Labor-Saving

Shim It Once and Done. SAVE

Grove Products, Inc. has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Looking for the right shim?

Grove Products, Inc. has the perfect shim for all your shimming needs. With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 1-800-72-GROVE

Visit us online to see all of our available solid 3x4 Shims. www.groveproductsinc.com Free Samples are Available Upon Request.

Grove Products, Inc. is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Fenestration Review 2018 Vol. 7 • Issue 3

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

ACCOUNT

COORDINATOR | Stephanie DEFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

CIRCULATION MANAGER | Urszula GRZYB ugrzyb@annexbusinessmeda.com 416.442.5600 ext. 3537

MEDIA DESIGNER | Emily SUN

GROUP PUBLISHER | Martin MCANULTY mmcanulty@annexbusinessmedia.com

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

email: subscribe@glasscanadamag.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

email: asingh@annexbusinessmedia. Tel: 416.510.5189

Fax: 416.510.6875 or 416.442.2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $21.50 (plus applicable taxes)

U.S.A. - 1 Year $38.00 (in US dollars)

Foreign – 1 Year $43.50

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com

Tel: 800.668.2374

Occasionally, Fenestration Review will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.fenestrationreview.com

CANADA’S WINDOW AND DOOR MAGAZINE

4

EDITORIAL

We need a way to rebuild trust with our customers.

6

INDUSTRY NEWS

WinDoor trys new things...NRCan maps the future...P.H. Tech bought... Hermiston steps back...

14 RIGHT ON THE WAVE

Thermoproof surfs a swell of success with a modern approach.

18 A BETTER INTERFACE

Jon Eakes wants to find a way to prevent wet wood around window frames.

10 FIT & FINISH

Like any relationship, a business relationship can end in divorce. by Chris Meiorin

22

WINDOOR SNEAK PEEK

Here’s some of the great products appearing in Quebec City at WinDoor 2018.

12 FENESTRATION CANADA

This association’s agenda is full of high-priority projects. by Jennifer Small

38 THAT’S RICH Don’t trip when balancing life and work. by Rich Porayko

Bring back the BBB?

by Patrick Flannery

Consumer trust in contractors is at an all-time low.

Arecent poll commissioned by RenoAssistance found around two-thirds of Canadians don’t trust general contractors and have similar levels of distrust for specialty contractors. Fenestration contractors weren’t specifically broken out in the information online – no doubt we score much better (gulp). Granted, this study was ordered by a company that offers contractor-verification services, but it was conducted by Ipsos, which has a reputation for credibility to protect.

I don’t even need to go into why this would be so. Everyone has multiple hair-raising stories of contractor malfeasance both from inside and outside the industry. If you threw a dart at a listing of contractors and hired the one you hit, your chances of ending up with a straight-up criminal are about as good as getting one who is professional, on-time and honestly priced. The survey above found six per cent of respondents in Toronto reported items being stolen – stolen! –from their homes by contractors working there. My own experience has been mixed. A referral I got from a work friend sent me to a terrific guy who did great work fast and cheap. Another time I was absolutely chewed out on the phone for simply calling to ask about a shower surround that was more than a week overdue (how’s it going over there, London Marble?). Toronto does seem particularly bad. Just about every friend I have who has embarked on a major renovation in Toronto has a tale of long delays, shakedowns for more money and “companies” that disappear with deposits leaving work wrong, incomplete or not even started.

These aren’t new problems, but they are problems I feel were less prevalent, say, 30 years ago but have been accelerating over the past decades. In my mind, the problem coincides

with the urbanization of our country. More of us are living in cities and our cities have grown to the extent that a company doesn’t have to safeguard its reputation the way it used to. There’s always another mark who hasn’t heard about the last person the contractor ripped off. Even single individuals can use online tools like Kijiji to reach unsuspecting homeowners at the same rate as larger companies with marketing budgets. When I was in high school in London in the 1980s it seemed that just about any company you dealt with was at least slightly known and familiar to you either from advertising or seeing its storefront. You could certainly ask anyone about it and get an opinion. Now, you often seem to be starting from zero with some organization you’ve never heard of before.

In the very old days before even the mullets and legwarmers of the ‘80s, people identified this problem and took measures to safeguard consumers against the unscrupulous. Organizations like the Chamber of Commerce and the Better Business Bureau gave companies a stamp of approval that consumers could use to choose vendors that had at least been looked at by some outside agency. And members of those organizations could skip the part where they had to convince a customer they were trustworthy, simply by showing the logo. I’m not entirely sure what happened to those groups as they seem to be a lot less relevant today, but I suspect it had something to do with them relaxing their standards in order to encourage wider membership.

Everyone’s lives would be easier if we could rediscover some way to establish trust with our markets in the face of the shenanigans that go on. Perhaps an injection of funds to the WindowWise program to advertise it to consumers?

INDUSTRY NEWS

WinDoor breaking new ground

WinDoor 2018, taking place Dec. 4 and 5 in Quebec City, will celebrate a few firsts. It’s the first time Canada’s trade show for the window and door manufacturing industry will be held in Quebec City, following up a successful event in Montreal two years ago. And for the first time there will be an added focus on the architectural glazing side of the market, with exhibits and education sessions aimed at those who specialize in curtainwall, storefront and custom aluminum fenestration for commercial, institutional, industrial and high-rise residential facade construction.

The commercial aspect has been developed in partnership with Glass Canada magazine and the Quebec glazing association, AVFQ. AVFQ membership has traditionally come from both sides of the fenestration industry, so it made sense to bring this element to WinDoor at its debut in Quebec City.

