Westeck sets the bar for energy-efficient innovation

Shim It Once and Done. SAVE

Grove Shims™ has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Grove Shims™ has the perfect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect alignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 978-534-5188

Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com Free Samples are Available Upon Request.

Grove Shims™ is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Fenestration Review 2021

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

Reader Service

Print and digital subscription inquires or changes, please contact Shawn Arul, Audience Development Manager

Tel: (416) 510-5181

Fax: (416) 510-6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE

EDITOR | Alex MACKENZIE amackenzie@annexbusinessmedia.com 416.510.6809

PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

BRAND SALES

MANAGER | Nav MATHARU nmatharu@annexbusinessmedia.com 226.931.5095

ACCOUNT

COORDINATOR | Barb COMER bcomer@annexbusinessmedia.com 519.429.5171

MEDIA DESIGNER | Curtis MARTIN

GROUP PUBLISHER, VP SALES | Martin MCANULTY mmcanulty@annexbusinessmedia.com

COO | Scott JAMIESON sjamieson@annexbusinessmedia.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

SUBSCRIPTION RATES

Canada - 1 Year $22.00 (plus applicable taxes)

U.S.A. - 1 Year $50.50 (in CDN dollars)

Foreign – 1 Year $58.00 (in CDN dollars)

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com Tel: 800.668.2374

Occasionally, Fenestration Review will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.fenestrationreview.com

Rough waters ahead for the Canadian window and door business?

How Westeck goes beyond current standards to meet tomorrow’s demands.

The growing pains of the Greener Homes Grant.

The case for balancing U-values and natural lighting in the name of efficiency and humanity.

How to set expectations for mask policies on the job and in the field.

COR safety accreditation is a good idea whether required or not.

Mixed reviews from industry on the Greener Homes Grant.

Screens, sealants, laminated surfaces and more to look for.

by Patrick Flannery

The vectors and sources of business pressure have changed in the last year.

In a previous incarnation, I sold CNC machine tools. I remember well the pressure to keep that pipeline full. It was a daily challenge to find the customers who were buying, thinking about buying or at least willing to talk about what I was selling. And I had some good stuff!

That pressure increased in the late ‘90s and early ‘00s when Chinese automotive manufacturers got in the game in a big way. Work had been migrating to Mexico for some time, but most of the more sophisticated machining had stuck around. Then, bids from Chinese companies started showing up with photos attached of huge, gleaming factories filled with the latest equipment. The prices were as low as 80 percent less than what our local shops had to charge. For that price, you could ship your product back and forth a few times to have mistakes fixed if you needed to. Smaller shops started to lay off and close their doors, and the market was flooded with used equipment from auctions. It was partly to get out from under that pressure that I took the different career direction that has me writing to you here today.

Pressure is mounting in business and manufacturing again today and, again, China is involved. But it’s coming from an entirely different direction. Rather than having trouble finding customers, we’re having trouble filling orders. Shortages are hitting just about everything we use to make windows and doors. Customers are sitting on piles of cash accumulated after a year of not being able to take vacations. They are looking at their old frames and itching to do something about the view. That scuffed and squeaky front door suddenly leaped into focus when they had to walk past it 20 times per day. Meanwhile, governments are “helping” with generous rebate programs aimed at driving sales of energyefficient products and retrofits. The phone is ringing off the hook, but I suspect some

salespeople are hiding under the desk rather than having to disappoint their client with an eight-, 10- or 16-week lead time.

The pressure has to be hitting the corner office too, because the cost of everything is rising even as volumes can’t rise to meet them. A lot of people laid off during the pandemic have not returned to work. There’s been next to no immigration for over a year – that’s a hit to the available labour pool that may be underappreciated. And, as if the pandemic wasn’t enough, there was the freak ice storm in Texas last spring that damaged refineries that provide many specialized polymer and resin products for the whole North American market. But probably the largest impact to supply shortages has been the choking off of overseas shipping. At first, it was the anti-COVID measures themselves preventing container ships from docking at ports. But even once that was sorted out, a bizarre problem revealed itself: a shortage of shipping containers. Apparently the slowdown in production in North America caused empty containers from Asia to pile up in ports and depots. For some time, they couldn’t even be returned empty because we thought they might transmit the virus. Once Chinese production ramped up again, there were not enough containers to carry the goods on order, especially with the backlogs. The result has been a decrease in availability of just about everything because there is very little produced in North America any more that does not have at least some Chinese components.

Some of this pressure may be vented in a re-thinking of our industrial supply chains and a willingness to pay a bit more in order to source supplies closer to home. Fenestration Canada had an online seminar recently where Tony Clement, the former federal industry minister, addressed these issues. Recommend you check out the Regional Week recordings at fenestrationcanada.ca.

MasterGrain Doors has announced the appointment of Laura Weil as the organization’s next president. Weil brings to the position a wealth of knowledge and an array of experience in the fenestration industry on a provincial and national level. She joined MasterGrain Doors on Sept. 8, 2021.

Preceding this role, Laura Weil held the position of vice-president of Euro Plus Glasshaus Windows and Doors and continues to hold the role of second-vice-president of Fenestration Canada.

Weil feels this is a tremendous opportunity to contribute to the sustainability and growth of the fiberglass market within the industry. “My roots are in Canadian window and door manufacturing and MasterGrain Doors is known in the industry to have a vertically integrated

manufacturing process and supply chain that ultimately brings refined fiberglass doors to an array of market sectors. I’ve admired MasterGrain Doors and Weber Technologies for years, so it is an honour to be selected to lead this exceptional team.”

