FOOD BEVERAGE

Higher demand for food for the growing population, means more work for farmers to produce more food.

The new way to enhance plant performance and reliability.

How CMMS enabled a 400 per cent Increase in work order completions.

Higher demand for food for the growing population, means more work for farmers to produce more food.

The new way to enhance plant performance and reliability.

How CMMS enabled a 400 per cent Increase in work order completions.

As the ebb and flow of restrictions on the food and beverage industry continues as a result of the COVID-19 pandemic, many people are once again making their own food creations at home.

Depending where you are within Canada, you may be able to go for a meal, and dine-in at any restaurant in your city. However, for many, especially in larger cities, the only option is either eating outdoors, or in some cases, getting your food for takeout/delivery.

In years gone by, eating at home was the norm, but as our lifestyles and eating habits have changed (I’m looking at you fast food), more people have been going out for meals.

Now, with the pandemic forcing many to spend more time at home (working from home, taking care of kids, etc), the love of making a meal is coming back. While this may not be good news for the restaurant sector, it is good news for the grocery/food sector.

Personally, my nine-year-old daughter, and even her little sister (twoyears-old) always want to help with making the daily meals. While in many cases that means washing the fruits/vegetables, spinning the salad, putting things into pans/pots/bowls, and getting all the ingredients, it’s the family time making the food that is what is important.

These days instead of buying frozen pizza, or takeout/delivery pizza,

we get all the ingredients from the grocery store (sauce, cheese, dough, toppings), and make homemade pizza at home. This is also true for many other meals, too numerous to list.

I suspect that I am not alone in taking advantage of the new found time to make food with my kids, and as a result of this, many restaurants and fast food establishments are seeing large drops in revenue year-overyear. Even Tim Horton’s parent company Restaurant Brands International recently announced it has seen a drop in revenue as a result of the changes in how people consume food. Many are no longer stopping at their favourite coffee shop on their way to or from work, as many are now working from home, and making their tea/coffee with their new or almost forgotten old brewer.

If anyone has an interesting story about how the pandemic has changed their food habits, or how it has changed how your company is doing business, don’t hesitate to let us know.

Good day,

Mario Cywinski, Editor

Aggressive cleaning practices are necessary to meet today’s food safety regulations. ABB, Baldor-Reliance® and Dodge® Food Safe motors, bearings and gear reducers can improve the reliability of clean-in-place procedures and provide you with the safe production you expect.

Improved cleanability. Extended life. Reduced maintenance. new.abb.com/motors-generators

Elmhurst 1925 plant-derived beverages are now available in Canada. Their beverages include almond, oat, cashew, walnut, hazelnut and hemp, and are made with six or fewer ingredients (unsweetened milks contain only two — the base nut or grain, plus water).

Elmhurst Milked products can be found at Whole Foods, Farm Boy, Pusateri’s Fine Foods, Healthy Planet and Eataly, and online at well.ca.

Nielsen Canada has announced they will form a strategic alliance with District Ventures.

“ We’re thrilled to be providing support and leadership to District Ventures ’ ecosystem and the District Ventures Accelerator Program, ” said Richard Lee, VP of Strategic Alliances, North America. “ Having access to Nielsen’s robust data assets will allow these entrepreneurial clients to better understand sales, demographic trends and consumer preferences to help develop, manufacture, market, distribute and scale their products for the Canadian marketplace.”

District Ventures will gain access to Nielsen’s retail universe in support of its investment decisions, and its portfolio clients will have access to retail measurement, consumer data, and innovation services to help facilitate data-driven decisions.

“District Ventures portfolio companies are on the cutting edge of Canada ’ s CPG space, and

with access to Nielsen’ s deep consumer insight and comprehensive data, they will be able to innovate, scale and sell even more quickly than they do right now,” said Arlene Dickinson, General Partner of District Ventures. “This strategic alliance is beneficial for our entrepreneurs, for District Ventures, and for Canada’s entire CPG entrepreneurial ecosystem.”

