HYGIENIC DESIGN DELIVERS CLEANLINESS AND COMPLIANCE

In food and beverage production facilities around the world, cleaning and sanitization are just as vital to an organization’s success as the taste and texture of the products they produce.

Although cleaning adds no direct value to a product, the cost of failing to do it properly can be enormous, both in terms of company reputation, and the risk of spreading potentially deadly illnesses. Even when working hard to operate in compliance with the strictest standards, food and beverage producers are forced to recall thousands of products each year, typically for one of three reasons: undeclared allergens (presence of milk, wheat, peanuts or soy which don’t appear on the label), pathogens (E.coli, salmonella or listeria), or physical contamination.

All food and beverage processors are affected by increasingly stringent food safety standards. These standards are contained in the FDA Food Safety Modernization Act (FSMA) in the United States, which is considered the most sweeping reform of food safety laws in over 70 years. FSMA affects almost everyone involved in the North American food supply chain, from manufacturers to shippers to retailers.

Sanitation design is critical to all food and beverage processing operations, but especially to those handling dairy, meat, and poultry products because cultures and other organisms can easily contaminate other

products processed using the same line. Preventing outbreaks of food-borne illnesses demands that processors establish and follow comprehensive cleaning and sanitation protocols, and schedules. However, although cleaning is crucial, it tends to be extremely time consuming. It has been estimated that, on average, 20 per cent of a food and beverage plant’s day is spent cleaning equipment.

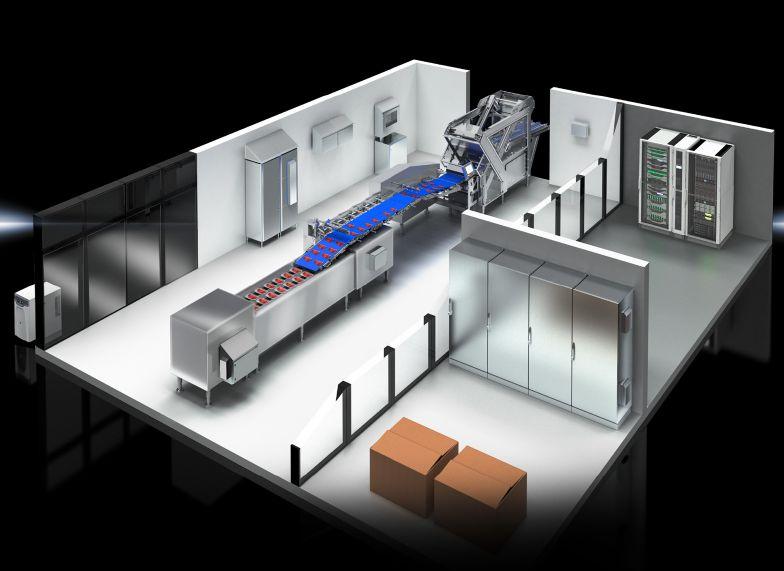

Every surface in a processing line requires regular decontamination, even those that might seem unlikely to come into direct contact with product, such as wall-mount housings and free-standing enclosures that protect the line’s mechanical and electrical control equipment.

In order to withstand harsh cleaning chemicals, high-pressure hot water, and steam, often required for disinfection, a growing number of mechanical engineers and plant operators are specifying stainless steel housings and enclosures for their facilities, which are designed to prevent corrosion from frequent washdowns and allow for shorter cleaning times while using less water and fewer chemicals.

SOLVING THE DISINFECTION DILEMMA

The most productive enclosure designs for the food and beverage industry allow for thorough disinfection without requiring extended scrubbing or expensive chemicals.

Important features to look for when choosing stainless steel housings and enclosures are:

• No gaps between the enclosure and its door or cover. For example, continuous silicone seal door gaskets will help prevent the intrusion of water, steam, or contaminants, and can be easily replaced when worn.

• A smooth surface grain that eliminates tiny pores that could harbour micro-organisms.