Weil will oversee developing, refining and executing MasterGrain Doors’ sales and marketing strategy while positioning the company for continued long-term growth. Weil will also be overseeing the operations of the MasterGrain Door manufacturing facility and ensuring exceptional product quality.

John Martini, the current president of MasterGrain Doors, will be staying on with the company in a supporting role as executive vice-president and will be continuing with sales and product development initiatives. “I am thrilled to have Laura come on board as our next president. I am sure Laura will continue on with a well-executed growth strategy that will always include the customer as our primary focus. Congratulations, Laura!”

AGC has announced it will sell its North American architectural glass business to Cardinal Glass Industries for approximately $450 million. The deal closed in July 2021. AGC cited the need for improvements in profitability and asset efficiency as the reason for the transfer and pointed to its prior relationship with Cardinal and Cardinal’s ability to make “effective use of AGC’s assets and personnel” as reasons to choose Cardinal as a buyer.

The Canadian Federation of Independent Businesses has made a new resource document available to members to assist them in developing a policy regarding COVID vaccination for staff. The template is not intended to provide a framework for mandating vaccines for customers or staff, and the CFIB explicitly recommends against doing so in its release. The CFIB announcement follows:

Our members are frequently contacting our business advisors about vaccination in their workplace. We are pleased to share our new vaccination policy template that we developed in collaboration with lawyers from Sherrard Kuzz. It’s a detailed resource to help you discuss vaccination issues with your staff without spending thousands on professional counselling. As vaccination is a complex topic, this policy can help you have this conversation sensitively and implement the right health and safety protocols for your business. It doesn’t mandate vaccination for your employees, but rather outlines your expectations as well as the employee’s rights. As a rule, CFIB does not comment

or advocate on medical issues. However, considering the many legal issues involved (health and safety, human rights, privacy and employment and labour relations), we felt it important to give you this tool to mitigate risks to your business and avoid fines, lawsuits and/or forced closures. CFIB recommends that you use caution in considering any policy that would require employees or customers to be vaccinated. As governments themselves are reluctant to mandate vaccines in settings like hospitals, a small business could face an expensive human rights or privacy-related lawsuit if it were to implement one. You can find it in our members-exclusive resource library that houses a variety of templates and documents every business owner should have, including the new vaccination policy, a drug and alcohol policy, the employee handbook, a social media policy, and antiharassment and anti-bullying policies.

Members of Fenestration Canada also receive membership in the CFIB and can access these policies at the CFIB website, cfib-fcei.ca.

Here we are, how many days, weeks and months later from...you thought I was going to say the COVID-19 shutdown, didn’t you? No, I’m talking about the GreenOn program of 2018.

As I write this, the Liberal party just won a minority government. Again, how many days, weeks and months did we just go through that for the same result? But let’s talk about the new federal Liberal program that the Trudeau government just recently launched: the Canada Greener Homes Grant. While SAWDAC worked with government entities on this before it was launched, we asked them to look for more development in the way of manufacturing and installer relief, along with a proper install certification program like Window Wise. We have what we have right now and continue to work with the ministries to help streamline processes for our members and consumers. After talking to many dealer members around this program, it is one that hasn’t gained the traction that the program was designed for and we have taken this information back to our contacts to let them know about the grassrootslevel information. One of the things we’re hearing is, “Once we go to the triple-

pane window to qualify for the grant it costs more to do than the original quote and the buyer balks at it and says no thanks,” says Mike Miski of Can-Pro Windows. This is what we are hearing from many dealers across the country, showing us that price elasticity is something to keep in mind when promoting the program with consumers walking through your door. If you would like more information on the Canada Greener Homes Grant, please drop us a line at the office as it includes all things in the house as a system envelope.

As an industry we are still hearing about 16- to 24-week lead times for install on windows and doors, but it’s not so much the glass holding manufacturers back now, its finding people to work and components. With CERB coming to an end, it should help alleviate the problem of finding employees as this has been a real struggle for not just the window and door industry but many businesses in Canada. Components, on the other hand, are something that has hampered the growth of our industry as many dealers are ready to install six or seven days each week to catch up. Hopefully, by the next article in Fenestration Review this will have subsided a bit, so stay tuned for that as we will continue to keep a close eye on this.

A couple of notes to leave you with. Window Wise and those certified dealers continue to set themselves apart during this window buying frenzy, and our RenoPlan financing program has been an amazing add-on to many businesses this year. It has helped dealers capture many more deals. Both of these programs together are gold standards in the industry and, if you are looking to set yourself apart from your competition, you should drop us a line or give us a call to see how we can help you.

From Oct. 1 to Dec. 31, SAWDAC members, in conjunction with FinanceIT, will gain access to exclusive pricing on some of our most popular promotional programs. We’ve slashed the prices on some of our deferral and buydown programs to help you grow your sales and finish the year strong. Offering up to 50 percent off our regular pricing on deferral programs and up to 63 percent on buydown options, this is our most competitive pricing yet. Take advantage of this exclusive offer available until the end of the year. Check out the link to this offer at financeit.io/sawdac. Or reach out to the SAWDAC office to take advantage of this great promotion.

