Excellence in Manufacturing Consortium is a full service, personalized and customized support team for all things manufacturing including productivity, quality, purchasing, supply chain, health & safety, continuous improvement, operations and human resources. We deliver industry-driven resources to the manufacturing industry.

EMC meets manufacturers where they are.

We connect consortium areas together through community relationships, production, benchmarking and best practice sharing while leading the change with trendsetting, industry savvy training, programming and funding solutions for everyday challenges and beyond.

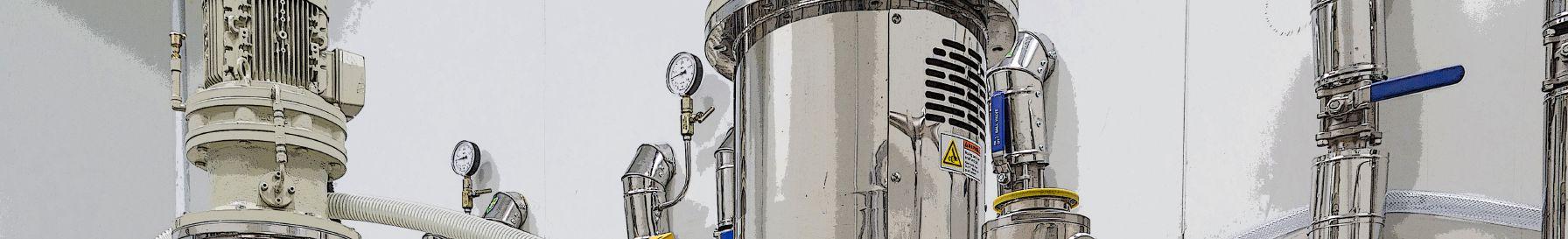

Advanced manufacturing and the digital transformation is here, and companies in the food and beverage sector are at the forefront. It includes artificial intelligence (AI), automation, robots, computerized maintenance management software (CMMS), sensors, and just about anything that used to be done manually, that is now digital.

The Government of Canada and Government of Ontario are seeing this, and have been investing in a variety of companies to help them with advanced manufacturing capabilities.

The Federal Economic Development Agency for Southern Ontario, through its Jobs and Growth Fund (JGF), has invested many millions so far in 2023. A few examples are:

• A Friendlier Company Inc. received a $500,000 investment to standardize its reusable takeout packaging system through a network of businesses across Canada.

• Unified Flex Packaging Technologies was given a $4-million investment, which will enhance production capacity at its new Woodstock facility, to increase manufacturing of its recyclable films.

• Omnia Packaging received over $3.7- million to help it purchase new equipment.

• Cedar Valley Selections Inc., in Oldcastle, Ontario, got a $375,000 investment to buy new equipment to improve its production capacity and meet the demand for its ready-to-make foods.

• Stanpac Inc. was given a $5 million investment toward the purchase of advanced manufacturing equipment to help expedite it’s transition to sustainable packaging. The new machinery produces fully recyclable and compostable products, including a new paper-based bulk ice cream container.

Mother Parkers Tea & Coffee, a coffee and tea manufacturer in Mississauga, invested $33.4 million to help boost local manufacturing and create jobs in the community. With the Government of Ontario providing $5 million through the Advanced Manufacturing and Innovation Competitiveness stream of the province’s Regional Development Program.

Also, the Ontario government is giving $100,000 to the Northern Ontario Farm Innovation Alliance (NOFIA) to study, assess and grow the network of agri-food producers, processors, distributors, procurers, and consumers in Northern Ontario.

This is just a small sample of the investments that have been made over the last few months. More are sure to come in the future, as the industry is “going full steam ahead” into a digital transformation.

Mario Cywinski

Food & Beverage Engineering & Maintenance

mcywinski@annexbusinessmedia.com www.mromagazine.com

Daemar’s lineup of Food & Beverage Seals provides design engineers with a wide range of seal styles & elastomers that not only fulfill the performance requirements of the industry but also comply with the rigorous regulations and standards set by the government for parts involved in processing operations.

