FOOD BEVERAGE

Toolbox of a

Toolbox of a

Supplement of Spring 2021

Lower the risk of food recalls with pneumatic system audits and upgrades.

How food and beverage processing is adapting with surveillance.

Looking

events.

PUBLISHER

Paul Burton pburton@annexbusinessmedia. com 416-510-6756

EDITOR Mario Cywinski mcywinski@ annexbusinessmedia.com (226) 931-4194

COO Scott Jamieson sjamieson@ annexbusinessmedia.com

MEDIA DESIGNER Jaime Ratcliffe jratcliffe@ annexbusinessmedia.com

In Co-operation with

ASSOCIATE EDITOR

Maryam Farag mfarag@ annexbusinessmedia.com 437-788-8830

ACCOUNT CO-ORDINATOR Catherine Giles cgiles@ annexbusinessmedia.com (416) 510-5232

CIRCULATION MANAGER

Beata Olechnowicz bolechnowicz@ annexbusinessmedia.com

PRESIDENT JP Giroux • jp.giroux@emccanada.org

(519) 376-0470 (866) 323-4362

CHAIRMAN OF THE BOARD, TREASURER Al Diggings • adiggins@emccanada.org

VICE PRESIDENT, MANUFACTURING SECTOR PERFORMANCE Scott McNeil-Smith • smcneilsmith@emccanada.org

VICE PRESIDENT, COMMUNITY PARTNERSHIPS AND STAKEHOLDER RELATIONSHIPS Bren de Leeuw • bdeleeuw@emccanada.org

We have now been living in the COVID-19 pandemic world for over a year. Those in the food services and drinking places industry (as they are categorized by Statistics Canada) have had to endure repeated opening and closing, depending on what their region is doing. As a result, they have had to adapt to a new way of doing business. In many regions, they have only been allowed to open for takeout/carryout, and not allowed to have indoor, or in many areas, outdoor dining.

Statistics Canada found that, as a result, 50.7 per cent of food service and drinking places are likely or very likely to keep pickup and contactless delivery permanently. While, 27.5 per cent already have an online sale platform or plan to implement one. This could be as a result of the fact that 30 per cent or more sales were achieved online by 19.4 per cent of establishments in 2020 (up from 9.1 per cent in 2019).

While many are pivoting to online to drive their business, the loss in revenue is not fully offset. In 2020, 86.5 per cent of places saw a drop in revenue, with 42.9 per cent seeing a drop of over 40 per cent, with the biggest numbers of places seeing losses being in Quebec (50.9 per cent), Manitoba (47.9 per cent) and Ontario (44.9 per cent). On the bright side, 6.7 per cent of food services and drinking places have seen an increase in revenue.

Looking into the future, 56.6 per cent of food and drink places believe their profitability to continue to fall, with 8.6 per cent thinking it will increase. The news is not looking good for many to survive, as 51.2 per cent do not know how long they can continue to operate without closing or considering bankruptcy. This is all to say that the future does not look bright for the food and drink

establishment industry. As the food processing industry relies to a degree on those establishments ordering products, it is concerning. However, as the pandemic restrictions are loosened, and more of the population is vaccinated, the trend should reverse, as a large part of the population is eager to go back to normal. And to the 97,000 restaurants, bars and caterers across Canada, stay healthy and stay safe. Good day.

Mario Cywinski, Editor

RITTAL ANNOUNCES ADVANCING WOMEN IN TECH SCHOLARSHIPS 2021

Rittal Systems Ltd. Canada announced it will award two Advancing Women in Tech Scholarships, of $1,750 each, to Canadian female undergraduates, to help further their studies and careers in the electrical and associated industries. To be eligible, the applicant must be a Canadian citizen or a legal permanent resident, be a current post-secondary undergraduate student, and enrolled in a full-time appropriate field of study, at an accredited college or university program. Application deadline is May 31. The student must have competitive grades in their current program, and be able to demonstrate leadership and involvement in their community.

Its demand across industries; life sciences, food and beverages, power generation and electronics, is surging to drive the growth in various regions such as Latin America, Europe (except Western Europe), the Middle East,Africa and AsiaPacific. Globally, the market is estimated to garner revenue of $3.4 billion by 2025 from $3.1 billion in 2020, up at a compound annual growth rate of two per cent.

With the fallout of the COVID-19 pandemic, the industry experienced a slowdown in 2020, but is expected to cross pre-COVID levels in the mid-term as economies adopt the necessary measures to combat the pandemic’s impact.

Despite higher prices, end-users such as food and beverage and pharmaceutical industries are likely to invest in oil-free compressors as a result of the regulations and benefits involved.

