If versatility is what you’re looking for, Big Dutchman provides the most combinations of CAGE-FREE and AVIARY systems to meet the various certification standards currently offered in the marketplace today.

If versatility is what you’re looking for, Big Dutchman provides the most combinations of CAGE-FREE and AVIARY systems to meet the various certification standards currently offered in the marketplace today.

BY KRISTY NUDDS

The Egg Farmers of Canada (EFC) announced a landmark decision on Feb. 5 that the organization will commence a “coordinated, systematic, market-oriented transition from conventional egg production toward other methods of production for supplying eggs.” (See page 6.)

The announcement is not unexpected and was inevitable, given the increasing pressure to ban conventional housing, as well as the number of foodservice companies making cage-free announcements.

However, the timeline given to make such an industry-wide transition – EFC says it will be completed by 2036 – has been met with criticism.

The Monday following EFC’s announcement I received a Letter to the Editor from Stephanie Brown, director, Canadian Coalition for Farm Animals, and Liz White, director, Animal Alliance of Canada, in which they applaud EFC’s efforts, but lament on the timeframe:

The February 5th announcement from egg farmers is focused on enriched cages for hens, not cage-free systems, as consumers are requesting. Eggs produced in enriched cages won’t satisfy retailer requirements for cage-free eggs. Tim Hortons, Burger King, McDonald’s, Starbucks, Taco Bell, General Mills, Nestle and others have responded to public pressure and are calling for cage-free eggs. It is regrettable egg farmers still promote cages for laying hens. Whatever the alternative caging is called –‘furnished’, ‘enriched’ or ‘colony’– it remains an unacceptable confinement system. About 95 per cent of laying hens in Canada are now confined to battery cages with each hen having less space than a standard sheet of paper. Even with growing public pressure against battery cages, the EFC wants until 2036 to change

from small battery cages to larger confinement operations. Twenty years is too long for the Canadian egg industry to move hens out of battery cages. The European Union made its change in 12 years.

Twenty years is a long time, but it is realistic. I would point the authors and other critics to a fantastically written article “The Insanely Complicated Logistics of Cage-Free Eggs for All” on Wired.com.

As the manager of the nation’s egg supply, EFC must ensure that eggs produced on Canadian farms are meeting consumer and customer needs – and meeting this obligation may not mean that 100 per cent of production must be cage-free, even 20 years from now.

Results from a commercial-scale study comparing enriched, conventional, and cage-free housing, commissioned by the Coalition for a Sustainable Egg Supply (CSES), show that both enriched and cagefree housing systems have welfare benefits, and that birds in enriched housing actually fared a little better. Mortality was considerably higher in the cage-free aviary system, so why is this deemed the gold standard? I don’t understand how it is OK to accept more animals dying just to have them in more aesthetically pleasing surroundings.

EFC has, in my opinion, done the right thing by commissioning research and participating in initiatives such as the CSES to try to make the best decisions for its growers, purchasers and the birds. This is ongoing and it could very well be that in 20 years, the market deems all egg production be cage-free.

However, at this time, it’s too premature to demand only one type of production and dismiss enriched housing based solely on its looks. n

@CanadianPoultry

FEBRUARY/MARCH 2016 Vol. 103, No.2

Editor

Kristy Nudds – knudds@annexweb.com 519-428-3471 ext 266

Digital Editor – AgAnnex Lianne Appleby – lappleby@annexweb.com 226-971-2133

Sales

Catherine Connolly – cconnolly@annexweb.com 888-599-2228 ext 231 Cell: 289-921-6520

Account Coordinator

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer

Brooke Shaw

Circulation Manager Anita Madden – amadden@annexbizmedia.com 416-442-5600 ext 3596

VP Production/Group Publisher Diane Kleer – dkleer@annexweb.com

Director of Soul/COO Sue Fredericks

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Circulation email: blao@annexbizmedia.com Tel: 416-442-5600 ext 3552 Fax: 416-510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

Subscription Rates

Canada - 1 Year $ 30.95 (plus applicable taxes)

U.S.A. - 1 Year $ 66.95 USD Foreign - 1 Year $ 79.95 USD

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2016 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

With nearly 70 years of experience developing innovative products for poultry producers worldwide, Lubing has established a reputation of leadership by introducing new, cutting-edge technologies to the poultry industry.

OptiGROW Nipple

The ultimate Broiler nipple Optimized for Growth!

SprayCabinet

Spraying/Disinfecting your chain... Simplified!

DripCanopy

Keep your floors mess-free with a DripCanopy!

Cantilever Drive Unit

Keep the clutter out of processing!

ChainKeeper

It’s like life insurance for your conveyor system!

BaitStation

Keep your rodent problems under control!

Got Lubing? Contact your local Lubing Distributor for more detailed information about our new, innovative products.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337.3767

Fax: (403) 337.3590

Egg Farmers of Canada (EFC) announced Feb. 5, that it has commenced a coordinated, systematic, market-oriented transition from conventional egg production toward other methods of production for supplying eggs. EFC says this collective approach will take hen welfare, human health, other resource implications, environmental impact and food production sustainability all into account.

“In response to the best available scientific research and in light of changing consumer preferences, I’m pleased that the entire industry has agreed to an orderly transition plan that will further diversify our production practices,” said Peter Clarke, chairman of Egg Farmers of Canada, in a release. “We see immense

potential to leverage research and innovation to achieve the best possible outcomes across all factors of sustainable food production, which includes everything from environmental impacts to food affordability,” he added.

This major shift will yield an almost 50 per cent restructuring in as early as eight years from now and includes a commitment to cease the installation of any new conventional housing. Presently about 90 per cent of egg production is in conventional housing. The other 10 per cent or so is in enriched housing, free-run, aviary or free-range. Under the plan, to be overseen by a national working group in collaboration with the entire egg supply chain, the industry expects to achieve about a 50-50 per cent mix in eight years, about 85 per cent (alter-

native production) in 15 years. All production would be in enriched housing, free-run, aviary or free-range by 2036 assuming the current market conditions prevail.

EFC says these projections represent a realistic forecast of what is achievable. The steady, coordinated and crosssupply chain approach will be executed with the utmost respect for ensuring supply— both that there are no supply shortages and that there is no production of eggs for which there is no market—while pursuing production diversification.

Alongside this announcement, EFC says the industry hopes to discuss with stakeholders and consumers the benefits of enriched housing, which do not seem to be well or widely understood outside of the industry.

Chilliwack B.C. poultry and egg producers Brian (37) and Jewel (35) Pauls have been named the 2016 B.C. & Yukon Outstanding Young Farmers (BCOYF).

For the first time in its 36-year history of recognizing outstanding young farmers, the BCOYF program has a second-generation winner. Brian’s parents, Frank and Elma Pauls, earned the same award in 1990.

The Pauls family have multiple egg and broiler farms in B.C. and Saskatchewan and include Canada’s first certified humane turkey farm.

To be eligible for the Outstanding Young Farmer award, farmers must be between 19 and 39 years and derive at least two-thirds of their income from farming. Nominees are judged on conservation practices, production history, financial and management practices, and community contributions.

The BCOYF program is sponsored by the B.C. Broiler Hatching Egg Commission,

Granny’s Poultry is expanding its Blumenort, Man., processing facility and has received $2.5 million in funding from the federal and provincial governments to help support the project.

The company is implementing a plant expansion

and renovation totalling $37 million, which will allow it to grow its business and purchase new equipment for processing, chilling, packaging and grading poultry, and improving production efficiency.

Craig Evans, CEO of Granny’s Poultry said in a release “the expansion and upgrading of our processing

Clearbrook Grain & Milling, Farm Credit Canada and Insure Wealth.

Brian and Jewel Pauls will represent B.C. at the national OYF competition in Niagara Falls, Ont., in November. The national competition is supported by AdFarm, Agriculture and Agri-Food Canada, Annex Business Media, Bayer Crop Science, BDO, CI, Farm Management Canada and John Deere.

facilities will keep Granny’s growing and competitive for years to come. Investing in state-of-the-art equipment will improve production efficiencies and help us develop new market opportunities for Manitoba poultry.”

The federal and provincial governments are investing $176 million of cost-shared programming in Manitoba under Growing Forward 2.

Canadian Poultry Consultants is hosting its second annual B.C. Poultry Symposium (BCPS) May 26 in Abbotsford.