Electro-Federation Canada (EFC) hosted its 7th Annual 2020 Marketing Awards Program, where Rittal Systems Ltd. won two awards. They won in categories for manufacturers under $50 Million: Integrated Marketing award, and Event Trade Show award.

“Rittal is honoured to be the recipients of two EFC Marketing Awards of Excellence, and the fabulous awareness that our AX-KX Compact Enclosure campaign, as well as our German Technology Days continue to receive because of recognition like this,” said Tim Rourke, President, Rittal Systems Ltd. “ Our team worked hard to roll out these projects and these awards are testimony of the success of these programs.” EFC ’ s Marketing Awards recognizes EFC member organizations that demonstrate marketing excellence and innovation within the Canadian electrical manufacturing and

distribution industry. All entries were reviewed and selected by an external panel of judges with expertise in this category.

“The EFC Marketing Awards provides great examples of companies addressing the pandemic, promoting organizational success, and celebrating employees, ” said John Jefkins, Vice-President Member Engagement and Corporate Partnerships, EFC.

ABB collaborating with Forescout to offer its customers more choice and cyber security capabilities. The collaboration will integrate Forescout ’ s cyber technology within ABB’s portfolio of industrial expertise and cyber security solutions to help operators ’ detect known and unknown control system threats.

“ The threats to businesses and infrastructure from network intrusion and data breaches are growing, and the rapid increase in remote operations in 2020 has fueled this further, ” said Pedro Abreu, Chief

Product and Strategy Officer, Forescout. “ Now more than ever, it is crucial that critical industries have robust, sophisticated cyber security solutions in place. Working with ABB, and its deep domain expertise in the energy and process industries sectors means that customers get the best of both worlds – world-leading industrial knowledge combined with the latest technology, to better

protect their control systems.

”

Through integration of physical technology and software, ABB will deliver efficiencies as the need for manual asset inventorying and noncyber security network monitoring is reduced.

“Cyber security is a real concern across industry, and there is significant value to be gained from better network monitoring. Breaches in

network security can cost millions of dollars in repairs and fines, have potential impact from unplanned downtime, and affect a business’ reputation,” said Gino Hernandez, Head of Digital, ABB Energy Industries.

“ABB’s partnership with ForeScout will give customers a high level of network visibility and greater protection across their systems.”

ABB will also provide, through a reseller agreement, Forescout’s eyeSight, eyeInspect and eyeSegment security solutions with a focus on addressing the convergence of operational technology, and information technology.

Dennis Group, announced a partnership with IFAB Engineering Partners, that will provide design and engineering services to a broad range of food and nutraceuticals sectors.

“ With so much opportunity, our goal was to build depth so we could offer our full services locally,” said said Tom Dennis, CEO, Dennis

Group. “ We ’ re very pleased and fortunate to have found a partner like IFAB that, like us, works exclusively in the food industry and has a reputation for excellence. We are looking forward to continuing to grow our local presence in this important market.”

The partnership is part of a strategic long-term growth plan for the companies.

Dennis Group will continue to operate its Toronto office, which it opened 2018. it had been serving Canada’s food industry before that. IFAB will continue with its name and headquarters in Cambridge and operate under its current leadership.

“ IFAB and Dennis Group ’ s

expertise and capabilities are very complementary, and we’re excited to offer expanded services including packaging integration, automation, modeling, and construction management,” said said Ron Usaty, CEO, IFAB. “Together we can execute fullscale projects of any size.”

Rittal Systems Ltd. named the Electro-Federation Canada (EFC) ‘ Women in Tech ’ Scholarship program winners.

“ Rittal is pleased to be able to motivate and support women in rechnical education and careers by partnering with EFC. We wish to thank all the talented women who applied for these scholarships,” said Tim Rourke, President, Rittal. “ We are confident that both Melissa and Osose are worthy recipients and will make us proud with their dedication to the industry and to advanced studies in their areas of expertise.”

Melissa Montenegro from Mohawk College and Itohansose

Itua from University of Waterloo, were given $1,750 each, to help pursue their careers in the electrical and manufacturing Industry.

