Productive Birds Need Performance You Can Count On

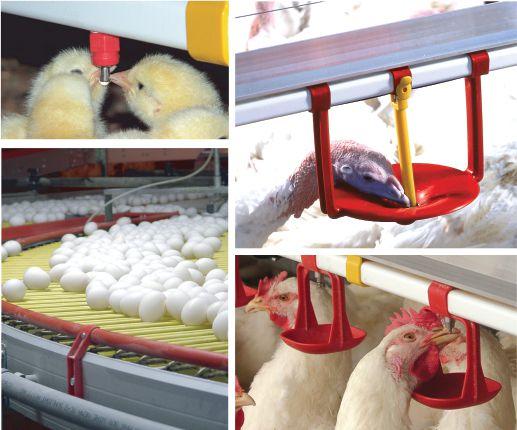

VAL-CO® Watering Systems

VAL-CO manufactures complete watering systems for broilers, roasters, breeders, and turkeys of any age. Only genuine VAL-CO drinkers are made with precision from stainless steel parts manufactured on Swiss screw machines. We only use the best quality materials, offering an excellent balance of mechanical strength and chemical resistance. VAL-CO drinkers are often imitated, but our genuine precision quality can never be duplicated. Trust only VAL-CO drinkers for performance you can count on.

VAL-CO® is a leading manufacturer of high-quality systems for commercial poultry and egg production, creating new and exciting products based on innovative thinking, technical research, and field experience. By controlling the manufacture of all the components, VAL-CO engineers its products to work together as complete systems, each expertly designed and produced with a distinct focus on the customer. Our worldwide presence and commitment to providing leading products and technical service make VAL-CO your key business partner whose performance you can count on.

FROM THE EDITOR

By LiaNNE appLEBy

an alternative to ugly sweaters

The holidays are a wonderful time of year, full of the sentiments that should last the whole year through.

in their wake come a lot of creative and yummy turkey recipes. unfortunately, the holidays are usually also followed by endless lineups to take back the gifts that don’t fit – or were simply bad choices. aside from getting back to normal life, we’re faced with decisions like whether to actually grow that Chia uncle si or regift it at the earliest possible opportunity. if you’ve realized that we’re now three months into 2014 and you haven’t yet decided what to do with the cash, cheques and gift cards that you grossed over the holidays, why not go out and grab yourself a copy of Eggs in Your Life (EIYL), by Peter surai and ray noble?

this little paperback, published in 2013, was lent to me by Peter Hunton, who often writes for Canadian Poultry. the copy was gifted directly to Peter by his close friend surai. When Peter sent it along to me, he attached a handwritten note: “Lianne – would like this back when you are finished with it. P”.

that was last summer…but i still have it. that’s because EIYL isn’t a book that you read once and shelve indefinitely. it’s a reference book. and, well, i don’t want to give it back.

EIYL touches on every egg-related topic imaginable: the role of the egg in human nutrition; its structure; how eggs are laid; the cholesterol debate; free-range versus conventional cages; organic eggs; what countries produce and consume the most eggs. it’s all there, and more.

not only that, but it’s full of uselessyet-interesting anecdotes like “Bizarre things People do with eggs.” if you were impressed when Cool Hand Luke ate 50 of the hard-boiled type in an hour, then

check out 43-year-old sonya thomas’s record.

“When i first read this book, i was at a loss to describe its target audience, and the authors could not help,” says Peter. “it contains a wealth of useful and valuable information, but for whom? it is somewhere above the head of the average consumer. We can wish that doctors, dieticians, teachers and other pundits who influence people’s decisions about food would read it, but there can be no assurance that they will.

“egg farmers and others in the industry will enjoy it because they are familiar with some of the content, but will surely learn a great deal more from the authors’ very wide range of information presented. it may end up as the egg industry’s responsibility to get the book to those in positions of influence (the abovementioned pundits) and this would be a worthwhile effort. i certainly believe that readers of Canadian Poultry would enjoy the book.” so if you think that eggnog is the only liquor derived from the Perfect Protein, you’d better turn straight to page 118.

Happy reading!

Kristy nudds resumes her role as editor of Canadian Poultry magazine, following her maternity leave.

Lianne appleby moves to the new position of digital editor – agannex with lead responsibilities for the digital division of annex Business Media’s agricultural publications.

Lianne will represent agannex at a cross-section of agricultural events.

FEBRUARY/MARCH 2014

Vol. 101, No. 2

Editor Lianne Appleby – lappleby@annexweb.com 226-971-2133

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 519-400-2424 888-599-2228 ext 237 • fax: 888-404-1129

Account Coordinator

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer

Alison Keba

Group Publisher

Diane Kleer – dkleer@annexweb.com

President Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710 REtURN UNDELiVERABLE CANADiAN ADDRESSES tO CiRCULAtiON DEPt., P.O. BOx 530, SiMCOE, ON N3Y 4N5. e-mail: subscribe@canadianpoultrymag.com.

Printed in Canada iSSN 1703-2911

Circulation e-mail: subscribe@canadianpoultrymag.com tel: 866-790-6070 ext 201

Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $30.00 per year (with GSt $31.50, with HSt/QSt $33.90)

GSt – #867172652Rt0001

USA – 1 Year $ 66.00 USD Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. if you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2014 Annex Publishing & Printing inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

A Tradition of Innovation.

With more than 60 years of experience developing innovative products for poultry producers worldwide, Lubing has established a reputation of leadership by introducing new, cutting-edge technologies to the poultry industry.

Find out What’s NEW at Lubing by visiting our site at www.lubingusa.com

OptiGROW Nipple

The ultimate Broiler nipple Optimized for Growth!

SprayCabinet

Spraying/Disinfecting your chain... Simpli ed!

DripCanopy

Keep your oors mess-free with a DripCanopy!

Cantilever Drive Unit

Keep the clutter out of processing!

ChainKeeper

It’s like life insurance for your conveyor system!

BaitStation

Keep your rodent problems under control!

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Tel: (519) 657.5231

Fax: (519) 657.4092

Tel: (450) 263.6222

Fax: (450) 263.9021

WHAT’s HATCHING HATCHING

A Eggs’ Environmental impact

new study published in Poultry Science shows that while u s egg production has increased over the past 50 years, the industry has also been able to significantly decrease its environmental footprint. researchers conducted a lifecycle analysis of u s. egg production from 1960 to 2010 to evaluate environmental performance measures for the complete lifecycle from crops to hens to the farm gate. study findings indicate that the environmental efficiencies are the result of a wide range of factors, including the reduction of natural resource use, improved hen feed, better disease control and advancements in hen housing systems.

“the u s. egg industry has evolved remarkably over the past five decades by incorpo-

rating new technologies to protect natural resources,” said Hongwei Xin, agricultural and biosystems engineering and animal science professor at iowa state university, director of the egg industry Center and the study’s lead researcher. “egg farmers have improved their production practices, allowing them to provide an affordable source of high-quality protein while using fewer resources and producing less waste.”

Key results of the study found that compared to 1960:

• the egg production process releases significantly less polluting emissions, including 71 percent lower greenhouse gas emissions.

• Hens now use 32 percent less water per dozen eggs produced.

• today’s hens use a little over half the amount of feed to produce a dozen eggs.

• at the same time, today’s

hens produce 27 percent more eggs per day and are living longer. due to increased feed efficiency, advancements in hen housing and manure management, egg farms now use less water and energy on a daily basis and release less polluting emissions. every aspect of the egg production process, from cultivating feed to raising the laying hens, has led to a reduced environmental footprint.

the study was funded by the american egg Board, the u.s. Poultry and egg association, the united egg association – allied and the egg industry Center. to obtain data for 2010, researchers conducted anonymous surveys with egg farmers and collected data on 57.1 million young hens and 92.5 million laying hens. For more information visit www. incredibleegg.org or to read the full text of the study visit www.poultryscience.org.

New Quota Lease Program

NoVA sCoTiA

nova scotia egg Producers (nseP) is introducing a program that will award selected new egg farmers with a no-cost quota lease for up to 500 laying hens provided that they are raised in alternative housing systems — free run, free range or certified organic.

the new entrant program, aimed at meeting increased consumer demand for locally

Electronic Quota Transfer

oNTARio

egg Farmers of Ontario (eFO) has received offers to transfer egg and pullet quota under the first scheduled operation through its new electronic quota transfer system in March.

Buyers and sellers of Ontario egg and pullet quota will now conduct transfers

produced specialty eggs, includes the creation of a class of leased quotas that will add up to 2,000 laying hens to nova scotia’s system of egg supply management.

Farmers who meet nseP’s eligibility requirements can enter a lottery in order to receive leased quota for up to 500 hens per farm. these special quotas cannot be transferred or sold and must be used to raise hens in alternative housing. Farmers must also comply with all nseP programs, including food safety and animal care. if an applicant’s business

through a transparent and accessible electronic transfer system.

under the new transfer system, there is a published schedule for the exchange to operate quarterly. if sufficient quota is offered to operate an exchange, the volume on offer is made public so potential bidders can take part in the exchange.

the offer deadline for the March exchange was January 23. 21,407 units of layer quota and 78,058 units

Egg Tracing System Launched

QUEBEC

the Quebec federation of egg producers (FPOQC) are the first commodity group in Quebec to be able to trace a food product from farm to table in the province.