CONFIRMED SESSIONS:

The Jeff Baker Show – Fenestration Canada technical consultant Jeff Baker will deliver his annual cross-country update of changes to building codes and energy-efficiency laws, explaining to fabricators what they will have to do to continue to provide compliant products. He’ll also discuss Energy Star and the upcoming tightening of requirements for that program. Baker knows what’s coming as well as what has been decided, so it is a good opportunity to get an advance look at where codes and standards will go in the future.

Nanoglass: New technology for rendering glass nonreflective and water-repellent – Advances in nano-scale glass surface treatment are achieving startling results in

Roadmap released

Natural Resources Canada has released its roadmap outlining its recommendations to push the Canadian fenestration market to deploy more energy-efficient products over the next 20 years. The roadmap will constitute part of Canada’s strategy to meet its commitments under the Paris Accords to lower greenhouse gas emissions. The document will be presented to the First Ministers meeting planned for this fall. It was developed following two workshops and extensive other consultations with industry and makes recommendations for initiatives to promote and fund research and development, information and awareness, training, incentives and codes and standards development. In short, the roadmap will be setting the direction for government regulation of windows for the foreseeable future. The roadmap recommends 11 broad initiatives for NRCan and stakeholders to undertake:

1. Research low-E coatings, thin triple pane windows, vacuum glazing, multiple coatings and smart glazing.

making glass non-reflective from almost every angle and super-hydrophobic – water literally leaps off the glass. And the best news is the process is likely scalable to architectural-sized panels at a feasible cost point. A Montreal tech startup, Edgehog, is working on commercializing the process and its co-founder, Mathieu Massicotte, will tell attendees all about the technology and their efforts to bring it to market.

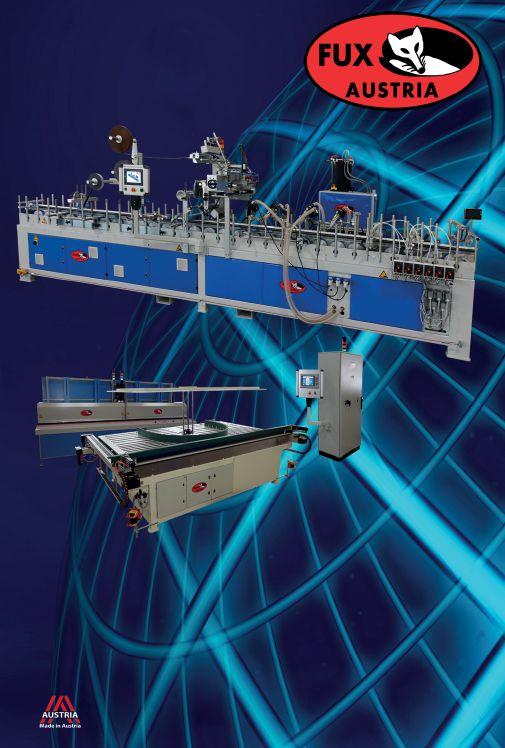

Automation benefits and challenges – Martin St-Arnaud from JSA Machinerie will use real-world examples from his company’s long experience helping window manufacturers automate their processes to educate attendees about the possbilities, advantages and potential pitfalls of robotic fabrication.

FIT bit – What good are great windows if they aren’t installed correctly? Fenestration Canada has taken over the Fenestration Installation Technician program in an attempt to help window installers across the country achieve and promote a higher standard of knowledge and expertise. Robert Jutras of CLEB and chair of FenCan’s Technical Committee will explain the program and what it can do for your installation team.

A window into Canadian fire safety codes and regulations – Amal Tamim of Technorm will introduce attendees to standards they must meet when fabricating and installing fire-resistant fenestration and discuss some ways to meet requirements. The old standards around “safety glass” have changed and you will need to be informed to bid on today’s ICI projects.

More sessions are in development. All sessions will be presented bilingually.

2. Research improved window designs.

3. Research to lower cost and durability of high efficiency windows.

4. Research to better understand the benefit of high efficiency windows.

5. Develop construction industry market pull for high efficiency windows.

6. Support consistent labelling for high efficiency windows.

7. Conduct education, training and market outreach.

8. Facilitate installer training and certification window programs.

9. Develop and implement incentives and other financial mechanisms.

10. Influence and support development and harmonization of codes and standards for windows.

11. Support the Energy Star specification program for high efficiency windows.

SAWDAC Newsletter

BUSIEST YEAR EVER

The first eight months of the year have blown up as the GreenON program has blown up. With this we have focused on WindowWise seminar training; dealer and manufacturer advocacy within the industry and to the government; and helping our members with GreenON and IESO. The focus on WindowWise training has culminated in registrations for the program being through the roof. SAWDAC is still setting training dates so that installers acting at the last minute can get up to speed as they are in very high demand right now. Keeping up with the Green Ontario Fund program has been allconsuming and changing in focus over the past eight months. It has shifted from training to WindowWise consumer information and to extensive lobbying around the program cut-off dates.

RENOPLAN

RenoPlan started off slow even with the huge sales volume from the GreenON program, but this has jumped drastically in the last four months. The financing deals have started to increase dramatically from the rebate program. Not only has the volume increased but also the average deal size. Any dealer that is looking to improve their business bottom line

should be offering the RenoPlan program offered through their SAWDAC membership. We see an increase of 20 to 30 per cent in businesses that start to offer financing as an option. Our RenoPlan program has many different options for your customer to take advantage of. For information on this, please visit our website or give us a call.