“ Beyond being a great financial support for me, this award has given me the satisfaction that everything I have done in my studies, volunteering, as well as support for Women in Tech, has led to this. I wish to thank Rittal and EFC for recognizing women in tech and giving them the opportunity to make a difference in their lives and to the future of Canada,” said Montenegro.

“I am honoured to be one of the first recipients of this scholarship as it will motivate me to continue to

Montenegro is an Energy Systems

EngTech candidate, and is experienced in power generation projects in oil and gas, and thermoelectric power plants.

strive for excellence as my program progresses. I hope this also inspires other girls who are interested in Tech to pursue it and to know that there is support for them. This funding will help me in my educational pursuits to relieve some of the financial burden that comes with studying at a distinguished University such as Waterloo, ” said Itua. “ I would like to thank Rittal and EFC for this scholarship and I admire their vision to empower people like me to be able to pursue their passions in the Electrical Industry. I am inspired to continue to give back to my community and to help others to achieve their goals as well.”

Itua is currently studying mechatronics engineering.

The United Nations estimates that the world’s population will climb from seven billion to nine billion by 2050. This means higher demand for food for the growing population, and more work for the farmers to produce more food.

Farmers will need fertilizers to do it, which is where potash comes in, as 96 per cent of the worlds production of potash is used in fertilizers. The 10 potash mines in Saskatchewan presently account for over

seven million tonnes of potash, about 25 per cent of the annual world production.

The mission of these potash mines is to help the world grow the food it needs. By striving to produce and deliver high quality, innovative crop

nutrition products, helping farmers rise to the challenge.

The simplest measure of the health of the potash industry is the price it commands on the world market.

Whether the price per tonne dips to $150 USD, as was seen in 2005, or skyrockets to $900 USD, like in the heady days of 2009, the true guarantor of success in the industry depends on cutting unnecessary expenses, ensuring safety, and benefiting from long-term planning made possible by market-leading processes, equipment, and technology.

Potash is not easy to process; demanding material characteristics combined with unique processing requirements, make it a challenge to mine. Since potash is a corrosive material, it can progressively destroy metal through chemical action. Potash creeps its way into nooks and crannies to eat into equipment, and hardens into sharp crystals that can cut and tear into seals.

When Scott Paish of Rittal, and

Jonathan Petryk of E. B. Horsman & Son, visited potash mines in Saskatchewan, doors of traditional Nema 4X enclosures were falling off due to caustic dust lodging inside the hinges, causing corrosion. The potash mines were looking for an enclosure to protect valuable automation, instrumentation, and electrical equipment that comes into contact with potash during processing.

“ Our main goal has been to find an enclosure that can withstand the corrosive atmosphere, offer allround protection, and last longer in potash mines‚ ” said Petryk. “ This will help keep the bludgeoning costs in this potash mining industry down, if the enclosures have some longevity.”

After evaluating and introducing hygienic design (HD) enclosures in two of the potash mines in Saskatchewan, they became convinced that they could have hit upon the perfect solution.

Secure blue seal: The seals around the enclosure doors often fail due to the corrosive potash destroying

them. The HD enclosures offer the ability to replace just the distinctive blue seal, not the entire door, thus saving huge costs. Furthermore, the one-piece secure air-tight silicone seal does not leave a gap around door for potash to seep through.

“Usually, the mine workers have to use a screwdriver or sharp tool to chip away the corrosion and buildup around the seals, and often, the enclosure gets damaged, ” said Paish. “ With the HD enclosures, this does not happen, leading to savings in time and costs.”

Inner hinges: Exposed hinges pose a significant problem, and keep rusting, disintegrating and falling off on all enclosures, no matter who the manufacturer is. HD enclosures are located on the inside of the box, protecting against corrosive dust prevalent in the potash mines.

Easy mounting: HD enclosures do not have additional holes for mounting, as they are able to be mounted any way needed by

welding directly to the enclosure. This enables them to be fitted into any space or orientation, and the absence of holes means less apertures for harmful potash dust to creep into and destroy.