Poultry producers, allied

trades, service persons, nutritionists, poultry scientists, veterinarians and other industry professionals are invited and encouraged to attend this meeting. The theme of the Sympsosium is “Discovery, Innovation, Solutions” and will cover a large range of the

most important issues facing the poultry industry today. To register please visit www.canadianpoultry.ca and follow the BCPS link or please use the following direct link: https:// www.regonline.ca/BCPS-

The registration deadline is April 30.

MARCH 2016

March 9-11, 2016

B.C. Poultry Conference 2016, Westin Bayshore, Vancouver, B.C. The four feather boards in B.C. are hosting a joint conference that will feature breakout sessions, trade exhibits, each commodity’s annual meeting and keynote speakers. For more information, e-mail: office@bcchickengrowers.ca

March 17-19, 2016

Midwest Poultry Federation Convention, Saint Paul RiverCentre, St. Paul, Minn. For more information, visit: www.midwestpoultry.com

APRIL 2016

April 6-7, 2016

London Poultry Show, Western Fair District Agriplex, London, Ont. For more information, visit: londonpoultryshow.com

April 25-27, 2016 65th Western Poultry Disease Conference, Vancouver Marriott Downtown Hotel, Vancouver, B.C. For more information, visit: http:// www.cevs.ucdavis.edu/ confreg/?confid=778

MAY 2016

May 25, 2016

Western Meeting of Poultry Clinicians and Pathologists (WestVet), Ramada Plaza & Conference Centre, Abbotsford, B.C. For more information, visit: www.westvet.com

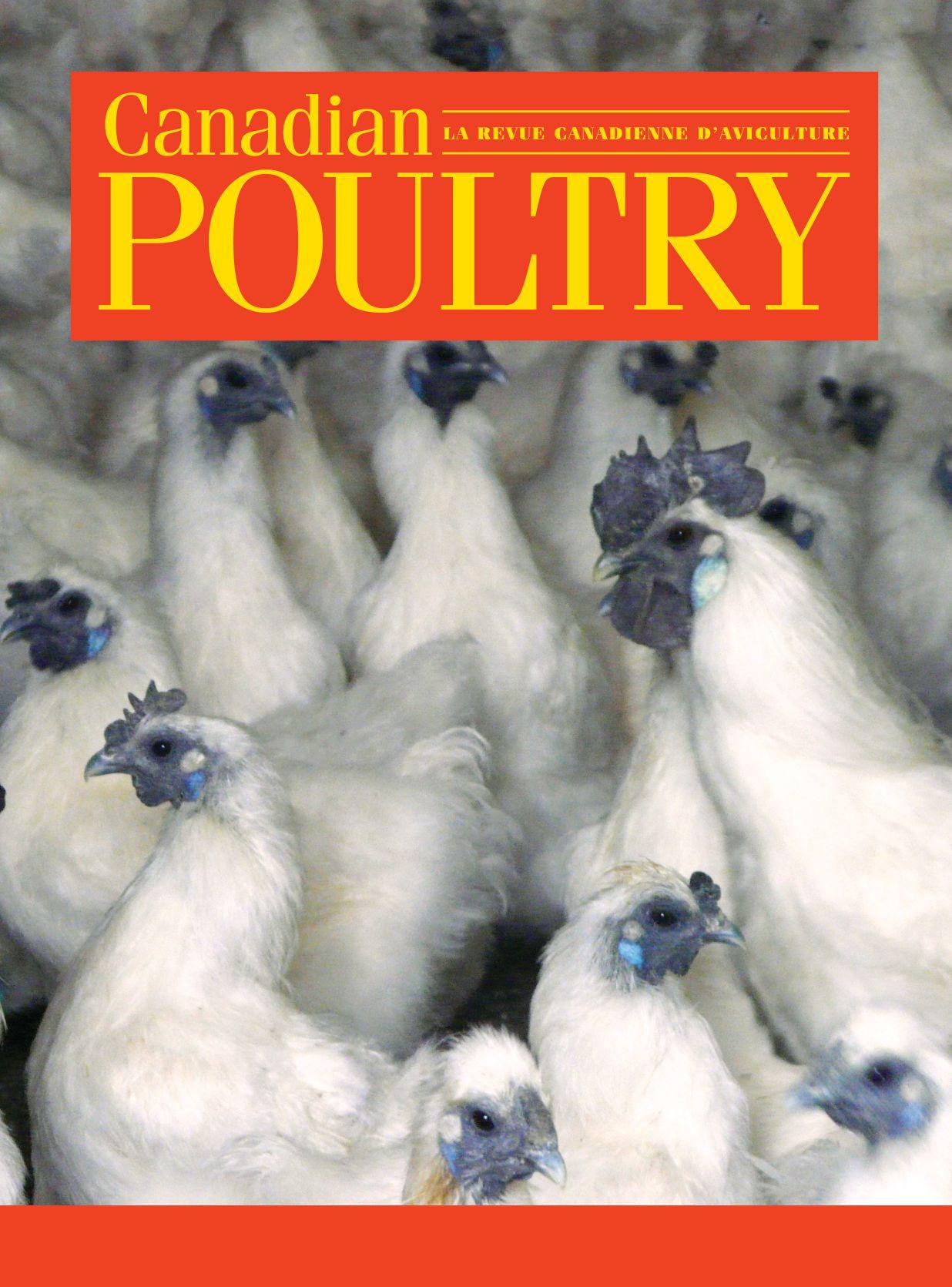

U.S. Poultry & Egg Association (USPOULTRY) recognized three companies that have been exhibiting for 55 or more years at the International Poultry Expo (IPE), part of the 2016 International Production & Processing Expo. Paul Hill, West Liberty Foods, Ellsworth, Iowa, and newly elected USPOULTRY chairman, presented plaques to each company in acknowledgement of their long-term exhibiting tenure.

Baader Linco and CobbVantress were recognized for 60 years of exhibiting at IPE. Hubbard LLC was recognized for 55 years of exhibiting at IPE.

“Your support of the International Poultry Expo has allowed the poultry industry to grow and advance, as we continue to invest show revenues back into the industry. We sincerely appreciate and thank you for your continued support,” commented Hill.

The 2016 International Production & Processing Expo (IPPE) had an estimated 30,000 poultry, meat and feed industry leader attendees from all over the world. In addition, the show had 1,301 exhibitors, a new record, with more than 464,750 net square feet of exhibit space. The central attraction is the large exhibit floor. Exhibitors demonstrated the most current innovations in equipment, supplies and services used by industry firms in the production and processing of meat, poultry, eggs and feed products. Numerous compa-

May 26, 2016

B.C. Poultry Symposium, Ramada Plaza & Conference Centre, Abbotsford, B.C. Registration deadline is April 30. For more information, visit: www.canadianpoultry.ca

JUNE 2016

June 15-17, 2016

Canada’s Farm Progress Show, Evraz Place, Regina, Sask. For more information, visit: www.myfarmshow.com

JULY 2016

July 11-14, 2016

Poultry Science Association Annual Meeting, Hilton New Orleans Riverside, New Orleans, La. For more information, visit: www.poultryscience.org

SEPTEMBER 2016

September 5-9, 2016

XXV World’s Poultry Congress, China National Convention Center, Beijing, China. For more information, visit: www.wpc2016.cn

September 13-15, 2016

nies highlighted their new products at the trade show. All phases of the feed, meat and poultry industry are represented, from live production and processing to further processing and packaging.

The wide variety of educational programs complemented the exhibits by keeping industry management apprised on the latest issues and events. This year’s educational line-up featured 25 programs, ranging from a conference on challenges and opportunities in meat product traceability, to a program on the Veterinary Feed Directive.

Canada’s Outdoor Farm Show, Canada’s Outdoor Park, Woodstock, Ont. For more information, visit: www.outdoorfarmshow.com

We welcome additions to our Coming Events section. Please send your event information at least eight to 12 weeks in advance of the event to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; email knudds@ annexweb.com; or fax 519429-3094. Please write ‘Event Submission’ in the subject line.

by Treena Hein

The demographics of southern Ontario continue to change and evolve, offering new areas for market growth, states the Chicken Farmers of Ontario (CFO). CFO noted recently that the Chinese and South Asian population is now over 1.3 million in the Greater Toronto Area, and many of these folks really like fresh ‘head and feet on’ chicken. Production of these birds (Frey’s Dual Purpose “yellow” chickens and Silkie chickens) is currently 0.4 per cent of Ontario’s annual chicken production, and the market is estimated to be over 3.0 per cent. All this, says the CFO, demonstrates that the Ontario specialty breeds chicken market is a significant business growth opportunity.

