Labor-Saving

Grove Shims has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Looking for the right shim?

Grove Shims has the per fect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for per fect allignment. No guesswork or realigning. Our shims save you time and money.

Need help? Just ask! We’re here to help. 978-534-5188

Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com

Free Samples are Available Upon Request.

Grove Shims is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Fenestration Review 2019 Vol. 8 • Issue 1

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

ACCOUNT

COORDINATOR | Stephanie DEFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

CIRCULATION MANAGER | Urszula GRZYB ugrzyb@annexbusinessmeda.com 416.442.5600 ext. 3537

MEDIA DESIGNER | Alison KEBA

GROUP PUBLISHER | Martin MCANULTY mmcanulty@annexbusinessmedia.com

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 email: subscribe@glasscanadamag.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

email: asingh@annexbusinessmedia.com Tel: 416.510.5189

Fax: 416.510.6875 or 416.442.2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $22.00 (plus applicable taxes)

U.S.A. - 1 Year $39.00 (in US dollars)

Foreign – 1 Year $44.50

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com Tel: 800.668.2374

Occasionally, Fenestration Review will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.fenestrationreview.com

CANADA’S WINDOW AND DOOR MAGAZINE

4

EDITORIAL

The possibilities of AI in manufacturing are mindbending. 9 PHILIBUSTER

Veteran window pro Phil Lewin weighs in on NRCan’s Roadmap. 10 MANUFACTURING VISION

19 SPRING HARDWARE SHOWCASE

Canadian manufacturers are finding ways to beat our toughest conditions.

Our look at Montreal’s Portes et fenêtres Président. FIT & FINISH

Lean can become an obsession, but in a good way. By Chris Meiorin

What’s new, what’s cool in window and door hardware technology. 20 FENESTRATION CANADA

Your association is going forward with a new look and new blood. By Jennifer Small

21 FENESTRATION CANADA 2019 MEMBERS DIRECTORY

THAT’S RICH Automation is for more than just the shop floor. By Rich Porayko

Automate or die

by Patrick Flannery

Technology may soon transform our lives and our businesses – again.

Did you watch Black Mirror on Netflix? God, I loved that series. I’ve always been a total nerd for science fiction and those episodes were the finest example of the genre since Twilight Zone. Science fiction in its purest form is about taking one advancement in science or technology and imagining what the effects will be on a future society, or maybe just one person. Black Mirror nails that – most of the episodes are about the ramifications of just one technology: brain implants that allow people to interface with computers directly. From that one idea you get the possibility of people recording and displaying their memories on screens; carrying the personalities of other people around in their heads (or in stuffed animals); or overlaying virtual reality to convince soldiers their enemies are monsters or children that there’s no evil in the world or criminals that they are in an elaborate torture scenario. But one Black Mirror episode deals obliquely with artificial intelligence and how society might look in decades to come when machines become better at just about anything we can do.

Essentially, the show depicts a world where there are only two jobs left: riding a stationary bike to produce electricity (to power the machines that do everything else) and being a contestant in a reality talent show. People ride bikes all day every day hoping to one day be selected to appear on the show. In between they live in tiny bachelor apartments where every night they are forced to…you guessed it…watch the show. There’s no money, only merit points for doing what the system wants and demerit points for “bad” behaviour (like not watching the show). Far-fetched? Sure. But it follows the ideas of a lot of serious thinkers who wonder what the end point is for our economy in a world where AI and robotics are quickly approaching human capabilities in unexpected areas. Take a look around your shop. Any of

the physical tasks happening are within the capabilities of machines using existing technology. What your workers have that machines do not is the ability to understand the job they are doing and the flexibility to adapt to changing and variable conditions to achieve it. So it’s their brains, not their bodies that are valuable to your process.

A while ago I was at a magazine conference and the presenter passed around a corporate press release that had been written by a software program. It was indistinguishable from one I might receive from a human writer. Admittedly, writing press releases is a low bar but it showed that technology has advanced to the point where at least some functions formerly considered the sole domain of a human mind can be achieved by artificial intelligence.

If an AI can be taught to understand window and door manufacturing and linked to machinery and robotics optimized for the task, where does that leave human workers? And if an AI can be taught to understand logistics and production planning, where does that leave the manager? If it can learn the principles of window design, what is left for an engineer to do?

And if AI and robotics take jobs away from some appreciable percentage of the population, who is going buy windows and doors?

The world faced a lot of these questions 200 years ago in the first industrial revolution and a lot of people find optimism in the fact that people were able to adapt and civilization did not collapse. Indeed, new jobs were created in fields that no one could have imagined even existing at the time, such as software engineers. It’s probably impossible to know if something similar could take place in a world where AI is better at everything. But regardless, I think the future belongs to those of us who get very familiar with automation, adopt it early and position ourselves to be the beneficiaries rather than the victims.

White Oaks Resort and Spa

Niagara-on-the-Lake, On.

INDUSTRY NEWS

Fenestration Canada reacts and rebrands

Fenestration Canada has responded to Natural Resources Canada’s Roadmap discussion paper on future window and door code requirements and energy regulation. In a document authored by FenCan technical consultant, Jeff Baker, the association has laid out its position on several issues that will influence policy going forward. In the response, FenCan expresses its concern that any federal regulation needs to align with provincial codes, laws and regulations or else risk setting up barriers to trade in window and door products across provincial borders and internationally. It also points out that the final

stage outlined in the Roadmap calling for 0.8 U-value/ ER40 performance by 2030, cannot be achieved with proven technology. For skylights and sliding glass doors, even Tier 2 proposed standards may be unachievable or at best impractical.

In other Fenestration Canada news, the association has announced a major rebranding to reflect the association’s mission of serving and supporting all fenestration industry stakeholders across Canada. The rebranding includes a top-to-bottom redesign of the association’s website, which will be unveiled in the coming weeks along with new logos, graphics and communication assets. Fenestration Canada’s new brand assets include a simplified red maple leaf logo (see photo) with an outline of a door and a window.

B.C. lays out steps to tighter energy standards

B.C. has announced its timeline for sequential code tightening that will require new buildings in the province to meet higher levels of energy efficiency in its Building Energy Step Code. As of 2022 builders will need to meet the performance requirements of Step Three for Part Nine buildings and Step Two for Part Three buildings to come within 20 per cent of net zero performance. Five years after that, the requirements will increase again to 40 per cent, then again in 2032 to 80 per cent. CleanBC has also specified that new standards for building retrofits will be developed by 2024, guided by the model National Energy Code. B.C. is also exploring an energy rating requirement for homes and buildings across the province intended to make it easier for buyers and renters to factor energy costs into their decisions

Code help at AAMA

while giving owners another incentive to make their buildings more efficient. An incentive program, the EfficiencyBC program, is planned to assist the transition. It will include targeted low-interest financing for energy-efficiency home upgrades; specialized support for small businesses and rental housing; specialized support for Indigenous and non-Indigenous communities; and high-efficiency equipment incentives for new construction. The province will also offer new incentives for builders, developers and manufacturers to stimulate the development and demonstration of low-carbon building solutions, with funds available for research (vacuum insulating glass is mentioned), commercialization of experimental technology and demonstration of ready technology that does not have wide market acceptance.

The American Architectural Manufacturers Association has announced the hiring of Kathy Krafka Harkema as its codes and regulatory affairs manager.

“Kathy has contributed to the fenestration industry for many years and has had an accomplished career in marketing and communications, including earning the AAMA Marketing Distinguished Service Award in 2011,” said Steven Saffell, AAMA technical manager. “We believe her strong strategic communication and research skills and decades of proven work experience will be a winning combination for AAMA.”

Krafka Harkema will oversee the efforts of AAMA code consultants in addition to her primary responsibility of helping the organization better understand the impact of the various code and regulatory agencies on the fenestration industry. Krafka Harkema will serve as a staff liaison for a number of AAMA code and regulatory groups and will lead member activities to facilitate the development of consensus AAMA positions on key issues. She will also develop AAMA social media posts, industry media articles and columns based on the overall scope of codes and regulatory work.

Kathy Krafka Harkema

SAWDAC

SAWDAC AND SOCIAL MEDIA

SAWDAC is happy to introduce our new employee, Sabrina Amaral, who started with us last year. Sabrina has been a great asset to the SAWDAC team. Sabrina takes care of the Window Wise program and our social media accounts. She is sending out daily updates and articles that we find would be helpful to our members and consumers. Don’t forget to follow us on Facebook, Twitter (@SAWDAC2) and on Instagram (#sawdacwindowwise).

SAWDAC BENEFITS

SAWDAC is continuously adding new member benefits. For more information on these benefits, such as RenoPlan, insurance discounts, cellphone discounts, RenoWorks software, inspections and more, reach out to our office.

SAWDAC BOARD OF DIRECTORS:

The SAWDAC board of directors met four times last year. The feeling at each meeting was positive on the direction the association is heading. There have been some changes to the board in the last year, with some directors retiring. If you’d like to sit on the board of directors, or would like to nominate a person, please contact our association.

2019 INDUSTRY PREDICTION

The industry looks to continue its employment growth in 2019, with 79 per cent of dealers reporting they plan to hire in the new year. Some dealers cited a lack of budget or a lack of qualified candidates as reasons they would not look to hire this year. The top three categories where dealers plan to add jobs in 2019 are installation, sales and management.

TRAINING

SAWDAC/Window Wise continues to offer Window Wise/SAWDAC Fenestration Installation Technician installation training. Check our website for upcoming dates.

WINDOW WISE

Window Wise is a quality assurance program for replacement windows. Homeowners who buy replacement windows from a Window Wise-certified contractor know that they’re getting a quality window, properly installed. Window Wise-certified contractors are the best in the industry because their products and workmanship are inspected and certified.

Window Wise has seen a large increase in window registrations. The Window Wise system is one that consumers are demanding to resist the race to the bottom on price. Consumers know there is always a cheaper price to be had out there but what they want is reassurance of quality and value.

