Burning Question

By Matt Dickson BCARDC

By Nerine T. Joseph, Ph.D.

FROM THE EDITOR

BY KRISTY NUDDS

Winning the #farm365 Battle

The realization that the food and farming sectors need to better communicate with the public has been growing for some time, and a lot of discussion has taken place on how best to achieve this. Some very creative and effective campaigns to engage consumers have been emerging — the Chicken Squad campaign by the B.C. Chicken Growers Association and the B.C. Chicken Marketing Board, plus the “Our Food, Your Questions,®” are good examples.

Individual farmers and farm groups have taken on the task directly on social media platforms such as Twitter and Facebook, where they engage directly with potential customers and suppliers while dispelling myths, sharing facts, finding market information and sharing the ups and downs of farming life. Social media has become a powerful and highly valuable tool for sharing information in realtime. And it’s also brought farmers from across the country together on common issues. If you don’t already, follow the hashtag #plant15 this spring and you’ll get a good idea of the camaraderie that exists.

But I have yet to see a hashtag related to farming cause such a firestorm right out of the gate as #farm365 has.

Created by southwestern Ontario dairy and cash crop farmer Andrew Campbell (@FreshAirFarmer), the hashtag has certainly achieved the goal of bridging the gap between consumers and agriculture, albeit with some unintended consequences.

The hashtag accompanies a photo taken on Campbell’s farm that he posts on Twitter each day, beginning on New Year’s Day. Inspired by other photo-a-day challenges on Twitter, Campbell wanted to show what goes on a typical farm, and hopefully start some conversations. His seemingly innocent attempt has done just

that — and then some.

Writing in his blog “The Highs and Lows of Week One on #farm365” for Letstalkfarmanimals.ca, Campbell said he knew animal rights activism was powerful, but “this has been a new lesson in experiencing it.” He says media attention about the hashtag made a few activists very angry and they banded together to “hijack” #farm365 to show people their views on animal agriculture. Advocates for veganism have been posting disturbing photos and anti-animal agriculture messages with the hashtag right from the start, and are still going strong more than a month since Campbell launched it.

But Campbell and other farmers from around the globe are rallying back. As Campbell writes: “It’s turned into a great force of farmers sticking up for themselves and consumers getting a better idea of what it takes to send food out of the driveway.” It’s also creating conversations with a curious public, who don’t understand what takes place on farms, and have a healthy bout of skepticism not to be easily swayed by activists and need to get reassurances right from the perceived villains.

In his blog, Campbell tells a great story of how answering questions about veal from a woman in Toronto put her at ease. The woman, who had heard negative things about veal production, wanted to hear from a farmer, to search “for information with substance and fact.”

Campbell tweeted this message February 9: “I’ve got to thank my fellow farmers again. They continue to open their barn doors and farm gates to the public through #farm365. Thank you!” ■

FEBRUARY/MARCH 2015 Vol. 102, No.2

Editor Kristy Nudds – knudds@annexweb.com 519-428-3471 ext 266

Digital Editor – AgAnnex Lianne Appleby – lappleby@annexweb.com 226-971-2133

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 519-400-2424 888-599-2228 ext 237 • fax: 888-404-1129

Account Coordinator

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer Gerry Wiebe

Group Publisher

Diane Kleer – dkleer@annexweb.com

President

Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5.

email: subscribe@canadianpoultrymag.com.

Printed in Canada ISSN 1703-2911

Circulation

email: subscribe@canadianpoultrymag.com Tel: 866-790-6070 ext 201 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $30.00 per year (with GST $31.50, with HST/QST $33.90)

GST – #867172652RT0001

USA – 1 Year $ 66.00 USD

Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2015 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Great productssell.

Got Lubing? Contact your local Lubing Distributor for more detailed information about our innovative products or vist our website at www.lubingusa.com

Scan code to see What’s New at Lubing.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

J. Dean Williamson Ltd. London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

With more than 60 years of experience developing innovative products for poultry producers worldwide, Lubing has established a reputation of leadership by introducing new, cutting-edge technologies to the poultry industry.

Our innovative products are produced with the most modern manufacturing capabilities giving our customers a profitable advantage in productivity.

Nipple Drinking Pullets, Breeders, Broilers, Layers,Turkeys

Egg Conveying

Curve Conveyors, Belt Conveyors, Dirty Egg Return Conveyors, Transfer Tables

Dead Bird Removal

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

WHAT’S HATCHING HATCHING USDA Proposes Salmonella Standards S

tandards recently proposed by the USDA aim to make chicken breasts, wings and legs safer to eat.

The purpose of the new proposed standards are to reduce rates of salmonella and campylobacter in chicken parts, ground chicken and ground turkey. The standards would be voluntary but designed to pressure companies to take steps to reduce contamination.

The USDA says the proposed standards could reduce raw poultry-related foodborne illnesses by about a quarter, or 50,000 illnesses a year.

Among the measures companies could take to reduce the rates of the salmonella and campylobacter: better screening of flocks and better sanitation.

The proposal would ask poultry producers to reduce

the rates of salmonella in raw chicken parts from an estimated 24 per cent now to less than 16 per cent, and campylobacter rates in raw chicken parts from an estimated 22 per cent to 8 per cent. Rates also would be reduced in ground chicken and turkey, and sampling would be done over a longer period of time to ensure accuracy.

The standards come after a lengthy outbreak of salmonella illnesses linked to California chicken company Foster Farms, which sickened more than 600 people between March 2013 and July 2014.

In 2013, USDA said inspectors at Foster Farms facilities had documented “fecal material on carcasses’’ along with poor sanitation.

Foster Farms took measures to improve its sanitation and screening, and the Centers for Disease Control and Prevention later said the company’s products were down to five per cent contamination.

Vilsack said the Foster Farms outbreaks led the department to realize it needed to be more focused on reducing salmonella in chicken parts. The department already had standards in place for whole carcasses, but not individual parts like breasts and wings. The new proposal would cover the various parts, which the USDA says is about 80 per cent of chicken available for purchase.

USDA also would make public which companies are meeting the standards or going beyond them, and which companies have more work to do, giving companies more incentive to comply.

Ashley Peterson of the National Chicken Council said the industry has already made improvements. She said poultry companies have been exploring options to reduce contamination, including strengthened sanitation programs, temperature controls and ways of processing.

CFO to Donate Fresh Chicken

Chicken Farmers of Ontario (CFO) and its 1100 familyrun farms across Ontario have launched a new program in support of the province’s hungry. The CFO Food Bank Donation Program will help facilitate the donation of up to 300 chickens per farmer each year to local food banks. CFO

Kerry and Anita Froese

Named OYF

Ayoung man who was “born to farm” is the recipient of the 2015 B.C. and Yukon Outstanding Young Farmer Award.

Abbotsford chicken grower Kerry Froese and his wife Anita, both 37, received the prestigious award from outgoing B.C. & Yukon Outstanding Young Farmer program chair Jennifer Woike and judges Walt Goerzen, Lisa Taylor and Al Timms during a small ceremony in Abbotsford, Jan. 15th. Froese’s parents began with a broiler breeder and raspberry farm, later adding a broiler farm. After Froese began managing the farms in his teens, the family converted the entire operation to broilers.

In the early 2000’s, the family consolidated the quotas into Triple F (Froese Family Farm) Enterprises and built two new double-decker 500X52-foot barns on a new 20-acre property.

has set an annual donation target of 100,000 chickens worth an equivalent retail value of $1 million.

The new program is made possible in part by the Government of Ontario’s new Food Donation Tax Credit for Farmers (introduced with the Local Food Act) which helps promote local food contributions by offering farmers a 25 per cent tax credit for the fresh food they donate to Ontario food banks. Prior to this program CFO and

its farmers supported the food bank system primarily through cash donations.

Gail Nyberg, Executive Director of Daily Bread Food Bank, could not be happier about this new campaign. She says being able to provide clients with healthy food choices is so important and this program with the Chicken Farmers of Ontario and the Ontario Association of Food Banks will ensure that clients have a fresh and local protein option on their table.

(l-r) OYF judges Al Timms & Lisa Taylor, B.C. OYF chair Jennifer Woike, 2015 B.C. & Yukon Outstanding Young Farmers Anita & Kerry Froese, judge Walt Goerzen.