FPOQC’s traceability system allows consumers to type in a code printed on each egg, starting with “QC,” printed on their eggs at www.oeufs. ca. there they can learn about

plan includes selling eggs to retail or food service outlets, the eggs must be graded at federally registered egg grading stations.

nseP is also increasing to 200, from 100, the number of hens that small-scale, diversified farmers are allowed to maintain without having to obtain quotas.

the objective of the increased small flock exemption is helping family farms take advantage of market opportunities to broaden their revenues, as well as boosting rural economies.

of pullet quota have been offered for transfer. Potential buyers now have until the bid deadline of February 27 to submit bids.

Ontario egg farmers will have a regularly-scheduled market where all buyers and sellers are guaranteed access and can participate on fair and equal terms.

“all buyers and sellers will benefit from the accessibility of an effective, organized quota transfer system,” Graham said.

PEOPLE IN THE NEwS

prof. Franco Vaccarino has been appointed the university of guelph’s eight president and vice-chancellor, effective aug. 15, 2014. Vaccarino is currently principal of the university of toronto scarborough (utsc) and vice-president at the university of toronto, a position he has held since 2007.

Terry pollard has been promoted to the position of senior Vice president, egg systems, u s. and canada with big dutchman usa terry’s focus will be to provide the marketplace with innovative equipment and systems, handle manpower requirements and continue to work with industry leaders and organizations.

the producer, the laying hen’s cage, breeder, hatchery and original reproductive flock, and view photos. the program is in response to the provincial government’s minimum regulations to trace eggs and other agricultural products from farm to table,

introduced last July. the tracking system was set up with the help of agri-

Steve Walcott has been promoted to the position of Vice president, egg system sales for u.s. and canada. in his new role steve will be responsible for the sales organization and aviary technical support group, which handles all equipment and systems needs for the commercial egg industry including the specialty egg market, as well as pullet growing facilities.

TERRY PollARd

sTEVE WAlCoTT

PRoF FRANCo VACCARiNo

walmart Expanding in Canada

Walmart announced in early February that it will open 35 more Canadian supercentres as part of nearly $500 million in planned investments this year.

the world’s biggest retailer said its long-term plan is to offer groceries in each of its Canadian stores, a move which will increase the pressure on its retail rivals.

Walmart said in a release

six of the stores will be new, 10 will be expansions and 18 will be retrofitted to add a fresh food section. One store will be relocated.

the company currently has 389 stores, including 247 supercentres that carry a combination of groceries, apparel, and household goods. it expects to have a total of 395 stores by the end of January 2015, with 282 supercentres and 113 discount stores.

espite inclement weather conditions, the 2014 international Production & Processing expo (iPPe) had more than 24,000 poultry, meat and feed industry registrants from all over the world. in addition, the show had 1,148 exhibitors with more than 410,000 net square feet of exhibit space. the main attraction was the large exhibit floor. exhibitors displayed the latest innovations in equipment, supplies and services utilized by industry firms in the production and processing of poultry, eggs, feed products and meat. all phases

march march 19-20, 2014

Midwest Poultry Convention Saint Paul riverCentre, saint Paul, Minn. For more information, visit: midwestpoultry.com

apriL

april 9-10, 2014

London Poultry Show Progress Building, Western Fair district, London, Ont. For more information, visit: westernfairdistrict.com

JUNE 2014

Canada’s Farm Progress Show evraz Place, regina, sask. For more information, visit: myfarmshow.com

JULy 2014

Poultry Science Association annual meeting texas a&M university, Corpus Christi, texas. For more information, visit: poultryscience.org/ psa14 or e-mail: psa@ assochq.org

of the poultry, feed and meat industry were represented, from live production and processing to further processing and packaging.

the “largest-ever” education slate complemented the exhibits by keeping industry management informed on current issues and events. this year’s educational line-up featured 16 programs, ranging from a conference on ground poultry pathogen reduction to antibiotic use in the meat and poultry industry to a program on how to export feed and feed ingredients to the united states.

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; e-mail knudds@annexweb.com; or fax 519-429-3094. Please write ‘Event Submission’ in the subject line.

“We’re

Maryse Forgues and Yves Robert – FCC Customers

Together, we’ll create the financing plan that works for you. We get to know you, your farm and how you want to grow. If you’re ready to get down to business, talk to one of our farm business experts. fcc.ca 1-800-387-3232

CPRC Update Funding Program Returns to Normal

The Canadian Poultry research Council (CPrC) dedicated its 2013 funding budget, plus additional funds from our member organizations, to our application under agriculture and agri-Food Canada’s science cluster section of the agriinnovation Program (aiP). CPrC is returning to its practice of issuing annual calls for Letters of intent (LOi) in 2014 with a call in early april.

CPrC issues calls for LOi under two of its five main priority areas each year:

1. avian Gut Microbiology

2. environment

3. Food safety and Poultry Health

4. Poultry Welfare and Behaviour

5. novel Feedstuffs these priority areas are well-aligned with those identified in the 2012 document National Research Strategy for Canada’s Poultry Sector (available on the research section of the CPrC website, www.cp-rc.ca). CPrC prepared the strategy based on a number of workshops, conferences, discussions with industry members and other industry stakeholders, and input from its member organizations.

1. Avian Gut Microbiology : the avian Microbiology n etwork (aviMicronet) is a communication network of researchers designed to encourage the investigation of the impact of gut microflora on the nutrition, feed conversion, pathogen carriage and health of poultry in an antimicrobial-free environment. this effort has been put forth in response to growing pressures to reduce, or possibly eliminate, antimicrobial drugs from animal feeds.

2. Environment: the CPrC’s research program on environmental issues in the poultry industry has

supported a number of projects in a wide variety of areas. these projects include studies of the prevalence and effect of veterinary pharmaceutical residues in the environment, the direct injection of poultry litter on agricultural land, the environmental implications of phosphorus and calcium flows in poultry production, workplace exposure to environmental contaminants in commercial poultry barns, useful products from spent hens, and emissions from poultry operations.

3. Food Safety and Poultry Health: this program covers a wide range of topics with potentially far-reaching implications for the sector, including immunization of broiler chickens against necrotic enteritis, understanding the biology of avian influenza virus and finding better ways to control it, novel multivalent vaccines for avian health, and new ways to control enteric pathogens.

4. Poultry Welfare and Behaviour research within this program covers such topics as the impact of ammonia on the welfare of laying hens, improving transport conditions for broilers, alternative methods of euthanizing turkeys, effects of lighting programs on leg weakness in broilers, improving welfare for beak trimmed hens, maintaining leg and bone structure in turkeys, implications of toetrimming turkeys, alternative feeding strategies for broiler breeders, and the impact of day length on turkey welfare and productivity.

5. Novel Feedstuffs: there is an

emerging need for research on the use of feedstuffs that could be an alternative to current grains, prices of which are anticipated to remain high. research is underway relating to the potential animal health benefits of feeding distillers dried grains with solubles (ddGs), the nutritive value of cold-pressed meals from various grain sources, and the economic and nutritive impact of processing alternative ingredients in turkey diets.

the CPrC also funds projects that are of significance to the Canadian poultry industry, but may not fit into the broad research areas listed above. researchers may apply for funding for these projects at any time throughout the year according to the CPrC policy on ad hoc proposals (see the research section of the CPrC website).

CPrC’s board of directors will decide on the two categories for the 2014 call for LOi in March, and the call will be issued in early april, with a submission date in early June.

For more details on any CPrC activities, please contact the Canadian Poultry research Council, 350 sparks street, suite 1007, Ottawa, Ont. K1r 7s8. Phone: 613-566-5916, fax: 613-241-5999, email: info@cp-rc.ca, or visit us at www. cp-rc.ca. ■

The membership of the CPRC consists of Chicken Farmers of Canada, Canadian Hatching Egg Producers, Turkey Farmers of Canada, Egg Farmers of Canada and the Canadian Poultry and Egg Processors’ Council. CPRC’s mission is to address its members’ needs through dynamic leadership in the creation and implementation of programs for poultry research in Canada, which may also include societal concerns.