Sawdac has partnered up with PandaPay for all your pointof-sale needs. They have great rates and offer amazing customer service and that is why we have switched to them at our office. They can save you a lot of money on your terminal transactions. If you’re curious to see how much you could save, reach out to us and we’ll give you a quote in minutes. Until the end of November, if you switch over to PandaPay you will receive 50 percent off your membership renewal.

For more information on these amazing offers, please drop us a line at jason@sawdac.com or call 800-318-9616.

You can see our phone numbers on this page, but there’s a lot of other ways to follow SAWDAC activities these days. Web sawdac.com

Annex Business Media is proud to announce Alex Mackenzie has joined Fenestration Review. Alex takes on the role of associate editor as Sukanya Ray Ghosh steps into her new role as editor for Manufacturing Automation and Pulp & Paper Canada. Alex graduated from Northern Michigan University in 2011 with a BS in psychology and subsequently earned their Masters in English in 2017 from Southern New Hampshire University. They bring with them diverse editorial knowledge and experience in the B2B publication sector having worked as associate editor for Allured Business Media’s Perfumer & Flavorist magazine from 2019 to 2021. One of Alex’s primary focuses in this role is to revitalize Fenestration Review’s social media presence across all platforms.

Jeld-Wen of Canada has announced a multimillion-dollar investment in its Quebec-based manufacturing facilities. The Saint-Henri, Que., facility currently manufactures Jeld-Wen’s line of moulded interior doors as well as insulated steel doors. Jeld-Wen’s second facility in St. Apollinaire, Que., is the flagship manufacturing location for the company’s premium line of vinyl and hybrid windows. The investment includes the purchase of new automated manufacturing equipment as well as a footprint expansion in Saint-Henri that will enable the company to substantially increase production capacity.

“We are committed to supporting our customers and their growth,” said Robert Conway, Jeld-Wen of Canada’s vice-president and general manager. “We have seen increased demand for our products nation wide, and we are grateful for the overwhelming support of the Jeld-Wen brand in Canada.”

Jeld-Wen’s Saint-Henri facility sits on 12-acres of land and the current facility spans 150,000

square feet. The facility has served as the Canadian manufacturing and distribution hub for interior and exterior door products for over 23 years. It provides Jeld-Wen with key access to a skilled workforce, a favourable business climate and railroad transportation. The expansion project will add 50,000 square feet to the facility and will be completed toward the end of 2021. The SaintApollinaire facility will receive a new state-of-the-art automated window manufacturing and packaging line which will also expand current capabilities to address growing demand. Combined, the company employs more than three hundred associates in the province of Quebec, making Jeld-Wen one of the the top two largest manufacturers of windows and doors in the province. Other operations in Canada include window and door manufacturing and distribution facilities in Toronto, Winnipeg and Moncton. JeldWen has sales representatives and customer support in every province across the country and offers several regional and national product lines.

ODL has announced Ron Woznick as its new CFO. Woznick, a Michigan native and graduate of the University of Michigan Ross School of Business, comes to ODL with meaningful financial executive experience at Wolverine Worldwide, a global footwear company located in Rockford, Mi. In his over 26 years at Wolverine, Woznick served in various key leadership positions, identifying and harvesting business opportunities to drive value and, most recently, led global sourcing in Hong Kong for the

company’s twelve brands. In his new role, Woznick will lead ODL’s global finance, accounting, IT services and legal teams, from his base in Zeeland, Mi., at the ODL corporate office.

“Ron compliments our performance-oriented culture, and we believe his reputation for execution and achieving results make him a great fit here,” said Jeff Mulder, chairman and CEO of ODL. “His experience and passion to join our purposeful, values-led organization will be a huge asset to our team.”

ODL supplies door glass and blind products to the Canadian window and door industry.

Greg Hildebrand, head of the facade engineering group at Exp Services and a leading technical expert in the Canadian window and door industry, passed away on August 23 after a long battle with cancer. In a LinkedIn post, Exp called Hildebrand “one of the great minds in building science.” Hildebrand was instrumental in guiding and developing many of the standards the industry uses today. He chaired or sat on committees for CSA A440, NAFS and ASTM, and was a tireless contributor and educator.

Thermoplast has acquired Nextrusions, a manufacturer of window and door profiles, from Vision Group. Following the transaction, the Nextrusions plant is renamed Thermoplast Nextrusions. This transaction allows Thermoplast to increase its production capacity and almost all employees will retain their positions. The Nextrusions plant is located in Anjou, Que., with 18 extrusion lines and nearly 100 employees. As part of the transaction Thermoplast and Vision signed a supply, service and technology agreement.

Martin Boulanger, partner and vice-president of finance

• One software – all possibilities

• Design, present, calculate, produce, invoice

• User friendly interface

• Increase profitability

and marketing, stated: “This transaction is entirely in line with our objective of always remain alert and continue to seek for growth opportunities. It ensures we will remain a highly competitive company for years to come.”

Jean Marois, partner and vice-president of sales and engineering, added: “We are now better equipped to maintain and expand our leading position in the Quebec and Maritimes markets and to continue to develop and offer innovative, high-quality products and a superior customer experience.”

by Amy Roberts, FGIA director of Canadian and technical glass operations

Over the past half century or so, the preferred design approaches for energyefficient construction have swung back and forth between restricting window-to-wall ratio and maximizing daylighting to reduce the lighting energy budget. It looks like another swing of the pendulum is underway. The development of the 2020 Canadian National Energy Code for Buildings (NECB) included a code change request (PCF 1541) to reduce the maximum allowable fenestration and door-to wall ratio, primarily in commercial buildings.

