Cloud computing advantages for F&B industry.

Achieving optimal control with enhanced sequencing software.

Building a culture of safety in F&B manufacturing.

From complex spreadsheets to completed work orders.

Cloud computing advantages for F&B industry.

Achieving optimal control with enhanced sequencing software.

Building a culture of safety in F&B manufacturing.

From complex spreadsheets to completed work orders.

Curious to see how much prices of various food items are increasing; I looked at Statistics Canada’s Monthly average retail prices for food and other selected products for March 2022 (the latest available version). The results showed that when comparing February 2022 prices to the same time last year (February 2021), the prices are much higher; however, when comparing to prices in Fall 2021 to now, the prices have not increased much, and in some cases have fallen

Looking at staple items that are bought most often:

• Partly skimmed milk (four litres) was $5.48 in February 2021 and was $5.90 in February 2022. This is the highest it’s been over the last year.

• Butter, 454 grams ($5.29 vs. $5.67), but it was $5.76 in January 2022.

• Eggs, dozen ($3.62 vs. $3.87), but it was $3.91 in August 2021.

• Bread, 675 grams ($2.87 vs. $3), highest over the last year.

• Flour, 2.5 kg ($4.42 vs. $4.65), but it was $4.69 in August 2021.

• Cooking or salad oil, one litre ($3.15 vs. $4.45), this is one of the larger increases by percentage.

• Ground beef, one kg ($11.06 vs. $12.52), highest over the last year.

• Chicken, one kg ($7 vs $8.04); however, it was at $8.51 in October 2021.

I could go on and on with different products, but overall, a similar story will be seen for different products. Some products are continually going up, like cooking oil, milk, bread, and beef. While others like butter, eggs, flour, and chicken have gone up and down over the last year.

Looking down the supply chain, Statistics Canada’s Farm product prices, February 2022, shows that canola prices grew 50 per cent from February 2021 to February 2022, while soybean went up seven per cent in the same time. Dry pea prices were up 82 per cent year-over-year, but the increase has slowed to between 2.1 and 7.3 per cent month over month depending on province.

Why are prices increasing? Much like other industries, the food industry is still recovering from disruptions from the COVID-19 pandemic, trucker protests/blockades earlier this year, as well as fuel price increases caused by the war in Ukraine.

If another disruption doesn’t present itself, there does seem to be a light at the end of the tunnel, as at least some food prices are stabilizing.

Mario Cywinski Food & Beverage Engineering & Maintenance

mcywinski@annexbusinessmedia.com www.mromagazine.com

The Ontario government is investing up to $25 million over two years through the Strategic AgriFood Processing Fund Program, to increase the province’s food processing capacity.

The Strategic Agri-Food Processing Fund will support industry investment in projects that address the processing capacity shortage. Agrifood businesses are eligible for up to $3 million in cost-share funding to either build new processing facilities, expand or modernize existing facilities and adopt new technologies to improve current operations.

“This strategic investment will boost competitiveness and create new opportunities for the Ontario food processing sector and the entire supply chain,” said Lisa Thompson, Minister of Agriculture, Food and

Rural Affairs. “By enabling more private-sector investments that increase local food production, we’re ensuring Ontario has a safe and stable food supply made right here at home while driving economic growth and creating good local jobs.”

The application intake for the Strategic AgriFood Processing Fund opened on April 1.

GORDON FOOD SERVICE ACQUIRES

MACGREGORS MEAT & SEAFOOD LTD

Gordon Food Service announced it has entered into a definitive agreement to acquire Macgregors Meat & Seafood Ltd., a Cana-

dian supplier to food service, retail, and private label customers.

“We are excited to welcome Macgregors employees and its brands to the Gordon Food Service family,” said Rich Wolowski, President and CEO, Gordon Food Service.

“Macgregors is among the most respected in the marketplace and like

for Fas t Moving Consumer Goods

Gordon Food Service, Macgregors operates with a people-focused culture. We expect our cultural similarities will make for a smooth transition for both our customers and employees.”

Macgregors’ partnerships include Certified Angus Beef, 44th Street, Niman Ranch and Jail Island Salmon.