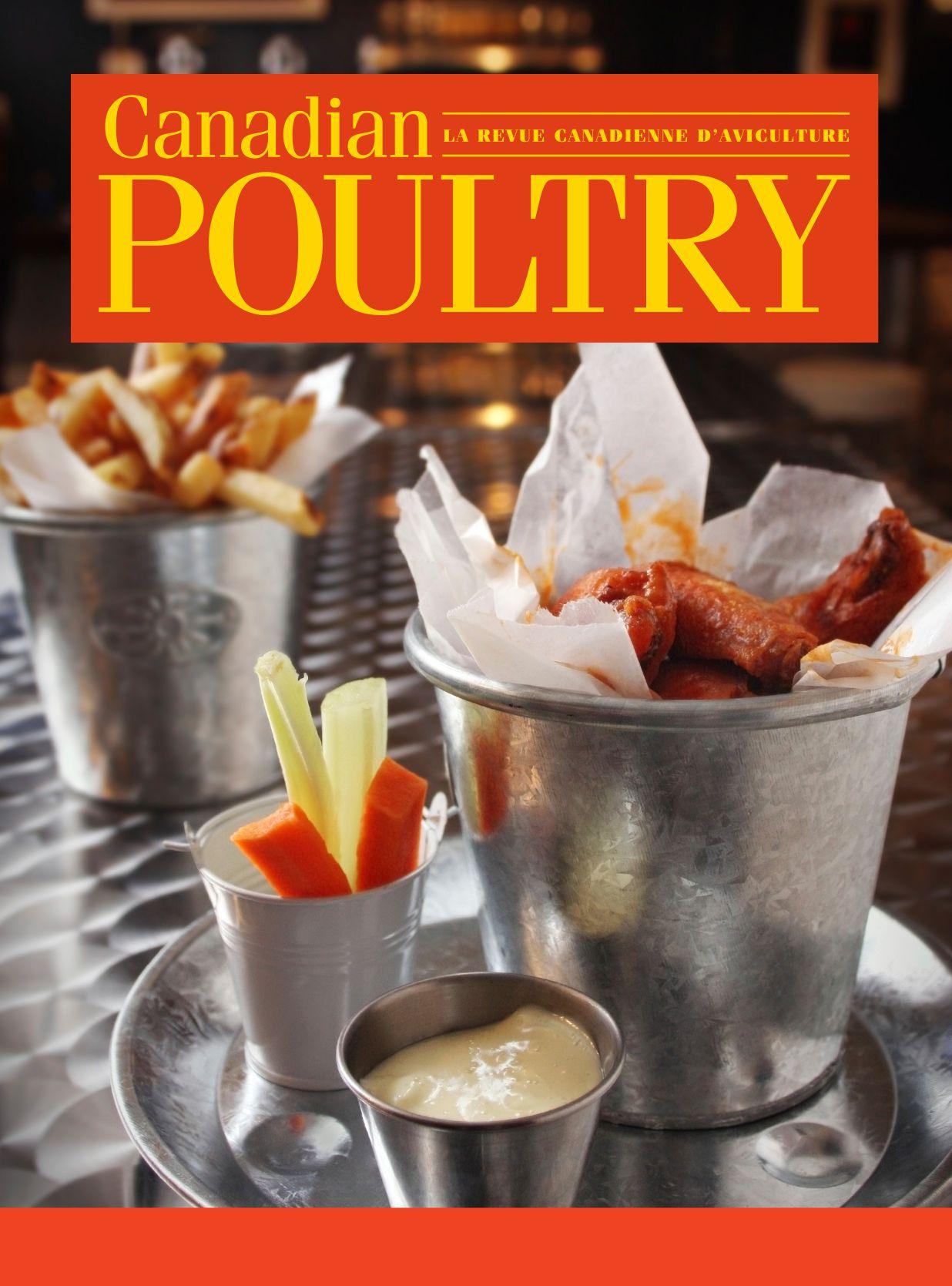

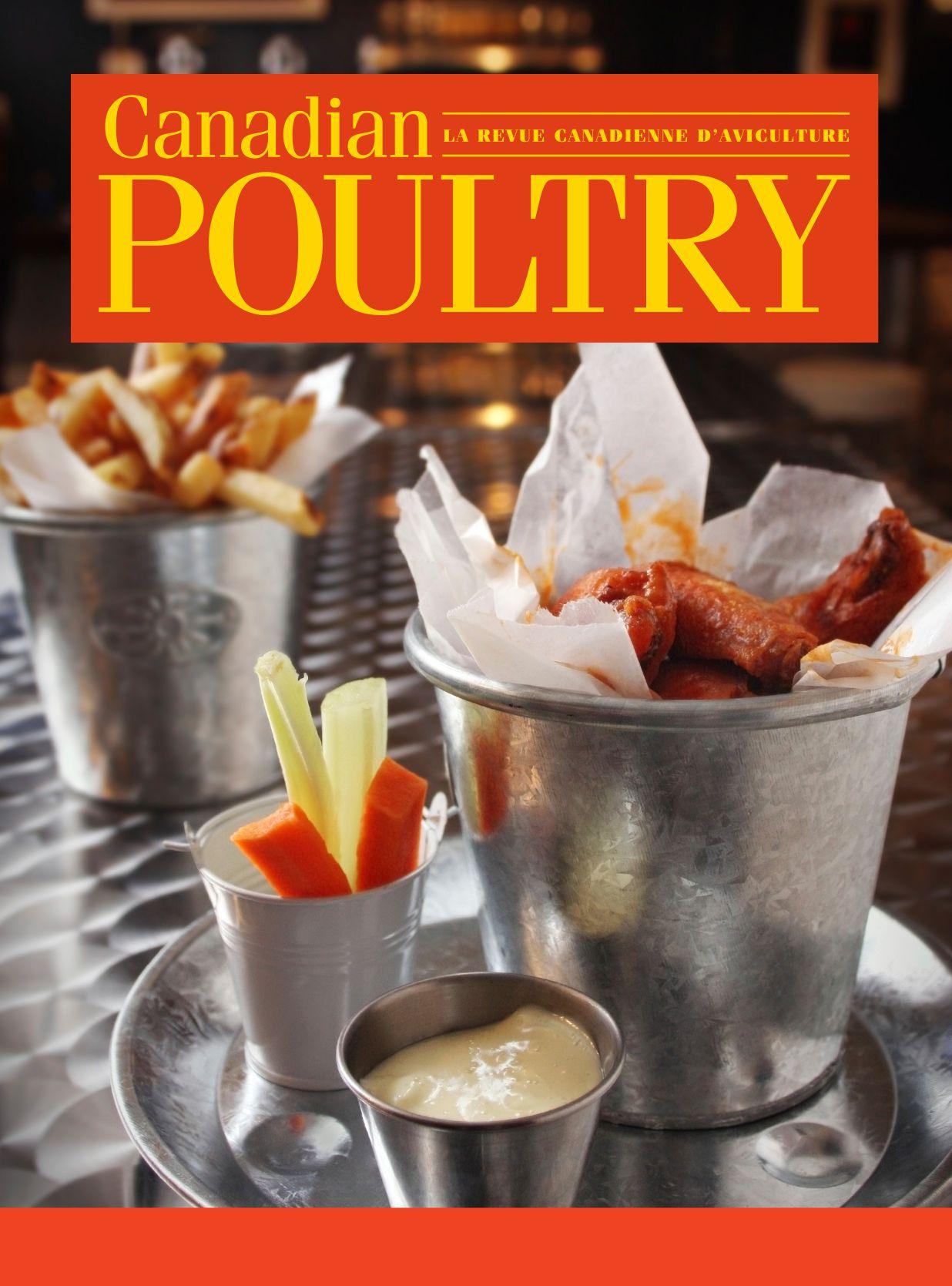

Cover Story Buffalo Wings go long

serving up the creation, history and future of buffalo-style chicken wings

BY T REENA H EIN

it is probably safe to say that teressa Bellissimo never foresaw that her Buffalo-style chicken would become such an enormous hit. she created and served the very first plate of wings in 1964 at the restaurant she and her husband Frank owned at the time in Buffalo, n.y., called the anchor Bar. the exact facts of just how and why they got on the plate aren’t completely nailed down, and since teressa, Frank and their son dominic have passed on, the story will always be a bit murky. Frank used to say it all started because their restaurant had received a shipment of wings instead of other chicken parts, and teressa created Buffalo wings as a way to get rid of them. dominic claimed they came about simply because he and his hungry teenaged friends dropped by the restaurant late one night and asked teressa for a snack. His mom, he says, decided to deep fry some wings and then covered them in her own special hot sauce – serving them with a side of blue cheese dressing and celery because that’s what she had on hand. and so, Buffalo wings were born.

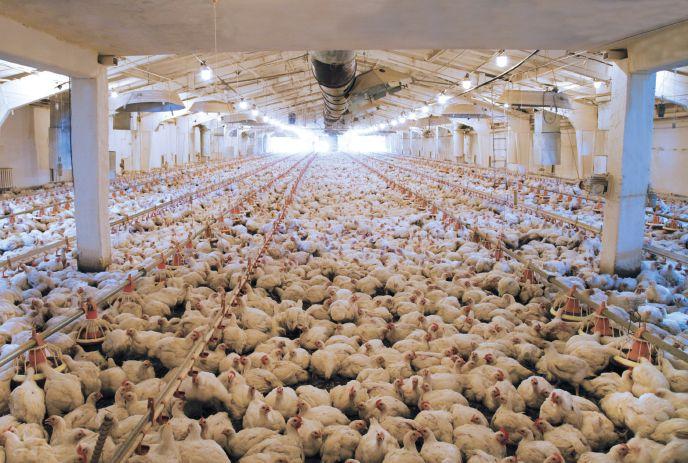

more than 100 million pounds of chicken wings were consumed during the 2012 superbowl, according to the u s national chicken council.

