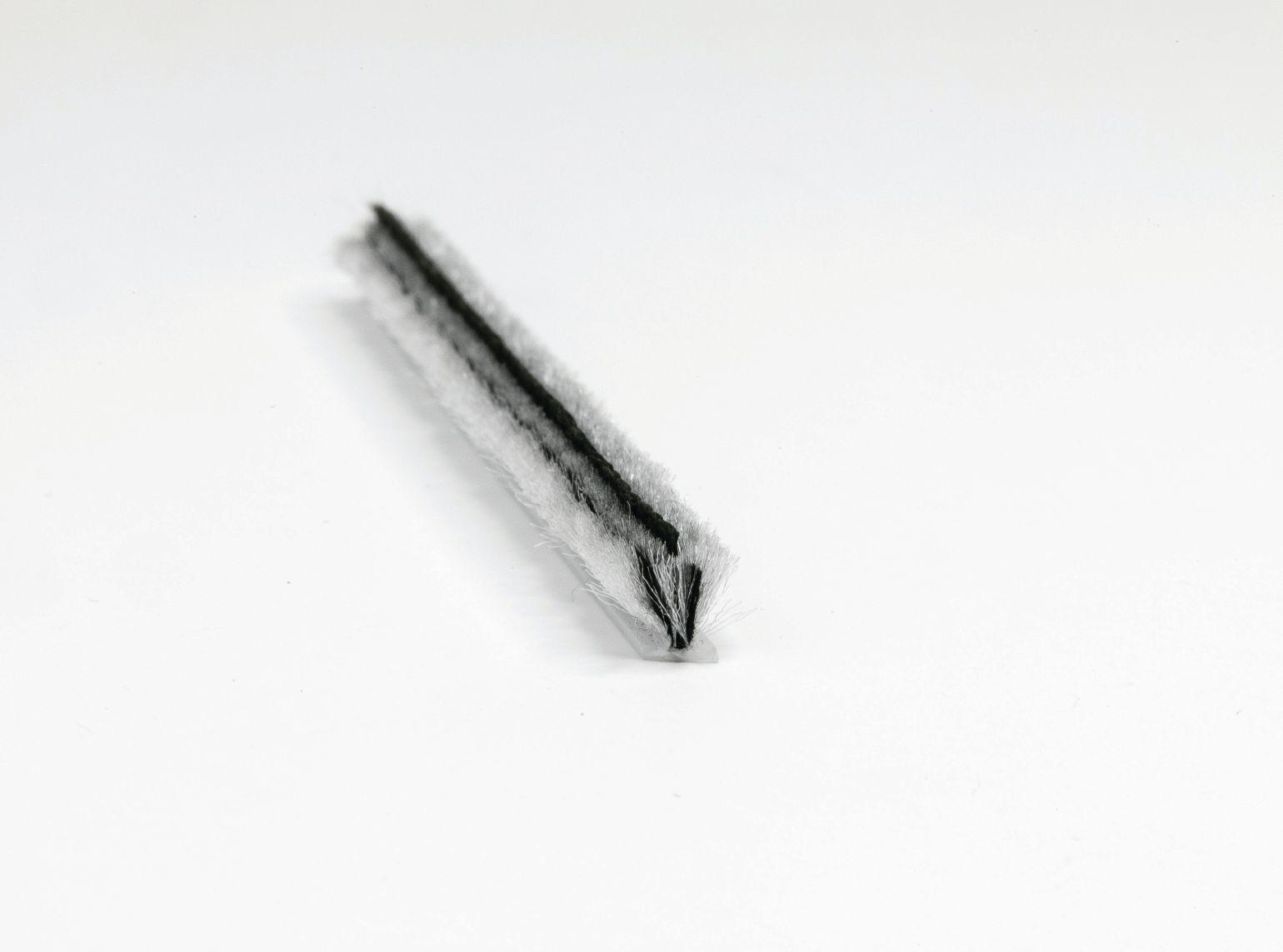

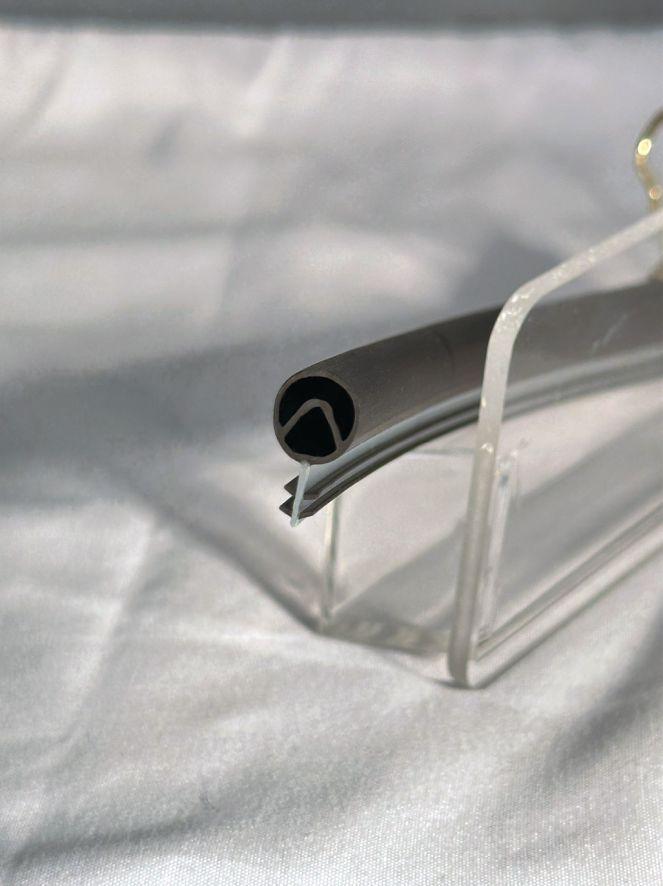

Reconfiguring supply chains would incur some short-term price inflation until suppliers could react by locating manufacturing in Canada. That is already happening, along with manufacturers looking at offshore options for products they used to buy from the U.S. So more Chinese and European resin, rubber, hardware and sealant in our windows and doors. But Canada has the ability to produce these things domestically – it just requires a rebuilding of capacity to meet demand. Glass, of course, is the big one. In a world without free trade, we would simply have to be able to make float glass in this country. To do that, there would need to be government incentives for primary glass producers to come here coupled with intervention to remove regulatory and procedural barriers like those that blocked Xinyi. Maybe the death of free trade would be the shock that spurs governments to take the necessary action.

A fenestration world without free trade looks likely to be smaller, but not without benefits for some.

SafeGard 2 Window Opening Control Device (WOCD) is the smart choice for egress windows, offering a balance of safety and ease of use.

ENHANCED SAFETY

Keep loved ones safe by limiting window openings to less than 100mm.

EMERGENCY READY

Easily opens fully during emergencies with two simple motions—and automatically re-engages when closed.

Don’t be fooled by an inferior product, explore our ASTM compliant WOCD solutions today at AmesburyTruth.com

Canada has been roiled by American tariffs on our exports announced in February. The measures, applied in violation of the Canada US Mexico free trade agreement on spurious national security grounds, were altered several times in February and March and their implementation paused twice. At the time of this writing, the U.S. has 25-percent tariffs in place on all aluminum and steel imports, including those from Canada. A 25-percent U.S. tariff has been applied to all goods from Canada imported outside of CUSMA, which accounts for about 40 percent of trade with the U.S. Canada has applied retaliatory tariffs on $30 billion of U.S. goods. On April 2 Trump announced “retaliatory” tariffs on almost all imports from all countries around the world. Canada and Mexico managed to get left off the list for new tariffs, except on automotive imports, but the existing tariffs on steel, aluminum and non-CUSMA exports remained. Canada had threatened a second wave of retaliatory tariffs on an additional $125 billion of U.S. goods if more tariffs were applied. For now, it does not appear those retaliatory tariffs will be implemented. This is good news, as the list includes just about all supplies used by the window and door industry, including float glass.