The proposed code change, submitted by the Standing Committee on Energy Efficiency (SCEE), was to significantly reduce the allowable glazed area in different Canadian climate zones. However, experience shows that reducing lighting energy, which often comprises the bulk of energy consumption in commercial buildings, is a more valid way to improve energy efficiency than reducing building envelope U-factor. FGIA took the position that this proposal was out of step with today’s high-performing fenestration products, and would have a number of negative impacts.

First, it ignored potential harm to occupant performance, health and well-being. The Illuminating Engineering Society has noted that people in modern societies spend 95 percent of their lives indoors. This highlights the importance of the physiological and cognitive effects of daylighting, revealed by several studies conducted in the early 2000s. These studies quantified the surprising degree by which students, employees and hospital patients perform better in a daylit environment. In retail settings, increased sales and more transactions are the result.

The proposal’s cost-effectiveness analysis does not consider negative financial and economic impacts on building owners. In addition to light quantity and quality issues, all facilities with judiciously designed daylighting can save significant operating costs in the form

of decreased electricity demand. A lack of daylighting can thereby increase costs while lessening desirability, adversely affecting property values and rental rates.

The proposal conflicts with precedents in other energy and green building standards and credits. These include model energy conservation and green building codes such as ASHRAE 90.1, the International Green Construction Code, ASHRAE 189.1, and LEED Daylighting and View credits.

Finally, the proposal threatened design flexibility without adequate justification. Codifying lower window/wall ratios discourages architects from seeking ways to maximize daylighting for the benefit of building occupants while minimizing heat transmission, such as by using new high-performance glazing products, such as spectrally-selective low-E glass, triple glazing, vacuum insulating glass or dynamic glazing. It also forecloses options for increased occupant comfort, connection to outdoors, esthetics and real estate value, with disparate impact on small retailers and owners.

All-in-all, a balanced systems approach in which a designer melds all aspects of a building to maximum effect has always been the best answer. The NECB already provides for this with trade-off and performance paths, which are being increasingly used with commercial buildings.

For these reasons, FGIA recommends following the ASHRAE 90.1 window-to-wall ratio of 40 percent. This would promote harmonization for the industry as a whole, while not following this recommendation could create a significant barrier to trade.

Based on this rationale, the industry was successful in stopping the code change proposal from going forward in the 2020 NECB. However, the SC-EE will be looking at other ways to drive further energy savings in future codes, and the industry will need to monitor this activity closely.

Mistify decorative doorglass is the playful combination of pattern and texture. The black drizzle pattern is fused to softly textured glass, resulting in a mesmerizing statement piece for any modern entryway and privacy for the home.

Give your showroom a fresh new look with these show stopping doorglass displays: Affluent, Salix and Mistify 1 Lite or 4 Lite and our new Blink Entry Doorglass.

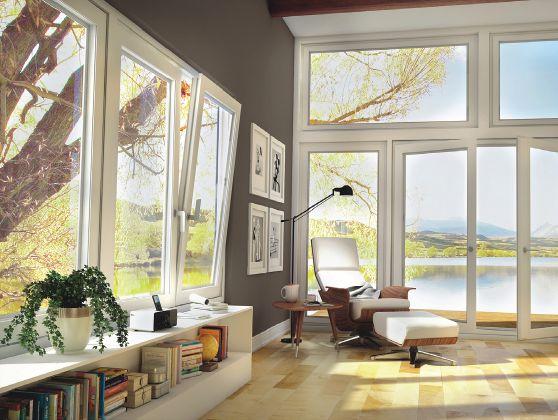

How Westeck’s products go beyond current standards to meet tomorrow’s energy-efficiency demands.

Westeck Windows and Doors has been at the forefront of the industry in terms of innovation and product firsts, delivering energy efficient options for custom home builds in western Canada and the northwestern United States.

by ALEX MACKENZIE

Westeck strives to not only meet the stringent energy efficiency standards of the Vancouver region but goes beyond to offer Passive House-certified quality products that are setting the stage for the future of eco-friendly housing.

The company has grown from a small start-up into an industry leader thanks to an ever-better mindset and ambition to stand as an example to others in the industry.

The Westeck team consists of over 250 employees with 30 project consultants across three manufacturing facilities located in Chilliwack, B.C. The company also boasts seven showrooms throughout British Columbia and Washington state. While its main focus is on production, Westeck also works with clients to arrange for the installation of its products via subcontractors that are familiar with the specific installation needs of Weteck’s unique products.

Will Tait, general manager for Westeck, has been with the company since January 2021 after 30 years in the industry in both western Canada

and the U.K. He began in accounts and finance and has been in management positions for over 20 years, with the past seven years in the role of general manager. “Looking at Westeck, they were one of those names, one of those companies, one of those competitors that were out there in western Canada that you look towards,” says Tait. “So, when the opportunity came for me to take this role, I basically jumped at the chance.”

The recent heat dome that seared the west coast of North America brought many conversations around environmental impact to the forefront. As a result, a large portion of the industry that is involved in building development is looking for ways to offer solutions that have a positive impact on energy efficiency and contribute towards the mitigation of climate change.

Westeck’s primary customer focus is currently centred on high-end single-family homes in western Canada, predominantly in British Columbia, with a large portion of sales coming specifically from the Vancouver market. As Vancouver, and B.C. as a whole, has some of the highest standards for energy efficiency and sustainability in the world, Westeck has spent a great deal of time and effort bringing its products in line with those standards and has even gone so far as to exceed them by offering Passive House-certified products.