For many years, Buffalo-style wings were a regional food in the new york area, but by the mid-1980s, the snack had spread across the country. the city of Buffalo has celebrated Chicken Wing day every July 29th since 1977, and

every year 100,000 people flock to Buffalo’s national Buffalo Wing Festival in early september. and it is not only new york, as Philadelphia is also crazy for wings, and has held a competitiveeating contest known as the Wing Bowl every year since 1993 on the Friday preceding the super Bowl, where approximately 20,000 people attend the

sold-out event every February. Just how many wings are consumed? the 2012 winner set the standing record of eating 337 (yes, 337) wings in 30 minutes. in 1990, Mcdonald’s began selling wings at some of its restaurants, with Kentucky Fried Chicken joining in a year later and domino’s Pizza three years after that. there are currently

KiNg oF sNACKs goiNg

several restaurant chains with wings as their star offering, and flavours now range from original to lemon pepper, hickory smoked barbecue, cool ranch and many more.

Of course, super Bowl weekend is unquestionably the time of the year that most wings are eaten. “More than 1.25 billion wings [were] consumed during super Bowl weekend in 2012, totaling more than 100 million pounds,” states the u s national Chicken Council on its website. “if the wings were laid end-to-end they would circle the circumference of the earth – more than twice – a distance that would reach approximately a quarter of the way to the moon.”

the nCC also says that about 23 per cent of those who watch the big game eat chicken wings, and that they are consumed by three times the number of americans on super Bowl sunday than on a typical sunday at any other time of the year. about half of the wings consumed are ordered from restaurants, while the rest are purchased from grocery stores.

he says. Whereas jumbo wings from heavier birds are more popular in the united states. However, in both countries, boneless wings (chicken breast meat formed into the shape of a drumette) are gaining popularity.

“they’re catching on in the u.s. more than in Canada, [but] some wing restaurant chains in the u s. reported 40 per cent of wing sales now are boneless wings,” de Valk reports. “Last year, wings were so popular that wing prices exceeded the price of boneless breast meat for several months.” He adds that, “high wing prices do force wings off the menu, but lower prices quickly result in bringing the item back. this does cause price volatility – but the north american consumer’s love for wings is steady.”

Because the supply of wings is limited to the total number of chickens produced, when the demand for wings is stronger than the demand for other chicken parts – usually every december and January in preparation for the super Bowl – the price of wings goes up. north of the border, “When the toronto Maple Leafs do well in hockey, wing sales in the Greater toronto area increase,” explains robert de Valk, general manager at the Further Poultry Processors association of Canada. He adds, “when the nHL strike was on, the wings piled up.”

de Valk notes that Canadian demand for wings outstrips production by about 30 per cent, and that we import about 30 million kilograms every year, especially during the hockey, football and basketball seasons in the fall and winter. de Valk also points out that over the super Bowl weekend, americans consume almost as many wings Canadians do over the course of a year – but per capita, Canadians consume more wings than their u.s. neighbours.

in terms of the actual wing, the nCC says, “proper Buffalo wings should be snapped in half so that they resemble tiny drumsticks rather than their original, harder-to-eat akimbo shape. the vast majority of wings, especially those destined for foodservice, are disjointed, with the third joint (the thin part known as the flapper) being exported to asian countries and the meatier first and second joints being sold domestically. the wing is usually split into two parts or portions, known as the ‘drumette’ and the mid-section or ‘flat’ and sold to food service or retail outlets.”

Chicken wings make a great super Bowl snack, in the opinion of Chicken Farmers of Ontario board member Murray Opsteen, because they are so delicious. “they come with so many types of sauces, they can be dusted or not, they can be small or large, drumettes or wingettes, so everyone can get what they want,” he says. Opsteen remembers a super Bowl party he and his family hosted many years ago that included five-alarm chili and suicide wings. “Perhaps we went a little far…with a competition to see who could handle the heat,” he recalls. “the person who won really didn’t feel like a winner an hour later.”

Canadians prefer bone-in wings with tip removed, notes de Valk. “Popular sizes in Canada are 10 to 14 wings per kilogram or eight to 10 wings per kilogram, which are a bit bigger,”

in the early 1990s many restaurant chains such as domino’s Pizza began offering chicken wings and they are now a key menu item.

the best Grey Cup party Opsteen has ever attended also included wings – and the actual trophy. “it happened after the argos won,” he says. “it’s nice to wash down wings by drinking out of the Grey Cup. i am sure saskatchewan fans will have that opportunity this winter.” Opsteen adds – in case you were wondering – that the Grey Cup holds 11 beers. “the most compelling reason wings make a good super Bowl snack

is that they can be eaten with one hand,” he adds, “to allow a free hand to enjoy your favourite beverage.”

rhonda tucker, owner of the Millstream Market and Grill in Wellesley, Ont., says wings are by far her best seller. “People want to come in and sit down and have a beer and a plate of wings,” she says. “they love it.”

every tuesday is “wing night,” when the restaurant serves a new flavour of wings, and these have included spicy caesar (with hot sauce, caesar salad dressing and parmesan cheese), pineapple curry and sweet chilli thai. “People text me to ask what this week’s flavour will be,” tucker says. “at 50 cents each on wing nights, they can try a few and see if they like them without breaking the bank.” tucker will likely double her order of wings from her supplier again this year for super Bowl sunday and hopes the Patriots will be on the field.

to see what sort of wing eater you are, take the Buffalo Chicken Wing Personality test at www.visitbuffaloniagara.com/ food-and-dining/chicken-wings/wing-personality-test/. ■

For more industry articles, visit www.canadianpoultry.com

Actually More Concerned With What Comes

Technical Service

Delivering the best advice and support

Cobb business units in North America, EMEA (Europe Middle East, Africa), South America and Asia have their own technical service teams. They are a group of specialists covering a range of disciplines including breeder and broiler management, microbiology, veterinary medicine, nutrition, environmental control, and processing. The Cobb technical service teams have the resources, direct access and responsibility to support the technical needs of assigned customers assisting to take full advantage of the Cobb genetic potential.

PIC Update

Understanding immune Enhancement

nanotechnology-based immune modulators are being studied tas potential antibiotic replacement

B Y K IMBERLY S HEPPARD , R ESEARCH C O - ORDINATOR

The use of antibiotics as growth promoters and as prophylactic treatments to prevent disease early in the rearing period has come under increasing pressure. this is in part due to the issue of antibiotic resistance development in bacteria. Public pressure and subsequent government legislation has further restricted the use of antibiotics. this is a trend that is not likely to be reversed. as such the poultry industry faces the challenge of finding alternatives to the use of antibiotics.

it has been shown that the immune stimulant cytidine-phosphate-guanosine oligonucleotides (CpG Odn) can be beneficial in protecting chickens from bacterial infections caused by E. coli and salmonella species. this immune stimulant is effective both in young chicks and in older birds and appears to act by stimulating the innate immune system. Host defense Peptides (HdP), also known as antimicrobial Peptides, are naturally antibacterial, antiviral and antiparasitic, and have been touted as “natural antibiotics.” HdP also have activities that correspond to many aspects of innate immunity. HdP have been shown to enhance immune responses and to protect against infection by bacterial pathogens.

public pressure and subsequent government legislation has meant a rethink of how antibiotics are used in livestock production.

the barrier to effective use in the protein industry is threefold. t he compounds are expensive, relatively high doses are required, and the effect is relatively short lasting. However, an effective delivery system could help overcome these barriers. a good delivery system would enhance the efficacy of the product and reduce the cost of vaccination. ideally the delivery system would be compatible with a number of different compounds and have a good safety profile.

Odn nanoparticles show great promise for biomedical purposes because their physicochemical properties allow them to pass through biological barriers to get to intracellular targets. it is possible to link the nanoparticles with other molecules such as CPG Odn and HdP. not only can other molecules be conjugated to Cnt but also it has been shown in short-term studies that these particles have very low toxicity in the host. these characteristics make nanoparticles excellent delivery systems for immune stimulating particles.

nanoparticles such as carbon nanotubes (Cnt) can be used with a wide variety of immune stimulants including CpG

Polyphosphazenes are a group of synthetic polymers consisting of a backbone with alternating phosphorus and nitrogen atoms and organic side groups attached to each phosphorus

FiNdiNg AlTERNATiVEs

PROTECT PERFORM PROFIT POULVAC® E. COLI

• Help minimize record storage especially related to OFFSAP. 877-816-9425 info@feathercentral.com

PIC Update

atom. Polyphosphazenes have been shown to act as adjuvants to enhance adaptive immunity and when used in formulation with immunotherapeutic agents such as CpG Odn result in enhanced innate immunity. Polyphosphazene polymers can be formulated either in their soluble state or as microparticles. Poly[di(sodiumcarboxylatoethylphen oxy)phosphazene] (PCeP) has been widely studied and has shown the ability to enhance both innate and adaptive immunity.