A $5 million investment was made to Stanpac Inc., by the Federal Economic Development Agency for Southern Ontario (FedDev Ontario). The investment is set to help Stanpac scale up the manufacturing of its compostable and recyclable packaging, and to create 30 jobs.

“This investment from FedDev Ontario has a significant impact on how Stanpac will be able to take our sustainable packaging innovations to market, not only here at home but to the more than 30 countries we export to presently, and beyond those to new markets,” said Matt Witt, Co-President, Stanpac Inc. “In addition, we will create more employment opportunities which in turn drive our continued sustainable packaging advances.” This investment, through the Jobs

and Growth Fund (JGF), supports the purchase of advanced manufacturing equipment to expedites Stanpac’s transition to sustainable packaging. The new machinery produces fully recyclable and compostable products, including a new paper-based bulk ice cream container.

“I am pleased that the Government of Canada is investing in an innovator like Stanpac. This funding is important because it will help the company to build and futureproof,” said Chris Bittle, Member of Parliament for St. Catharines.

The investment announcement was made during an event at Stanpac. The Honourable Filomena Tassi, Minister responsible for FedDev Ontario, Vance Badawey, Member of Parliament for Niagara Centre and Parliamentary Secretary to the Minister of Indigenous Services; and Bittle, were on hand.

“Ontario’s manufacturing industry is the engine that drives our national economy, and our government is investing in the people that make it run,” said Tassi. “I’m honoured to support Stanpac as they create good local jobs and develop greener packaging products.

We will continue working together to deliver more for Canadians and grow an economy that works for everyone.”

The Government of Canada invested over $8.2 million for three food packaging companies to develop and scale green, Canadianmade packaging solutions and products, and create over 120 jobs across southern Ontario.

“Plastic pollution is a growing problem globally, affecting both the economy and the environment,” said Lloyd Longfield, Member of Parliament for Guelph. “That is why I am pleased to see today how these three businesses, including

two based in Guelph, are developing innovative, environmentally conscious packaging products and solutions to help reduce single-use plastic use and create good jobs for the future.”

A Friendlier Company Inc. was given a $500,000 investment, Friendlier will now standardize its reusable takeout packaging system through a network of businesses across Canada. It will support a circular economy by cleaning and reusing the same packaging up to 100 times. It will also create 10 jobs.

“Our mission at Friendlier is to simplify the world’s transition away from single-use packaging, and this funding will allow us to reach significant milestones towards that goal,” said Kayli Dale, CEO and co-founder, A Friendlier Company. “The funding will allow us to accelerate our growth across the country, creating jobs and reducing waste through a circular supply chain in Canada. We believe Canada should be at the forefront of the transition away from single-

use packaging, and this funding will help us continue to lead the movement towards a circular economy in packaging.”

Unified Flex Packaging Technologies gets a $4-million investment, which will enhance production capacity at its new Woodstock facility, to increase manufacturing of its recyclable films used for food packaging and pouches. It will also create over 60 jobs.

“Unified Flex Packaging Technologies is excited about our partnership with FedDev Ontario. This funding will help train and develop highly skilled teams specializing in automation and manufacturing,” said Al Aman, vice-president business development, Unified Flex Packaging Technologies. “By investing in lean manufacturing processes, we will reduce costs and improve our global competitiveness to deliver world-class packaging solutions.”

Omnia Packaging will receive over $3.7- million investment to help it purchase new equipment.

This investment will support leading companies reduce plastic waste and create 50 jobs.

“With this $3.7-million investment, FedDev Ontario is boosting the project, allowing Omnia to purchase and operate the equipment earlier, creating jobs earlier than scheduled,” said Paulo Sunino, CEO, Omnia Packaging. “This will also allow Omnia Packaging to in troduce 100 percent sus tainable packaging in the market for the harvest season of 2023 instead of 2024.”

EMC’S NEW

Excellence in Manufacturing Consortium (EMC) have unveiled a new logo.