Passive House is a voluntary standard that seeks to create ultra-low-energy-use buildings

Architects and builders love to see the combination of living wood and velvety, powdered aluminium. The trend combination for windows, doors and facades can be implemented easily and flexibly with the exterior finishes for building elements from skai®: skai® Mattex impresses with a realistic powder coating structure and is the absolute flattest matt finish ever. Equipped with proven cool colors technology and available in current trendy colors, it is the f irst choice for exterior f ilms, even in extreme climates. skai® Woodec and skai® Mattex – the clever wood-solid color matt look. Visit us at the Windoor exhibition 2021 from November 17–18 in Toronto. www.skai.com/exterior

by reducing the amount of energy needed to heat or cool the spaces within. This is often achieved by ensuring air tightness and proper insulation. A key factor in this endeavour is the quality and high performance of the windows used. That’s where Westeck comes in.

Westeck offers a Passive House lift-and-slide door as well as a North American-style wood outswing casement window. The company also pushes for high efficiency standards across its product lineup to get the best U-values possible and provide its customers with future-facing, energy-reducing products. As Tait puts it; “We want to keep it functional and good looking, but at the same time, it has to be able to hit or exceed the current code that the city of Vancouver, if nowhere else, will be continuously pushing forward.”

Westeck achieves the high level of efficiency in its products by using tripleglazed argon- and krypton-filled units with multiple coats of low-E to allow for a thinner, smaller frame that helps reduce weight and increase efficiency. Furthermore, Westeck does its own inhouse testing for performance, research and development and quality control purposes before any products are sent out to the accredited test lab facilities for validation of compliance and certification. This allows the company to redesign its products as many times as needed to achieve the maximum efficiency ratings, structural stability and compliance certifications.

Custom high-density fiberglass mullion reinforcement can exhibit roughly 200 times less conductivity while maintaining its structural integrity due to its geometric design. Westeck has gone to lengths to mitigate it’s use of traditional metallic reinforcements, which inherently decrease the overall thermal performance of products due to their extremely high material conductivity.

Current industry-wide thermal modeling and labelling techniques aimed to enable consumers to conduct a like-for-like product comparison do not always take mullion reinforcement into account. Producing a product larger than the standard modelled size often increases the metallic reinforcement required, and thus creates poorer thermal performance levels. Westeck’s custom fiberglass mitigates these effects.

As housing trends begin to shift away from single-family homes towards more communal, multi-family buildings, such as condos and townhomes, Westeck is keen to move into those markets through its foothold in the renovation market. Another factor driving trends in the market that cannot be overlooked is the impact that COVID-19 has had on purchasing and home-buying trends. People are in their homes more and spending more money, time and effort towards making those homes comfortable, affordable and sustainable. Windows and doors are often high on the replacement list as older units are far less energy efficient than modern options.

Tait foresees this continual push for higher energy efficiency and environmental standards will make it more difficult for many in the industry and will result in some consolidation. Those that will be able to meet the rising standards will serve as an example in the industry,

and Westeck aims to be that example. Westeck is now benefiting greatly from the foresight of its previous management, which set the company on its current path of producing windows and doors to the highest standards of energy efficiency –standards that are rapidly moving from voluntary measures to compulsory qualities.

When product innovations become the daily norm, it seems reasonable that a company could let their foot off the gas and enjoy their moment in the spotlight. Not Westeck. The company maintains its momentum through a company culture and ambitious team mindset that have been cultivated by members of senior management over the past 20 years. “We want to be the best in the industry,” says Tait. “We want to be the company that other window fabricators look up to. But maybe not even just in the window industry.” Indeed, Westeck has set itself out as the company to emulate when it comes to innovation, especially with

regard to energy efficiency and environmental impact.

But how does a company plan for the future in such an uncertain present? According to Tait; “We have to constantly be looking at what the long-term expectations are and what we can do to build and improve on that.” And those improvements come into play at all levels of the company, not just product innovation.

Westeck’s new system was a year and a half in development and, like so many large changes recently, the switch came during the height of the pandemic. “Now that it’s there and it’s ready and we continuously improve on it, how do we go beyond that? How do we make more improvements?”

The technical team as well as the sales team are always on the lookout for those improvements, wherever they can be found. This tireless drive towards excellence is what keeps the company churning out new products that don’t merely push current standards but, in many cases, blow right past them.

Navneet Matharu has joined Fenestration Review as a Brand Sales Manager. She brings 10 years of high-level media sales experience to the position.

“I’m super thrilled to be joining Fenestration Review. Looking forward to working with marketing professionals and business owners in the window and door industry to help them grow their businesses.”

Nav is available to discuss all of Fenestration Review’s dozens of marketing and advertising opportunities. Get your 2022 media kit today!

Certificates of

are a growing part of the industry landscape.

Each year in Canada, the Certificate of Recognition (COR) safety program becomes more well known and a little more widespread in the construction industry. Window and door manufacturers and installers may choose to become COR-certified for a variety of important reasons.

by TREENA HEIN

COR-certified companies send the message that they take safety seriously and therefore fare better in the labour market.

Start with a quick look at the program. COR accreditation verifies that companies are meeting national occupational health and safety standards. It began in Alberta more than 20 years ago. It’s overseen by the Canadian Federation of Construction Safety Associations but implemented by provincial agencies such as the BC Construction Safety Alliance (which also serves as the current contact for CFCSA inquiries.)