SOCIAL MEDIA

We are working on advertising through the SAWDAC site as we have had numerous manufacturers and suppliers ask about these options since we have had a huge influx in unique views to our site through the GreenON program. Gentek was the first to jump on board with this and you will see their logo on the site that links to their web page. If you would like more information about this, please email us.

We continue to use Facebook and Instagram as we want to capitalize on the views through our social media channels. It is one of the cheapest ways to hit the market with great insight and demographic information. We are looking to add and rampup an Instagram account as it is all about photos, which people love to see in this industry.

We are currently looking to bring in another co-op student to manage this piece of

the business. We would suggest you look into bringing in a co-op as I hear a lot of people in the industry say they don’t know how to use social media or don’t want to tie up an employee’s time with it. This is a great way to increase your social media footprint while working with the community, and Millennials love to show off their social media skills to their family and friends.

A FUN DAY ON THE GOLF COURSE

A relaxed and upbeat atmosphere prevailed at the SAWDAC golf tournament on Sept. 20 in Cambridge, Ont., with many of the participants clearly welcoming the opportunity to break away from this summer’s grind of desperately trying to fill the glut of GreenON orders before the Oct. 31 deadline. Music played from golf carts, the beverage carts were popular and at least one golfer committed a serious dress code violation (see photo).

There was even a tour-like aspect as all 75 participants created a gallery on the putting green at the end of the day to watch Greg Gordaneer (Home Trust), Tony Ferreira (Royal) and Jesse Hilliard (Royal) putt off for secondplace honours. Gordaneer took the contest.

Low score went to Alex Fairless, Cary Baldwin, Sean

Martin and Dave Wellman of Ventralux. Ventralux may be spending too much time on the golf course, as Will Wellman, also of Ventralux, won long drive. Mario Cairo of Dorplex got closest to the pin and Greg Shirk took home a big bottle for winning the putting contest with proceeds going to Kids Can Play, a local charity that promotes participation in music, art and sports. The contest raised $260.

“I know a lot of people couldn’t be here because everyone is so busy with GreenON,” Jason Neal, SAWDAC executive director, commented. “But I think we had a great day anyway.”

Here’s looking forward to a great fall season!

INDUSTRY NEWS

Kogovsek steps forward at Fenestra

Brian Hermiston has stepped back as general manager of the Fenestra Purchasing Co-operative. He has served as the only general manager since the co-op’s inception in 2011. Hermiston will remain to complete supplier partner negotiations for the next year. J.F. Kogovsek will take on the role of general manager of Fenestra. Kogovsek is a long-time industry expert who has, for the past two years, been the national sales and

P.H. Tech bought by private equity

BDG and Partners, a privately held Canadian fund with its head office in Montreal, and Caroline Dallaire, president and CEO of P.H. Tech, announced the acquisition of the company and its subsidiaries in early August. The current management team has remained in place and all the production sites will keep operating the same as before the acquisition.

“We are pleased to become partners with a

Window war

The federal government announced in June retaliatory tariffs on imports from the U.S. of many steel and aluminum products, including “doors, windows and their frames and thresholds for doors.” The tariffs are in response to American tarrifs announced in May on steel and aluminum entering the U.S. from Canada. The tariff on fenestration products will be 10 per cent. The Canadian Department of Finance said in a release:

On May 31, 2018, the United States announced tariffs on imports of certain steel and aluminum products from Canada at the rates of 25 and 10 per cent, respectively. Taking into consideration feedback received from Canadians through over 1,000 submissions during public consultations, on July 1, 2018, Canada will impose countermeasures (surtaxes) against $16.6 billion in imports of steel, aluminum and other products from the U.S., representing the value of 2017 Canadian exports affected by the U.S. tariffs. These countermeasures will only apply to goods originating from the U.S. These countermeasures will take effect on July 1, 2018, and will remain in place until the U.S. eliminates trade-restrictive measures against Canadian steel and aluminum products. The countermeasures will not apply to U.S. goods that are in transit to Canada on the day on which these countermeasures come into force.

The U.S. Window and Door Manufacturers Association has criticized the tariffs:

“WDMA was critical of the imposition of U.S tariffs on

marketing manager. J.F. brings over 30 years’ experience in the industry of doors and windows with specialized expertise in this industry in Quebec, Canada and the United States. The Fenestra Purchasing Co-op founded in 2011 is member-owned and represents over 40 independent window and door fabricators from coast to coast to leverage their combined purchases, create supply chain efficiencies and lower input costs.

great team that has a long history of growth and job creation in the region,’’ said Jean-Lou Paquet, a partner at BDG.

“The partnership with BDG will allow P.H . Tech access to capital and expertise to sustain its growth initiatives and to continue developing and introducing new and innovative products to its clients,” said Dallaire.

steel and aluminum and this new action by Canada further escalates trade tensions between the two nations,” said WDMA CEO Michael O’Brien. “These actions will only lead to additional price increases in the residential and commercial building markets in both countries, hinder progress in the renegotiation of NAFTA and resolving the softwood lumber dispute.”

Fenestration Canada also released a statement criticizing the Canadian government for the tariffs:

Fenestration Canada members are feeling the effects as Canada imposed counter-tariffs in retaliation to U.S. import tariffs on steel and aluminum products. These counter-tariffs include “ Doors, windows and their frames and thresholds for doors” under the aluminum products group. This increases the price of U.S.-manufactured goods sold in Canada, appearing to give Canadian-manufactured goods a competitive advantage. Although this may seem favourable to Canadian fenestration manufacturers, many raw materials and components used in these windows, doors and related products are affected by the U.S.-imposed steel and aluminum tariffs. This increases the cost to manufacture Canadian fenestration products, putting additional pressure on fabricators. In the end, consumers will feel the pressure of rising window and door prices in both countries. Fenestration Canada will provide support to our members during these challenging times as the trade war escalates and evolves.

