Labor-Saving

Grove Shims has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Looking for the right shim?

Grove Shims has the perfect shim for all your shimming needs. With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money Need help? Just ask! We’re here to help. 978-534-5188

Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com Free Samples are Available Upon Request.

Grove Shims is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Fenestration Review 2019 Vol. 8 • Issue 3

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

ACCOUNT

COORDINATOR | Stephanie DEFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

CIRCULATION MANAGER | Urszula GRZYB ugrzyb@annexbusinessmeda.com 416.442.5600 ext. 3537

MEDIA DESIGNER | Alison KEBA

GROUP PUBLISHER, VP SALES | Martin MCANULTY mmcanulty@annexbusinessmedia.com

COO | Scott JAMIESON

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

email: subscribe@glasscanadamag.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

email: asingh@annexbusinessmedia.com Tel: 416.510.5189

Fax: 416.510.6875 or 416.442.2191 Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $22.00 (plus applicable taxes)

U.S.A. - 1 Year $39.00 (in US dollars)

Foreign – 1 Year $44.50

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com Tel: 800.668.2374

Occasionally, Fenestration Review will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.fenestrationreview.com

CANADA’S WINDOW AND DOOR MAGAZINE

4

EDITORIAL

Charity is great, but companies contribute most through their day-to-day business.

18 HELP HIRING HELP

Advice from an expert on government funding for hiring and training.

15 PHILIBUSTER

Fourth-surface low-E may not be such a great idea in Canada. by Phil Lewin

6

INDUSTRY NEWS

Everlast opens in Thunder Bay...Happy 50th to York... Graby steps down from AmesburyTruth...more...

