Excellence in Manufacturing Consortium’s Manufacturing Essentials Certification programs are an initiative designed to help manufacturers increase their workforce productivity and become more competitive in a growing global marketplace.

Manufacturing Essentials Certificate delivers learning material in training cluster groups, providing up to 40 hours of skills training, using industry validated learning programs. Programming is provided using live workshops, facilitated online learning with on-going support from professional trainers and a workplace action-based learning project.

Kurtis Bachman, McCain Foods FULLY & PARTIALLY FUNDED OPPORTUNITIES AVAILABLE

The program provided a platform for all in attendance to grow and develop skills theydidn’t know or were unsure how to improve. I witnessed great dedication to the projects that each team had chosen, teams overcoming challenges and having a sense of pride in the finished product.

Supplement of Summer 2022

Paul Burton

pburton@annexbusinessmedia.com (416) 510-6756

EDITOR

Mario Cywinski mcywinski@ annexbusinessmedia.com (226) 931-4194

ASSOCIATE EDITOR

Monica Ferguson mferguson@ annexbusinessmedia.com (416) 510-5206

NATIONAL ACCOUNT MANAGER

Ilana Fawcett ifawcett@annexbusinessmedia.com (416) 829-1221

BRAND SALES MANAGER

Chander Verma

cverma@annexbusinessmedia.com (416) 510-6797

ACCOUNT CO-ORDINATOR

Catherine Giles

cgiles@annexbusinessmedia.com (416) 510-5232

MEDIA DESIGNER

Graham Jeffrey

CIRCULATION MANAGER

Beata Olechnowicz bolechnowicz@ annexbusinessmedia.com

COO

Scott Jamieson sjamieson@ annexbusinessmedia.com

Amy Edwards, Training Manager aedwards@emccanada.org 1-866-323-4362

PRESIDENT

JP Giroux • jp.giroux@emccanada.org

(519) 376-0470 (866) 323-4362

VICE PRESIDENT AND GENERAL MANAGER

Amanda Doman • adoman@emccanada.org

VICE PRESIDENT, MANUFACTURING SECTOR PERFORMANCE

Scott McNeil-Smith • smcneilsmith@emccanada.org

MARKETING & COMMUNICATIONS MANAGER

Tiffany Robbins • trobbins@emccanada.org

Recently I was able to moderate Food and Beverage Engineering and Maintenance’s first ever virtual event. After a plethora of legwork and connecting with industry experts to put on an informative event, the end result was a great cross-section of speakers.

The Max Uptime event brought together speakers from across the food and beverage industry. We had a speaker who had experience working for Kraft (Coffee Division) as Manufacturing Engineer – Leader of Continuous Improvement and at Nestle Waters as Regional Continuous Improvement Manager. We had another who managed operations for his own family enterprise for over 20 years. As well as an independent marketing strategist focused on the automation, robotics and advanced manufacturing industry. And last but not least, a speaker who has worked with manufacturing customers for over 30 years.

Just visit: https://www.mromagazine. com/virtual-events/max-uptime/.

Id like to thank Mariela Castaño, Senior Vice-President and COO of Kunst Solution, who was one of the speakers at the Max Uptime event, and wrote an article for Food and Beverage based on her presentation at the event, Uptime optimization through use of visual management tools.

In this issue we are also covering employment topics by looking at Building an innovative workplace reputation, and Intentional culture of change. Along with health and safety, with Responsibilities of workplace health and safety.

One last note, we are always looking to grow the Food and Beverage brand, as such, if you have any topics/ideas you would like us to cover at an upcoming event, podcast, roundtable, or an article, do not hesitate to send them to myself or any member of the team.

All the combined knowledge was definitely on display. As the three hours was jam packed with useful take away information for the nearly 100 attendees. Thank you to all those who atteneded, our speakers, and the sponsors, the event would not have been a success without you.

We have an overview of the event on page 8, and if you missed the Max Uptime event live, all presentations are now available on the events page.

Good day,

Mario Cywinski

Food & Beverage Engineering & Maintenance

mcywinski@annexbusinessmedia.com www.mromagazine.com

GLOBAL INDUSTRY IS ACCELERATING INVESTMENT IN ENERGY EFFICIENCY: SURVEY

Global survey commissioned by ABB and conducted by Sapio Research highlights current and future plans of companies to invest in en-

ergy efficiency to achieve net zero; 90 per cent will increase spending over the next five years, while 52 per cent plan to achieve net zero within the same period.