Industry groups are working hard to have float glass removed from the list of retaliatory tariffs. Fenestration Canada hired a third-party lobbying firm to bring its message to the Minister of Finance and released the following statement:

“As the trade association representing the fenestration industry of Canada,” the FenCan statement read, “we and our various partners are writing to you as we have reviewed Phase 2 goods proposed to go into effect March 25th [later revised to April 2] and collectively were disturbed to see nearly all of the parts and components we use to manufacture windows and doors included. This includes glass, hardware, gaskets, steel, aluminum, wood, uPVC, and fibreglass in both material and finished form. As a whole, we disagree with the use of counter-tariffs in our current conflict with the U.S. If this second round of counter-tariffs goes through,

it is not hyperbole to expect the Canadian fenestration industry to collapse. Our interdependence with the U.S. for materials and standards has merged the value proposition for both U.S. and Canadian consumers in such a way that sourcing or selling abroad is only possible with a wholesale dismantling and re-inventing of our industry. Float glass (HS code 7005.10.00) is specifically worrisome as Canada does not have float glass manufacturing and a majority of the glass (approximately 89.6 percent) our suppliers use comes from the U.S.”

The Siding and Window Dealers Association of Canada also issued a statement (see SAWDAC newsletter on page 7) and sent letter to government officials urging Ottawa to refrain from imposing tariffs on critical fenestration supplies from the U.S.

The Fenestration and Glazing Industry Alliance has also responded with an open letter to Canadian officials [see the full letter at fenestrationreview.com]. Amy Roberts, director of technical and Canadian operations wrote, “This letter urges the government of Canada to carefully evaluate the impact of these measures on essential industries. By removing materials that lack domestic alternatives or face critical supply constraints, the government can mitigate unintended economic harm while still maintaining a strong trade position.”

Radisson Industries, a St-Lambert-de-Lauzon, Que.,-based window hardware manufacturer, has announced Lolex Sales Agency is now its representative in Ontario.

“Lolex Sales Agency has been a solid partner of Radisson Industries for the past five years, servicing our customers in the Maritimes as well as in the Quebec market,” the Radisson release reads. “This announcement attests to our long-term growth strategy in Canada.”

Radisson goes on to point out that Lolex owner,

Mathieu Hebert, has 16 years’ experience in the fenestration industry. “His vast knowledge enables him to provide a technical sales solution approach to support you and your team.”

In a LinkedIn post, Hebert said, “Exciting news! Lolex Sales Agency is expanding to Ontario with Radisson Industries. Radisson Industries is a Canadianbased manufacturing company that has designed and supplied casement window and door hardware solutions for the North American fenestration market for over 25 years.”

The imposition of a 25-percent U.S. tariff on Canadian goods, coupled with Canada’s retaliatory measures, marks a significant shift in our economic reality. This development, effective March 4, signals the commencement of a trade conflict, impacting our industry directly. The Siding and Window Dealers Association of Canada acknowledges the severe challenges this poses to its members. While immediate relief is unattainable, we are committed to long-term support. We recognize the need for adaptation and resilience in this turbulent climate.

In the short term, we delivered a public letter to provincial and federal politicians, advocating for the exclusion of essential U.S. goods, notably glass, from countertariffs. Long-term, we are developing a prioritized list of initiatives to address the evolving window landscape, ensuring our member feedback shapes our support strategies. We will continue to gather input from members to tailor our efforts effectively.

The U.S. tariffs, now paused, triggered Canada’s Phase 2 counter-tariff proposal, which heavily impacts window and door component imports, notably glass. SAWDAC is actively advocating against these tariffs, particularly those affecting glass sheets and IGUs. We’re engaging with provincial and federal governments, as well as working with Fenestration Canada to drive home this message as an industry whole.

SAWDAC published results of a member survey regarding tariffs earlier this week.

Here are the results from the 26 respondents, all in Ontario:

1. Do you presently sell or intend to sell windows or doors into the United States?

Yes: 1 No: 25

2. Do you buy U.S.A.-manufactured windows or doors to sell in Canada?

Yes: 6 No: 19 No response: 1

3. Do you expect U.S.A. tariffs to affect your business?

Yes: 23 No: 3

4. Do you support Canadian reciprocal tariffs on U.S.A.-manufactured windows and doors?

Yes: 21 No: 4 No response: 2

5. If Canadian window and door manufacturers suffer from the current trade war, do you believe Canadian and provincial governments should take any action to support them and if so, what?

Responses included:

“Would rather governments not get involved with the window and door business.”

“No. Like the phoney $100 grant for windows, not worth the effort.”

“The best way to deal with Trump is to not get into a fight with him.”

“Yes, homeowner grants.”

“Promote energy rebate plans.”

“Use the monies taken in [from reciprocal tariffs] to support manufacturers.”

“We should be subsidized, otherwise the industry will come to a standstill.”

“Lower taxes or eliminate taxes for consumers.”

“Need to support all dealers and suppliers affected as well.”

“They should NOT list float glass, IG and caulk in the reciprocal tariff list.”

“Increase the current government grant

to $200 per opening.”

“All Window Wise registrations to be paid by the provincial or federal government.”

“Yes in the short term, but a better solution is needed for the long term.”

“Higher incentives for window replacements.”

One respondent went on at more length:

“If we are going to lose business due to tariffs, costs go up and existing exported windows and doors flood the market.

The loss will be all financial. If customers can’t afford to buy in a further-decimated economic climate, sales will be reduced further or nonexistent. If cash flow cannot be sustained, jobs will be lost, companies will go bankrupt. If installers don’t install and manufacturers don’t manufacture and suppliers don’t supply, the industry will be a disaster if not destroyed. Government needs to be doing a lot:

• Alternative markets for exports;

• Get rid of the tariffs;

• Eliminate the regulatory/government burdens and costs to run a business;

• Reduce business costs to employers (taxes, payroll overheads, administrivia burdens);

• Incentives to Canadian businesses;

• Incentives to public to encourage buying;

• Incentives to attract suppliers (glass manufacturers) to build in Canada.

SAWDAC welcomes all perspectives as we take our members’ messages forward to Ottawa and provincial governments. Please reach out to executive director Jason Neal at jason@sawdac.com with any comments, questions or suggestions.

Everlast Group of Companies has announced the addition of Lance Carroll to its team as branch manager for its new Sudbury Design Centre. Carrol was born and raised in Sudbury with a decade of experience in the construction and building materials industry in north and northwestern Ontario. He started with roofing and siding then shifted focus to windows and doors in his three years with Gentek. He did a brief stint with anchors, fasteners and tools and has returned to where his true passions lie: windows and doors.

The Sudbury Design Centre will serve Sudbury and northern Ontario including Sault Ste. Marie. It is located at 1351 Kelly Lake Road Unit 101.

“We are excited to welcome Lance to the team,” said Mike Bruno, president. “The fact that he is from the Sudbury community was important as are his years of experience and relationships in northern Ontario.”

“I was familiar with Everlast’s products and a few team members from my previous job and I am very excited to be able to now work with them directly,” Carrol said “I look forward to representing the company in northern Ontario and especially excited about the new design centre that will be coming soon. If memory serves me right, they all come with an espresso machine!”

CSA Group has posted seven videos and two PDF documents on its website educating visitors on how to install flanged and box windows according to its A440.4:19 Window, Door and Skylight Installation standard. The content is free and publicly available. The video titles are The Importance of Proper Window Installation; Installing Flanged Windows (three videos); and Installing Box Windows (three videos). The PDFs detail box and flanged window components and provide official definitions.

“CSA works with subject matter experts for various standards to create static images and videos hitting the high points of selected standards to provide enough guidance to apply the standards correctly,” explains George Torok (Stantec), chair of the A440.4 technical subcommittee. “This is a great initiative by CSA to make it easier for the low-rise residential industry to improve the quality of window installation.”