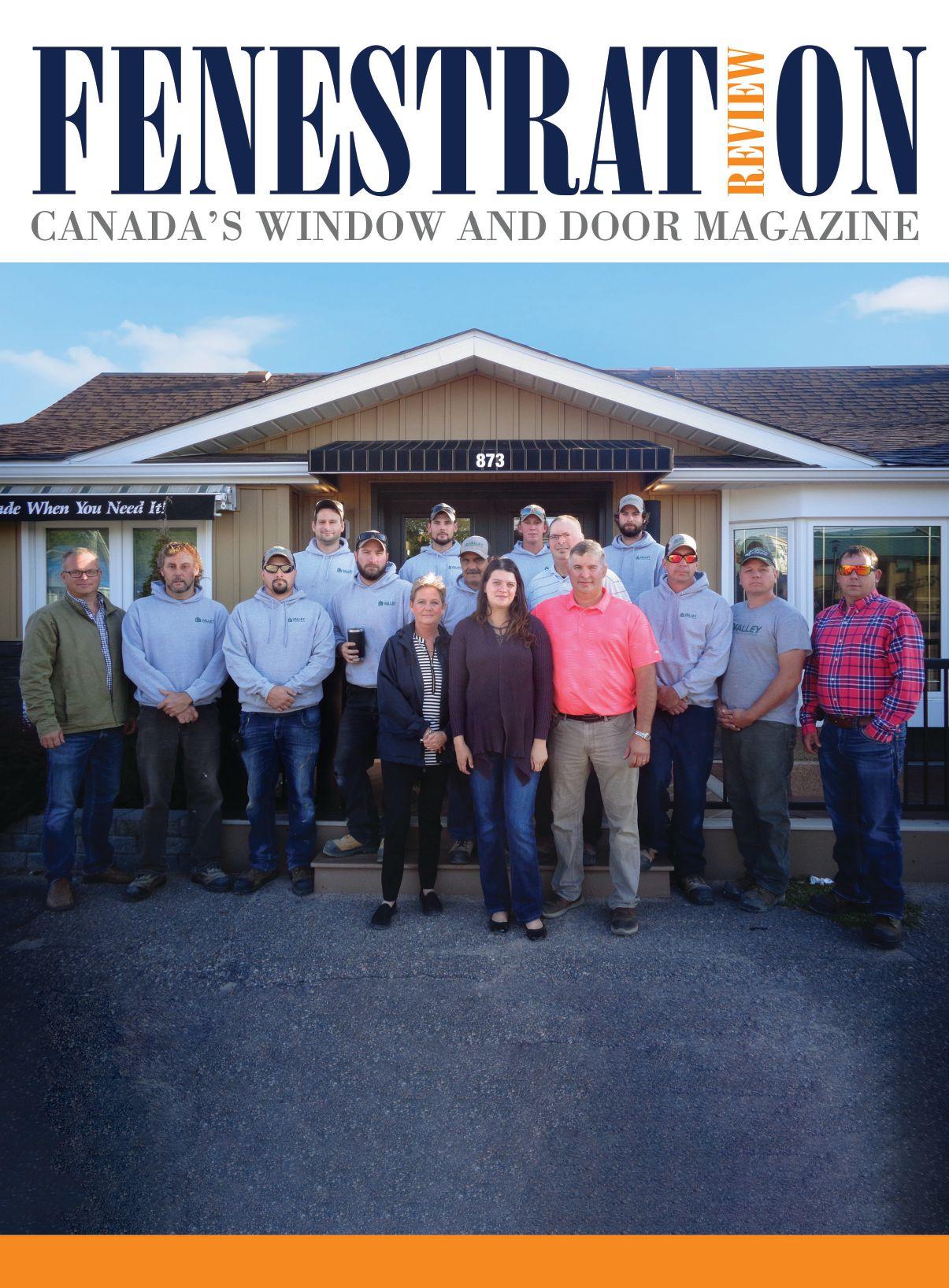

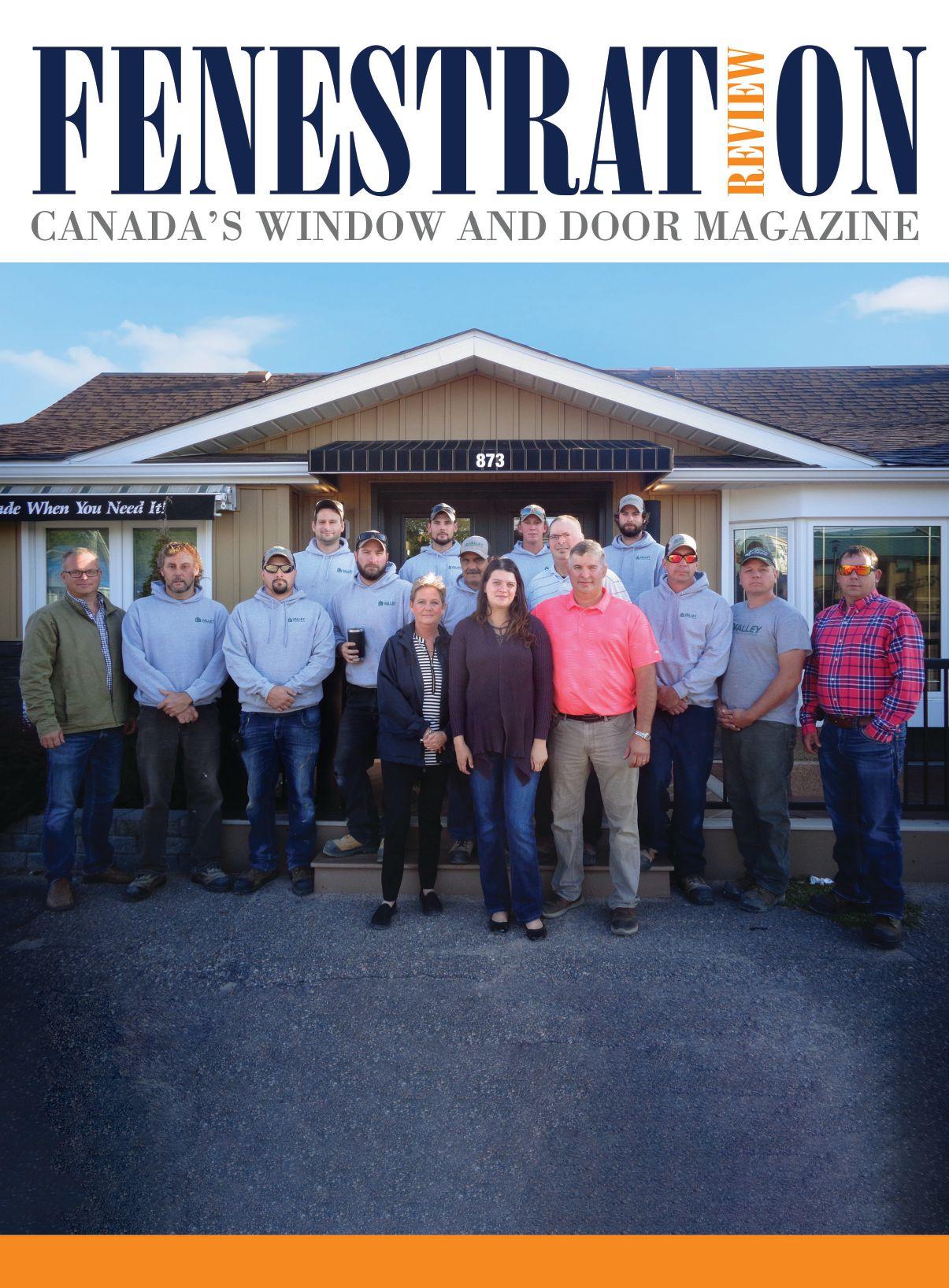

12 REPUTATION AND DIVERSIFICATION

Trying new things in a traditional way is a winning combination for Valley Window and Door.

WINDOOR 2019

20 FIT & FINISH Energy regulations are driving consolidation in our industry. by Chris Meiorin 22

26

Canada’s window and door show returns Nov. 20 - 21.

WINDOOR SNEAK PEEK

Here’s a sample of what you’ll find on the floor at WinDoor.

30 THAT’S RICH

A sense of entitlement is a bad look for a business professional. by Rich Porayko

Sticking to the knitting

by Patrick Flannery

Companies improve the world by making money.

The Economist had an excellent opinion leader this summer (Aug. 24 to 30, “What companies are for”) discussing the rising trend toward big corporations taking positions on political and social issues. The piece points to statements by the CEOs of companies like Walmart and JPMorgan Chase stating outright that their organizations have a broader responsibility than maximizing shareholder value; that they also have to serve their customers, staff, suppliers and communities.

The article brought to mind Nike’s recent ads featuring Colin Kapernick (the NFL quarterback ostrasized for his sideline protests over police shootings) and hijabs designed to wear while playing sports. Clearly, Nike has calculated that there is some benefit to be gained in being seen to be on a particular side of certain issues. The question of the sincerity of the positions I’ll leave for others to debate. We’re often told the next generation of consumers and workers wants to feel like the companies they are associated with stand for something, allowing them to feel good about their patronage beyond just getting value for their money. Some major corporations appear to have decided this effect is powerful enough for them to take sides even on controversial issues, risking alienating one group of potential customers in order to increase enthusiasm in another.

Even the broader question of whether corporations should take on social responsibilities beyond making money is not easily answered. It might seem obvious that donating to a Habitat for Humanity build or sponsoring a local hockey team is a good

thing, and it probably is. But The Economist calls the larger concept of companies being seen as providers of social welfare “collective capitalism” and cautions that it carries risks, at least at a very macro level. It points to the examples of GM and AT&T that made alliances with unions and governments to hire more people, open more facilities and offer higher wages and benefits than a pure business case might have justified. Here in Canada we might think of Bombardier and SNC Lavalin as companies that became “too important to fail” based on the perceived social benefits to their communities.

These examples are pretty far above the pay grade of the average window and door company. But what happened to them as they took their eyes off the ball of shareholder value and started making decisions based on a self-perception as community organizations is instructive. Innovation stalled as the incentive to stay ahead of the competition was diluted. Flexibility was choked off as it became difficult or impossible to make the hard decisions, like cutting staff. Public resentment grew as they inevitably failed to meet the lofty standards of good behaviour and public benefit expected of governments.

I think things work better when organizations stick to what they are designed for. Companies are good at making money, not so good at designing laws and public policy. Leave that to governments, who at least can get thrown out periodically, and let the community benefits flow from your thriving business. But do sponsor the hockey team. Some of the parents in the stands might need new windows.