• Internal hinges mounted inside the sealed zone to simplify cleaning.

• An integrated, non-detachable rear panel to guarantee reliable hygiene and sealing in an area that is difficult to monitor.

• Side panels that are screw-fastened from the inside to eliminate threads or other crevices that could harbour dirt or bacteria.

• Hexagonal screw fasteners without the head slots that could allow debris to collect, and with external seals to keep moisture out of the enclosure.

• Easy-to-clean stainless-steel locks and cable glands.

• Sloped tops and sealed access points to prevent water or cleaning agent infiltration that could result in electrical failure, unscheduled downtime, and expensive repairs.

• An ingress protection (IP) rating that is consistent with the line’s cleaning protocol. Common IP ratings for food and beverage applications include IP 66 (dust tight and protected from high pressure water jets from any direction), and IP 69K (dust tight and protected from steam-jet cleaning).

Article was provided by Rittal Canada.

COOLING THE QUENCH

Patriot Forge “presses on” with advanced HDPE cooling towers to maintain optimum bath temperatures for quenching metal forgings and cooling hydraulic systems.

BY ED SULLIVAN

F or Patriot Forge, a Canadian custom opendie forging company, feeling the heat is nothing new. Forging is the process of shaping metal by applying extremely high temperatures, and a variety of powerful compressive forces. The process results in products that feature optimum toughness, ductility, and both impact-, and fatigue-strength. Due to those attributes, forged materials are

often the only option for a number of highly critical machinery and equipment applications. The process of forging metal requires dealing with temperatures which can reach up to 1,150°C. Controlling the process hinges on dependable cooling tower technology.

Cooling towers work by taking the hot water coming from the cooling system and reducing the temperature by exhausting the heat into

the atmosphere. The water is then returned to the cooling system through a closed loop. This process is similar to a number of industrial applications such as refineries, metal foundries, and manufacturing plants.

FORMING ALTERNATIVE SOLUTIONS

Patriot Forge produces products in a variety of materials ranging from carbon, alloy, stainless

steel, nickel-based alloys, and aluminum, at its plants in Branford and Paris, Ontario.

Producing for demanding industries requires consistent quality, including the vital hardness characteristics of forgings ranging from two kilograms to 50 tonnes.

The company recently decided to replace its aging, multi-use stainless steel cooling tower at its Branford plant.

“The tower was simply rotting out,” said Derek Hynes, Senior Mechanical Engineer, Patriot Forge. “It is common with metal models which tend to rust and corrode, which requires us to try and plug the water flow, and that can interfere with cooling capacity.”

Located in Building One, the cooling tower expels heat from the quench system, a 160,000 litre water tank into which parts are submerged in water or polymer baths in order to achieve the desired hardness.

Having spent months, and a lot of worker hours, trying to repair and maintain the steel tower, Hynes and his team went looking for an alternative to metal and stainless steel. Part of that research lead him to investigate high-density polyethylene (HDPE) cooling tower design options that provide reliable, trouble-free operation for a longer period of time.

HDPE cooling towers are impervious to

corrosive environments, and require lower amounts of water treatment chemicals and less downtime for repair or replacement. Hynes team went with a HDPE tower model with energysaving features such as direct drive fan motors

that reduce electricity costs.

“We saw that this was a polymer-based tower that was UV-protected, and included a 20-year warranty, so we were convinced that it would offer long-term dependable service,” said Hynes.

HDPE EXCEEDS EXPECTATIONS

According to Hynes, the switch to HDPE was so successful, and exceeded expectations, so Patriot Forge chose to acquire another HDPE cooling tower, supporting multiple systems within the Building One.

The new tower had to cool the water that flowed through a heat exchanger used to draw heat off the hydraulic systems of three large pieces of production equipment. This included a rail-bound manipulator, a hydraulic ring roller, and a 5,000-tonne press, which plays a primary role in the forging processes of the plant.