FIT & FINISH

Business divorces

Partnership breakups

always sting, but can be creative.

by Chris Meiorin

As I prepare to write this column, I am about to celebrate 30 years of “marriage” – in the sense of a long-standing relationship with a supplier. For the most part, it has been a very rewarding partnership. I have shown much respect and support towards my partner, speaking very favorably about them and dedicating time and effort toward their wellbeing and development. We’ve worked through some tough times and had always planned to grow old together. But things changed. Actually, in my view, they changed because of outside influences that weren’t favorable to the relationship. They lost respect, they lost vision, they forgot about our past and didn’t care about our future. Although it wasn’t a marriage in the classical sense, but rather a business partnership, it still feels like a marriage in trouble.

Regular readers will know I have come to value the business relationships I have formed over the years. They are important to not only me, but they give our work group confidence and comfort. I believe in promoting our business partners and leveraging our strengths in an effort to promote their businesses. It’s not to suggest, however, that it’s a selfless act. Actually, it’s quite the opposite – in return for this level of support I hope to gain value: value in the form of price, quality and service. It’s a great model for both sides of the relationship...until one partner decides otherwise.

I read Mark McCormack’s book What They Don’t Teach You at Harvard Business School the same year I started our fenestration business. One of the key takeaways from the book was that partnerships will ultimately fail, and that it’s not a matter of if a partnership will fail but when. And the longer the partnership, the messier the breakup. Interestingly enough, though I read this book over 30 years ago, it’s the one point that had really stuck and the one point I continue to ignore in practice. However, with every failure, partnership or otherwise, there is often a silver lining. It took a few failures to figure this out but

I think I’m starting to get the hang of it. In fact, it might be suggested that if you look for failure you will find success. This remains an interesting philosophy as we move our respective businesses through a rather tumultuous time.

Business partnerships can take on different forms. It can take the form of an equity partner, a collaborative partnership or a support-based partnership where respective companies work together to support each other’s businesses. You can find that last kind in a social media engagement group, and it’s this type of partnership that I find most interesting at this juncture of my business career. It allows each of the respective partners to make a contribution in a fashion and in the environment in which they are most comfortable working. In my case, I seek out opportunities that allow me to create, with this column being a perfect example. In return for my efforts here, my contribution allows me open dialogue with not only the publication, but with my peers, content providers and industry professionals, all of whom I value and appreciate very much. But these reciprocal relationships can take on different forms, perhaps between vendors and purchasers, and these I find equally if not more valuable as those creativity-based collaborations. That being said, it’s important to monitor these relationships and when the contribution is longer reciprocal, it’s important to recognize this fact and move your efforts to a vendor or customer that recognizes and appreciates contributions and returns the favour.

It’s hard to sum up the 700 words I’m mandated to write, but my advice would most certainly be to pick your partners wisely and, when it no longer works, get out and find a new partner that is as interested in your business or personal gain as you are in theirs. And perhaps take a cue from another book by McCormack: Never Wrestle With A Pig.

Chris Meiorin is owner/operator of Euro Vinyl Windows and Doors.

A very busy time FENESTRATION CANADA

by Jennifer Small

The agenda is full of important projects these days.

In recent months, we have been involved in many activities, including energy regulations, building codes, tariffs, WinDoor planning, membership recruitment and installation certification. With lots of enthusiasm coming out of our June board of directors and annual general meetings in Calgary, we continue to increase awareness and engagement among fenestration stakeholders, build our partnerships with key decision makers for regulations, standards and codes and to ensure high standards of professionalism in our activities.

WinDoor 2018 is fast approaching. In an effort to engage Quebec fabricators, we will be holding the show in Quebec City from Dec. 3 to 5. New this year, we are expanding the show to include a commercial fenestration component, with suppliers and education sessions tailored to this sector of our industry including sessions on glass fabrication technology and fire-rated glazing. We have updates on codes and standards affecting our industry, sessions on automation and lean manufacturing and presentations about new technologies in commercial applications.

Throughout the summer, Fenestration Canada consulted with affiliate organizations the Siding and Window Dealers Association of Canada (SAWDAC), the Quebec fenestration association (AVFQ), Fenestration Manitoba and the Fenestration Association of B.C. to develop a joint message to the Ministry of Foreign Affairs in relation to Canadian tariffs on imported aluminum window and door products into Canada. Representing the entire country and its fabricators, we made recommendations at the federal level and voiced our objections to the tariffs. We will also support our members by providing a webinar on navigating the tariffs. In August 2018, at the Energy and Mines Ministers Conference, Natural Resources Canada (NRCan) presented a roadmap for national regulation of residential windows sold in Canada. FenCan’s NRCan task group

provided key feedback on the roadmap, which took into consideration both technical and market challenges in achieving proposed targets. Proposed targets in the short term (by 2020) are that all residential windows for sale in Canada meet an average U-factor of 1.6 (or an ER of 25). Medium term (by 2025) targets are a U-factor of 1.2 (ER of 34) and long term (by 2030) demand a U-factor of 0.8 (ER of 44). One of the first initiatives NRCan is trying to determine is which performance metric to use – U-Factor or ER – as they want to standardize this across the industry. Also in consideration outside the roadmap, but highlighted in the report, is the need for a nationwide compliance system, which forms part of the federal government’s efforts to regulate residential windows. Fenestration Canada will be consulted in the key decisions above which will directly affect our members and the products they manufacture. Our fabricator members will also have the opportunity to participate in research and development projects and possibly receive funding to complete these. As we continue to work closely with NRCan, we will communicate and seek input from our member companies to help support and shape the roadmap to ensure the viability of our Canadian fenestration manufacturing industry.