New 2248 Vented Door Lite

Corner Screw Holes

One piece injection molded frames

Large ventilation area

Safety lock preventing forced entry

Polypropylene will not fade in the sun

All venting door lites available in a wide variety of textured glass and bar designs

INDUSTRY NEWS

Everlast opens Thunder Bay location

The Everlast Group of Companies held an open house to launch its new facility in Thunder Bay, Ont. President Mike Bruno says the plan is to bring his contemporary styles and colours of both windows and doors to a market Everlast was already actively serving. The new location was purchased from A.R. Ross and is located at 612 S.High St. The existing space was renovated to showcase both Everlast products as well as siding and windows from PlyGem/Mitten. As part of its move to Thunder Bay, Everlast is supporting the local Habitat for Humanity with donated product for two homes and laptops for each of the children that will eventually live there.

“The families were ecstatic,” Bruno reports. “The story aired on local news stations and The Chroniclel Journal newspaper as well.”

In the weeks leading up to the grand opening night,

manager Rob Buie and T.J. Chiodo organized a raffle in support of Habitat for Humanity to take place at the event. The grand prize was tickets to a Toronto Maple Leafs game and a $500 prepaid Visa card to assist with travel expenses. The night was a great success with over 100 people enjoying some food and beverages inside the showroom and under the tents outside. The guests did not disappoint as they generously opened their wallets and managed to raise $3,520 for Habitat for Humanity.

York Aluminum celebrates 50 years

York Aluminum is celebrating 50 years in business. The Torontobased manufacturer of storm doors, porch enclosures and storm windows was started in the Weston area of Toronto in 1969 by Ernie Weidner. Today, it is run by his sons, Ed and Kurtis, and his sister, Marnie. It an operates out of a 35,000-square-foot facility in Etobicoke.

“York Aluminum was started by my father in a 2,000-square-foot unit,” Ed reports. “We have relocated six times over the years and been in

Drew and Choe take

Etobicoke since 1974. We pride ourselves in quality, reliability, honesty and customer service. I strongly believe that’s why we are here today carrying on what my dad started 50 years ago.”

York Aluminum manufactures custom-sized aluminum storm doors, screen doors, porch enclosures, entrance enclosures, storm windows and professional weather-stripping. It is 100 per cent Canadian family-owned and operated. York serves a network of independent window dealers and installation contractors. The company can also provide custom-sized storm and screen door designs, glass and screen enclosure panels, a wide selection of handles including security options, sand etched glass, bevelled glass and quality heavy-duty hardware.

leadership roles at FenCan

Fenestration Canada has announced new appointments to its board of directors and executive committee. Eddie Choe, director of business development at Trimlite, has been appointed to the board to fill a vacancy. Cam Drew, managing partner at Thermoproof Windows has joined the executive committee for the 20192020 term of office.

“I am both humbled and proud to serve on the board of directors for Fenestration Canada, and I am eager to contribute to our continued progress,” Choe said.

“I’ve always been impressed with the work that FenCan has done on behalf of our industry,” Drew commented. “I’m looking forward to playing a part going forward.”

“I am thrilled to be working with Eddie and Cam,” said executive director, Stephane Labelle. “They will be an important part of what FenCan is looking to accomplish in the future.”

Cameron Drew

Eddie Choe

SAWDAC Newsletter

A LOOK AHEAD

After surveying many dealers and manufacturers throughout Canada. the industry has a positive outlook around the end of the year and into 2020. A majority of our membership are forecasting a modest increase in sales for the back half of 2019. Dealers and manufacturers responded the most postively about sales in 2019, with almost 70 per cent of these members saying that sales would increase. This is great news especially for the Ontario region after the GreenON program seemed to have moved sales forward from the first half of the year.

WORKING WITH COLLEGES

With this growth we keep hearing of the shortage in skilled labour to help support this growth. We get many calls at the office discussing this. We are currently trying to work with numerous colleges to integrate the Window Wise installation course into some of the programs they offer for graduates interested in the window and door industry. This is currently in the pilot stage.

SALES TRAINING

Another area we always hear about from our members is the need for qualified sales

people. We will be hosting sales training seminars in the fourth quarter of 2019 and the first quarter of 2020 to help alleviate the shortage. If you would like to add your sales staff to this list, please reach out to us and we’ll make sure they are added to enhance their sales tool belt.

INSURANCE BENEFITS

SAWDAC has recently reintroduced our partnership with Federated Insurance to the membership base as they have offered some great value-added services that only SAWDAC members can receive. Specifically, they have a legal advice service that they offer to anyone who is covered by Federated Insurance. Drop us a line if you would like to receive more information or have Federated Insurance give you a quote.

SOCIAL SAWDAC

Another area that SAWDAC has ramped up over the past six months has been our social media presence. We have been trying to capture as many new followers to the window and siding industry while showcasing many of our members to them. If you would like to ask questions about our social media coverage and how you can be highlighted

It was good driving weather for SAWDAC executive director Jason Neal at the annual tournament on Sept. 19. About 65 members convened at Turtle Creek Golf Club in Guelph, Ont., for a fun scramble and a delicious pork barbeque after. The putting contest raised $320 for Kids Can Play.

or added please reach out to sabrina@sawdac.com

JOIN THE BOARD

Looking forward to next year, our board will be looking for engaging and qualified individuals that would like to be a part of the SAWDAC board. If you have a passion to help drive the window and door industry

forward in an energetic and ethical way we would love to see you add your name to the list of nominations. We will be sending out the nomination forms in late December and then sending out the voting proxies in January. If you would like to be a part of this or have any questions please email jason@sawdac.com

INDUSTRY NEWS

Executive moves at AmesburyTruth

AmesburyTruth has announced a change to its executive leadership team. After five years of leading AmesburyTruth and two years prior as leader of the Truth Hardware business, Jeff Graby has decided to step down as president of the company. Graby led AmesburyTruth through a significant transformation, including the integration of the Amesbury and Truth businesses, complementing this with the acquisitions of Bilco and Ashland. Bob Burns, president of Ashland at the time of acquisition,

CSE and Pro-Line join forces

CSE Automation and Pro-Line Automation Systems have announced a joint marketing agreement to expand the distribution of each other’s full range of products throughout Canada and the U.S.A.