Typar has announced that its new Clear Acrylic Flashing received the Best of IBS Award for Most Innovative Building Material at the 2025 NAHB International Builders’ Show (IBS). The awards recognize outstanding products and services in various categories that set benchmarks in design, technology and functionality. Typar Clear Acrylic Flashing was recognized by the judges for its ability to simplify and streamline window installation and inspection

by giving visibility to nail and screw fin patterns, as well as its advanced acrylic adhesive. The flashing allows the pattern on the window nailing fins to be completely visible upon installation, ensuring proper attachment and reducing callbacks. This is especially advantageous on large-scale multifamily and commercial projects where approval of numerous window openings is required. The transparency is achieved with an advanced

FGIA Summer Virtual Conference Online fgiaonline.org

Oct. 6 - 9 FGIA Fall Conference Indianapolis, Ind. fgiaonline.org

Oct. 8 - 9 WinDoor fenestrationcanada.ca

Nov. 4 - 6 GlassBuild Orlando, Fla. glassbuild.com

December 3 - 5 The Buildings Show Toronto informaconnect.com

acrylic adhesive that is waterproof, self-healing and able to be applied at temperatures down to -6.7C. It also incorporates a split-release liner for easy film removal.

The Fenestra buying group held its annual Advantage Acceleration event in Calgary Feb. 10 through 12. About 50 member fenestration manufacturers and suppliers gathered at the airport Marriott in Calgary for networking, group discussions and the famous speed networking sessions. The Fenestra speed dating networking event was once again a great chance for members and suppliers to catch up and share information about their businesses. Suppliers sat at tables and members rotated through the room having 15-minute meetings at each station. Fenestra honoured loyal members and suppliers with attractive trophies. Fenestra executive director Frederick Gauthier presented Christan Guerard of Adfast and Sam Van Seters of Bethel Windows and Doors with Supplier and Member of the Year, respectively. The education sessions included a keynote talk by John Galbraith of The Data Integrators and a panel discussion with Van Seters, Adriano Iannetti of Auroral Portes et Fenetres, Matthew Denniston of Modern Windows and moderator Patrick Flannery of Fenestration Review. The panel talked about the industry experiences of the three Millennial-aged leaders and how they saw Fenestra benefitting their businesses now and into the future. They all pointed enthusiastically to the chance

to have close relationships with other members and the suppliers – to get together at events like Advantage or to be able to have their call taken any time, sometimes by managers of much larger companies. Aside from the official proceedings, there was ample opportunity for good food, drink and conversation in breaks and after hours. More than ample opportunity for some, as flights back to Ontario and Quebec were cancelled by a winter storm and many attendees had to stay another day. That worked out well as it gave them a chance to watch Team Canada play Sweden in the Four Nations Cup at a local craft brewery.

Constantly looking for advantage in the highly competitive window and door market, Berdick Windows and Doors, located just over 100 kilometres southwest of Winnipeg, combines sophisticated automation equipment, end-to-end Enterprise Resource Planning (ERP) software and new ideas introduced by its skilled staff.

by CARROLL McCORMICK

In the hunt for improved designs, Berdick sends its technical experts including its director of operations, Henry Dueck, to the colossal window show Fensterbau Frontale in Nuremburg, Germany, every other year. Over 600 exhibitors from the windows, doors and facade industry pitched their wares there in March 2024, according to Fensterbau.

“The newest technology and ideas seem to come from Europe. Our tech guys attend these shows and come back with ideas that are not even seen in North America,” says Sheldon Fehr, general manager. “Europe is way ahead in window design and development of North America. Our goal is to be first to market in Canada concepts being developed in Europe. We are always looking for ways to improve and optimize our products.”

For instance, the company has been running a tilt-and-turn windows line, a type associated with European homes, for just over four years now. “We are producing them in-house and are also doing some deals with imported products. This is new for us though,” Fehr says. “Tilt-and-turn is our fastest-growing market segment. We are making a lot of traction with North American customers.”

Another recent addition to their product line are multi-point locking doors where pins – either shoot bolts or mushroom-style pins – come out of the slab and engage keepers in the frame. “You can’t break these doors. The equipment that our external lab uses could not break this door,” Fehr says. Nor could a thief who tried hacking his way through one with an axe. Yet, he says, “The difference in price is the cost of a lock set.”

To achieve the precision necessary for such products, Berdick has invested heavily in new automated equipment, such as the Proline CNC for milling the roughly 3,000 steel and fiberglass door slabs it purchases from, respectively, Novatech and Mennie Canada.

Berdick is building this modern approach off a long history. Back in the 1960s, brothers Bert and Dick Groenheide founded Berdick and began building aluminum windows for recreational vehicles. By 1980, they had moved on to other window markets. A gentleman by the name of Abe Wiebe, who became a partner in 1969, purchased the company in the mid-1990s and ran it as a family business until it was sold to another entity in 2009. Fehr, who joined Berdick as general manager in 2015 to lead the company back to a solid footing, has a background that includes a stint as COO for Polar Windows in Winnipeg and at two companies in the extrusion business.

Fehr and Berdick’s senior leadership team set a goal to tighten the focus of the product line from “selling anything to anybody” to focusing just on custom windows and doors and establishing mutually beneficial customer partnerships. Berdick operates in a 40,000-square-foot plant with 65 employees and sells made-to-order windows. It produces anywhere from 120 to 150 boxes in its windows plant per day, including its fast-growing fiberglass windows line. It also supplies doors through a network of some 150 dealers in Alberta, Saskatchewan, Manitoba, and Ontario, plus dealers in Boston, Minnesota, Wisconsin and even Alaska.

Ninety-five percent of the company’s clientele is residential: multi-family, single family, renovation

and new home construction, the latter of which accounts for 90 percent of its business, according to Fehr. “Berdick can fill any hole to what’s required, but our bread and butter is new home construction and multi-family apartment buildings.

“Our market is discerning buyers –those with a high focus on quality. We don’t sell to tract home builders, we don’t win price wars, and a ‘flipper’ wouldn’t invest in our product.” As well, he adds, “We do a lot of commercial jobs such as schools, using fiberglass windows.”

Berdick has been manufacturing PVC windows and residential entrance sys-

tems since 1980, fiberglass windows since 2011, and PVC tilt-and-turn windows since 2020. Its in-house product testing, which is verified by reputable external test labs, ensures that everything rolling off the production lines meets a variety of standards, including 2008 and 2011 NAFS, CSA 440-S109 and NFRC thermal performance certifications, as well as certifications by the National Accreditation and Management Institute.

“Our test results are comprehensive, and we can deliver any performance required for any of the areas we sell into. This is a definite competitive advantage

for Berdick,” Fehr says. “Basically, any test report that an architect or building envelope group needs, we have.”

To meet its high standards, and to allow the company to fill what are exclusively custom orders – Berdick offers no stock windows or doors – the company has purchased several pieces of high-end automated manufacturing equipment. They include a Sturtz dual-strand saw, dual-stack welder and a two-head corner cleaner. Other equipment includes Tiger Stop CNCs for door jam and slab milling and specialized fabrication equipment for its tilt-and-turn operation. “The CNC

machinery we have is extremely helpful in meeting tight tolerances, which are absolutely critical, especially for products such as our multi-point locking door,” Fehr explains.

Berdick has three paint booths, capable of solvent or water-based paint, and a temperature and humidity-controlled paint curing room. “We’ve been doing our own painting and staining for roughly 10 years, and we recently added another paint booth to accommodate increased demand,” he says.

Supporting the production equipment – everything, in fact, from order entry to production control, manufacturing, inventory control, shipping and invoicing – is FeneVision ERP software from FeneTech. “Our dealers can even place orders from their laptops. The program controls every aspect of our business from order entry to production to shipping,” Fehr says.

Berdick practices lean manufacturing, but that does not mean just-in-time delivery of materials, Fehr says. “We are practical when it comes to Lean. I won’t drop raw material inventory to the point that it’s difficult to run product. To me, you can Lean yourself to the point of hindering sales or production. In fact, we may make decisions to buy more raw materials in order to take advantage of volume rebates or where raw materials are in short supply. If I hear of a particular raw material that is in short supply, I usually try to buy enough so that we won’t be negatively impacted if a shortage does affect the industry. During COVID, many window companies ran out of key materials. We never did. You can’t sell out of an empty wagon.”