COR aims to provide employers with an effective safety and health management system to reduce safety incidents, accidents and injuries as well as their associated human and financial costs. Its effectiveness at lowering

injury rates has been proven though recent independent impact evaluations in B.C., Alberta and Saskatchewan conducted by researchers at the University of British Columbia School of Population and Public Health in collaboration with BCCSA and WorkSafeBC (see CFCSA website for the research briefs).

To achieve COR certification, companies must demonstrate many aspects of workplace health and safety, culminating in an external audit, including policies and procedures, training, hazard assessment, emergency response and incident investigation. Companies must train their own internal auditors to ensure compliance between external audits (generally every three years).

The benefits of COR certification are many for anyone involved in residential construction, including lower annual insurance premiums. In Alberta, for example, COR (or SECOR, Small Employer COR) qualifies employers for Workers Compensation Board premium rebates of up to 20 percent. And, in B.C., with COR certification, a company scores a 10 percent rebate from WorkSafeBC. “Over time,” adds BCCSA director of COR and injury management Vernita Hsu, “with lower injury rates and lower claim costs, insurance premiums will reflect additional savings.”

In Ontario, COR is being migrated to COR 2020 to help workplaces qualify for financial rewards and recognition from the Ministry of Labour, Training and Skills Development and the Workplace Safety and Insurance Board. COR2020 has a new format and the audit tool has a reduced number of elements.

COR-certified companies might also have an easier time with recruiting

tradespeople. “In an increasingly competitive labour market, where workers have more options for employment, they will choose to work for companies who have their best interests at heart,” Hsu explains. “If you have the option of working for an employer that has a system in place that will ensure you have a close-to-20-percent-better chance of avoiding injury and, more importantly, serious injury – all things being equal, the choice becomes obvious.”

COR is also a practical way of demonstrating to customers and the public that you take safety seriously, adds Hsu. “COR certification makes a strong statement about a company’s commitment to protecting the well-being of workers and maintaining a culture of safety on jobsites,” she says. “Having a third-party audited system shows the world that someone beyond the company thinks your safety system is ‘good.’”

Beyond all these benefits is the fact that COR certification is becoming a requirement of doing business on larger

projects. COR is now frequently used as a pre-qualifying and/or condition of contract by both public and private project owners across Canada. Indeed, in part because more of these owners consider COR preferential for bidding purposes or in some cases a pre-requisite, COR participation in B.C. has increased substantially in recent years, almost doubling since 2010.

Sobi Ragunathan, an external COR auditor for the Infrastructure Health and Safety Association (which administers COR in Ontario) at 4S Consulting Services in Markham, Ont., notes that there is a huge demand for COR certification across Ontario. She says many municipal infrastructure projects require COR certification or to be ISO 45001 registered for bidding. “It began with the city of Toronto,” she notes, “and has expanded from there.”

So, to make sure a bid is successful, larger contractors increasingly only want subcontractors that are also CORcertified. In addition, having everyone

COR is already an assumed requirement on commercial jobsites. But residential builders are starting to look for it, too.

on the jobsite COR-certified means that every worker’s health and safety activities are aligned.

Adoption of COR has been very successful among residential contractors in Manitoba. The Construction Safety Association of Manitoba began promoting COR among smaller contractors for many years by offering practical resources, including associated checklists and guides. “Now, over half the payroll in construction in Manitoba is COR-certified and, for reden-

COR certification is granted by various authorities in each province and territory. A straightforward process is available to companies that have achieved COR and would like to request equivalency in another jurisdiction. See the program overview at cfcsa.ca/cor.php.

BC Construction Safety Alliance bccsa.ca/cor

Two COR programs are offered depending on company size.

Alberta Construction Safety Association youracsa.ca/cor-secor Offers COR and SECOR (Small Employer COR).

Saskatchewan Construction Safety Association scsaonline.ca/programs/cor

The Heavy Construction Safety Association of Saskatchewan also offers COR (hcsas.sk.ca/programs-courses).

tial construction, COR is required to be a member of the Manitoba Home Builders Association,” notes CSAM executive director Sean Scott, who also chairs the CFCSA National Technical Committee and COR Committee. “Overall, about 1,000 building construction companies are COR certified in Manitoba, and 39 percent of those have 10 or fewer employees. Once achieving this prestigious designation, almost 100 percent of all companies maintain their COR certification year after year.”

Scott notes that financial incentives definitely play a role in becoming COR-certified, but they are only one of the benefits. “In 2020, we had about $2 billion in construction payroll in Manitoba and $3.5 million in prevention rebates provided to COR-certified employers,” he reports. “In 2019, severe injuries were reduced by 14.4 percent from the year before and that’s directly influenced by COR certification. It’s an established and creditable program that results in fewer time-loss incidents, improves morale and retention and provides a systematic approach to doing a job. It allows safety to become an integrated part of production, quality and efficiency.”

While the time to achieve COR certification will vary depending on the size and complexity of a contractor’s operations, Scott puts the minimum time at three to six months. The CSAM offers the required COR training courses every month, adaptable templates, personal consultation and more to ensure swift implementation. The cost is $775 for the required training and audit in the initial year of COR in Manitoba, and $550 for maintenance years.

“Our sense at the BCCSA,” says Hsu, “is that COR demand will continue to grow, particularly because the program has been empirically proven to reduce injuries. There is no other system that can claim that.”