The Energy Efficiency Investment Survey 2022 targeted 2,294 compa-

nies in 13 countries, ranging in size from 500 to 5,000 or more employees. A key finding is that over half (54 per cent) of the companies are already investing in energy efficiency measures to achieve net zero, while 40 per cent plan to make energy efficiency improvements this year.

Growing impact of energy costs on profitability means that energy efficiency is receiving a higher priority yet cost and downtime are major barriers to investment. The survey comes in the wake of a recent UN report calling for concerted action from countries to cut greenhouse emissions at a faster rate.

Industrial motor-driven systems hold huge potential for energy efficiency measures. Almost two-thirds of the survey respondents are upgrading their equipment to bestin-class efficiency ratings, such as high-efficiency electric motors controlled by variable speed drives.

The report highlights areas of concern, half of the respondents listed cost as the biggest barrier to improving energy efficiency and 37 per cent

felt downtime was a barrier. While 41 per cent of respondents felt they had all the information needed regarding energy efficiency measures.

Nine out of 10 respondents indicated that rising energy costs are at least a minor threat to profitability, while over half (53 per cent) perceived it as a moderate or substantial threat. Despite cost being a significant barrier to investing in improving energy efficiency, cost savings were the most important reason for investing (59 per cent).

The Energy Efficiency Investment Survey 2022 is available here.

Motion Industries announced the formation of its fluid power business brand, Mi Fluid Power Solutions (Mi FPS).

Mi FPS is a provider of fluid power, integrated electronic controls and electro-mechanical technologies for industrial and mobile equipment. Mi FPS’s main focuses are hydraulics, pneumatics, lubrication, fil-

tration, process pumps, precision industrial tooling and factory automation products.

Mi FPS has over 65 on-demand retail fluid power hydraulic and industrial hose assembly stores and support facilities, including repair, build and engineering capabilities.

Dispersa is scaling the world’s first waste-derived biosurfactants for greener cleaning and personal care products.

Surfactants are the active components in detergents, creams, and hand soaps. Most are currently manufactured from petroleum or palmoil. Biosurfactants replace these conventional surfactants. Dispersa aims to further reduce the environmental impact and cost of these key ingredients.

Dispersa recently launched PuraSurf, its first biosurfactant product line for the cleaning and personal care market. Active client partnerships are underway

with major cleaning product companies based in Canada.

To produce biosurfactants, microbes must be fed various materials like oils and sugars. Dispersa has developed a proprietary process, BioEterna, that converts food waste into circular biosurfactants.

Waterloo Brewing is investing in eco-friendly packaging, replacing its single use plastic shrink wrap for recyclable cardboard packaging. The changes will happen on

Seagram Island Time Anytime can packs, Seagram Island Time Coconut Lime can packs and LandShark Lager can packs.

Waterloo Brewing upgraded its existing can line and installed a new can line with energy efficient pasteurization equipment, installed energy-efficient lighting, upgraded cooling systems, installed Energy Monitoring System, and installed two high-efficiency boilers to reduce its carbon footprint.

The new Seagram packaging will begin to appear at the The Beer Store, LCBO and select grocers soon.

CULT Food Science announced that Lejjy Gafour, CEO, has been invited to join the Food Supply Council by the Canadian Chamber of Commerce (CCC).

Launching in June 2022, the Council is an invitation-only group created to bring together businesses and non-government organizations and consists of a maximum of 25 food industry leaders from across Canada.

The CCC intends for the Council to build on the undertakings of

Canada’s FoodLink and address the connections between agriculture, production, inputs, value-added services and transport.

The Council’s members have been asked to commit 20 hours of their time over the course of the year and attend one meeting per month, on average, in-person or virtually. There are currently 11 other confirmed members.

Phyto Organix Foods intends to purchase 15 acres of land in Strathmore, Alberta as the location of netzero emission plant protein processing facility.

The $225 million facility will be the largest capital investment in Strathmore and provide a base for Phyto Organix to grow its plant protein business. When operational in 2024, Phyto Organix will use proprietary wet fractionation technology to annually process 40,000 metric tonnes of yellow peas, grown near the facility, into soluble and insoluble

protein isolates, processed fibre and starch, and dietary pea hull fibre.