• Of fering more than 1,0 0 0 st andard component s & modular kit s for individual solut ion s

• Excellent su ppor t throughout the whole produc t life c ycle

Planet Based Foods Global Inc. announced the appointment of Dave Wilbern as Vice-President of Sales.

Wilbern is an accomplished sales executive with a diverse background in sales, marketing and operations at privately held and publicly traded Fortune 500 companies. Specializing in new business development and strategy, his experience spans national accounts, group purchasing organizations and local and national broad-line distributors.

“We are very pleased to have Dave join Planet Based Foods at such an exciting time in our growth,” said Braelyn Davis, President and CEO, Planet Based Foods. “Dave is a talented executive with a proven track record in successfully expanding companies

through smart sales programs and strategic relationship building. As we continue to scale our brand, his wide-ranging experience will be a great asset to the Planet Based Foods team.”

The Ontario government is providing $5 million through the Northern Ontario Heritage Fund Corporation (NOHFC) to 25 agriculture, aquaculture and food processing projects in Northeastern Ontario. Projects receiving NOHFC funding include:

• $754,775 for Manitoulin Trout Farms Inc., in Little Current, to purchase new cages and nets.

• $328,520 for Local Food and Farm Co-ops, in MarkstayWarren, to administer its

Healthy Food Distribution North initiative.

• $250,744 for Oshadenah Holsteins, in Tehkummah, to purchase equipment, build a new barn, renovate its existing barn and construct a manure storage pit.

• $114,530 to establish Gorham Farms, in McKerrow.

• $106,118 to establish Ije’s Place, in Desbarats.

“Our government is committed to supporting a robust agri-food sector in Northern Ontario,” said Lisa Thompson, Minister of Agriculture, Food and Rural Affairs. “That’s why we are making important investments to help these regions innovate and overcome the barriers for growth. These investments further strengthen the economic potential of the North where there is great opportunity to build our sector, and continue to provide safe, quality food made right here in Ontario.”

CULT Food Science Corp. has entered into a binding Letter of Intent with Cella Food Systems Inc. to accelerate its cell-based product development capabilities via Cella’s patent portfolio, machine learning data and prototyping IP toolkits.

CULT continues to build “defendable moats around its cellular agriculture intellectual property, patent and investment platform through the additive commercial arrangement.”

“This is expected to ultimately result in multiple future revenue and royalty streams for CULT as it contributes not just capital, but also cutting-edge technologies across its portfolio.

“This is the first step in the Company’s strategic plan to harness the upside of the nascent cellbased foods markets not only as an investor, but as a principal,” said Lejjy Gafour, President, CULT.

Digital transformation has accelerated significantly over the past two years. Much of this transformation is enabled by cloud computing, which emerged in the early 2000s and is still driving change in the way industries operate, including the food and beverage industry.

operations across the board. For example, you can use cloud computing infrastructure to gather and analyze food crop data from the field to warehousing, shipping, and the retailer that sells it to the end consumer.

This is more cost-effective and less resource-intensive than previous models. Businesses had to purchase hardware and software and install, maintain, and upgrade it at significant capital and operational costs.

BY STEVE RICHMOND

Although the F&B sector has been slower to adopt cloud technology and digitalization, we are now seeing increased demand from businesses looking to optimize their operations and gain a competitive advantage. Cloud computing technology - or remote data centers - enables productivity, cost, and efficiency improvements.

Due to its decentralized nature, cloud computing allows for data to be uploaded from anywhere, giving business owners insights into their

Software-as-a-Service (SaaS) models, where expert providers sell access to software solutions monthly for a fee per user, are driving innovation. Cloud computing provides the backbone, and SaaS provides the specialist software. Companies investing in these solutions can respond faster to changing environments as they are not tied to technology; they can shift what they use as their needs change.

The increasingly digitized nature of the F&B market globally is compelling industry players to track and manage all data related to their products across the entire lifecycle and supply chain. Take up is proving rapid.

Foundry noted in its recent Cloud Computing Study 2022, that “69 per cent of companies have accelerated their cloud migration over the past 12 months, and the percentage of companies with most or all IT infrastructure in the cloud is expected to leap from 41 per cent today to 63 per cent in the next 18 months.”