Logan Carden was named Nashville division Vice-President and will be responsible for overseeing the sales growth initiatives of 20 branches located in parts of Indiana, Tennessee, Kentucky, Mississippi and Alabama. He will report to Chris Pacer, VP Group Executive – Central. Bill Carroll was promoted to VP of the new Philadelphia division (Pennsylvania, New Jersey and West Virginia). He will be responsible for overseeing 13 branches’ sales and guiding their market growth, reporting to Phil Donnelly, VP Group Executive – East.

Tami DeWeese was named VP of the pacific northwest division. DeWeese will oversee the sales growth, strategy and operations of 19 branch and shop locations. She will report to Jeremy Barton, VP Group Executive – West. Dan Pike was promoted to St. Louis Division VP and will be responsible for the sales growth and management of 17 branch operations throughout Missouri and Arkansas. He will report to Austin Amos, Senior VP Group Executive – Midwest. Dave Purvis was named midwest group area VP, replacing Pike. Purvis will

be responsible for leading the midwest group corporate accounts team, which involves managing existing corporate accounts, and report to Amos. Steve Kammeyer was named Area VP for corporate accounts, west group. He will directly engage with field personnel and leadership in creating sales-driven initiatives, while reporting to Barton. Lisa Solomon was promoted to Area VP for corporate accounts, central group, and will lead its corporate accounts team. She will be responsible for enhancing existing national account relationships. Also, James Howe is now Executive Vice-President of eCommerce, Sales Excellence, Strategic Pricing

and Corporate Accounts, and Joe Limbaugh is Executive Vice-President of Supply Chain, Operations Support, Marketing and Enterprise Excellence.

Howe served as SVP of eCommerce, sales excellence and strategic pricing in 2020, and recently took on the responsibilities of corporate accounts group. He has been with Motion since 2002 and held several field roles.

Limbaugh started with Motion in 1983. He has served as SVP, responsible for procurement and inventory, distribution centre operations and productivity, branch support, facilities and lease management, and marketing strategy.

The tools you will find in a F&B facility maintenance technician’s toolbox, and why.

BY SEAN SILVEY

The tools of the trade for food and beverage maintenance technicians should include tools that help them diagnose issues and keep the facility in compliance with the strict health and safety standards developed and monitored by the U.S. Food and Drug Administration. Failure to properly maintain equipment in a food and beverage manufacturing facility could lead to diminished product quality, potentially harmful products, insecure packaging and more.

Here are some of the tools you will find in a food and beverage facility

maintenance technician’s toolbox, and why.

The problem of food safety is serious. Health officials require the use of strict procedures for high-risk areas of food production, such as meat, poultry, seafood production, and fruit and egg process plants. Food borne illnesses may be caused by physical or chemical contamination or by allergens contained naturally in foods. Temperature control is one of the most critical factors in ensuring food quality and safety.