Window Wise is for manufacturers, too! Here are some reasons why fabricators

should join:

Service call reduction

The majority of complaints from consumers are the result of faulty installation. Manufacturers will see a drop in service calls when their installation teams are trained by Window Wise

Increased demand

Window Wise means higher quality and customers know it

Increase in associated product sales

More installations can lead to more sales

Networking

Be part of a high-quality group of industry-leading dealers

Stop missing out

Seventy-five per cent of the traffic on our Window Wise website is consumers looking for an approved manufacturer

RENOPLAN FINANCING

RenoPlan continues to grow.

The approval ratios from Home Trust are approximately 96 per cent. The online portal makes it simple for members to submit applications for approval. The amount of dealers using the RenoPlan program has grown 12 per cent in the last year.

Tony Ferreira of Royal got into the putt-off at last fall’s golf tournament but came up just short to Greg Gordaneer of Home Trust.

INDUSTRY NEWS

Report from Fenestration West

Fenestration Review’s Rich Porayko attended the Fenestration Association of B.C.’s Fenestration West conference last fall and sent the following report.

Plygem’s Dave Goldsmith told the audience that some architects in B.C. are now specifying sash restrictions that are compliant with ASTM F2090 “Window Fall Prevention Devices” with emergency escape-release mechanisms. “This is applicable in the U.S.,” Goldsmith said. “From Canada’s Part 9 of the NBC, each bedroom should have at least one outside window operable from the inside without the use of keys, tools or special knowledge without the removal of sashes or hardware.”

Code talker Anton Van Dyk from Centra Windows highlighted the quandary about climb-ability. “The step, that’s a guard rule, that’s not a window rule,” he said. “That lives in the guardrail section of the code. The code interpretation says to apply guard loads to windows. So the issue is, does the climb-ability aspect of a guard load come into play with the window? My

La belle expo

Privately, many wondered how WinDoor’s first edition in Quebec City would be received. Would the added distance from the big centres of Toronto and Montreal depress attendance? With over 750 window and door industry folk walking the show floor on the first day alone, the answer turned out to be a resounding “No.”

Organizers and exhibitors were pleasantly suprised at the robust turnout that included many new faces not always seen at the show’s traditional venues. “Everyone is stoked,” new Fenestration Canada executive director, Stephane Labelle, said of the show. “We’ve had 750 people through here already and that’s a crazy number if you look at past years. People are signing contracts on the floor. Three years ago people were thinking we can’t do anything with this and now people are really happy and expectations are higher as a result.”

“It’s been great,” said Jennifer Small of Screenco, FenCan president. “There’s a good buzz on the floor and everybody has given me really positive feedback. They love the venue, they love the location. All the feedback from the exhibitors has been great.”

Another experiment that appears to have been successful

interpretation is no. The City of Richmond interpretation is yes. What that means is that all the windows in the City of Richmond require four-inch restrictors. In a Part 3 townhouse complex that is unsprinklered, if you put four-inch restrictors in all the windows, now you have an egress problem. So what do you do? You have to now go and say, ‘Okay all the buildings need to be sprinklered in order to solve this problem.’” Van Dyk provided an example that if you’re providing a building envelope retrofit on building from the 1980s that has a sill height of 36 inches from the finished floor and now you want to bring that window up to code, if you keep the sill height at 36 inches you need to put a fourinch restrictor on it. “But it’s a bedroom window, and it needs an egress point,” said Van Dyk. “So how do you get egress and fall protection at the same time? You physically cannot solve this problem unless you hire a code consultant who’s going to tell you what to do. There’s a huge conflict by just applying the simple term, ‘guards’ to windows. I don’t know how many windows out there are compliant to this.”

Layton Consulting’s Edward Lau told attendees Vancouver’s Flexibility Provision allows for products that don’t meet a 1.4 U-value. “You have to do an average overall value of your whole project which is based on the area-weighted average method,” he said.

is WinDoor’s inaugural offering of education and exhibits aimed at the commerical market. According to Labelle, 18 exhibitors brought offerings to the show of interest to the architectural glass market. The education sessions on nanotechnology glass treatment, fire-rated glazing and balustrade standards were well-attended and attracted many questions and comments for the presenters.

The real star of the show, however, was Quebec City itself. The opening night bus tour of the historic areas around the scenic downtown drew excited comment over the European look and feel of the city with its narrow streets lined with 400-year-old buildings (well, those that hadn’t burned down at some point in the past) populated with an endless variety of small shops, bistros and bars. Clearly, Quebeckers love to go out. Wrapped in a snowy blanket and twinkling with Christmas lights, Quebec was just lovely to look at. The Monday evening event leveraged this to good effect by hosting a reception in the Chappelle, a beautiful deconsecrated church featuring stained glass, towering cathedral ceilings and an impressive backdrop to the altar. The window and door industry has never felt so classy.

WinDoor 2019 is scheduled for Nov. 20 to 21 at the International Centre in Mississauga, Ont. Mike Bruno of Everlast has already almost sold out the evening Main Event gala.

Roadmap to a dead end?

The problem is real, but some of the solutions are not.

by Phil Lewin

Ibelieve climate change driven by human activities is real and is well past the crisis point. The problem is, the solutions being discussed for the window industry will fail. They say windows account for 35 per cent of energy use in residential homes. So we can agree that it is a critical area where more needs to be accomplished. Raising the bar on U-values in particular is a reasonable goal. They say the technology exists in the lab at this time and will be ready within a decade or so. So that’s the implementation period for the extreme prescriptive requirements NRCan lays out in its roadmap.

Here are some factors that they may not be considering or even be aware of because, in my experience, they do a great job consulting engineers, consultants, lab personnel and government employees and a lousy job actually talking to industry. I have personally attended two large meetings where, of approximately 60 attendees, 57 were from the first group and three were actually from the window and door industry.

As far as I can tell, there are two technologies that may be considered to meet the extreme requirements NRCan has specified. Let’s start with triple- and even quad-glass windows. Let’s start with the reality that even now, where most sealed units are still doubles, requiring up to 50 per cent more float glass creates a problem. The glass is not available in the quantity required. Could more float glass factories be constructed? Sure, but who is paying for it and who is shouldering the risk that the extreme requirements go the way of the dodo bird after a federal election? Entrepreneurs are actually quite risk-adverse and without government participation and guarantees, supply will be a problem.

What about low-E? To get the required ratings, a triple unit would require three coatings of low-E. As one participant put it at the meeting last January, “So, we’re going to be selling windows with sunglasses?” Maybe we will be, but homeowners will not be pleased. To what

extent will they rebel at the ballot box if this is forced down their throats?

The cost of these triple units will also be hard for homeowners to swallow. A lot of triple was sold this year in Ontario, but that was primarily due to the GreenON rebate and these units did not require a third low-E coating.

Here is another factor that may anger homeowners: triple units are not as durable as double sealed units. Why? Simply, there is twice the length of seal, so there is more room for a serious defect or weakness. The extra weight may put more pressure on the unit to shear and lose seal if not properly glazed. (Of course, we want to say that every unit is properly glazed, but….) Homeowners won’t be happy even if they only have to cover the installation costs of replacement units under warranty.

So is there an alternative? Yes, Virginia there is a life-saving technology in the lab, waiting to burst on the scene and save the world. It is the much-awaited vacuum sealed unit. I have an extremely reliable industry contact who has whispered to me that he has solved the edge seal problem. This individual has tremendous credibility and a track record, so there is hope. I’ll let the individual make the product public when it’s ready for prime time.

The question is who will take the long-term liability for a new product in the field. Any of you remember getting burned by swiggle seal in our climate? (Just asking!) Without a decent timeframe to prove success in the field, I do not expect industry to take the liability. Will government step up to the plate?

If government only changes the code, Houston, we have a problem. Rebates will only exacerbate the industry issues. What we will need are public/private partnerships to add capacity for float glass in Canada. Government could even sell warranties for vacuum units.

I’m all in favour of saving the planet. I have kids. I want to live in a modern world and not a returned Stone Age. But let’s be careful out there, people!

