FenestrationMasters provides a unified measure of success for professionals across the glass, glazing and fenestration industries through education and professional development.

Why become a FenestrationMaster?

Broaden your knowledge—Learn about a wide range of industry topics.

Stay current—Keep up-to-date on industry standards and best practices. Make it official—Certification validates your industry expertise.

Access from anywhere—Online courses and proctored exams provide a fully digital experience. •

Elevate your expertise. To become certified, sign up at FGIAonline.org/FenestrationMasters.

Fenestration Review 2024 Vol. 13 • Issue 1

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Rep.

Tel: (416) 510-5113 • Fax: (416) 510-6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

BRAND SALES

MANAGER |Leslie OSBORNE losborne@annexbusinessmedia.com 647.280.5885

ACCOUNT

COORDINATOR |Barb COMER bcomer@annexbusinessmedia.com 519.429.5171

MEDIA DESIGNER | Curtis MARTIN

AUDIENCE DEVELOPMENT MANAGER |Shawn ARUL sarul@annexbusinessmedia.com 416.510.5181

GROUP PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 226.931.0375

CEO | Scott JAMIESON sjamieson@annexbusinessmedia.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

SUBSCRIPTION RATES

Canada - 1 Year $22.44 (plus applicable taxes)

U.S.A. - 1 Year $51.51 (in CDN dollars) Foreign – 1 Year $59.16 (in CDN dollars)

ANNEX PRIVACY OFFICER Privacy@annexbusinessmedia.com Tel: 800.668.2374

Occasionally, Fenestration Review will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.fenestrationreview.com

19 6 Fenestration Review 2024 Vol. 13, No. 1

4

EDITORIAL

Here’s where we come down on AI-generated content.

14 TAKING THE PRESSURE OFF

Jon Eakes reports on his research into pressureequalized window installation. 10

7 SIDING AND WINDOW DEALERS ASSOCIATION

14

6 INDUSTRY NEWS

Owens Corning buys Masonite...bye bye Canada Greener Homes Grant... WOCD clarity in Alberta...

19 2024 FENESTRATION CANADA MEMBERS DIRECTORY

10

BIGGER AND BETTER Bigfoot Door invests to grow in its oversized fenestration niche.

13 FENESTRATION AND GLAZING INDUSTRY ALLIANCE

18 FENESTRATION CANADA

Not for a very long time to come. Here’s why.

When you read something written by a human there are layers of assumption involved that we aren’t even conscious of. The most fundamental of these is that the person who wrote the text understood what they were writing and intended the specific message conveyed in the text to be received by the reader. AI completely lacks both these attributes. It is simply putting words and letters together in response to a set of algorithms that will generate an intelligible response. All deeper context is absent.

A simpler way to put this is to say that a human writer has some basis to know whether what they have written is correct or not. Why? Because they are human and all their thought rests on a lifetime of experience. Anything they produce is consciously or subconsciously checked – even before it is written – against that experience. Absurdities jump out immediately and are probably not generated in the first place. AI is pretty good at not generating absurdities (though much worse at it than humans) simply because it is drawing exclusively from things humans have said and written…and humans don’t usually publish absurdities except for fun.

But go even one layer of analysis deeper into the truth or falsity of statements and AI completely loses its way. That’s because, to a surprising degree, what we acknowledge as true or false depends on something called “perspective.” Where does the statement fit into our larger picture of reality? And does it address the topic we are intending to address and deliver the message we are intending to deliver? Nothing an AI produces has any reference to perspective because the AI has none. It doesn’t know what the topic is; what the distinction is between real and

by Patrick Flannery

fantasy; why it is writing something in the first place; who might be reading it and why; what the message is; or what the intended effect of the message is on the reader.

But who cares as long as the information is not factually inaccurate and is intelligible, right?

To illustrate why the lack of assumed perspective is a problem, let’s look at an example statement that an AI could produce.

“The shape of the Earth is a controversial topic.”

An AI can say this with a straight face because there are whole groups of kooks on the internet who like to argue with varying degrees of seriousness that the Earth is actually flat and all the science showing it is round is a hoax. Given those surface facts, nothing in the statement is wrong.

But a human knows what’s going on here. The world is full of weirdos who say silly stuff. The shape of the Earth is not controversial among anyone who’s opinion matters. When you read something written by a human, you can apply the context that they bring this perspective to what they’ve written. That affects how you read and receive it. Presenting AI-generated copy as if it were written by a person is therefore, in my opinion, fundamentally dishonest.

As AI continues to get better at producing original text, we have been having many conversations here at Annex Business Media about whether it’s a threat or a challenge and how to use it or not in our content. For the reasons above, I’ve come down on a policy that there won’t be AI-generated content in the Fenestration Review channel unless its identified as such. It’s important for you to be assured that everything you read here has human perspective behind it… no matter how weird.

Canada’s premier certified fabricator of Schuco and Reynaers products. All tested in North America to meet NFRC and North American Fenestration Standards. Uncompromised quality, service and support for over 40 years.

High performance, all aluminum construction. Made in Canada.

Owens Corning and Masonite have announced they have entered into a definitive agreement under which Owens Corning will acquire all outstanding shares of Masonite for $133 per share. The implied transaction value is approximately $3.9 billion. Owen Corning said the addition of Masonite’s doors business creates a new growth platform for it, strengthening the company’s position in residential building materials and extending its offering of products and brands. Leveraging Owens Corning’s commercial capabilities and market model serving contractors, builders and distributors, the company expects to build on Masonite’s strong track record of innovation, brand quality and category excellence to further grow in the doors market. Founded in 1925, Masonite designs, manufactures and markets doors and door systems with a vertically integrated manufacturing model serving both repair and remodel and new construction demand. Masonite operates 64 manufacturing and distribution facilities, primarily in North America, and has over 10,000 employees globally.

“We are excited by this opportunity to add a scalable new growth platform for our company,” said Brian Chambers, board chair and CEO of Owens Corning. “Masonite is a market leader that complements our existing residential interior and exterior product offering and has consistently demonstrated top-line growth and margin expansion. The combination of our commercial, operational and innovation capabilities allows us to accelerate our long-term enterprise growth strategy with a clear line of sight to meaningful synergies and increased cash flow generation. We look forward to welcoming the talented Masonite team to Owens Corning and working with them to deliver enhanced value to customers and shareholders.”