Steep sloping roof: The 30˚ roof angle allows liquids to run off so the enclosures can withstand frequent high pressure wash downs, and the steep slope and smooth surfaces prevent bacteria and harmful build-ups on the surfaces.

In potash mines, it is important to ensure that the critical automation equipment housed inside the enclosures is working efficiently at all times. After all, reduced downtime leads to more potash for fertilizers, and ultimately, increased food production.

“ The good news is that so far, weve had nothing but positive feedback on their performance and we are looking forward to expanding their use,” said Petryk.

Article and photos provided by Rittal Systems Ltd.

•30˚ forward sloping, overhanging roof

•Joint-free exterior blue gasket

•Stainless steel construction

•Internal hinges

Get our HD Brochure

Tight margins, shorter production schedules, aging equipment, and growing consumer demand are putting food and beverage (F&B) manufacturers under more pressure than ever before.

BY MIRVIL BRUNO

To thrive and grow F&B manufacturers need to know that they can rely on the availability and cost-efficiency of their manufacturing plant. A potential enabler is digitalization, based on the integration of data and real-time optimization of processes across the value chain. At the heart of digitalization is a new generation of wireless smart sensors, and drive-based digital services.

The various sectors in the F&B industry, such as dairy, meat, brewing, and

sugar all have their own specific requirements and challenges. One size certainly does not fit all when it comes to finding a digital solution. Intensifying these challenges is that the average plant may be 30 to 50 years old with only isolated pockets of automation, limited to programmable logic controllers (PLCs), and supervisory control and data acquisition (SCADA) systems. Another challenge is that solutions from different vendors often use different communication protocols, making it hard to bring them together to provide a seamless overview of how the plant is performing.

Cost is of course a major factor. Not only the cost of the digital technology, but also the cost of implementing it, and training staff in using it effectively. Therefore, any digital solution must be easy to accomplish and show clear benefits under the tight scrutiny given to prospective large capital expenditure (capex) projects.

One way to do this is to adopt an incremental approach, working with existing automation systems, and seeking to reduce the number of isolated islands of control. Ideally, all pockets of automation would be brought together under a single over-arching system. The adoption of open communication protocols will also avoid being locked into proprietary

standards that might limit future expansion and upgrading options.

A key development in plant digitalization is the arrival of a new generation of wireless smart sensors that utilize the industrial internet of things (IIoT) in the form of cloud computing, data analytics, and mobile data transmission. With no hard wiring requirements, these smart sensors enable permanent monitoring at a fraction of the cost of traditional condition monitoring systems. Smart sensors can convert traditional motors, mounted bearings, gearing, and pumps into smart, wirelessly connected devices. The sensor picks up data on vibration, temperature, and other assetspecific parameters to provide an overall health check of the equipment. Smart sensors can even identify energy-saving opportunities to optimize energy consumption and lower costs.

Variable speed drives (VSDs) are now supported by a range of scalable digital services that allow plant operators to assess, manage and optimize their drives and operations without having to be physically on-site. These digital services make it possible for maintenance teams to monitor,

benchmark, back up, predict needed service, and fix drives in a F&B production facility from a safe and comfortable distance, across the factory or across the world.

Adopting digital services for drives can deliver many tangible advantages and benefits, the most important being improved safety and efficiency of the production and people. If problems arise, drive experts can establish a remote presence to analyze the situation rapidly, and make fast recommendations to solve the issues.

The next step in digitalization is to group individual components with sensors, along with variable speed drives, into a digital powertrain. Implementing condition monitoring for powertrains gives plant operators the opportunity

to check the health and performance of one unified system. By gaining full visibility, operators can take action to optimize performance, prevent downtime, and extend equipment life.