dr. Brenda allan and her research team at the Vaccine and infectious disease Organization (VidO) have been studying whether carbon nanoparticles can be used to maintain the biological function of CpG Odn and/or HdP while enhancing the biological activity of immune stimulant without significantly compromising the host immune response and safety in the chicken model. the initial plan of the researchers was to combine both CpG Odn and HdP in a single formulation. However, the chemistry used to link HdP to the Cnt was different than that needed for CpG. this precluded the use of a single formulation that included both CpG Odn and HdP with the Cnt. Work done determined that the HdP they intended to use did not provide immune stimulation in poultry. Considerable work done in the laboratory also failed to identify a suitable candidate. thus the researchers concentrated their efforts on the formulation of CpG Odn for enhanced activity.

gkehl@firstpinnaclefinancial.com

Bifano 250-503-7438 Western Canada jbifano@firstpinnaclefinancial.com

through these efforts, the researchers have optimized the formulation of CpG Odn with Cnt using in vitro studies. they have also tested the effect of this combination in vivo using a salmonella challenge model of young chicks. Preliminary work showed that conjugation of CpG Odn to Cnt showed promise in lowering the dose of CpG required. However, they were unable to repeat these results in subsequent experiments. they therefore elected to test the effect of formulation of CpG Odn with either soluble or particulate polyphosphazenes as these formulations had been effective in other species and had shown promise in poultry. unfortunately, these formulations also did not provide enhancement tot the activity of the CpG Odn despite the failure to identify a delivery system that enhanced the activity of CpG Odn, dr. allan believes that this immune stimulant shows great promise for the replacement of antibiotics in the poultry industry. Further research is needed to develop a delivery system to make its use economically feasible, however. to read more, please visit www.poultryindustrycouncil.ca. ■

Health

FAo Urges increased Precautions

the risk of re-emergence of avian influenza a viruses requires increased surveillance and precautions

BY SA R AH FERGUSON

As flu seasons begins, the risk of re-emergence of avian influenza a viruses (aiVs) increases. in light of this, the Food and agriculture Organization of the united nations (FaO) is urging increased precautions and continuous surveillance by all countries.

Past aiV outbreaks have caused huge economic losses in the food and agriculture industry. the H7n3 aiV outbreak in British Columbia in 2004, for example, caused an estimated loss of over $300 million.1 Of even greater concern, however, is the potential risk of livestock-to-human transmission of aiV causing zoonotic disease, and the recent outbreak this year of the deadly H7n9 reported in China exemplifies this. While this outbreak may seem to be far away geographically, experience with the toronto sars coronavirus outbreak in 2003 illustrates just how closely we are linked by air travel in a way that nullifies any geographic distance.2

aiVs are classified as either highly pathogenic, which cause high mortality rates in poultry species and can infect humans, or low pathogenic, which are commonly associated with mild clinical symptoms in birds.3,4,5

Wild bird populations provide a continuous reservoir for the pathogenic aiVs, but high pathogenic strains are not usually found in these populations.5

proper biosecurity practices go a long way toward keeping your birds protected against diseases that are transmissible by wild fowl.

recent surveillance statistics show no evidence of highly pathogenic aiVs in Canadian bird populations, but low pathogenic viruses have been identified in most provinces, including Ontario.6 Because of its high pathogenicity in humans, there is concern about the H7n9 subtype in China, but because of its low virulence in birds, it remains difficult to detect and monitor disease transmission.

Most highly pathogenic aiVs belong to the H5 and H7 subtypes, and their occurrence must be reported to the Oie

World Organisation for animal Health.5 those that are highly pathogenic are believed to arise in poultry through genetic mutations that occur after infection with a low pathogenic strain from wild birds.4,7 transmission occurs primarily via infected fecal matter and contaminated water, but it also can occur via inhalation of infectious particles.5 since most poultry barns in Canada are contained populations, risk of transmission arises from secondary transfer by humans, vehicles and machinery moving among

BiosECURiTY EssENTiAl

Profile industry Tribute

celebration and appreciation of frank robinson’s contribution to the industry takes on a unique twist

BY KAREN DALLIMORE

if there were an Olympic award for poultry research and education, Frank robinson would have won it. an emmy? sure. an Oscar? that too, and maybe even a Country Music award after the recent 2013 Poultry service industry Workshop (PsiW) banquet in Banff, alta.

With fellow university of alberta researcher Martin Zuidhof on the guitar and the rest of the meeting delegates donning chicken hats, robinson was serenaded by his colleagues and friends with a version of Kenny rogers’ “the Gambler,” Cluck Style, as they saluted his long career of service to the poultry industry.

On a warm summer’s evenin’ in my barn north of Red Deer

I met up with my service rep, these birds just wouldn’t lay.

So we took turns a staring at the growth charts and the feed guide

‘Til inspiration struck him, and he began to speak.

He said, son I’ve made my life out of reading bird weight records

Of knowing how their birds fared, by the way their fleshing lies

So if you don’t mind me sayin’, I can see you’re out of aces

To save your production, I’ll give you some advice.

We picked up my dusty scale, and walked into the lay barn

Then we grabbed a chicken and held it by its thighs

And the night got deathly quiet and his face lost all expression

singing a tribute to their friend and colleague were (l to r): rob renema (renema poultry consulting), doug korver (university of alberta), Val carney (poultry research and extension, alberta agriculture and rural development), carlos lozano (grad student and winner of the psiw student scholarship) and martin Zuidhof (university of alberta).

Said if you’re gonna play the game boy, ya gotta learn to play it right.

robinson was being honoured as the 25th recipient of the annual PsiW Worker of the year award. When his name was put forth for nomination, the immediate reaction around the table was, “What? He hasn’t won already?” said Valerie Carney, for whom robinson has been a master’s supervisor, mentor and fellow researcher.

Carney co-wrote the Kenny rogers knock-off along with dustin Banks and Brenda schneider. they modelled their

presentation after a highly successful “edutainment” initiative created by robinson called “Heifer in your tank,” which challenges students to answer questions about agriculture through a series of skits and songs, bringing agriculture to everyone from children to seniors. the program was awarded the 2005 Canadian agri-Food award of excellence for agriculture awareness and education. Carney has been inspired to take this approach to producer meetings

Continued on page 39

ColoURFUl CHoRUs

“All

Johnny Heemskerk of Heemskerk Farms Ltd. owns and operates a broiler chicken unit in Norwich Ontario, where he has been farming since 2001. Johnny averages 21,000 per crop and has 5.8 crops per year.

Johnny has been using drySTART® on the floors of his chicken barns since 2011. He was using straw and was finding that it would stick and cake to the floors. After watching the drySTART® information DVD, he decided to give drySTART® drying powder a try. Once he tried it, Johnny said, “The difference was like night and day, the manure did not stick to the floors, which greatly reduced clean-out times and the birds looked a lot healthier and cleaner.”

Johnny uses drySTART® on both concrete and plywood floors. He applies drySTART® followed by a layer of straw. Some things Johnny has to say about the benefits of using drySTART® are: “All areas of my production have improved since I started using drySTART®. My birds are a lot more even and I have less condemns, clean-out times are a fraction of what they used to be and my hydro bill is less because I do not have to use my fans as much to keep the barn dry.”

Johnny has found great success in using drySTART® and looks forward to continuing to see the benefits in his chicken barns.

Johnny Heemskerk Heemskerk Farms Ltd. Norwich, ON

Business Making Transitions

determining what you would like the future of your business and your life to be

BY LAURA AIKEN

To put into scale how big of an issue succession planning is in Canada right now, consider that in the next five to 10 years, 70 per cent of today’s businesses will change hands. Or, as Grant robinson, director of the BdO successCare Program, likes to phrase it, “three out of four businesses will have reached retirement age in the next one to two car leases.”

robinson addressed an audience of food processors at a recent state of the industry event hosted by the Guelph Food technology Centre (GFtC). He works closely with family businesses across Canada and has a compassionate view of why succession planning is at the bottom of many people’s priority lists.

“succession to most entrepreneurs sounds like dying or neutering,” he said. “But most businesses transition hands many times.”

it feels negative because succession implies retirement, which is defined as taking something out of use, said robinson. People see their friends disliking retirement, and the view permeates. there will come a time when your business will be sold, voluntarily or involuntarily, and everyone will have two options for that sale: inside or out. at its bare bones, this decision seems straightforward, but robinson noted that it could take 10 years to make the choice.

“there’s no downside to getting ready to make an inside sale because you can always make the outside sale,” he said. according to robinson, less than 50

communication is the ticket to a positive succession plan for your business, as research suggests that 60 per cent of families failed to consider the effect of a communication breakdown in their business.

per cent of businesses have a succession plan, and around 80 per cent want to keep it in the family, but only half of them think it’s a reality. Currently, around 30 per cent of businesses successfully transition through to the second generation, while less than 10 per cent survive the third. in dollar values, demographics suggest that $1 trillion will change hands in Canada in the next decade. seventy per cent of wealth transitions in families are unsuccessful and 60 per cent of families failed to

consider the effect of a communication breakdown within their business.

starting with this last point, there are some strategies that can prevent a communication breakdown during the transition of your business to the next generation and focus on preparing for an inside sale.

the positive mental approach is to treat the future of your business as a transition

MAKiNg A PlAN

YoU lEAd THE WAY

rather than a succession, said robinson, adding that most entrepreneurs have transitioned their business many times without realizing it. Most importantly, this is an initiative that you need to lead.

robinson’s GFtC talk outlined several different considerations you will need to take into account when planning for the next generation, such as the wellbeing of family members, continuing a profitable and successful enterprise, and establishing a cohesive ownership and vision. it is helpful to develop a plan to transition all types of capital as well: physical (equipment), social (staff) and intellectual (the business environment of competition, consolidation or decline). For you to make a smooth transition to the next adventure in your life, you need to ensure their business can thrive without you.

the business and provide direction on topics such as compensation –in essence, the components of a shareholders agreement should be addressed.