“We went from 15 floors with minimal automation in two locations to four floors with state-of -the- art automation on one farm,” Froese says.

Froese has since added inbarn cameras, weigh scales and innovative LED attraction lights to improve production and a large air compressor and thermal jet fogger to make cleaning and disinfection faster and more thorough.

While producing 1.9 million kilograms of chicken/year might be enough for most, Froese’s passion is to be an “AGvocate” for supply management and for young people in agriculture. He is a founding member of B.C. Young

Farmers and president of the Canadian Young Farmers Forum.

After serving as vice-president and president of the B.C. Chicken Growers Association, Froese was elected to the B.C. Chicken Marketing Board in 2013. His efforts to promote agriculture and willingness to poke fun at himself were clearly evidenced when he played the villain in the extremely popular You Tube “Chicken Squad” videos the BCCGA produced last year.

Kerry and Anita Froese will represent B.C. at the national OYF competition in Edmonton in November.

COMING EVENTS

MARCH 2015

March 17-19, 2015

Midwest Poultry Federation Convention Saint Paul RiverCentre, Saint Paul, Minn. For more information, visit: www. midwestpoultry.com

March 22-25, 2015 64th Western Poultry Disease Conference Capitol Plaza Holiday Inn, Sacramento, Ca. For more information, visit: www. cevs.ucdavis.edu

APRIL 2015

April 22-23, 2015

London Poultry Show

Agriplex (*note: new building location), Western Fair District, London, Ont. For more information, visit: www.westernfairdistrict. com

MAY 2015

May 6, 2015

PIC Research Day hosted by the Poultry Industry Council (PIC), OMAFRA Building, 1 Stone Rd. Guelph, Ont. For more information, visit: www. poultryindustrycouncil.ca

May 27, 2015

B.C. Poultry Symposium Ramada Plaza and Conference Centre, Abbotsford, B.C. For more information, tel: 604-8546600

JUNE 2015

June 17-19, 2015

Canada’s Farm Progress Show

Evraz Place, Regina, Sask. For more information, visit: www.myfarmshow.com

HATCHING HATCHING

Hybrid Finalizes Agreement

Effective January 30th

2015 Hybrid Turkeys USA, LLC (Hybrid) and Willmar Poultry Company, d/b/a Ag Forte (Ag Forte) have finalized their agreement where Hybrid will take ownership and responsibility of Ag Forte’s U.S. grandparent operations. Additionally, Ag Forte will produce commercial eggs and poults under contract to Hybrid. Hybrid will have direct responsibility

for sales of commercial eggs and poults in the U.S.

Over the next 12 months Hybrid will assume full responsibility for the sales of all Hybrid commercial poults produced under contract by Ag Forte. This will allow Hybrid as a primary breeder to focus even more on the needs of the customers in the U.S., while Ag Forte focuses on producing top quality poults.

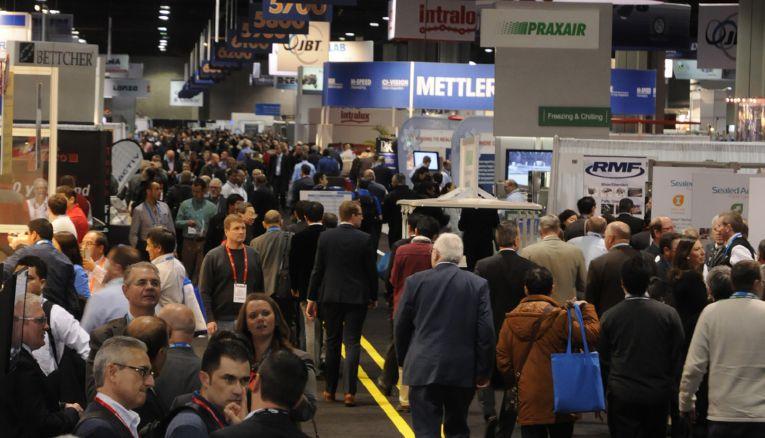

IPPE Breaks Record

The 2015 International Production & Processing Expo (IPPE) is the largest show on record with 30,350 poultry, meat and feed industry leader attendees from all over the world. In addition, the show had 1,284 exhibitors with more than 490,000 net square feet of exhibit space. There were 7,245 international visitors from 103 countries, setting another record for international attendance. The largest group from a single countr y outside the U.S. was Canada with 1,233 visitors. The largest region represented was Latin America/Caribbean

with 2,811 visitors. All phases of the poultry, feed and meat industry were represented, from live production and processing to further processing and packaging.

The “largest-ever” education slate complemented the exhibits by keeping industry management informed on the latest issues and events.

Other featured events included the International Poultry Scientific Forum, Pet Food Conference, Pork 101 Workshop, Tech XChange program, Meat Me in @LANTA activities and publisher-sponsored programs.

COMING EVENTS

JULY 2015

July 14, 2015

North American Manure Expo Chambersburg, Pa. For more information, visit: www.agannex.com/manuremanager/manure-expo

July 27-30, 2015

Poultry Science Association annual meeting Louisville, Ky. For more information, visit: www. poultryscience.org/psa15

SEPTEMBER 2015

September 15-17, 2015

Canada’s Outdoor Farm Show

Canada’s Outdoor Park, Woodstock, Ont. For more information, visit: www. outdoorfarmshow.com

OCTOBER 2015

October 6-8, 2015 Poultry Service Industry Workshop

Banff Centre, Banff, Alta. For more information, visit: www.poultryworkshop.ca

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; email knudds@ annexweb.com; or fax 519429-3094. Please write ‘Event Submission’ in the subject line.

Cover Story

Burning Question Managing litter in B.C.

by Matt Dickson BCARDC

Anyone who works in B.C.’s poultry industry is aware that a creative, cost-effective disposal solution is required for the excess volumes of used poultry bedding accumulating from the over 100 million chickens and turkeys produced annually. Finding a way of turning this abundance of bedding into a valuable resource is even harder. But that was the goal of the B.C. Agriculture Research and Development Corporation (ARDCorp), B.C. Sustainable Poultry Farming Group (SPFG), Ritchie-Smith Feeds and Diacarbon Energy, who optimistically embarked on a trial to turn this material back into fodder.

Used poultry bedding has been used for centuries as a soil fertilizer. But only so much of the bedding can be used on the land before the nutrients start leaching into the environment, becoming a risk rather than an asset.

Similar to blackened charcoal found at the bottom of extinguished fires, biochar is black carbon created by heating organic material at high temperatures in oxygen-free or low oxygen environments.

With a relatively low moisture content of 30 to 40 per cent, it is possible to transport broiler litter to nutrient deficient areas for land application. However, on average, a tonne of broiler litter contains less than 200 lbs of nitrogen, phosphate and potash, while a tonne of commercial fertilizer contains over 700 lbs. Due to its low nutrient content to weight ratio (when compared to commercial fertilizer), it is often uneconomical to transportation broiler litter over long distances. While this distance depends heavily upon transportation costs and the cost of commercial fertilizer, a good rule of thumb is that broiler litter should be used within 50 to 100 kilometres of the source. For the Lower Mainland, which raises close to ninety per cent of B.C.’s poultry, the current nutrient surplus is a concern. The poultry sector’s quest for a viable alternative to the land application of bedding was the reason for this recent feed study.

In other parts of the world, some success has been achieved

with turning used broiler bedding into biochar and adding it to broiler feed, thereby improving the broiler’s feed conversion and increasing final weight. Fueled by the success of others, ARDCorp, the SPFG and the Ministry of Agriculture hoped that through conducting their own experiment, they could create demand for roughly ten per cent of the used broiler bedding in the Lower Mainland; and, at the same time, improve production.

Biochar is made by burning biomass material at extreme temperatures of over 500C in an oxygen-free environment. This process, called pyrolysis (thermochemical decomposition), is a very effective disinfection technique, ensuring that the biochar is free of any possible pathogens.

When applied to soils, the high surface area and porosity of biochar act as a catalyst for plant growth by helping to retain water and by providing a habitat for beneficial microorganisms to flourish.

More recently, there has been interest in how biochar aids in the grinding process and provides a habitat for beneficial microoganisms in the digestive system. It has been claimed that the consumption of biochar by broilers can increase update of foodstuffs and the energy contained within them. Increased uptake can thus result in increased weight gain and/or improved feed conversion.