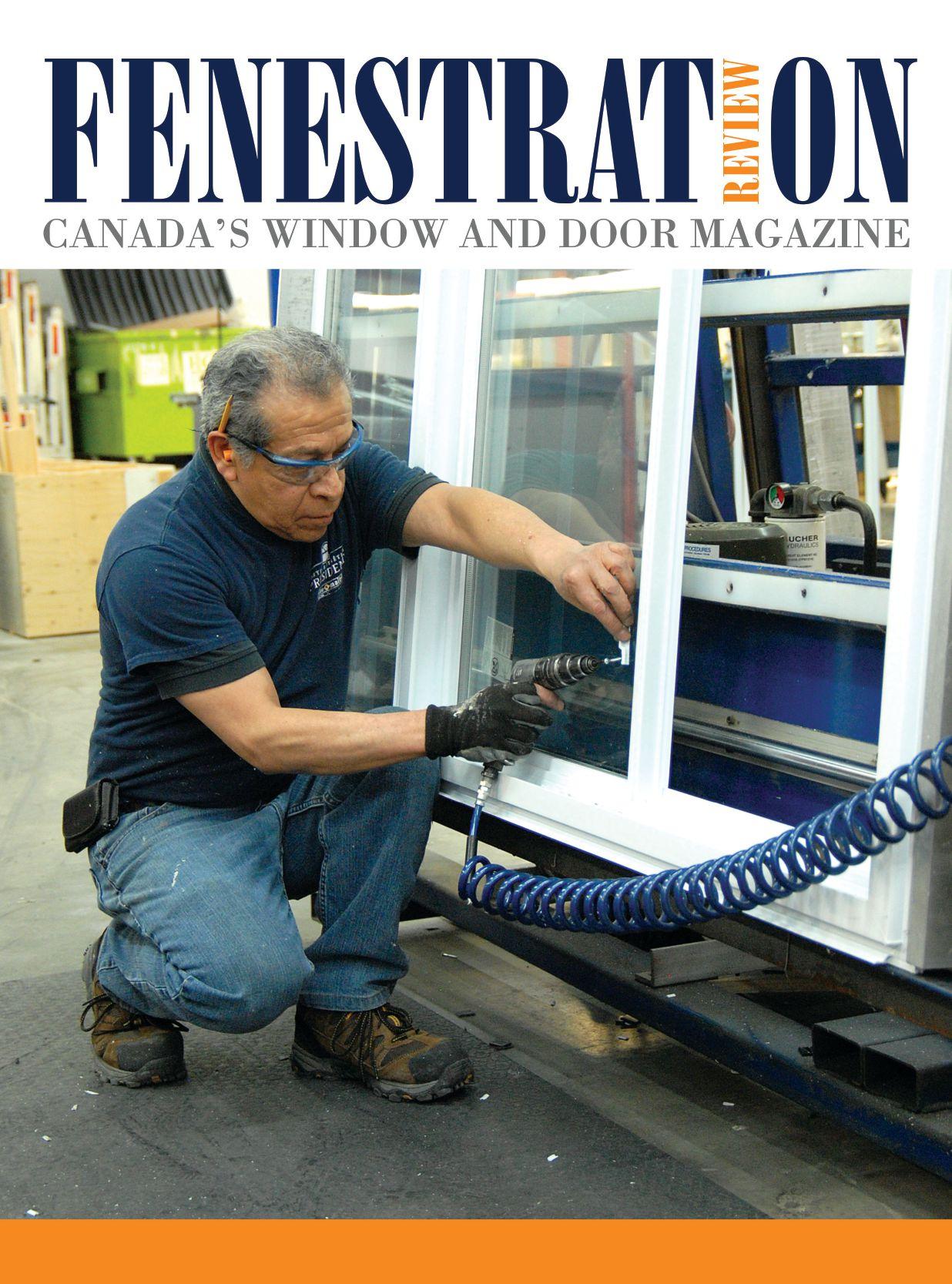

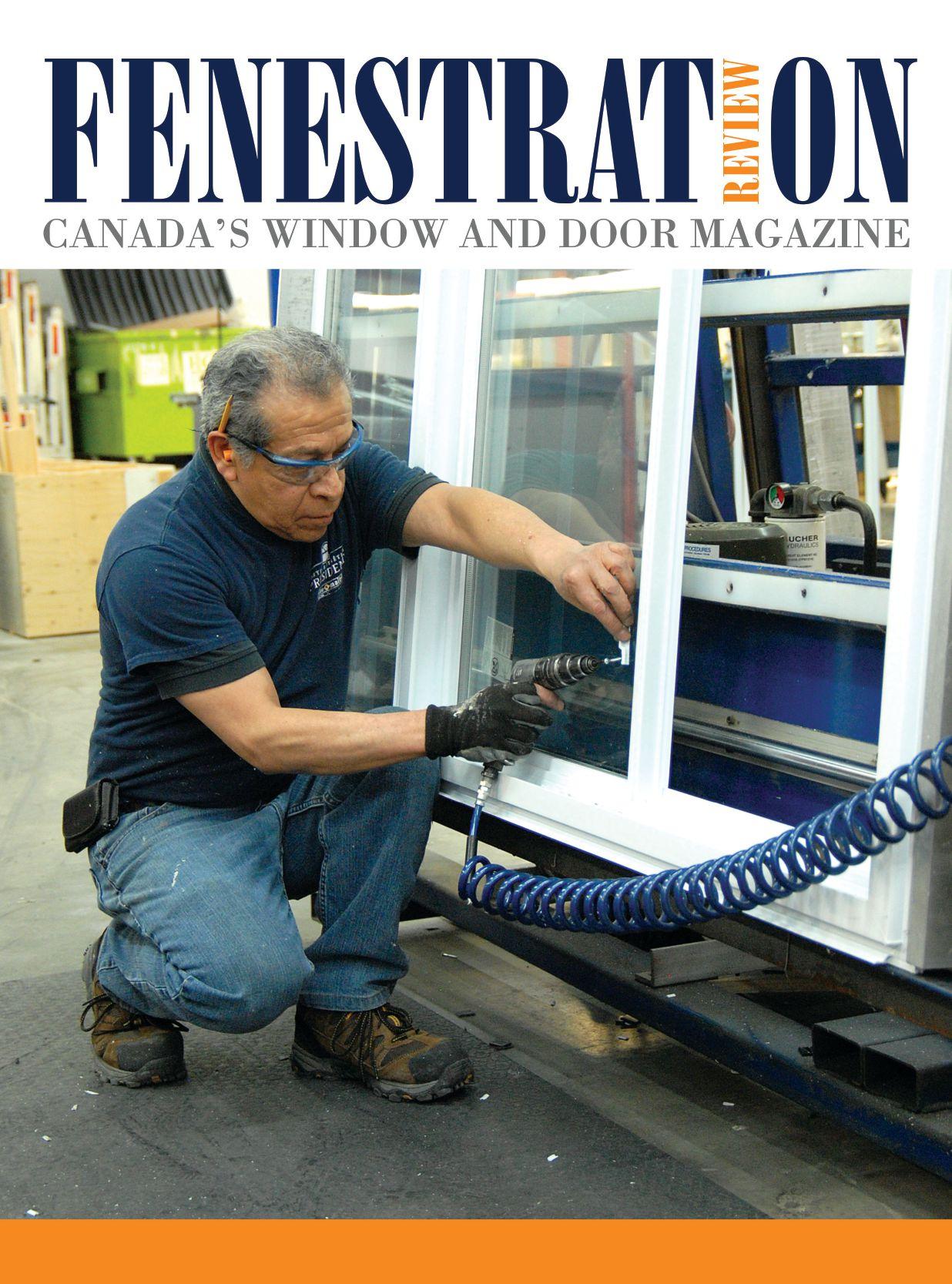

COVER STORY

SUCCESS WITH STYLE

A new generation takes the reins at Président.

With the transfer last fall of Portes et fenêtres Président by founders Christiane Parent and Yvan Houle, the new owners - their two children and an entrepreneur - see growth opportunities and regulatory challenges ahead.

by CARROLL MCCORMICK

It is near the end of the work day at Portes et fenêtres Président, located on Montreal’s South Shore, in the industrial park framed by Highway 132 and Autoroute-20. An automated welder rotates a large window frame and a router trims away excess PVC. Staff, surrounded by work tables, dust collectors, jigs and bins of stock, cut PVC-wrapped wood pieces to length, attach hardware and install window screens. The production area, increased by 11,000 square feet three years ago, is spacious and quiet. It gets much busier when all hands are on deck.

Marie-Pier Houle, the founders’ daughter, left her career as a paralegal five years ago to join the company as director of administrative services when Parent retired. “It started as a family company with my parents. Now it is me, my stepbrother Marc-André and Benoit. With Benoit joining us we call it a modern family now,” Marie-Pier Houle says.

Marc-André Villemure has been the director of operations since 2013. Formerly involved in technical operations at Montreal’s Olympic Stadium, Villemure joined the company in 2007. “I was the first employee to work here. I trained the first salesmen,” he says.

Benoit Dubord, a lawyer-turned-entrepreneur, bought into Président last year to round out the trio of co-owners in the role of CEO.

As second generation (well, two-thirds secondgeneration) owners, they are a bit of a rarity in the Quebec window and door industry, according to Dubord. “There is not a lot of transfer of ownership to the younger generation, a number of window companies having been sold or closed.”

Yvan Houle continues to contribute valuable industrial engineering expertise, which, for example, has made it possible for the company to purchase and modify second-hand equipment to meet Président’s needs. “He is the product development guy and he answers our technical questions. We prefer to buy second-hand and adapt the equipment. We reconfigure [equipment we purchase] every time,” Dubord says. A staff electro-mechanic keeps the equipment in good running order.

Not only is the passing of the family torch in this industry uncommon, but smaller players have been disappearing as the industry consolidates, Dubord says. “Take a picture 15 years ago and today. There are fewer manufacturers. Years ago, every town and village had a window and door manufacturer. No one has started a window and door manufacturing company since 2007.”

That was the year Yvan Houle, having accumulated some two decades of industry experience, founded Président. “He understood the products and the production lines. He had contacts across Canada. Yvan knew the industry,” Dubord says. By 2016 the company had outgrown its original, 17,000-square-foot shop. “Ten years ago, the place was too big for us. Three years ago, it was too small,” Villemure says. Dubord adds: “We were fortunate enough to have a landlord with space for us to expand. We have excess capacity now. There is room to add machines and to add manufacturing capacity to the existing machines.”

While Président designs and manufacturers its own windows, it contracts others to make its doors to its own specifications and door hard-

ware. It specializes exclusively in the retrofit market. “Our typical clients would be our relatives and neighbours, with a house built in the 1970s. They are homeowners,” Dubord says.

Dubord divides window manufacturers into three groups: those who make windows and doors for sale in renovation centres such as Réno-Depot and Rona; those who make windows and doors for sale by distributors or contractors out of specialty stores; and those who sell directly to customers. Président works in the latter niche, with some vertical integration that distinguishes it from its competitors.

“I think that is where Yvan did the

best, and this is a differentiating factor for our business. He cut out the middleman. We are a fully integrated business here. We design and manufacture the products, do our own sales and marketing and our own installations and services. It allows us to better serve our customers,” Dubord explains.

As their website puts it, “... we select our installers for their competence, positive attitude and ability to install our products according to written protocols – all to maximize our products’ efficiency. Each of our installers is certified by the Régie du bâtiment du Québec [unofficially translated as the Quebec Building Authority].”

Dubord says, “At every step in the process we try to differentiate ourselves from the competition. We go to the client’s house, spend time at the coffee table, listen to them, propose products that meet their needs. We do a good job managing their expectations.

“Our installers follow a written protocol that indicates from A to Z how work should be done - from how to act with the customer to how to protect the house during the work, and which materials should be used, etcetera. We have an after-service sales team who can support the installers. It can come out and troubleshoot problems right away.”