Traditionally, plant maintenance in the F&B industry is on a time-based preventative basis. This is like changing the oil in a motor vehicle every six months, whether the change is needed or not. The fixed schedule doesn’t account for actual operating conditions. Meaning some lightly used equipment is being maintained or replaced more often than needed. At the same time, some critical heavily-used equipment is being serviced less often than needed. This creates the potential risk of unplanned downtime that can cause lost production and consequently, major financial losses.

With condition monitoring for powertrains, all its components send vital condition and performance data to the cloud. This data is then analyzed and made visible to the plant operator on a dashboard showing availability, environmental conditions, operational variables, and fault events. Real-time health information ensures that maintenance is only carried out when needed.

Powertrain assets that are functioning correctly show up as green; yellow indicates there’s something that needs to be checked,

while red means that there is something wrong. This increases process reliability as operators can detect any potential equipment issues before they happen, shifting maintenance from reactive to predictive. The ability to monitor remotely also keeps employees safe by limiting exposure to potentially dangerous process equipment such as mixers, grinders, and cutting machines.

A unique aspect of Absolut Vodka is that it has a single production line serving the entire world. Process reliability is, therefore, critically important to the company’s existence.

After researching various methods to implement conditionbased monitoring and maintenance, it was recommended the distillery install small sensors as the basis for a cost-effective and easy-to-use condition monitoring solution. The sensors, each about the size of a mobile phone, were installed on motors in the mash preparation process, a continuous function critical to the overall distillery operations.

Soon after the sensors were fitted to the motor housings, an abnormal vibration curve was detected on an agitator motor, indicating possible bearing failure. In-depth analysis confirmed that there was indeed a faulty bearing. Early detection allowed Absolut to fix the problem during a planned shutdown, avoiding lost productivity caused by unexpected downtime.

At the same time, the sensors uncovered a second possible problem, significant vibration in one of the pumps, also on the mash preparation line. At first, engineers thought it might be a bearing issue, but it turned out to be a valve that had shifted

accidentally, resulting in pump cavitation. These two events illustrate how smart sensors can prevent expensive downtime.

Ultimately, all F&B plants will need to adopt digitalization to some extent, simply to keep pace with the changing nature of the industry. Early adopters are reaping the rewards and, after taking advantage of low-hanging fruit, and establishing a long-term digital strategy, they stand the best chance of success in the future.

BY ERIN SIDWELL

Nichols Farms operates a pistachio processing plant in San Joaquin Valley, California. The family-owned business employs over 300 people. The leadership team wanted computerized maintenance management system (CMMS) software to help increase asset reliability. However, they were unsure how to choose a system and needed an expert to help launch it.

Maintenance planner Christopher Kennedy was hired, and his first job was to find and implement a CMMS. Kennedy had experience using CMMS software and knew a basic system would not be powerful enough to support Nichols Farms ’ demanding goals, including achieving world-class maintenance. After researching and testing several systems, he selected a highly configurable CMMS that would enable users to tailor mandatory fields, layouts, work orders, forms, and workflows.

“Nichols was at a point in their business life where they were ready to take the next step in regard to maintenance and asset reliability, ” said Kennedy. “If we wanted to achieve world-class maintenance, we needed a CMMS. I was able to demo several systems, and one of them completely outperformed the rest. The

deciding factor was that we would be better able to configure the software to fit what we do, to what our needs are, and what we want to accomplish.”

The organization set out to fully leverage the system’ s flexible features and numerous capabilities. The company’s leaders recognized that first, they needed buy-in from its 22 technicians and several managers to achieve implementation success.

Change and cultural barriers were two significant hurdles. Kennedy caught the maintenance team ’ s attention by demonstrating how the system could help them identify

Before implementing the CMMS, Nichols Farms had a small, basic preventive maintenance or inventory management program. Spreadsheets were used to document completed work, and only 10 per cent of all the work orders were captured. Forty per cent of those were labeled reactive, and data was not reliable.