And who exercises the necessary judgement and control over all this technology and the company overall? About that, Fehr goes straight to the humans in the loop, insisting that it is the employees that deserve the credit for the company’s success. “I don’t want to take credit for anything. We have very talented people at Berdick. They have my utmost respect and deserve all the credit. I usually get told of problems after they’ve been fixed. That speaks volumes about the senior

leadership and staff we have at Berdick. We have a phrase here: If we look after Berdick, Berdick will look after us.” Fehr is effusive about his employees, from the delivery team and their cube vans that gets product to customers in one piece (“If I can, I don’t want to have anyone else touch our stuff”); to his automation specialists; the staff that Berdick sends to Germany every year; and the rest of

the team. “I’d put our group up against anybody. This is an extremely high-performance team.”

Because bringing in technicians from Germany to service the Sturtz equipment was expensive, Berdick decided to train its own people to do the work. “All of our maintenance, including programming, is done in-house now. We do not rely on any outside services. I have a highly capable technical team that is extremely proficient at installing automation,” Fehr explains.

He tells a story about how a third-party IT firm was responsible for monitoring and protecting the company against any cyber-attacks. One day, Berdick’s IT manager noticed a hacking attempt before that company did, and Berdick’s senior leadership took this as a sign that his people could take care of this task just fine. Now, Fehr says, “We have an IT manager who is expert in all things cyber who can protect Berdick in these perilous times.

“It takes a team around you to make a company run well. I surround myself with very talented people. I don’t micromanage or look over their shoulders. It is really the people around you who make it happen.”

by Amy Roberts

The British Columbia Building Code recently introduced a maximum design temperature limit of 26C for a single living space in each dwelling unit to minimize the risk to health and safety of residents from overheating. This requirement applies to new residential constructions only. The new provision is intended to reduce heat-related deaths that occur because of the increase in extreme heat events in B.C.

Safe temperature in a designated living space in each dwelling unit can be maintained by using a combination of mechanical cooling systems and passive design measures.Passive design measures include optimizing building orientation to take advantage of natural ventilation, maximizing natural light and reducing unwanted solar heat gain. Another effective passive design measure would be improving the thermal performance of building envelopes to better regulate heat transfer. It is important to note that thermally efficient buildings tend to overheat because they’re unable to shed internal heat as well as lesser performing buildings. Therefore, improved thermal performance must be explored along with other passive and active cooling measures to reduce the risk of overheating.

Buildings can also be designed with overhangs over windows, ideally on the south elevation, or with vertical shading on the east and west elevations to limit solar heat gain in summer while allowing solar heat gain in winter, thus reducing thermal energy demand during cold months.

Exterior sliding shade panels and exterior roll shutters are suitable options because they can be deployed, as needed, by occupants. Exterior shades, such as perforated screens, vertical shades, semi-transparent shades, and horizontal overhangs, have been found to be an effective at passive cooling, as they prevent solar gains from entering the space entirely. On the south facade, horizontal overhangs are recommended as they block the high angle summer sun while allowing low angle passive solar heating in winter.

Attention must be paid to the glazing’s solar heat gain coefficient, which is described as the

fraction of solar radiation transmitted through a window and expressed as a number between 0 and 1. Glazing with appropriate SHGC will prevent overheating while reducing a building’s thermal energy demand. The lower the SHGC, the less solar heat is transmitted by the window. A SHGC of 0.4 means 40 per cent of solar heat gains landing on the outside surface of a window enter the living space. A low SHGC reduces the risk of overheating. However, an SHGC lower than 0.28 starts to impact visible light transmittance. This will make spaces darker, demanding additional lighting energy and inevitably adding more heat to the space. Conversely, a high SHGC allows more solar radiation to pass through the glazing, which reduces the building’s need for heating energy in winter but can increase the risk of overheating in summer. Therefore, it is recommended to optimize SHGC based on heating and cooling loads, as well as occupant comfort and safety.

It is well known that the orientation of windows and the window-to-wall ratio can impact a building’s heating and cooling loads. Care must be taken to ensure windows are not placed on elevations with high solar exposure, unless they are protected with some type of shading. Additionally, it’s recommended to minimize glazing on east and west elevations in order to control solar heat gain during summer.

The Designing Climate Resilient Multifamily Buildings report commissioned by the University of British Columbia determined that reduced WWR and glazing with reduced SHGC are “two essentially zero incremental cost design measures with a considerable impact on annual cooling energy demand and peak cooling load. However, both strategies may reduce winter solar gains and increase thermal energy demand.” Therefore, it is best to evaluate the suitability of both strategies by assessing heating and cooling loads, as well as the other performance metrics of individual projects.

Amy Roberts is FGIA’s Director of Canadian and Technical Glass Operations.

Set yourself apart with the premier education and certification program for glazing and fenestration professionals.

FGIA’s flagship program now includes new coverage of the NAFS Canadian Supplement, Canadian codes and energy, and insulating glass.

Expand Your Expertise —Learn about a wide range of industry topics.

Stay Current—Keep informed of evolving industry standards and best practices.

Stand Out—Certification proves your professional expertise

Learn Your Way—Online courses and proctored exams designed for your schedule

Customize Your Learning – Explore new à la carte options

Elevate your career and join the ranks of over 500 industry leaders. Sign up today at FGIAonline.org/FenestrationMasters.

While today’s regulations make it pretty hard to overstate environmental claims, companies need to be careful in light of Competition Act updates. Today’s consumers tend to seek products and services that are more environmentally friendly – or appear to be, anyway.

by TREENA HEIN

Fenestration manufacturers are all under pressure to promote their products or services as “greener”: more insulating and made without materials or processes that contribute to climate change or toxins in the environment. But as stated recently by the Osler law firm, “When these environmental claims are misleading or unsubstantiated, businesses are considered to be engaging in ‘greenwashing’ and expose themselves to liability under the deceptive marketing provisions of the Competition Act.”

According to Anton Van Dyk, fenestration division manager at JRS Engineering in Vancouver, Canada’s fenestration industry has come a long way from where it was when it comes to using exaggeration in marketing. “Those who’ve been around a while will recall that up to about 20 years ago, misleading claims were somewhat common,” he explains. “Firms would often list a value for thermal efficiency of a window but, in the small print, this was identified as being the centre-of-glass value. You can’t get away with that anymore. Back in the 1980s, the U.S. government said to the industry that if you don’t regulate yourself, we will do it for you. So the U.S. industry created the North American Fenestration Council and the Canadian industry later adopted it. It created various values and standards and labelling requirements and now codes address the whole window.” The emergence of rock-solid certification bodies like UL and CSA has helped. Van Dyk also points to the

The world of advertising may feel like the Wild West but there are rules.

emergence of more fleshed-out sustainability standards like Net Zero and PassiveHouse, which provide a framework for what can be considered environmentally friendly.

However, Terry Adamson, technical director at Fenestration Canada, notes that there are some shenanigans still afoot, such as some claims being made by fenestration suppliers that new windows will “cut 30 percent” off heating costs. “I have seen several of these with varying

numbers, and none can be substantiated,” he notes. “Energy savings have far too many variables to assign a savings value to any product upgrade. This practice is still going on. I often see it in online ads for renovation windows.”

As to concerns about claims related to imported windows, Adamson says it depends who you talk to, but notes that the bulk of imported windows are higher-end, with data to back up claims. For its part, the Competition Bureau handles marketing related to both imported and domestic products. Indeed, each year the Bureau receives thousands of complaints from Canadians about all kinds of products, including greenwashing complaints (however, staff cannot share whether any of them are related to windows or doors).

“Our role is to investigate misleading advertising and deceptive marketing practices, including any representation related to the environment that has been made for the purpose of promoting a product, including an imported product or business interest,” states a Bureau spokesperson. “The Competition Act also prohibits performance claims that are not based on adequate and proper testing. This includes any form of statement, warranty or guarantee of a product’s performance, efficacy or length of life.”