Bernard Létourneau installs wood components on Président’s 11,000-square-foot production floor. The company is vertically integrated, taking retrofit projects from design right through installation.

Credit: Carroll McCormick

COVER STORY

Villemure adds, “Before we deliver the windows, we bring in a technician. Five percent of homeowners will have an unexpected surprise; for example, a plumbing or electrical problem.”

Marie-Pier Houle completes the thumbnail course in what Président offers its customers: “We can do carpentry. We can open up the wall wider, replace a window with a door, make a window smaller. We do that frequently.”

This is how the company interacts with the outside world. Inside its plant walls, things have evolved somewhat. For example, there is more automation. They changed to PVC frames (Président does not build aluminum or wood-framed windows). The operators have changed. Invisible to see in their assembled windows is a unique-in-Quebec product feature the company perfected: the PVC frames are filled with foam insulation.

While history has its place, the trio much prefers to talk about changes coming down the turnpike, such as expansion plans, challenging new regulations and environmental responsibility.

On expansion: “For us, there is still space to grow in our natural market. We are also looking to grow through strategic acquisitions in markets we are not in now and partnerships,” Dubord says. For example, he says, “Some clients want aluminum windows. There could be value in acquiring a manufacturer that makes aluminum windows.”

On new regulations, Dubord explains, “The government has proposed new code standards and Energy Star ratings for windows. We will see a lot of changes in the next few years. We will have challenges to keep meeting the requirements. There is a lot of pressure on the industry.

“The concern for manufacturers like us is market acceptance. We could have products that meet the new standards, but they are expensive. Triple-glazed is more expensive to make and transport, and more difficult to install. There is a reality check between government proposals and what the market will accept. There is uncertainty among manufacturers about code and Energy Star standards. The final requirements aren’t known, or when they will be put in force. What we know for sure is that the products we are

making today will not be the products we will be selling in five years.”

On environmental responsibility: “Environment is a big buying tool. We are examining our manufacturing processes, for example, recycling. If you talk about trends in the industry, they are shaping products and customers. What we think will drive changes down the road is the environmental consciousness,” Dubord says.

As interesting, exciting and important as these things are, the trio have plenty of the usual day-to-day tasks to keep them busy, while also making changes that

improve their game. One example was the recent rearrangement of the production line to eliminate a bottleneck and open up more floor space.

Président invests in its employees by participating in government training programs. “The government approached us with a program – 12 weeks in school –matched with employees from other companies to improve their trades. Two of our employees are in this program. They will come out of it with a diploma. We have also taken on students for internships. We invest in our people,” Marie-Pier Houle says.

The new owners of Portes et fenêtres Président (L-R): Marc-André Villemure, MariePier Houle, Benoit Dubord. Yvan Houle, the company founder, still contributes his technical advice.

Credit: Carroll McCormick

Sharing obsessions

“If you define the problem correctly, you almost have the solution.” – Steve Jobs

by Chris Meiorin

Those who know me sometimes say I have an obsessive personality. So at a risk of proving them right, I’m going to return to my latest area of obsession: Lean manufacturing.

The Lean manufacturing process, or simply “Lean,” is defined as the minimising of anything that does not bring value to a process. The best-known way to achieve this state is through a commitment to “continuous improvement.” It’s a very simple goal, yet the process can be monumental. Anyone who has been on this journey knows that CI is an endeavour with a perpetual learning curve. Fortunately, our industry has recently taken notice of this trend and is making available this knowledge via independent learning or, more commonly, via trade associations. As a case in point, lets look at Fenestration Manitoba’s FenCon19 conference and expo. A quick scan of the two-day schedule will make clear their focus on this topic, and in true Lean fashion it removes from the schedule anything that does not bring value to the attendee. For those who follow Lean, it should come as no surprise that Manitoba manufacturers have embraced Lean as a group, unlike anywhere else in the country.

Geographically, Manitoba is well situated to fill this role. It is, for all intents and purposes, pretty much the centre of our vast country and northern neighbours to some of the continent’s largest fenestration manufacturers. Geography aside, the efforts of Canadian Manufacturers and Exporters could explain why Manitoba remains a hotbed for this pursuit. Although CME acts as a national association, there is no denying that much of their Lean focus takes place in Manitoba. As a result, I headed back to Winnipeg in March for my third foray into Lean manufacturing learning.

At my early point in this Lean journey one of the key points is the focus on the philosophy and culture of Lean rather than focusing on specific tools and methodologies that a structured Lean certification might provide. Lean certification and can play an important role in the success of a Lean objective, bringing to the table the tools and practical knowledge necessary to execute and manage a Lean plan, but the focus of this column is on the realm of leadership and culture.

It is widely accepted that the successful implementation of Lean manufacturing requires a strong commitment on the part of senior management. However, the Lean journey is a long one and it is easy as managers to allow our attention to this process to slip. Further to this, the involvement of employees in ongoing and daily improvements is also critical to the success of a Lean business plan. That’s where the Lean challenge really begins. How do you change a culture? How does a manager impart their vision and goals as a cultural shift to all stakeholders within an organization? This is the part of Lean that a course can teach but requires another level of devotion to implement. Perhaps an obsessive level of devotion.

This brings me back to my opening. Once the Lean journey begins, its success depends on the engagement of others. A sustained cultural shift. In order for Lean to succeed within an organization, it must be viewed as a philosophy – a journey – and it must consist of the right combination of long-term initiatives, processes, people and problem-solving in order for it to succeed. With the resources now available to us to make this happen, we as a collective group stand a better chance to remain an important and viable industry on the ever- increasing competitiveness of a global market.

INTRODUCING THE COMMDOOR FOLDING DOOR SYSTEM

Designed for spectacular year-round enjoyment. Connect your outdoor oasis with the indoors: private residences, restaurants, cottages, patios, event centres, and entertainment complexes. Experience the full potential of your space today.

commdooraluminum.com

by TREENA HEIN

EXTREME WINDOWS

Manufacturing for the toughest environments.

Our window and door manufacturers and installers have always had to rise to the challenge of making fenestration for extreme environments in Canada. But in the past, just putting in a leaky product and cranking the heat was always an option.

Today, tightening energy and air/water ingress standards are pushing us to actively develop and test windows and doors with new materials and designs that can better handle harsh climates and special conditions, including fire risk and high altitude.

It’s no surprise that windows and doors in coastal Canada have to resist significant and ongoing wind-driven rain. Steve Alward notes, however, that it’s the installation of windows on the east coast that has evolved over the last decade to meet this fact of life, and that manufacturing materials and methods have changed little. “We already concentrate as a manufacturer on the best materials for preventing water penetration,” says Alward, who is product manager at window and door manufacturer Atlantic Windows in Port Elgin, N.B. “It’s more these days about tightening the marriage

between the window and building envelope. There is more of a focus now on proper installation of flashing and making a waterproof seal.” This emphasis is due to two factors, in Alward’s view: building envelope changes (such as window-to-wall ratios as demand for larger windows has grown), and the increase in wind-driven rain and the number of storms in the Maritimes.

During in-house training for its customers’ contractors, Atlantic Windows strongly emphasizes the need to follow A440.4 window, door and skylight installation instructions. “We really want to make sure flashing and caulking is done correctly,” says Alward. “A proper connection between the nailing flange and the window is needed so that water sheds properly off the building and off the window. And at the bottom, drainage must be good.”

Rain, cold and wind… oh my! Canadian window and door manufacturers have been dealing with extreme conditions forever and come up with some novel solutions.

And, like others across the country, Atlantic Windows is now also focusing on the new installation technician training program from Fenestration Canada, launched in January. Alward believes this program will bring consistency to the best installation practices that most Canadian manufacturers are trying to promote across the country, but he reiterates that “here on the East Coast, where we constantly deal with a lot of wind-driven rain and have done forever, there won’t be a lot of change.”

Wet weather is obviously also a factor on Canada’s western coast, and to make sure its products and installations are topnotch, Cascadia Windows and Doors in Langley, B.C., chooses materials carefully. “We’ve always selected materials that are corrosion-resistant and moisture-resistant, and fibreglass frames are excellent on both these fronts,” notes Cascadia technical director, Michael Bousfield. “There are also some installation materials that provide advantages for wet conditions, such as membrane products applied as a liquid and not a sheet. They can be applied to wet surfaces, cure faster as they are moisture-cured, and provide overall better flexibility and site-tolerance. An example that’s well-known is Fast Flash.”

Bousfield believes that, in general, understanding of proper

installation practices to prevent moisture issues is more scattered in B.C.’s residential market, but it’s quite consistent at the commercial level. “It’s trickling down, however,” he observes. “Maturation of installation practices across the board will also result from the introduction of the B.C. Energy Step Code, which has whole-building energy intensity as a focus.”

COMBATING COLD

“Energy efficiency is everything in window and door production right now,” notes Terry Adamson, technical director at Westeck Windows and Doors in Chilliwack, B.C. “There are some people out there right now with very innovative ideas and they’re hitting some impressive targets.” Indeed, those people include Adamson and his colleagues. After years of development, they’ve just launched a wooden casement system and a PVC tilt-and-turn system that both meet the European Passive House standard. “We are also releasing new casement and new slider systems this summer with E-values less than 1.0 and 1.2 respectively,” Adamson says. Westeck has also developed a PVC patio door with an E-value of less than 1.3.

Cascadia chooses fibreglass frames for the way they handle extreme cold as much as for its corrosion and moisture-resistance properties. Cascadia says fibreglass provides eight times less expansion and contraction than other energy-efficient materials such as vinyl, and its thermal movement coefficient is very similar to glass.

For his part, Alward believes that most windows will have to be triple-glazed to meet future Energy Star ratings, which will make them 50 per cent heavier. And the larger and heavier the triple-glazed window, the more challenging to install. However, manufacturer and installer Northerm Windows in Whitehorse, Yukon, (with an office in Anchorage, Alaska) has never let weight deter it – it’s been making quad-glazed window systems since 2009. “We were installing so many windows in the 1980s, we decided to start manufacturing windows and then also our own vinyl frames,” explains general manager Dave Borud. “Back then it was double-pane and triple-pane, about half and half, and we looked at fibreglass but chose to stay with vinyl. Many of our windows from 30 years ago are still functioning well today.”