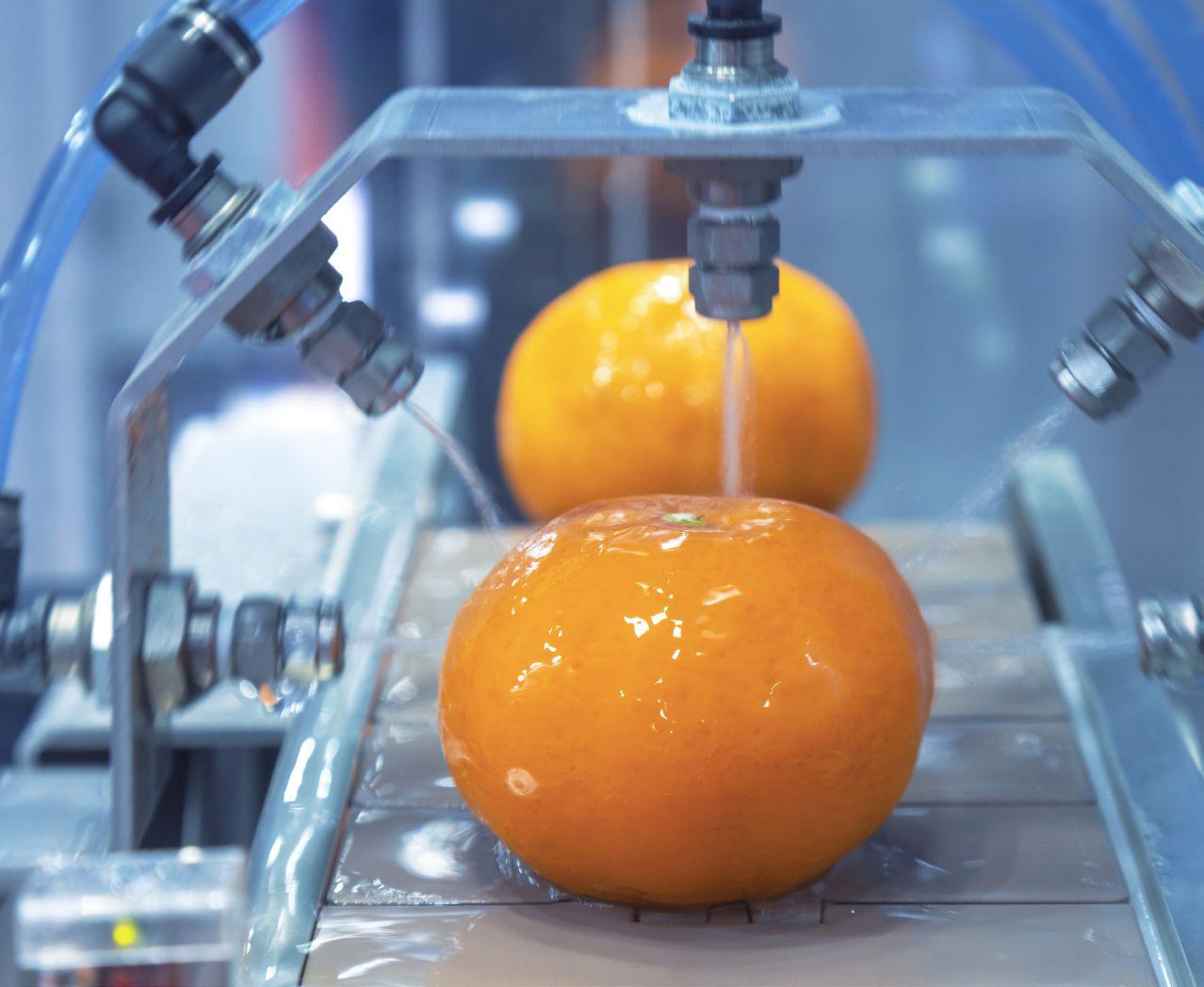

Leaks in condensate traps, couplings, fittings, flanges, FRLs (filter, regulator, lubricator combinations), hoses, packings, pneumatic holding tanks, quick disconnects, threaded pipe joints, tubes, or valves compromise the quality and potentially the safety, of compressed air systems. Here are just some of the ways compressed air and gas systems are used in food and beverage manufacturing processes: Nitrogen flushing is used to fill bags to air cushion delicate foods and

prevent damage. Compressed air is purified and filtered to ensure food safety, and to maintain the proper pressure dew point needed to prevent microbial growth.

In preparation for packaging, pressurized air jets efficiently remove peels from fruits and vegetables.

High-pressure compressed air is used to cut foods as a cleaner alternative to knives or blades.

Compressed air increases oxygen levels to complete the bacterial fermentation process.

Air compressors reduce residual oxygen during bottling, and bottles are flushed with carbon dioxide and filled with beer, for example, using pneumatically powered machinery. Air leaks are a big issue because they are abundant and hard to find. Once found and fixed, more leaks tend to pop up due to normal wear and tear on the system.

Use an acoustic imager to scan the entire compressed air system along all lines, connections and outputs starting at the compressor. As the imager detects a leak, the visual representation will appear on the tool’s screen. The leak can be recorded with a photo or video, and tagged, so that the location is evident when returning for the fix.

Acoustic imaging cameras with the right technology will identify the size of the leak, which allows the user to prioritize which leaks are most critical to fix first. After the leaks are fixed, scan the system again to verify the leaks are truly fixed and that no other peripheral leaks are detected.

Imagine a vessel on three load cells is filled from a hopper above with around 1500 pounds of grain, depending on the recipe. The slide gate metering the grain is controlled by a PLC-5 based on weight read from the scale terminal. The vessel pressurizes and the grain is forced out the bottom into a transport pipe, sending the grain across the building to processing. When empty, the blower purges the line.