Phyto Organix’s 100,000 square foot facility will be the first net zero plant protein processing facility in North America.

As part of the new facility, Phyto Organix received $1 million over two years, cost-shared by the federal and provincial governments through the Canadian Agricultural Partnership,

to support engineering costs and the purchase of equipment.

Claridge Food Group will investment $40 million in WeCook Meals.

Investissement Québec will coinvest with a $13 million investment, and Desjardins Capital reinvests $3 million in the company

in addition to joining the new investment vehicle.

WeCook Meals aims to accelerate its annual sales growth, relyingon its food processing, quality meals, menu customization and digital marketing.

Modern Meat has entered into a one-year renewable supply agreement with Northland Properties, whose brands include Moxie’s, Denny’s, Chop Steakhouse, Shark Club, Boulevard Kitchen & Oyster Bar, and CRAFT Beer Market.

Through the supply agreement, Modern Meat will be the sole supplier for a plant-based ground meat alternative. This product was created for one of Northland’s dining chains.

The products are being distributed to each location through distributor Gordon’s Food Service, which is the largest privately held food distributor in North America.

Around 100 food and beverage industry professionals attended Food and Beverage Maintenance and Engineering magazine’s Max Uptime virtual event recently.

BY MARIO CYWINSKI

Max Uptime looked at how an organization’s food and beverage production capabilities are highly dependent on the state of its capital assets. Additionally, how the goal of any organization is to maximize uptime.

It offered maintenance and reliability professionals in the food and beverage sector knowledge and techniques on how to easily identify an asset issue, react to solve problems, and prevent unexpected and costly breakdowns.

Four industry experts presented, covering a wide cross-section of the food and beverage industry with topics ranging from visual management tools, data-driven warehouse operations, to robotics, and best practices for food and beverage manufacturing.

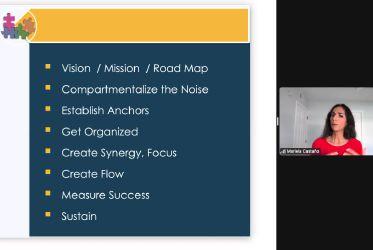

Mariela Castaño, Senior Vice-President and COO of Kunst Solutions led the opening presentation. She shared tips and tricks that can be applied within the work environ-

ment to improve observation that processes are in control and running at rate. As well, a method to keep team members engaged and helping to detect potential problems early.

“Working in the food industry I learned some of the most important lessons in my life. It is where I learned the power of visual management and its effects in uptime, efficiency, productivity and ultimately profitability,” said Castaño. “It was a real pleasure to participate in the MRO Max Uptime event and briefly share a summary of my learnings. This industry needs not only heroic actions but also a wellplanned and executed improvement journey to ensure sustained and efficient results.”

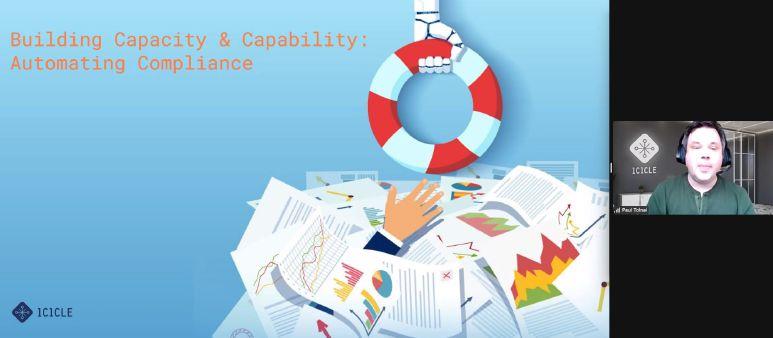

Paul Tolnai, Business Development Manager at Icicle spoke about the benefits of automation. More spe-

cifically, how to build capacity for lean production teams through supply chain challenges, how to optimize maintenance to ensure sustained productivity and why reducing waste to meet profitability and sustainability goals is valuable.

He discussed how building supply chain agility and flexibility through supplier and formula management and how to achieve operational excellence through a unified datadriven approach.