Development of quad windows stemmed from a request by the Yukon Housing Corporation. Borud says the corporation

Most windows will have to be triple-glazed to meet future Energy Star ratings.

had big concerns with existing windows that let in the cold and produced a lot of condensation, resulting in rotting sills and walls. Northerm quad windows, by comparison, are very comfortable in the home and also provide great soundproofing (in fact, Northerm has sold some quad windows in New York and other states for customers wanting very lownoise environments). Northerm sells about 60 per cent triple-

A cutaway of Northerm’s quad window. Readying to produce this product required changes to everything from plant layout to overhead cranes.

FEATURE STORY

glazed windows and 40 per cent quad. About 30 per cent of its total production (8,000 to 10,000 units per year) is sold in Alaska. Quad-pane costs about 25 per cent more than triple.

JOURNEY TO GET THERE

While Borud reports that his firm tapped into a few government programs for a bit of funding support, the journey to create their quad windows was accomplished through their own trial and error over a period of several years. By 2009, Northerm had a product that was certified to insulating glass standards, with a framing system that adequately supports four panes. They also created the associated (and patented) fabrication method, which required changes in the firm’s plant layout and the addition of overhead cranes. Northerm says it is still the only window manufacturer in North America with a regular quad production run. The windows have an R-value of 7.69 (the glazing actually has a larger R value than the frame) and a U-value of 0.13. Northerm applies a low-E coating to the two outside panes and uses argon gas. “We’re working on our second phase of the quad system now,” says Borud. “We’re going to be testing some new exterior low-E coating products such as Cardinal’s i89. When you put them on the exterior, it greatly improves thermal efficiency. Krypton gas would be an alternative to boost efficiency, but it’s too costly right now.”

HURRICANES, BLASTS,

FIRE AND HIGH ALTITUDE

Cascadia is now doing some exploration of hurricane and blast resistance, the first step being a study by an outside party that will determine the likely resistance of the firm’s existing products. “Hurricane ratings relate to impact from outside objects but also to the ability to withstand both inward and outward wind pressure,” Bousfield explains. “Along with the glass, the hardware has to be capable of surviving these conditions over many hours. Blast resistance relates to withstanding one event.” In terms of fire-resistant products, Cascadia uses a fire-resistant resin in the manufacture of windows for tall non-combustible buildings, a resin made from fibreglass by Cascadia’s supplier, Inline Fiberglass. Bousfield also notes that Natural Resources Canada research has been completed on the combustibility of window and door materials. The results are expected to lead to future code changes, he says, as well as expanding applications for Cascadia’s fiberglass windows (and several other materials) to full-facade, high-rise glazing.

Serving primarily the east coast market, Atlantic has to know a thing or two about resisting water ingress. Above, one of its products gets blasted in the test lab.

With the Rockies in B.C., high-altitude installations are another challenge for Cascadia. Windows are generally manufactured at a lower elevation and Bousfield explains that tolerances of window seals for temporary exposure to high elevations (delivery of windows through a mountain pass) obviously don’t have to be as extreme as permanent high-elevation installations. Overall, Bousfield notes that the amount of stress experienced by glass unit seals due to air pressure issues depends on three factors: thickness of glass, space between the panes and window shape. “Low-stress glass units are squarish rather than narrow, with thinner glass and a thinner airspace,” he explains. “There are tables that indicate what size and shape should be used at which altitudes. Some manufacturers add capillary tubes to allow pressure to equalize. However, that increases the risk of fogging and also introduces a drop in efficiency because argon or another similar gas can’t be used. We don’t prefer to use capillary tubes, so we work with our customers on modifying the size and shape of the windows as a first step.”

New solutions from top suppliers for safety, esthetics and ease-of-use.

HARDWARE SHOWCASE

AUTOMATIC RE-LATCH

8amesburytruth.com

AmesburyTruth has engineered, patented and manufactured a releasable limit device for residential windows. The SafeGard 2R has been developed to meet the ASTM F2090 safety requirements code for selfresetting, egress-capable, fall prevention devices. This product limits the opening of the window to less than four inches, however it can be released in case of an emergency to achieve egress or for cleaning purposes. By code, dual-action release mechanisms are required to open the window fully for egress. This operation can be performed without the use of keys, tools, or special knowledge. SafeGard 2R will automatically re-latch when the window is fully closed. In addition to the safety provided by limiting the sash opening, SafeGard 2R is

easy to install in the factory and can be adjusted inside the home after window installation. The unit is fully concealed when the window is in closed position and does not interfere with the operation or performance of the window. SafeGard 2R can be used on casement, awning and hopper windows and is also available for commercial applications.

CORROSIONRESISTANT

8fentro.com

Fentro Technologies is offering high performing, superior-quality hardware for manufacturing facilities from Siegenia Hardware. Featuring the Titan AF series, this modern hardware system has undergone diverse product enhancements. It allows for flexible integration into existing production processes and reduces installation time, thereby opening up significant opportunities for saving costs to fabricators. Moreover, the Titan

Silver Finish has been certified as Class Five (by IFT Rosenheim) for corrosion protection, having been subjected to more than 480 hours of spray test conditions. Using only highquality materials, Siegenia Hardware provides efficient workability and maximum functionality while offering extensive design options for more individual room comfort. With superior functionality and performance, Siegenia meets the main hardware requirements of every manufacturer of tilt-and-turn window and door systems. In addition to Siegenia hardware, Fentro Technologies offers window and door handles, accessories and ancillary products made by world-renowned European manufacturers including Hoppe handles, CES locking systems, Wemaro specialized tools, PHI shims and blocks and Spax screws.

SECURE LOCKING ACTION

8interlockna.com

The latest design option within Interlock’s expertly engineered Nova casement and awning hardware is the Vesta casement furniture series, where

high performance meets high style. Combining sleek esthetics and clean lines with flexibility and ergonomic operation offered in all of Interlock’s casement operating and locking systems, the Vesta casement cover, handle and lock provide a modern casement hardware solution to fit today’s architectural and interior design demands. The snap-on handle and cover offers styling flexibility and minimized inventory cost, while special packaging helps prevent transit and job site damage with convenient post-construction installation. The Vesta casement lock handle offers a flush profile to eliminate interference with blinds and window treatments. The non-handled design is available in single- or multi-point configurations allowing for 48 millimeters of lock bar travel to provide secure progressive locking action.

FENESTRATION CANADA

Surging forward

by Jennifer Small

Events, management and education all seeing progress.

Fenestration Canada’s board of directors has been hard at work over the past six months to improve our management structure so we can provide better services and added value to our members. A major step in this plan was to engage a new full-time executive director, Stephane Labelle, to help lead and execute all the operational activities related to FenCan. Stephane brings with him a combination of experience in business development, marketing, project management and sales along with his volunteer experience as WinDoor committee chair and FenCan board director. At the same time as bringing Stephane on board, we engaged Redstone, a new passionate and professional team of experts in event and association management, who we are confident will have a positive impact on our association.

As a board, we have had some directors move on to other challenging careers. I would like to thank Gary Blad and Ryan Dudeck for all their contributions and hard work and wish them the best of luck in their new ventures.

We started 2019 coming off of an exciting WinDoor 2018, held for the first time in Quebec City in December. With record attendee numbers, FenCan attracted current and new members, AVFQ members and other fenestration industry stakeholders. The opening event at the Chapelle, meticulously organized with the help of the AVFQ, was set in a beautiful deconsecrated church. Thank you to Lisa Bergeron and Nancy Thompson for all your help. The show floor was buzzing with product demonstrations and a full lineup of experts sharing their knowledge. Fabricators and suppliers alike learned about codes and standards, Energy Star and NRCan regulations and we had presentations on Lean manufacturing, automation and product performance. The WinDoor committee is already moving full steam ahead planning for WinDoor 2019, happening Nov. 20 to 21 in Toronto. Don’t miss it!

In late December, we showcased a webinar about linking customer complaints to customer satisfaction teaching us how to turn a challenge

into an opportunity. For 2019 in education, we are bringing keynote speaker John Eakes to our regional event on April 9 in Edmonton. John is a teacher of all things relating to renovation and home building. He is an expert on cold climate housing and is often called upon by governments and related associations for his expertise and knowledge in the building industry. At our Spring Conference and Annual General Meeting in June, we have keynote speaker Deborah Kimmett. A comedian and expert in change management, Deborah is sure to entertain us as she discusses the challenges of accepting new business realities. Mark your calendars for June 3 to 6 at White Oaks Conference Centre in Ontario’s Niagara Region. Across Canada, fabricators are all facing NRCan aspirational goals for windows starting in 2020. These goals have serious impacts on fabricators and the competitiveness and viability of manufactured window and door products in our country. In December, FenCan submitted its feedback on NRCan’s discussion paper, as did many of our members. Although NRCan understands some of the challenges that current product offerings face, they have a mandate to reduce greenhouse gas emissions, of which residential and commercial windows account for 17 per cent. Residential windows account for up to 35 per cent of a home’s heat loss, so setting new higher standards for energy efficiency on windows and doors helps achieve the government’s mandate. As we navigate this new reality, FenCan provides support, education, technical expertise and advocacy. Our members benefit from our association by having a unified voice on industry challenges by learning together and by challenging one another. If you are not a member, come join us and don’t be left behind. If you are a member, thank you for your support and let us work together for the better of the Canadian fenestration industry.

Jennifer Small is the president of Fenestration Canada and of Screenco, a North American manufacturer of window and patio screen products headquartered in Concord, Ont.

MEMBER DIRECTORY

A & D PRÉVOST

305 12e avenue Richelieu, Richelieu, QC, J3L 3T2

Tel: (450) 658-8771

Contact: Claude Cardin

Email: ccardin@prevost-architectural.com www.adprevost.ca

AABEN WINDOWS AND DOORS LTD.