In recent years, EMC has seen the transition to online business that has been unwavering. EMC is embracing this transi tion and plans to evolve

to become a more powerful, more recognizable brand, to benefit Canadian manufacturing sector.

“Our refreshed logo expands EMC’s signature cube to showcase an explosion of idea generation and program offerings that support manufacturers across Canada. The elements of EMC are represented by each surface of the expanded cube - the value of excellence, the focus on manufacturing and the collaboration of consortiumbased networks,” said JP Giroux, president, EMC.

The

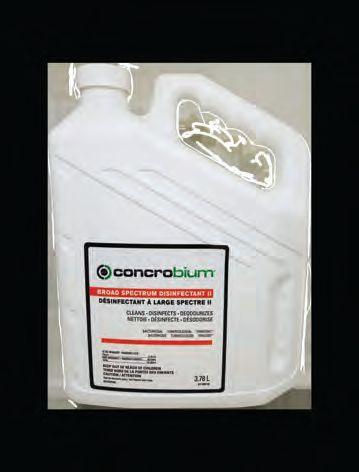

Concrobium Broad Spectrum Disinfectant II is a broad-spectrum virucidal hard surface disinfectant that is expected to inactivate SARS-CoV-2, the virus that causes COVID-19.

The food and beverage industry is constantly evolving, driven by shifting consumer behaviors, technological advancements, and increasingly stringent regulations.

BY STEVE RICHMOND

In recent years, consumers have become more focused on maintaining healthy lifestyles, adding to the transformation of this dynamic sector. As a result, companies in the industry must continually adapt and innovate to stay ahead of these trends and meet the changing needs of the market.

In such a competitive landscape, it’s crucial for businesses to position themselves to confront and overcome the challenges posed

by these rapid changes. Now is the time for companies to implement modern technology solutions that will set them apart from competitors, establish them as industry leaders, and ensure their long-term success.

The latest technologies, such as AI-driven chatbots and cloudbased enterprise asset management (EAM) systems, can help the F&B industry to reduce human error, optimize the supply chain, reduce

wastage, and manage costs. From enhancing customer service and supply chain operations to improving sourcing, logistics, and disaster response, these advanced technologies offer numerous opportunities for innovation and growth.

Technology has revolutionized how industries operate, enhancing their efficiency, cutting costs,

and transforming their interactions with customers. According to a recent report by Deloitte, companies with higher digital transformation maturity reported 45 per cent above industry average revenue growth. The report states, “Digital transformation is about both doing old things better, faster, and cheaper and doing new things that weren’t possible before.”

One industry that has significantly benefited from AI-based chatbots

like ChatGPT is F&B, where chatbots are proving to be a game-changer, especially for customer service efficiency. ChatGPT is a powerful tool that can assist F&B companies in being more responsive to customer requests and providing readily available information. Chatbots automate the ordering and delivery process by allowing customers to place orders and track delivery status via messaging. This can help reduce wait times and eliminate the need for manual input.

AI-driven chatbot can handle customer queries far more efficiently than traditional call centres, reducing the need for human operators, and saving on labour costs. Additionally, during challenging times such as food recalls, ChatGPT can manage the sudden influx of customer questions and concerns via text or voice, streamlining the communication process and providing timely, accurate information.

With vast amounts of data available from the F&B industry, AI technologies like ChatGPT can analyze information on the sourcing, processing, and distribution of products and provide insights on improving logistics and delivery times and reducing spoilage. By integrating AI systems, companies can optimize their supply chains and make more informed decisions, resulting in cost savings and improved customer satisfaction.

Chatbots can provide real-time inventory management by tracking stock levels and updating inventory records automatically. This can help companies manage inventory more efficiently and avoid stockouts. They can also proactively resolve potential issues such as order delays, out-of-stock items, or incorrect orders. In addition to enhancing customer service and supply

chain management, AI technologies can help the F&B industry optimize sourcing and logistics operations.

By analyzing real-time weather data and its impact on crops, AI solutions can also suggest better ways to source key ingredients for finished products. This information enables companies to make well-informed decisions about where to procure their raw materials from, considering factors such as crop growth rates and regional weather conditions.