“The combination of proven business strategy with smart automation technology ensures that food manufacturers can take challenges

in stride. Data-driven food manufacturers increase worker productivity and manufacturing uptime in a way that yields rewards beyond improved profitability,” said Tol-

nai. “They build resilient and innovative businesses that stand the test of time despite notoriously razor thin margins, delivering an elevated level of safety, quality and trust with their customers.”

Jim Beretta of Canadian Food Innovation Network explored how operation teams can integrate technology into their plants to achieve efficiency and open new business opportunities for their organizations. He spoke about how research, automation and data are driving

the 4.0 food industry towards innovation for food service and grocery customers. Beretta used a selection of videos to convey his topic.

“As a follow up to my presentation on food and robotics: Robotics in action, Seeing is Believing, on behalf of the Canadian Food Innovation Network (CFIN), one of the most important advancements of Industry 4.0 and IoT has to do directly with MRO,” said Beretta. “Unplanned downtime can be almost eliminated by harvesting data we already have access to in our facilities. All that’s required for Canadian companies, is

planning and leadership to take advantage of these technologies.”

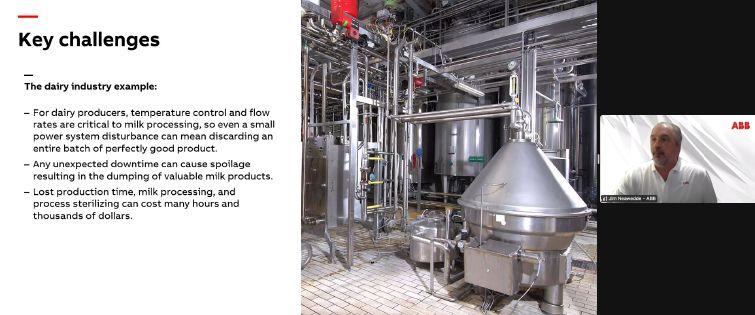

Jim Neawedde, Food and Beverage Segment Manager at Motion Division - Drives Business at ABB, discussed how many components play a part in maximizing uptime in a food and beverage facility. He mentioned how running lean has become the mantra of most manufacturers. When instead, the focus needs to be on the core competency

“Unplanned

downtime can be almost eliminated by harvesting data we already have access to in our facilities. All that’s required for Canadian companies, is planning and leadership to take advantage of these technologies.”

– Beretta

of producing quality products. As food and beverage plants become more automated, processes need to be efficient, maintained, and repaired when needed.

Neawedde also spoke about how system design impacts uptime, how energy efficiency plays a role, how to make improvements, and what tools and resources can help you create efficiencies that drive uptime.

“The Max Uptime was a fantastic virtual event featuring a unique panel of experts who provided insight

into the newest trends driving improved operational efficiency,” said Neawedde. “I was honoured to present solutions and techniques for mitigating electrical harmonics, moving from preventive to predictive maintenance, improving process efficiency, and reducing energy costs.” Each presentation was followed with an insightful Q and A session. Max Uptime presentations are available online here: https://www. mromagazine.com/virtual-events/ max-uptime/.

Mario Cywinski is the Editor of Plant magazine, Machinery and Equipment MRO magazine and Food and Beverage magazine, and a member of the Automobile Journalists Association of Canada. He has 15 years of editorial experience; four years of maintenance, reliability, and operations experience; over 16 years of automobile industry experience, and small business industry experience. Reach him at: mcywinski@mromagazine.com.

EMC hosted Maxine Labbe, Montana HR, and Daniel Goulet, Systemair at a recent event. Here we look at an overview of that discussion.

In today’s employment landscape, jobseekers are only interested in positions that provide them with a tangible benefit to their career. Disposable, low-pay roles have become obsolete — modern workers want secure, sustainable employment that can increase their sense of worth in addition to fair compensation. Meeting jobseekers’ expectations can be difficult for manufacturers who haven’t kept up with timely employment trends but moving past long-held employment

practices and embracing change is critical to attracting modern workers. By stoking a culture of progress, ambition, and mutual success in their workplaces, manufacturers can appeal to today’s workers, keep them onboard, and secure their engagement and motivation.