“This agreement allows both companies to maintain their independence while providing a more comprehensive sales and service presence to our customers. It’s a win for everyone involved,” said Todd Tolson, director of sales for Pro-Line.

Both Pro-Line and CSE will be turn-key sources for each other’s products and will collaborate on new offerings in their respective market segments. Pro-Line will maintain its existing facilities in Woodbridge, Ont., and Wadsworth, Ohio, and CSE will maintain its existing facility in Omaha, Neb., and sales office in Cleveland, Ohio.

“Collaboration between two formerly competing companies in a particular market seldom happens. We’re

Michael Glover, 1947 - 2019

In a joint statement, Lauren International and Quanex Building Products announced the passing of Michael Glover. Glover, who was the original founder of Edgetech and co-inventor of Super Spacer, passed away on Sept. 1, leaving behind a legacy of innovation and vision that helped shape the fenestration industry into what it is today.

“Michael was first a family man who was full of kindness and second an entrepreneur who was always looking for new solutions to old challenges,” said Kevin E. Gray, CEO of Lauren International and former president of Edgetech I.G. “It was an honour to have worked with him for many years and to watch his vision become reality. My condolences go out to Michael’s family, colleagues and many friends. He will be missed.”

Erin Johnson, marketing director for Quanex, also

has been appointed to take over executive leadership of AmesburyTruth. Burns led the Ashland business from 2013 to the present and has been a driving force for significant improvements in its financial and operational performance by focusing on quality and delivery metrics. Prior to joining Ashland, Burns was COO for Atrium Windows, and formerly vice-president of operations for Baldwin Hardware. In his new role, Burns’ priority is to drive innovation, communication, and operational improvements with an emphasis on delivery performance and customer satisfaction.

pleased to partner with Pro-Line and look forward to providing our customers with a more complete product offering while improving our coverage and support in Canada,” added Franc Guido, operations manager for CSE.

Pro-Line is a manufacturer of machinery and fabrication systems for the aluminum and vinyl building products industries since 1990 and is based in Woodbridge. CSE, founded in 1974 and based in Omaha, is a manufacturer of assembly solutions for the cabinet, furniture, and fenestration industries.

commented, “Michael was the visionary behind Edgetech and Super Spacer, and his legacy lives on today through his family and through his contributions to creating higher-performing building products. After 30-plus years in the field, his invention is still making a tremendous impact in homes and buildings around the globe. On behalf of Quanex and all of us who knew and worked with Michael, our thoughts are with his family and friends.”

Glover incorporated Edgetech I.G. in Canada in 1987, which became a subsidiary of Lauren Manufacturing in 1989. It remained a subsidiary of Lauren International until 2011 when it was purchased by Quanex Building Products. He is survived by his wife, Annie Dalton-Glover; children Alexandra Glover (Ryan Ward) and Christopher (Natalia Panyushkia); step-children Leslie Dalton (Brittany) and Rachael Price (Gregory Price); and several grandchildren.

INDUSTRY NEWS

AMMA, IGMA vote to merge

The memberships of the American Architectural Manufacturers Association (AAMA) and the Insulating Glass Manufacturers Alliance (IGMA) have both voted to proceed with combining into one organization with a new name: the Fenestration and Glazing Industry Alliance (FGIA). The formal ballots of the AAMA and IGMA memberships were released on July 2, along with the full prospectus outlining the strategy for structuring, operating and branding the new organization, which included adjustments and clarifications to the proposal, based upon member feedback.

AAMA and IGMA announced unification discussions a year ago, with the goal of creating a new organization that can better serve the North American fenestration industry. During that time, an exploratory team from both organizations developed a framework for the new organization, and information was continually shared with members during development. Beginning in August, the two existing boards began working together to execute the unification implementation steps throughout the remainder of 2019. A strategic planning meeting has been held to blend the vision and priorities for the new organization for the next three to five years. And the new organization brand development has begun.

“The value of the new organization will be a stronger industry voice, offering members and the industry

INT adds sales staff

INT Machinery was established in 2016 by Luca Tosetti and Emin Osun, who between them have over 30 years’ experience in the industrial equipment industry. In the last few years, INT Machinery has shown exceptional growth and added new lines of European machinery. In addition to Mecal and Yilmaz, INT Machinery has now added Thorwesten, iVision, Pressta Eisele and KMW Engineering. With their continued growth and addition of the new lines, INT has also invested in the addition of experienced sales professionals, John Martin and Alex Carrol. Martin handles sales in British Columbia and Carrol handles sales in Ontario. With the addition of Martin and Carrol, they have also added Amy Pitre for in-house sales support.

single-source access to critical information,” said AAMA board chairman, Donnie Hunter of Kawneer. “With knowledgeable professionals from both the fenestration and glass industries, better synergy for the whole finished fenestration product will be available, as well as direct access to Canadian market, codes and regulatory expertise. A combined organization also delivers expanded technical competencies and a broader document base to support more extensive educational opportunities for members.”

IGMA board president, Nathalie Thibault of Prelco, added, “These expanded technical competencies will further support educational opportunities. Plus, members can look forward to enhanced conference programming through an expanded content offering and broader networking opportunities through combined events. There will also be more resources available by harnessing the intellectual knowledge of the associations. A stronger financial position allows for future investments in industry research, technical resources and educational programs, which solidifies the new organization’s position as the single source for the industry moving forward.”

While both boards recognize the many combined benefits available to AAMA and IGMA members, the organizations also acknowledge the value in retaining separate brand equity in certain services such as technical standards and certification programs. Therefore, the branding strategy allows for an indefinite time period where the brand equity of both AAMA and IGMA are maintained for these aspects of the new organization

Rayner passes

Andrew Rayner, a partner at Azcor and AquaSurTech, passed away July 14 at the age of 74. Rayner was also well known in the coatings and paint industry from his time at Royal Bond.

"Andrew was a pioneer in the industry," said business partner and friend, Ross Vallesteros. His dedication and passion for his work was unparalleled. His love for his employees was second to none."

