annexbusinessmedia.com

mfarag@annexbusinessmedia.com

annexbusinessmedia.com

mfarag@annexbusinessmedia.com

I would like to welcome all of our readers to my first edition as the editor of Maintenance and Engineering in Food and Beverage magazine. Throughout these pages, you’ll find insightful articles, expert opinions, and case studies highlighting the latest trends and best practices shaping our industry. Whether you’re a seasoned veteran or a newcomer to the field, there’s something here for everyone to learn and apply in their daily operations. The topics of sustainability and food waste and safety continue important considerations within the food and beverage maintenance and engineering industry in Canada. Efforts to minimize waste generation and increase recycling are central to sustainability initiatives in the industry. Maintenance and engineering teams work to improve waste management systems, implement recycling programs for materials like cardboard, plastic, and metals, and explore opportunities for composting organic waste. This is why, in this issue, we shine a spotlight on sustainability initiatives within the sector. From energy-efficient practices to waste reduction strategies, the push for environmentally conscious operations is driving innovation and fostering a more responsible approach to production. Furthermore, we examine the intersection of food safety and engineering excellence. In an industry where consumer trust is paramount, maintaining the highest standards of quality and hygiene is non-negotiable.

We explore how advancements in sanitation practices and equipment design are helping food and beverage companies uphold their commitment to product integrity and public health.

As we navigate the complexities of an ever-evolving industry, collaboration and knowledge-sharing are more important than ever. We encourage you to engage with your peers, share your experiences, and leverage the insights offered within these pages to drive positive change within your organizations.

Thank you for your continued support and readership. Together, we can shape a future where innovation, efficiency, and sustainability converge to create a thriving food and beverage industry.

My door is always open for comments, suggestions and feedback, please reach me at mfarag@annexbusinessmedia.com.

Maryam Farag

Food & Beverage Engineering & Maintenance

mfarag@annexbusinessmedia.com

www.mromagazine.com

Bearing Isolators

Encapsulated O-rings

Daemar’s Food & Beverage Seals offer design engineers unparalleled performance and compliance. With a diverse array of seal styles and elastomers, we not only meet but exceed industry standards and rigorous government regulations for processing operations.

Metal Detectable Seals

After hitting a record $165 billion in food and beverage manufacturing sales last year, 2024 is expected to see sales moderate in sync with slowing inflation and tighter household budgets.

Despite sector-specific headwinds and changing consumer shopping habits, the overall outlook is more positive. Population growth and stabilizing input costs are two reasons margin improvement is expected in 2024.

“High inflation and interest rate increases over the past two years have put pressure on household budgets, leading to changes in consumer spending habits,” said FCC chief economist, J.P. Gervais in highlighting the evolving consumer landscape. “As a result, Canadians spent less on average on food and

beverages in 2023.”

“While changing shopping habits may pose challenges, they also present opportunities for food and beverage manufacturers,” said Gervais.

“Taste remains the top consideration for consumers, but price sensitivity has increased, leading processors to innovate and meet evolving consumer demands.”

“FCC Economics is projecting a slight decrease of 1.4 per cent in food and beverage manufacturing sales for 2024. However, we anticipate gross margins to improve by 1.7 per cent on average. One wildcard in our forecasts is the resilience of the U.S. economy, which could lead to growth in exports,”added Gervais.

Many commodity prices have declined which will work their way through the supply chain. These trends are anticipated to continue, boosting margins in 2024.

The report forecasts a decrease

in the inflation rate for food purchased at grocery stores, falling below 2.0 per cent this spring and stabilizing around pre-pandemic levels thereafter.

“While challenges persist, 2024 holds promise for Canadian food and beverage manufacturers,” said Gervais. “By adapting to changing consumer preferences and leveraging opportunities presented by population growth, the industry can navigate the year ahead with cautious optimism.”

The annual FCC Food and Beverage Report features insights and analysis on grain and oilseed milling; dairy, meat, sugar, confectionery, bakery and tortilla products; seafood preparation; and fruit, vegetable and specialty foods, as well as soft drinks and alcoholic beverages.