Lakeside Game Farm is the largest provider of fresh ‘head and feet on’ Silkies into the Ontario market.

Production of specialty birds such as Silkies is currently 0.4 per cent of Ontario’s annual chicken production, and the market is estimated to be over 3.0 per cent. All this, says the CFO, demonstrates that the Ontario specialty breeds chicken market is a significant business growth opportunity.

Henry Ebert began marketing the blackskinned, dark-fleshed chickens on his game preserve about 20 years ago alongside ducks and geese, when someone made a request that he do so. His son Jim has taken over the business, officially buying it in 2010, but it was back in 2004 that Silkie production on the farm grew substantially. “We were stuck with some birds that someone ordered but didn’t pay for, and we found a market,” Jim says. “After that, we kept production at about 5000 and now it’s at 8000 birds a week.” He sought some contractors to supplement his production

around 2004 and has three of them right now.

Silkies take longer to reach market weight than standard broilers – 11 to 12 weeks for roosters, and 13-14 weeks for female birds. Other than that, Ebert says production and health concerns are similar and he feeds an all-grain standard ration. He sends birds for processing two to four times a week, and has 14 groups of differently-aged birds in four different rooms in his brand new barn (each one at a different temperature) in order to keep up with fresh production flow. “I’m renovating my layer barn as well,” Ebert reports. “I supply myself and my contractors with chicks. It’s a unique operation in the poultry business, to do it all, start to finish.” Ebert does almost everything on the farm, from bird care to delivery of birds to the processing plant, with the help of two part-time employees.

Ebert’s success is the result of working steadily for years to establish himself in the Silkie market, and he says he now has only one competitor in the province. However, that wasn’t always the case. Ebert observes that over the years, there were people who would jump into production after hearing there was money to be made, people who would create too much supply and then undercut each other. Everything changed last year though, when CFO began regu-

lating Silkies under its Specialty Breeds Chicken program (see sidebar). “You need a permit now,” Ebert explains.

Lakeside Game Farm produces about 9000 chicks a week depending on the time of year, and recently purchased a new incubator to boost the hatch rate. “My incubators were 20 years old, so it was time,” he says. “I went with a multistage Jamesway unit, which was a big investment, but it’s paying for itself. The hatch rate has gone from 60 per cent to 80 per cent, and the chicks are doing five per cent better too. They’re just healthier and they’re fed the same day they’re hatched.”

Ebert sits on the CFO Specialty Breeds Chicken program committee, and says that members are trying to learn more about how fresh specialty markets work. “There’s a desire for producers like me to weigh each bird before it goes for processing, but I just can’t do that because it would be very time-consuming and it would delay me, as I have all sorts of orders coming in all the time, many of them last-minute,” he says. “I am very much in favour of continuing on with using an average weight per bird.”

Ebert says that because there are still many frozen specialty chickens being imported into Canada where a fresh product is very much desired, the market for Silkies will continue to grow. He believes using a permit system, as opposed to quota which is very expensive for new growers, is the best way to grow the market.

For his hard work, including optimizing the use of his new hatchery and his barn investments, Ebert just won a 2015 Premier’s Award for Agri-food Innovation Excellence. “It’s nice to win the money and get some recognition for hard work,” he says. “Before, you wanted Silkies to be a secret. You didn’t want to advertise, because someone would jump into the market and prices would go down. Now that’s not going to happen with the regulation in place. The stability is great and the barn inspections have been great for my contractors to improve production.”

Silkies are well known for their calm, friendly temperament and considered an ideal pet chicken. They are one of the most popular ornamental breeds. Hens are exceptionally broody and make good mothers, so they are commonly used to hatch the eggs of other breeds and species.

poufy plumage, black skin, black bones and grayish-black meat (melanism). Melanism which extends beyond the skin into an animal’s connective tissue is a rare trait, and in chickens it is caused by a rare genetic mutation believed to have first appeared in Asia. In addition to the Silkie, several other breeds descended from Asian stock possess the mutation.

The Silkie’s most well-documented point of origin is ancient China, but other places such as India and Java have been named as possibilities. As early as the 7th century, traditional Chinese medicine has held that chicken soup made with Silkie meat is a curative food. The earliest surviving written account of Silkies comes from Marco Polo, who wrote in the 13th century during his Asian travels of a furry chicken. Silkies most likely made their way to the West via the Silk Road and by marine shipping trade. Once they became more common in the West, many myths were perpetuated about them. Early Dutch breeders told buyers they were the offspring of chickens and rabbits. The breed was recognized officially in North America in 1874.

Silkies have an extra toe or two and

The Silkie got its name for the feel of its plumage. The feathers of a Silkie are furry and fluffy, feeling silk-like, because they lack functioning barbicels, which hold feathers on other bird species down. This lack of barbicels in its feathers also leaves the Silkie unable to fly. The breed does not generally produce as much meat as conventional chickens. Silkies are often mistakenly called a bantam breed, and although they are considered bantams in some countries, the bantam Silkie is actually a separate variety. Almost all North American strains of the breed are bantamsized, with the males weighing 1.8 kg and females weighing 1.4 kg. Jim Ebert’s birds (male and female) average about 1.45 kg.

Black chicken meat is generally considered unusual in European and American cuisine, but several Asian cuisines consider Silkies a gourmet food. Common dishes include soup, braised dishes and curries.

Adapted from Wikipedia

Lakeside Game Farm produces about 9000 chicks a week depending on the time of year, and recently purchased a new incubator to boost the hatch rate

In September 2014, Chicken Farmers of Ontario (CFO) approved a new program to support increasing consumer demand for alternative breeds of chicken. The program also brings Ontario into alignment with the national Chicken Farmers of Canada specialty breeds policy. Two common breeds of specialty chicken are included, the Frey’s Special Dual Purpose “yellow” chickens and Silkies, both processed with head and feet left on. CFO’s director of communications and government relations Michael Edmonds says the new program was promoted through an advertising campaign and supported by a series of farmer information sessions throughout the province. “The response to the program and information sessions was strong, with significant numbers of interested farmers seeking information,” he notes. “Since the launch a year ago, the program has increased threefold in volume with 21 farmers now supplying the market with more than 50,000 Frey’s Dual Purpose (15 producers) and Silkie chickens (6 producers) per week.”

In order to further promote and support this emerging market, CFO has hired a specialist to work with retailers, processors and farmers to identify opportunities and ensure the supply management system adequately anticipates and supplies growing demand. “The program also places a major focus on compliance to CFO’s Animal Care and On Farm Food Safety Assurance programs,” Edmonds notes. “This focus on quality has resulted in significant investments, upgrades and improvements to the participating farm facilities, particularly in Silkie production. The program has been successful to date and so no significant changes are being considered at this point.” n

We will be taking on the next 100 years like we did the past 100– with excitement and highest expectations. Thanks for helping us look ahead to our next innovation. And hang on. We have a strong grip on the shape of things to come.

Probiotics are live organisms that, when administered in adequate amounts, confer a health benefit on the host through improvements to the intestinal microbial balance. In poultry production, interest in probiotics stems from their use as alternatives to antibiotic growth promoters and also as a strategy for control of intestinal colonization with enteric microbes that cause food-borne illness in humans, e.g. Salmonella. The mechanism of action of probiotics in poultry is thought to include the maintenance of normal intestinal microbiota, changes in metabolism and improvements to feed intake and digestion. Administration of probiotics has been shown to improve weight gain and feed utilization and to decrease mortality of poultry. Treatment with probiotic bacteria, particularly Lactobacilli, is capable of modulating multiple aspects of immune responses and can also enhance immune competence in chickens.