“Essentially, all three machines are cycling the water that flows through their hot hydraulic heat exchangers and then through this cooling tower. This enables us to keep the hydraulic fluids at a stable 43.3° C,” said Hynes.

EXTENDING THE BENEFITS

Hynes mentioned that thus far the towers have required zero requests for repairs and much less

maintenance or attention. Earlier this year, Patriot Forge needed another cooling tower to help cool the quench tanks in Building Two, so they chose another HDPE. This time, they selected a twincell HDPE cooling tower that would service the company’s heat treat system.

“Both of the quench tanks are about 400,000L, and we use the cooling towers to help maintain a heat level of approximately 38°C,” said Hynes. Patriot Forge designated induced draft models for this building. A major benefit of these towers

is the ability to configure them in combination of up to six units with cooling capacity from 250 to 2,500 cooling tonnes. The modular design gives the end user the opportunity to add cooling capacity as their processing needs grow. The new cooling towers installed at Building Two are installed in a two-cell configuration with combined cooling capacity of 836 cooling tonnes.

“We decided on this size and configuration because the quench tanks in Building Two are much larger,” said Hynes. “So, there is a lot more

water you have to process through the towers.”

Hynes says the towers feature vibration sensors on all fans, which eliminates the need to climb the towers in order to check out the operating performance of the fans, a benefit that Hynes feels is particularly appealing because one of the towers tops out at 65 feet, “a long way up.”

Ed Sullivan is a Los Angeles-based freelance writer with over 30 years of expertise in the mechanical engineering, HVAC, and process cooling industries.

It has been a spring like no other, and undoubtedly 2020 will be a year of unforeseen challenge and great change, as a result of COVID-19’s impact.

However, it also paints a picture of a country coming together, pivoting to a new reality, proving our abilities to be adaptable and flexible in a time of crisis, and persistent at finding results. In the end, the events of 2020 have opened the door for creative growth and opportunity in markets never previously explored.

First, as the battle against COVID-19 continues, we cannot help but have a considerable amount of gratitude for our front line and emergency workers across the board; from healthcare, to retail, to manufacturing, and all points in between. Thank you for all you have done to keep our families, our colleagues, and our leaders, as safe as possible. This has been an incredibly surreal year and the support of Canadians to flatten the curve, by isolating themselves, by donning personal protective equipment (PPE) when required, and by the practicing of necessary and effective protocols, has been incredibly admirable. Food and beverage processors and select food service industries make up an important part of essential companies, identified by the government as most necessary during the pandemic to keep product on our grocery shelves and readily available through takeout services. Processors have engaged their teams, provided and implemented necessary PPE protocols, and drove ongoing communication with employees, to ensure questions are answered, resources provided, and everyone is coping. It’s a time when solid leadership is paramount to guide the organization as deftly as possible.

COVID-19 caught some off guard and businesses had to go into a reactionary state. Second and possibly third waves are likely, they are yet to come and the severity is unknown. We can approach these situations with more enhanced business and emergency preparedness plans, that are built on the experiences the first wave provided, allowing us to be better equipped, trained, and prepared.

I do not believe that either our team at Excellence in Manufacturing Consortium (EMC) or I, could communicate how proud of Canadian manufacturers we are, it’s beyond words. To aid in their navigation of current legislation, or how they can assist others, and to witness all layers of government, community partners, colleges and universities, and associations, all coming together ensuring manufacturers across the country have the information they need to produce the necessary products; is fabulous.

We are extremely fortunate to live in a country where we have the capacity to help each other and have the willingness to share our expertise and knowledge to aid during the pandemic.

EMC has witnessed many changes in industry over the past three decades, but this by far has been the biggest challenge that businesses have has faced. EMC, like many of our community partners, has worked tirelessly to ensure resources are available: from the most current government regulation and legislation requirements, to basic development of policies and procedures, to providing helpful resources and web links, to answering of specific COVID19 related queries.