As the provider manages SaaS solutions, they are always up to date, and upgrades occur without any intervention from the user. Users can consequently keep updated as industry requirements like standards and regulations change without having to do anything to the systems to keep them current.

Beyond the general business benefits, cloud computing brings several advantages to the F&B sector.

This is particularly relevant for food safety companies that need to comply with strict regulations and keep detailed records of their compliance. Hosting applications in the cloud means these companies have instant access to data as it is updated in the system, so they can access compliance data and documents in real-time. Food safety measures will always be up to date. As a result, maintenance and collaboration are streamlined.

In rapidly changing industries, pulling up-to-the-minute data on the fly to make data-driven decisions is critical. The big data, analytics, and reporting features enabled by cloud computing solutions provide business decision-makers with the data they need when they need it. Everything from product inventory to

sales figures is available to help F&B execs make decisions on shelf-life, stock levels, and product quality.

Cloud computing and SaaS offerings have a clear advantage over older, on-site solutions, as they are easily and rapidly changeable. Meaning businesses can scale computing requirements up and down as the business needs change, accessing more compute power around month-end and reducing the requirement over quieter weeks.

Introducing Stainless Steel Hygienic Liquid Tight Metallic Conduit and Hygienic Flex Fittings to the Calbrite Flex Family. Calbrite Hygienic Flex products are made from 316 stainless steel, making them ideal for food processing facilities where washdown and high temperatures are required. Calbrite Hygienic Flex products are designed to provide excellent absorption of motion and vibration, protecting electrical wires and cables in any location.

Calbrite offers an extensive line of flex conduit and fitting solutions for every application. Find our product datasheets here: calbrite.com/flex-conduit-and-fittings

Cloud infrastructures are accessible from anywhere that a company’s users have an appropriate device and an internet connection, making it effortless to serve one or multiple sites.

The reduced IT requirement helps lower costs for businesses that adopt cloud computing. Companies can save on the hardware, software, and resources needed to manage and maintain these. This frees up capital expenditures to be allocated to other value-adding activities.

An increasingly wide range of applications is available as a service as SaaS grows and is adopted by more businesses. These are flexible and easy to integrate into existing systems. This means less complexity in business’ IT systems, lower staff overheads, and security benefits, because an expert SaaS provider manages all aspects of the offering, including access, backups, upgrades, and patching.

Cloud also delivers economy of scale advantages, businesses can scale their use up or down as their user base grows or shrinks. Opening new branches, for example, means adding new users, not adding an entirely new infrastructure rollout.

All of this, simply put, enables F&B businesses to focus on core operations and areas of growth, and leave the IT infrastructure to an outsourced expert.

Article provided by Projetech Inc.

Steve is the founder of Projetech Inc. He was educated at the University of Cincinnati and embarked on a career in the mechanical contracting business. Steve is a published author and accomplished speaker. He is also an active member of the Forbes Technology Council.

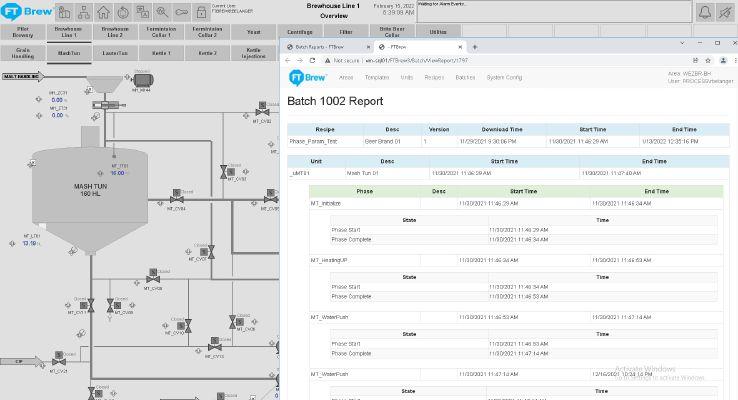

Operational optimization in food and beverage (F&B) and brewing production environments bring many challenges, which can be solved with innovative production controls and automation.

BY RHEAL BELANGER

Akey focus for project managers, brewmasters, operations and engineering management is keeping up with the constant transformation. The need to reinvent and adapt is essential in the context

of where manufacturing is today: blurred product lines between manufacturers, changing workforce, health and safety, greater B2B and B2C demands, inventory and supply chain issues, more technology adoption and innova-

tion. Keeping this in mind, production is looking for assistance from automation suppliers to provide enablement and advancement to meet the demands of the market.