Today, the Honourable Lawrence MacAulay, Minister of Agriculture and Agri-Food, announced more

than $97 million under the Agricultural Clean Technology (ACT) Program. This funding will support 162 projects across Canada that will keep farmers on the cutting edge with clean technologies.

Minister MacAulay made the announcement at Folly River Farms Limited, a 74-year-old familyowned dairy farm in Debert, Nova Scotia. The farm operation received $49,280 under the Adoption Stream of the ACT Program to purchase and install a solar energy system. This project uses solar energy to replace electricity from the grid, significantly reducing the farm’s greenhouse gas (GHG) emissions.

The ACT Program provides farmers and agri-businesses funding to help develop and adopt the latest clean technologies to reduce GHG emissions and boost their long-term competitiveness. The funding is focused on three priority areas: green energy and energy efficiency, precision agriculture; and bioeconomy solutions.

Across Nova Scotia, the ACT Pro-

gram has supported 24 projects to date, representing a total of more than $6 million. The Government of Canada will continue to support the research, development and adoption of clean technology to help the sector adapt to climate change, so Canadian farmers can continue feeding our country, and the world.

“Canadian farmers fully understand the need to take care of the environment and they are constantly innovating to find new solutions to reduce their emissions. Our investment in the Agricultural Clean Technology Program will help keep our farmers and ranchers on the cutting edge, so they can make their operations more resilient today and for generations to come.”

Said The Honourable Lawrence MacAulay, Minister of Agriculture and AgriFood 414 projects have been announced to date under the ACT Program, totalling up to nearly $196.9 million. These projects complement the work already underway to help farmers reduce carbon emissions

and develop technology to adapt to climate change.

MicroHarvest, a biotechnology company pioneering the production of sustainable protein ingredients through microorganisms, has become the first biomass fermentation player to join Food Fermentation Europe (FFE), the industry alliance in Europe for the food fermentation sector.

With FFE already comprising pioneering precision fermentation companies, MicroHarvest’s inclusion in the alliance validates the acceptance of biomass-fermented ingredients within the sector and opens the doors to cooperation with other industry players in deliv-

ering a more sustainable food system and wider uptake of the next generation of animal-free food.

CEO Jevan Nagarajah stated: “We are delighted to welcome MicroHarvest into our alliance as our first biomass fermentation member. Leveraging their unique perspectives, we

will continue to chart new frontiers for European food systems and pave the way for a more environmentally conscious future.”

While precision fermentation is a technology that allows the rewiring of microorganisms as ‘production factories’ for specific functional ingredients, biomass fermentation

uses the high protein content and rapid growth of microorganisms to efficiently make highly scalable amounts of protein-rich foods.

Commenting on the development, MicroHarvest Co-Founder and CEO Katelijne Bekers said: “We’ve made some great progress alone but together with FFE we can make an ever greater impact, we are thrilled to join the ranks. We look forward to listening to different partners and exploring the full potential of fermentationenabled solutions. By communicating and, most importantly, acting together, we can drive positive change in the food system. We believe the world will be eager to learn what food fermentation can do for it.”

Based in Hamburg and Lisbon, MicroHarvest has experienced exceptionally fast growth since its inception in 2021. Having raised EUR 10M to date, the company has already successfully achieved several milestones towards commercialization, including the launch of its pilot plant last November in Lisbon and securing a manufacturing partner.