“Our world-class team is transforming the door industry with differentiated solutions for the home,” said Howard Heckes, president and CEO of Masonite. “The combination with Owens Corning enables the acceleration of our Doors That Do More strategy, while delivering immediate and substantial value to our shareholders. This agreement brings together two storied companies with a common focus on innovation and making life better at home for the people who use our products every day. As we begin our next chapter after nearly 100 years in business, I am looking forward to Masonite joining the Owens Corning team.”

Owens Corning is a global roofing and insulation provider headquartered in Toledo, Ohio. It is best known for its famous pink fibreglass insulation.

The Canada Greener Homes Grant, a federal program that offered rebates of up to $5,000 for energy-efficient home upgrades, came to an abrupt end earlier this year as the program reported it had allocated all its budgeted funds at least a year earlier than planned at its launch in 2021. Natural Resources Canada warned in November 2023 that it was considering shutting down the program. The announcement came on Feb. 5 that the program would not accept any new applications after Feb. 12. However Enbridge, the utility company delivering the program in Ontario, announced it was ceasing to accept new applications immediately and

May 1

Fenestration Canada Ontario Chapter Event Woodbridge, Ont. fenestrationcanada.ca

May 9

Fenestration Canada Quebec Chapter Event Quebec City fenestrationcanada.ca

May 28

Fenestration Canada Spring Conference Kananaskis, Alta. fenestrationcanada.ca

June 3 FGIA Summer Conference Montreal fgiaonline.com

Sept. 11

SAWDAC Golf Tournament Milton, Ont. sawdac.com

Sept. 30 GlassBuild Dallas, Texas glassbuildamerica.com

Nov. 13 WinDoor Montreal fenestrationcanada.com

only projects with completed energy pre-audits would be eligible. This left many fenestration providers in a position where they were holding orders from clients expecting to get the rebates – and in some cases had started fabricating the orders – and now the clients were cancelling because their energy audits were not complete or would not be completed on time. Canada Greener Homes Loans remain in place, offering up to $40,000 interest-free loans for similar projects. NRCan is promising a new version of the Canada Greener Homes Grant that targets low- and mid-income families.

The Canada Greener Homes Grant, the grant no one needed in our industry at the time, is gone. Now we do need it and don’t have it. This has been a common theme throughout our membership: the bad timing of programs like these. As everyone looks back, the grant questions abound – good, bad, indifferent. But it was there and just not what our members wanted at the time. So where do we go?

Enter the Canada Greener Homes Loan program. “The Canada Greener Homes Loan offers interest-free financing to help Canadians make their homes more energy efficient and comfortable. The loan can help you finance eligible retrofits that are recommended by an energy advisor and that have not yet been started.”

The gist of it is a maximum $40,000 loan with a minimum of $5,000 interest-free for 10 years. Sounds great for the consumer but here’s the crux for SAWDAC members working with this program and their clients: you don’t get paid right away once the job is complete and can be left waiting for funding for two to six months! So our business partners are left holding a large chunk of costs for that time. To make matters

worse, some of our members found out about this after they did the work and ordered the materials and paid their employees. We notified our members of this at the time, but the message hasn’t always gotten through. Again, we go back to the original question, where do we go or what do we do?

SAWDAC has worked with our members through our RenoPlan program to secure bridge loads for that time frame so that cash flow doesn’t become a problem. We see this as a needed step to help our members through tough times. We have help, you just need to email us to get it: jason@sawdac.com.

The SAWDAC golf tournament will be Sept. 11 this year at Turtle Creek in Milton, Ont., once again. Email us to make sure you have a spot as we sold out last year and the weather promises to cooperate again as we’re looking for another sellout.

We have partnered up with Conestoga College to work with them on training carpentry students proper window and door installation using the Window Wise installation process. So we are looking forward to hopefully having these graduates join the window and door installation family in the near future.

SAWDAC is relaunching our

vinyl siding training so make sure to look for the coming announcements. If you want to get ahead of the curve, please email us to get on the list.

Two thousand twenty-four is here and we have a new president and two new board members. We are happy to announce that Chris George from the Douglas Window and Door Group has stepped into this role. We look forward to having Chris guide the ship with his 20-plus years in the industry, from learning to install right up to owning the company and everything that goes with that over the years. With that said we would like to say thank you to Jennifer Beingessner-Dietrich from Beingessner Home Exteriors for her service as president over the last term. We have added two new board members: Robbin Lindsay from R. Lindsay Sales Solutions and Freddie Hamilton (not Fred Hamilton) from Lincoln Exteriors in Calgary. Robbin represents top-quality building products manufacturers, providing technical, design and sales solutions to architects, designers, distributors, retailers, general contractors and trades. Lincoln Exteriors specializes in windows, doors, siding, soffit, fascia, gutters and residential roofing.

Everlast has welcomed Ron Sharma into the ownership group. Sharma brings a wealth of window and door experience to the team. Prior to joining Everlast in 2020, Sharma worked in leadership positions at Ply Gem and Lift Renovations. He is a consummate sales professional and expert at dealing with complex projects and providing responsive service to clients. Everlast looks forward to seeing Ron’s continued growth as it continues to succeed in the challenging and exciting window and door industry. Everlast manufactures aluminum, vinyl and wood window and door systems for some of the finest home builders and distributors in North America. Manufacturing facilities are located in Toronto and Calgary with distribution facilities in Thunder Bay and Saskatoon.

Alberta has issued STANDATA variance 23-BCV-001 amending its 2023 building code to recognize window opening control devices (WOCD) as an allowable way to meet both the requirements for egress from bedrooms and to prevent windows from opening far enough for children to fall out. Section 9.8.8.1 Required Guards of the variance reads, “...openable windows in buildings of residential occupancy shall be protected by a) a guard, or, b) a mechanism that can only be released with the use of tools or special knowledge to control the free swinging or sliding operation of the openable part of the window so as to limit any clear unobstructed opening to not more than 100 mm measured either vertically or horizontally.”