Alex Carrol

John Martin

Donnie Hunter

Nathalie Thibault

Amy Pitre

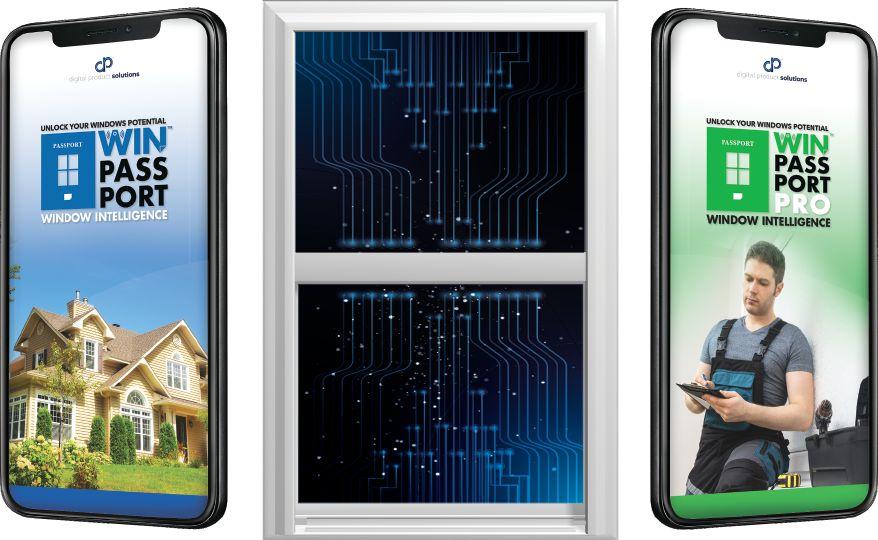

Introducing WIN™, window intelligence utilizing Near Field Communication (NFC). It’s the first system to create a digital double of your window or door through cloud computing, accessible through your hand-held mobile device.

WIN works with your Enterprise Resource Planning (ERP) software and builds a complete dossier of a window or door then tracks it throughout its life-cycle. The product information is accessed through mobile applications: WIN Passport, designed for the homeowner/facility manager, and WIN Passport Pro, designed for professionals, installers and contractors. Available for iOS® and Android® Systems, the applications offer options for testing data, service, reporting or warranty claims, and more. See it live at Windoor 2019, VEKA booth #225.

digital product solutions

Windoor booth #525

PROFILE

at times like we couldn’t run a business,” he says. “Because we couldn’t fit some potential customers in by the program end date that was announced when the new provincial government took over, we had dozens of them threaten us, telling us they would sue us, never hire us again and so on. Some told me to hire more people and I would tell them I have already increased my window install crews as much as I can reasonably do, and asked them that if I were to hire people off the street and send them to their houses if they would want them there. Some understood in the end, but I was literally trying to talk potential customers out of suing us instead of helping them meet their needs. It forced me to stand up for my company and talk to people in ways that I am not used to and don’t like, but I was in a corner. It was the biggest challenge in my 25 years in this industry and I never want to see anything like it ever again.”

However, the business’s solid reputation remains, and Jessup and Lloyd are confident it will see them through. “There’s a reason we’re still here after 25 years,” Jessup says. “If we make a mistake, we fix it and we don’t ask for any money until everything is done. We learned that from the old owners and we will always run things that way. And we respond to service calls very fast, and we always have our own service person go out for urgent calls. It’s important to us that it’s not a manufacturer’s service person who goes in. We want our own person to go.”

GROWTH BEHIND, AND AHEAD

Lloyd and Jessup have already grown the business to double what it was in 2011. Besides building the renovation side of things, they have expanded their entire customer radius to a twohour drive, east to communities like Bancroft and farther into Quebec across the Ottawa River, where all their services are fully licenced. They’ll continue to do radio and Facebook marketing, but word-of-mouth will likely always be the mainstay. They’ll also continue to look at new opportunities

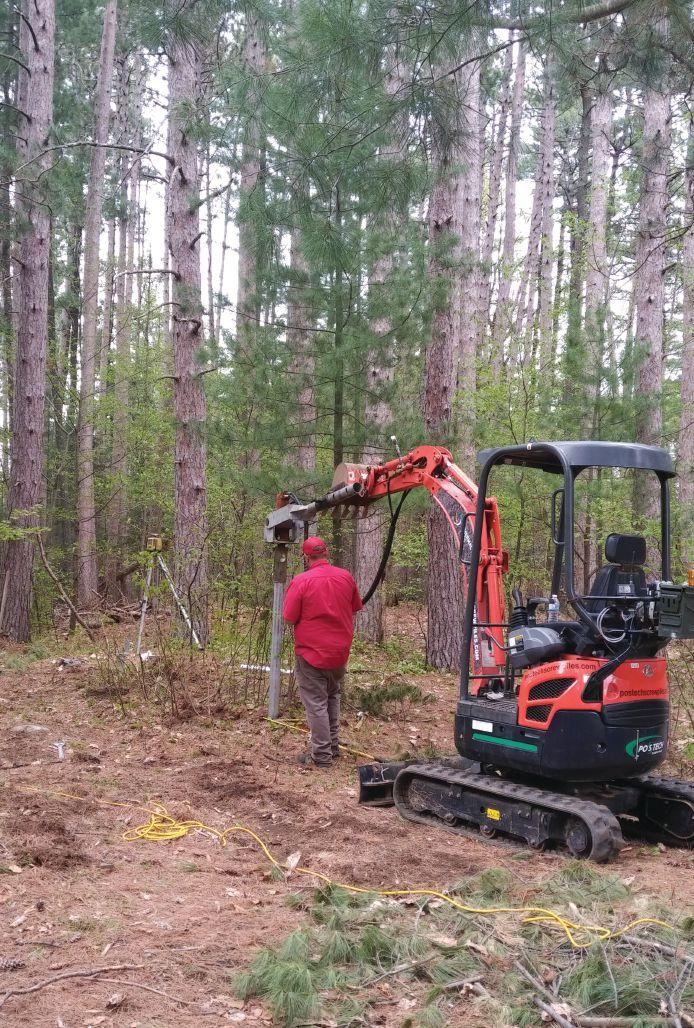

Valley found a novel solution for sunroom foundations that sets it apart from the competition: screw piles instead of concrete. The steel piles penetrate below the frost line and are insulated to prevent bending from freeze/thaw.

that might be a good fit.