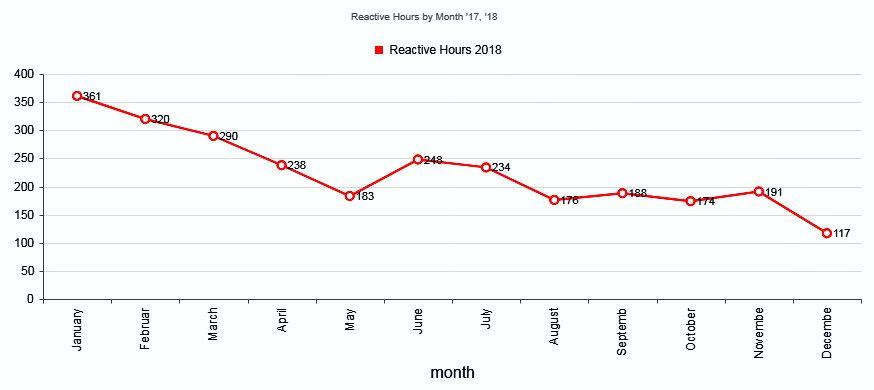

Nichols Farms reduced reactive hours from 40 per cent to between 12 to 15 per cent with help of a CMMS.

equipment problems easier by viewing an asset ’ s work order history stored in the CMMS.

“ I showed them a reactive work order where it took them an hour or two to figure out what the root cause was or what the fix was,” said Kennedy. “ I then demonstrated to them how to go back into a work order history. They were able to see how different shifts had handled the same problem and how each technician had fixed the equipment.”

Fully understanding the capabilities of a CMMS is the only way to maximize the system. It ’ s also the fastest route to a return on investment (ROI).

Before Kennedy started using the system, he immersed himself and the team in various training offerings supplied by the vendor, including seminars, demonstrations, and online courses. He also attended the supplier’s annual maintenance and reliability training, innovation, and education conference in Florida.

Next, he developed a strategy and a pathway to a world-class maintenance status. The immediate priorities:

• Increase worker productivity;

• Eliminate manual processes; and,

• Improve work completion rates.

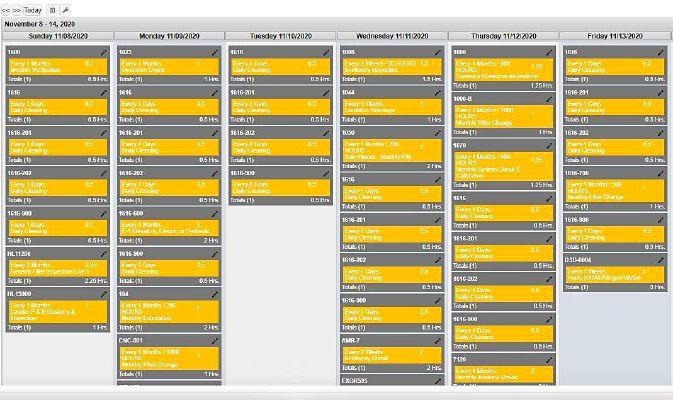

• Before and after CMMS implementation The system ’ s scheduling feature provided a way to restructure and organize work, automate PMs, and track labour. The team helped capture corrective, reactive, and safety work order data to build a reliable database enabling Kennedy to measure continuous improvement.

“In just one month, we saw a 400 per cent increase in work order completion, ” said Kennedy. “ And that was just with using the basic work order management system. We were scheduling technicians their workloads and their downtime.”

Kennedy confirmed the metric by comparing a year of past work order completions with a year of current work order completions.

“I counted the number of work orders that they had completed in a given month,” said Kennedy.

“Luckily, they had that information in the system for about a year. So, for the first year, I was able to track our work order completions month by month. And then, I put together a report using the CMMS that showed me the number of work orders we completed since we started using the system.”

Compliance with food and beverage safety regulations is a critical deliverable within the industry. With the 2015 Food Safety Modernization Act (FSMA), food-and-beverage companies are now required to keep a digital record of assets.

Audit preparations used to take Kennedy hours to compile. Now they only take a few minutes. Additionally, because he configured a mandatory field within work orders requiring technician sign-off, regulatory compliance is assured.

of a successful implementation. During the system roll-out, Nichols Farms bought laptops for all of its technicians and beefed up the plant ’ s Wi-Fi to make sure teams stay connected to the CMMS.