Allowable WOCD mechanisms are detailed in ASTM F2090 “Standard Specification for Window Fall Prevention Devices with Emergency Escape (Egress) Release Mechanisms.”

The variance resolves a long-standing conflict between fire-egress requirements that a bedroom window be openable to 380 millimeters and fallprotection requirements that restrict windows less than 900 millimeters off the floor from opening more than 100 millimeters. It makes Alberta the second Canadian jurisdiction after Quebec to acknowledge WOCD in code – all other provinces continue to have conflicting standards for fire egress and fall protection with no clear way to resolve them.

Quanex has announced the sudden passing of Larry Johnson.

Johnson, 66, bravely fought a two-year battle with bladder cancer, having undergone a very successful surgery to remove it. He was able to be home recovering and unforeseen complications sent him back to the hospital for additional surgeries. Unfortunately, the strain on his body was too much and he passed peacefully with his family and close friends by his side on March 22. He is survived by his wife of 25 years and glass industry veteran, Erin Johnson, and children Kori, Tolbert, Alex and Ava. He loved living on Lake Norman, golfing, a good cocktail with friends, fast cars and, most of all, his family.

“More than a colleague, Larry was my friend for over 30 years,” said Bob Daniels, president of North American Fenestration at Quanex. “There was never a shortage of laughs or people when he was around. His industry knowledge and contacts were second to none and he had a knack for this business that never ceased

to amaze me. He will be greatly missed by all who knew him and we will continue to recount our memories of him for years to come.”

Johnson joined Quanex in 2001 as the executive vicepresident for Edgetech. After Quanex acquired Edgetech in 2011, he continued to lead the sales, technical and customer service departments as the vice-president of sales for the North American Fenestration group. With 42 years’ experience in the industry, Johnson held multiple roles, starting at UltraFab as vice-president for 16 years. During his tenure, he developed several patents for various building material solutions. Later, he worked at Veka as new business development manager and was also the president of Vinyl Source, a PVC product manufacturer focused on decking and extrusions. Johnson was an active member and attendee of industry associations such as FGIA and NGA and contributed towards driving awareness and product standards. He loved working in the industry, largely due to the friends and colleagues he met along the way. Many of these relationships turned into lifelong friendships. Interestingly, Larry and Erin’s first meeting was credited to an industry trade show.

by Anton Van Dyk

The 2020 National Building Code changes that were recently introduced contained some of the most significate changes to fenestration since the introduction of NAFS about a decade ago. The two main items are the limitations applied to the Part 5 path for engineered fenestration and the relaxation of combustible frames and sashes on noncombustible construction. These might be viewed as a threat or an opportunity depending on your position in the market.

Navigating these changes may feel to some manufacturers overwhelming and complex, especially as new step/tier codes are starting to be introduced across the country. Designers are also seeking lower and lower U-values. But I want to change your perception of all of this and suggest you think of compliance as a business strategy, no different than a marketing, sales or pricing strategy.

I hear two common responses to technical changes of this kind. The first is, “NAFS is not enforced in our region so why should we do anything to prepare this time?” and the second is, “How do we convince an architect to specify our product?” What if I told you that you could prepare for enforcement as well as get architects to specify your product at the same time?

The key with this is to look at compliance as offence and defence. Setting up your product to pass enforcement is defence, but convincing architects of your product’s ability is offence. The work you put in for both and the resulting product are the exact same. Making a product that satisfies the architect will win sales and place you beyond the reach of enforcement. It’s a win/win!

Here are three of the most common variables I have experienced over my career combined into one compliance strategy.

Product approvals: Like all goods, what good is it if no one wants to buy it? In the construction industry, the product must go through many layers of approvals by third-party “influencers” – architects, building envelope consultants, general contractors, developers, government housing providers – before it can be used. Each one of these influenc-

ers will have their own unique expectations of your product that have to be met regardless of what the code says. If you cannot meet their expectations, you will have a tough time being selected.

Enforcement: For some regions and some manufacturers, it has become a strategy to comply only to the level of enforcement. However, the lack of enforcement does not give you a path into the future as enforcement tends to lag regulation. Eventually, it will catch up. Do you have a backup plan for when a building official does not pass the inspection? My recommendation for poorly enforced regions is to simply do the right thing and when enforcement comes, you are prepared.

Liability: While consulting in the U.S., I discovered a developer’s willingness to implement any kind of standard is more focused on the liability they would take versus what the code said. It is just a risk-versus-reward analysis. Maybe your product meets the code for U-value, but one component is non-thermally broken creating a risk of localized condensation. Or you might use a surface 4 low-E as opposed to triple glazing to achieve a certain U-value. That might work in Vancouver but will have issues in Edmonton. So it’s not about meeting a certain U-value anymore, it’s how you achieve that U-value and how the overall product meets a customer’s expectation.

So, what is the value of having a compliance strategy that goes beyond just code compliance? Well if you can achieve approval fast and easily, you will have a great sales and marketing strategy. If your product meets and is prepared for future enforcement expectations, you will reduce the stress of your project managers who have to deal with reacting to failed inspections, which tend to result in project delays and credits given back. And reducing liability is always a good thing when it comes to reducing your business’s operating costs.

The best defence is a good offence and a compliance strategy can be a really good form of offence.

Anton Van Dyk is a fenestration consultant at Layton Consulting.

An automated CNC processing and cutting centre is driving faster throughput and more precision fabricating at custom entrance specialist, Bigfoot Door.