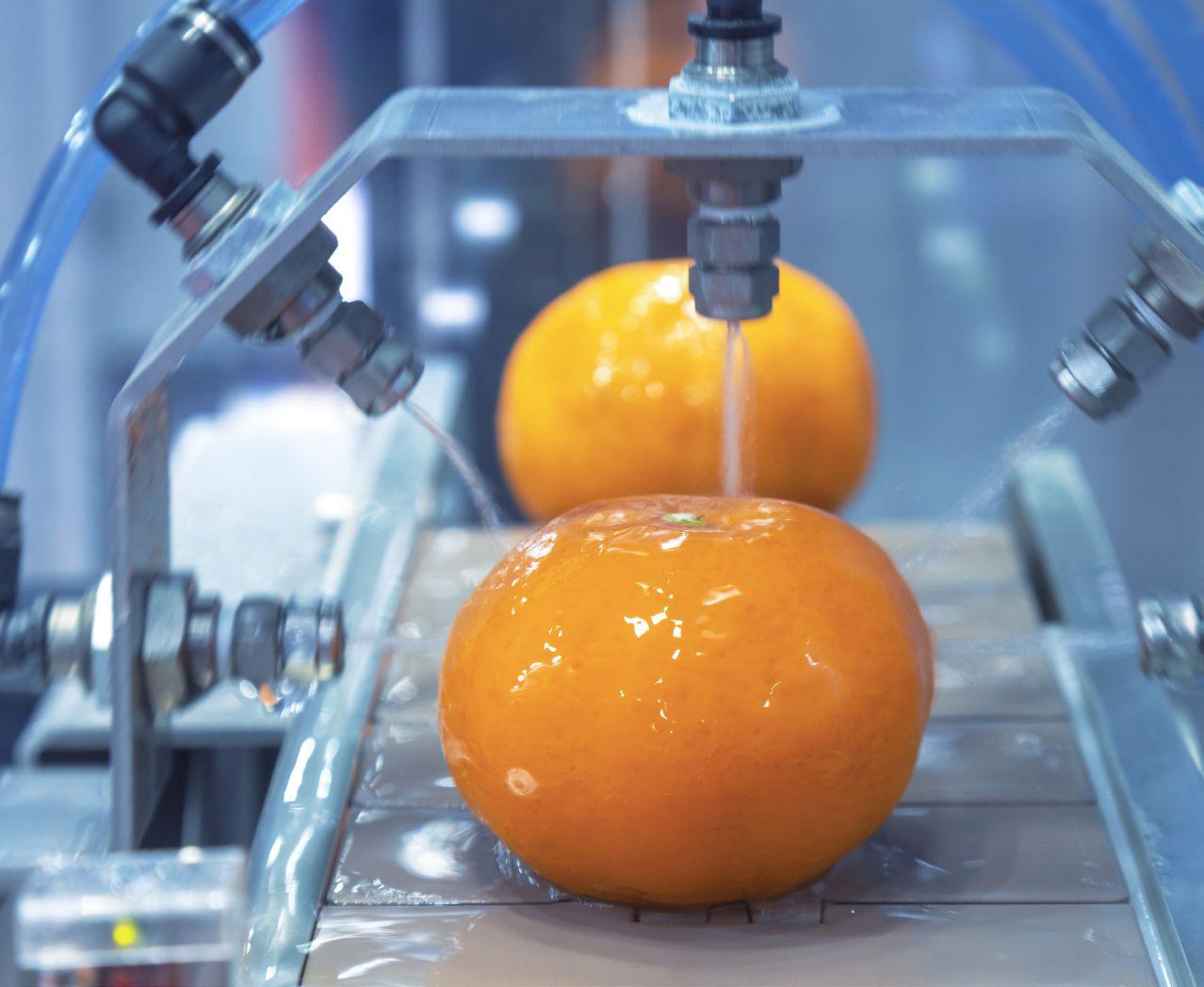

What happens when the scale is indicating irregular batch weights? For example, say the weight indicated on a Wonderware terminal would occasionally jump low, but the weight shown on the scale display was stable. After a first attempt at diagnosis, the 4-20mA signal from the scale to the PLC seemed stable with a digital multimeter. Another signal connected to the same channel seemed stable, but was evaluated with the system idle.

This is when the maintenance technician needs to pull out their trusty industrial oscilloscope to connect in series and record a batch. This exact scenario was described by a customer who shared that the first batch recorded showed no obvious signs of trouble. They also noted that the filling and discharging weight seemed smooth, although the empty current was a little low. The results of the scope record showed dips at 120 hertz, leading the

Failure to properly maintain equipment in a food and beverage manufacturing facility could lead to diminished product quality, potentially harmful products, insecure packaging and more.

maintenance technician to believe there was a bad capacitor after a bridge rectifier somewhere.

After consulting the scale manual, the interconnect diagrams showed that the analog output module on the back of the sale got 120-V AC in and the loop power originated on-board. In the analog board, C8 and C10 are 470 μF 35 V. C9, between them, is 47 μF 25 V. The technician replaced all three caps and solved the problem.

One customer described their experience with a package filling machine. The machine’s main air supply is controlled by two solenoid valves that are powered by the machine’s e-stop circuit. If the e-stop button is pushed, the machine goes into a zero-energy state. The electric power shuts down and the solenoid valves de-energize; one isolates the incoming air and the other dumps all residual air pressure.