Despite the beneficial effects, a limited number of probiotic products are currently available with proven immune enhancing capabilities in chickens. Dr. Shayan Sharif and his research team from the University of Guelph have developed a defined probiotic formulation containing several Lactobacilli with the ability to enhance immune responses and reduce Salmonella burden in chickens. These Lactobacilli were obtained from the intestines of healthy chickens, as these bacteria are normal inhabitants of the chicken intestine. Effects on growth, feed efficiency, immune system development and immune responsiveness of birds were measured to further evaluate this probiotic formulation and to determine its safety and optimal route of administration. The long-term objective

of this research is to develop cost-effective probiotic formulations for chickens that can enhance production, reduce colonization of food-borne pathogens and enhance immune competence.

The safety of the selected probiotic formulation was assessed to ensure its suitability for use as a probiotic product. Laboratory (in vitro) and live-bird (in vivo) trials demonstrated that the probiotic formulation was capable of decreasing Salmonella colonization at specific doses, and could be delivered via a number of ways without reducing its effectiveness. Administration of this probiotic formulation into eggs (in ovo) had no adverse effects on hatchability and general condition of the hatching chicks. Chicks all had Lactobacillus present in their intestines at the time of hatch. The posthatch growth performance of broilers that received probiotics was examined and the overall body weight gain, feed intake and feed conversion ratio were comparable to those of the chickens receiving growth promoting antibiotics in their rations. Chicks received the probiotic treatment on day of hatch or in ovo to determine how early colonization with probiotic Lactobacilli affects the development of the intestine. Overall the results demonstrate the ability of probiotic formulations to promote the development of the intestine.

In order to determine the effects of early administration of the probiotic formulation on the stimulation of immune response and protective immunity, the researchers measured the antigen-specific antibody response to Avian Influenza Virus in chickens treated with the probiotic on the day of hatch. Results show that probiotic treatment improves the overall immunity of chickens and their ability

to fend off influenza virus. The immune enhancing activity of the probiotic formulation was not limited to immunity against avian influenza virus and similar results were obtained when the probiotic formulation was used with a Salmonella vaccine. Overall, this study showed that under normal conditions, there is virtually no difference in some of the key production parameters in broilers fed antibiotic- or probiotic-supplemented diets. Also, chickens fed probiotics had lower Salmonella burden in their intestines and also had higher immunity against avian influenza virus and Salmonella

The findings show that this probiotic formulation is safe and highly effective in terms of reducing Salmonella burden in broiler chickens. This Lactobacillus-based probiotic has the capacity to enhance broiler immune competence of broilers. Comparison of the effects of probiotics and antibiotics on production parameters found that probiotics and growth promoting antibiotics had comparable effects on these parameters. This research demonstrates that probiotics can provide a safe and effective feed supplement in broiler production.

This research was funded by the Canadian Poultry Research Council and the Natural Sciences and Engineering Research Council of Canada.

CPRC, its Board of Directors and member organizations are committed to supporting and enhancing Canada’s poultry sector through research and related activities. For more details on these or any other CPRC activities, please contact The Canadian Poultry Research Council, phone: (613) 566-5916, fax: (613) 2415999, email: info@cp-rc.ca, or visit us at www.cp-rc.ca.n

A

BY KAREN DALLIMORE

When it comes to developing a vaccine in response to emerging diseases that threaten the lives of animals, a pharmaceutical company needs to move quickly. What it comes down to is being “first to know” and “fast to market”, said Dr. Raja Krishnan, formerly senior director of Swine and Poultry Research and Development for Zoetis and now of companion animal and equine biological research. Speaking to the Poultry Industry Council Health Day in Stratford, Ont., Krishnan put a global perspective on some of the corporate thought processes that precede his company’s decision to develop a vaccine.

“The world is becoming a smaller village,” said Krishnan. Zoetis, a leading pharmaceutical company with 10,000 employees in 120 countries, has access to global surveillance networks that use targeted regional surveillance to help guide rapid, high quality product development. As an example, Krishnan called Avian Influenza (AI) a “disease that is travelling around the world, creating headaches.” With that kind of migration, how do we become proactive? How do we get ahead of the next round of disease? “It’s a decision that can’t wait,” said Krishnan. “Seasons change whether we’re ready or not,” leaving the company to do the right thing for their customers and the entire

Dr. Raja Krishnan of Zoetis put a global perspective on some of the corporate thought processes that precede his company’s decision to develop a vaccine at the PIC Health Day last year

industry, sometimes making those decisions in a matter of minutes.

The AI outbreak affected over 48 million birds between December 2014 and June 2015. A lot of questions swirled around the decision to develop a vaccine; the disease was moving quickly. Did the industry want a vaccine? Would they use it? Would the government endorse it? Would the USDA recommend culling or

vaccinating? Even if a product were developed, would it be relevant? Does it make sense?

Adding to this uncertainty is the fact that AI doesn’t play by the rules. The virus can mutate rapidly, meaning that the vaccine needs to be changed frequently. That’s one of the challenges. “AI constantly surprises us,” said Krishnan.

Krishnan admitted that sometimes a vaccine works in a test tube but falls apart in the real world.

“Nothing beats preparedness but we may have to coursecorrect collectively.”

When asked about the drivers behind the U.S. poultry industry deciding to use or not use the AI vaccine, Krishnan listed several of the questions such as, when will the product be available? Is there a risk of AI going into broilers as we go into the winter? Will this pressure us to act?

“Let’s not underestimate the economic and trade implications,” said Krishnan, what he called “the political aspects.” Will use of a vaccine result in trade restrictions? How does the issue get played out in the news? How does the consumer view the issue? What will the government do? How will pressure from retailers like Walmart affect vaccine use? He described the vaccination issue as “a jigsaw puzzle with so many uncertain parameters.”

Under a similar disease challenge in April 2013, Porcine Epidemic Diarrhea (PED) was identified in the United States; by September 2014, conditional vaccine licenses were being issued in the U.S. Everything happened rapidly, said Krishnan, fuelled by a commitment to U.S. pork producers and the veterinarians who support them to help contain an outbreak in 30 states that was responsible for the deaths of more than seven million piglets in the U.S..

What if their company goes down the wrong path? Krishnan admitted that sometimes a vaccine works in a test tube but falls apart in the real world; sometimes a disease doesn’t cause a problem, in which case the resources will be pulled back and re-invested.

With AI, are we headed in the right direction? Is it easier to cull the birds, clean up and move on? “That’s the million dollar question,” answered Krishnan. Thirty years from now we’ll have stories to tell. n

If you could protect your farm this way, you wouldn’t need any cleaners or disinfectants.

These are some of the products eligible for the Vetoquinol Club points program. Sign up today at vetoquinolclub.ca and reap the benefits. club

Vetoquinol would like to remind you of the importance of a good biosecurity protocol and its implementation on a daily basis.

NEED MORE INFORMATION? CONSULT YOUR BIOSECURITY SPECIALIST.

BY TREENA HEIN

As is the case in so many sectors, egg processing leaves material behind that ends up in the landfill site. But what if the inedible egg leftovers (called slurry or spinnings) could themselves be processed into something valuable? That’s exactly what Perth County Ingredients (PCI) of St. Mary’s, Ont., has accomplished, through upgrading a processing facility and working for a year to work out processing bugs.

Raw materials from local farms, grading stations and egg processors is converted into a high-protein powdered ingredient used in animal feed and pet food manufacturing. “Currently, the demand is very high for this product for the pet food industry and new opportunities are opening up for the future,” says Austin Currah, PCI’s plant and sales manager. “Right now, this product is shipped all over Canada and we have some current interest from Australia and Japan.”

It was 1952 when PCI’s parent company, Vanderpol’s Eggs Limited, decided to get into egg processing. Vanderpol’s established the Perth County plant in St. Mary’s in 1984, where workers use advanced processing and drying technologies to make dried, liquid and frozen egg products. These include standard dried albumen, high-gel albumen, highwhip albumen, standard, dried and free flow yolk, standard, dried and free flow whole egg, spray-dried whole egg and spray-dried high-protein egg product.

HIGH-VALUE SLURRY

Perth County Ingredients has developed a process to convert raw materials to a high-protein powdered ingredient used in animal feed and pet food manufacturing

Plant employees also isolate and extract lysozyme, a natural antimicrobial found in egg white.

PCI ingredients are used in a large range of products in the food, beverage and sports nutrition industries (domestic and international), including baked goods of all kinds, protein drinks, nutrition bars, fish cakes, sausages, pasta, sauces and much more.