700 Progress Ave, Kingston, ON, K7M 4W9

Tel: (613) 384-3163

Contact: Michael Braby

Email: michael.braby@aaben.com www.aaben.com

ADFAST CORP.

2685, Diab Street, St-Laurent, QC, H4S 1E7

Tel: (514) 617-1579

Contact: Denis Perron

Email: denis.perron@adfastcorp.com www.adfastcorp.com

AGC GLASS NORTH AMERICA

11175 Cicero Drive, Suite 400 Alpharetta, GA, 30022

Tel: (905) 738-9400

Contact: Marilyn Moore

Email: marilyn.moore@ca.agc.com www.us.agc.com

ALL WEATHER WINDOWS LTD.

18550 - 118A Avenue NW, Edmonton, AB, T5S 2K7

Tel: (780) 451-0670

Contact: Tracy Nadiger

Email: tnadiger@allweatherwindows.com www.allweatherwindows.com

ALLSCO WINDOWS AND DOORS

70 Rideout Street, Moncton, NB, E1E 1E2

Tel: (506) 853-8080

Contact: André Doiron

Email: adoiron@allsco.com www.allsco.com

AMBERWOOD DOORS INC.

80 Galaxy Blvd., Unit 16

Toronto, ON, M9W 4Y8

Tel: (416) 213-8007

Contact: Colin Fraser

Email: cfraser@amberwooddoors.com www.amberwooddoors.com

AMESBURYTRUTH

3600 Minnesota Drive, Suite 800, Edina, MN, 55435

Tel: (800) 866-7884

Contact: Mathieu Hebert

Email: mathieu.hebert@amesburytruth.com www.amesburytruth.com

ANDERSEN CORPORATION

100 Fourth Avenue North, Bayport, MN, 55003-1096

Tel: (651) 264-5570

Contact: Mark Mikkelson

Email: mark.mikkelson@andersencorp.com www.andersenwindows.com/

ANDERSON WINDOWS

46 Cheryl Crescent, P.O. Box 510 Sundridge, ON, P0A 1Z0

Tel: (705) 384-5341

Contact: Cheryl Anderson

Email: sherianderson@bellnet.ca www.andersonwindows.ca

ANIG WINDOW

MANUFACTURING LIMITED

2040 Ellesmere Road, Unit 1 Scarborough, ON, M1H 3B6

Tel: (416) 438-7213

Contact: Enzo Angheloni

Email: enzo@anigwindows.com www.anigwindows.com

AQUASURTECH OEM

2148 Trans-Canada Highway, Dorval, QC, H9P 2N4

Tel: (514) 684-2628

Contact: Michael Braeuel

Email: mbraeuel@aquasurtech-oem.com www.aquasurtech-oem.com

ARCHIE HARDWARE

NORTH AMERICA INC.

513 Mayflower Street, Waterloo, ON, N2K 3Y7

Tel: (416) 708-9288

Contact: Mark Straub

Email: mark.straub@archiehardware.com www.archiehardware.com

ARMWOOD WINDOWS & DOORS

Highway 1A West, P.O. Box 8, Portage la Prairie, MB, R1N 3B2

Tel: (204) 856-2320

Contact: Brent Otsuji

Email: brent@armwood.ca www.armwood.ca

ASHLAND HARDWARE

545 E John Carpenter Freeway, Suite 610 Irving, TX, 75062

Contact: Vanessa Gonzalez

Email: Vanessa.Gonzalez@ashlandhardware.com

ATIS GROUP

1111, rue St-Charles ouest, bureau 952, Longueuil, QC, J4K 5G4

Tel: (418) 881-3950

Contact: Bertrand Nadeau

Email: bnadeau@laflamme.com www.atisgroup.ca

ATLANTIC WINDOWS LTD.

49 East Main Street, Port Elgin, NB, E4M 2X9

Tel: (506) 538-2361

Contact: Greg Dickie

Email: greg.dickie@atlanticwindows.com www.atlanticwindows.com

AURORA WINDOW SYSTEMS INC.

535 Manitou Rd. SE, Calgary, AB, T2G 4C2

Tel: (403) 291-2851

Contact: Kent Schultz

Email: kent@aurorawindowsystems.ca www.aurorawindowsystems.ca

AVFQ

2065, rue Frank-Carrel, bureau 216, Quebec, QC, G1N 2G1

Tel: (418) 688-1256

Contact: Gilbert Lemay

Email: glemay@avfq.ca www.avfq.ca

BASCO WORLD

1141, rue Reynald, Laval, QC, H7W 1N2

Tel: (514) 241-9686

Contact: Jean-Sébastien Basilico

Email: js@bascoworld.com www.bascoworld.com

BERDICK WINDOWS & DOORS

404 Roblin Boulevard, Winkler, MB, R6W 0N4

Tel: (204) 325-8053

Contact: Victor Soto

Email: victor@berdick.com www.berdick.com

BIG GLASS OPENINGS INC.

11 King Street, Unit 7

Barrie, ON, L4N 6B5

Tel: (705) 915-1616

Contact: Paul Marasse

Email: admin@bigglassopenings.com www.bigglassopenings.com

BONNECHERE VALLEY WINDOWS LTD.

2824 Fourth Chute Road, RR 6

Eganville, ON, K0J 1T0

Tel: (613) 628-3056

Contact: Andreas Vornweg

Email: andreas@b-v-w.com www.b-v-w.com

BROWN WINDOW CORPORATION

185 Snow Boulevard, Concord, ON, L4K 4N9

Tel: (905) 738-6045

Contact: Pino Marinelli

Email: pinom@brownwindow.com www.brownwindow.com

MEMBERDIRECTORY

CALDWELL MANUFACTURING NORTH AMERICA LLC

P.O. Box 92891, Rochester, NY, 14692-8991

Tel: (585) 429-0270

Contact: Nancy Bostwick

Email: nbostwick@caldwellmfgco.com www.caldwellmfgco.com

CANADIAN HOME BUILDERS ASSOCATION

Tel: (613) 230-3060

Contact: Jack Mantyla Email: mantyla@chba.ca

CAN-BEST

38 Regan Road, Unit 4, Brampton, ON, L7A 1C6

Tel: (905) 840-2014

Contact: Elie Alkhoury

Email: elie@can-best.com www.can-best.com

CARDINAL IG COMPANY LTD.

534 Wasaga Crescent, Waterloo, ON, N2V 2Y8

Tel: (519) 590-3194

Contact: Mike McAndrew

Email: mmcandre@cardinalcorp.com www.cardinalcorp.com

CENTENNIAL WINDOWS & DOORS

687 Sovereign Rd., London, ON, N5V 4K8

Tel: (519) 451-0508

Contact: George Warren

Email: george.warren@centennialwindows.com www.centennialwindows.com

CLEARBROOK GLASS 2007 LTD.

33470, South Fraser Way

Abbotsford, BC, V2S 2B5

Tel: (604) 308-5267

Contact: Bruce Friesen

Email: bruce@clearbrookglass.ca www.clearbrookglass.ca

CLEARVIEW INDUSTRIES LTD.

45 Fenmar Dr., Toronto, ON, M9L 1M1

Tel: (416) 745-6666

Contact: Tom Marsala

Email: tmarsala@clearview.on.ca clearview.on.ca

CLEB LABORATORY INC.

1320, Lionel-Boulet Blvd., Varennes, QC, J3X 1P7

Tel: (514) 923-6611

Contact: Robert Jutras

Email: rjutras@cleb.com www.cleb.com

COLOUR VISION COATING INC.

285 Vaughan Valley Blvd., Woodbridge, ON, L4H 3B5

Tel: (905) 856-4464

Contact: Bernice Martin

Email: sales@colourvision.ca

CONTINENTAL

Salinenstrasse 1, Zip 74679 Weissbach, WH, Germany

Tel: (540) 550-4596

Contact: Marco Patermann

Email: Marco.Patermann@gapser.com www.skai.com

CSA GROUP

178 Rexdale Rd., Toronto, ON, M9W 1R3

Tel: (866) 797-4272

Contact: Mohamadou Diallo

Email: mohamadou.diallo@csagroup.org www.csagroup.org

CUSTOM WINDOW DESIGNS

3495 Laird Road, Unit 1 Mississauga, ON, L5L 5S5

Tel: (905) 569-1329

Contact: Peter Petrovski

Email: peterp@customwindowdesigns.ca www.custonwindowdesigns.ca

DALMEN PRO WINDOWS AND DOORS

18 Bentley Ave., Ottawa, ON, K2K 6T6

Tel: (613) 706-4181

Contact: Chris Papineau

Email: Chris@dalmenpro.com Www.Dalmenpro.com

DAN DARCY & ASSOCIATES INC.

46 Diana Grace Avenue, Dartmouth, NS, B2W 6A2

Tel: (902) 462-6114

Contact: Dan Darcy

Email: dandarcy@accesswave.ca

DEL WINDOWS & DOORS

241 Arvin Ave, Stoney Creek, ON, L8E 2L9

Tel: (905) 561-4335

Contact: Ed Bremer

Email: ebremer@delwd.ca delwd.ca

DOOR COM PRODUCTS

285 Vaughan Valley Blvd., Woodbridge, ON, L4H 3B5 Tel: (905) 850-5352

Contact: Daniel Sardella

Email: daniel@wintek.ca www.doorcom.ca

DOORSMITH

(A DIVISION OF CAN-SAVE)

411 Bayview Drive, Barrie, ON, L4N 8Y2 Tel: (705) 722-7283

Contact: Ryan Eccleshall Email: ryane@cansave.ca www.cansave.ca

DOORTEK INC.

109 Advance Blvd., Brampton, ON, L6T 4H8 Tel: (416) 613-9663

Contact: Rohit Kalia

Email: rohit@doortek.ca www.doortek.ca

DORPLEX INDUSTRIES LTD.