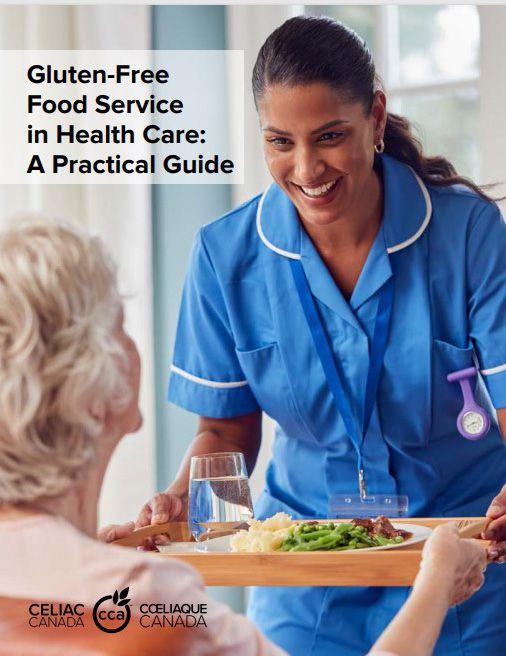

Celiac patients in hospital and longterm care residents who cannot advocate for themselves are often served food containing gluten, which can lead to horrendous symptoms and even death if they’re fed unsafe food for long enough. Tiny amounts of gluten can have severe consequences.

Many healthcare workers and managers have not been trained in gluten-free food service and are unaware food they serve may make those in their care sicker. The guide solves a serious problem that could save lives.

“I wish my mother’s care home workers had the guide to keep her safe. Unfortunately, after repeated cross-contamination she deteriorated rapidly until her death. This guide could save thousands of lives,” hopes Linda Sill of Kitchener, Ontario.

1% of Canadians have celiac dis-

ease (CD), an auto-immune condition that triggers the body to attack itself after ingesting gluten from grains like barley, rye, and wheat. CD has 200+ physical and neurological symptoms.

“Given pressures in healthcare, it’s challenging to meet the needs of a variety of diets, and many workers haven’t had the chance to get trained,” explains lead author Doris Foster, who was a Registered Dietitian and Director Nutrition Services in hospitals for many years. “We did a global scan but found very few fully comprehensive, all-in-one training resources for gluten-free food service in healthcare.”

So, Celiac Canada (CCA) created a free guide with downloadable tools that make it easy for managers to teach staff key points. “Learning to serve safe, great-tasting gluten-free food improves patient health and quality of life significantly,” explains Foster.

Canada’s largest food service provider, Sysco is sharing the guide with customers, at healthcare & senior liv-

ing events across the country and on LinkedIn. “It’s a great tool operators can use to learn how to support this growing dietary challenge,” explains Sarah Emmerton, RD, VP, Healthcare & Senior Living.

The number of people diagnosed with gluten disorders is growing. Celiac Canada plans future resources for the food service sector to help people with CD eat safely when away from home.

BY EMILY NEWTON

People within and outside Canada enjoy eating seafood. However, they may not immediately think of the role advanced freezing plays in preventing waste that could occur before the delicious options reach their plates. Conversely, food and beverage industry professionals are highly familiar with why they must explore ways to reduce seafood waste with appropriate freezing techniques. Here are some of the benefits such practices bring.

The internet has eliminated geographical boundaries, introducing restaurant owners, food critics, cooking enthusiasts and others to foods not usually available in their areas. Advanced freezing techniques make it easy for consumables to travel safely through numerous countries before reaching their destinations.

In one recent example, the Japan External Trade Organization hosted a Japanese Seafood Fair in Vancouver. Frozen goods travelled all the way from Japan so attendees could enjoy samples from nine participating restaurants and try new specialty dishes highlighting particular seafood products.

One of the event’s goals was to show Canada’s restaurant owners or managers compelling reasons to include Japanese seafood on their menus. They will understandably be much more interested in exploring that option if they know advanced freezing methods support food travelling to Canada and will not compromise its safety.

Elsewhere, people from China’s Guangdong province hosted a forum introducing Toronto attendees to ready-to-eat meals that included and spanned beyond seafood. For example, one participating company had already successfully brought some products to Canadian supermarkets. One offering was fotiaoqiang, a thick soup containing various seafood ingredients.

The options spotlighted at this forum were frozen, ready-to-cook options. Such possibilities show people in Canada’s food industry that it’s easy to prepare these meals once they reach restaurants, consumers’ shopping baskets or other destinations. Individuals who know advanced freezing techniques keep food well-preserved from China to Canada or anywhere else feel more confident about serving or selling it in their establishments.

Freezing keeps the food in the right condition throughout its supply chain

journey to reduce seafood waste. This encourages people to broaden Canada’s seafood product assortment.