In mid-2024, the Competition Act was given sharper teeth with regard to unsubstantiated claims.

Read that again slower: “...prohibits performance claims not based on adequate and proper testing.” That means that performance claims that don’t have a certification attached to them could be found to be in violation of the Act...even if they turn out to be true when challenged.

In fact, in mid-2024, the Competition Act was given sharper teeth with regard to unsubstantiated environment-related product and service claims, with a new requirement to base them “on adequate and proper substantiation in accordance with an internationally recognized methodology.” There were two rounds of public consultation about the changes and their implementation, with the second having ended in February 2025.

Osler describes the changes as “broad in scope and materially increasing the potential exposure of businesses in Canada to enforcement activity, as well as financial penalties, litigation and monetary claims from private parties. Businesses operating in Canada are advised to consider their market strategies and conduct carefully in light of the amendments and to assess whether adjustments are needed to reflect the new grounds for enforcement, legal standards and potential exposure.”

Environment-related claims can now be challenged under two new provisions, where businesses now bear the onus of proving

their own statements, warranties or guarantees. And these provisions also do not require the applicant to establish that the representation is materially false or misleading in any respect.

Van Dyk says he doesn’t see the intentional greenwashing situation in Canada’s window and door sector as significant. He does, however, see issues with the Energy Rating value used by Natural Resources Canada’s Energy Star program and in the National Building Code.

“It has no units, and the way it’s calculated – combining solar heat gain, U Value and air leakage – is very confusing to homeowners,” he explains. “It may lead them to buy the wrong product and I consider it unintentional greenwashing. The main problem is that a value of 30 or higher signifies a high-efficiency window but that window could have high solar heat gain. That can really heat up a house in some areas of Canada like southern B.C. in the summer.”

Interestingly, Van Dyk notes that, in B.C., the problem has been somewhat recognized. In short, the ER value was not used as a criteria in the recent Clean BC rebate program.

“There were people at BC Hydro who understood the situation: that with ER used in the program, lots of windows would be installed that would cause more air conditioner use in the summers. So they advised against using ER,” Van Dyk explains. “The Clean BC program leaders listened.” He adds that there is also awareness of the issue on a national scale. “It looks like the plan is to put a cap on solar heat gain in the calculation,” Van Dyk reports. “But then ER values will come down and become meaningless. The formula won’t work anymore and so I can’t see the ER value lasting.”

(Laboratory & Field)

ISO 17025 SCC & AAMA

Envelope

• Windows, Doors & Curtain Walls

• Insulating Glass Units

• Fenestration Computer Simulation

• Safety Glazing

• EIFS • Cladding & Building Systems • Air Barriers • Thermal Performance • Condensation Resistance • Instrumentation & Test Equipment

38 Regan Road, Unit 4, Brampton, Ontario, Canada L7A 1C6

Tel: (905) 840-2014 • Fax: (905) 840-2847 email: lab@can-best.com www.CAN-BEST.com

Clients who are sad about performance make complaints.

But there’s more. Van Dyk also sees a similar greenwashing issue in labelling a house as an Energy Star home. “If you bought that house,” he notes, “you’d assume all of it was energy efficient: the windows, appliances, the insulation, etcetera. But it might overheat in summer. So we have to avoid lumping everything together because it creates the perception that everything is looked after, and you don’t have to look deeper into what you’re getting. It results in people having to find out later why their homes aren’t comfortable, when they could have avoided the problem had they known about it. In B.C., we have the Energy Step Code, which is more useful.”

Lastly, Van Dyk and others take issue with using “high-performance” as a general energy efficiency claim. “Yes, a window may be high-performance, but it’s a spectrum,” he says. “There are windows higher in performance than that window, and others that are lower. There’s truth in it but it’s not the whole picture. So we need to provide context with that term and other terms. In our business we’ve used the term ‘all-season,’ but it has meaning and we provide all the data. It’s a window that isn’t great for summer or winter, let’s say, but its benefits are balanced for the whole year. It makes sense for the Vancouver area, where winters are not too cold and summers not too hot.”

Vitro Architectural Glass is an example of a glass provider that takes pride in vetting its claims. In 2017, it published third-par-

ty-verified Environmental Product Declarations (EPDs) listing the contribution to global warming (GWP) each of its products represents.

When asked whether EPDs should be legally required as a window and door product claim, Vitro’s technical services manager, Michael Hammond, isn’t definitive. He does see value in EPDs that are third-party certified and verified to be based on the North American product category rules in helping people understand the environmental impacts of their purchases and believes they should be used to help companies make better environmental choices. Furthermore, in Hammond’s view, flat glass EPDs should be used for all glass products since the majority of the GWP for an IGU comes from the flat glass itself. “This approach prevents hundreds of window makers from incurring significant costs to generate EPDs for each of their products,” he says, “costs which would ultimately be passed on to consumers.” He adds that the potential error in an EPD can be significant. “For example, if the error margin is plus or minus 20 percent, it could be as large as all the other processing steps combined in making an IGU, given that 75 to 80 percent of the GWP comes from flat glass manufacturing.” Errors this large could endanger a fenestration supplier who relies on unverified EPDs to make public claims about their product.

Many members of the global window industry believe lifespan is an important measure of environmental friendliness and should serve as a useful and important “green” claim. Rate of replacement obviously strongly impacts the raw materials and energy which go into windows, doors and buildings over their lifespan. Hammond is of this view. He explains that even if a product claims a lower GWP or lower environmental impact but needs to be replaced twice as often over a building’s lifespan, “the true environmental impact is much greater for the product that requires more-frequent replacement. I believe the life expectancy of the North American PCR for glass is 30 years. If all glass manufacturers are basing their third-party verified EPD on the North American PCR, then one could reasonably expect a 30-year life expectancy of the glass under normal use.” Better make sure your windows actually last 30 years before claiming that they do.

In the end he concludes that, “When companies make claims without rigorous verification, it undermines the trust and transparency that are essential in our industry. False or unverified claims also have the potential to create an uneven playing field, where companies like ours that invest in sustainable practices and accurate reporting may face unfair competition and the consumer stands to lose the most by paying for a product that is not accurately represented.”

Overall, he’d like everyone to play on a level field. “If companies are taking advantage of or cheating the system, they should be held accountable,” he says. “Everyone should adhere to the same rules.” No doubt the framers of the Competition Act had exactly the same opinion.

Consolidate machines, reallocate labor, improve ergonomics, lower costs and enhance part quality

Save at least $800,000/year in material costs with our Zero Scrap Saw and lineal optimization software

“Catalog-only” doesn’t cut it

Your specs are our marching orders — customizing controls, outfeeds and tooling is just part of the job

Unthinkable throughput targets

Need two complex parts completely cut, fabricated and ready for the next step in under 60 seconds? No problem

josephmachine.com sales@josephmachine.com

There are things you can do to protect your business in a trade war.

by Adrian Edge

Back in January when I originally wrote this article, I opened it up with some basic definitions of what tariffs are. Here at the end of March, the conversation about tariffs has become so commonplace I’m sure that isn’t needed any more. Unlike the the COVID supply chain challenges we just recovered from, tariffs create price pressures and therefore drive demand down. The threat and enactment of tariffs is already driving business and consumer choices. Businesses are rethinking their expansion plans, suppliers and trades are laying off workers and consumers, on both sides of the border, are rethinking their buying choices. Without de-escalation, Canada and the U.S. seem to be headed toward a drawn-out and painful trade war. The greatest pain will be felt by small and medium-sized companies and consumers at large.

The problem with tariffs is in their nature to act as a double-edged sword. For any damage inflicted on one country, damage is done to both. The unintended consequences are painful and inevitable. The best example of this is the Smoot-Hawley Tariff Act passed in 1930 as a means to support domestic agriculture. The damage done to trade between the U.S., Canada and Europe was devastating. Once all countries had retaliated, trade overall had decreased by nearly 60 percent. With significant tariffs and countertariffs being threatened by most of the world, we seem to be going in a similar direction.