100 Norfinch Drive, Toronto, ON, M3N 1X1

Tel: (416) 744-3667

Contact: Paul Moseley

Email: info@dorplex.com www.dorplex.com

DROLET EQUIPEMENT CNC

2665, Terra-Jet, St-Cyrille-de-Wendover, QC, J1Z 1B3

Tel: (819) 474-2149

Contact: Josee Therrien

Email: info@drolet-equipementcnc.com www.drolet-equipementcnc.com

DUFFERIN WINDOWS LTD.

115 Centennial St., Shelburne, ON, L9V 2Z4

Tel: (519) 925-3111

Contact: Karen McCabe

Email: karen@dufferinwindows.ca www.dufferinwindows.ca

DURABUILT WINDOWS & DOORS INC.

10920 178 Street NW, Edmonton, AB, T5S 1R7

Tel: (780) 577-2004

Contact: Sami Sakalla

Email: samis@durabuiltwindows.com www.durabuiltwindows.com

DUXTON WINDOWS & DOORS

45 Higgins Avenue, Winnipeg, MB, R3B 0A8

Tel: (204) 339-6456

Contact: Al Dueck

Email: apdueck@duxtonwindows.com www.duxtonwindows.com

E J MACHINE SALES & SERVICE INC.

20 Barr Rd., Ajax, ON, L1S 3X9

Tel: (905) 427-3400

Contact: Melissa Colquhoun

Email: melissac@ejindustries.ca

ELTON MANUFACTURING

8400 Lawson Road, Unit 2

Milton, ON, L9T 0A4

Tel: (905) 876-1290

Contact: Andrew Beavan

Email: sales@eltonmanufacturing.com www.eltonmanufacturing.com

ENDURA PRODUCTS INC.

8817 W. Market St., Colfax, NC, 27235

Tel: (336) 668-2472

Contact: Mark Fortun Email: mfortun@enduraproducts.com

ENERGI FENESTRATION SOLUTIONS

3035, boul. Le Corbusier, Laval, QC, H7L 4C3

Tel: (450) 687-5115

Contact: Diane Loisel Email: diane.loisel@energifenestration.com www.energifenestration.com

ENTRYGUARD DOORS INC.

8150 Keele Street, Concord, ON, L4K 2A5

Tel: (905) 532-0740

Contact: Frank Luccisano

Email: frank@entryguarddoors.com www.entryguarddoors.com

MEMBERDIRECTORY

EURO VINYL WINDOWS & DOORS INC.

167 Caster Avenue, Unit 8

Woodbridge, ON, L4L 5Y8

Tel: (905) 851-9711

Contact: Chris Meiorin

Email: chris@evw.ca www.evw.ca

EUROLINE WINDOWS INC.

7620 MacDonald Rd., Delta, BC, V4G 1N2

Tel: (604) 940-8485

Contact: Isbrand Funk

Email: isbrand@euroline-windows.com www.euroline-windows.com

FENESTRA PURCHASING CO-OP

140 Fullarton Street, Suite 208 London, ON, N6A 5P2

Tel: (514) 779-9674

Contact: JF Kogovsek

Email: jfk@fenestra.coop www.fenestra.coop

FENESTRATIO

159 King St., Unit 304 Peterborough, ON, K9J 2R8

Tel: (888) 853-0011

Contact: Aaron Clarke

Email: aaron@fenestratio.com

FENESTRATION ASSOCIATION OF BC

P.O. Box 36117, Surrey, BC, V3S 7Y5

Tel: (778) 571-0245

Contact: Zana Gordon

Email: zgordon@fen-bc.org www.fen-bc.org

EVERLAST GROUP OF COMPANIES

299 Carlingview Drive, Etobicoke, ON, M9W 5G3

Tel: (800) 897-5118, (416) 241-8527

Contact: Vince Porcelli

Email: Vince@everlast.biz www.everlastproducts.ca

EXOVA INC.

2395 Speakman Drive, Mississauga, ON, L5K 1B3

Tel: (905) 822-4111

Contact: Jennifer Wren-McDonald

Email: jennifer.wrenmcdonald@exova.com www.exova.com

EXP SERVICES INC.

1595 Clark Boulevard, Brampton, ON, L6T 4V1

Tel: (416) 356-4419

Contact: Greg Hildebrand

Email: greg.hildebrand@exp.com www.exp.com

EXTREME WINDOW & ENTRANCE SYSTEM

80 Loftus Street, Moncton, NB, E1E 2N2

Tel: (506) 384-3667

Contact: Darren Bannister

Email: dbannister@extremedoors.ca

FABELTA

3840 Georges Corbeil, Terrebonne, QC, J6X 4J4

Tel: (450) 477-7611

Contact: Karine Papineau

Email: kpapineau@fabelta.com www.fabelta.com

FENESTRATION COMPONENTS

INTERNATIONAL INC.

P.O. Box 1544, Okotoks, AB, T1S 1B5

Tel: (403) 938-1064

Contact: Ted Paetkau

Email: ted@fci-inc.ca www.fci-inc.ca

FENESTRATION MANITOBA

PO Box 434

Pinawa, Manitoba R0E 1L0

Contact: Ryan Dudeck

Email: rdudeck76@gmail.com fenestrationmanitoba.ca

FENESTRATION REVIEW

PO Box 530, 105 Donly Drive South, Simcoe, ON, N3Y 4N5

Tel: (226) 931-0545

Contact: Patrick Flannery Email: pflannery@annexbusinessmedia.com

FENETECH INC.

260 Campus Dr., Aurora, OH, 44202

Tel: (330) 995-2830

Contact: Matt Batcha

Email: matt.batcha@fenetech.com www.fenetech.com

FENETRES FORMTECH

192 rang 6, St-Rosaire, QC, G0Z 1K0

Tel: (819) 758-7392

Contact: Luc Letourneau

Email: luc@t4s2009.com www.formtech-inc.com

FENÊTRES MAGISTRAL WINDOWS INC.

705, boulevard Industriel, Blainville, QC, J7C 3V3

Tel: (450) 433-8733

Contact: Claude Charron

Email: CCharron@fenetresmagistral.com www.fenetresmagistral.com

FENPLAST INC.

160, boulevard de l’Industrie, Candiac, QC, J5R 1J3

Tel: (514) 990-0012

Contact: Michel Leclerc

Email: michel.leclerc@fenplast.com www.fenplast.com

FENTRO TECHNOLOGIES

150 Grant Street, Morden, MB, R6M 1Y4

Tel: (204) 822-1405

Contact: Eduard Braun

Email: eduard.braun@fentro.com www.fentro.com

FERCO FERRURES DE BÂTIMENT INC. / FERCO ARCHITECTURAL HARDWARE INC.

2000, rue Berlier, Laval, QC, H7L 4S4

Tel: (450) 973-1437

Contact: Sabin Dery

Email: dery.s@Ferco.ca www.ferco.ca

FIBERCRAFT DOOR COMPANY

321291 Concession 2 SDR, RR 1 Hanover, ON, N4N 3B8

Tel: (519) 506-2117

Contact: Bruce Schaus

Email: fibercraft@wightman.ca

FIBERLINK INC.

55 Valleywood Dr., Markham, ON, L3R 5L9

Tel: (905 475 2300

Contact: Sherry Peng

Email: psherry@fiberglassfiberlink.com www.fiberglassfiberlink.com

FORHOMES LTD.

991 Matheson Blvd East, Unit 6, Mississauga, ON, L4W 2V3

Tel: (905) 212-9499

Contact: Kris Karpinski

Email: kris@forhomes.ca www.forhomes.ca

GAULHOFER CANADA

117 - 5718 1a Street SW, Calgary, AB, T2H 0E8

Tel: (403) 475-6403

Contact: Kent Halluk

Email: kent@gaulhofercanada.com gaulhofercanada.com

GEM ALUMINUM MANUFACTURING COMPANY LTD. (1992)

1590 The Queensway, Etobicoke, ON, M8Z 1V1

Tel: (416) 533-4331

Contact: Spiros Christopoulos

Email: spiros@gemwindows.com gemwindows.com

GENTEK BUILDING PRODUCTS, A DIVISION OF ASSOCIATED MATERIALS, INC.

3773 State Road, Cuyahoga Falls, OH, 44223

Tel: (330) 922-2119

Contact: Steve Harp

Email: sharp@alside.com www.associatedmaterials.com

MEMBERDIRECTORY

LAURELWOOD MILLWORK LTD.

1509 Snow Valley Road, Unit 1, R.R. 3

Minesing, ON, L9X 1K3

Tel: (705) 737-5315

Contact: Rob Rodgers

Email: info@laurelwoodmillwork.com www.laurelwoodmillwork.com

LAYTON CONSULTING LTD.

19978 - 72 Ave, Suite 301 Langley, BC, V2Y 1R7

Tel: (604) 530-6611

Contact: Ashlee Flierl

Email: ashlee@laytonconsulting.com www.laytonconsulting.com

LEPAGE MILLWORK

141, chemin des Raymond, C.P. 1298 Rivière-du-Loup, QC, G5R 4L9 Tel: (418) 862-2611

Contact: Pierre-Luc Bellavance

Email: plbell@lepagemillwork.com www.lepagemillwork.com

LES CARTONS CORRUGUARD INC.

101 Des Ateliers, Lavaltrie, QC, J5T 3R3

Tel: (450) 586-0666

Contact: Marie-Hélène Hotte

Email: mhhotte@cartonscorruguard.com www.cartonscorruguard.com

LES INDUSTRIES RADISSON

136, Rue Léon-Vachon, Saint-Lambert-de-Lauzon, QC, G0S 2W0

Tel: (418) 889-9032

Contact: Gabriel Parent

Email: gparent@industriesradisson.com www.industriesradisson.com

LOEWEN WINDOWS

77 Highway 52 West, P.O. Box 2260 Steinbach, MB, R5G 1B2

Tel: (204) 326-6808

Contact: Duane Koop

Email: duanekoop@loewen.com www.loewen.com

MARITIME DOOR & WINDOW

118 Albert St., Moncton, NB, EIC 1B2

Tel: (506) 383-7114

Contact: Michael Mann

Email: mike.mann@maritimedw.com www.maritimedw.com

MARLBORO WINDOW & DOOR MFG. LTD.