To hone its competitive edge as a niche fabricator of custom, highperformance architectural aluminum windows and doors, Mississauga, Ont.,-based Bigfoot Door purchased a German-made, automated processing and cutting centre – the first of its kind to be set up in Canada.

by CARROLL MCCORMICK

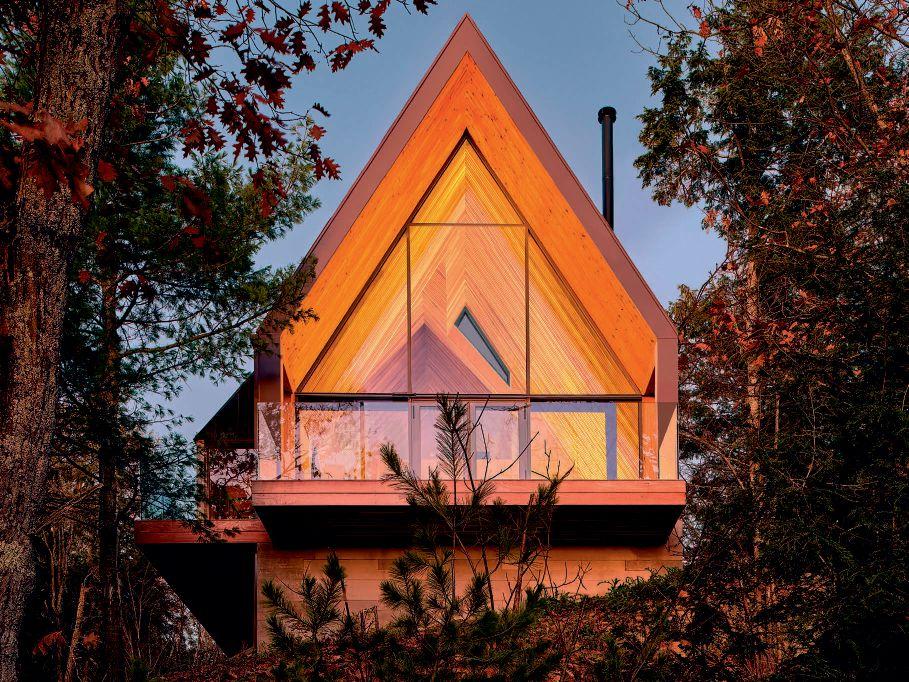

LEFT: Projects like this put the “big” in Bigfoot. The company has made curtainwall assemblies that weight over a tonne.

RIGHT: The new Schirmer cutting and processing centre can do all the cutting, milling and drilling on a profile, eliminating a long list of manual tasks.

This January, after a year-and-a-half of intensive planning and preparation, the company flipped on the switches and has been enjoying a rewarding increase in throughput.

Manufactured by Schirmer Maschinen and purchased through Mississauga-based INT Machinery, the Schirmer machine will help Bigfoot maintain its competitive edge and meet the increasing demand for its high-end products. Bigfoot has a reputation for high-quality work, but it operates in an industry where quality is sometimes sacrificed in the drive for lower prices. Competing on pricing while producing top-

notch domestically produced North Americancertified window and door systems is an everpresent challenge, explains Daniel Zigante, the president. “Over the past few years, the number of imported windows and doors that fail to meet North American standards and certifications has grown significantly. We have seen a rise in projects using them that have had significant issues. A common concern is the quality of the window and workmanship.”

Daniel’s father, Justin Zigante, launched Just Aluminum & Glass in 1980, which grew to eventually establish Bigfoot Door. A machinist by

trade, his early focus was on residential projects: aluminum windows, doors, soffits, and siding installations. Between 1986 and 1994 his three sons, Denis, Dean and Daniel, joined the company. Each brought skills and vision that added depth to the operation and a strong work ethic that Justin and his wife, Nela, who managed the office for 35 years, taught the boys. Denis brought his technical skills and Dean added his architectural and project management skills and introduced CAD technology. When Daniel, the youngest of the three, came on board in 1994, they launched a PVC window manufacturing division called Trillium Window and Door Systems.

Over the next 25 years, the operation grew from just 3,000 square feet in 1986 to its current 80,000-square-foot facility. Branching out into commercial projects, their offerings gradually came to include high-profile retail storefront glazing contracts, high-end custom residential installations and specialized aluminum fabrication. Today the company has 60 employees and is seeing “significant” growth opportunities beyond Ontario in Canada and in northern U.S. markets.

In 2012 the company founded Bigfoot Door, upping its game even further as the demand for highly specialized fenestration grew. By 2017, Daniel says, “To meet the increasing demand we decided to shut down PVC production and shift personnel and shop floor space to specialize exclusively in aluminum window and door production. “Increasing size, weight and functionality were limiting what we could offer with PVC frames.”

Higher performance requirements such as triple glazing and new thermal break technology simply outstripped the ability of PVC and fiberglass to handle the added weight in large-format windows and doors, according to Daniel. “We began to research high-performance aluminum window systems and found it better suited for the market and design demands.”

These turning points marked Bigfoot’s transformation into a purely custom manufacturer, with expertise in making huge windows and curtainwall that regularly weigh in at 500 kilograms, and occasion-

Justin and Nela Zigante established Just Aluminum and Glass in 1980 doing anything and everything in residential fenestration. Today, sons Denis, Dean and Daniel have sharpened the focus to high-end custom aluminum windows, entrances and curtainwall.

ally exceed a metric tonne.

“The systems that we offer are the highest performing and we are capable of supplying massive sizes that PVC or fiberglass just cannot achieve. Our knowledge, experience and in-house manufacturing allow us to be part of very complex projects that very few companies can execute successfully,” Daniel says.

Bigfoot specializes in new residential builds but does take on some major renovation contracts. “We are experiencing growth in replacement window and door projects. We also do commercial projects that require high performance ratings, including Passive House-certified projects,” Daniel says.

“By the mid-2000’s we were getting recognized for our work on custom residential projects. Our expertise, passion and commitment to perfection opened doors to create relationships with the best architects, designers and contractors. As modern architectural design gained in popularity, we saw growth opportunities in a very niche sector,” Daniel adds.

With new opportunities came new challenges. To meet them, the company

invested in more specialized and capable fabrication equipment, allowing it to tackle more creative design challenges and attract ever more specialized projects. “Our whole operation is now laserfocused on high-performing fenestration products,” Daniel emphasizes.

The company, which custom fabricates its windows and doors from preengineered and pre-designed products, has benefitted from a decade-long partnership with Germany-based Schuco International, a global provider of system solutions for windows, doors, and facades; Bigfoot is North America’s largest fabricator of Schuco products, according to Daniel.

And recently, he says, “We are excited to have begun a partnership with [Belgianbased] Reynaers Aluminium that brings the latest in high-performance window and door technology. These strategic partnerships allow us to offer our customers Canadian-made products that have been tested and certified in North America to meet all North American Fenestration Standards and National Fenestration Rating Council requirements that

architects and builders are demanding.”