AI technologies can also play a crucial role in responding to natural disasters and other unforeseen events. By analyzing data on the affected

Realize your vision with Festo‘s approach to smart automation for food processing and packaging. Partner with Festo today.

The F&B industry is undergoing a significant digital transformation, driven by the need to stay agile and competitive. As companies navigate the challenges posed by shifting consumer behaviors, technological advancements, and regulatory pressures, embracing innovative solutions such as AI-driven chatbots and cloud-based EAM systems is essential for future success.

population, geographic location, and specific needs, AI systems can quickly determine the necessary resources for disaster-stricken areas, such as providing millions of bottles of water in the aftermath of a hurricane. This capacity for rapid, datadriven response helps the F&B industry minimize the impact of natural disasters on their operations and deliver much-needed aid to affected communities.

Equipment and machinery availability and reliability are crucial for F&B manufacturers. The dynamic nature of the industry often necessitates shifts in production schedules and the relocation of output capacities.

In such situations, an EAM system is essential for assessing the condition of manufacturing capabilities at new or repurposed production sites. AI is critical to the optimization of EAM solutions. AI-driven EAM ensures that the necessary workers, equipment, parts, and resources are prepared for the changes

and that the transition proceeds smoothly.

Cloud-based EAM solutions offer connectivity and security, ensuring that companies have continuous access to vital information about their assets and can quickly address any maintenance issues. Further, in an industry that is no stranger to the impacts of natural disasters – which can disrupt power, water supply, and displace workers – a cloud-based EAM system can be invaluable in enabling a swift recovery.

With data stored securely in the cloud, companies can access their EAM system as soon as power and internet connectivity are restored, facili-

tating the process of repairing equipment, coordinating teams, and resuming operations.

In an industry grappling with rising costs and inflation, cloudbased EAM solutions can play a pivotal role in managing and containing expenses not directly related to raw materials. By providing real-time data and insights, EAM systems can help companies make informed decisions about their assets, optimize maintenance schedules, and minimize downtime. This increased efficiency ultimately leads to cost savings and better resource allocation.

Although the F&B industry has been slower to undergo digital transformation, migration to the cloud is now accelerating as companies seek to be nimbler and more responsive to rapidly changing market conditions. Cloud technology enables significant improvements in productivity, cost efficiency, and data accessibility because it’s decentralized. In addition,

Software-as-a-Service (SaaS) is fostering innovation by providing specialized software solutions on a subscription basis.

According to Foundry’s Cloud Computing Study 2022, 69 per cent of businesses have sped up their cloud migration within the past year. Managed by providers, SaaS solutions allow users to remain current with industry requirements, standards, and regulations without any intervention. This presents numerous benefits to the F&B sector, such as enhanced quality control, streamlined reporting, increased business agility, and cost savings. These advantages enable F&B businesses to concentrate on their core operations and growth while outsourcing their IT infrastructure to specialists.

The F&B industry is undergoing a significant digital transformation, driven by the need to stay agile and competitive. As companies navigate the challenges posed by shifting consumer behaviors, technological advancements, and regulatory pressures, embracing innovative solutions such as AI-driven chatbots and cloud-based EAM systems is essential for future success.

By leveraging the power of advanced technologies, F&B businesses can enhance personalized customer service, automate ordering and delivery, streamline processes, manage inventory in real time and provide proactive issue resolution. The result is an enhanced customer experience, improved operational efficiency, and increased revenue. Additionally, digital transformation enables companies to stay ahead of industry trends, and ultimately thrive in an increasingly complex landscape.

Steve Richmond is the CEO and Founder of Projetech.

EFFORTS AND BENEFITS

Within the automation industry, standardization can sometimes feel like an inevitable undertaking whether you are a food and beverage plant operator, a software developer, or an equipment manufacturer.