Although the idea of supplementing broiler feed with biochar made from broiler litter may seem strange, it should be noted that processed poultry litter has been used as a feed ingredient for almost 40 years in the U.S.

For this study, used broiler bedding was taken from a commercial broiler barn in the Fraser Valley and dried before being delivered to Diacarbon’s pyrolysis unit in Agassiz. Once processed, the resulting biochar was transported to Ritchie-Smith Feeds in Abbotsford where it was incorporated into commercial

MINERAL-RICH PRODUCT

starter, grower and finisher broiler feed. The feed was delivered to S.J. Ritchie Research Farms Ltd in Abbotsford for a floor pen study.

The study involved 288 broiler chicks arbitrarily placed into twenty-four specially constructed pens. The chicks in each pen were given feed supplemented with biochar or feed without biochar for 35 days. The broilers were weighed individually once weekly and the weights recorded. All feed was also weighed weekly and any feed remaining in the feeders was weighed back and replaced.

Unfortunately, the hoped-for outcomes of the study did not come to pass. From the results of this study it can be concluded that supplementing broiler feed with broiler litter biochar had no statistically significant impact on broiler weight gain and/ or feed conversion (Table 1). While unknown as to why, it could be because of the nutrients in broiler litter; a result of the droppings and spilled feed that gets mixed in with the bedding material. It is therefore possible that the supplementation of broiler litter biochar resulted in the broilers being feed too high levels of certain nutrients. This assumption would go some way to explain the high levels of Sodium (Na) and Chlorine (Cl) found in the litter from T2 and T3 pens (Table 2).

In other studies that have found significant benefits from supplementing broiler feed with biochar, other feedstocks were used to make the biochar; including oak, pine, coconut shells, corn cobs and peanut hulls. It is therefore possible that had an alternative feedstock be used (such as pine instead of broiler litter), supplementing broiler feed with biochar may have been

feed

FUTURE OPPORTUNITIES

While the biochar feed study might have ruled out one opportunity, it has opened doors for others. The main objective, after all, is to find sustainable ways of managing used broiler bedding. And if supplementing broiler feed with broiler bedding biochar did not work as expected, then the question should be: where can the industry look next?

Allen James, Chair of ARDCorp, and a member of the SPFG hopes researchers can find a positive way to convert the poultry bedding into energy. “As long as there’s an excess of bedding, we’ll be looking for a solution.” He is hopeful we will find a local solution to our local situation.

Other applications of biochar have proved successful, but perhaps not economically feasible for the Lower Mainland. Biochar has been used as a soil conditioner to improve water retention and nutrient density to aid in the growth of plants and increase yield. Biochar is also considered a superior growing medium in hydroponics, which is a rapidly growing technology. All of these areas could be expanded upon, creating financial opportunities for the poultry industry.

“Many studies have been done in the U.S,” explains James, “but none of them relate to B.C. and our particular situation. We’ll keep pressing on as long as the industry has this situation to

a statistically significant impact on broiler weight gain and/or

conversion.

Used broiler bedding was taken from a commercial broiler barn in the Fraser Valley and dried before being delivered to Diacarbon’s pyrolysis unit (shown here) in Agassiz. Once processed, the resulting biochar was transported to Ritchie-Smith Feeds in Abbotsford where it was incorporated into commercial starter, grower and finisher broiler feed.

Cover Story

deal with.”

For B.C., a new study is planned for 2015 to convert poultry litter into heat and electricity. This project could potentially have positive impacts on both the environment and animal waste management, and be one solution to how we can turn trash into treasure. We will have to wait for the results to come in, and look forward to future projects, which will help answer the burning question.

Any inquiries about this study and requests for details should be directed ARDCorp’s Senior Program Manager Jaclyn Laic (604) 854-4483. ■

Funding for this project has been provided by Agriculture and Agri-Food Canada and the B.C. Ministry of Agriculture through the CanadaB.C. Agri-Innovation Program under Growing Forward 2, a federal-provincial-territorial initiative. The program is delivered by the Investment Agriculture Foundation of B.C.

Average broiler weight gain by treatment

Table 5: Laboratory Analysis of Broiler Litter

Laboratory analysis of broiler litter

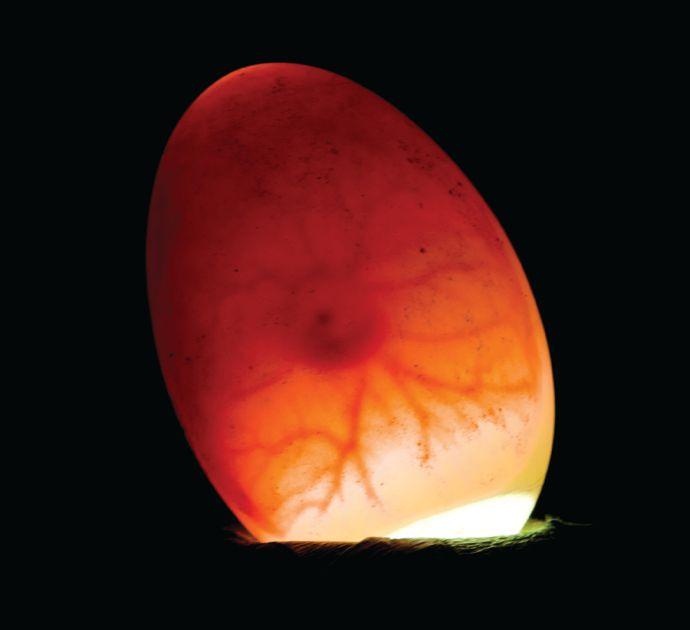

WHICH CAME FIRST?

CPRC Update Project funding and Scholarship Award

The CPRC completed its 2014 funding process at the Board of Directors November meeting by providing approval for eight projects that address several poultry industry priorities. Final approval for some projects is based on the researchers securing full funding for their proposed research projects, while other projects are fully funded and ready to begin. The board also awarded the 2014 Postgraduate Scholarship, a difficult task because of the very strong group of applicants.

Genetic Preservation

Carl Lessard, an Agriculture and AgriFood Canada researcher located at the University of Saskatchewan (U of S) and curator of the Canadian Animal Genetic Resources program, will conduct research on conservation and regeneration of chicken and turkey breeds using adult gonadal tissue. The CPRC has funded a series of projects to examine the potential for cryopreservation of poultry genetic material and this project carries that research program forward.

Poultry Welfare and Behaviour

Three projects address welfare and behaviour issues. Tina Widowski from the Poultry Welfare Research Centre at the University of Guelph (U of G) will evaluate existing and new euthanasia technologies for chickens and turkeys. Karen Schwean-Lardner plans to conduct tests of the impacts of infrared beak trimming on young pullets’ behaviour, water consumption and ability to peck. Martin Zuidhof from the University of Alberta and Gregoy Bedecarrats from the U of G, will cooperate on research to optimize lighting for precision broiler breeder feeding. Zuidhof developed a computerized precision feeder in prior research to ensure optimum broiler

breeder weight is maintained to help maximize production.

Immune System Enhancement

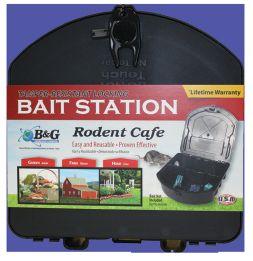

Improving the innate immunity of poultry is a major industry priority with the increasing discussion of the use of antimicrobials and potential for increased antimicrobial resistance in animals and humans. Three projects look at methods to improve the poultry immune system. Shayan Sharif from the Ontario Veterinary College at the U of G, will investigate the effect of in ovo delivery of nutrients and feed additives on the development of the chicken immune system. Susantha Gomis, from the U of S, will continue research previously funded by the CPRC that looks at the use of CpGODN to stimulate the innate immunity in poultry. Mohamed Faizal Careem, from the University of Calgary, will test the use of in ovo delivered innate immunesystem stimulants to increase resistance to respiratory viruses. This research is also a follow-up to work that the CPRC previously co-funded.