As part of the nationwide compliance efforts of fenestration products, Fenestration Canada is in the process of re-launching its fenestration installation certification (FIT) exam. This exam can be taken online or at a proctored centre by appointment. We are also working on a training program to support the exam content, based on current standards and codes. Through training and certification, we are on the way to standardizing installation across the country.

Jennifer Small is president of Fenestration Canada and of Screenco, a Concord, Ont.,based manufacturer of window and patio screen products.

RIGHT ON THE WAVE

Thermoproof uses a modern approach to beat challenges.

Cam Drew is a busy guy. As the managing partner of Chemainus, B.C.,-based Thermoproof Windows and Doors, Cam has the same responsibilities that any person in charge of growing a busy manufacturing and installation company with more than 50 employees would have.

by RICH PORAYKO

Drew (right) and production manager Shaun Goode take Lean-inspired “gemba” walks through the shop where they visit each work station to check on employees’ morale, collect suggestions and troubleshoot problems. The proactive approach has measurable benefits for productivity.

A key difference is that Drew walks the walk when he speaks about supporting the community. He’s been recognized twice with the distinguished Paul Harris Fellow award from two different Rotary Clubs. He also has the Scroll of Honour from the City of Duncan and is an honourary Kinsman and past president of the SPCA. And when we say community involvement, we mean involvement with his business community as well. Drew sits on the steering committee for the Home Performance Stakeholders Council of B.C. that is tasked with driving higher energy efficiency in the renovation market, and is part of the advisory group for the Pan-Canadian task force, which is working with the federal government to set out aspirational goals for energy efficiency until 2030. “The government is going to put a

lot of pressure on Canadian window manufacturers to meet these goals,” explains Drew.

Fenestration Review caught up with Drew at the 2018 GlassBuild in Las Vegas to find out what sets Thermoproof apart from the competition.

“We have five values that we work with,” says Drew. “Safety, quality, communication, teamwork and innovation. When we do our regular reviews with our team, those are the five areas that we focus on.”

Drew and his team know the geographic location their windows are going to live in.

“On the west coast, especially Vancouver Island, you need to build a rainscreen. We know they are going to get a lot of rain. You have to design the window appropriately. It’s all about moving water away.”

They are also going to get a lot of salt water

COVER STORY

spray because most homes are within a few kilometers of the ocean. According to Drew, all the parts that Thermoproof builds into a window are either stainless steel or non-corrosive. “We can literally dip the window in salt water and it would be fine. If we’re going to back it with a lifetime warranty, we better put good components in it.”

Thermoproof was founded in the Chemainus Valley on the east coast of southern Vancouver Island in the late 1970s, manufacturing wood and aluminum windows. Drew, his wife, Maeve, and Drew’s shareholders acquired the company in 2007, about one year before the Great Recession. “We enjoyed around 14 good months before six challenging years,” recalls Drew with a laugh. With the changes to the B.C. Energy Efficiency Act, Thermoproof discontinued aluminum products in 2009 shortly after the acquisition and went strictly vinyl. “We were making our own sealed units but discontinued around 2011 to make room for more growth. In 2012, we added new construction and installations to our area and stayed as a supplier for the rest of Vancouver Island and the Gulf Islands.”

Drew shares that installation has been a helpful way to grow the company without putting as much pressure on capacity. “Our plant isn’t very large. We have 18,000 square feet under roof. We’re running pretty tight. I just talked to the guys. They’re pouring more cement and adding more outdoor storage right now. We’re maxing out our property because we want to stay. And we’ve got the extra locations.”

Thermoproof built a new showroom and added a warehouse in Duncan and then, in 2016, Drew acquired a building 140 kilometers north in Courtenay, B.C., allowing the company to open another showroom and provide supply and installation to the largest city in the Comox Valley.

Before being acquired by Drew and his partners, Thermoproof offered a 10-year pro-rated warranty. “We found that if a window was out of warranty, we were still fixing it. Customers are often surprised if we go back for a window that’s 18 or 19 years old and we completely refurbish it and fix it up for them. We decided that if we’re going to go any-

Production flexibility is key when building windows for the varying conditions in different parts of Vancouver Island. Happy workers help.

ways, we might as well give the lifetime warranty. And include labour and the screens. It’s been a great selling feature. Customers want peace of mind.”

Servicing the Gulf Islands with water access only can be tricky. “We coordinate scheduling directly with the barge, however there is that window of opportunity. It’s tide-specific. It can’t just be any time of the day and you want to make sure your order is full because you’re going to an island somewhere.”

Like many manufacturers, Thermoproof is on a Lean journey. “Our commitment to a daily ‘gemba’ walk has been very successful,” says Drew. Gemba, which loosely translated means “where the work is happening,” is a part of the Lean manufacturing philosophy. “Every morning at 9:00 a.m., our management team, up to five individuals, will start at the last work station and then we swim upstream. It even includes administration and can take up to an hour. The questions that are most important are, “How was your day yesterday?”; “How is everything today?”; and “Do you need anything?

“We check their metrics and quality control. We’ve found is that it really cuts down on recuts and reworks. Quality has drastically improved. Communication has increased. People are being heard. If somebody has a good idea or if something’s gone wrong, we’re never more than 24 hours away from hearing. That’s been a very valuable tool in running our

company on the production side.”