BY MARCUS MIELKE

Simply, standardization is the pursuit of creating and implementing technical standards based on the consensus of different groups. Within automation, we can look at this in terms of specifications for processes, systems, and products. The different groups with stakes in the industry can be generally narrowed down to plant operators and equipment manufacturers, and these are the two perspectives which benefit in different ways from standardization efforts. The end user, or F&B plant operator, benefits from a common approach within a given facility. Everyone is on the same page, all their technology integrates seamlessly and reports automatically, and all their staff teams enjoy a consistent manufacturing process, which simplifies training and maintenance.

OEMs, on the other hand, enjoy the ability to standardize the design of their equipment and processes, which enables a greater level of con-

sistency in terms of what they offer to customers, and greatly simplifies their design and engineering process, and streamlines the responsibilities of their in-house service team. Ultimately, all organizations will discuss standardization, at some point, for some reason or another, but either the end user or the OEM will prevail when it comes to designing standardized systems and processes. Either OEMs solely manufacture equipment that suits their standards, or end users only purchase things that fit their own standardized approach. Which side wins out will be based on the experience of the end user, and their relationship with manufacturers. The automation industry itself is marked by rapid change, with con-

stant advancements and optimizations being pushed by new technologies and ideas. Standardization works to ensure that these rapid changes are integrated into existing facilities and systems, providing the maximum benefit possible to both users and manufacturers. Looking at how standardization improves the quality of a facility’s output, bolsters interoperability, increases efficiency, and ultimately saves cost.

The first benefit is an improvement in terms of the quality and consistency of a F&B plant’s output. With a strictly laid out and defined set of standards, processes are carried out the same way each time, so the output will be the same each time. Clearly defined quality standards, in combination with well thought-out process standard, enable a higher level of quality and consistency, which benefits a manufacturer and their customers.

Manufacturers can be confident, even if they were to expand their facility or open a new plant, their products will meet quality control standards and be made with the same consistency and quality. Customers can be assured that they are buying products with integrity, that meet their expectations in every aspect. In turn, this improves the reputation of that manufacturer within the industry.

Standardization contributes to increased interoperability between equipment and systems, as sticking to a set of standards when it comes to software and controls, enables seamless cooperation between equipment within a plant’s manufacturing line. By having equipment and systems designed to fit a spe-

cific set of standards, integration is greatly streamlined, and communication between those systems is improved.

Data exchange and reporting are also made much easier by a standardized system working in harmony. Reports can be generated through a single piece of software, which aligns with all the equipment in each production line, instead of multiple data reports being pulled from each individual machine and manually compiled and analyzed. Standardization enables greater visibility for plant operators, who can more easily visualize and compare data across several production lines or several facilities.

All aspects of a facility can be monitored and contrasted to assess performance and identify issues if a technical standard has been established which enables monitoring software to handle everything at once.

Above all, standardization cuts down on complexity. Although standardization can be complicated and time-consuming, they are worth the investment thanks to the many ways they simplify operations and procedures for plant managers.

Typically, end users may have been buying machinery or process components from OEMs that get the job done at the time of purchase. However, over time, this can cause issues when a production facility grows larger and inevitably becomes more complex. In turn, the amalgamation of interconnected parts is likely to be the victim of several competing standards working together. Different OEMs could use different control platforms or components for their offerings, potentially interfering with integration efforts within a facility. If two control platforms are present, but not expressly compatible, or reporting software can only integrate

with half of a plant’s equipment, problems begin to materialize as time goes on.

To achieve maximum efficiency, plant operators must keep the equipment running. OEMs will provide a list of recommended spare parts to their customers and will advise them to have these parts on hand at any given time to expedite repairs and replacement processes. With different OEMs and different standards present in one facility, the list of spare parts can grow exponentially and become complicated and expensive as plant operators work to stock spare parts from different suppliers in different countries, with different standards.

Improving the consistency of a plant’s output, increasing potential for interoperability, and boosting efficiency will all contribute to cost savings. For any plant operator, having a facility where different platforms and systems are at play which lack technical standardization will lead to increased overhead costs, specifically when it comes to training. Operations and maintenance staff must be cross trained for different aspects of a production facility, and while operator training is one thing, it is really maintenance training that can balloon budgets, with individuals requiring intricate knowledge of multiple systems and equipment types to effectively service facilities. The more systems and different platforms within a facility, the more maintenance staff, new and old, need to learn to be effective.