Poultry Health

Screening of birds for disease is used to identify potential outbreaks that could damage a flock or increase risks to poultry production in a region or the country as a whole. Present approaches to testing for exposure to avian influenza for the national surveillance program are based on taking blood samples from birds and sending them to a laboratory for analysis. Kathleen Hooper-McGrevy of the Canadian Food Inspection Agency’s National Centre for Foreign Animal Diseases will evaluate a standardized test to use egg-derived immunoglobin for screening of antibodies to avian influenza to avoid the stress and cost associated with handling layers and taking blood samples.

CPRC Scholarship Award

The CPRC awarded its 2014 Postgraduate Scholarship to Alexander Bekele Yitbarek, a Ph.D. student under the supervision of Professor Shayan Sharif at the U of G. Yitbarek completed his M.Sc. at the University of Manitoba in 2009 and then worked with Juan Carlos RodriguezLecompte as a research technician until 2013. He followed that as a research associate with Nutreco Canada until commencing his studies with Sharif.

Yitbarek’s research will look at poultry immunology and developing a better understanding of the role of different toll-like receptors and cytokines in modulation of the immune system in chickens. His research focus will be mainly in understanding the role of TLR receptor ligands in controlling avian influenza virus. He will also conduct research on the effect of probiotics as nutritional modulators in the search for the replacement of antibiotic growth promoters in poultry diets.

For more details on any CPRC activities, please contact The Canadian Poultry Research Council, 350 Sparks Street, Suite 1007, Ottawa, Ontario K1R 7S8, phone: (613) 566-5916, fax: (613) 241-5999, email: info@cp-rc.ca, or visit us at www. cp-rc.ca. ■

The membership of the CPRC consists of Chicken Farmers of Canada, Canadian Hatching Egg Producers, Turkey Farmers of Canada, Egg Farmers of Canada and the Canadian Poultry and Egg Processors’ Council. CPRC’s mission is to address its members’ needs through dynamic leadership in the creation and implementation of programs for poultry research in Canada, which may also include societal concerns.

Clean, Disinfect & Medica te

Stenner Manufactures Reliable Peristaltic Pumps

• Inject straight into the water line

• Unaffected by water quality, scale or solids

• Effortless tube replacement with patented pump head

Water Meter Activated, Compact and Self-Priming

Stenner’s medicator, the Econ Stennicator, injects livestock supplements at a fixed ratio of 1:128. The adjustable potentiometer has contact rates of 1 pulse per liter or 1 or 10 pulses per gallon For disinfectants and acids, the Econ Integrator™ injects a fixed amount of solution per water volume as determined by the water meter. The operating times are digitally adjusted from 0.1 to 60 seconds.

Additional Meter NOT Required

Both pumps can adapt to the farm’s existing water meter and/or a house controller. Without interrupting the meter signal, either pump can accurately inject or can be placed in standby. Multiple pumps can be activated by one meter.

Stenner Pump Company FL • NY • KS

Metering Pumps | Tank Systems | Meter Systems 904 641 1666 www stenner com international@stenner com Made In The USA

Econ Stennicator

Econ Integrator™

Econ Meter System

Issues Sustainability is Good for Business

It’s also about continuous improvement

BY USPOULTRY

With significant increases in food production needed over the next few decades to support the growing population, agricultural industries must learn to communicate more specifically and unambiguously with stakeholders, customers, and others about their sustainability programs, observed Dr. Marty Matlock, executive director, University of Arkansas Office for Sustainability, at the Animal Agriculture Sustainability Summit held during the 2015 International Production & Processing Expo.

“When we talk in big, glib, hand waving ways, it does not help us to communicate to our constituents what we are doing. When people ask what sustainability is, I want you to say that sustainability is good for business. It increases efficiency, and it drives down negative things. The second thing you need to say is that sustainability is about continuous improvement,” Dr. Matlock said. He emphasized that continuous improvement means defining and identifying key performance indicators, measuring and benchmarking them, and implementing goals and strategies to achieve them.

Elaborating on the benchmarking aspect of sustainability initiatives, Dr. Greg Thoma, Ralph E. Martin professor of Chemical Engineering at the University of Arkansas, reviewed case studies remarking that sustainability initiatives often rely heavily on life cycle assessment (LCA). A LCA is a technique to assess

SUSTAINABLE PRODUCTION

Dr. Hongwei Xin, director of the Egg Industry Center at Iowa State University, says U.S. egg production advanced dramatically between 1960 and 2010 while the environmental footprint declined

the environmental aspects and potential impacts associated with a product, process or service and are used to quantify inputs and outputs in terms of a standardized unit of measure. Important characteristics of a LCA include that it be grounded in scientific methodologies, the data should be transparent, validated, widely available and inexpensive, and the same data and models should be used by producers, retailers, policymakers, nongovernmental organizations and consumers. “The process of developing and working with a LCA should be largely by consensus, and

the guidelines should be pragmatic,” Dr. Thoma said.

Results of a 50-year review of the U.S. egg industry indicate production advanced dramatically between 1960 and 2010 while the environmental footprint declined, according to Dr. Hongwei Xin, director of the Egg Industry Center at Iowa State University, Ames, Iowa. Dr. Xin is also a distinguished professor and chair for research in the Agricultural and Biosystems Engineering Department.

The work was published in the February 2014 issue of Poultry Science. The objectives

were to quantify what in production has changed over 50 years, characterize the supply chain footprint and identify hot spots for further improvement. The data obtained from sources, such as books and publications from 50 years ago and an elaborate survey system for 2010 data, yielded data on 57.1 million pullets and 92.5 million laying hens, representing about one-third of the total national inventory in each industry. The research found that comparing production performance levels to 1960 birds, 2010 hens have 26 per cent lower feed intake, 26 per cent lower feed intake, 27 per cent higher egg production rate, 42 per cent better feed conversion, 57 per cent lower mortality and 32 per cent lower water use.

A poultry industry sustainability program is in its early stages following two meetings last fall and formation of a workgroup of representatives from the broiler and turkey industries tasked with defining the mission and goals of the program and subsequently developing it. Workgroup members Lankford Ruffin, corporate environmental manager for Butterball LLC; Paul Helgeson, sustainability manager at GNP Company; Cameron Pruitt, head of corporate affairs and sustainability at JBS USA; and Jamie Burr, environmental health and safety manager at Tyson Foods, discussed their progress and their plans during the Animal Agriculture Sustainability Summit as part of a panel.

Responding to questions from the audience, the panel concurred that interest in establishing sustainability programs at individual facilities extends throughout the supply chain, including the farm level. “The interest goes to where the risk is, to where the vulnerability is,” Pruitt said. “Today it is on farms; it is on animal welfare. That does not mean that is necessarily where it is going to reside 10 years from now. Sustainability is basically an analysis of what the hotspots are in the entire value chain, including the ultimate consumption and disposition of the product.”

AGRO-DESIGN CONSTRUCTION Ltd.

Welfare Poultry Welfare in the 21st Century

Bas Rodenburg of Wageningen University discussed future challenges and possible solutions at a recent lecture at OVC

BY KAREN DALLIMORE

With the ban on conventional cage systems in Europe in 2012, the same birds that once lived in cages of four are now living in groups of 30 to 100 birds in furnished cages or up to 6,000 birds in open systems. A further ban on beak trimming, already in place in Scandinavia, Switzerland and Austria, will come into force in 2018 in the Netherlands.

For Bas Rodenburg, assistant professor at the Behavioural Ecology Group at Wageningen University in the Netherlands, these restrictions have created a sense of urgency to mitigate specific welfare issues with all systems: feather pecking, cannibalism, keel bone fractures and smothering.

Rodenburg’s focus is to optimize breeding, rearing and management strategies in laying hens to prepare them for life in a complex large flock, non-cage environment. His research is coupled with dialogue with the industry to see what actually works.

The transition from caged housing systems has been both positive and negative, Rodenburg told the audience at a lecture hosted by the Campbell Centre for the Study of Animal Welfare at the University

Bas Rodenburg’s focus is to optimize breeding, rearing and management strategies in laying hens to prepare them for life in a complex large flock, non-cage environment. His research is coupled with dialogue with the industry to see what actually works

of Guelph. Birds now have more space, access to a nest and perch, and some litter for scratching and dust bathing. The negative? The birds are more challenging to manage, with the possibility of problems and panic reactions spreading through the entire house.