“We had only been running the company for a year and a half when the Energy Efficiency Act came into place,” Drew remembers. “Some of our dealers thought it was us forcing them to put low-E in. We had to educate them that for one, it’s mandated. But two, it’s a really good idea.”

Drew and his team also trained Thermoproof’s dealers about elevationspecific glass. With thermal performance regulations set to change again, no one knows where the moving target will land. “Every company is in the same boat, we don’t know where we need to be and when,” says Drew. “Canadian manufacturers know now how to build a window so it’ll be structurally sound. We need to work on new designs to increase our thermal performance. We just don’t know how much we need to do and when because if we go all the way to the highest thermal performance possible, the customer will not be able afford it.”

“Right now in Canada, timing is everything. You can’t be ahead of the curve. You can’t be behind the curve. You’ve got to be right on that wave.”

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company located in Metro Vancouver, B.C. richp@constructioncreative.com

by JON EAKES

A BETTER INTERFACE

A proposal to prevent wet window frames.

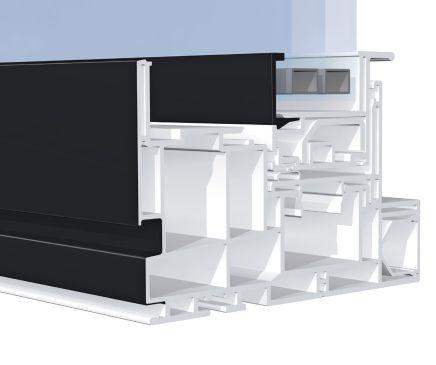

There are many variations on how to install a window into a wall, largely differing between new construction and renovation, but there is one almost universal principle presently in practice: stop both the water and the wind at the outer face of the crack between the wall and the window – the window/wall interface.

Many window manufacturers slide over the questions of installation, leaving that responsibility to the installer while staying as far away as possible from responsibility for work they cannot control. Often, on site, one person builds the wall, another applies moisture protection to the wall framing, a third attaches the window, a fourth applies insulation and perhaps a fifth attempts to seal the whole operation. Sloped sill supports are rare and shims are often simply left out because of the convenience of the mounting flanges. Even in cases where far more care and coordination takes place, windows tend to eventually leak. The best current efforts are centered on simply doing a better job of sealing out water.

I tend to work mostly in renovation and the golden rule of a window change-out is to pull out the whole frame, repair the water damage in the structure, then install the new window much like the old one was installed. But why

do we accept rotten wood under or around windows as normal? Maybe there is a bigger problem than just poor workmanship. With today’s building science knowledge and modern materials one would think we could find a way to install windows that are easy to get perfect in the field and provide permanent protection against water getting to any wood. Understanding the rainscreen principle, commonly used for both commercial and residential walls, and applying it to this narrow but so-vulnerable space between walls and windows might just be the key, allowing us to have leak-proof windows with no exterior caulking to age or be subject to poor maintenance. That is the challenge I launched at FenCon18 last March. I based my drive for a way to apply this moisture control technology on two research projects published in 2011 and 2013 by the IRC (Institute for Research in Construction, part of the National Research

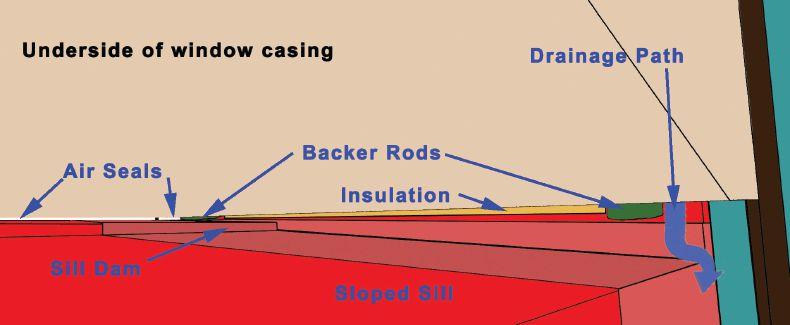

A sloped drainage sill is a critical component of the concept, flowing water back outside the wall. Surprisingly, the debate is open as to whether this dead air space needs any insulation.

TECH TALK

Council of Canada). I began to look at why there is so little change in window installation despite significant failures, especially in colder climates. The primary conclusion of these two research projects was that you should not attempt to stop both the water and the wind on the same plane.

That has interesting ramifications. When we caulk on the outdoor side of a whole assembly, we break this rule right from the start. We flow water over caulking that was imperfectly applied (ever seen that?), or that is inadequately maintained, and then subject the water flowing over an open crack to the full force of the wind. You lose – the water is forced inward.

So why not simply accept that the outermost assembly of a window does no more than most siding? It sheds the major portion of rain but is not entirely responsible for waterproofing the installation.

Inside, we can make a far more effective moisture barrier by shedding water that gets through the siding and the window trim – again, without attempting to make it totally waterproof. We are not building with wishful thinking about perfect workmanship and perfect materials that never age or move. So although the wind is buffered by the siding, the wind pressure always gets behind the siding. Most facades are actually made to permit that to happen – it is called a rainscreen wall. So we get a reduced amount of water flowing over the window/wall interface with a slightly reduced wind pressure.