Understanding your workplace’s existing culture is necessary to advancing it. Consider the wants and needs of your current workers. Consider the new kind of worker that you’re looking to attract. How

are the expectations of each of these groups being met? Do you have a strong grasp of your existing and potential employees’ values and demands? Remember that modern manufacturing workers are opinionated, informed, and well-connected with their peers; if they feel in any way underserved, they won’t

be interested in your business, regardless of how successful it is.

To overcome ambiguities in your workplace’s culture, perform a cultural assessment — a detailed analysis of your labour bases’ satisfaction with their jobs. Having this information will allow you to make accurate improvements to your com-

pany’s culture and will demonstrate to jobseekers both your timeliness and your willingness to improve. Hold cultural assessments at your organization regularly to prevent your culture from falling behind, and you’ll easily build an innovative reputation with modern jobseekers.

Keep in mind that effective employment is not only limited to recruitment. Once employed, workers must stay passionate and engaged to meet their potential and maintain productivity. When performing your regular cultural assessments, aim to gain an understanding of your employees as individuals instead of a collective. Offering personalized benefits to employees makes them feel valued beyond their technical abilities and provides them with an incentive to remain loyal to your organization. Trust is tantamount to a worker’s motivation — they must feel as though decisions are being made in their best interests by employers. Stay aligned with these values by

promoting changes that affect your workers directly: fair compensation, stable job security, effective safety measures, and equitable treatment.

Employees (especially new employees) that can experience these benefits firsthand will see the value in working at your business and will become invested in your organization’s success.

Meeting the demands and expectations of modern workers is one of the strongest competitive advantages an organization can have. Employees from any background and in any department or industry will always see the value of an employer that takes a genuine interest in their individual progress and will understand how the success of their business is interwoven with their own personal achievement. Make the effort to communicate, analyze, and recognize your employees regularly, and you’ll find that your workplace’s culture is conducive to long-term engagement and productivity.

Article provided by Excellence in Manufacturing Consortium (EMC).

Maintaining and promoting health and safety in the workplace is important throughout the employee journey. Whether they’re a new worker or a seasoned professional, training (and retraining) is a key factor that can help staff stay safe while on the job.

BY CANADIAN CENTRE FOR OCCUPATIONAL HEALTH AND SAFETY (CCOHS)

In addition to providing training, employers must abide by several occupational health and safety responsibilities. Many of these elements including, employee rights and employer responsibilities, are similar across jurisdictions in Canada. However, the specifics around occupational health and safety legislation and how these laws are enforced can vary from one jurisdiction to another.

Workers must perform in compliance with occupational health and safety legislation and use personal protective equipment (PPE) and clothing as

directed by the employer. Employees also have a duty to work in a safe manner, use the prescribed safety equipment, and report workplace hazards and dangers to their supervisor or employer.

To carry out their responsibilities, workers need to know what they are, and that’s where managers, supervisors and employers come in.

Managers and supervisors are required by law to take every reasonable precaution to protect their workers, and they must ensure that workers are performing their jobs safely and are following occupational health and safety legislation. This means that workers need to be trained on potential and ac-

tual hazards associated with their job, provided with written instructions on the measures and procedures taken to protect them, and use all appropriate PPE and devices.

Here are some ways you can implement health and safety measures at work.

Health and safety programs are a requirement in any workplace, and having a written policy is key to its success. Think of a policy as a plan of action. It indicates the degree of the employer’s commitment to health and safety and should reflect the special needs of your workplace. The policy should also be explained and understood by any and every worker and provided in written form in the language of staff. It should be positive in tone (for example, focus on what the worker should do rather than what they should not), and periodically reviewed to evaluate its effectiveness.

The policy should be signed by leadership and include items and statements such as the employer’s duty to give health and safety education and training to all employees, the development and maintenance of health and safety rules and procedures, and planned programs that support the commitment to workers’ health. It should make clear that cooperation on the part of all employees is vital to the success of the health and safety policy and

should be actively incorporated into the workplace and regular workplace duties and actions.

It’s important to make sure all employees understand the policy. Workplaces can achieve this by holding regular safety talks, posting signs at the workplace, writing articles about the poli-

cy in company newsletters, and posting on the internal web site.

Most workplaces are legally required to have a health and safety committee or representative.