In addition to the macro requirement of satisfying the expectations of the sophisticated and educated customer, F&B and brewing need to control costs and meet product yield and quality demands. There are cutting-edge software solutions available, that empower production and deliver results such as

cost savings, quality improvement, waste reduction and an increase in manufacturing throughput.

A 2021 F&B plant survey commissioned by the American Institute of Baking, showed that at least 78 per cent of executives were actively preparing for the next global pandemic, because they expect to see another one within the next decade. Two essential crisis preparation methods they will be implementing, as per Euromonitor International, is re-

shaping their digital strategies and greater investments in production automation tools.

In most instances, industrial process and packaging equipment relies on the information located within a programmable logic controller (PLC) for their operation. The basis of the automation resides within the PLC, and if something breaks or there’s an issue, the operator needs to call maintenance to address the problem. The consequences of relying on such systems are lost production time, resource utilization and material losses that can lead to market shortage. These issues should be quite limited; however, what is more often the case is when a production manager needs to

optimize a sequence, they require a maintenance electrician to do so. With enhanced sequencing software, this process to modify/changing data within the PLC is eliminated and the operator is provided full control via a web interface that can be accessed anywhere using their mobile device or desktop computer. This interface also provides enhanced visualization of their process on-the-spot and in real time.

Euromonitor’s Voice of the Industry COVID-19 Survey, conducted in October 2020, indicates 25 per cent of manufacturing companies plan to increase investments in automation tools. Investments in manufac-

turing automation are expected to accelerate from now until 2025. For example, a client in the consumer-packaged goods industry is launching a greenfield project. They intend to equip their new facility with an innovative software solution that places real system control - in the hands of their operations staff. They want something customized but can also support their future technology and automation requirements.

There are many moving parts in this type of open application. It’s flexible enough to address the varying needs of the customer at each plant but standardized to the point where staff at various production sites can share knowledge and support one another. In the case of the consumer-packaged client, we preconfigured and tested the solution in-house to ensure a rapid installation and keep the capital expenditure to a minimum. The exception-based reporting analytics are available in real-time. In fact, the

system sends email alerts directly to the operator when a process deviation occurs allowing them to remain informed. Enhanced operator troubleshooting tools, allow problems to be readily identified and addressed in short order.

The digital transformation of production in this new era means that equipment, processes, and upgrades are never finite. Changes are essential to keep the operation up and running at maximum efficiency and minimal losses. The power of intelligent sequencing allows F&B producers to keep up with the demand, by optimizing the flow of material to maximize throughput and take advantage of every bit of the capacity that has already been invested in. There are many ways to evaluate the success of sequencing software. Consider your goals, aside from taking less time and resources, did it lead to:

More production per day; less waste; better consistency; improved quality; lower installation costs; faster implementation; greater process analytics; closer fit for size; and, elimination of ongoing support costs.

Improvements in any of these areas can offer production continuity to meet consumer demand. However, during this time of constant upheaval, it’s essential that production facilities work with automation technology and software partners who offer solutions that are scalable. Solutions that will grow with company manufacturing activities and that offer full support throughout and beyond any upgrade, improvement, or optimization project lifecycle.

Rheal Belanger is the Client Manager with Actemium Toronto. He has been working in the food beverage and brewing sectors providing automation solutions for over 20 years. He can be reached at Rheal.Belanger@Actemium.com.

Due to sector-wide labour shortages and continuing effects of the COVID-19 pandemic, the Canadian F&B manufacturing industry now relies upon temporary workers more than ever.

While the usage of short-term labour can certainly prevent losses in productivity, employers must be cognizant of the effect temporary employment has on food safety. Workers in F&B manufacturing have a unique set of responsibilities that they must fulfill without error to prevent con-

tamination of their product. If established food safety guidelines are not met, the resulting fallout can be catastrophic.

It is important for F&B manufacturers to create and maintain effective food safety protocols throughout their facilities, and ensure that these rules are followed regardless of a worker’s employment status.