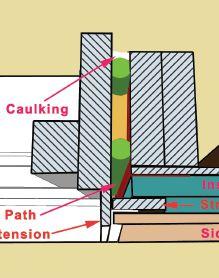

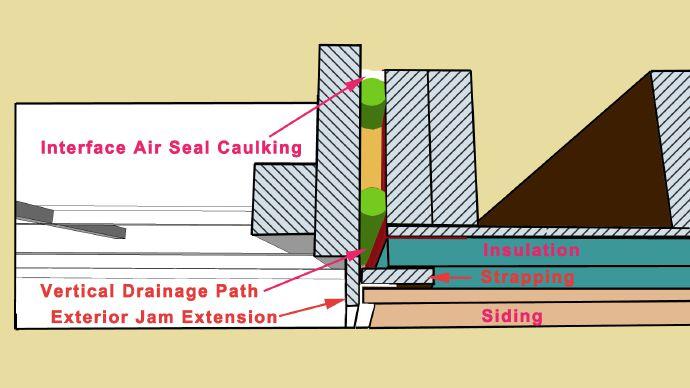

We can apply the rainscreen principle to the window/wall interface by leaving a small empty drainage path totally free and open behind the moisture barrier. This could be behind the mounting flange or, in the absence of a mounting flange, behind strapping that butts up to the window casing itself or even further back behind insulated sheathing that is not sealed. Behind this is a backer rod that controls where the insulation stops, leaving the drainage path free and open. At the bottom of the drainage path that flows down the sides of the window is an open and sloped waterproofed sill, directing any water to the outdoors. But you are not done until you fulfill

Attempts to completely stop water at the first plane of the window/wall interface are doomed to fail eventually. A rainscreen concept allows some water to enter, but then evacuates and dries the cavity with a drainage layer.

the other important element of a rainscreen: totally air-seal the window/wall interface on the inside of the window assembly. This creates a dead air space that will pressurize with any wind flowing up from below (without carrying any water) eliminating the driving force of the wind across the moisture barrier where the water has been stopped. Small imperfections in the moisture barrier will let very little water through and what does get past the barrier is not blown in further by the force of the wind but simply flows down to the sill region. There is no driving force on this water, it just drips out.

With modern elastomeric sheets or liquids we can easily waterproof the rough framing. With backer rod and caulking we can efficiently create a perfect air seal on the inside because of the indoor working conditions. With properly placed water shedding and open drainage paths we have a window installation that will permanently keep the house structure dry, with no maintenance.

There is a lot of discussion to have about the advantages of recessed glazing and the elimination of thermal bridging, and even just how much and what type of insulation we really need when we are working with dead air spaces. I am starting from the acceptance that all joints with both water flow and wind pressure have a high chance of eventually leaking. I feel that all moisture shedding joints should be arranged in a shingling fashion

so that the actual seal is less important. We need definite clear drainage without air flow to carry water inward. Pressure equalization, to the extent it works, will help.

I have re-grouped with a growing number of manufacturers, consultants and researchers who are rising to my challenge with an ad-hoc prairie window interface committee. We have not perfected how to do all of this efficiently and economically as yet. Personally, I feel we will need more and better external jam extensions and the elimination of the window mounting flange – but that is not yet a consensus. This is a work in progress that came out of FenCon18 and I am sure will continue right up to FenCon19.

If you are interested in getting the links to the IRC research reports and to see a little video that attempts to visually demonstrate water, wind, air sealing and pressure equalization, go to my website: joneakes.com/trades-training and scroll down to the Window Installation drawer. At the bottom of that article there is a link for you to send me your comments or questions. Together we may actually make window installations as good as the windows we are installing.

Jon Eakes is a trades educator and communicator based in Montreal. He’s been talking construction in public since first appearing as CTV’s Mr. Chips in 1978.

DEC 3 - 5

Quebec City Convention Centre Quebec City, QC

Canada’s Premier Industry Event Showcasing the Best of the Window & Door Industry is Coming to Quebec City!

NEW: WinDoor expands to the commercial market with suppliers and education sessions tailored to this sector of our industry. Conference and Tradeshow featuring the latest innovative products, machinery and services. Education Sessions for the business, technical and operations minded.

Main Event Extravaganza a networking party with your industry. Book your booth and sponsorship today! Contact asif@fenestrationcanada.ca for details.