Bigfoot’s next step, and it was a big one, was to add production equipment that would increase manufacturing precision and throughput. In mid-2022 Bigfoot purchased a Schirmer machine and set about preparing their facility for its arrival and installation in December 2023.

A year and a half certainly sounds like a generous amount of time to prepare for the addition of another piece of production gear, but this was not your average machine. “The equipment came from Germany in four closed containers and one massive 15-tonne crate. We had to rent a 30-tonne forklift to unload the central cutting station. This was a very intense procedure,” Daniel says.

“You can never prepare too much for something like this. As much time as you have to get everything ready – from purchase, to optimising a new shop layout, to installation – you are also running a business that cannot be disrupted too much,” Daniel explains.

Preparing for the arrival of the Schirmer machine necessitated tasks such as dismantling racking systems and installing new electrical and air lines. One messy task (among many, no doubt) was cutting out a 20- by 40-foot section of the concrete floor and filling the hole with a 12-inch thick, fibre-reinforced slab capable of supporting the enormous weight of the central cutting station.

Bigfoot flew a team to Germany last September to spend five days at the Schirmer plant in Verl for the commissioning of the fully assembled machine and the first round of training. Then Schirmer chased the machine back to Canada this January, where its technicians gave Bigfoot’s production technicians two weeks of on-site training on the live machine.

“We were training on live jobs, which was great, but scary at the same time. Things went as smooth as you can hope for,” Daniel says. He has nothing but praise for the INT and Schirmer teams

for making the training a success.

Maintenance procedures are being finetuned and better understood as Bigfoot gains experience on the machine. While Bigfoot equipment operators handle daily maintenance tasks, INT takes care of scheduled maintenance and troubleshooting, and maintain the spares inventory.

While the Schirmer machine presents new fabrication possibilities, its main task is to increase capacity and precision. “It has increased the output of processed bars (machined and cut) and increased the accuracy of all processes,” Daniel explains. “This end-to-end processing - cutting, milling, drilling holes – eliminates a long list of manual tasks, allowing our production teams to focus on assembly. This has had an immediate impact.

“Our whole team did a phenomenal job in preparation, training and execution throughout this whole process, and we are proud of every single effort made. This was truly a team effort.”

The Federal Plastics Registry threatens chaos as it is presently conceived.

by Amy Roberts

Recently, the federal government concluded a public consultation on the creation of a Federal Plastics Registry, which will be used to monitor and track plastic from the time it is produced to the end of its life.

The registry would require producers to report annually on the quantity and types of plastic they place on the Canadian market, how that plastic moves through the economy and how it is managed at end of life. This includes PVC and other resins involved in the manufacturing of plastics.

The government proposes to implement the Federal Plastics Registry in four phases, beginning in 2025. “Producers” are expected to submit the required information annually through an online portal. The construction sector would start reporting on the amount of plastics placed on the market in phase two, which is expected to launch in June 2026. The rest of the data reporting requirements for the construction industry will start in phase four, projected to start in June 2028.

There are many concerns with the proposed program. As it stands today, the program is simply too broad and too vague in its scope. The 2026 launch date doesn’t provide manufacturers and material importers sufficient time to comply with the proposed program. For example, windows, doors and skylights are durable products that last for decades. Most fenestration manufacturers do not yet have visibility into what happens to their products after they are sold and do not have the mechanisms in place to track products to end-of-life. Further, companies will need substantial resources and time to successfully design, test and implement traceability systems. The proposed timeline doesn’t take this into account.

There are grave concerns about the confidentiality of data that will be collected by the government. It’s not fully clear what safeguards

will be implemented to protect trade secrets and proprietary information collected from manufacturers. Additionally, there are disparities between provincial/territorial interpretations of what constitutes a “producer,” and the federal definition, which creates ambiguity and conflict, especially across jurisdictions.

It will be essential to provide specific details on the minimum reportable amount for resins. The government must also determine whether various manufacturers along the value chain (window, profile and resin, as well as specialized products like painted or laminated profiles, weatherstripping and hardware) are all required to submit reports. If everyone is expected to report, one wonders how the program will streamline reporting, verify data and avoid redundant data collection.

It’s clear the industry requires more information and clarity. Therefore, it may be more beneficial for the government to concentrate on reducing the use of single-use disposable plastics with short lifespans. A pilot program focused on a specific type of single-use plastic should be launched initially to test and perfect processes and validate the effectiveness of the regulatory frameworks under consideration.

After the regulations are finalized, it is recommended the government defer mandatory reporting requirements for a minimum of three years so that manufacturers and others in the value chain have adequate time to prepare for compliance.

In my experience, adequate time along with clear communication and collaboration with all stakeholders across the entire value chain of plastics and waste disposal must take place for a program of this magnitude to be successful.

Amy Roberts is FGIA’s director of Canadian and technical glass operations.

As far back as 2005, the practice of sealing the weather barrier of a house to the frame of the window in an effort to control moisture penetration was questioned enough to justify seven years of research at the Institute for Research in Construction of the National Research Council of Canada.

by JON EAKES

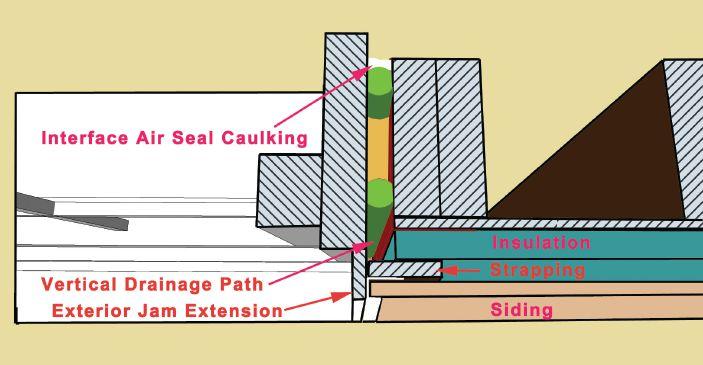

LEFT: The sill zone of the frame/wall interface is baffled but not sealed in the George Brown test, blocking the entry of rain but allowing air to pass in and out of the drainage cavity freely.