Just as some food industry professionals outside Canada want to bring their goods into the country, Canada’s seafood industry is doing well and attracting attention from foreign buyers. The Indo-Pacific region contains 40 markets Canadian exporters target with their seafood products.

China is the top buyer, while Japan, South Korea and Hong Kong are other key markets. Lobster, crab and salmon are some of Canada’s top seafood exports, with each product representing industries of more than $1 billion.

However, these seafood products’ good taste and high quality aren’t the only characteristics that catch foreign buyers’ interest. People accepting seafood exported from Canada want to verify that the sellers use advanced freezing techniques to reduce seafood waste and maintain acceptable standards. Offering such consistency will increase the chances of food professionals continuing to buy Canadian goods.

Selling frozen goods allows Canadian companies to reduce seafood waste by broadening their potential purchaser pool and moving into new markets. Additionally, Canadian sellers have found themselves in good positions to benefit from trade-related tensions within the Indo-Pacific region.

In 2022, China banned all Japanese seafood due to the controversial dumping of a nuclear plant’s water into the Pacific Ocean. Some analysts believed Canadian exporters could readily fill the associated gap. For example, China bought 2,340 metric tons of Canadian scallops in 2022. The country could easily purchase more if

buyers found suitable sources in Canada to meet new, increased needs. Advanced freezing techniques would be instrumental in proving to Chinese buyers that the seafood would arrive in ready-to-use condition. Blast freezers are popular methods of providing the desired quality. They keep food at temperatures of at least minus 30 degrees Fahrenheit and ensure the thawed food closely matches the fresh-caught taste.

Economic trends over the past several years have made some shoppers feel

like they can never know what to expect during each trip to the supermarket. For example, some areas experienced worsened or first-time food insecurity during the COVID-19 pandemic. More recently, people have had to adjust their shopping preferences due to inflation.

As consumers look for practical ways to reduce seafood waste while catering to smaller budgets, they find frozen products meet their needs. One poll found that 87% of Canadians eat seafood regularly. Fortunately, many can keep doing that while maintaining their budgets, even if feeling inflation’s squeeze.

They may not realize that even fish that looks fresh at the supermarket was probably in a freezer at some point. People who catch fish use techniques such as dry ice and vacuum sealing to preserve them as soon as they come from the water.

Many culinary experts also advocate purchasing frozen fish instead of options sold fresh. Frozen fish brands usually use advanced freezing techniques, carefully optimized processes and the latest equipment.

Local supermarkets are usually comparatively less precise regarding when they begin thawing frozen fish and selling it as fresh. Relatedly, such retailers are less justified in buying expensive freezing equipment that accounts for only a relatively small portion of their business models.

Another selling point of frozen fish is it’s usually cheaper than options in a supermarket’s fresh-fish display case. Besides saving money by choosing the less expensive option, consumers can reduce seafood waste by planning to prepare only the amount they know their households will eat. They can then store the rest in their freezers, enjoying the convenience of knowing it will taste as good as fresh after thawing and preparation.

Advanced freezing techniques play significant roles in seafood export, import, safety and enjoyment. Many people who love such dishes don’t live near enough to the water to feasibly prepare fish the same day it’s caught. However, freezing equipment and techniques preserve that fresh-caught taste and support safe transfer from the ocean or preserving facilities to consumers’ plates. This makes it easier and safer for consumers to enjoy seafood from all over the world and reduce waste, which saves money and also benefits the planet.

BY L. (TEX) LEUNGER

Equipment reliability is reduced (or ends), whenever a failure occurs, depending upon the criticality of the failure, so it is necessary to understand what is considered a failure. Any incident or condition that reduces a machines ability to carry out its intended function should be considered a failure. Not everyone believes this. There are some who believe that certain levels of machine degradation are acceptable so long as production continues and it is unfortunate that some organizations permit machinery to continue to operate in a degraded state, always resulting in reduced production, increased costs, and potentially much more serious damage to the machine.