And along with their reputation, the solid partnership between Lloyd and Jessup will always be a strength. “We’re similar in some ways but different in others and we respect each other’s ‘territory,’” Jessup says. “It’s nice to have each other to rely on as opposed to being a sole owner. Because we both worked here as installers, we both

understand what our crews are going through and we can support them. And between the two of us, we’ve never had a situation that we couldn’t overcome.”

Moving forward, they are both cautiously expecting that sales levels in 2020 will be back to what they were in 2017. “We will get there,” says Jessup. “Things started to pick up in mid-summer and we’re really busy this fall.”

Go fourth and condensate

by Phil Lewin

Giving credit where it is due, in February of 2014 Jim Plevecsky wrote a blog on fourth surface low-E use as it was just emerging in the goliath south of the Canadian border. Everything he said was accurate, so, with some simplifications and embellishments, here is my update.

Why did this become an issue? Simply put, as the U.S. version of Energy Star raised its standards, numerous American companies had a problem meeting it. The reason being, their windows were never designed to accommodate triple glazing. Any window with a maximum overall glazing thickness less than threequarters of an inch can’t accommodate the air space required. (I only say less because the U.S. companies generally have used twomillimeter glass, not three-millimeter glass. You could get a pair of quarter-inch air spaces on that basis.)

So, some bright-eyed individual came up with the idea of a second low-E on the interior surface of a dual-pane sealed unit. Problem solved! The U-values of the windows now qualified for Energy Star. There was peace in the world and all the companies with half-inch OT glass could sleep at night again.

Why should the Canadian industry care about this solution designed for the warmer climes of the southern half of the U.S.A.? Of course, these units cost less than a triple unit and don’t have the weight limitations, making them very attractive in our price-conscious industry. But, as Jim pointed out, there are other considerations in a cold climate.

I remember the ‘80s where, as the temperature outside began to tank, the industry braced itself for the inevitable angry phone calls as homeowners began to experience condensation on their brand-new windows. Of course, these windows had sealed units without any low-E coatings at all. The issue was the surface temperature on the fourth surface. Of course, why would anyone consider a clear sealed unit when we’re talking about making units with not one, but two surfaces with a low-E coating?

(Outside – Inside)

And, just for fun, here is a basic triple unit (1 3/8-inch OT). C180(s2) – Argon (90%) – Clear 14.8 All units 7/8-inch OT and three-millimeter glass. Outside air -18C and inside air +21C.

I’m not the best person to use the LBL simulation program, but I think I can do the centre-of-glass surface temperature (see the chart above).

See what I see? The fourth-surface low-E sends condensation resistance back to the last century! I can’t imagine that the sales people promoting this are giving a proper disclaimer to potential buyers beyond touting the great U-value. To me, fourth-surface low-E is not a valid alternative to triple in a cold climate like Canada (parts of B.C. excepted, of course).

What do those glass manufacturers have to say about this? A couple of years ago I recall being assured it was not an issue. Lately, I hear rumours that this is one of two issues that have started to come back from the field. Two issues? Yes. One of my many mantras is, “I’ve never seen an exposed coating that an innovative and creative homeowner couldn’t damage.” From what I’m starting to hear, this one is no exception to that rule of thumb. (Don’t get me started on damage to self-cleaning coatings when they were first introduced. Maybe a future article on homeowner expectation and reality in regard to self-cleaning coatings?).

Phil Lewin is sales and marketing manager for GEM windows. He’s been annoying people in the window industry since 1984.

FEATURE STORY

REBATE TO INNOVATE

Government funding is out there for common product improvement efforts.

Innovation was the theme at a recent FenCon conference in Manitoba. The panel gave the industry low marks for trying new things. The keynote speaker talked about disruptive technology and how it is transforming traditional businesses (minimum 50 references to Uber).

by KIRA KUPERMAN, PRO-ACTIVE FENESTRATION SOLUTIONS

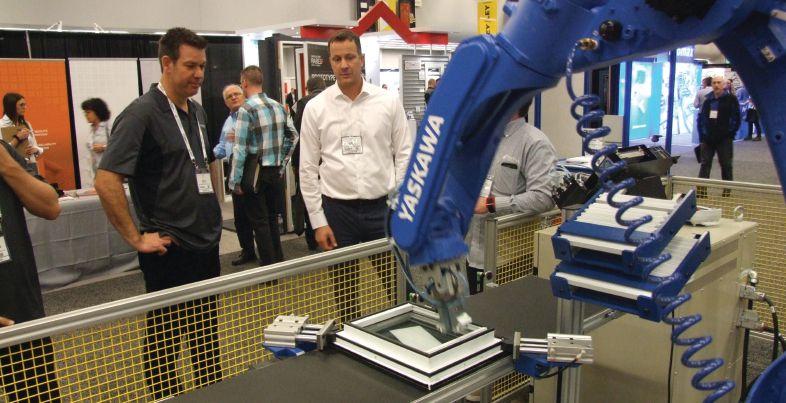

Robots have been around for a while. But no one uses them. The SRED program can help mitigate the risk of trying new technology.

Seminars urged window and door fabricators to look at new finishes, automated processes, updated software, continuous improvement programs and other routes to becoming different and better. The message was clear: innovate as if your life depends on it!

But innovation is special because it is hard, time-consuming and costly. There is help, we are told, from government R&D funding programs to defray some of the costs of innovation. As you’ll see in the following case study, getting access to that funding can be easier than many assume – if you have help from someone who knows what they are doing.

Pro-Active Fenestration Solutions worked with a medium-sized window manufacturer in

Ontario (that we’ll call Awesome Windows) to reduce the overall service costs the company was experiencing. As they went through the service records, Pro-Active realized the service call volume was too great for the number of units Awesome Windows was making per day. Service records clearly showed that glass was the number-one concern. Dirty glass units, seal failures, chipped glass, tiny cracks – you name it, it was all there. What’s more, glass replacement was a big problem. After a couple of meetings with the general manager, the company decided to review the entire glass unit production flow to identify problem areas and come up with new ways to reduce glass problems. Some of the simpler issues such as dirty

glass were easy to identify and rectify by implementing a cleaning station at the end of the glazing line. Other more serious concerns such as seal failure required more in-depth examination.

Fast forward a year. With Pro-Active’s help, Awesome Windows received more than $62,000 in cash refunds for this development work. And their glassrelated service calls have been reduced by half.