Meetings should be conducted with an agenda with an open conversation with fellow employees about areas of concern. i f you fail to find the

structure on your own, bring in family council or an advisory board.

However unpleasant to think about, this is a good time to be transparent about what is in your will.

“ avoid the golden handcuffs. d on’t force kids to be in the business or to partner with each other,” added r obinson. “ d on’t let your kids find

Watering Wisdom 3

Water spillage and dry litter? Yes it is possible.

Key Principle:

in preparing for an inside sale, don a “we” focus and take into account the dichotomy of business and family life. t he principles, values, history, relationships, moods and personalities of those involved are an important factor to consider. On the other hand, there are the structural realities of common interests and facts between the involved parties (which robinson noted are negotiable because perception is reality). Bear in mind that 96 per cent of family business transition plans fail to find a positive outcome by focusing on the past, and 70 per cent succeed by focusing on the concrete side of common interests and facts.

Getting everyone on the same page is critical, r obinson stressed. e ighty per cent of transition planning is communication on subjects like policies for family promotion, accountability, responsibility and authority (the latter being the one that is typically not addressed). e veryone needs firm rules about how people will exit the business. t herefore, it is advisable to create documents that support paying for people entering and exiting the company in ways that don’t harm

Even when litter under the drinker line is dry, water spillage can still be happening because other factors (such as ventilation, heating and litter materials) can mask spillage to the extent that dry litter is artificially maintained.

Aggressive ventilation keeps litter artificially dry.

With this in mind, a focused producer will adjust water column pressure throughout the year to match seasonal and weather related changes. This may mean, for example, that a producer should use significantly lower column pressure settings during cooler weather or when ventilation is reduced in order to maintain dry litter.

Key Directive: Drinker line column pressure must be adjusted throughout the year to match changing environmental conditions. Learn about best management practices and much more at Ziggity’s Poultry Watering U website.

How-to videos • Poultry Watering U news • Management downloads

FACToRs To CoNsidER

Polar proof!

• Tested under Arctic conditions ( -33°C / -27°F )!

• Will guarantee a reduced icing and all mechanical parts will stay in function

• Reduces energy costs massively by ongoing forced ventilation (no cycle timer)

• Spreads the temperature uniformly inside the stable, minimum ventilation rates can be achieved to the requirements of the animals

out what you’ve done through the will unless a Ouija board works because there’s going to be questions.”

in preparing for an inside sale for your business, the purchaser may or may not be family. in Effective Succession Planning/Ensuring Leadership Continuity and Building Talent from Within, author William J. rothwell outlines a 10-step plan for developing internal candidates for promotion:

• Step 1: identify the key position(s) for which the individual is being trained and ensure the person is aware and interested.

• Step 2: determine how much time is available to develop the person for their new role.

• Step 3: Figure out which skills he or she still needs to learn by thinking about it as a performance appraisal, but from the vantage point of the position he or she is being groomed for.

• Step 4: Be specific about the learning objectives you determined in step 3. decide what equipment, education or what else will be needed to close the information gap. How will you measure the learning objectives and under what conditions must the person perform?

• Step 5: Lay out the learning strategies needed to achieve step 4, and be aware that here may be things needed such as time away from work for further training, mentoring, or experience with specific equipment.

• Step 6: develop clear measurements and provide feedback on progress as concrete evidence of accomplishment.

• step 7: determine how performance evidence will be validated: through passing training? Oral testing?

• Step 8: review the plan with others, such as a spouse, peers or colleagues.

Frozen fresh air inlets present major problems for livestock owners

Reventa Poultry mar

• Step 9: Carry out the plan with an eye on time span and consider the consequences of failing to implement the plan.

• Step 10: evaluate where the person stands on the outcomes when you look at the goals.

Business

remember, you are far from alone on this journey!

“Because everybody is unique, we are very much the same,” said robinson. ■

Laura Aiken is a Toronto-based full-time editor at Annex Business Media and has been a working journalist for over 10 years.

For more on business, visit www.canadianpoultrymag.com

there are many reasons why exiting your business is a terrifying prospect. Firstgeneration entrepreneurs put everything into the business, said robinson, and then can end up 60 years old and on allowances. He has seen many cases of typical entrepreneurs having a specific type post-business ownership experience: ninety days after the business is sold, the phone stops ringing and they go a bit stir-crazy. eighteen months later they start investing in things they know nothing about. if you know someone doing these things, rest assured they are not alone.

although small business owners may be reluctant to admit it, their identity is wrapped up in their business and this is one of the biggest exiting issues, said robinson. if it is a lifestyle business, there is essentially nothing to sell but the equipment. if the business is professionalized and there is a team that can run it without you, then there is an entire business to sell. the decision may be to sell off the equipment and close up shop, and that is perfectly OK. it seems fair to say it’s best when that happens voluntarily.

remember, the transition of your business rests on your leadership.

“if left to the spouse and kids to sort it out, that’s where people spend tens if not hundreds of thousands of dollars on accountants and lawyers,” said robinson. there are resources to help you along the way – the BdO website (www.bdo.ca) has a discovery Questionnaire intended for family/stakeholders to answer and then discuss the results together. the Canadian association of Family enterprise (www.cafecanada.ca) also has a variety of resources at its disposal.

Static flow rates are meaningless.

Key Principle:

You can’t use an invalid concept to create drinker standards.

Birds drink by pecking intermittently on the side of the trigger pin (dynamic flow), so why set a standard based upon lifting and holding a trigger pin straight up (static flow) for one minute. This makes no sense! Unfortunately many in the industry still use this false procedure to evaluate drinkers even today.

1

It is also assumed that a drinker with a higher static flow rate will discharge proportionally more water when triggered dynamically. However, tests prove this assumption is false! (see video at poultrywatering.com/4).

Key Directive: Don’t use “static flow rate” to evaluate a drinker’s merit or to manage a drinker line. Learn about best watering management practices and much more at Ziggity’s Poultry Watering U website.

• How-to videos

• Poultry Watering U news

• Management downloads

2

should be designed to work in harmony with the way birds drink-intermittent pecking (Fig. 1).

Holding the drinker trigger pin up (“static flow”) does NOT replicate the way birds really drink (Fig. 2).

Peck Release Peck Release Drinkers

Fig.

Fig.

Industry Checking in with the CPEPC

increased government relations, ensuring consumer confidence lead cpepc efforts in 2014

BY L ILIAN S CHAER

The core issues of supply management, food safety, animal welfare and animal health are the focus of activities for the Canadian Poultry and egg Processors Council (CPePC) in 2014. this stems from the recent completion of the organization’s strategic plan, a real milestone for 2013, says CeO robin Horel in a new year’s interview.

“Finalizing and implementing our strategic plan is a real success for us in the last year. it’s administrative, but it was a real process to work through and get a plan and goals for the organization in place that all members in all provinces and all sectors could agree to,“ he says. “We’re now beginning to implement the plan, which sets our mandate and will govern our activities for the coming year.”

CPePC is a voluntary industry trade association that represents approximately 170 poultry and egg processors, egg graders and hatcheries, as well as close to 60 associate members that include industry partners and suppliers. now in its 64th year, the organization’s membership represents over 90 per cent of Canada’s volume in chicken, turkey, eggs and hatcheries, and includes all of the major industry participants. the council elects directors to each of the four national feather agency boards, with three seats on the egg Farmers of Canada and two seats each on

looking back on 2013, increased animal activist pressure and work on new food safety regulations were key focus areas for cpepc robin horel, ceo, talks about the goals of the organization through 2014 and beyond.

the Canadian Hatching egg Producers, turkey Farmers of Canada and Chicken Farmers of Canada.

“the tie that binds all of us together is the poultry industry and supply management,” he says, noting that membership numbers have been fairly stable in recent years. “What makes us different from other national commodity

organizations is that they represent the farmers and we are the next step in the chain. We are customers of the farmers, with the exception of the hatcheries who are suppliers to chicken, egg and turkey farmers.”