Severe feather pecking is a common issue related to normal foraging behaviour that is then re-directed to other birds, said Rodenburg. It is more likely to occur with

more sensitive birds, especially if there are external stresses: the birds don’t sleep, become agitated and the result is feather pecking.

This behaviour has a strong genetic component. Rodenburg pointed to a PhD thesis done by Elske De Haas at Wageningen University in the Netherlands, investigating if there could be less feather damage by selecting birds that were less easily stressed?

WHAT ACTUALLY WORKS

Watering Wisdom 4

Static flow rates are meaningless.

Key Principle:

You can’t use an invalid concept to create drinker standards.

Birds drink by pecking intermittently on the side of the trigger pin (dynamic flow), so why set a standard based upon lifting and holding a trigger pin straight up (static flow) for one minute. This makes no sense! Unfortunately many in the industry still use this false procedure to evaluate drinkers even today.

It is also assumed that a drinker with a higher static flow rate will discharge proportionally more water when triggered dynamically. However, tests prove this assumption is false! (see video at poultrywatering.com/4).

Key Directive: Don’t use “static flow rate” to evaluate a drinker’s merit or to manage a drinker line. Learn about best watering management practices and much more at Ziggity’s Poultry Watering U website.

www.PoultryWatering.com

• How-to videos

• Poultry Watering U news

• Management downloads

should be designed to work in harmony with the way birds drink-intermittent pecking (Fig. 1).

Holding the drinker trigger pin up (“static flow”) does NOT replicate the way birds really drink (Fig. 2).

Of the two genotypes studied, Dekalb White birds were more sensitive to stress, while ISA Brown cross birds were more sensitive to the environment, said Rodenburg. Basically, there was more to be gained in white hens from selection for decreased stress sensitivity and more to be gained in brown hens from changes to the environment.

What about feather pecking during rearing? Rodenburg says this behaviour appears at five weeks of age, both gentle feather pecking, where the victim doesn’t move away, and severe feather pecking, which usually develops as an adult. Coincidentally, five weeks of age is when birds are usually set free in rearing systems.

Since feather pecking is re-directed foraging behaviour, Rodenburg said litter is of key importance: giving them forages or litter can help re-direct their pecking. De Haas’ research has shown that if litter is disrupted or limited before five weeks of age, an increase in feather pecking will result at 40 weeks of age. Rearing systems where the chicks hatch, drop down into litter and have immediate access to feed and water – as Rodenburg says, “get on with life” – may be favourable for their early development.

At 40 weeks of age, four featherpecking factors remained significant. During rearing, those that displayed high feather pecking at five weeks continued to do so at 40 weeks; birds showing a high fear of humans were also more inclined to feather peck. During the lay, there was more feather pecking damage in floor houses – older systems – than in aviaries; larger groups also had more damaged feathers.

Where birds were considered high fear, Rodenburg suggested habituating the birds to different people or different colour clothing to reduce stress. He also noticed that feather pecking was more of an issue where farmers had not modified their management – those that fed alfalfa hay, turned on the radio or supplied pecking blocks had fewer feather-damaged birds.

Rodenburg offered four solutions to

Peck Release Peck Release Drinkers

Fig. 2

Fig. 1

TD is committed to helping farmers build for the future.

The Franke twins first came to us in 2001 with an ambitious plan to grow their grandparents’ farm. Though they were barely over 20, their TD Agriculture Specialist quickly recognized their potential and backed their plan. Over the years, Jolene has been there for every major financial decision affecting the farm, helping it grow to thousands of acres and over 250 head of cattle. A personalized approach to agriculture finance, like Jolene’s, is something all TD Agriculture Specialists bring. Maybe it’s time you brought one to your farm.

reduce feather pecking, beginning with further exploring novel methods of group selection such as the white/brown difference. Reducing the fear and stress to the parent stock can be accomplished by exposing the birds to more people. During rearing, continuous access to litter, especially at five weeks of age, should reduce

“We know this farm like no one else.”

Joel Dykstra – FCC Customer

feather pecking; and for laying hens, continuous access to litter remains important. He also suggests that assessing the fear level of the birds at five weeks can be used as a predictor of later behaviour.

At all links of the chain, Rodenburg points to management factors such as feed composition and quality, litter quality,

and limiting fear and stress to reduce the incidence of feather pecking.

What about keel bone fractures? It’s a new problem, said Rodenburg, but the major causes remain unclear. One Swiss study has shown moderate to severe deformities in six to 48 per cent of birds, and including slight deformities increases the incidence of fractures to 83 per cent. Do they physically just have a lot of accidents, hitting the cage system with their keel bone? Is it about bone health? Layers deposit a lot of calcium into their eggshells that may lead to weaker bones. Both hypotheses could be right, said Rodenburg.

In his study from 2008, Rodenburg found that 62 percent of birds had minor fractures in furnished cages compared to 87 per cent in non-cage systems. How do minor fractures affect welfare? That’s another area to explore, said Rodenburg.

Housing system characteristics may be a factor as well. Using wire floors increased the incidence of fractures versus plastic floors, in the work of PhD student Jasper Heerkens at the ILVO in Ghent, Belgium. Was plastic a better landing surface? Yet another area where more research is needed, said Rodenburg.

Work done by Ari Stratmann in Bern, Switzerland, suggested that extra ramps in aviary systems resulted in less fractures, as did soft perches. Her genotype selection work proposed that selection for stronger bones resulted in fewer fractures but poorer egg quality. Can we find a balance, asked Rodenburg, or use nutrition to accommodate the difference? Research is also now studying training the birds to use new, complex, three-level systems to reduce fracture rates.

Smothering is another welfare issue that is seen in non-cage or free range systems. The birds at the bottom can die. “It’s difficult to tackle because it’s difficult to predict,” said Rodenburg. Smothering is not as big an issue with white hens that tend to be more agile and keep a larger personal space, as opposed to brown hens that are more likely to aggregate.

As a possible solution, Rodenburg described the “Eyenamic” monitoring

Remarkably Clean

Virkon

Industry B.C. Deals with AI Outbreak

Better prepared than in 2004, the outbreak was less devastating and well-contained

BY DAVID SCHMIDT

After a month with no new cases of avian influenza (AI) being reported, the B.C. poultry industry is hoping the worst is over and it can start getting back to normal.

The high path H5N2 outbreak was first confirmed at a broiler breeder and a turkey farm on Dec. 1st, 2014. Three days later, AI was confirmed on two more broiler breeder farms. By Dec. 19th, the virus had spread to a total of 11 commercial premises (seven broiler breeder farms, three turkey farms and one table egg farm) and one non-commercial (hobby) farm.

This was the largest AI outbreak since AI hit 42 farms in the Fraser Valley in 2004, resulting in the complete shutdown of the local industry and the depopulation of over 17,000,000 birds.

“As an industry, we feel good about how the virus has been contained,” B.C. Poultry Association president Ray Nickel said in mid-January.

The Canadian Food Inspection Agency (CFIA) is more cautious since the highly pathogenic virus was found more recently in waterfowl just across the U.S. border as well as in non-commercial flocks in southwestern Washington and northwestern Oregon.

“We know the threat is still out there but if we get any new case of AI we will consider it a new outbreak,” Nickel says.

He and B.C. Chicken Marketing Board

B.C. Poultry Association president Ray Nickel says the industry’s on-farm biosecurity program and an improved working relationship with the Canadian Food Inspection Agency and the B.C. Ministry of Agriculture helped keep the outbreak in check.

administration manager Katie Lowe credit the industry’s on-farm biosecurity program and a “much improved” working relationship with the Canadian Food Inspection Agency and the B.C. Ministry of Agriculture for keeping the outbreak in check.

“In 2004, we started with a low-path AI which mutated to high-path and ended

up with 42 infected farms. This time we started with a high-path strain and kept it to 11 premises,” Lowe notes.

The biosecurity program B.C. developed after the 2004 outbreak includes a formal emergency response protocol and an ID program for all commercial poultry premises (still the only such program in Canada). That kicked into high gear the

IMPROVEMENTS MADE

moment the first case was confirmed.

“We learned about the first case on a Monday morning and by Tuesday afternoon, we had notified all producers and given CFIA the location and contact information for every poultry barn in B.C.,” Lowe notes.