Believe it or not, the Canada Revenue Agency (CRA) wants to give you money for work that fosters technological advancement. But millions of dollars go unclaimed every year because the owners of most qualifying businesses simply never apply. Many have never even heard of the Scientific Research and Experimental Development program (SRED) – even though it’s been around since 1985 – or assume they won’t qualify for benefits when they probably would.

For business owners who do take the time to apply, the rewards are very real. Every year, the SRED program hands out more than $4 billion in cash or investment tax credits to more than 18,000 companies – mainly small businesses – throughout Canada. Most companies that apply for the benefits end up receiving them.

In order to qualify, a business has to seek to innovate and improve product or process regardless of the outcome. There are three main requirements to qualify for refund.

First, your research needs to be seeking technological advancement that will improve your product or methodology. Research that has no benefit to your business is not supported, and neither is finding existing technology to help you.

Secondly, the research must include experimental work or an initiative with some uncertainty of the outcome at the end of the work. The SRED program is meant to reduce the risk in failure for companies that want to try something new. Simply implementing a tried-andtrue process or cost-cutting measure does not fall within its parameters. Because you are conducting research, you’ll need contemporaneous documentation. A record of the work should be maintained as it is carried out.

Finally, you’ll have to show SRED that you are actually investing funds into research and development. Trying new things that don’t cost anything will not attract a grant.

None of the above has to mean high-

This is what most people think of when they hear the term R&D. But governments today understand that industrial research is not always a matter of people in white lab coats looking through microscopes. Things you do on your shop floor every day to improve your products may qualify for funding.

tech experimentation. In fact, the vast majority of SRED claimants qualify for payouts by making practical improvements to the products they sell and install every day. Some companies perform experiments on industrial materials. Others design new tools and parts. Still others gather mathematical data about their products, or engineer new solutions to common problems, or test and refine existing ideas in their industries. All these forms of R&D will usually qualify a business for payouts, whether they apply for those benefits or not.

In the window and door industry, we perform R&D all the time, often without realizing that’s what we’re doing. We test our windows, doors and curtainwall for air leakage, water penetration, structural load and wind load resistances. We troubleshoot and problem-solve installations in progress. We perform quality assurance on existing installations. We compare the pros and cons of different materials and draw up reports on our findings. A good portion of this work may qualify for cash refund under the SRED program

If your company works to improve the structural performance of windows and mullion deflection, to improve window and door ratings per CSA A440 and NAFS, or to improve corner welding and

cleaning performance – or to make any other type of improvement to windows and doors – the Canadian government is ready to pay you to keep doing that work.

Commercial success – or lack thereof – has nothing to do with these benefits. As long as you’re putting in work on experimentation and research, you almost certainly qualify regardless of what you end up doing with that research. In fact, if you are improving on product design without absolute or conclusive advance knowledge of the exact technological outcome, your company is likely performing qualified SRED activities.

ABOUT PRO-ACTIVE

Pro-Active Fenestration Solutions is a highly focused consulting firm dedicated strictly to the window and door industry. Its senior consultants all have over 30 years’ experience in the window and door industry from window and door design to profile and tooling design as well as all aspects of product testing, production and sales and marketing. In addition to technical assistance, Pro-Active also can help companies understand the SRED program offered by the Canadian government and assist fabricators to claim benefits under the program.

HELP HIRING HELP

Window and door companies can get government money for hiring and training.

Does the government truly give away money?

When people hear that the government gives money away, their first reaction is one of disbelief. Why exactly would the government give businesses money? Well, the reality is the government does receive something in exchange for the money they give away: increased tax revenues.

by BONNY KOABEL CGA, CPA

Yes, Virginia, the government does sometimes give money back to businesses. There are several programs that reimburse companies for hiring and training new workers.

It is estimated that for every dollar the government gives out to businesses they receive $3 in return in the form of higher tax revenues: HST, payroll taxes or corporate taxes. Government funding has increased over the years because it benefits both businesses and government. Businesses receive the funds they need to operate, grow and expand their operations. The government receives increased tax revenue to implement its mandates.

TYPES OF EMPLOYEE FUNDING AVAILABLE

A few of the employee funding programs available to fenestration companies include appren-

tice salary refunds, hiring grants and training grants. The amounts can be significant: up to $12,000 per apprentice per year (retroactive for four years), up to $10,000 per new hire or up to $10,000 per new employee.

Companies are not restricted in the amount of funding they can receive over time. As long as a company qualifies for funding it is able to access it. There is no upper limit to how much a company may receive and these funding programs may be used on a yearly basis.

APPRENTICE SALARY REFUNDS

Apprentice salary refunds have been around since 2004 and are incentives given to business-

es to hire and train apprentices. The governments started these funding initiatives to incentivize businesses to hire and train more apprentices. Since it takes years of training for an apprentice to become a journeyperson, most companies are reluctant to hire apprentices and invest valuable time and money in training them.

Employee incentives for training apprentices are very generous. Ontario offers the largest amount of funding with up to $10,000 per apprentice per year, retroactive for three years. This applies to the first four years of the employee’s apprenticeship, whether or not the apprentice is still with the company. It does not matter how short a period of time the apprentice was with the company – it could be one week or the last four years.

In order for an apprentice to qualify for funding they must be on staff, receiving a regular paycheque and registered as an apprentice in a qualifying trade in the province where your company operates. In the fenestration industry, apprentices will include electricians, glaziers and millwrights. If you have had apprentices on staff and they are not registered with the province, unfortunately you will not qualify for funding. If you are hiring an employee who is already a registered apprentice, you need to call your apprentice training representative with the provincial government and make sure the new employee receives a transfer of apprenticeship to your company. If this does not happen, your company will miss out on funding.

Two of the biggest reasons why companies do not receive apprentice salary refunds are not registering their apprentices with the government or not receiving transfers of apprenticeships for new employees who were already registered apprentices with other companies.

The apprenticeship salary refund program applies to foreign-owned companies and even divisions of companies that have had apprentices and are now closed. As long as the company is not dissolved, it is able to apply retroactively for the last four years for funding.