Let’s bring us back to the present and what businesses can start doing about it. Over the last month, I’ve talked with a variety of trade experts on this subject and here are some lessons learned and tools you can start to review.

First, review your contracts with anyone in the U.S. you do business with. Understanding the various Incoterms (international commerce terms) and who owns what responsibility when it comes to shipping and duties is going to be critical. Using terms like “FOB” or Free on Board

comes with legal authority to help define what the seller and buyer responsibilities are. There are 11 such terms that you can review and decide which is best for your business and customers. There’s additional language that could be added to further clarify rights. The point I’m trying to make here is do not assume that your U.S. customer will be responsible for U.S. tariffs. Unfortunately, it’ll come down to what you’ve written into your contract.

Next, get to know the harmonized code system (HS) better and what the rules are regarding substantial transformation and how they impact potential remissions and drawbacks you could be requesting for products you use in your business. Ideally, brokers should be an excellent resource to get your team up to speed. Fenestration Canada members, feel free to reach out to me if you need support. An example of a simple change you can do is to ensure freight and shipping costs are broken up separately from the remaining line items, as freight and shipping is not duty-applicable.

Last, and arguably most important, make time for an intentional strategy session to sit down with your team and discuss how you’ll manage these changes. Look at your supply chain and how you’ll need to pivot. Take a good look at how your systems break up invoices and how accounting is able to capture them. The requirements to both use the HS system effectively and maintain your books is likely one of the more difficult tasks in the coming months.

We may have escaped the worst-case scenario of tariffs for now. But as we’ve seen, the posture of the American government can change overnight and without warning. We recommend having contingency plans in place and optimizing your import and export practices.

Adrian Edge is director of codes and regulatory affairs for Fenestration Canada. Reach him at adrian@fenestrationcanada.ca.

0482345

60 Weller Court

Cobourg, ON, K9A 5K3

(905) 377-1461

Davis Allan

davisallan861@gmail.com

AABEN WINDOWS AND DOORS LTD.

700 Progress Ave

Kingston, ON, K7M 4W9

(613) 384-3163

Michael Braby

michael.braby@aaben.com

aaben.com

ACCESS WINDOW AND DOOR DESIGN

CENTRE LTD.

565 Cargill Road

Winkler,MB, R6W 0K4

Helly Wiens

helly.wiens@accesswd.ca

ACRO ALUMINUM INC.

5430 275th Street

Langley, BC, V4W 3X7

Brent Friesen

brent@acroaluminum.ca

ACTON OSTRY ARCHITECTS

111 East 8th Avenue

Vancouver, BC, V5T 1R8

Jennifer Linehan

info@actonostry.ca

ADFAST CANADA INC.

2685, Diab Street

St-Laurent, QC, H4S 1E7

(514) 617-1579

Christian Guerard

cguerard@adfastcorp.com

adfastcorp.com

AERLOC INDUSTRIES LTD.

64 Head Street

Dundas, ON, L9H 3H7

Edward Laman

edwardlaman@aerloc.com

aerloc.com/

AGM GLASS INC.

30 Burks Way

Winnipeg, MB, R5T 0C9

Gordon Seier

gordon@agm-inc.com

ALL WEATHER AT HOME

18550 - 118A Avenue NW

Edmonton, AB, T5S 2K7

(780) 451-0670

Tracy Nadiger

tnadiger@allweathergroup.ca

allweatherathome.ca

ALL-WEST GLASS

1011 Victoria St

Prince George, BC, V2L 0C8

(250) 563-1555

Mike Kuemmerle

mikek@awgwd.com

awgwd.com/

ALLIANCE DOOR PRODUCTS

#100 - 55 Furniture Park

Winnipeg, MB, R2G 4G1

Lauren Sabeski

lauren.sabeski@alliancedoorproducts.com

alliancedoorproducts.com

ALUMINC CANADA LTD.

7250 Keele St., Unit 203 Concord, ON, L4K 1Z8

(416) 953-5550

Aluminc

info@aluminc.ca

ALUPLAST GMBH

Auf d. Breit 2

Karlsruhe, Germany76227

+49-721-47171-214

Amir Bahrami

amir.bahrami@aluplast.net

aluplast.net/eng-int/index.php

AMBERWOOD DOORS INC.

191 Atwell Drive, Unit 3

Etobicoke, ON, M9W 5Z2

(416) 213-8007

Colin Fraser

cfraser@amberwooddoors.com

amberwooddoors.com

AMESBURYTRUTH

3600 Minnesota Drive, Suite 800 Edina, MN55435

(800) 866-7884

Donna Cockrell

Donna.Cockrell@amesburytruth.com

amesburytruth.com

ANDERSEN CORPORATION

Michael Johnson

MichaelAJohnson@andersencorp.com

APOLLO WINDOWS & DOORS

3530 32nd Street NE, Unit 26

Calgary, AB, T1Y 6G7

(403) 568-0777

Vishwa Naidu

vnaidu@apollowindows.ca

ARMWOOD WINDOWS & DOORS

Highway 1A West, PO Box 8

Portage la Prairie, MB, R1N 3B2

(204) 856-2320

Brent Otsuji

brent@armwood.ca

armwood.ca

ASSA ABLOY

1105 Southrock Blvd

Reno,NV89502

(775) 852-8808

Marc Lauzon

marc.lauzon@assaabloy.com

interlockna.com/en/site/interlock/

ASSOCIATED MATERIALS, INC.

3773 State Rd.

Cuyahoga Falls, OH,44223

(330) 922-2119

Jessica Dunegan

jdunegan@associatedmaterials.com

ASSOCIATION DE VITRERIE ET DE FENESTRATION DU QUÉBEC

3060 Maricourt Avenue, Bureau 250

Quebec City, QC, G1W 4W2

(418) 688-1256

Maggie Champagne

mchampagne@avfq.ca

avfq.ca/

ATLANTIC WINDOWS LTD.

49 East Main Street

Port Elgin, NB, E4M 2X9

(506) 538-2361

Greg Dickie

greg.dickie@atlanticwindows.com

atlanticwindows.com

ATTRAVERSO INC.

6141 Atlantic Dr. Mississauga, ON, L5T 1L9

Raisa Temnova

r.temnova@attraverso.ca

attraverso.ca

AURORA WINDOW SYSTEMS INC

535 Manitou Road SE Calgary, AB, T2G 4C2

Kent Schultz

kent@aurorawindowsystems.ca

aurorawindowsystems.ca

BASCO WORLD

288 boulevard curé-labelle

Laval, QC, H7P 2P1

(514) 241-9686

Jenny Desjardins

jenny@bascoworld.com

bascoworld.com/

BC BUILDING AND SAFETY STANDARDS BRANCH, MINISTRY OF HOUSING

BC

Jun’ichi Jensen

Junichi.Jensen@gov.bc.ca

BDA FACADE

77 Auriga Dr., Unit 6

Ottawa, ON, K2E 7Z7

Nicholas Martin

nmartin@bdag.ca

BECK CONSULTING

Scott Beck

BENDINI ENTERPRISES INC.