Construction Safety Association of Manitoba constructionsafety.ca/cor-program

Also offered by the Manitoba Heavy Construction association (mhcaworksafely.ca/cor-program).

Infrastructure, Health and Safety Association (Ontario) ihsa.ca/cor-home

ASP Construction (Quebec) asp-construction.org

Newfoundland and Labrador Construction Safety Association nlcsa.com/cor

New Brunswick Construction Safety Association nbcsa.ca/programs/cor

Construction Safety Nova Scotia constructionsafetyns.ca/cor

by James Hong

COVID-19 mask wearing is required when keeping six feet apart is not possible. Having said that, I consider that rule to be inconsistent with the reality of the construction work environment and the nature of our hardworking construction teams. I challenge anyone to show me an instance where a worker has the time to be considering whether they are moving in and out of situations determined by footage proximity. It’s simply not practical and our people are far too busy focussing on doing a professional and safe job to be spending energy on this rule. The solution is to keep your mask on.

Here’s a company-wide email I composed not so long ago:

Subject: Regarding the direction to hold daily safety toolbox meetings covering COVID-19 protocols.

It’s been a difficult year for everyone. Due to recent findings that job site workers are either removing their masks or wearing them incorrectly, we need to firm up our commitment to keeping everyone safe.

Masks are mandatory at all times while on the job site, even when working alone. COVID-19 is airborne and spreads through breathing from the mouth and nose, as well as other airway access.

“We need to remind ourselves that COVID-19 mask-wearing is essential PPE.”

Removing or wearing a mask incorrectly has the potential to contaminate the air around you, and especially with new variants in the pandemic, we don’t know exactly how long that strain stays alive in the air. Let’s not forget that people can be carriers without any symptoms and inadvertently infect those around them.

We do not have control over who might enter the job site every second of the day, especially when working alone. Visitors and other

unexpected persons could enter the jobsite and be infected, or you could be infected from their unprotected breath. Crowded jobsites pose an extra severe threat for exposure when mask protocols are not followed.

All job sites have mandated requirements for mask posters on site, instructing how to wear a mask properly. The daily safety meetings are to happen at start of shift and for every shift during the job. This is a touch base, reminder, question and answer session to include mask wearing information.

Daily toolbox safety mask topics:

• State the reason for the meeting.

• Remind people that masks are mandatory at all times on the job site.

• Use the poster to instruct how to wear a mask properly.

• Instruct to always cover the nose and how to do so when wearing a mask.

• If people need some air, they are to go outside and take their mask off while following distancing protocols.

Please be diligent. We’re almost out of this, now is not the time to relax. Keep yourselves, your families and your co-workers safe. No one wants to be the mask police; unfortunately, it falls to us to keep a close eye out to protect ourselves and those around us. When you see someone without a mask, or not wearing a mask properly, that requires immediate corrective action. It cannot wait until break time or one hour or even one minute, it must be corrected on the spot and must be reported in your daily log.

The report is a tool for following up, to ensure our workers are trained to properly wear a mask.

The sentiments I’ve expressed in the above email are heartfelt and if I may say so, applicable to everyone no matter their working circumstances. We need to remind ourselves that COVID-19 mask wearing is essential PPE, just as important as a fall protection harness and other essential PPE.

Be safe. Be well.

James Hong is chief of OHS for the construction industry.

The window industry weighs in on the impact of the Canada Greener Homes Grant.

by ANDREW SNOOK

There are mixed reviews coming from the industry when asked about the impact of the Canada Greener Homes Grant.

The grant, rolled out by the government of Canada, was designed to incentivize homeowners into retrofitting their homes to make them more energy-efficient while stimulating domestic green supply chains, fighting climate change and creating thousands of jobs for energy advisors. Homeowners can receive a subsidy upwards of $5,000 for qualifying energy-efficiency upgrades.

In the world of windows and doors, all products must be Energy Star-certified to qualify for the grant, and an EnerGuide evaluation must be performed in advance of the installa-

tions. Homeowners are reimbursed for the cost of the EnerGuide evaluation if they complete the full retrofit process.

There’s only one problem. The energy auditors are in short supply in some regions of the country.

Zana Gordon, executive director of the Fenestration Association of B.C., says the grant is increasing sales and driving business for some members, whose customers are aware of the program. However, she says the EnerGuide audits have been a nightmare.

“There are not enough people that are

LEFT: To qualify for the Greener Homes Grant, all windows and doors must be Energy Star-certified.

RIGHT: Although homeowners can receive up to $5,000 through the grant, for many, the incentive is too little compared to the high cost of qualifying products.

trained to do these, and the ones that are trained do not know enough about how window performance works,” she says.

Jason Neal at the Siding and Window Dealers Association of Canada says his association is pleased to see the government stepping forward offering these grants, but has heard of similar concerns related to the number of available energy advisors.

“There’s quite a bit of demand for energy-efficient green products, but we don’t have the database of energy advisors,” he says.

Ben Polley, president of Evolve Builders Group in Guelph, Ont., says that he has heard of some energy auditors being backed up as much as three months in the Kitchener-WaterlooCambridge area before they can perform the necessary EnerGuide evaluation for homeowners.

Part of the challenge with having enough energy auditors available to perform the EnerGuide evaluations may stem from the cancellation of previous similar green rebate programs when provincial or federal governments change after an election, Polley speculates.

When governments change and cancel rebate programs and grants for homeowners, it can generate disruptions in the industry. Many energy auditors that lose their jobs once these grants go away leave the profession altogether.