Stay connected to the industry by subscribing to MRO Food & Beverage eNewsletter, reaching more than 20,000 subscribers. This monthly eNewsletter is an update of everything you need to know about the maintenance and operations of the Canadian food and beverage manufacturing sector.

Our eNewsletter content mix includes topics covering several news facets, including maintenance in food and beverage manufacturing, machinery and equipment performance and repair, food and beverage industry trends, as well as the latest hires and innovations by companies specializing in food and beverage manufacturing.

NOW!

Among other things, their role is to recognize and evaluate workplace hazards and participate in the development and implementation of programs to protect the employees’ safety and health. They respond to employee concerns and suggestions about safety and can create and promote programs to improve employee training and education.

To help identify hazards in your workplace, perform risk assessments of specific job tasks. During this process it is important to consult with the health and safety committee or representative, workers that perform the tasks being evaluated, and supervisors. Once the hazards and risks have been identified, determine the appropriate control measures to protect workers. When selecting control measures, consider the hierarchy of controls, which includes elimination or substitution controls, engineering controls, administrative controls, and personal protective equipment. Risk assessments will also help identify the specific training needs of your workers.

The process of training workers can help keep everyone safe. While training is incredibly important for new staff, keep in mind that workers who are returning after an absence or are taking on

Although workplaces have traditionally looked at workplace health from a strictly occupational health and safety perspective, mental health should be integrated in your occupational health and safety policy.

new roles and responsibilities need to go through this process.

Training should cover topics like worker rights and responsibilities, your organization’s specific safety rules and policies, and who to ask for help. Tour each work area in the facility to review potential hazards, safe work practices, and emergency and evacuation procedures. Provide staff with a contact list of the health and safety committee members or representatives. They should also know how to participate in the health and safety process, like how to report hazards. Depending on the nature of work and the potential hazards specific training may be required.

Although workplaces have traditionally looked at workplace health from a strictly occupational health and safety perspective, mental health should be integrated in your occupational health and safety policy. Research has shown that employees who feel they have psychological support have greater job attachment, satisfaction, involvement, and performance, and more positive work moods. To help

keep your employees psychologically safe, make mental health a priority. Promote work-life balance and encourage staff to take their breaks. Show compassion and understand that priorities come up outside of work. Check in with employees. Even a simple “How are you?” can go a long way.

Worker safety isn’t just one tip, tool, or training process. It’s a journey. And just like any journey, there are many different routes you can take. But no matter which way you go, don’t go it alone. By involving your staff and clearly communicating the path forward, you’ll get there together, safe and sound.

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well-being — physical, psychosocial, and mental health — of workers in Canada by providing information, advice, education, and management systems and solutions that support the prevention of injury and illness. Visit www.ccohs. ca for more.

BY MARIELA CASTAÑO-KUNST AND RICHARD KUNST

Whether digital or manual the most important aspect is that the medium triggers a response through a visual stimulus. When we look to integrate visual management tools to monitor a process, we always stay true to the rule of five by 15 to 50, meaning within five seconds from a distance of 15 to 50 feet, we can see the normal or abnormal attributes occurring within the process. For the rule to work we first need to achieve stability. In many cases the process is irregular as organizations try to push the process for optimization when sometimes it is better to ‘slow down, go faster’ by having a stable process. As we observe our process we can identify disturbances to flow, which become jewels of opportunity for process improvement.

The key after establishing process stabiliza-

tion is to support your team members through a servant leadership style. Your team members understand the process best, complete with sights, smells, sounds and nuances, but they need leaders to assist with problem solving and process enhancement.

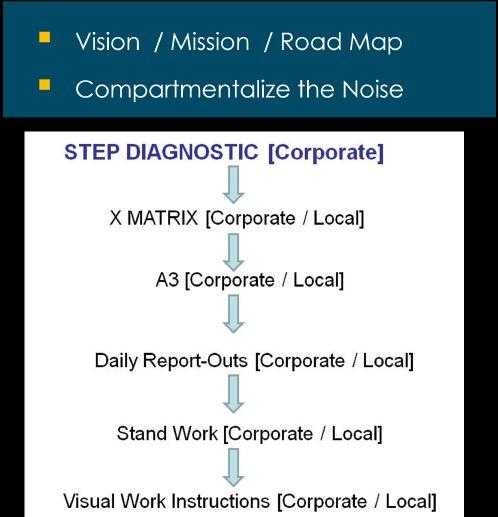

Uptime optimization is not simply a corrective action but a journey of continuous improvement that involves strategic and tactile methods. As depicted in the graph (on right), the flow-down strategy is intended for the entire organization to understand the five-year vision to achieve overall improvement strategy.