While the filter was running, the main air would suddenly release and shut off the machine, then reenergize in a split second.

The maintenance technician traced the circuit and monitored the e-stop relays and all associated

contactors. Nothing was obviously apparent. They tightened all the screw terminals and replaced contactors and solenoids. The problem persisted. The technician used the trending function on the digital multimeter to monitor the contactor action, but found nothing out of the normal. The next step was to go further into the circuit and monitor the 24-V DC power, feeding the line side of the contact.

When the machine went down again, the technician stopped the “record” function in the digital multimeter and analyzed the results. The screen display indicated a spike-like dip in the 24 V from one of the DC-power supplies.

After further investigation, based on this evidence, the technician discovered that the supply’s cooling fan had gone bad. When it overheated, its output would drop, shutting off the air to the machine.

Sean Silvey has been a Product Application Specialist at Fluke for the past five years. Prior to that, he was a residential/commercial HVAC technician, and most recently a field service manager. Sean’s focus is on application awareness and product education.

cGMPs provides details on the cleanability and cross contamination standards that plants must meet for food safety. But how do plants manage and upgrade older systems quickly and cost-effectively?

BY STEVE BAIN

It goes without saying that a product recall is an event that food and beverage companies wish to avoid, but it takes more than good intentions to eliminate all potential contamination sources. Increased vigilance in the form of regular audits and upgrades can uncover issues which are generally overlooked or just beginning to develop.

The FDA Food Safety Modernization Act (FSMA) is intended to prevent the health and economic impacts of badly processed foods. Current Good Manufacturing Practices (cGMPs) under FSMA CFR Title 21 117.40 underpin this effort. Title 21 details the cleanability and cross contamination standards that plants must meet for food safety, and provides a good baseline on which to inform purchases of new equipment. But how do plants manage and upgrade older systems quickly and cost-effectively? Much can be achieved at relatively little cost through regular audits.

Some sources of contamination can be eliminated through employee training. Others are inherent in the design of machines. However, many individual electromechanical components are relatively inexpensive to monitor and upgrade. Here are eight steps for reducing potential sources of biologic, allergen and particle adulteration:

• Ensure compressed air intended for food contact does not contaminate it.

• Evaluate all potential contamination points related to compressed air.