“The technicians get here, they get their mobile devices, and they look at what they have for that day,” said Kennedy. “ They take them to the asset whenever they do work. That way, they can accurately charge time, add notes, and look up work order histories.”

Nichols Farms also harnesses the system’ s Ranking Index for Maintenance Expenditures (RIME) function to plan, schedule, and prioritize maintenance tasks. RIME is used to rank and label work orders and work order types by importance, such as reactive, safety, or preventive. Before RIME, technicians

“ We added a procedure to all of our PM work orders stating that, ‘By checking this box, you ’re ensuring that all parts were removed from the floor, accounted for, and tools were cleaned upon completion, ’ ” said Kennedy. “The auditor loved it.”

reacted to every equipment issue, no matter what type.

“Now, when operators believe they have a reactive situation, they submit a work request using the CMMS,” said Kennedy. “If it’s labeled reactive, the maintenance supervisor will immediately determine whether it is, in fact, a reactive situation or not, and take the appropriate action.”

Technology is a critical component

Nichols Farms continues to improve and strives for world-class maintenance every day by following preventive maintenance best practices. These days, the plant operates between 12 to 15 per cent reactive, much lower than in the past.

Erin Sidwell is an enterprise account executive, managing the food-and-beverage category for eMaint, a division of Fluke Reliability. She joined Fluke two years ago, after spending 14 years focused on the supply chain for fresh produce.

This year has been one that will remain in our memories, full of challenges and opportunity. The pandemic forced us to adapt and change in ways we never thought possible. It tested emergency preparedness plans, leadership teams, business strategies, and customer bases. All inevitably leading to new ways of conducting business, producing products, managing work forces, and meeting consumer needs. If anything‚ we have all become more familiar with “change” and “flexibility” than pre-2020.

As we head into a winter of unsureness with COVID-19, and flu and cold season upon us, we can take assurance in the fact we are armed with more tools, knowledge, and readily available resources, that did not exist earlier this year (as we began our initial battle with the pandemic).

Recognizing that we are better educated, prepared, and equipped, it’ s time to think about the future and “the way forward. ”

To plan ahead we need to cast a glance behind us, reflecting and appreciating where we have been, the wins we have made, those we are still working on, and most importantly, the lessons learned along the way. How will you apply this knowledge to your current and future operations, so that you can continue to grow your business, or hone your role within the organization?

No matter your position – in maintenance, health and safety, human resources, or president – we all have been impacted in some way by this year’s events, and by change in all aspects of our organizations. Multiple

disruptions from COVID-19 compliances, workforce management, sourcing and supply chain needs, project completions, customer demands and customer loss, employee wellness, motivation, and morale; representing just a few of any number of issues that needed attention.

Each of these also presented a challenge to make things better, more workable, and suitable to ensuring a safer and competitive environment. The future of manufacturing was here, is here, how could we pivot to meet customer demands, reinvent ourselves, pave the way forward, employ automation, robotics, digitalization; do things better, more effectively and safely?

Excellence in Manufacturing Consortium (EMC) is a not-for-profit association of manufacturers across Canada that has had its ear to the ground for the last three decades, listening to the challenges industry faces day in and day out, and responding with connections, resources, services, and programs.

Through conversation with companies and community partners from coast to coast, virtual networking sessions, and ongoing Industry Pulse surveys, we have heard from companies about the lessons learned to date. Answers include the need for effective leaders who can chart the company course during stormy weather, importance of communication, intricacies of planning and management of on-site and off-site labour, and ensuring that risk assessments, business continuity, and emergency preparedness plans are encompassing and understood by everyone.

There are many different lessons that can be extrapolated from this year,

including the importance of empathy, mental health awareness, ongoing training, and keeping people feeling involved and engaged. COVID-19 has taught us that people are the most important aspect of our organizations and we, as companies, are not as invincible as we have thought. Our ability to innovate or pivot, or bend, to meet the demands placed upon us are all stepping stones to ensuring companies are better prepared for the future.