Here is what this typically looks like:

A five period journey showing the methodologies needed and the corresponding key performance indicators. The benefit of this diagnostic is two-fold:

1) It breaks down the race into a series of sprints with each sprint having a goal.

2) The journey will require many strategies using different methodologies and showing how the methodologies synchronize it deafens that potential ‘flavour of the month’ organizational syndrome.

This 12-month strategy map combines organizational goals, resources required, project timelines and links to departmental projects in a way

that is easy and quick to review to ensure the working plans meets the numbers.

A3 – Includes an in-depth and granular approach to ensure a big project is broken down into simple tasks to be completed by assigned individuals within a four-week timeframe. However, are still focused on accomplishing the larger goal identified within the X-matrix.

Daily report-outs – Also referred to as huddle meetings. It should focus on the previous 24-hour performance measured against KPI and the potential disturbances to flow within the next 24 hours. Creating the ideal opportune time for servant leadership to coach and facilitate stability and predictability into our process.

Standard work and visual work instructions – To ensure the sustainability of methods in the process, you can view it as either distributed accountability, performing to the vi-

sion of the process creator or current best practice which becomes the baseline for potential improvement.

Workplace organization (5S) – Is a foundational element required to be able to determine the abnormal from the normal. Though, pay caution that your landscape project is not just a housekeeping exercise, but its purpose is to improve process efficiency. Shadow boards are efficient to improve sanitation compliance segregating and colour-coding our implements as food contact, nonfood contact and floor cleaning.

Sanitation – Specifically within the food industry where paranoia of potential product recalls is always looming, excessive sanitation procedures may be accepted but most likely contribute to negatively impacting your uptime optimization. It is prudent to pause at times to perform.

Enterprise value stream mapping –

Along with creating your spaghetti

diagram to document process as it currently operates and then as a team reflect and optimize for an improved process. For example, micro-stoppages, which plague highspeed processes, and which are so brief they often do not become a data point indicator, this is where personal observation is best. Visual indicators that are verified through data can monitor process performance through overall equipment efficiency or at minimum, provide a monthly reflection that serves

as vital feed-back if your visual indicators are effective.

Ultimately your visual indictors need to become efficient observation tools in support to allow a monitor process to our rule of five by 15 to 50, so we can see the normal or abnormal attributes occurring within the process and affecting your uptime.

Mariela Castaño is Senior VP and COO, and Richard Kunst is President and CEO at Kunst Solutions.

EMC hosted a best practice event for its members in Atlantic Canada on the importance of intentional workplace cultures. It was presented by Rick Benoit, McWane Canada, and Tim Kelly, Workplace Health Outcomes HR.

Being able to attract new workers is critical to survival, let alone growth and operational success. However, attracting jobseekers is a difficult proposal for manufacturers who haven’t kept up with modern recruitment trends — workers in the 2020s have a vastly different set of priorities compared to their predecessors, and aren’t interested in stagnant, immobile employers.

Manufacturing processes are changing more rapidly now than ever before and, without a flex-

ible, progressive ideology to address these changes, businesses will find themselves unable to compete with leaders in their field, driving away new labour. If manufacturers want to stay at the forefront of their sector’s advancement and reap the benefits of an innovative reputation, they’ll need to develop and maintain a strong culture of adaptivity throughout their workplaces and be proactive in constantly updating their processes.

Developing a new workplace culture, or building upon an existing one, requires a significant deal of contextual awareness. Often, manufacturing leaders can fall out-oftouch with their workers, leading to reduced engagement, interest, and ultimately, productivity.

To effectively determine how a business’s culture should change, employers should build strong channels of communication with their labour bases to ensure that they are consistently recognized and acknowledged.

I n addition to the myriad of ben-

Showcasing the positive impact that change can have on typical employee experiences (through hours worked, wages, safety) provides those workers with the incentive to accept it and can make them into ambassadors for change themselves.

efits that worker communication has on an organization’s activities, frequent correspondence and discussion is critical to identifying problems and opportunities with current workplace processes. Keep in mind that a culture is driven by its participants, and workers that don’t feel sufficiently understood will likely have no interest in supporting their culture beyond their day-to-day activities.