2370 Stevenage Drive, Ottawa, ON, K1G 3W3

Tel: (613) 736-1441

Contact: David Dubrofsky

Email: david@marlborowindows.com www.marlborowindows.com

MARVIN WINDOWS & DOORS OF CANADA

1455 Courtneypark Drive E, Mississauga, ON, L5T 2E3

Tel: (905) 670-5052

Contact: Barb D’Alessandro

Email: bdalessandro@marvincanada.com www.marvincanada.com

MASONITE INTERNATIONAL

2771 Rutherford Road, Concord, ON, L4K 2N6

Tel: (800) 798-3667

Contact: Mark Woolnough

Email: mwoolnough@masonite.com www.masonite.com

MASTERGRAIN C/O WEBER MANUFACTURING TECHNOLOGIES INC.

16566 Highway 12, P.O. Box 399 Midland, ON, L4R 4L1

Tel: (416) 917-1007

Contact: Lyn Jauncey

Email: Lyn.Jauncey@mastergrain.com www.mastergrain.com

MAXAM/MAXFEN

C.P 252, Saint-Bruno, QC, J3V 4P9 Tel: (450) 723-1257

Contact: J.F. Kogovsek Email: jfk@maxammarketing.com www.maxammarketing.com

MENNIE CANADA

LOTHAR’S INDUSTRIAL SALES LTD.

2717 Rena Rd., Mississauga, ON, L4T 3K1

Tel: (905) 678-2397

Contact: Sarah Colberg

Email: Info@lothars.ca

MAPLESPHERE HARDWARE LTD.

45 Carisbrooke Cir, Aurora, ON, L4G 0K4

Tel: (416) 998-6205

Contact: Hao Ling

Email: linghao@maplesphere.ca maplesphere.ca

111 Advance Blvd., Brampton, ON, L6T 4H8

Tel: (416) 748-0088

Contact: Kinson Cheung

Email: kinson@menniecanada.com menniecanada.com/

MENUISERIE BASQUE & FILS LTEE. 390, rue Snowball, C.P. 3609 Succ. Bureau Chef, Tracadie-Sheila, NB, E1X 1G5

Tel: (506) 395-2733

Contact: Alderic Basque

Email: mbf@nbnet.nb.ca www.mbfwindows.com

MILLCRAFT SYSTEMS INC.

369 Concession Rd 6 E, Millgrove, ON, L0R1 V0

Tel: (905) 689-9502

Contact: Lauren Malek

Email: lauren@millcraftsystems.ca millcraftcustomwindows.com

MORRISON WINDOWS LTD.

8400 124 Street, Surrey, BC, V3W 6K1

Tel: (604) 539-1315

Contact: Gurtej Dhillon

Email: gdhillon@morrisonwindows.ca www.morrisonwindows.ca

MOUSTIQUAIRES MSA SCREENS

690, chemin Olivier, Levis, QC, G7A 2N2

Tel: (418) 831-3035

Contact: Jean-Robert Mathieu

Email: jrmathieu@moustiquairesmsa.com www.msascreens.com

MSR WEATHERSTRIPPING INC.

115 Cowan Court, London, ON, N6C 5E3

Tel: (519) 871-5088

Contact: David MacDougall

Email: msrweatherstripping@gmail.com

NAMI INC.

4794 Washington Memorial Highway, Hayes, VA, 23072

Tel: (804) 684-5124

Contact: Tanya Wix

Email: tanya@namiinc.com www.namicertification.com

NATURAL RESOURCES CANADA

Tel: (613) 995-6741

Contact: Steve Hopwood

Email: steve.hopwood@canada.ca

NEWMAR WINDOW MANUFACTURING INC.

7630 Airport Road, Mississauga, ON, L4T 4G6

Tel: (905) 672-1233

Contact: Carlos Martins

Email: cmartins@newmar.com www.newmar.com

NEXTRUSIONS INC.

10 500, Rue Colbert, Montreal, QC, H1J 2H8

Tel: (514) 881-2090

Contact: Gérald Gravel

Email: ggravel@nextrusions.com www.nextrusions.com

NORTH STAR WINDOWS & DOORS

40684 Talbot Line, St. Thomas, ON, N5P 3T2

Tel: (519) 637-7899

Contact: Gary Husen

Email: ghusen@northstarwindows.com www.northstarwindows.com

MEMBERDIRECTORY

NORTHERM WINDOWS & DOORS

1-17 Burns Road, Whitehorse, YT, Y1A 4Z3

Tel: (867) 668-5088

Contact: Rick Gingell

Email: rgingell@northerm.yk.ca

NOVA DOORS AND WINDOWS LTD.

46 Williams Avenue, Burnside Industrial Park, Dartmouth, NS, B3B 2B3

Tel: (902) 468-3850

Contact: Jason Sadler

Email: jason@novadoorsandwindows.com www.novadoorsandwindows.com

NOVAGARD SOLUTIONS

5109 Hamilton Avenue, Cleveland, OH, 44114

Tel: (216) 881-8111

Contact: Joe Borak

Email: JBorak@Novagard.com www.novagard.com

NOVATECH GROUP INC.

160, rue de Murano, Sainte-Julie, QC, J3E 0C6

Tel: (450) 922-1045

Contact: Robert Latour

Email: robert.latour@groupenovatech.com www.novatechgroup.com

NZP FENESTRATION

2459 rue de la Province, Longueuil, QC, J4G 1G3

Tel: (514) 360-9215

Contact: Alain Dorais

Email: alain@netzeroperformance.com www.netzeroperformance.com

OCEANVIEW PATIO DOORS LTD.

5145 Steeles Ave. W., Suite B, Unit 4 Toronto, ON, M9L 1R5

Tel: (416) 741-2600

Contact: Frank Nicolazzo

Email: fnicolazzo@oceanviewdoors.ca www.oceanviewdoors.ca

P.H. TECH INC.

8650 boul. Guillaume Couture, Levis, QC, G6V 9G9

Tel: (418) 833-3231

Contact: Caroline Dallaire

Email: cdallaire@phtech.ca www.phtech.ca

PARAMOUNT WINDOWS

105 Panet Road, Winnipeg, MB, R2J 0S1

Tel: (204) 233-4966

Contact: Tim Dudeck

Email: tim.dudeck@paramountwindows.com www.paramountwindows.com

PAULINE RICHARDS

562 Fallingbrook Drive, Waterloo, ON, N2L 4N4

Tel: (519) 570-6917

Contact: Pauline Richards

Email: prichards.ap@gmail.com

PEINTURES INDUSTRIELLES

MULTI-PRO INC.

9732 Boul. des Hêtres, Shawinigan, QC, G9N 4Y3

Tel: (819) 539-6303

Contact: Guy Adam

Email: bureau@peinturesmultipro.com

PELLA CORPORATION

102 Main St., Pella, IA, 50219

Tel: (641) 621-6096

Contact: Joseph Hayden

Email: jahayden@pella.com www.pella.com

PELLA WESTERN CANADA

53 Christina Close, Sherwood Park, AB, T8H 2G7

Tel: (780) 720-8576

Contact: Kevin Chichak

Email: chichakk@pella419.com

PERMA SEAL WINDOWS & DOORS LTD.

9505-56 Avenue N.W., Edmonton, AB, T6E 0B2

Tel: (780) 434-9487

Contact: Gordon Gauvin

Email: office@permasealwindows.com www.permasealwindows.com

PLY GEM

7140-40th Street S.E., Calgary, AB, T2C 2B6

Tel: (403) 863-0473

Contact: Dave Goldsmith

Email: dave.goldsmith@plygem.ca www.plygem.ca

PMC GROUP

601 West, 8th Street, Lansdale, PA, 19446

Tel: (215) 368-1661

Contact: John Pruett

Email: jpruett@pmc-group.com pmcvinyladditives.com

POLLARD WINDOWS INC.

1217 King Road, P.O. Box 507

Burlington, ON, L7R 3Y3

Tel: (905) 634-2365

Contact: Damascino Sousa

Email: dsousa@pollardwindows.com www.pollardwindows.com

PORTES ET FENÊTRES PRÉSIDENT INC.

2292 de la Province, Longueuil, QC, J4G 1G1

Tel: (450) 670-4777

Contact: Yvan Houle

Email: yhoule@pfpresident.com www.portesetfenetrespresident.com

POSTERITY GROUP CONSULTING

43 Eccles St., 2nd Floor Ottawa, ON, K1R 6S3

Tel: (613) 897-3783

Contact: Chris Pulfer

Email: pulfer@posteritygroup.ca www.posteritygroup.ca

PREFERENCE NORTH AMERICA, INC.

36 York Mills Rd., Suite 504 Toronto, ON, M2P 2E9

Tel: (416) 498-7751

Contact: Rose Estrella

Email: restrella@prefna.com www.prefna.com

PRESTIGE WINDOW & DOOR LTD.

25 Brier Estates Way N.W., Medicine Hat, AB, T1C 0B2

Tel: (403) 504-4664

Contact: Tyler Hopfner

Email: prestigewindows@telus.net www.prestigewindow.ca

ODL CANADA

65 Courtland Avenue, Vaughan, ON, L4K 3T1

Tel: 1-800-253-3900

Contact: Tom Newton

Email: tom.newton@odl.com www.odl.com

OSTACO WINDOWS & DOORS

248 Bowes Road, Concord, ON, L4K 1J9

Tel: (905) 660-5021

Contact: Jacques Charlebois

Email: jacquesc@ostaco.com www.ostaco.com

PHIFER INC.

P.O. Box 1700, Tuscaloosa, AL, 35403-1700

Tel: (800) 854-9473

Contact: Alan Gray

Email: alan.gray@phifer.com www.phifer.com

PRO-ACTIVE FENESTRATION SOLUTIONS INC.

35B-10520 Young Street, Suite 285, Richmond Hill, ON, L4C 3C7

Tel: (416) 804-1985