Asking about lessons learned, how business is faring, where challenges lie for companies, and opportunities they would like to explore, are all part of EMC Strategic Interest Group (SIG) networking events. In over 60 consortiums across Canada, manufacturing members gather together (virtually at the moment), to share best practices, act as sounding boards, and lend support. EMC has worked to build more competitiveness in manufacturers through, not only peer networking, but a plethora of other programs and services.

We care about companies and the people within those organizations. We do our best to listen, and our programs and networking are based on your needs and interests. We foster a culture of learning, motivation, engagement, and responsibility; and create an atmosphere for benchmarking and leadership skill development through training programs, ongoing peer activity, and value-added program development.

A database of 1,500 topics with policies, procedures, and connections, provides manufacturing members with readily available answers, support materials, and valuable peer insight. Further we source and implement cost

reduction programs, enhanced learning activities, and provide alternative supply chain mediums through B2B opportunities and shipping program. We engage industry expertise to assist with human capital matters, energy cost reduction, funding, and training.

When the crisis began, our organization pivoted with ready assistance sharing COVID-19 related policies, procedures, guidelines, and protocols for any manufacturer regardless of membership across Canada.

We have continued that support with legislative events bringing the latest news and requested compliances to all our consortiums. Nationally, provincially and regionally, invitations have been forwarded to companies, inviting them to participate in networking activity. We have gained insight from manufacturers across the country, as they navigated their organizations through COVID-19, willingly sharing details for others to learn from.

We have learned a lot over the past few months, now all officially being experts at Zoom, Microsoft Teams, and other platforms. We are adept at working from remote locations, for some becoming a permanent state of that role/position for a given business.

When we look forward, with 2021 in sight, what lies ahead for your company? How will you navigate future opportunities? What does your business need to be successful in the marketplace? How do you envision the future of manufacturing in your sector, one, five, or 10 years from now?

These are questions that we will be asking through our ongoing networking activity, industry pulse surveys, and national sessions.

Reflecting on 2020 and taking stock of lessons learned personally, and through manufacturing members and community partners, I appreciate the fact that we are better prepared and better equipped, and it’s time for leaders to chart “the way forward” to a positive 2021. If you are interested in learning more about involvement in EMC’s programs and services including SIG or our special food and beverage sector networking sessions, please feel free to reach out, and we would be happy to share information on what is coming up in your region.

November 17 to 19, 2020, EMC will participate in the Strategy Institute’s Food Safety and Regulatory Virtual Summit. This three-day forum presents an opportunity for anyone interested in participating. There will be presentations by CFIA and FDA, and a line-up of manufacturers’ and SME’s sharing information relating to conference themes. This will be an immersive experience allowing participants to gain insight from best practice presentations and subject matter expertise.

We will finish our 2020 EMC Food and Beverage sector year with an educational Best Practice Session on Environmental Monitoring hosted by 3M

Canada in Milton, Ont. 3M Canada – Food Safety, in partnership with Cornell University, recently completed an Environmental Monitoring Handbook for the food and beverage industry. At this event, we explore the concepts of environmental monitoring, including controls, risk assessments, and recalls. We are hoping that this will remain an in-person event, but COVID-19 may require us to move this virtually.

How do you get involved? If you are interested in learning more about EMC and the Food Sector Initiative, please feel free to touch base with Bren de Leeuw, Vice-President, Community Partnerships and Stakeholder Relations (bdeleeuw@ emccanada.org), anytime.

17-Nov-20 to 19-Nov-20

02-Dec-20

Food Safety & Regulatory Virtual Summit Toronto, ON www.foodsafetycanada.com

An interactive Summit hosted by the Strategy Institute that provides insight from CFIA, FDA and Industry Leaders on all matters related to Food Safety

EMC Food, Beverage & Bio Sector Networking Event

Host: 3M Canada Company – Milton, ON Best Practices – Environmental Monitoring