Implement methods of collecting and responding to employees’ thoughts and feelings, and you’ll find that your workers become eager to make informed cultural changes.

Another important element of cultural development in the workplace is promoting change and espousing the value it can have to employees throughout the organization. Some

workers comfortable in their current positions may want to reject change outright, which can harm an organization’s ability to innovate and grow.

It’s crucial that, when implementing new policies or updating existing ones, manufacturing leaders clearly state the way that their actions will benefit employees directly. Showcasing the positive impact that change can have on typical employee experiences (through hours worked, wages, safety) provides those workers with the incentive to accept it and can make them into ambassadors for change themselves.

Clearly broadcasting a willingness to change benefits parties outside of the organization — new employees will see that the company is eager to continuously improve

and will understand the direct benefit this employer can have on their own professional development. If cultural changes are promoted enough, they may even reach other key players in the manufacturing sector, defining the organization as a leader in its space.

Adaptivity is key to success for businesses in the 2020s, and, if properly utilized, it can help organizations become leaner, smarter, and more productive. Today’s workers respond well to companies with progressive, innovative cultures. Organizations that can meet jobseekers’ expectations will have access to a sustainable source of engaged, motivated labour.

Discarding tried-and-true processes, activities, and ideologies can certainly be a challenge, but the benefit that change can have on every aspect of a manufacturer’s workplace makes it well worth the implementation.

Article provided by Excellence in Manufacturing Consortium (EMC).

Embraco X Generation compressors, models include, EMX, NTX, NJX and NEX. Each platform has higher levels of energy efficiency and extended cooling capacity over previous generations. They are designed for the use of natural refrigerant. This line can handle larger flammable refrigerant charges increased from 150g to 500g, in open cabinets and to 300g in closed ones. Enabling the adoption of R290 products in larger commercial refrigeration applications. www.embraco.com

Rollon has updated its Smart System lineup of belt-driven linear actuators with a design that supports heavy loads and low maintenance operation in automated manufacturing, packaging machines, and food and beverage equipment. The actuators have a self-sustaining anodized

aluminum frame and a steel reinforced driving belt, they are engineered to provide stiffness for greater load capacity. Symmetrical heads on both ends of the actuators allow users to assemble the gearbox in one of four different positions. The Smart System is designed to make it easy to create multi-axis systems such as a twoaxis Y-Z system, two parallel axis system or a three-axis X-Y-Z system using simple brackets and plates.

Designed to deliver speeds up to five metres per second with possible acceleration of 50 metres per second squared, Rollon Smart System actuators achieve accuracy of ±0.05 millimetres.

www.rollon.com

ATC Diversified Electronics scalable technology allows for remote monitoring of critical processes in a range of conditions.

Sensors can be hard wired directly to the Sensert base unit or wirelessly connected via the Sensert remote I/O for wireless, remote, online capability. Sensor data is monitored in real time and alerts are triggered based on cus-

tomizable thresholds, configurable through the Sensert mobile app or web portal. Each channel can be configured for a high and low threshold value. Sensert works with commercially available volt sensors.

Sensert is engineered to monitor sensors in critical processes and provide alerts to the user in different environments. It can monitor a range of conditions including level, temperature, pressure, flow, current, vibration, presence of voltage, and others.

www.sensertio.com

The podcast features conversations with industry experts about maintenance, reliability, and operations. Topics that are of utmost importance to MRO readers. Previous guests and topics have included:

• Scott MacKenzie – Maintenance at TMMC Plants with a Focus on the Environment

• Martha Myers – Importance of Networking and Education in Maintenance

• Doc Palmer – Focus on Scheduling and Planning of Maintenance

• James Reyes-Picknell – Managing Maintenance and Reliability

• Shawn Casemore – Engaging Your Employees in a Safety Culture For sponsorship opportunities, contact Paul Burton, Senior Publisher, pburton@annexbusinessmedia.com

For guest/topic suggestions, contact Mario Cywinski, Editor, mcywinski@annexbusinessmedia.com A Podcast brought to you by