The company says that its high-quality dried eggs products offer a wide range of cost-effective advantages in comparison to liquid eggs, related to performance, storage and shelf life.

It was in 2011 that Vanderpol Eggs began looking into how inedible

You know that a well-designed rotation program is critical for resistance control in your flock. But did you know that this means rotating through different classes of ionophores and not just rotating through products? 1

Make sure your rotation program is on track! Talk to your Zoetis territory manager to discuss the most recent anticoccidial data and find out the latest on Avatec® 20—the only divalent ionophore available in Canada and an excellent solution to help control resistance and prevent disease in your flock.

Reference: 1. Chapman HD. Rotation programmes for coccidiosis control. International Poultry Production. 2007;15(1):7-9.

Feeding the world is not just a big responsibility, it’s big business – with a world population over 7.3 billion, it has to be. However, many consumers don’t associate large-scale business with family business, even though 98% of

Canadian farms are family-owned and operated. As a result, many consumers don’t trust their food supply. We need to make sure the story of the family farm is being told, and that “big” doesn’t mean “bad.”

98% of Canadian farms are family farms

Almost all of the farms in Canada are family-owned and operated, and producing healthy, sustainable food is their first priority. Remember, farmers feed their own families the food they produce.

Family farms have evolved

They look different today than they did 50 years ago. But that doesn’t mean our food supply isn’t safe and healthy anymore. New technology has allowed farmers to do more with less, making agriculture more sustainable today. Farmers protect the environment because they want to pass their business on to the next generation.

Farming is a complex business

Families must manage food safety and traceability, detailed budgets and accounting, marketing, employees, everchanging technology, and more. Modern farms must be run as a business, and it makes good business sense for many family farms to incorporate. As a company, farms can minimize taxes. Plus, family members can own shares in the company, making it easier to pass the farm from generation to generation. But their business structure doesn’t change the fact that family members work side by side every day, bringing to life their shared passion and dedication for producing safe, healthy food.

We all have stories we can share, whether you grew up on a family farm, or you work in an industry that serves farm families. Look for opportunities to tell the real story of Canadian agriculture, whether it be online, in the grocery store or at the dinner table.

Everyone in the industry needs to work together to help improve perceptions. By being open and proactively communicating with the public about how we grow food and why we operate in the ways we do, we can maintain consumer trust and continue to produce high-quality, nutritious food in ways that are efficient and sustainable.

The importance of family is something everyone can understand and relate to, whether you’re in ag or not. It’s common ground that can start a conversation.

Visit AgMoreThanEver.ca/resources to find a collection of photos that you can easily share on social media to start or support conversations about family farming.

The land is my lifestyle and my livelihood, but it’s also my legacy.

Providing safe, healthy food for my family is important to me too.

That’s why I farm.

I love ag for the life it gives my kids now…and the opportunities it gives in the future

Or, even better, share your own pictures and make your story personal.

“Agriculture is a fast-growing business, and it has to be run as a business. It involves family, of course, but we’re always looking at the latest research, we’re looking at what practices are evolving in other countries, and we’re adapting those practices so we can become more efficient to get our product into the marketplace.”

– John Thwaites, Ontario fruit and vegetable grower

“My farm is a family farm. It is 100% owned by myself, my husband and his two parents. We love everything about agriculture with a fierce passion. We have never, ever, sold a product that we wouldn’t happily serve to our children. Every decision on the farm takes more than just finances into consideration. Our number one goal is to leave a farm to our children that is both environmentally and economically viable.”

– Adrienne Ivey, Saskatchewan rancher

Watch The power of shared values webinar featuring Charlie Arnot, CEO of the Center for Food Integrity, who shares three simple steps to gain consumers’ trust by tapping into the power of shared values. Charlie helps bridge the divide between science and consumer perception and offers great insight into creating messages that are proven to resonate with consumers.

Visit AgMoreThanEver.ca/tag/webinar

There are 2.1 million Canadians working in agriculture and agri-food. Imagine the impact we could make if we all made a commitment to improve perceptions of agriculture. There are simple ways you can start being an agvocate today. Just choose to do one of the following:

1. Search the hashtags #FutureFarmer, #AgMoreThanEver, or #Farm365 and find a positive post to retweet.

2. When you overhear a misleading or inaccurate conversation about farming, find an appropriate time to share your story.

3. Dedicate one day to volunteer at an event that promotes agriculture such as Open Farm Days or Ag Literacy Week

4. Tell a friend or co-worker about the need to speak up, and ask them to take the agvocate challenge.

“ We take pride in knowing we would feel safe consuming any of the crops we sell. If we would not use it ourselves , it does not go to market.”

– Katelyn Duncan, Saskatchewan

“ The natural environment is critical to farmers – we depend on soil and water for the production of food. But we also live on our farms, so it’s essential that we act as responsible stewards.”

– Doug Chorney, Manitoba

“ The welfare of my animals is one of my highest priorities. If I don’t give my cows a high quality of life, they won’t grow up to be great cows.”

– Andrew Campbell, Ontario

Safe food; animal welfare; sustainability; people care deeply about these things when they make food choices. And all of us in the agriculture industry care deeply about them too. But sometimes the general public doesn’t see it that way. Why? Because, for the most part, we’re not telling them our story and, too often, someone outside the industry is.

The journey from farm to table is a conversation we need to make sure we’re a part of. So let’s talk about it, together.

Visit AgMoreThanEver.ca to discover how you can help improve and create realistic perceptions of Canadian ag.

spinnings could be converted into a powdered high-protein ingredient (named SD 50% and SD 65%). While staff at Perth County Ingredients restarted a moth-balled facility that had been closed for five years, staff at

Vanderpol Eggs did all the research and development on the processing itself. “The St. Mary’s plant is central to several large egg and hatchery operations, so it became a great opportunity, but it took a lot of capital to get the things up and

running,” Currah says. “In 2011, we had to get a business plan together and we were able to access some provincial and federal funding to deal with the initial start-up costs. We are always doing testing and continue to work with our current government to get assistance to hopefully help the facility grow.”

The process to make the spinnings product employs high-tech dryers, a pressurized membrane system and modified centrifuge technology. “The main steps include reducing the moisture content and raising the solids of the inedible raw material before the drying process occurs,” Currah explains. “We maximize the dryer performance for maximum throughput.” Challenges in making the process work included fine pits of shell in the finished product and trying to keep the slurry from the different processors at a more constant level. “Overall,” Currah says, “it took about a year of tests and trials to get the protein and fat levels that we are at today.”

The facility started in 2011 with about 15 people and currently employs 31, with plans of an expansion in 2016 that will result in hiring ten more people. Currah says the expansion will involve installing a third dryer capable of drying egg yolk and whole egg for the food industry.

Owners of egg processing and hatchery operations in the area are very pleased about PCI making something out of spinnings. “This material was a big waste for the local egg industry and yes, they are now getting paid for what they use to have to dump or pay to get rid of,” says Currah. “It’s worked out well for everyone.”

For its hard work in developing a new egg industry product and markets PCI won the Premier’s Award for Agrifood Innovation Excellence in late 2015. In Currah’s words, the achievement shows PCI’s commitment to helping the egg industry sustain a great future in southwestern Ontario. “Anytime you can take a waste product and find a use for it,” he says, “is great in the type of economy we have today.” n

Management should make it hard for the system to fail

BY USPOULTRY

When you are suspicious, it is very important to have fast lab results and quick depopulation of live birds if the results are positive. As the disease progresses through a farm, the environmental contamination grows and promotes the spreading,” said Dr. Jill Nezworski, Blue House Veterinary, during her presentation at the “Highly Pathogenic Avian Influenza – Lessons Learned” education program held during the 2016 International Production & Processing Expo (IPPE) in Atlanta, Ga. Nezworski discussed “Lessons Learned in the Layer Industry” in which she provided comparisons and contrasts between early detection of highly pathogenic avian influenza (HPAI) on farms and late detection due to mortality.

Nezworski observed that diagnosis of HPAI should be communicated to employees in an organized chain of command, and every hourly employee must also be educated and empowered. “False alarms may come up, but it is more important to create a culture in which it is fine to be wrong or overcautious,” she says. She emphasized that it is essential to have a quick and realistic depopulation plan, as well as a primary plan and a backup plan for carcass disposal. After depopulation is over, she underscored the need for the entire site to be decontaminated with the thought that even outside premises still likely accumulate viral contamination.