RIGHT: Baffle flashing prevented almost all windblown water from entering the cavity when pressure was equalized.

The guiding principle that came out of that detailed scientific research was, “Don’t try to stop the wind and the rain on the same plane.” Few people paid any attention and window installers all over the country continued to seal the exterior interface between the window frame and the cladding. Because any sealant eventually breaks down (even if it achieved a rare 100-percent seal in the first place) residential window installations still have water penetration problems that lead to rotten and mouldy framing and casements. Face sealing is an unforgiving practice in that any water that gets into the wall cannot get out.

Back in 2014, Joe Lstiburek of Building Science Corporation proposed designs for residential

window pressure equalized window frame profiles. Murry Frank of Constructive Home Solutions, for one, is already teaching these techniques in Vancouver. I’ve added my own wrinkles. Others are stepping forward with similar ideas. In brief, the concept rests on three changes to how we install windows. The first is to leave a small drainage path open behind the weather barrier, allowing air to exchange between the outside and the insulated window/wall cavity. The second is to ensure there are vertical drainage channels on the window frame and a drained sill, using jamb extensions if necessary. Finally, we do not air seal the frame/cladding interface on the exterior of the building but rather on the interior of

the window assembly. Water flow control with drainage layers and wind pressure equalization is a forgiving technique which continually dries out the wall. There is lots more to it – for more details visit joneakes.com or see my article in the 2018 fall edition of Fenestration Review, “A better interface.”

After presenting these ideas to several window industry conferences, I succeeded in initiating two college research projects on the use of pressure-equalized principles in the window/wall interface itself, totally independent of the presence or absence of a rainscreen behind the wall siding. The first project was with the BETAC labs of Red River College in Winnipeg, which included quantifying the thermal penalty (if any) for trading off some insulation space in the interface to allow for a pressureequalized drainage path around the window. The second project was with George Brown College in Toronto specifically on the applicability of pressure equalization in low-rise residential window installations.

After a shutdown for COVID and thanks to pretty good staff retention, the final George Brown College report on pressure equalization in the residential window/wall interface was the first to be made public in January 2024. The landing page for the George Brown College report and other related and upcoming material, including some video clips from GBC, and a link to Joe Lstiburek’s work on pressure-equalized residential window profiles, can be found on my website.

The tests revealed that, of the window installation configurations used in this study, the best performance of these principles came from an uncompromised air barrier. Water projection simply stopped when plugs were put into the Plexiglas air barrier.

Performance was also best with open drainage paths inside the

window/wall interface all around the window. This was true of all the configurations, allowing for a free flow of air and water. This allowed quick, if not instantaneous, pressurization with varying wind pressures and unrestricted flow of water to the drain. Dripping from the jam drainage paths onto the sill was seen visually to be happening only near the weather side of the installation even under strong wind conditions. With pressure equalization, there was no driving force projecting water deeper into the cavity.

The expected but counterintuitive finding was that less water came in with generous sill zone air entry. The larger the sill zone air entry, the less the water penetration.

Line-of-sight baffling was also important. There was no airborne water projection in any window section that was fully baffled, although there was controlled water penetration.

We also looked at elements that compromised this performance. Water penetration was directly proportional to the degree of compromise of the air barrier – open or closed plugs. Open sill zones with no capping allowed the wind to pick up accumulated water on the sill and throw it deep into the window/wall interface. The fully capped window avoided this but required significant spacing where the capping overlapped the wall below the window for quick air flow in…more space than is necessary to let water drain out. We noted it does not take much air flow to pressurize the relatively small drainage paths.

The line-of-sight opening on window #3 was a water-control failure, but a simple unsealed baffle over the crack was a success.

George Brown College kept to the challenge and demonstrated that letting wind into the sill area and up into vertical drainage paths did counteract the driving force of the wind and prevented deep penetration of wind-driven rain. This was a small “proof of concept” study but one that clears the way for a more quantified study.

At the time of the final report, BETAC at Red River College had not yet published their findings on thermal penalties for leaving out insulation to create the window/wall interface drainage path. In March the BETAC report confirmed with data that insulating the interface cavity had little incidence on thermal losses. This gives us free reign to optimize the size of the drainage path for water flow control.

I was surprised and discouraged with what was reported in the BETAC study, although it did have one good piece of information on thermal losses. Otherwise, it appears the researchers decided not to pursue my line of inquiry into pressure-equalized window installation at all and instead made sure their experiments were relevant to the current practice of face-sealed installations in Manitoba. I only learned about this change in direction while watching the Fenestration Canada webinar on their final report.

For the thermal loss question, I had proposed comparing insulating the interface from the inside face of the window up to the glazing plane, compared to full insulation and no insulation at all. The intention was to make way for working on water control with a window/wall interface drainage path. The idea of testing thermal

Here’s the simplified concept: use backer rod to create a small space around the window and seal only the inside interface.

losses when the interface is not completely insulated was apparently the only part that stuck as the objective of their project. They devised a model of fully insulating the bottom half of a window and having no insulation in the top half that eliminated any presence of a drainage plane.

The one important result of BETAC’s study was providing quantified data confirming that there was hardly any influence on the thermal performance of the window when comparing a foam-filled window/ wall interface cavity to a totally empty cavity. They didn’t test insulating just up to the window glazing plane, which would have even less influence on the thermal performance of the assembly than the minor penalty from no insulation. Their results corroborate the comment by one participant in the Fenestration Canada webinar that the studs and the window frame itself have much more to do with thermal losses than the dead air space of the window/ wall interface, as was predicted by the IRC research over 15 years ago. In the same portion of their research, BETAC also concluded that faults in the air barrier compromised everything. These two findings confirmed that the George Brown College pressure equalization study was valid even though no insulation was used at all. It corroborated the GBC conclusions as to the need for an impeccable air barrier.

Perhaps most disappointingly, the BETAC researchers seem to have dismissed out of hand the pressure-equalization

concept without studying it. In presenting their results in a Fenestration Canada webinar, they themselves posed the question: “Is it possible to permanently seal water out of a window/wall interface?” Their answer: “When a window is tested for water leakage, the window is facesealed against water leakage with correct installation of the membrane. A properly face-sealed out-of-the-wall window will function. Water leaks will result from either a deficient window manufacturer or installation. But [with] correct design and simple detailing including effective quality controls in place, [it] can be achieved.”