*FDA Approved

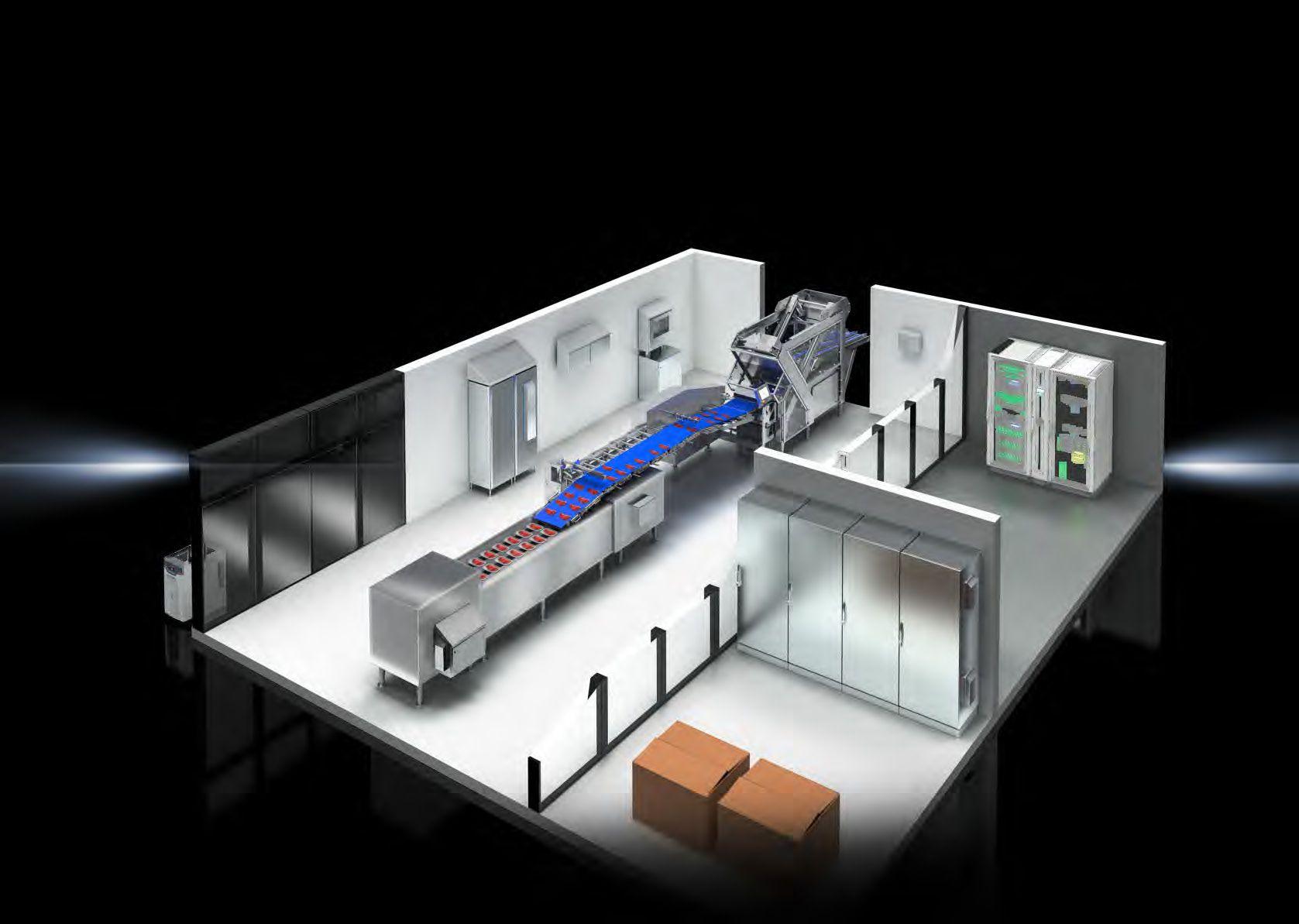

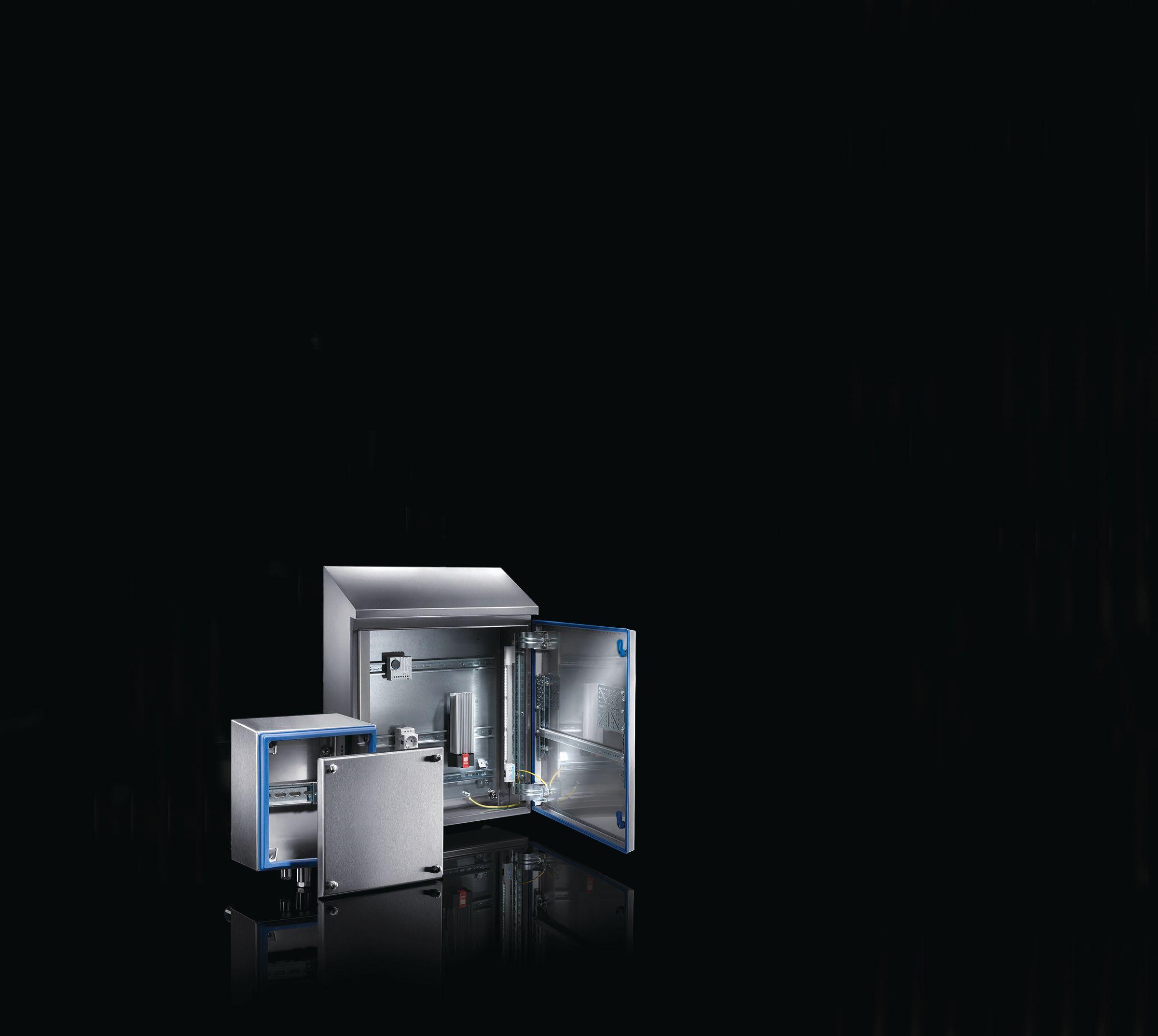

HD Junction Boxes, Wallmount & Freestanding Enclosures, Climate Control & Accessories are designed to handle the unique hygiene needs of the Food & Beverage industry, when traditional enclosures may fail to provide required levels of protection!

30˚ forward sloping roof repels water, bacteria & objects

Joint-free exterior blue gasket easy to see, clean, replace Hinges are internally located, durable, esigned for easy cleaning

mooth, stainless steel parts shapes for easy cleaning

*Visit rittal.ca/hd for your F & B Guide, or contact marketing@rittal.ca for more information

• Ensure pneumatic tubing is FDA-approved and resistant to aggressive cleaning processes.

• Eliminate difficult-to-clean fittings.

• Eliminate components that corrode easily.

• Ensure components can be cleaned easily and are properly rated for cleaning processes.

• Ensure actuators utilize foodsafe grease.

• Conduct component fitness audits at scheduled intervals.

Assuring proper air quality is a plant operator’s first and foremost concern. The air we breathe contains a host of impurities, and in food plants adulterating and allergenic particles may be added to the mix. Compressed air systems, if improperly configured or maintained, may further boost the density of contaminants. Compressed air intended for direct contact with food or used in end-of-line packaging systems must be made as clean as

possible through filtration. The filtration level you adopt is up to you. But various organizations have published recommendations.

For example, Safe Quality Food recommends a final filtration stage of 0.01 micron with a filtration efficiency of 99.999 per cent to be located at the point of use for direct food contact.

Plants that have not made their own risk assessment should consider meeting this standard at all times.

Next, there are additional ways to eliminate contamination in pneumatic components and in system design.

Fittings: Leaking fittings and tubing in compressed air systems may exhaust directly over food production. Prevention requires not only checking nozzles and cylinders, but finding and stopping leaks. Such preventive maintenance lowers risk of contamination and reduces energy costs. Leak detection options from handheld devices to energy efficiency modules incorporated into compressed air system.