Nazanin Souri

bendinisystem.com

BETHEL WINDOWS AND DOORS

1504 12th St

Coaldale, AB, T1M 1M3

(403) 345-4401

Samuel Van Seters

sam@bethelwindows.ca

bethelwindows.ca/

BIG CITY WINDOWS AND DOORS

2615 Lancaster Rd., Unit-18-19

Ottawa, ON, K2G 1E8

(613) 979-4515

Vladimir Solovyov

vladimir@bigcitywindows.com

bigcitywindows.com

BIGFOOT DOOR

1677 Aimco Blvd., Unit A Mississauga, ON, L4W 1H7

Daniel Zigante

daniel@bigfootdoor.com

bigfootdoor.com/

BONNECHERE VALLEY

WINDOWS & DOORS

2824 Fourth Chute Rd

Eganville, ON, K0J 1T0

(613) 628-3056

Shane Charania

shane@bvwd.ca

bvwd.ca/

BOTHWELL-ACCURATE

6675 Rexwood Rd

Mississauga, ON, L4V 1V1

Aladin Matinong

amatinong@bothwell-accurate.com

BROUILLETTE PORTE ET FENÊTRE

91 Rue des Oblats

Trois-Rivières, QC, G8T 8X1

(819) 375-1131

Cédrick Therrien

cedrick.therrien@brouillette-qc.ca

BROWN WINDOW CORPORATION

185 Snow Boulevard Concord, ON, L4K 4N9

(905) 738-6045

Pino Marinelli

pinom@brownwindow.com

brownwindow.com/

BUCALU

Lina Guo

nana@bucalu.ca

CAD-PLAN

Frankfurt, Germany60314

Jan Krutsky

krutsky@cad-plan.com

CAHILL COMMERCIAL

139 John Cavanaugh Dr. Carp, ON, K0A 1L0

Saad Odeh

saad@cahillcommercial.ca

CAN-BEST TESTING LABORATORIES

38 Regan Road, Unit 4 Brampton, ON, L7A 1C6

(905) 840-2014

Elie Alkhoury

elie@can-best.com

can-best.com

CANADIAN VINYLTEK WINDOWS

587 Ebury Place Delta, BC, V3M 6M8

(604) 540-0029

Steve Finlayson

steve@vinyltek.com

vinyltek.com/#hgtv-michael-buble

CANPLEX LTÉE

3175 Avenue de la Gare Mascouche, QC, J7K 3C1

(450) 474-1191

Marco Stoccchero

marcos@canplexextrusions.com

canplexextrusions.com

CAPACITY ENGINEERING LTD. Ottawa, ON

Maurice Quinn

mquinn@celottawa.ca

CAPITAL REGION SERVICE COMMISSION

860 Prospect Street Fredericton, NB, E3B 2T8

(506) 453-2956

Thomas Harding

tharding@capitalrsc.ca

rsc11.ca/planning/

CARDINAL GLASS INDUSTRIES

534 Wasaga Crescent Waterloo, ONN2V 2Y8

BOTTERO FLAT GLASS INC.

121 Shields Park Drive

Kernersville, NC27284

(336) 992-5623

Grant Mason

grant.mason@bottero.com

bottero.com/

(519) 590-3194

Mike McAndrew

mmcandre@cardinalcorp.com

CARTONS CORRUGUARD

101 Des Ateliers

Lavaltrie, QC, J5T 3R3

(450) 586- 0666

Marie-Helene Hotte

mhhotte@cartonscorruguard.com

cartonscorruguard.com/

CASCADIA WINDOWS

Amber Mengede

amengede@cascadiawindows.com

CENTENNIAL WINDOWS & DOORS

687 Sovereign Rd London, ON, N5V 4K8

(519) 451-0508

Lindsay McGhie

lindsay.mcghie@centennialwindows.com

centennialwindows.com

CENTRA WINDOWS

Langley, BC

Jeff Clarke

jclarke@centra.ca

CITY OF NANAIMO

411 Dunsmuir Street Nanaimo, BC, V9R 0E4

Matt McMaster

Matt.McMaster@nanaimo.ca

CITY OF RICHMOND

6911 No. 3 Road Richmond, BC, V6Y 2C1

(604) 276-4113

Shilin Sun

SSun@richmond.ca

CITY OF VANCOUVER

Brad Marsh

brad.marsh@vancouver.ca

CITY OF VANCOUVER

Scott Williams

Scott.B.Williams@gov.bc.ca

CLEARREX INC.

125 Adesso Drive Concord, ON, L4K 3C3

(416) 669-0747

Saranjan Mahadevan

saranjan@clearrex.com

CLEARVIEW INDUSTRIES LTD.

45 Fenmar Dr. Toronto, ON, M9L 1M1

(416) 745-6666

Tom Marsala

tmarsala@clearview.on.ca

clearview.on.ca/

COLOUR ALLIANCE INC.

8 - 60 Healey Rd Bolton, ON, L7E 5A6

(905) 857-8072

James Martin

james@colouralliance.ca

colouralliance.ca

COMPETITION GLASS COMPANY LTD.

1850 Springfield Rd Kelowna, BC, V1Y 5V6

(250) 860-7155

Invoicing Accounts Payable

invoice@compglass.com

compglass.com/

COMPONEX

10 Westcreek Drive, Unit 15

Woodbridge, ON, L4L 9R5

(647) 367-0006

Maxim Zolotarev

info@componex.ca

componex.ca

CONSTRUCTIVE HOME SOLUTIONS

INC. DBA BUILDING IT RIGHT

1039 Parana Drive

Port Coquitlam, BC, V3C 6P8

(604) 464-0596

Murray Frank

murray@buildingitright.com

buildingitright.com/index.html

CONTINENTAL / KONRAD HORNSCHUCH AG

Salinenstrasse 1 Weissbach, Germany74679

+1 540 550 4596

Marco Patermann

marco.patermann@marcorp.global

skai.com/en/exterior/

CORNERSTONE BUILDING BRANDS

7140-40th Street S.E.

Calgary, AB, T2C 2B6

(403) 863-0473

Dave Goldsmith

Dave.Goldsmith@cornerstone-bb.com

cornerstonebuildingbrands.com/

COSSINS WINDOWS LTD.

2908-19th Street NE

Calgary, AB, T2E 7B1

(403) 291-3960

Brad Cossins

brad@cossins.com

cossinswindowsanddoors.com/

CSA GROUP

Ken Phu

ken.phu@csagroup.org

DAN DARCY & ASSOCIATES INC.

46 Diana Grace Avenue

Dartmouth, NS, B2W 6A2

(902) 462-6114

Dan Darcy

dan@darcyasscs.ca

DASHWOOD INDUSTRIES INC.

28648 Centre Rd

Strathroy, ON, N7G 3H6

(519) 228-6624

Dennis Foran

dennis.foran@dashwood.com

dashwood.com/

DAYSIDE WINDOWS & DOORS

441 Henry Street, Unit 2

Brantford, ON, N3S 7V6

(519) 759-5222

Sarah deBoer

sarah.deboer@daysidewindows.com

dayside.ca/

DECEUNINCK NORTH AMERICA

351 N Garver Rd

Monroe, OH,45050

(513) 393-5633

David Pirwitz

David.Pirwitz@deceuninck.com

DEL WINDOWS & DOORS

944 South Service Road

Stoney Creek, ON, L8E 6A2

(905) 561-4335

Edward Bremer

ebremer@delwd.ca

delwd.ca/

DELTA BALANCE SYSTEM

1673 Rue Cunard

Laval, QC, H7S 2B4

(514) 887-1352

Neeman Malek

neeman@delta-balance.com

DEPARTMENT OF FOREIGN AFFAIRS

Ottawa, ON

Mir Ali

mir.ali@international.gc.ca

DISTRICT OF OAK BAY

2167 Oak Bay Ave

Victoria, BC, V8R 1G2

Heather Stewart

hstewart@oakbay.ca

DISTRICT OF WEST VANCOUVER

BC

(604) 925-7095

Sima Cheema

scheema@westvancouver.ca

DOORCOM

285 Vaughan Valley Blvd.

Woodbridge, ON, L4H 3B5

(905) 850-5352

Daniel Sardella

daniel@wintek.ca

doorcom.ca

DOORSMITH (A DIVISION OF CANSAVE)

411 Bayview Drive

Barrie, ON, L4N 8Y2

(800) 461-5411

Ryan Eccleshall

ryane@cansave.ca

doorsmith.ca/

DORPLEX INDUSTRIES LTD.

100 Norfinch Drive

Toronto, ON, M3N 1X1

(416) 744-3667

Paul Moseley

paul@dorplex.com

dorplex.com

DOW

NY

Scott Waechter

scott.waechter@dow.com

DURABUILT WINDOWS & DOORS INC.