This answer was speculation based on short-term research to answer a longterm question. What became evident in the webinar was that they simply didn’t believe in drainage planes or pressure equalization and chose to make sure that this research would not challenge the status quo of surface-sealing window installations. They did, however, answer an important question by documenting that there was no significant thermal penalty when leaving some interface space uninsulated to allow for the creation of a windpressurized water control drainage plane.

Research should dare to study promising alternatives to lead the way to improvements in building science. I am certain that BETAC at Red River College, with their impressive technical equipment, does an excellent job of testing to standard protocols. However, we are going to have to look

elsewhere if we are looking for research leading to innovations in building technology. For me, this BETAC research project was a lost opportunity that delayed me for several years from initiating the research elsewhere that I feel needs to be done.

The building codes and standards provide for many possibilities in installing windows, although they are moving toward better water control than simple face sealing because, with face sealing, when water does get in it has no way out. The National Building Code already requires provisions for drainage and is proposing in the next cycle, full internal wrapping of the rough window opening. Both the next NBC and the CSA A440.4 to .5 are looking at removing insulation in favor of drainage. Organizations familiar with Ontario’s code process are saying the province is likely to pick up on all of this. Already, both codes and standards permit everything I had proposed in this research. So adapting pressure equalization to low-rise wood frame housing is simply the missing piece to make this drainage plane into a dynamic water control system. Since it is coming, we might as well study how to apply these ideas before they are forced upon us.

We still have much to do to quantify all of this with the objective of helping manufacturers, installers and inspectors to move from theory to practice with confidence, away from face-sealing to using the wind to control the rain. The George Brown College research tells us this is possible.

George Brown College and Red River College (BETAC) final reports webinars fenestrationcanada.ca/videos

Links to the above and more at joneakes.com

by Laine Atkins

Fenestration Canada will welcome the industry to the Kananaskis Mountain Lodge in Alberta for this year’s Spring Conference, May 28 to 31. Our Spring Conference is an event not to be missed, including quality and informative education sessions; the President’s Dinner; a Suppliers Showcase; offsite events and the Extended Experience.

Our Suppliers Showcase will take place during the conference where attendees can interact with different suppliers to discuss products and services. We have taken attendee feedback and have added in more time for these conversations.

This year’s education content will include the Farnsworth Group who will speak on the Fenestration Canada Canadian Fenestration Market Study. Brad Farnsworth will be presenting a sneak peek at the results from the Market Study project as well as present and discuss current Canadian economic fundamentals. This survey will be available for members in both English and French and will be an important piece of documentation for the Canadian fenestration industry.

Terry Adamson, Fenestration Canada technical director, will lead an update session on technical activities from this past year. Topics will include VOC regulations, the Canadian Plastics Registry, the Fenestration Canada installer training program, operable guards changes and more.

Jacob Carter, director of government affairs with the U.S. Window and Door Manufacturers Association, will be presenting U.S. regulations on PFAS (per- and poly-fluoroalkyl substances) with a peek at how Canada is responding north of the border.

Adam Buist from Natural Resources Canada will provide an update on their activities regarding the Canadian fenestration industry.

The update will include a review of recent projects as well as a look into what the future holds for fenestration performance criteria.

A full list of our education sessions can be found on our website at fenestrationcanada.ca/spring24.

As well as our education lineup, we have some great events planned for attendees including our President’s Dinner which kicks off the conference on the 28th. This evening honours the recipient of our prestigious President’s Award and provides some great networking opportunities.

On May 29, guests should get ready for an evening at Boundary Ranch. Ideally located in the spectacular natural beauty of Kananaskis Valley, Boundary Ranch is the perfect setting to discover the authentic cowboy experience and Western hospitality. The evening will include ranch games, horse-drawn carriage rides, a barbeque dinner and a local band to dance the night away!

On May 31 we welcome those who are staying for the Extended Experience to join us at the Kananaskis Country Golf Club including 18 holes on this scenic course. The day includes transportation to and from the course, a buffet breakfast, 18 holes of golf on an amazing course in the mountains and a barbeque steak dinner.

And for those who prefer not to golf, we have arranged a day at the spa at Kananaskis Mountain lodge’s Nordic spa. This option includes Nordic Spa access, a lunch voucher and then transportation to meet the group at the golf course for dinner.

We invite you to view the schedule for more information and to register online at fenestrationcanada.ca/spring24.

Laine Atkins is operations manager for Fenestration Canada..

BONNECHERE VALLEY WINDOWS & DOORS

2824 Fourth Chute Rd Eganville, ON, K0J 1T0

Tel: (613) 628-3056

Contact: Shane Charania

Email: shane@bvwd.ca bvwd.ca/

BOTON ALUMINUM CO. LTD.

Contact: Renbin Peng

Email: botonalum@gmail.com

BOTTERO FLAT GLASS INC.

257 Gretas Way, Suite 100 Kernersville, NC, 27284

Tel: (336) 992-5623

Contact: Grant Mason

Email: grant.mason@bottero.com www.bottero.com/

BROWN WINDOW CORPORATION

185 Snow Boulevard Concord, ON, L4K 4N9

Tel: (905) 738-6045

Contact: Pino Marinelli

Email: pinom@brownwindow.com www.brownwindow.com/

BSM CONSTRUCTION SALES INC.

Tel: (905) 803-0366

Contact: Mike Murphy

Email: mike@bsmconstruction.com

BVGLAZING SYSTEMS

Tel: (905) 738-8600

Contact: Andrew Bates

Email: info@bvglazing.com

CAD-PLAN

Frankfurt, Germany

Tel: +496980081897

Contact: Jan Krutsky

Email: krutsky@cad-plan.com

CAL-TECH GLASS SERVICES LTD.