Within days of the outbreak, the CFIA put the southern half of the province into a primary control zone to satisfy international trading partners who immediately banned the import of Canadian poultry. This allowed continued free movement of Canadian poultry and egg products not originating or processed within the zone.

To contain the spread, subsidiary three to 10 kilometre “restricted” zones and a one to three kilometre “infected” zones were created around each infected premise. All farms within the control zone need a permit from the CFIA before moving captive birds, poultry products and by-products on or off the property. Eggs or poultry may only leave a farm within an infected zone after the flock tests AI-negative. No eggs and/or chicks may be brought onto a farm within one km of an infected premise until the infected flock has been euthanized and heat-treated (composted) in its barn.

Infected farms will only be allowed to repopulate 21 days after their birds have been removed and all their barns, feed bins, piping and manure storage have been cleaned and disinfected to CFIA standards.

Farms within the restricted zone must maintain strict health records and have all their mortalities sampled to obtain permits.

“We didn’t have these procedures in 2004,” Nickel states. “The one km zone didn’t exist and we didn’t heat treat all birds in-barn. Now, birds are only removed when we are sure the virus is dead which helps limit the spread.”

B.C. Primary Poultry Processors Association president Scott Cummings admits the permitting process was “particularly challenging,” but says processors and the CFIA worked “diligently” to minimize delays. In a typical example, one grower within the infected zone reported vets spent five hours taking samples before

Industry

his broilers could be shipped.

Since 2004, the B.C. Ministry of Agriculture upgraded its animal health lab in Abbotsford to a fully-accredited Level 3 lab, which has made a huge difference. In 2004, all samples had to be sent to Winnipeg for testing, a process which could take up to five days. In 2014, samples were sent to the Abbotsford lab. Lab staff worked double shifts, seven days a week, to turn around samples in just 4-6 hours.

Because of the international bans on B.C. poultry, B.C. chicken processors cancelled their export programs that account for about eight per cent of total production. The reduced demand for chicks meant the loss of eggs from the infected broiler breeder farms did not cause an immediate problem for local hatcheries.

Instead, says Western Hatchery manager Ernie Silveri, the real impact will come when export production resumes. “That’s when we’ll feel a big crunch because we won’t have the egg supply back yet.”

The CFIA will compensate farmers whose barns are depopulated. Although the Health of Animals Act formula accounts for the type and age of the birds, the compensation does not include the cost of cleaning and disinfection or lost business. There is also no compensation for the 17 chicken growers not allowed to repopulate since they were located within infected zones. Most were able to mitigate their losses by leasing out quota to other growers.

“Because we didn’t have the export program, growers had barn space to take up that production,” Silveri points out.

Since 2004, government and industry have been working on creating a captive AI insurance company to cover C&D and other costs not covered by the CFIA. The four poultry marketing boards had set aside start-up funds in hopes of having the company in place by at least the fall of 2014 but the B.C. Farm Industry Review Board threw a huge wrench into those plans when it refused to allow the boards to collect mandatory levies. Organizers insist the company would only be liable if all poultry producers are required to pay levies.

FIRB believes the boards do not have

authority under the Natural Products Marketing Act to collect levies for such a purpose.

“There was no point in approving it if it was going to fail a judicial review,” says FIRB chair John Les.

B.C. Chicken Growers Association president Ravi Bathe, a director of the proposed company, says the AI outbreak “puts more pressure on government” to make the legislative changes needed to allow the company to proceed.

Although the insurance company would have paid for the increased surveillance and covered infected growers’ C&D costs, the outbreak pointed out some holes.

“We discovered it would not have covered the costs of non-infected growers in the infected zone so we will revise that before we proceed,” Nickel says.

Migratory waterfowl are believed to be the source of the outbreak but that has yet to be confirmed. BCMA chief veterinary officer Jane Pritchard notes there were no “commonalities” between the two original farms. The outbreak on the second and third broiler breeder farms was due to those farms having received “spiking” roosters from the first broiler breeder farm just days before the outbreak was detected.

B.C. Broiler Hatching Egg Producers Association president Bryan Brandsma says spiking will continue but expects changes in how it is done.

“Biosecurity surrounding spiking males has been discussed for some time,” Brandsma says. “Previous to this outbreak more producers had already begun to think about finding space, or building a simple facility, to grow their own spiking males.”

Nickel admits finding additional infected premises was a “shock” to the industry, given its improved biosecurity practices. He says there will be a complete industry debriefing after the outbreak is over, including a review of the epidemiology information and results of CFIA’s trace back on each infected farm.

“It would be helpful to know if the virus walked in or was blown in so we can adjust our biosecurity program to better deal with a future situation.” ■

BIOSECURE:

COST

Health Water Quality and Quantity

How it influences flock performance

BY MISSISSIPPI STATE UNIVERSITY EXTENSION SERVICE

Water is the most critical, but also the most overlooked, nutrient when it comes to flock performance in the poultry industry. Water is essential for many functions within the body, such as moving feed through the digestive tract and carrying nutrients throughout the body. Water is also needed for the many enzymatic and chemical reactions in the body, body temperature regulation, lubrication of joints and organs, and excretion of waste products from the body.

Most growers are more worried about the quantity and availability of the water they supply to their birds than they are about its quality. However, because of the variability in quality and the potential for contamination, water quality plays a major role in flock performance. Water quality has the potential to affect digestion and absorption of nutrients, as well as flock health. Water intake in your birds is roughly twice the weight of feed intake. However, during periods of extreme heat stress, water intake may triple or even quadruple. Therefore, it is essential to have a safe and adequate water supply at all times in order to achieve efficient poultry production.

WATER QUALITY

There are several different ways to characterize water quality, including taste, colour, odour, alkalinity, acidity, hardness, turbidity (cloudiness), pH, presence or absence of

Water is the most critical, but also the most overlooked, nutrient when it comes to flock performance

bacteria, etc. The composition of water will vary with the geological makeup of the region. Additionally, water quality can also change from season to season based on the water source and the environment surrounding that source, such as flooding, drought, and farming practices.

Dissolved minerals in water can also create issues with equipment. This can have detrimental effects on the growth rate of pullet and broiler flocks, and it can reduce reproduction and egg numbers in breeder flocks. Pressure regulators

and water lines can become clogged with mineral deposits, restricting water flow to the birds.

It is always best if drinking water is clear and has no odour, colour, or taste, although often this is not the case. For example, water with high sulfur content has a rotten egg smell, water with high iron content has a reddish-brown colour, and water with high copper content has a blue colour. Iron or manganese sulfates can cause a bitter taste. High concentrations of sulfates can combine with magnesium

QUALITY, QUANTITY MATTER

Now available in Canada, POULVAC®

Bursaplex is the unique innovative antigen-antibody complex vaccine with simple, safe, and efficacious protection for broiler chickens against infectious bursal disease, regardless of maternal antibody level. WITH ONE SINGLE DOSE IS ALL IT

Health

to form Epsom salt or with sodium to cause a laxative effect, resulting in wet litter. High concentrations of sodium and chloride (salt) may increase water consumption and also result in wet litter. High salt levels in the water can lead to toxicity when combined with salt in the feed.

High levels or combinations of calcium, magnesium, and sulfate can cause scale buildup in the water system. Nitrates in water may indicate bacterial contamination. So even if water appears clear, odourless, colourless, and tasteless, it should not be assumed to be safe.

Contaminants in water are measured as milligrams per liter or parts per million (ppm). Even though ppm is a tiny amount, birds are provided a balanced diet through their feed, and any additional minerals provided in the water may be detrimental to their health and performance. Decreased weight gain, fewer eggs, poor feed conversion, and wet litter can be problems when high levels of minerals are present in water.

On the pH scale, 7 is considered neutral. Anything lower than 7 is considered acidic and anything higher than 7 is considered alkaline. A high pH is often characterized by high levels of calcium and magnesium, which can build up over time and clog the water system. Water that is highly alkaline may also cause poor feed conversion and reduced water and/or feed intake, along with possible diarrhea and digestive upsets. The high mineral content can also cause scale buildup in water lines and drinkers, resulting in leaky nipples and a decrease in the effectiveness of chlorine or other sanitizing agents you may be using to treat the water.