10920 178 Street NW

Edmonton, AB, T5S 1R7

(780) 577-2004

Patrick Kiernan

patrickk@durabuiltwindows.com

durabuiltwindows.com

DUSCO DOORS

11825 Av. J.-J.-Joubert

Montréal, QC, H1E 7J5

(877) 290-0941

Lorne Dubrofsky

lorne@duscogroup.com

DUXTON WINDOWS & DOORS

45 Higgins Avenue

Winnipeg, MB, R3B 0A8

(204) 339-6456

Al Dueck

apdueck@duxtonwindows.com duxtonwindows.com/

EBSA LIMITED

Richard McAlpine

richard@ebsacanada.ca

ECOTECH WINDOWS & DOORS

7-34 Futurity Gate

Concord, ON, L4K 1S6

(888) 880-6827

Mark Ginzburg

mark@ecotechwindows.ca

EDISON ENGINEERS INC.

ON

Matt Charbonneau

mcharbonneau@edisonengineers.ca

EFFICIENCY MANITOBA

MB

Rob Spewak

rob.spewak@efficiencymb.ca

efficiencymb.ca

EITEL KIRSTEIN CONTRACTING

Admin

admin@eitelkirsteincontracting.ca

ELEMENT MATERIALS TECHNOLOGY

475 Speers Rd

Oakville, ON, L6L 2X9

(905) 822-4111

Luiz Rios

luiz.rios@element.com

element.com/

ELTON MANUFACTURING

8120 Lawson Road, Milton,ON, L9T 5C1

(905) 876-1290

John Wolak

sales@eltonmanufacturing.com

eltonmanufacturing.com/

EMBALLAGES LM PACKAGING INC.

25, rue de l’Étang

St-François-de-la-rivière-du-sud, QC, G0R 3A0

Jonathan Gendron

jonathan.gendron@emballageslm.com

FIELDSTONE WINDOWS & DOORS LTD.

4160 19th Avenue

Markham, ON, L6C 1M2

(416) 533-0999

Douglas Tremblay

doug@fieldstonewindows.com

fieldstonewindows.com/

FINISHING TRADES INSTITUTE OF BC

12277 Industrial Road

Surrey, BC, V3V 3S1

(604) 580-3112

Olmo Hernandez

ohernandez@ftibc.ca

ftibc.ca

FISHBURN SHERIDAN & ASSOCIATES LTD.

201-11 Hines Road

Kanata, ON, K2K 2X1

(613) 831-7293

Mohammed Sabra

mohammed@fsaeng.com

FOLDING SLIDING DOORS CANADA LTD

105-1155 St. Paul Street

Kelowna, BC, V1Y 2C6

(250) 448-6418

Branden Hoult

branden@foldingslidingdoors.ca

foldingslidingdoors.ca/

FORIMPEX

200-D Rue Ste Christine

Saint-Joseph-de-Beauce, QC, G0S 2V0

Mario Levesque

Mario.Levesque@forimpex.ca

FRANK

248 Bowes Rd

Concord, ON, L4K 1J9

(905) 660-5021

Marco Greco

marcog@frankwd.com

FUSION GLASS GROUP

Yama Noori

info@fusionglassgroup.com

GARIBALDI GLASS INDUSTRIES INC.

Burnaby, BC

(604) 420-4527

Carey Mobius

michelles@garibaldiglass.com

garibaldiglass.com

GEALAN

Germany

Paulius Aleksejevas

paleksejevas@gealan.lt

GEM WINDOWS AND DOORS

1590 The Queensway

Etobicoke, ON, M8Z 1V1

Vito Ferrone

vito@gemgroupbp.com

GEORGIAN BAY WINDOW & DOOR LTD.

1189 Sideroad 20

Allenford, ON, N0H 1A0

(519) 934-2690

Curtis Hansler

curtis@gbwd.ca

GIDEON WINDOWS INC.

3392 Wonderland Road S, Unit N London, ON, N6L 1J9

Alex Dudarenka

alex@gideonwindows.com

GLASS CANADA

330 Exeter Road

London, ON, N6L 1A3

(519) 642-4100

John Pawley

john.pawley@glasscanada.ca

GLOBAL WINDOWS & DOORS

128 Industrial Park St., PO Box 2823

Richibucto, NB, E4W 4A4

(506) 523-4900

Allan Doyle

allan@globalwindows.ca

globalwindows.ca/

GOLDEN WINDOWS LTD.

888 Guelph Street

Kitchener, ON, N2H 5Z6

(519) 579-3810

Tarek Elewa

telewa@goldenwindows.com

goldenwindows.com/

GOVERNMENT OF NEW BRUNSWICK

460 Two Nations Crossing Fredericton, NB, E3C 1E7

(506) 453-8915

Timothy Scammell

Timothy.Scammell@gnb.ca

GRAF INDUSTRIES INC.

5-6750 Langstaff Rd

Vaughan, ON, L4H 5K2

(416) 931-5265

Giacomo Zotta

g.zotta@grafindustries.com

grafindustriesinc.com

GREENFOX WINDOWS & DOORS

18528 111 Avenue NW Edmonton, AB, T5S 2V4

(780) 437-1151

Pavlo Bezko

Pavlo@greenfoxwindows.ca

greenfoxwindows.ca/

GREENLITE GLASS SYSTEMS INC.

2414 St Johns St #200

Port Moody, BC, V3H 2B1

Jeremy Nightingale

jeremy@greenliteglass.com

GTA ARCHITECTURAL SALES INC.

Etobicoke, ON

Matt Misra

matt.misra@ftg-group.ca

GUARDIAN GLASS

27413 55 Ave

Langley, BC, V4W 3Y1

(604) 607-4500

Geoff Shellard

geoff.shellard@guardian.com

H.B. FULLER

1200 Willow Lake Blvd.

St. Paul, MN,55110

(833) 672-1482

Michael Speicher

NA-Glass@hbfuller.com

HAFFNER MACHINERY

6630 Macdonald

Hampstead, QC, H3X 2X4

Stephen Kucer

stephen.kucer@haffnerna.us

haffnerna.us

HANGZHOU WINTEK BUILDING PRODUCTS CO.

Shengao Xixi Mingzuo 2-703, Quiqiao Road, Yuhang District

Hangzhou, China,311121

Ten Chen

sales1@wintekco.com

wintekco.com

HARTUNG GLASS CANADA

7344 Winston Street

Burnaby, BC, V5A 2G9

Taslim Ishani

tishani@hartung-glass.com

HEGLA

HEGLA GmbH & Co. KG, Industriestr. 21 Beverungen, Germany,37688

Thomas Bechill

thomas.bechill@heglaus.com

heglaus.com

HERR WINDOW & DOOR O/A HERR VENTURES INC

Edmonton, AB

Office

office@herrv.ca

HI-TECH ENERGY WINDOWS

1530 Erin St. Winnipeg, MB, R3E 2T1

Sean Kapusta

skapusta@hitechwindows.ca

HOMEFLASH INC.

290141 - 48 Street East Foothills, AB, T1S 3S1

(403) 938-6100

Richard Mclauchlan

info@homeflash.com

homeflash.com/

HURON WINDOW CORPORATION

345 Mountain St. South Morden, MB, R6M 1J5

(204) 822-6343

Brodie Fehr

brodief@huronwin.com

huronwin.com

IGE GLASS TECHNOLOGIES INC.

2875 Jupiter Park Dr., Suite 100 FL,33458

Heinz Wiedmayer

heinz@igesolutions.com

IGEsolutions.com

INKSTER PARK MILLWORK LTD.

1512 Church Ave. Winnipeg, MB, R2X 1G6

Gary Glowa

gglowa@inksterpark.ca

INLINE FIBERGLASS LTD

30 Constellation Court

Toronto, ON, M9W 1K1

(416) 679-1171

Bernard Rokicki

brokicki@inlinefiberglass.com

inlinefiberglass.com/

INNOTECH WINDOWS + DOORS

25452 52 Avenue

Langley, BC, V4W 4B2

(604) 854-1111

Jessica Owen

jessica.owen@innotech-windows.com