That said, not all regions are having the same challenge.

James Baker, vice-president of Heritage Renovations Windows and Doors in London, Ont., reports no complaints about backlogs for energy audits as they try and ensure their customers are prepared for all aspects of the rebate process.

Shannon Ruffell, vice-president of Heritage Renovations, says they have had customers go through the entire

process of the grant program with positive results.

“Normally we would be the ones they would come to right away saying, ‘I need help with this,’ or ’I need assistance to push this through,’ and we really haven’t got any of those requests. So, from our side, it seems like everything is going really smooth with the program.”

Another challenge related to the grant program may be the level of incentive being offered.

“I have not observed the same kind of momentum and interest in energy efficiency updates through this program as we have through the provincial program that was cancelled two or three years ago,” Polley says. “I would personally say that with the current program, the incentives are too low to actually motivate or create a decision they would otherwise have not been able to afford or consider.”

In his personal opinion, Polley says the current grant is small enough that all it is really doing is subsidizing people that were already going to do the work.

On the flip side, at Heritage Renovations, the company is enjoying a very positive experience with the Canada Greener Homes Grant program.

“We’ve been using it quite a bit at Heritage,” Ruffell says. “We found it’s been very exciting for customers. A lot of customers are doing renovations right now anyways.

“We were hearing rumblings of this several months before it officially got launched, that they were coming out with something that was in the final stages. When it did get launched, we immediately jumped into doing as much research as possible on it,” Ruffell explains.

She says that the majority of the

rebate applications her company is submitting are in the $125 range.

“Often, to get into the bigger amounts, the upgrades that are needed to hit those limits outweigh the rebates that people are getting back,” Ruffell says.

While some companies have aggressively sent out information on the rebate program, it is unknown how much effort has been made by the federal government to let homeowners know the Canada Greener Homes Grant is available.

“The awareness on the consumer level hasn’t been as robust as a lot of people would have expected. It’s mostly at the dealer level. When they did the Green Ontario program there was a mass marketing blitz on it, and I don’t think it’s the same right now,” Neal says, adding that with the backlog of energy advisors, the government likely wants to address that issue before it markets the grant program aggressively.

A portal set up by Natural Resources Canada can be used by residents across Canada to apply for the subsidy, except for those in Quebec (applications must be through RenoClimat) and Nova Scotia (applications must be submitted via the Home Assessment Program.) The program will accept qualifying retrofits dating back to Dec. 1, 2020, if they have been recommended by an EnerGuide evaluator. This grant can be obtained in conjunction with additional grants from a homeowner’s provincial and regional governments.

For more information, visit NRCan’s Canada Greener Homes Grant webpage at nrcan.gc.ca/energy-efficiency/homes/ canada-greener-homes-grant.

Our association continues to make progress despite challenges.

by Mike Bruno, president of Fenestration Canada

Although the season is changing, it looks like there have been no changes to our industry struggle in 2021 and it is starting to look no different for 2022. I hope everyone is doing well and keeping safe.

FenCan has been working on several tech talks and education topics over the last year virtually, which have been received well by our members. One advantage of being online is that we are able to target our sessions at specific regions of the country without having to travel to be there in person. We took advantage of this most recently with our Regional Week event in October. That event opened with a national presentation on supply chains featuring the former federal industry minister, the Hon. Tony Clement. Then we hosted four more sessions over the next two days, each concentrating on a particular region. The B.C. region heard about solar heat gain; the prairies heard about their local supply chain issues; Ontario got an installer training talk; Quebec learned about their special supply chain challenges; and Atlantic discussed building and installing heavy triple-glazed units. Recordings of all these presentations are available on our website and YouTube channel.

“We are stronger together than alone.”

We look forward to continuing to provide the current method of delivering information to our members, but are extremely excited about WinDoor 2021 in Toronto, with an in-person and virtual experience and, of course, the much anticipated return of our Main Event and Hall of Fame night. The focus is going to be on our new Hall of Fame inductees, complete with an awards-show look and theme. Recognizing and

honouring the amazing men and women who built this industry is one of my favourite things we do as an association – especially when you get them talking about the old days.

We have seen an increase this year in our membership drive and look forward to continuing to strengthen our regional committees. This year, more than ever, the regional committees have played an integral part in our association and will continue to do so, as we continue to struggle with restrictions being imposed across the country. As things open up, we would like to have regional in-person meetings across the country so that we can ensure we deliver the best possible information to our members. Now, more than ever, the ability to share information from an association standpoint and from best practices shared among members is critical to anyone’s success. We are stronger together than alone.

Speaking of “together,” I want to remind everyone about our great partnership with the Canadian Federation of Independent Businesses. Your Fenestration Canada membership gives you automatic membership in the CFIB and access to all their incredible resources and benefits. The CFIB now represents over 95,000 small and medium-sized businesses across the country, so this partnership definitely gives us some added clout! Did I mention that Fenestration Canada membership is free until the end of the year?

The spring conference was a great success, with over 250 registrations. All the presentations are available online in Marketplace by WinDoor. We also announced that WinDoor will be a hybrid event this year. It will take place in Toronto for the in-person event and also online for those that can’t join us. I am sure everyone is looking forward to the in-person show and, of course, to participating in the Main Event. You can buy tickets for the Main Event and reserve your booth for this event right now. Contact Laine Atkins at laine@fenestrationcanada.ca.