The question of how facilities can be standardized may remain, and the answer is variable based on the level of commitment possessed by the F&B plant operator. It could be as simple as all the hardware contained in

Into the future, standardization will become more common, and more necessary to optimize plant operations. It enables companies to more easily expand existing facilities, or create new ones, as their standardized methods can be easily applied to new spaces.

a main control panel having standard components and a standard layout. Meaning operators can work with the control panel in different contexts and be instantly familiar, and maintenance staff can apply their training to all the main control panels across multiple facilities. Some more complex standardization efforts could come in the form of standardized data formats, which simplify the exchange of data between different systems, and enable reports to be generated across entire production lines without the need for manual collection, contextualization, and reconciliation of data.

Although standardization is a beneficial undertaking for users and OEMs alike, there are several limiting factors when it comes to its adoption. These are challenges which exist across various industries and will likely be eased by the passage of time and standardization efforts becoming increasingly common within automation.

The largest challenge to standardization is an industry that is often resistant to change. There exists a reluctance to adopting new technologies, due to factors such as cost, time-to-implement, and unknown risks of moving to new technology. Plant operators may also fear the disruption they perceive will affect their facilities during the standardization pro-

cess. Moving from old systems to new, standardized systems is complicated and does take time, so there are concerns over lowered productivity during the transitional phase.

Although standardization works to lessen variance across systems and processes, it is often the case that each user or OEM will adhere to their own standard, which can make universal standards across the industry difficult. Even between different regions of the world, there could be different, competing standards which complicate standardization efforts of individual companies.

In the pursuit of consistent technical standards, existing systems and processes may need to be upgraded, which can be a challenge for companies working with older systems and processes. There could be multiple barriers facing companies with older hardware, with upgrades being prohibited by budgets or time.

Into the future, standardization will become more common, and more necessary to optimize plant operations. It enables companies to more easily expand existing facilities, or create new ones, as their standardized methods can be easily applied to new spaces. Within the automation space, it is likely that software reporting platforms will become increasingly agnostic, rendering them as more flexible solutions that can fit into a wider array of technical standards. This flexibility will likely become a main selling point, as companies create their own internal standards and need a software that can easily integrate into their operations.

Marcus Mielke is the perimeter director at Actemium Canada. His 30 years of experience within the automation industry is marked by his commitment to the success of his customers and the accomplishments of his team.

Keeping quality and safety standards high.

BY MICHAEL CREPPS

With the rising costs of ingredients, labour shortages, changing consumer preferences, increasing competition, and regulatory pressures, the food and beverage industry is feeling the pinch from every direction.

To stay competitive and thrive in the F&B industry, companies need to adapt to changes and find innovative ways to address these challenges. Keeping systems up and running, and ensuring quality, should be at the top of the list.

Maintaining equipment in a F&B manufacturing facility is critical to ensure the quality and safety of the products produced. The U.S. Food and Drug Administration has strict health and safety standards that must be adhered to.

Therefore, F&B maintenance technicians must have the necessary tools to diagnose issues and maintain the facility in compliance with these standards.

TOOLS A F&B MAINTENANCE TECHNICIAN NEEDS IN THEIR TOOLBOX

• Infrared thermometer: ensuring food safety One of the most critical factors in ensuring

food quality and safety is temperature control. Food-borne illnesses can be caused by physical or chemical contamination or by allergens contained naturally in foods. Therefore, an infrared thermometer is a necessary tool in a F&B facility maintenance technician’s toolbox. This tool helps to ensure that the temperature in high-risk areas of food production, such as meat, poultry, and seafood production, and fruit and egg process plants, is under strict control.