Research into equipment failures have resulted in the determination that all machine failures belong in one or more of seven root cause failure classifications. These include; faulty machine design, material defects, manufacturing errors, assembly or installation defects (by the manufacturer), or off design or unintended service, improper operation, operating procedures or maintenance (by the plant operator).

Now, determine your specific practises. Are they logical and effective?

DOES YOUR MAINTENANCE GROUP OVERHAUL A MACHINE OR REPLACE CERTAIN COMPONENTS BASED ON THE MACHINES AGE?

Overhauls and component replacements based on machine age is illogical because the result is a much higher life cycle cost that many people believe

is normal. Metal fatigue of a particular component such as a rolling element bearing is the only failure related to age that should be considered. Does your maintenance department replace machine components based on a maintenance program dependent on calendar time or hours?

Too frequent component replacements can actually increase premature failures due to improper methods, poor assembly procedures, incorrect specifications and faulty workmanship caused by time constraint demands.

IS YOUR OPERATIONS DEPARTMENT FULLY TRAINED AND COMPLETELY KNOWLEDGEABLE WITH REGARD TO THE OPERATING PROCEDURES OF THE PRODUCTION MACHINERY IN YOUR PLANT?

Many plant and machine failures can be directly attributable to poor operating conditions or procedures, or inadequately trained operators.

DOES YOUR PLANT HAVE A WELL DESIGNED, CORRECTLY APPLIED CONDITION BASED PREDICTIVE MAINTENANCE PROGRAM?

Failures will usually be surprises unless effective condition monitoring of all critical machines is regularly and consistently applied based on hours of operation, that monitor such machine or applicable component conditions as temperature, vibration, lubricant quality and contamination.

WHEN A FAILURE DOES OCCUR, DOES YOUR MAINTENANCE GROUP APPLY AN EFFECTIVE INVESTIGATIVE PROCESS LEAD BY A TECHNICIAN FAMILIAR WITH THE PROCESS?

An effective process includes a determination of the initiating cause by asking the first five of six applicable questions depending on the failure type; ‘what’ failed?, ‘when’ did it fail?, ‘where’ did it fail?, ‘who’ was at the site during the failure? (this is important because the operator will have first hand knowledge of what may have lead to the failure), ‘how’ did it fail? was it mechanical, such as misalignment, excessive loads or speeds, ineffective sealing, or was it a lubrication problem related to corrosion, contamination or lubricant quality.

ONCE THE PREVIOUS QUESTIONS HAVE BEEN ANSWERED DOES THE FAILURE INVESTIGATOR DETERMINE THE POTENTIAL CAUSE OF THE FAILURE BY ASKING THE LAST QUESTION ‘WHY’ DID IT FAIL?

The investigator must now consider these possibilities. Did operating conditions change? Had recent machine modifications been carried out? Could more effective or timely condition monitoring have predicted the failure? What was the last maintenance activity carried out on the failed machine and could PM changes prevent a recurrence of the failure? Was there human error involved? Are

operational or maintenance training improvements necessary?

DOES THE ORGANIZATION UNDERSTAND THAT THE PURPOSE OF A ROOT CAUSE FAILURE ANALYSES IS TO COMPLETELY PREVENT RECURRENCES OF ALL FAILURES?

Many plants increase production capacities by increasing machine loads or speeds through modifications without consideration to their effect. An example is the increased speed of conveyors without considering the increased load on the conveyor support bearings. Another example is that of increasing

the size of a loader bucket without considering the excessive and damaging load on the operating hydraulic system components.

IF IT IS NECESSARY TO CONSULT WITH AN ORGANIZATION THAT OFFERS ELECTRON MICROSCOPY ANALYSIS, DOES YOUR MAINTENANCE GROUP KNOW WHAT THAT ENGINEERING SERVICE REQUIRES IN ORDER TO PROVIDE CONCLUSIVE RESULTS?

The scanning electron service provider will of necessity require complete information about the equipment type, operating conditions such as load and speed, lubricant type in use at the time of the failure and as many related details as possible, in addition to the failed component(s) itself including everything noted in the concluding recommendations below.