Calcium, magnesium, and sodium are the primary components of total dissolved solids (TDS), which is a measure of the inorganic salts dissolved in water. Water with a high level of dissolved minerals is often referred to as “hard” water. Hardness measures the tendency of water to precipitate soap and form scale. Water “softeners” reduce the hardness in water by replacing calcium and magnesium with sodium. However, chickens are very sensitive to excess sodium and thus in most cases, it is not recommended to use water softeners on poultry water supplies. If you do so, monitor sodium levels on a regular basis to prevent sodium from reaching unacceptable levels. High levels of TDS may cause loose droppings and other harmful effects in poultry production.

In general, birds accept water on the acidic side better than they do water on the basic (or alkaline) side. A pH in the range of 6.2 to 6.8 seems to work well for chickens. Acidification can lower the pH of the water and increase water quality, improving the health and performance of your flock. Acidification lowers the pH of the gastrointestinal tract, which reduces the growth of pathogenic organisms, improves chlorine availability and prevents scale buildup in drinker systems.

The true quality of well water is unknown unless laboratory tests are conducted to determine mineral levels and bacterial content. Seek professional help with instructions, sample collection, and interpretation of the results from an analysis. If sample results indicate a problem, be prepared to take steps to correct

Health

that problem. This could mean one or more of several water treatment options. Many growers have added a sand filter to their water system to compensate for water with a high mineral content. Acidification (mentioned previously) lowers the pH of the water supply. Chlorination is the most commonly used water treatment method for eliminating bacterial contamination.

Chlorine is the least expensive water sanitizer, but other products such as hydrogen peroxide and chlorine dioxide are available and work well. Some growers with low pH water supplies will run hydrogen peroxide-based products through the drinker lines with the medicator for 24 hours once a week while birds are in the house. Sanitizers and strong water line cleaners can be used between flocks to prevent buildup over time of rust, mineral deposits, algae, and biofilms.

WATER QUANTITY

A high-quality water supply can’t deliver its full potential if birds can’t access it. Modern broiler flocks have significantly increased their water intake over the last 20 years. Genetic advancements made over the years have improved weight gain, feed intake, and feed conversion ratios. However, we sometimes fail to consider how these advancements have affected water requirements and the water intake patterns of broilers. If you don’t already do so, make it a habit to check water consumption on a daily basis. Most controllers now have built-in water meters and keep a history of water consumption throughout the flock. If you monitor water intake every 15 minutes during the afternoon and notice a plateau in consumption during the heat of the day, there is a good chance that supply is not keeping up with demand. Monitor water consumption in each house and know what is going on with water intake. Also monitor stand pipes on nipple drinker systems to make sure you have adequate water volume the length of the line.

Water intake, as a general rule, should increase every day from placement to harvest. If it is down more than a day at a time, start looking for a problem because something is wrong somewhere. Remember that feed intake closely follows water intake. If water intake was down today, feed intake was also down today. You don’t need to weigh the feed to know this; that’s just the way things work. If feed intake goes down, some growth potential is lost.

If water intake plateaus the last week or 10 days of the flock and fails to steadily increase all the way up to catch day, your water system may not be able to deliver the required volume for your birds to perform at their best near the end of the flock. Your supply lines, well pumps, and so forth may simply be undersized to handle the whole-farm water demands of your operation. This may be especially true for older farms with less than 2-inch supply lines from the well and/ or small gallon-per-minute capacity pumps in their wells. Again, feed intake follows water in- take. If water intake plateaus, so does feed intake. When birds are performing at their best, feed intake is increasing each day. ■

Take your place in the conversation

There’s been a lot of talk about food and farming lately – online, in the media and at the dinner table.

That’s a really good thing. It means people are concerned about their health and wellbeing, and that they’re in a position to make positive choices about what they eat. It also spells opportunity for Canada’s agriculture industry. What we do has never been so important to so many people here at home and around the world.

Unfortunately, too many of these conversations are generating false perceptions about what we produce and how we produce it. That’s often because for all the people talking about food, too few are actually part of the agriculture industry. And if we’re not telling our story, someone else will. The good news is, it’s not too late – and we’ve got lots of positive news to share.

Canadian agriculture is remarkably diverse and dynamic. Yet for all the change

the industry has seen over the years, one important constant remains: the family farm. In fact, 98 per cent of Canadian farms are family farms. That’s a key part of the conversation, because from the ground up, what we eat every day is produced by people who want the same things all families want: safe, nutritious food. Those same values also extend to how our food is produced. Canadian farms produce more than ever in ways that are more sustainable than ever. What a great legacy for future generations!

You’re an important part of the conversation. So speak up – tell the real story.

Every fact

Canadian agriculture has a lot going for it, and sharing the facts is a great way to join the conversation. Our resource section is filled with timely, interesting content – including dozens of easy-to-share fact photos. And each one tells an important story. Here are just a few:

Canadian agriculture has a lot going for it, and sharing the facts is a great way to join the conversation. our resource section is filled with timely, interesting content –including dozens of easy-to-share fact photos. and each one tells an important story. here are just a few:

Source: CropLife Canada

Canada’s opportunity: world food demand is set to grow 60% by 2050

The world is growing, and everyone deserves to have access to safe, high quality food. It’s a huge responsibility and an incredible opportunity for Canadian agriculture. Canadian farmers are responding by producing more food than ever, all while using fewer resources. That’s good news here at home and around the world.

In

56,000

Thanks to Canada’s ag and food industry, more than 2.2 million Canadians are bringing home the bacon (pardon the pun) every day. That’s like the entire population of Vancouver. The impact on Canada’s economy, and on our communities and families, is truly remarkable.

Never has Canadian agriculture offered more – and more diverse – career options than right now. There are opportunities in research, manufacturing, financial services, marketing and trade, education and training, and more. And all of these positions need to be filled by talented, energetic people. Visit the website and consider what the facts mean to you. Then join the conversation! AgMoreThanEver.ca

source: an overview of the Canadian agriculture and agri-food system 2014 (agriculture and agri-food Canada)

Be an AGvocate agvocates

unite!

looking to channel your passion for ag? adding your name to our agvocate list is a great way to get started. you’ll join a community of like-minded people and receive an email from us every month, with agvocate tips to help you speak up for the industry.

Visit AgMoreThanEver.ca/agvocates to join.

Resources to get you started

Joining the ag and food conversation isn’t always easy. What you say is important. So is how you say it. If you’re feeling a little unsure about what to do next, you’re definitely not alone. Fortunately, we’ve got practical expert advice to help you become an effective agvocate.

Our online webinar series brings recognized experts in communication, social media and media relations right to your screen. Topics include:

• The art and science of the ag and food Conversation

• Social media 101 for agvocates

• Getting in on the tough conversations

• Working with the media as an agvocate

Visit AgMoreThanEver.ca and click on Ag Conversations.

We a ll sha re t he sa me ta ble.

Pul l up a c hai r.

“ The natural environment is critical to farmers – we depend on soil and water for the production of food. But we also live on our farms, so it’s essential that we act as responsible stewards.”

- Doug Chorney, Manitoba

“ We take pride in knowing we would feel safe consuming any of the crops we sell. If we would not use it ourselves it does not go to market.”

- Katelyn Duncan, saskatchewan

“ The welfare of my animals is one of my highest priorities. If I don’t give my cows a high quality of life they won’t grow up to be great cows.”

- andrew Campbell, o ntario

Safe food; animal welfare; sustainability; people care deeply about these things when they make food choices. And all of us in the agriculture industry care deeply about them too. But sometimes the general public doesn’t see it that way. Why? Because, for the most part, we’re not telling them our story and, too often, someone outside the industry is.

The journey from farm to table is a conversation we need to make sure we’re a part of. So let’s talk about it, together.

Visit AgMoreThanEver.ca to discover how you can help improve and create realistic perceptions of Canadian ag.

PIC Update

PAACO Training

An updated poultry auditor training course is to be offered in May 2015

POULTRY INDUSTRY

COUNCIL STAFF

The Poultry Industry Council (PIC) is the Canadian delivery agent for the Professional Animal Auditor Certification Organization’s (PAACO) Poultry Auditor training course. The 2015 Canadian PAACO Poultry Auditor course will be offered May 26–28, 2015 in Woodstock, Ont.