Dr. Jill Nezworski, Blue House Veterinary, speaking at the “Highly Pathogenic Avian Influenza – Lesson Learned” education program held during the 2016 IPPE in Atlanta, Ga.

Nezworski stressed that big risks should be addressed, and management should make it hard for the system to fail.

During his presentation on “Lessons Learned in the Turkey Industry,” Dr. Ben Wileman, Ag Forte, reflected that a clear sign of HPAI on a turkey farm is when a person enters the house and the turkeys are quiet. Wileman observed that when sick, animals develop neurologic signs, twist their necks and have tremors. He recommended, “When in doubt, test it.”

Dr. Lindsey Garber, USDA APHIS,

Veterinary Services, provided an overview of the “Epidemiology of the Recent AI Outbreak” that addressed the results of two studies, one with HPAI infected layer farms and the other with turkeys. The two studies concentrated on potential risk factors for the spread of HPAI, including rendering and garbage trucks, shared equipment use, visitors, wild bird presence, etc. The result from both studies centered on the need for effective and efficient biosecurity measures at all levels. n

BY MELANIE EPP

On April 27, 2015, Center Fresh Group in Iowa was hit with avian influenza. Within a matter of weeks, Center Fresh Group lost 9.9 million birds – 8 million layers and 1.9 pullets. Just six weeks earlier, Center Fresh Farm, which suffered a 3.8-million layer loss, had passed a full government-audited biosecurity inspection. The audit went so well, in fact, that it received a score of 100 per cent. When AI hit the U.S., Jim Dean, CEO of Center Fresh Group, thought that they’d be fine. “We thought we had the most robust biosecurity program that we could even think of,” he told the crowd at the 2015 International Egg Commission conference in Berlin, Germany. “We thought that we were fine.”

When all was said and done, though, they weren’t fine, and Center Fresh Group suffered enormous losses. Center Fresh Egg Farm lost 3.8 million layers; Sioux County Egg Farm lost 1.7 million layers; Centrum Valley Farms lost 2.5 million layers, and Sioux Center Pullets lost 1.9 million pullets. Since that time, Center Fresh Group has been working to repopulate its operations. The process began in September 2015 and will carry on into the first quarter of 2017.

When did you first find out that AI had hit your operations?

JD: I was in Las Vegas at the Urner Barry conference. My son received a call from

WHAT WENT WRONG

Jim Dean, CEO of Center Fresh Group in Iowa, talks about the company’s experience with HPAI last year

our company veterinarian who said that we had high mortality and textbook clinical signs of avian influenza. Considering how fast the disease was moving and the number of infected farms, I had mentally prepared for the worst. I told my sons that we would get through this and that we will recover. Put your best face on and go out and tell the industry we’ve been hit… Hopefully to help others to get better prepared.

What steps did you take to stop further losses to AI?

JD: We lost both Center Fresh and Sioux County on the same day; the farms are four miles apart. When Centrum Valley was infected in mid-May, my son decided to euthanize the infected flock that night to stop the spread of the disease. We were able to save one farm about a half mile away, which ultimately saved 3.5 million birds within four miles. Due to our success

in stopping the disease our government is now recommending euthanizing infected flocks within 24 hours.

How prepared would you say you were for this event?

JD: We had initiated extra measures to fight off the disease, but we feel there was so much of the virus in the air that it was attaching to almost anything that moved, including wind, so it broke through the best bio-security programs.

How bio-secure would you say your facilities were at the time?

JD: On March 11, 2015, Center Fresh Farm went through a full government audited bio-security inspection. We received a score of 100 per cent without any deficiencies. We were infected April 27, 2015.

What happened following that first call?

JD: We notified the appropriate government agencies and started to develop an action plan. It would be impossible to list all the measures taken to try to mitigate the spread. There were many lessons learned.

euthanizing and removing 200,000 birds per day. We couldn’t keep ahead of the spread of the virus. The disease causes a horrible painful death for the birds over a three to four-day period.

Managing the mass depopulation of our flocks was overwhelming, timeconsuming and difficult for our teams. What was terrible is that the disease was killing our hens more quickly than we could remove and humanely depopulate them. We also learned that swift depopulation was critical to limiting the spread of the disease. Working closely with our veterinarian, we used a variety of approved methods, including carbon dioxide gas. Again, our focus was on moving swiftly to prevent the disease from spreading to other flocks.

A challenge with disposal of mortality was that there were a number of options, including: burial, landfills, incineration and composting. But all had their barriers. Specific protocols varied from farm to farm and were based on a number of considerations. On our farms we used a combination of burial and composting for mortality disposal, always working collaboratively with the USDA and state and local authorities to ensure the

Dean is the founding/managing partner and CEO of Center Fresh Group, which includes Center Fresh Egg Farm (3.8 million layers), Fremont Farms, L.C. (900,000 layers), Hawkeye Pride Egg Farm (4.6 million layers), Sioux County Egg Farm (1.7 million layers), Centrum Valley Farms (7.5 million layers), Trillium Farm Holdings (12.5 million layers), Center Fresh Africa, and Sioux Center Pullets (6 million annual pullet capacity). Jim was the founding partner/ CEO of Fremont Farms of Iowa.

Dean is the past Chairman of the Board of Directors of United Egg Producers (UEP), serving as Chairman until October 2015. UEP is a trade cooperative with membership that represents over 95 per cent of the egg industry in the United States. Today, Dean continues to serve on UEP’s finance committees.

Dean is also a past board member of the Iowa Poultry Association, the U.S. Egg Marketers, and the Midwest United Egg Producers. In 2014, he was honored as United Egg Producer’s egg industries Producer of the Year. In 2009,

One of the purposes of practical housing and equipment is to provide for the biological, economic and welfare needs of the birds.

Fortunately, the scientific literature contains a great deal of information on these needs, so that a recommended approach to practical problems is to start with an appraisal of the requirements and responses of the birds. Then, designers and engineers can provide for these needs.

This book provides information on the needs and responses of poultry to aspects of the climatic environment, by means of reviews of the scientific literature. Biological responses to environmental factors are discussed, as well as some principles of the movement of air through and within buildings.

Many of the principles apply to both indoor production and to the housing attached to free range systems.

owned the adjacent farm, which we could use for composting. We did have days where we could remove more birds, but the birds had already died from the disease. There’s work being done to find better alternatives for mass euthanizing, it must be completed humanely and should be done within 24 hours of contracting the virus to stop the spread.

Did you ever find out how AI made its way onto your operations?

JD: I’m not sure anyone will know for sure. Two complexes broke on opposite ends of the complexes. One was not near a doorway, so we believe wind. The other one broke possibly by a door, so a worker could have tracked it in.

During the crisis, did you receive help from any outside organizations? If yes, who and how?

JD: Our community, Sioux Center, IA, had prayer services for our staff and companies, and the federal government provided for removal, disposal and disinfecting. It was the government and private industry working together.

Looking back now, is there anything you would have done differently?

JD: The governments, both state and federal, must do a better job of stamp out and eradication. At the time the state governments wanted to protect the identity of the infected operation as opposed to protecting the non-infected.

Are there any lessons you’d like to share with Canadian poultry farmers?

JD: If and when the virus hits, get the message out as quickly as possible through private industry and trade association. It’s imperative to act quickly – within 24 hours – to euthanize the birds to stop the spread of the virus. Centrum Valley proved that the virus could and can be stopped quickly. All producers are concerned about the well-being of their birds; it is much more humane to euthanize the birds quickly than to watch them die from the disease. n

The Provision Coalition is addressing the question: what is sustainability?

BY KAREN DALLLIMORE

It’s called the Provision Coalition: a group of twelve food and beverage manufacturing organizations from across Canada that have teamed up under Growing Forward funding with the sole mandate of providing resources, programming and advocacy for sustainability.

Which leads directly to an obvious question: what does sustainability mean?

That’s where there is some confusion, said Cher Mereweather, even within their membership. As the executive director of the Provision Coalition, Mereweather addressed the 2015 Canadian Poultry Sustainability Conference in London, Ont.

presently define sustainability, which include economic, social and environmental considerations. That’s a good start, but from there, the discussion becomes complex.