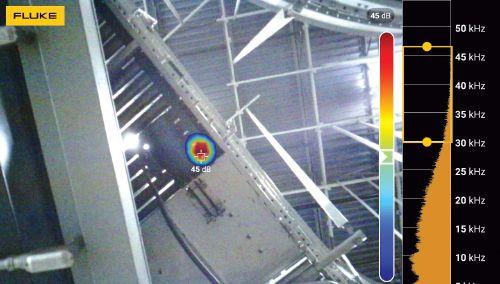

• Acoustic imager: detecting compressed air leaks.

Leaks in compressed air systems in a F&B manufacturing facility can compromise the quality and safety of the products produced. To ensure that compressed air and gas systems are in good working condition, a maintenance technician must use an acoustic imager to scan the entire system along all lines, connections, and outputs starting at the compressor.

The imager detects a leak and displays a visual representation

on the tool’s screen. The technician can record the leak with a photo or video and tag it, making it easier to find the leak when returning to fix it. Additionally, the technician can prioritize which

Simple. Clean. Safe.

Powered by Wainbee expertise, Parker’s PURE food grade hoses enable a clean and safe transfer of a wide variety of foods, beverages and sanitary materials.

leaks to fix first by identifying the size of the leak. After the leaks are fixed, the system is scanned again to verify that all leaks are fixed and that no other peripheral leaks are detected.

• Oscilloscope: diagnosing electrical issues.

Sometimes, when diagnosing issues, the maintenance technician may need to use an industrial oscilloscope. For example, if a vessel on three load cells is filled from a hopper above with around 1500 pounds of grain, and the scale indicates irregular batch weights, the technician can connect an oscilloscope and record a batch. By analyzing the results, the technician can determine if there is an issue, such as a bad capacitor after a bridge rectifier somewhere and replace the faulty parts.

• Digital multimeter: troubleshooting electrical problems.

Another critical tool for a F&B maintenance technician is a digital multimeter. This tool can help diagnose issues with machines, such as package filling machines. In one recent example, a machine’s main air supply was controlled by two solenoid valves powered by the machine’s E-stop circuit. The technician monitored the E-stop relays and all associated contactors, but nothing was apparent. They tightened all the screw terminals and replaced contactors and solenoids, but the problem persisted. The technician used the trending function on the digital multimeter to monitor the contactor action but found nothing out of the ordinary. The technician then went further into the circuit and monitored the 24-V DC power feeding the line side of the contact. When the machine went down again, the technician analyzed the results from the digital multimeter and found a spike-like disturbance in the 24-V DC power, which was causing the problem.

F&B maintenance technicians must have the necessary tools to diag-

nose issues and maintain the facility in compliance with strict health and safety standards developed and monitored by the U.S. Food and Drug Administration. Failure to do so could lead to diminished product quality, potentially harmful products, insecure packaging, and more.

It is essential to have tools such as infrared thermometers, acoustic imagers, industrial oscilloscopes, and digital multimeters to ensure that F&B manufacturing facilities are safe and produce high-quality products.

Michael Crepps, Fluke application specialist, joined Fluke in 2016 as a technical support engineer. He has been providing support and training on electrical test and measurement tools for the past seven years. Prior to Fluke, Crepps worked in the bio-tech industry providing technical expertise in manufacturing and development.

Many manufacturers in the food and beverage industry have already implemented automation into their operations. As the lingering effects of the COVID-19 pandemic continue to slow industry recovery from labour shortages, manufacturers are now looking to the next generation of automation solutions.

The good news, there are government programs and subsidies to help businesses fund the R&D required to take advantage of evolving automation technologies.

Automation has been key to F&B manufacturers since the early days of assembly lines. Today, advances in robotics increase personnel efficiency and overall production speed. Quality control is enhanced through machine vision systems, which optically check products for foreign material, read contamination test strips, and can “see” contaminants that human eyes cannot.

The mechanical automation of traditionally dangerous tasks, such as meat-cutting, greatly improve employee health and safety. As well,

speed the development of new formulations in recipes and flavours and anticipate issues in the supply chain.

However, advances in technology also require people to run and maintain those advanced manufacturing systems. Specialists in robotics, industrial internet of things (IIoT), and other advanced technologies will need to be hired or contracted.