In order for the consulting engineering/scanning electron failure analyses company to conclude a sound root cause failure analysis for the plant, it is necessary that the following materials be provided to that firm; a sample of the used oil in use “at the time of the failure” as well as a sample of the new oil used in order to obtain comparative results for base or acid number and viscosity, to determine oil quality. The oil filter from the failed machine should also be provided. This will permit the engineering laboratory to analyze the oil from the filter (if a used oil sample cannot be provided), to determine elemental wear particles, but also to determine the presence of contaminants that standard oil analyses may not determine.

These results should compare with the QEM SCAN/SEM/ XES analysis results that may confirm the particular cause of failure, such as large particle contamination scoring, excessive wear caused by adhesion, abrasion, corrosion, electrical discharge, or

metal fatigue. Where the component failure is related to cooling systems such as radiators, cooler cores or boiler tubes, the analysis should include XRD analysis to determine if mineralogical/crystalline materials are present. Good luck with your root cause failure analyses!

L. (Tex) Leugner, the author of Practical Handbook of Machinery Lubrication, is a 15-year veteran of Royal Canadian Electrical Mechanical Engineers where he served as a Technical Specialist. He was the founder and operations manager of Maintenance Technolgy International Inc. He can be reached at texleug@shaw.ca.

BROUGHT TO YOU BY EMC

Canada’s food & beverage manufacturers have multiple ambitious goals to achieve:

● Minimize recalls and preserve food safety

● Lead the way in food waste reduction

● Advance toward Net Zero

With consumers scrutinizing food costs and supply chains, manufacturers are under pressure to show progress on food safety, waste, and climate issues. None of these endeavors can be compromised to help improve another, so how are food producers expected to strike

a balance? Augmenting core business processes such as training and tracking can significantly impact success in all areas.

Food safety is strictly legislated in Canada. Non-compliance can result not only in fines, but also in negative public opinion. Two key requirements in food safety are training and traceability. Ensuring that employees at all levels know what needs to be done is an essential step. Tracking food from the supplier to the consumer will demonstrate compliance, identify risks,

and minimize the scope of recalls. Improving these core processes is a strategic way to support food safety best practices.

According to the National Zero Waste Council, more than a third of food produced and distributed in Canada never gets eaten. Lack of traceability and human error are cited as reasons for food loss and waste by Canadian Manufacturing. Tighter controls and technologydriven solutions are strategies that could help manufacturers reduce food waste. Solid training and tracking processes help form the foundation needed to see improvements.

Pressure is on Canada’s manufacturers to make the necessary changes required for a green, low-carbon economy. Climate-related disclosure requirements are no longer in the planning stages, they’re here. Federally regulated financial institutions

must disclose information about how they are meeting emissions standards starting soon (learn more from the Office of the Superintendent of Financial Institutions). That means manufacturers need to be prepared to submit carbon footprint tracking when requesting insurance coverage and financing.

In the EMC Industry Pulse Survey 2024: Green Manufacturing and Clean Technology Adoption Report, we discovered that a top issue preventing manufacturers from adopting clean technology was unclear measurements and reporting require-

ments, as well as lack of internal skills and workforce capabilities. Help is available. For example, the Golden Design Rules for Plastic Packaging developed by The Consumer Goods Forum’s Plastic Waste Coalition of Action provide a framework to reduce plastic packaging and ease recycling. These rules include increasing value in PET recycling, removing problematic ele-

ments from packaging, eliminating excess headspace, and 6 other rules.

More information about the Golden Design Rules for Plastics Packaging is available at goldendesignrules. plasticspact.ca.

Another option to reach sustainability goals could be edible packaging. Whether or not this type of packaging is appropriate will depend on several factors, including shelf life, storage, and shipping. As adoption of sustainable solutions increases, more innovations can be expected.

Reducing waste, ensuring food safety, and increasing sustainability are essential components for successful food production. Efficient, effective business processes including training and traceability are the underpinnings of success. Programs and guidance are available through EMC to help manufacturers adopt best practices and reach their objectives.

EMC is Canada’s largest manufacturing consortium, connecting manufacturers through community relationships, production, benchmarking and best practice sharing.