Horel and his staff of five spend approximately half of their time working on lobbying and advocacy specific

MAKiNg A PlAN

Industry

to supply management, and the remaining time on other government relations activities, including working with the Canadian Food inspection agency (CFia), Health Canada, agriculture and agri-Food Canada (aaFC) and international trade Canada.

the new CPePC strategic plan is built on four pillars, and three mirror the supply management pillars of the national feather agencies – price setting powers, the authority to set supply and production at a level that matches demand, and addressing the rules around poultry imports. CPePC’s fourth strategic pillar is focused on continuing to build trust with customers and consumers, both in general and on key issues such as food safety, animal welfare and animal health. One such issue is the threat of avian influenza (ai), the biggest disease threat facing poultry at the moment. Horel says the industry has made a lot of progress on ai preparedness since the 2004 outbreak, including work on zoning, surveillance, cleaning and disinfection procedures, and containment and elimination protocols in case the disease is found in Canada.

Looking back on 2013, increased animal activist pressure and work on new food safety regulations through CFia and Health Canada, as part of the new federal Safe Food for Canadians Act, were key focus areas for CPePC.

MULTIHEAT WARMWATER HEATERS FOR PERFECT CLIMATE CONDITIONS

l No CO2 production in the house

l Ammonia reduction

l Dry litter

l Even spread of temperature

l Less energy costs

l Improved chicken health

l Suitable for heating and cooling

l 25-50-60-70 kW

(+31) 342-712033 Fax + (+31) 842-104525

Netherlands

“Food safety is and always will be a huge issue for us. animal welfare is also becoming a bigger and bigger issue, so we have to work closely with the feather agencies, aaFC and CFia on a number of animal welfare files, including animal health issues around disease,” he said.

to address these issues, the organization has invested time and energy into the national Farm animal Care Council, is working with CFia on transport regulations and is also collaborating with customers who have requirements for animal welfare audits in processing plants. However, Horel says that the biggest challenges for his members last year were allocation and supply setting, particularly for chicken.

“the commodity boards have the power to determine production levels. Last year, in our opinion, they got it wrong and produced too much chicken for the demand, and when that happens, prices go down to get it through the marketplace,” he explains. “My members have invested a lot into this system as well so it has to work for us not just farmers. We had expected a good year for chicken in 2013, but it didn’t transpire.”

Getting that allocation right is the number 1 priority for both chicken and turkey for 2014, he says, adding that generally CPePC would like all of its members to have more ability to influence the annual allocation numbers.

Overall, 2014 will see CPePC increase its focus on government relations and building the organization’s profile, especially with respect to influencing the modernization of supply management. Horel believes that if that’s not done, the industry will quickly become at risk of losing the consumer and government support the system currently enjoys, which will jeopardize its future existence.

“We need to modernize supply management to keep it going and we want to be a positive agent for change in that process. Government supports supply management through trade deals, but to keep that, in our opinion, we need to keep that consumer licence for our system,” he says. “Consumers need to support allowing farmers in every province to produce poultry and to make a fair return doing that. We believe consumers will continue to be supportive if they feel the system is working.”

Horel says that 2014 will also be a big year for regulatory change driven by modernization efforts at the CFia. He sits as a member of an ad hoc advisory committee with CFia senior management that is providing input into the regulatory changes during the development stage.

“this is driven by a real need to ensure that food is safe and if we get it right, it will be good for all of us. anything that [helps] consumers have high confidence in poultry products is a good thing, but we have to make sure it is done correctly and that the burden is not unwarranted,” he said. “the amount of change that CFia is working through is impressive and i’m pleased to be part of that process.” ■

AlloCATioN KEY

Industry Beyond the Crisis

Quebec egg farmers have nothing to hide, but how can this confidence be conveyed to buyers?

B Y A NDR é D UMONT

CtV’s W5 story showing bad treatment of layers and chicks on alberta farms was never aired in French, but it did have repercussions in Québec. a t the Fédération des producteurs d’oeufs de consommation du Québec (FPOCQ – Quebec e gg Farmers), serious brainstorming is going on, to find ways to reassure egg buyers.

the images that Mercy for animals Canada provided to W5 caused the phone to ring at the FPOCQ, and communications manager Philippe Olivier had consumers asking about housing systems. “after talking to them, they understood a lot better. i explained that animal cruelty is not related to a specific cage system,” he says.

More importantly, inquiries came from major egg buyers. in the egg processing and retail industries, the big players are the same across Canada, says FPOCQ president Paulin Bouchard. the crisis had an impact on all egg farmer associations, he says.

“We have no doubts about our farmers’ behaviour with their birds,” says Bouchard, an egg producer in saint-Gédéon-de-Beauce. “We know our members and they know their trade very well. i don’t think there are actual animal welfare problems out there. the real problem is how to communicate and reassure the people.”

Bouchard was able to identify the different types of housing systems

TRANsPARENCY

inside fpocQ’s egg interpretation center, 48 layers are housed in battery cages. canadian retail council vicepresident nathalie st-pierre.

used in amin Valji’s two edmonton-area farms. “i didn’t see housing equipment problems,” he says. “What i saw were human behaviour problems with bird handling and euthanasia methods. they are all things that could have been corrected in 10 minutes.”

However, the harm is done. How can the damage be repaired?

Bouchard uses an analogy: if you were accused of mistreating your kids, what could you do to reassure people in the community who no longer trust your parenting skills? take your kids to disney World, or publish pictures of you caring for them?

‘’We have great trust in our members, but how can we transmit this trust to

Photo courtesy Mary-Lou VandenOuweland

L’ industrie Aprés la crise

les producteurs d’oeufs Québec n’ont rien à cacher. mais comment transmettre cette confiance aux acheteurs?

PAR A NDR é D UMONT

les images de mauvais traitements de poules et de poussins tournées en alberta et diffusées à l’émission d’enquê te W5, sur le réseau CtV, ont eu des répercussions jusqu’au Québec. à la Fédération des producteurs d’oeufs de consommation du Québec (FPOCQ), on réfléchit sérieusement aux moyens pour rassurer ceux qui écoulent les œufs aux consommateurs.

tournées clandestinement pour le compte du groupe Mercy For animals Canada, ces images ont fait sonner le téléphone à la FPOCQ. Philippe Olivier, agent aux communications, a du expliquer les systè mes de logement à quelques consommateurs. « aprè s leur avoir parlé, ils comprenaient beaucoup mieux et condamnaient beaucoup moins », dit-il.

Les échos les plus importants sont venus des grands acheteurs d’oeufs, qui demandent des explications. du côté de la transformation et de la vente au détail des oeufs, ce sont les mê me principaux joueurs partout au Canada, explique le président de FPOCQ, Paulin Bouchard. La crise touche donc tous les regroupements d’éleveurs, soutient-il.

« nous n’avons pas de doutes sur le comportement de nos producteurs. On les connait, on les côtoie et ils connaissent trè s bien leur métier. Je ne pense pas qu’il y ait de réels problè mes sur le terrain, affirme Paulin Bouchard, lui-mê me producteur d’oeufs à saintGédéon-de-Beauce. Le véritable problè

TRANsPARENCE

à l’intérieur du centre d’interprétation de l’oeuf, 48 poules sont logées dans des cages conventionnelles. nathalie st-pierre, viceprésidente au conseil canadien du commerce de déstail.

me, c’est de communiquer et rassurer les gens. » en visionnant les images tournées sur deux fermes appartenant à amin Valji, prè s d’edmonton, Paulin Bouchard a bien pu distinguer les types de logement utilisés. « Je n’ai pas vu de problè me d’équipement, dit-il. il y avait des problè mes comportementaux, dans la manipulation des poules et les méthodes d’euthanasie. Ce sont toutes des choses

qui auraient pu ê tre corrigées dix minutes plus tard. »

Le mal est fait. Comment réparer les dommages?

Paulin Bouchard s’explique par une analogie : supposons qu’on vous ait accusé de maltraiter vos enfants. Quels gestes poserez-vous pour rassurer la communauté? emmener vos enfants à disney World, diffuser des images en train de les bercer?

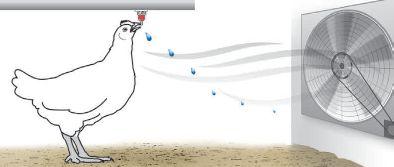

Centrifugal Cooling System

fan

• 12” – 24” diameters • Polyethelyne housing

• with Multifan or Performa+ Leeson motors

Genius picture Ge-430

• Genius 430LS Livestock climate control

• User friendly Interface (hot Keys)

• Large Display Screen for easy viewing

• Up to four variable stages and 30 off/on relays

• Expandable to 50 relays with relay module

• Up to 12 temperature sensors , one Humidity sensor

• Up to 12 heat zones, 12 cool stages, 2 light programs

• Up to 5 water metering, 2- 0-10volt outputs for dampers

• can operate Dual, natural and tunnel ventilation

• “Solarwall boost”, outdoor, humidity over-ride logic

Poultryhouse

• High quality material and aerodynamic air inlet

Fan

• Variable speed Performa+ motor

• Dual voltage, fully enclosed motor

• Low energy consumption and noise level

• 16” and 20” models producing 2792 and 4770 cfm

• Includes hanging hardware

SELECT DOSER

• Select Doser dispenses products accurately into low and high pressure watering systems through it’s tubing via compression and peristalic action.

• Aggressive products and powders never pass through the pumps mechanism that can cause premature wear and maintenance.