Proudly Presented by

WinDoor

Quebec

City will feature some exciting new technology

WINDOOR SHOW FLOOR PREVIEW

SHARES ORDERS

ACROSS LOCATIONS

8 fenetech.com

Booth #607

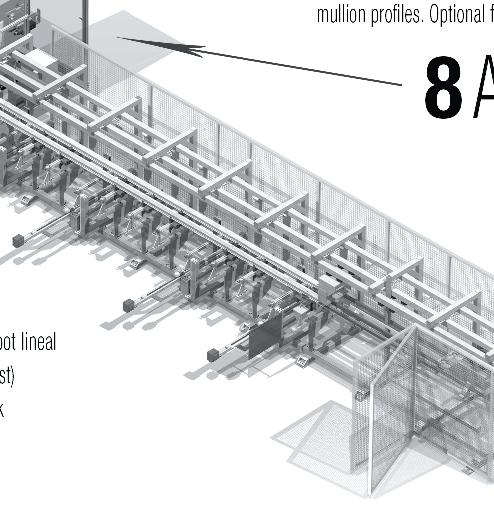

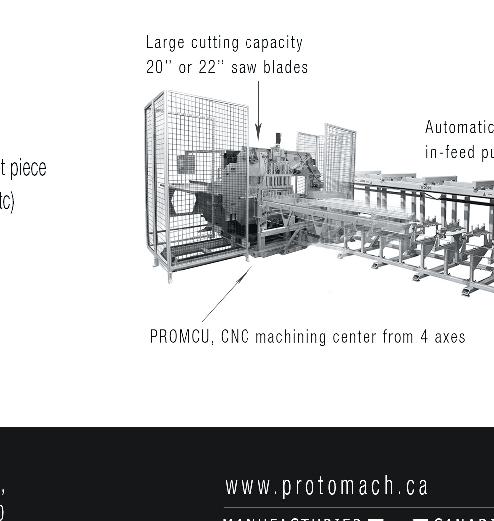

Ohio-based FeneTech, a global leader in fully integrated ERP software solutions for the fenestration industry, will display its next-generation software FeneVision Ultimate at WinDoor. FeneVision Ultimate includes many new features and offers even greater ease of use. Designed for glass fabrication and window and door manufacturing companies, FeneVision Ultimate is its most comprehensive software version released to date. In addition to the established features of FeneVision Core (which have also been further enhanced), FeneVision Ultimate includes scores of new functions including a fully integrated customer relationship management module, enhanced return material authorization functionality, additional mobile apps as well as additional optimized features for multi-site companies, corporations and large enterprises. With FeneVision Ultimate, it is possible to plan capacities across multiple production sites without having to issue separate orders among sites of a multi-site corporation. Status control is provided

across those branches. Fully automatic and transparent status visibility is available across all involved sites—all from one single-source sales order—no matter how complex the product to be produced may be. Additionally, eventual changes to original orders are automatically shared among involved production companies.

TURNKEY FAST DRYING

8 regalead.com

Booth #507

Global specialist in coatings and doorlites, RegaLead, is back at WinDoor, this time in conjunction with Schuberts Technical Services, a market leader in smart drying solutions. Recognised in Europe as a top coatings supplier for vinyl/PVC and fiberglass/ steel doors, RegaLead will

not only be showcasing its range of ultra-low VOC, mixon-demand paint solutions, but, with Schubert’s support, visitors will see start-to-finish turnkey solutions for coatings and finishing, including a new range of woodstain effects, smart booth drying systems and everything required for a company to bring door spray-painting in-house. Regalead’s mix-ondemand offering allows customers access to over 10,000 colours in-house, minimising waste, reducing lead times for colour and thus addressing one of the industry’s biggest challenges. Sharing the Booth with RegaLead is Schubert’s Technical Services, a global leader in low-energy, gascatalytic drying systems. With up to 80 per cent lower operational costs compared with electrical equivalents and typical drying times of 20 to 30 minutes for fiberglass doors using either traditional solvent 2K or water-based RegaLead coatings, the Schuhbox has proven itself across the globe.

Regalead recently appointed York Towne Supplies of Richmond Hill, Ont., as distributors for Ontario, but the company is actively seeking distributors and agents across the country.

CERTIFIED BY PASSIVE HOUSE 8 quanex.com

Booth #801

Quanex Super Spacer®

After revolutionizing warmedge technology 30 years ago, Quanex Super Spacer continues to lead the market and is used in energy-efficient window designs in residential and commercial applications all over the world. As architectural applications grow bolder, Super Spacer has the established track record of proven performance that stakeholders can trust with its inherent flexibility and superior performance. Super Spacer offers manufacturers an energy-efficient and sustainable solution for high-volume production of dual- and triple-pane insulating glass. A true dual-seal warm-edge spacer line, Super Spacer products use a highperformance acrylic adhesive for their structural seal, backed by a moisture-vapour

seal. Super Spacer systems are certified by Europe’s Passive House Institute. All three Super Spacer systems exceed the required minimum levels of specific edge resistance and are certified for arctic climates and below. With more than 20 facilities around the world and international shipping capabilities, Quanex is positioned to support customers with consistent, quality products and localized support.

SUPPORTS FLEXIBLE INTEGRATION

fentro.com

Booth #401

To further support window and door fabricators with innovative solutions, Fentro offers high-quality hardware manufactured by Siegenia. Featuring its best-in-class Titan AF series, this mod-

ern hardware system has undergone diverse product enhancements. The system allows for flexible integration into existing production processes and reduces installation time, thereby opening up significant opportunities to save costs. Using only highquality materials, Siegenia hardware provides efficient workability and maximum functionality while offering extensive design options for more individual room comfort. To supplement its hardware portfolio, Fentro likewise offers window and door handles and accessories made

by world-renowned European manufacturers. These include Hoppe handles, CES locking systems, Wemaro specialized tools, PHI shims and blocks and SPAX screws.

WIDE OPENING

phtech.ca

Booth #411

This year, P.H. Tech will be displaying Celesta, an all-new multi-track patio door, among other high-quality products. Celesta boasts a much wider opening than classic patio doors and is available in a three-panel and six-panel version. Multiple finishes and contemporary handles are available and are perfectly tailored to meet your needs.

Thanks to Celesta’s triple roller track, the panels – welded or mechanical – overlap to create an opening that can be as wide as 23 inches. Each operating panel has a set of stainless steel tandem rollers that support the weight of the operating panels during motion. Moreover, its robust profile design offers superior thermal performance, strength and durability, without reinforcement. The multiple panels slide easily thanks to the carrier piece which has a rubber bumper firmly fixed on it. Even the assembly is easier with a higher clearance to insert the sashes. P.H. Tech also took every imaginable opportunity to provide an immaculate finish and easy upkeep, with details like identical jamb covers in and out with no visible screws and an anodized aluminum sill cladding.

skai® jet black – The Cool Sensation Design Meets Function

Experience skai® jet black @ Windoor 2018 Quebec City, December 4-5, Booth # 528.