Control and exhaust valves: Often, valves mounted near or above the food zone can pose an exhaust hazard. They should be distanced as far away as possible from food and packaging. If the valve cannot be moved, then the exhaust should be ducted to a safe area. If at all possible, avoid quick exhaust outlets on pneumatic actuators by installing the controlling valve closer to the application. By locating an IP69K valve manifold close to food production, tubing lengths can be significantly reduced, which improves machine speed and often eliminates the need for a quick exhaust. If quick exhausts still are required, they should be ducted to a safe area.

Tubing: Plastics and elastomers with direct food contact must comply with FDA directives. The material must not give off or absorb any hazardous substances, must resist stress and be cleanable. Environmental influences can cause microscopic cracking in pneumatic tubing that can trap contaminants. Approximately, 90 per cent of the defects in pneumatic tubing are traceable to chemical, microbiological

or physical influences. Upgrading with proper tubing like hydrolysis-resistant polyurethane can minimize or eliminate such failures.

Threading: Exposed threads provide perfect breeding grounds for contaminants. The small spaces between threads are difficult to clean.

Any threads that cannot be avoided should be closed off with suitable blanking caps and sealed. Several thread types are used in pneumatic connections. BSPP, also known as G-thread, is a parallel thread featuring a clean design that seals flush to a gasket. Utilizing G-threads wherever possible is an easy choice for improved FSMA compliance. Tapered threads, such as R-thread and NPT seal, pose an elevated contamination risk and should not be used.

Other corrosion/contamination risks: Design considerations and correct component selection can eliminate potential sources of contamination. All machine parts must be resistant to corrosion and mechanically and chemically stable to ensure safe, effective cleaning. They must not react with

the cleaning agents or disinfectants, or provide any dirt/contaminant traps. Stainless steel actuators are always preferred. The actuator also utilizes NSF-H1 grease and FDA-approved seals. NSF-H1 grease complies with CFR 21 178.3570 and should be used for equipment and components that come into even occasional contact with foods and packaging. Leakage of unsafe grease from the nose of cylinders is an often overlooked issue in packaging systems. Any such cylinders should be replaced with those with NSF-H1 grease.