The one common theme that she has heard so far in conversation with manufacturers and vendors is a passion in people to do the right thing. Low cost production alone isn’t enough; sustainability begins with awareness, like knowing how much water and energy you are using to make a bottle of wine. Starting with employees, it can be as simple as using one finger to turn off a light. “It’s not only an obligation but it makes good business sense,” said Mereweather. “Just start. You’ll be surprised.”

What does transparency mean to the poultry industry? Who is responsible for it? Each link of the supply chain needs to be able to supply the answers to questions, driving the need for collaboration as we move towards a ‘clean label’ on our food, as consumers continue to ask, what’s in my food? Where is it from? What is its impact on the environment?

The impact of this consumer questioning is very real. Mereweather looked at some of the big players to show how consumers have influenced them and in turn, influenced primary production. A common theme has emerged.

15HY010-HybridDramaticAds_1/4page(4)_CanadianPoultry_vf_3.pdf 2 2015-07-28 11:23 AM

She focused on the three pillars that

The Provision Coalition represents one tier of the farm-to-fork industry, where every segment of the chain is responsible for the links surrounding it. In this chain, transparency has become the buzzword, and one of the top issues we face.

Walmart, now the world’s largest grocer, is working directly with farmers on precision agriculture. Loblaws, Canada’s largest grocer, made the sweeping statement “We will source close to home to support local, regional and national Canadian producers/growers and to give our customers fresh, wholesome food while ensuring the health and vitality of

food sources, including oceans.”

A&W launched a concept but forgot to talk to the supply chain, resulting in a lot of backlash when the industry could not respond quickly enough. They are now trying to re-build those relationships.

McDonald’s has been taking a more collaborative approach, such as with their 2014 Verified Sustainable Beef program, and Mereweather expects them to take the same approach with poultry.

Driven by their need to innovate Prime Brand, Maple Leaf Foods assures consumers that they are moving to feasibly grow antibiotic free production –“Canadian Farm Raised” – with no growth hormones, like all poultry in Canada.

With this push to the holy grail of sustainability, farmers will need to be able to provide transparent and verifiable information in the move towards big data collection, certifications and auditing, as well as a global database.

They can expect questions about how the farm manages people, the environment and operations. It’s a theme the food companies call ‘responsible sourcing’, looking back to the farmer to help gain the trust of the consumer. There will always be money pushing the agenda, said Mereweather, but if you’re transparent, honest and real, trust will come.

But who pays? Is this just the new cost of doing business, she asked? It’s time to look at innovation, changing our mindset to ask how we can do business differently. We may uncover opportunities.

The Provision Coalition has started the ball rolling. It’s not just farmers, said Mereweather, feeling the same pressure. In this case, the industry needs to lead but the government needs to support, quite the opposite to the usual process of having the government lead.

So far Mereweather has run into some typical roadblocks while simply searching

for collaboration. Each link is protective between competitors so the discussion hasn’t been easy. She has had to focus on what she calls pre-competitive collaboration, while making sure there is government and non-government representation in the room to avoid collusion to fix prices or market share.

There is also a need to avoid redundancy. These ‘Made In Canada’ discussions may start provincially, but need to align nationally as well as speaking to a larger marketplace, and build upon current programs such as the Environmental Farm Plan.

As Merewather says, sustainability isn’t something that can be built in isolation. Right now the focus of the Provision Coalition is to focus on a harmonization of efforts and consistency of information requests; collaboration is the key. As she admits though, “We won’t get there anytime soon.” n

Looking forward, proactive engagement in sustainability is essential

BY KAREN DALLLIMORE

The poultry industry has a long and complicated supply chain, incorporating a wide spectrum of costs and benefits.

When you think about sustainability in that chain, it doesn’t make sense to improve one part of the system if that change may unintentionally burden another part of the process and outweigh the advantages achieved.

Nathan Pelletier is the president of Global Ecologic, an independent sustainability consulting firm that measures and manages strategy in food and other industrial systems. Speaking at the 2015 Canadian Poultry Sustainability

be used to help analyze the past, present and future of the poultry industry in the quest for sustainability.

Life cycle thinking – changing from a management perspective to a systems perspective – is an analytical process that helps to examine the relevant interactions associated with the production of goods and services, allowing us to pinpoint which aspects of the supply chain have the biggest impact.

The results of life cycle thinking can often be counterintuitive, flying in the face of our current thoughts. For example, is local food more sustainable? With life cycle analysis, this argument is no longer credible if you factor in the efficiencies of transport over long distances by rail, truck or boat. “There will always be trade-offs,” said Pelletier. “We need to be conscious of these to make decisions regarding our own priorities.”

For the poultry industry, he sees no alternative but to embrace this management philosophy throughout the supply chain, but Pelletier says it won’t be a

from agreeing on definitions of sustainability to operationalizing the information, but he predicts that life cycle thinking will become a requirement in the new marketplace, coming to the forefront of regulatory guidelines within 10 years.

Looking back over 50 years, in an indepth historical life cycle analysis published in the Poultry Journal in 2014, Pelletier compared the environmental footprint of the poultry industry in the U.S. in 1960 versus 2010, putting some hard numbers around poultry production.

The modern poultry industry is not the same as it was 50 years ago, and that’s an interesting story itself. His results show astonishing changes.

While egg production in the U.S. has risen 30 per cent in 50 years, the environmental footprint per kilogram of eggs produced in 2010 is 65 per cent lower in acidifying emissions, 71 per cent lower in eutrophying emissions, 71 per cent lower in greenhouse gas emissions and 31

According to Pelletier, the reduction could be attributed to factors such as feed and manure management. Up to 30 per cent of the improvement is based in improved efficiencies of background systems, for example supply chain efficiencies in transportation and energy use. Thirty to 44 per cent was from changes in feed composition, reflecting efficiencies realized in crop production with less inputs for increased yields. Another 28 to 43 per cent was due to improvements in genetics, feed conversion and bird health.

Productivity has increased 50 per cent, from 195 eggs to 297 eggs annually. In 1960, 3.1 kg of feed equaled one kg of eggs; now only two kg of feed is needed per kg of eggs. Not only that but the birds are healthier, with 63 per cent lower mortality.

This is a good news story, but how does poultry stack up against other protein sources? It’s hard to compare unless studies have been done with the same protocols, said Pelletier, but in general, monogastrics are more efficient. The most efficient protein source is pork, followed by eggs, both better than beef. This matters because sustainability is becoming such a differentiating factor in the marketplace, for social license, regulatory compliance and market access. In this respect, poultry is well positioned for the future.

Looking forward, Pelletier suggested that proactive

engagement in sustainability is essential, making four suggestions.

First, develop a Canadian life cycle inventory of consistent data to support production. Defending any kind of comparison requires such data.

The poultry industry also needs to develop and implement a transparent, multi-criteria sustainability benchmarking program for producers, to support sustainability initiatives and provide benchmarking and goal setting targets.

He sees a third opportunity in acting as a leader in pushing new frontiers. “Don’t be too attached to the status quo,” said Pelletier. “Just think about the changes in your industry over the past 50 years, and imagine where you could be 50 years from now?” Support and participate in the research that will be necessary to define the sustainable poultry production systems of the future.

Finally, formalize a commitment industry wide by engaging all stakeholders in a round-table discussion on sustainability, defining a common vision and a strategy to achieve it. As Pelletier says, “use it as an opportunity to see sustainability not as a challenge or as a hoop to jump through, but as a source of competitive advantage, as an exciting and necessary collaborative journey toward that shared vision of the future.” n

BY KAREN DALLLIMORE

If you do a Google search of the Internet, 157 million definitions of sustainability will come up. Is sustainability meeting the needs of the future and the present at the same time? Or is it really just producing more with less?

For some, sustainability means simply having food, while for others it may

over competing protein.

Speaking to delegates of the 2nd Annual Canadian Poultry Sustainability Symposium, Horel pointed to factors such as energy efficiency, carbon emissions, feed conversion, land and water usage, and waste management as areas where poultry production shines.

But as Horel explained, there are many other factors involved in sustainability. His list begins with environmental impact, food safety, worker safety, animal health and welfare, and food affordability, growing from there, with varying levels of importance based on each factor.

Sustainability can mean different things to different people. Industry, farmers, activists, and consumers - everyone has different ideas. Around the world, a

sumers primarily base their choices in food service and retail on price, quality and food safety, with factors such as local, welfare and the environment becoming more important.