Building a culture of food safety shouldn’t be a dry, tedious process, for maximum employee engagement, leaders must understand the needs of their workforce, and make efforts to address them in an interesting, engaging way.

Communication is key to establishing an internal culture. As such, employers should possess a strong,

up-to-date knowledge of their workforce’s demographics to accurately utilize informational messaging. Determine your employee base’s communication skills:

• Can your workers comprehend English?

• Do they prefer verbal or written instructions?

• What kind of phrasing and

word choice resonates most effectively with them?

The high level of temporary labour utilized by F&B manufacturers will likely necessitate the creation of instructional material in more than one language. Bilingual messaging isn’t the only effective form of inclusive communication, but also visual-heavy instructional materials (like photographs, videos, or illustrations), workers of any background can understand food safety practices and other important information. Using pictorial directions also allows for thorough demonstration of complicated processes, further reducing the likelihood of miscommunication and preventing on-the-job mistakes. To enhance visual-based messaging, consider the implementation of digital technologies through company tablets or employees’ own mobile phones, and develop instructional content that can be easily accessed at any time.

Interaction is a vital component of information retention, and employees that are actively engaged with a culture of food safety will likely have a far greater understanding of their guidelines than those that only follow them passively.

As with any form of positive workplace behaviour, adherence to food safety rules should be incentivized through systems that validate and acknowledge employee efforts.

For example, many successful F&B manufacturers hold regular “town hall” sessions where workers of any employment status are given the opportunity to voice their thoughts in a public setting, allowing majority interests to be immediately gaged by and presented to leadership. Other businesses utilize contests, quizzes, and giveaways to promote and reward knowledge of food safety practices, heightening employee engagement through the appeal of tangible compensation.

In addition to strengthening employees’ knowledge of food safety guidelines, participation in workplace events can reinforce the bonds between workers of any type, and can

help increase company loyalty, potentially spurring interest in full-time commitment from temporary workers.

At a time when the Canadian supply chain is under an incredible load, ensuring employee adherence to food safety standards is crucial to maintaining productivity, efficiency, and profitability. By establishing a fun, active, and engaging workplace culture, F&B manufacturers can feel confident in their employees’ knowledge and discipline, and can reap the numerous benefits of a compliant, high-performing organization.

Article provided by Excellence in Manufacturing Consortium (EMC).

Effective management is crucial to the operations of any manufacturing organization.

Not only do managers bear the responsibility of their departments’ performance, but they also act as critical links between employees and company leadership, facilitating communication and the spread of important data throughout the corporate ladder. In an era when skilled labour is more difficult to acquire than ever, managers take on an additional role: ensuring that employees remain loyal to their organizations.

Over the past decade, workers’ mental health has become an increasingly prominent issue, and one that has a significant impact on employee retention. As the form of leadership that work-

ers most commonly interact with, managers must understand how to constructively address the emotional needs of their labour force to keep them motivated, engaged, and interested in their positions. By doing so, managers contribute heavily to the sustained productivity of their companies and achieve their primary goal of ensuring employee success.

One of the challenges that managers often run into after being promoted is an inability to communicate with their workforce. Leadership is functionally different from manual labour, and newly appoint-

ed managers may require some form of immediate guidance to prevent mistakes from being made.

Fortunately, a wide variety of resources are available to leaders for help with understanding their new role’s responsibilities. Through leadership training initiatives managers can gain and develop essential employee administration skills from experienced HR professionals and discover timely leadership strategies to empower their workers’ efforts.

These courses allow leaders to apply several different management strategies in a controlled environ-

One of the challenges that managers often run into after being promoted is an inability to communicate with their workforce. Leadership is functionally different from manual labour, and newly appointed managers may require some form of immediate guidance to prevent mistakes from being made.

ment, and as they are typically attended by supervisors across a diverse range of industries, offer ample opportunity for building and learning from a consistent peer network.

Another issue that can prevent supervisors from maintaining mutually beneficial relationships with their workforce is an imbalance in employee dynamics. Differences in roles and responsibilities can often create boundaries between leaders and labourers, preventing effective communication from being held. Managers can circumvent these challenges by taking a proactive role in employee engagement.