Furthermore, there is the cost of scientific R&D.

Boost Your Business Technology Grant. Boost Your Business Technology can help get your business online, give your e-commerce presence a boost, or digitalize your business’s operations. These grants are designed to help Canadian businesses become more competitive.

In addition to helping your business scale up its technology and become more resilient and competitive, the program also offers wage subsidies to hire youth to support the implementation of new technology and strategies.

Post-pandemic labour shortages are not likely to ease anytime soon. By investing now in further automation, you can both futureproof your business and take advantage of timely incentives.

advanced systems monitor and optimize energy efficiency, increasing profitability while reducing an operation’s carbon footprint.

Artificial Intelligence (AI) is being used in everything from increasing the accuracy of food sorting, cleaning, hygiene, and safety on the production line, to using predictive analytics to

To help with these costs, the Government of Canada offers Scientific Research and Experimental Development (SR&ED) tax credits. These include deductions against income as well as investment tax credits (ITCs) for at least 15 per cent—and as much as 35 per cent—of your qualified SR&ED expenditures.

Further to these tax credits, consider applying for a Canada Digital Adoption Program (CDAP)

Applying for government incentives can seem like a challenge, but you can also get help with this.

EMC provides free assessments for your potential SR&ED tax credits, Grants, or both. EMC partners with experts in the field to understand your unique production needs and strategic initiatives, as well as the programs you could qualify and apply for. You can find out more about these services at emccanada.org/research-insights/sr-ed.

ABB STAINLESS STEEL MOTORS

ABB Baldor-Reliance

Food Safe motors has made enhancements in performance and protection to its Food Safe stainless steel motor line.

STEEL GOLD BEARINGS

Regal Rexnord Corporation Sealmaster stainless steel (SS) gold bearings feature a triple lip contact seal with an integrated flinger for multi-directional sealing.

FKM seal lip material is chemical resistant and capable of withstanding high temperatures. Sealmaster SS Gold bearings are IP69K certified.

The bearing housings are constructed from 316 passivated stainless steel. The 440C stainless steel inner and outer rings provide great load capacity and corrosion resistance.

Baldor-Reliance Food Safe motors exceed IP69 ingress protection ratings for washdown conditions. It covers single to three-phase ratings, with TEFC or TENV enclosures, in foot-mounted and footless configurations. Features:

• Bearing protection ring;

• 360-degree rotatable conduit box;

• Plugged drain holes;

• All stainless-steel construction - including housing, conduit box, drain plugs, hardware, fan cover and endplates;

• IP69 laser marked nameplate;

• Hardened epoxy resin encapsulation;

• Two-barrier mechanical shaft seals; and

• High-temperature Class H insulation with low-temperature (Class B) rise. www.abb.com

www.regalrexnord.com/SS-Gold

Emerson ASCO Series 641, 642 and 643 aluminum filter regulators can handle the high flow rates of any regulators in their class and provides pressure regulation to downstream instruments.

Highest flow rate capabilities of up to 10,500 liters per minute. Higher flow rates provide more air to the valve actuator, which increases the opening and closing speed of process valves. Specialized powder coating ensures operation in harsh, corrosive process environments.

This three-tiered regulator line provides quarter-inch to one-inch coverage and is customizable. Features such as quick relief, which enhances safety and operational certainty by exhausting downstream pressure if supply air pressure is lost, and low-temperature and low-copper variants, manual and automatic draining, global certifications.

www.emerson.com

A food and beverage organization’s production capabilities are highly dependent on the state of its capital assets. The goal of any organization is to maximize uptime.

Join us on August 29 as we discuss with a panel of experts how to leverage the availability of key production assets in order to meet quotas and maintain profit margins.

This half-day educational forum is presented by Machinery and Equipment MRO and Annex Business Media. It will allow maintenance, reliability and maintenance professionals in the Food and Beverage sector to learn techniques to easily identify an asset issue, and react to solve problems, preventing unexpected and costly breakdowns.

TUESDAY, AUGUST 29 , 1-4PM PRESENTED BY