EMC established a COVID-19 Member Needs Help forum for all manufacturers, and distributed questions from plants across Canada three times a week. Thousands accessed this resource and made use of the current and key information and business support, assessments, communication tools, policies and procedures, and available documentation, provided.

Through our B2B opportunities and representatives across the country, we have connected companies with industry peers who wanted to lend their assistance, experience, or to partner on COVID-19 projects. We have facilitated introductions with manufacturers and entrepreneurs looking for additional start-up and production space, or in search of materials, sanitation, trucking, and supplies.

Our Field Service Team has fielded EMC member questions and answers, and continues timely and engaging dialogue through webinar formats, instead of our regional consortium in-house plant Strategic Interest Group (SIG) events. Legal updates have been held across the country, and topics on leadership, mental stress, and exploring the next stages of business as 2020 unfolds.

Currently, we are working on gaining insight from companies on current challenges and labour force requirements, to help with next steps as we prepare for the “new normal,” through a weekly industry pulse survey. EMC has been busy, but so have our community partners, who have been supplying as much information as possible to keep companies abreast of where we are, and where we are heading.

Adaptability, flexibility, and perseverance are attributes I want to remember this year, and for our resolve as manufacturers and as a country to meet this challenge head on, together. These things should open the door of opportunities.

From the beginning of this pandemic, we adapted to the changing landscape. A baseball was thrown at us, and we chose to hit it as far as we could. We might have had a couple of strikes early, but we adjusted. As a result, we learned to work from home, utilized new resources, and ways of communicating. We looked at our equipment from a different lens and plotted how to make it least contaminated for those working on or near it, while looking at how to maintain production with less personnel.

We all reviewed our methods for staying healthy by instituting the best protocols possible. We looked for an opportunity to hit a home run with our goals, whether retooling to produce a new piece of PPE, essential equipment, or product, to working with other companies on projects or process improvements, or through ongoing production in a manner that kept our employees as safe as possible. We hope that we keep hitting those home runs.

Through this, we can be sure our methods of approach regarding food safety, traceability, logistics, and warehousing, have become more heightened. We come to appreciate the rigid programming the food and beverage sector has had in place. It has enabled production to continue relatively uninterrupted and for food safety representatives to build upon and enhance existing programs from a continuous improvement standpoint.

Industries and partners took on what needed to be done; changing work environments by implementing physical distancing procedures while maintaining production and day-to-day activities, implementing PPE, sanitation protocols, and overall cleanliness processes, keeping the lines of communication open, and formulating next step plans to keep employees safe, product on the shelf, and business productive. Industry tackled opportunities with a positive attitude, with some transitioning from one product to something entirely different, with a “what do we need to do to make this feasible?” attitude versus a stoic “it can’t be done.”

Finally, is the commitment to develop and manufacture essential products at home, recognizing the need for ongoing production to ensure Canadian companies can meet the essential equipment and PPE needs of Canadians in any subsequent waves of COVID-19. Despite current product lines, companies engaged their people to come together to create and formulate designs using equipment on hand to meet the needs of front line workers, organizations, peers, colleagues, and family and friends across the country. Things will never be the same, as a new normal is developing. One we hope is full of opportunities to help companies grow, be safer, be more cognizant of business continuity and risk assessment plans, and strategies to build upon for the future. Our organizations are more adaptable, flexible, and perseverant as a result of our experience with this pandemic. Looking ahead, there is a world of opportunity ready to meet us, Canada

is a strong nation with incredible companies, fabulous people, and untold support from government, community partners, educational institutions, and from all of us at EMC. We are in this together.

If you are interested in learning more about involvement in EMC’s SIG or our special Food and Beverage Sector networking sessions, feel free to reach out and we would be happy to share information on what is coming up in your region.

How do you get involved? If you are interested in learning more about EMC and the Food Sector Initiative, feel free to touch base with Bren de Leeuw, Vice President, Community Partnerships and Stakeholder Relations (bdeleeuw@emccanada. org) anytime. 19-Aug-20 to 20-Aug-20