Positive acknowledgement by leadership is important — recognizing employee successes, identifying worker strengths, rewarding high levels of passion and loyalty —but leaders should also have the ability to address their labour force’s emotions. Contextual awareness is an extremely important part of man-

agement, and leaders that demonstrate a genuine willingness to listen to and provide support for their employees during periods of high stress help to foster a safe, comfortable working environment that labourers will be eager to perform in.

Having a supportive, trustworthy leader that they can consistently rely upon eliminates feelings of reluctance and anxiety in workers, keeping them focused on fulfilling their own duties.

There’s no doubting that the role and expectations of managers, supervisors, and leaders has changed throughout the past several years. By meeting and surpassing these expectations, managers re-assert their organizations as ideal places to work, keeping their labour forces content and stoking productivity and efficiency throughout every rung of the corporate ladder.

Article provided by Excellence in Manufacturing Consortium (EMC).

It can be challenging to stay on top of all necessary maintenance tasks for a facility.

However, modern technology has made it easier to keep track of everything. Complex spreadsheet programs can now be replaced by work order management software that does the same job a fraction of the time. By automating tedious and time-consuming tasks, work

order management software allows managers to focus on more important things.

Work order management systems are designed to automate and simplify work order management processes. There are many different types of work order management software on the market, with each offering unique features and benefits.

One of the most common ways of tracking work orders is through spreadsheets, which are simple and easy to use. This makes them the

obvious choice for small businesses or businesses with simple work order management needs. However, spreadsheets can be difficult to scale and become cumbersome as companies grow. WHY?

Typically, manual systems have

history card or excel spreadsheets where maintenance history, asset information, and maintenance procedures are tracked. This system is inefficient as it forces employees to look through every card or review all maintenance data. Recording data in this manner can lead to inaccuracies and wastes time. Since manual systems leave room for error, essential data that can lead to company decisions might not be recorded.

The most popular work order management software is computerized maintenance management systems (CMMS). CMMS is designed to streamline work order management processes by providing a centralized database for storing work or-

ders, tracking employees’ time, and managing inventory levels.

The mobile feature allows anyone to access CMMS software from any location for the maintenance history and other essential data. Management and work crews can update work orders and maintenance schedules from their smartphone and other mobile devices, reducing labour and streamlining the scheduling process.

By automating tedious and time-consuming tasks, work order management software allows managers to focus on more important things.

Thanks to CMMS’s efficient and robust nature, tracking activities within a company have been simplified. Most CMMS programs are available on the cloud, as such, service requests, work orders, and inventory requests, can be dispatched to relevant parties as they happen. Response times are significantly increased, and repairs are performed sooner. Therefore, work order management systems are essential for tracking work orders and asset management. A CMMS can automate many tasks related to work order management, such as creating work orders, assigning employees, and updating statuses.

Article provided by Eagle Technology Inc.

AutomationDirect LUTZE SILFLEX FBP control cables are designed for all UL and FDA requirements for cabling in F&B facilities. The design has been evaluated by third-party tester Ecolab for resistance to commonly used cleaning agents and reduction of contamination risk.

LUTZE SILFLEX cables are available in sizes 20AWG to 12AWG in shielded and unshielded versions. Phthalate-free jacket is resistant to

oils and fats, while reduced cable diameters allow for routing and installation in a conduit. Cables can run without a conduit in some areas due to the external wiring approval, washdown certification, and food-contact rating.

SILFLEX FBP control cables can be ordered cut to length in one-foot increments, with a 20 ft. minimum.

EnWave Corporation announced that its vacuum-microwave toll drying facility, REVworx, is officially open for business. REVworx offers on-demand contract manufacturing services for the production of vacuum-microwave dried snack and ingredient applications for food companies.

Located at EnWave’s head office in Vancouver, B.C., the REVworx facility incorporates complimentary up-

stream and downstream equipment required to process food applications at scale. REVworx is equipped with a 60kW tray-based REV machine, a 10kW REV unit for smaller batch production, a commercial scale air dryer for pre-processing, preparation equipment such as cutters, corers and slicers for fruits and vegetables, a fryer and seasoning station, and a bulk packaging area for shipment preparation. The company is pursuing Certification 84 Safe Quality Food (SQF), which requires three consecutive months of line trial production, which will be completed March to May, with full SQF certification expected for June.