HIRING GRANTS

Hiring grants have been available for the last 30 years, regardless of the government in power. They are in essence a redirection of Employment Insurance funds. The

government makes hiring grants available to businesses because they would prefer to compensate a business to train a new employee than to have that person sit at home, not doing anything and collecting EI. Working for a business allows a new employee to gain new skills and knowledge that will allow them to be employed for years to come.

Hiring grants have been around for so many years because they benefit all parties involved. The new employee receives a job, the business is subsidized while the new employee undergoes goes on-the-job training, and the government receives additional payroll tax revenue for the new employee for as long as the employee is with the business. For the government, the return often far exceeds the hiring grant they initially gave the business.

Hiring grants are available for any new employee you plan to hire that is not an apprentice. This applies to all potential new hires including pre-apprentices, administrative staff, sales staff, estimators, engineers and general labourers. To qualify for funding, the new employee must be currently unemployed. Also, the new employee cannot be leaving a job to take a position with your company. Funding is available to a variety of hiring candidates including recent graduates (high school, college and university), new immigrants to Canada, self-employed people taking on a paid position with the company, women re-entering the workforce after raising a family, and anyone else that is currently unemployed that requires on-the-job training. The new employee’s position must be a paid hourly or salary position. Pure commission jobs will not qualify for funding. Also, the job must be a full-time position with a minimum of 25 hours per week. Temporary and part-time positions do not qualify for funding. The goal of the hiring grant program is to create long-term employment.

Hiring grant funding works very differently than apprenticeship salary refunds. In order to qualify for funding, a company needs to apply for funding before the new employee starts their first day of work. Once the business knows they would like to hire a new employee, a hiring grant application is submitted to the government. The government will get back to the business within two days and if the

new employee qualifies for funding a meeting will be set up to meet the new employee. This is to determine the hiring grant funding amount for the business to train the new employee and to prepare the hiring grant agreement. It takes up to seven business days to get a hiring grant agreement in place.

Hiring grants vary depending on the province and are up to 50 per cent of an employee’s wage to a maximum of $10,000 for a period of six months. Once an employee qualifies for funding, the company will receive funding for the period of time the new employee worked, even if the employee is fired or quits.

TRAINING GRANTS

Training grants are available to existing employees to increase their skill set. Training must be through a Canadian third party, including colleges, universities and specialized training providers. This includes sales, customer service and ERP system training. The Canada Job Grant program was introduced in 2014 with funding committed to 2020. Routine training such as WHMIS, health and safety, forklift re-certification and fall arrest do not qualify for funding.

Funding is up to $10,000 per employee. If your company has under 100 employees you will receive a reimbursement of 80 per cent of the training costs. If your company has over 100, the reimbursement rate will be 50 per cent.

Training grant funding works similar to hiring grant funding. In order to qualify for funding, a company needs to apply for funding at least one month before the employees receive training. The application is completed and submitted online. It will take up to seven business days to hear back from a government representative who will review your application and let you know if the application is approved. Once the application is approved, the employees are now able to take the training. Once the training is completed and the invoice for training has been paid, an application will need to be sent to the government for reimbursement. The government will send out the refund cheque four to six weeks after receiving the invoice.

Bonnie Kaobel is CEO of AKR Consulting, a Mississauga, Ont.,-based management consulting firm.

FIT & FINISH

Billionaires club

Regulations are hollowing out the fenestration middle class.

by Chris Meiorin

If you are reading this, the degrees of separation between you and your local billionaires club is less than you think. As the fenestration industry continues to evolve, so does the news of mergers and acquisitions within the industry. But where typically the values have been reported in the millions of dollars, the B-word is now creeping into the discussion and bringing with it greater challenges to the small and mediumsized assemblers that once dominated the fenestration industry. Never has this been more evident while reading of the recent purchase of several large window and door companies by private equity groups. With reports of a price tag exceeding $2 billion dollars U.S. for the takeover of Ply Gem Holdings and Atrium Windows and Doors by private equity firms, we see the chasm that separates the small companies from the now larger-than-life conglomerates.

While it’s easy to buy into the idea that traditional large companies can’t innovate at the same pace as their smaller counterparts, the large corporation is more likely to maintain its dominant position by acquiring its smaller cousins and essentially buying market share. Add to this the growing R&D expenditures of large firms and the increasing pressures (and costs) of product certification, the gap between large and small companies will continue to grow. This fact, however, may bring some success to the micro and niche operators, who often work outside of the usual regulatory bodies and cater to a specific demographic. With continued suggestions of unreported earnings within this segment of the market, the gap between large and small companies remains at an all-time high.

Ask any fenestrator that has sat through any of NRCan’s recent Market Transformation Roadmap meetings. The beads of sweat that appear on their foreheads are largely due to the burning question of how to finance the R&D needed to conform to the new reality mandated by the government. Everything from engineering, testing and even labeling now requires the continued input and monitoring

of professional service providers, which are often out of reach of the small manufacturer. Add to this scenario the need for a dedicated HR department to recruit and maintain a workforce in a shrinking labour pool and it suddenly becomes apparent that the operators and owners of fenestration SMEs are no longer able to focus on the day-to-day matters of making windows and doors. Rather, the owners and operators of these companies are spending the bulk of their days navigating the increasing complexity of the Canadian government’s national regulations and trying to better understand how to finance the cost of conforming to a standard for which the technology does not yet exist. The government is off-loading the required R&D onto what is an already fragmented fenestration industry. Our government continues to grandstand, pretending to lead the world in the transition to a low-carbon economy. Just look at the location of their conference, “Paving the Road to 2030,” in Iqaluit, Nunavut. The location was prohibitive to most all of our industry stakeholders except those travelling on the government’s tab. The report that followed this conference went on to discuss how key stakeholders were assigned to each initiative, including windows and doors, yet these initiatives were moved forward with little or no representation by our industry. The report proudly announces the development of a “national compliance strategy” and the vast amount of R&D that will be required to accommodate these performance initiatives, with little or no mention as to how it will be financed.

So it shouldn’t come as any surprise to read about the next big acquisition or merger in our industry. Nor should it come as a surprise that, with the governments’ continued meddling, fenestration’s “middle class” will potentially cease to exist and take with it the heart that literally drives the Canadian economy.

Chris Meiorin is president of EuroVinyl Windows and Doors in Woodbridge, Ont.