“It’s a changing consumer; not easy to follow,” said Horel, “but we have no choice.”

Look at eggs, for example. The retail shelves for eggs used to be about six to eight feet long, with white or brown and a few size choices. Now there are white and brown with half a dozen methods of production: organic, free range, Omega 3, raised without antibiotics. The claims are endless, and each claim carries its own segregation, labeling and auditing considerations. Other poultry products fall under the same claims, which can also include different processing meth-

15HY010-HybridDramaticAds_1/4page(4)_CanadianPoultry_vf_3.pdf 4 2015-07-28 11:23 AM

said Horel. Canadian meat consumption peaked in 2000 and has declined by 12 per cent since then, but chicken has grown its market share. Turkey consumption on a per capita basis has remained flat, but measured against declining meat consumption, it has gained a small bit of share as well. Can poultry continue to increase compared to other sources of protein against this backdrop of declining meat consumption in Canada?

In terms of sustainability, poultry is well situated to do just that. What are the practical applications of sustainability factors to poultry at the retail level? Trust and transparency rank high.

Horel pointed out that above all, Canadian customers and consumers prize safe food. Any recall issues for any poultry product not only affect consumer trust in that particular product but their trust in all poultry products.

CPEPC president and CEO Robin Horel says poultry and eggs do have some advantages over competing protein in terms of sustainability

Brands are also important to the Canadian customer. If a supplier doesn’t tow the line, brand protection comes to the fore with videos or recalls resulting in suppliers being dropped; processors and graders will also cut off a farm to protect their brand.

As for label claims, Horel said don’t bother using up label real estate to suggest that chicken or turkey contains no hormones because it’s a waste of time and confusing to consumers. We are fortunate to have CFIA guidelines to guide labeling, said Horel. Under their guidance, you are not allowed to claim ‘no hormones’ unless you also say, ‘like all other chicken’. The label claim of methods of processing is generally acceptable, as long as they aren’t linked to further implied benefits. A good example of this would be high-pressure pasteurization, which is effective against listeria in packaged turkey or chicken products. You can tell the consumer that you’ve used the process, but you can’t claim it’s safer than other products as a result.

At the producer level, food safety is still at the top of the list. On-farm food safety programs need to be mandatory, with transparency maintained from processors, graders through to hatcheries needing information so they can provide traceability.

Looking forward, Horel suggested that two poultry food safety issues on the radar are salmonella and campylobacter. A new baseline survey report by CIPARS (Canadian Integrated Program for Antimicrobial Resistance Surveillance) will soon be released to the public indicating salmonella levels are “not as good as we’d like”. The pressure to reduce salmonella will intensify very soon, and the pressure will be on farms, starting with hatcheries.

Another issue in the forefront is the transition to enriched cages. Consumers often don’t know the trade-offs involved with

such changes to the production system or how pressure on one area of production would “yank the wheel out of round” since all production components are inter-related.

As Horel explained, when you take laying hens out of cages there are going to be consequences: an impact on economics, on food affordability. There will also be increased pressure on the environmental component and possibly food safety. “If you don’t manage this properly you may adversely affect animal welfare, which is why you made the changes in the first place.”

Euthanasia is another difficult animal welfare issue to deal with, not only for the customer but also for farm workers, while loading and transportation is part of the production process that is most visible to the public as trucks moving down the highway. Preventative use of antibiotics and disease control also rank high on the list of issues under consideration.

“The result of processors and farmers having the same goals, if we are successful, is that we will not have to have multiple standards, audits, segregation issues, and confusion for consumers,” said Horel. “In order to get there, we need to translate the codes of practice into on-farm, practical terms.”

With regard to animal welfare, the goals of producers, processors, and graders should be the same: to ensure our customers have faith in our national animal care programs. They should trust that we are good caretakers and take our job very seriously, and that non-compliance is not tolerated. They need to trust that our codes are a good standard, and trust value chain members as an information source to deal with questions and undercover videos.

Horel listed five basic principles that need to govern animal care programs: they need to be national, based on the codes of practice, mandatory, third party audited, and transparent. Egg Farmers of Canada (EFC) and Chicken Farmers of Canada (CFC) have both agreed to these five principles and their animal care programs reflect this; Turkey Farmers of Canada (TFC) is moving to acknowledge the five principles within their Flock Care Program by the middle of next year. CHEP, Canadian Hatching Egg Producers, are the furthest away from the customer but, as part of the supply chain, the spotlight is going to hit them soon. As Horel says, “the pressure is on.”

In the end, what does sustainability mean for the poultry industry? Transparency, cooperation, and common goals of food safety, animal welfare and health, said Horel. These goals have to be shared by all to continue to build public trust in farming in Canada, in our industry and our products. If the per capita consumption numbers for poultry are any indication, we’re doing the right thing. n

BY KAREN DALLLIMORE

As an industry pioneer tackling the issue of sustainability at the producer level, the Egg Farmers of Alberta (EFA) started on their journey of developing a sustainability platform for egg production farms in 2014. The development of the strategy looked like a familiar three-legged stool: stakeholder engagement, to open a dialogue so that the players understood each others’ views and values; accountability and transparency by measuring and monitoring progress; and integrating the PEEP (Producer Environmental Egg Plan) program with current work and processes.

The EFA sustainability platform was created with the consumer in mind but the target audience is all value chain partners, from government to special

interest groups, to inform them about egg production at the farm level and to engage them as they pursue their own sustainability goals. “If our value chain partners want farmers to educate the public, we can help,” said Jenna Griffin, industry development officer for the EFA.

The sustainability platform was distilled down from seven key areas to a simplified four pillars: Healthy Birds, Healthy Eggs, Healthy Farms, and Healthy Communities. This has allowed them to engage farmers, making it easier to understand how their day-to-day practices can help to achieve sustainability goals.

EFA released their first sustainability report, outlining some statistics and metrics, in 2015.

As Griffin explained to the audience at the 2nd Annual Canadian Poultry Sustainability Symposium in London, Ont., the sustainability platform will join other EFA on-farm programs that include PEEP, Start Clean Stay Clean, and the Animal Care Program.

Sixty per cent of the producers in Alberta enrolled in the sustainability

• Maximum air performance

• High efficiency, high durability

• Optimal aerodynamic air intake

• Low noise level

• Easy to maintain, install and clean for optimal hygiene

• Lifetime bearings

• Optimal air distribution in the poultry house with the purpose to create an ideal climate

• Create an active microclimate at animal level

• Control humidity level

• Constant low airspeed at animal level

• Reduction in energy costs through vertical airflow with a special aerodynamic shaped conical outlet

• Exacon’s brand name since 1987

• Available in sizes 12” to 60”

• White or Black polyethylene flush mount housings

• Designed to meet the rigorous demands of farm/agricultural ventilation

• Energy efficient Multifan, MFlex or North American motors

• Fiberglass housings available in 50” and 60” diameter

• Recovers wasted heat from exhaust and transfers to incoming air

• Reduces humidity and improves air quality for improved livestock performance

• Large tube type heat exchange core vs plate type stays cleaner longer and is, fully accessible for easy cleaning

• Many installations in poultry, swine and commercial applications have proven these models are cost efficient and effective

• Recovers in excess of 50% of wasted exhaust heat

• New split core for ease of cleaning

• Select Doser dispenses products accurately into low and high pressure watering systems through it’s tubing via compression and peristalic action.

• Aggressive products and powders never pass through the pumps mechanism that can cause premature wear and maintenance.

• New improved Model 640 is now simple to use with one tube size

• New Select Doser Max can now operate in high pressure and volumes

• The well known and proven Genius control line is now available as a Touchscreen interface

• Navigates like an I-Pad by simply touching, swiping or dragging on a 7” or 10” touch screen

• Available with up to 8 variable stages and between 15 to 30 on/off relays

• A slave is available to expand to 50 on/off relays

• Many options including light control, bird scales, perch scales and bin scales

• Built-in wifi allows easy access to the internet for managing, viewing and recording history on FarmQuest website

program in 2014, increasing to 68 per cent in 2015. Of those, 11 producers switched from incandescent lighting, reducing their carbon footprint by the equivalent amount of 158,000 km not driven or 41,372.06 kg of CO2. That’s the type of change that can be monitored through the program over time.