• New improved Model 640 is now simple to use with one tube size

• New Select Doser Max can now operate in high pressure and volumes

PSI

• Total stainless steel construction

• Hi-Low switch

• Watertight enclosures

• Propane and natural gas

• Available in 40,000 to 225,000 BTU units

• Available in pilot or spark Unvented Unit Heater

RECOV-AIRE HEAT EXCHANGERS

• Recovers wasted

72” fan

• Heavy Duty fiberglass housing

• Heavy Duty 6 blade alum. Propeller

• Twin gates Size A belts with Auto tensioner

• 3 hp , single or 3 phase motor

• Optional cone for max air flow

traP/ Dark OUt

• High light reduction

• Low resistance to air flow

• Simple Installation

• Easy to clean

• Uses P.V.c. snap release spacers

« nous avons confiance envers nos producteurs, mais comment transmettre cette confiance aux consommateurs, ou à ceux qui mettent en marché nos produits? », se demande le président des FPOCQ.

dans un premier temps, la FPOCQ

L’ industrie

a entrepris de dresser la liste des intervenants et groupes de l’industrie chez qui les activistes animaliers peuvent semer des doutes au sujet du bien-ê tre des pondeuses. reste à déterminer les moyens de communication pour les rejoindre efficacement.

La révision du Code de pratiques pour les poules pondeuses n’apportera pas grand changement, soupç onne Paulin Bouchard. Les audits existants viennent déjà confirmer que les éleveurs utilisent des systè mes de logement adéquats. « Le problè me est d’ordre comportemental, dit-il. On n’aura jamais un programme qui permettra de surveiller à temps plein la faç on de se comporter nos producteurs et leurs employés » si ce qu’il faut pour rassurer les détaillants sont des audits non annoncéèws, réalisés par des tierces parties, la FPOCQ ne s’y opposera pas. « il faudra s’entendre sur l’objet des audits. Comment fait-on pour vérifier un comportement? », se demande Paulin Bouchard.

La FPOCQ encourage déjà ses membres à se comporter comme s’ils étaient surveillés. « Je dis à nos membres : faites comme s’il y avait une caméra dans votre poulailler. si un journaliste ou un inspecteur débarquait à l’improviste, vous pourriez toujours ê tre fier de montrer ce que vous faites », raconte Philippe Olivier.

Presque à tous les ans, un producteur d’oeufs accueille le grand public lors de la Journée Porte-Ouverte de l’uPa, qui a attiré plus de 200 000 visiteurs sur une centaine de fermes en septembre dernier. en 2013, FPOCQ a aussi fait visiter un pondoir à des représentants des chaînes de détaillants, du gouvernement et d’autres acteurs de l’industrie.

Pour mieux informer le grand public sans compromettre la biosécurité des fermes, la FPOCQ a mis sur la route en 2005 son Centre d’interprétation de l’oeuf. à l’intérieur d’une remorque de 16 mè tres, 48 poules logent dans des cages conventionnelles, à une densité identique à celle retrouvée chez les éleveurs.

« au début, on avait un peu peur, mais la réaction des gens a été trè s positive, rapporte Philippe Olivier. Les visiteurs comprennent pourquoi les poules sont dans des systè mes de cages. »

Le Centre d’interprétation de l’oeuf se déplace dans les écoles, les festivals et lieux publics. à ce jour, 150 000 visiteurs en ont franchi les portes. ■

Profile

Continued from page 22

through a similar program she calls “Cluck,” acting out answers to biosecurity questions, for example, in a memorable way.

Frank robinson joined the university of alberta in 1986 as assistant professor in poultry production and physiology, with two dozen graduate students under his supervision over the years. His research placed an emphasis on reproductive efficiency of broiler breeders, something that captured his curiosity early in his career. “as you select for growth, reproduction becomes more of a challenge,” he says. He feels fortunate to have forged links with industry so that his team was able to work closely with primary poultry breeders to keep their research close to reality.

robinson has since received numerous awards, including the prestigious rutherford award for excellence in teaching at the university and the 3M national teaching Fellowship – what Frank calls “the big one” – recognizing exceptional contributions to teaching and learning at Canadian universities. additionally, in 2006, robinson was inducted into the alberta agriculture Hall of Fame.

along with his poultry team, he received the World Poultry science association education award for the university of alberta’s Poultry research Facility in 2004 in recognition of an outstanding contribution to the development of the poultry industry.

His dedicated fellow poultry faculty members, known collectively at one point around the university as the “Coop of seven,” have been awarded numerous group

awards for teaching as well. together they have helped to turn out practically trained students that have problemsolving skills and are able to think on their feet. robinson has been instrumental in bringing together academia and industry with the development of the alberta Chicken Producers Poultry technology Centre at the university of alberta, which features a Lilydale classroom, a student computer laboratory, a poultry processing and packaging laboratory, and an incubation and hatching facility. the Center has now expanded to include exploration of valueadded areas of meat and egg science, and it also provides the home base for the ‘adopt a Heritage Chicken’ Program, where people pay to sponsor an antique hen in exchange for receiving weekly fresh eggs. the program now has 600 subscribers and a waiting list while the funds help pay to preserve unique genetic lines.

While he still enjoys the opportunity of teaching in the introductory animal science class, in 2008 he moved into full-time administration as viceprovost and dean of students at the university of alberta, with a student population of 38,000.

“the opportunity to have been able to work with younger generations of poultry people and to help shape them to lead the industry has been a highlight of my career,” robinson concluded. “in every respect the Canadian poultry industry has been supportive in having the arena for this to take place. this next generation is an outstanding cohort who are already advancing the science of poultry production in new ways.” ■

Optimum Egg Quality

The Optimum Egg Quality Handbook describes in detail all the main egg defects, internal and external, and looks at the possible causes and corresponding control measures. A comprehensive practical guide to improving egg quality.

A fresh egg, with a clean, smooth, brown or white shell, a pure, deepyellow yolk and a translucent, firm white — this is the ideal of the egg producer and the consumer. How can producers make sure that hens lay more eggs like this, and fewer with shell or internal defects?

The Optimum Egg Quality Handbook describes 15 shell defects and 9 internal defects, each illustrated with a colour photograph. It explains the possible causes and corresponding control measures for each defect. Egg producers and anyone else interested in poultry management will find this book a comprehensive, yet clear, simple and practical guide to improving egg quality.

THE BACK PAGE

By roy maxWELL

drug addiction in agriculture

As i sit applauding from a front row seat, the Canadian poultry industry will officially end the preventive use of Category 1 antibiotics on May 15, 2014. For parent breeder flocks, the date is May 15, 2015. this new policy does not include Category 1 antibiotics used to treat diseases.

Category 1 antibiotics are of concern to human health agencies because they belong to the same family of drugs that human medicine depends on, especially when treating some very difficult cases. they contribute to the global problem of bacterial resistance to antibiotics. these antibiotic-resistant bacteria are often called “superbugs” and they have become a serious and worsening problem, particularly in hospitals and nursing homes.

My own interest in the subject stems from a personal and professional interest in this issue. My father was allergic to penicillin and needed to wear a medical bracelet because if he was given penicillin, it could have killed him. He also had a problem with eating meat, which was an ongoing frustration for him because he was a meat and potatoes kind of guy. sometimes, he broke out in a nasty and itchy rash, while other times he did not. eating meat was always a gamble. dad wasn’t a scientist and neither am i, but between the use of penicillin in agriculture and his rashes after consuming meat, we concluded it was more than a coincidence. i understand that antibiotic residues and antimicrobial resistance are two separate issues, but, nonetheless, it was my father’s penicillin allergy that piqued my interest in the use of antibiotics in agriculture.

disease in the Ontario chicken industry. therefore, May 15 is going to be just another day at the hatchery and on the farm –for Ontario chicken growers, at least.

By 2009, most Ontario hatcheries had stopped using Category 1 antibiotics for prevention and no major companies have used them since 2011. Hatcheries focused on how to control inputs, and they studied the root causes of dependency on antibiotics. they recognized that chick health and mortality can stem from a bacteria problem in the breeder flock, the hatching egg, or the barn environment. they began by encouraging hatching egg producers and u s. suppliers to provide a consistently higher quality egg from domestic and imported breeder flocks. this required more diligence regarding biosecurity, handling and sanitation. then they focused on the hatchery process – egg transportation, storage, incubation, and sanitation methods and products used in all of these processes. issues such as cross-contamination were effectively negated. attention to detail and introduction of HaCCP principles at hatcheries became the norm.

Hatcheries report that chicken farmers have embraced the hatcheries’ decision to supply only

1 antibiotic-free chicks.

My professional concern began when, early in my poultry industry career, one of my first activities was to tour a feed mill. as part of the tour, i was shown the “drug room” and when i saw a bin marked “penicillin,” i thought of my dad. in the fall of 2013 – almost a quarter of a century later – i was delighted when the Ontario Broiler Hatching egg and Chick Commission (OBHeCC) invited me to meet with four members of the Ontario Hatcheries association who sit on the OBHeCC board of directors. We spoke for an hour and i learned a lot, including the fact that Ontario hatcheries have already stopped using antibiotics as a precautionary measure to prevent