4450 104 Avenue SE Calgary, AB, T2C 1R7

Tel: (403) 250-5726

Contact: Jim Brady

Email: jim@cal-techglass.com

CAN-BEST TESTING LABORATORIES

38 Regan Road, Unit 4 Brampton, ON, L7A 1C6 Tel: (905) 840-2014

Contact: Elie Alkhoury

Email: elie@can-best.com www.can-best.com/

CANADIAN VINYLTEK WINDOWS

587 Ebury Place Delta, BC, V3M 6M8

Tel: (604) 540-0029

Contact: Steve Finlayson

Email: steve@vinyltek.com www.vinyltek.com/#hgtv-michael-buble

CANPLEX LTÉE

3320 rue marconi Mascouche, QC, J7K 3W6

Tel: (514) 730-4120

Contact: Marco Stoccchero

Email: marcos@canplexextrusions.com www.canplexextrusions.com

CAPACITY ENGINEERING LTD.

2D - 220 Terence Matthews Crescent Ottawa, ON, K2M 0E2

Tel: (613) 325-7735

Contact: Svitlana Sinitski

Email: admin@celottawa.ca www.celottawa.ca/

CAPITAL REGION SERVICE COMMISSION

860 Prospect Street Fredericton, NB, E3B 2T8

Tel: (506) 453-2956

Contact: Thomas Harding

Email: tharding@capitalrsc.ca www.rsc11.ca/planning/

CARDINAL GLASS INDUSTRIES

534 Wasaga Crescent Waterloo, ON, N2V 2Y8

Tel: (519) 590-3194

Contact: Mike McAndrew

Email: mmcandre@cardinalcorp.com

CARDINAL GLASS INDUSTRIES

Tel: (905) 738-9400

Contact: Marilyn Moore

Email: marilyn.moore@agc.com

CARTONS CORRUGUARD

101 Des Ateliers Lavaltrie, QC, J5T 3R3

Tel: (450) 586- 0666

Contact: Marie-Helene Hotte

Email: mhhotte@cartonscorruguard.com www.cartonscorruguard.com/

CASCADIA WINDOWS

Contact: Amber Mengede

Email: amengede@cascadiawindows.com

CENTENNIAL WINDOWS & DOORS

687 Sovereign Rd London, ON, N5V 4K8

Tel: (519) 451-0508

Contact: Lindsay McGhie

Email: lindsay.mcghie@centennialwindows.com www.centennialwindows.com

CENTRA WINDOWS

Tel: (604) 882-5010

Contact: Jeff Clarke

Email: jclarke@centra.ca

CENTRAL VALLEY GLASS

977 Laurel Avenue Kelowna, BC, V1Y 7G4

Tel: (250) 860-0571

Contact: Joseph Clohessy

Email: joseph.clohessy@cvglass.ca

CHINOOK GLASS AND SCREEN LTD.

321-16 Ave NW Calgary, AB, T2M 0H9

Tel: (403) 277-2456

Contact: Poppy Nissen

Email: pnissen@chinookglass.com

CITY OF NANAIMO

411 Dunsmuir Street Nanaimo, BC, V9R 0E4

Tel: (250) 755-4429

Contact: Matt McMaster

Email: Matt.McMaster@nanaimo.ca

CITY OF RICHMOND

6911 No. 3 Road Richmond, BC, V6Y 2C1

Tel: (604) 276-4113

Contact: Shilin Sun

Email: SSun@richmond.ca

CITY OF VANCOUVER

BC,

Contact: Brad Marsh

Email: brad.marsh@vancouver.ca

CLEAN-CUT GLASS SUPPLY INC.

2777 Steeles Ave. W., North York, ON, M3J 3K5

Tel: (647) 561-1951

Contact: Neptune Guillermo

Email: neptune@clean-cutglass.com

CLEARVIEW INDUSTRIES LTD.

45 Fenmar Dr. Toronto, ON, M9L 1M1

Tel: (416) 745-6666

Contact: Tom Marsala

Email: tmarsala@clearview.on.ca clearview.on.ca/

COMPETITION GLASS COMPANY LTD.

1850 Springfield Rd Kelowna, BC, V1Y 5V6

Tel: (250) 860-7155

Contact: Invoicing Accounts Payable

Email: invoice@compglass.com compglass.com/

COMPONEX

10 Westcreek Drive, Unit 15 Woodbridge, ON, L4L 9R5

Tel: 647-367-0006

Contact: Maxim Zolotarev

Email: info@componex.ca www.componex.ca

CONSTRUCTIVE HOME SOLUTIONS INC.

DBA BUILDING IT RIGHT

1039 Parana Drive Port Coquitlam, BC, V3C 6P8

Tel: (604) 464-0596

Contact: Murray Frank

Email: murray@buildingitright.com buildingitright.com/index.html

CONTINENTAL / KONRAD HORNSCHUCH AG

Salinenstrasse 1 Weissbach, Germany 74679

Tel: (540) 550-4596

Contact: Marco Patermann

Email: marco.patermann@marcorp.global www.skai.com/en/exterior/

CORNERSTONE BUILDING BRANDS

7140-40th Street S.E. Calgary, AB, T2C 2B6

Tel: (403) 863-0473

Contact: Dave Goldsmith

Email: Dave.Goldsmith@cornerstone-bb.com www.cornerstonebuildingbrands.com/

COSSINS WINDOWS LTD.

2908-19th Street NE Calgary, AB, T2E 7B1

Tel: (403) 291-3960

Contact: Brad Cossins Email: brad@cossins.com cossinswindowsanddoors.com/

CSA GROUP TESTING & CERTIFICATION INC (CSA GROUP)

CCIC-CSA International Certification Co., Ltd, No. 10, Ke Yan Road Science Park Guangzhou, China 510663

Tel: (866) 797-4272

Contact: Mohamadou Diallo

Email: mohamadou.diallo@csagroup.org www.csagroup.org

DAN DARCY & ASSOCIATES INC.

46 Diana Grace Avenue Dartmouth, NS, B2W 6A2

Tel: (902) 462-6114

Contact: Dan Darcy

Email: dan@darcyasscs.ca

DASHWOOD INDUSTRIES INC.

28648 Centre Rd Strathroy, ON, N7G 3H6

Tel: (519) 228-6624

Contact: Dennis Foran

Email: dennis.foran@dashwood.com www.dashwood.com/