Third party auditing is increasingly being demanded throughout the sector, accompanied with the importance of documented employee training. The PAACO Poultry Auditor course is designed to suit individuals who are directly involved in poultry production, as well as those involved indirectly, such as purchasers and retailers of poultry products. An introduction to the Canadian poultry industry and an overview of standard practices within each sector are covered, followed by detailed classroom instruction from experienced auditors on third party auditing of broiler, layer, turkey and broiler breeder facilities throughout all stages of the production cycle. The skills, knowledge and ethical considerations required to successfully audit a Canadian poultry facility are also featured. The final component of the Poultry Auditor course involves species-specific on-site audit training at a hatchery, farm and processing plant.

After completing the course— which

The PIC is once again offering PAACO Poultry Auditor training

includes an exam — trainees must successfully complete two shadow audit sessions with a certified PAACO auditor in order to achieve their own certification. In order to maintain certification PAACO auditors are required to complete annual continuing education requirements. Current auditors are also invited to register and participate in the May 2015 training to satisfy these requirements.

CANADIAN FOCUS

After hosting two successful training sessions in 2012 and 2013 which focused on examples from American audit

schemes, training materials were updated to instruct auditor trainees based on Canadian tools whenever possible. “Our stakeholders saw the value in the availability of third party auditor training, but felt the course materials could better reflect content of current Canadian animal care auditing programs” Laura Bowers, education and extension programs manager with the PIC said. The updating process involved an advisory group including input from national and provincial government and marketing boards.

For registration and further information, please visit PIC’s website at www.poultryindustrycouncil.ca. ■

IN DEMAND

•

•

•

•

•

•

•

•

•

Centrifugal Cooling System

• 12” – 24” diameters • Polyethelyne housing

• with Multifan or Performa+ Leeson motors

Genius picture Ge-430

• Genius 430LS Livestock climate control

• User friendly Interface (hot Keys)

• Large Display Screen for easy viewing

• Up to four variable stages and 30 off/on relays

• Expandable to 50 relays with relay module

• Up to 12 temperature sensors , one Humidity sensor

• Up to 12 heat zones, 12 cool stages, 2 light programs

• Up to 5 water metering, 2- 0-10volt outputs for dampers

• can operate Dual, natural and tunnel ventilation

• “Solarwall boost”, outdoor, humidity over-ride logic

Poultryhouse Fan

• High quality material and aerodynamic air inlet

• Variable speed Performa+ motor

• Dual voltage, fully enclosed motor

• Low energy consumption and noise level

• 16” and 20” models producing 2792 and 4770 cfm

• Includes hanging hardware

SELECT DOSER

• Select Doser dispenses products accurately into low and high pressure watering systems through it’s tubing via compression and peristalic action.

• Aggressive products and powders never pass through the pumps mechanism that can cause premature wear and maintenance.

• New improved Model 640 is now simple to use with one tube size

• New Select Doser Max can now operate in high pressure and volumes

PSI

• Total stainless steel construction

• Hi-Low switch

• Watertight enclosures

• Propane and natural gas

• Available in 40,000 to 225,000 BTU units

• Available in pilot or spark Unvented Unit Heater

• Recovers wasted heat

, up to 4 variable, 20 off/on • New Genius Dimmable Light control

72” fan

• Heavy Duty fiberglass housing

• Heavy Duty 6 blade alum. Propeller

• Twin gates Size A belts with Auto tensioner

• 3 hp , single or 3 phase motor

• Optional cone for max air flow

• High light reduction

• Low resistance to air flow

• Simple Installation

• Easy to clean

• Uses P.V.c. snap release spacers

Extension Making a Difference

Egg Farmers of Canada is now part of Project Canaan

BY LESLIE BALLENTINE

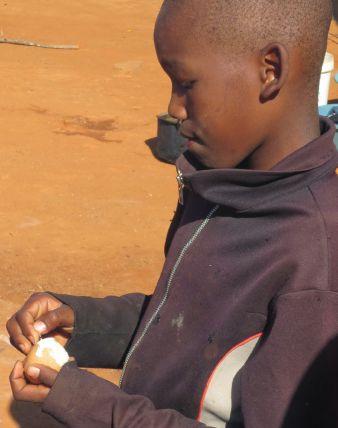

In a land far far away, Canada’s egg farmers are helping to make a difference. The tiny kingdom of Swaziland is nestled between South Africa and Mozambique. A country about the size of Wales, Swaziland is a developing country of 1.2 million people. While classified as a lower-middle-income country, most Swazis live in chronic poverty where unemployment runs at 70 per cent, and 75 per cent practice subsistence agriculture. Nearly 25 per cent of children die before the age of five from a combination of disease, malnourishment and abandonment. HIV/AIDS, which generally goes untreated, affects 43 per cent of the population. This combined with cultural practices and taboos has led to an estimated 500,000 orphaned and vulnerable children, adding to the burden.

That is where eggs and Canadian egg farmers fit in. According to Egg Farmers of Canada (EFC) executive director Tim Lambert, members of the International Egg Commission (IEC), such as EFC, have long been involved in food assistance programs round the world. EFC has for example been sending egg powder to feed children in third world countries for more than 20 years amounting to more than 16 metric tonnes per year of “nature’s perfect food.” In 2014 the IEC turned these independent actions into a cohesive strategy with the formation of the charitable IEC Foundation.

In concert with the UN Food and Agriculture Organization (FAO) and the World Health Organization (WHO), the IEC Foundation is now a part of a wider move to provide self-sufficiency and sustainable food development in

Farmers and staff with Egg Farmers of Canada provided the hands-on experience needed by Project Canaan.

countries of need. The groups include the International Dairy Federation (IDF), International Meat Secretariat (IMS), International Poultry Council (IPC), International Egg Commission (IEC) and the International Feed Industry Federation (IFIF).

Canadian egg producers have taken on this new approach by spearheading the addition of an egg farm to Project Canaan, a sustainable farming and economic development initiative started by two Ontario business people under their

charitable Heart for Africa organization. Begun in 2009, the project is the first for Heart for Africa and will serve as a model for future projects. While Janine and Ian Maxwell have no farming background they have relied on those who do and in five short years have turned 2,500 acres of empty land into a thriving mixed farm and rural community. The project has two sides to it. Farming and raising abandoned babies at the onsite Children’s home. In this way the project is doing double duty. The farm provides

HELPING HAND

local employment and supplies locally produced food while giving children the care and education they otherwise would not get. The farm is being built with donations and is run as a commercial business that also teaches Swazi locals adapted farming practices commonly used throughout Canada. Altogether the project

Extension

employs over 220 local people.

The goal, Janine recently wrote on her blog, is to expand the farm and to generate the profit needed to be self-sustainable by the year 2020. Already, the farm runs a dairy and a goat operation, markets fruits and vegetables, produces cash crops and hand-made crafts. These enterprises are

www.hybridturkeys.com

Partner of Choice

Our commitment and dedication to the Canadian turkey industry has spanned the last 60 years. Today, the lasting relationships we have developed, ongoing investments in research and the performance of our products are assurances that Canadian turkey farmers will continue to benef ifit from the advantages Hybrid Turkeys has to offer:

> a network of trusted Canadian distributors

> aff iliations with agricultural research institutions

> a team of global technical experts

Partnering for your success.

generating revenue and food used to help feed their own 86 orphans and employees plus supplying rural church sponsored food programs. The egg farm is the next step in making the farm, on-site orphanage, schools, women’s shelter and medical clinic self-sustaining.

It was during the formation of the IEC Foundation that EFC learned of Heart for Africa and their Project Canaan. EFC’s Tim Lambert explains that the capacity building project is being supported by EFC for many reasons. “Canadian egg farmers enjoy the privilege of supply management and from a social license perspective it is important to use that privilege wisely,” says Lambert. He notes that egg production is a logical step since production of egg protein is a sustainable, efficient, scalable and affordable means to feed the world. “EFC believes that the Heart for Africa project will demonstrate that,” he says. If all goes to plan, by the end of 2015 the farm is expected to be housing 5,000 hens using a dual purpose African adapted strain. As with the other farming activities, production will be labour-based and low technology. Using their gravity fed water system, natural light and ventilation, hand feeding and manual clean-out, the eggs will be hand collected and then boiled for preserving. Eggs not used on the farm will be shipped to feed other needy children. Future plans include expanding the flock as needs and marketing opportunities come about.