In the washdown area, intensive cleaning can wash lubricating grease out of a cylinder, which is a contamination problem, and also impairs cylinder operation.

Cylinders may come with multiple seal options; ideally, choose FDA-approved dry-running seals to provide clean, optimum operation even when the grease has been washed out.

A high gloss surface finish is essential on components that come into contact with food to reduce microbial contamination. This can be achieved by using a mean peak-to-valley height of 0.4 to 0.8 μm within the food zone. High-quality surface finishes and large radii make cleaning the actuator quick and easy.

Small radii and corners pose a hygiene risk because flow velocities of the cleaning agents and disinfectants are substantially reduced in tight spaces; the required cleaning effect is not achieved. Components should have a minimum radius of three millimetres on parts. Furthermore, avoid dead spaces in machine design and system component selection. Dead spaces are difficult if not impossible to clean thoroughly. All machines and system components must be designed to eliminate dead spaces. Components should be either completely open or completely sealed.

Product remnants in dead spaces are difficult, if not impossible, to remove. Components must be designed to be either completely open or completely sealed as shown in the following illustration. Cleaning processes often employ the use of high-pressure hoses.

Equipment and components must be designed to withstand these processes. Resistant surfaces and a high IP protection class are designed for such harsh environments. Pneumatic systems are not static. Components wear out and vibrations can loosen fittings. New components are available that are easier to clean, more rugged and more capable in harsh environments. It is not cost effective to replace every older machine, but it is worthwhile for regulatory compliance and overall equipment effectiveness to maintain and upgrade pneumatics and automation components through regular audits.

Steve Bain is Industry Segment Manager for Food and Beverage, Festo North America.

Introducing Stainless Steel Hygienic Liquid Tight Metallic Conduit and Hygienic Flex Fittings to the Calbrite Flex Family. Calbrite Hygienic Flex products are made from 316 stainless steel, making them ideal for food processing facilities where washdown and high temperatures are required. Calbrite Hygienic Flex products are designed to provide excellent absorption of motion and vibration, protecting electrical wires and cables in any location. FoodBev_Calpipe_Spring21.indd

Calbrite offers an extensive line of flex conduit and fitting solutions for every application. Find our product datasheets here: calbrite.com/flex-conduit-and-fittings

BY GAVIN DALY

Like many others in recent months, food processing operators had no choice but to change their operational protocols. Many are updating facilities to be more prepared for future crisis situations. In the last year, manufacturers have buckled under the pressure of changing operational requirements and market demands due to the pandemic. This has led to many re-assessing and addressing their current facilities and renovating or upgrading them with new technologies that allow for product safety, employee safety as well as improvements in processes and production lines.

Smart surveillance technologies can help operators manage the evolving demands instilled on them by the current pandemic. This can help them meet food safety compliance and provide continuity of operations. Food and beverage processing is a complex business that requires a hierarchy of control methods for the screening and monitoring of workers and the cleaning, disinfecting and sanitation of equipment used in the process and the facilities themselves. Here are fourteen recommendations where intelligent surveillance solutions can play a valuable role in the security, safety, monitoring and optimization of these critical infrastructures now and in the future:

1. Low touch entry with facial recognition or wave switch sensor: employees and visitors can gain entry into a facility without having to touch a call

button or use an un-sanitized guest fob. This is possible with a SIP phone/ touch device, door station technology and facial recognition.

2. Occupancy estimator: facilities can keep track of how many staff are in a common space with real-time alerts that go off when the limit is exceeded at single or multiple entrances. This is facilitated with a public view monitors, a specific audio message, and lights that illuminate with an automatic locking mechanism.

3. Directional flow control: use automated triggers through audio clips to keep the flow of employee traffic moving in a designated direction. When the direction of traffic flow is hampered, the trigger would release an audio message over a speaker system.

4. Physical distance detection: an IP camera with an analytic appliance can detect when there are too many people in a two-metre/six-feet zone. This solution can be used for tracing the touchpoints and alerting employees to physical distance in an area.

5. Hand hygiene reminder: a camera application platform and speaker can trigger an event to play automated reminder messages for when individuals enter or leave a specific premise to wash their hands.

6. Delivery and curb-side pickup: there is an easy and simple way to prepare for deliveries and pick-ups without direct physical human interaction. This is performed with a camera, an analytic, a speaker device and a mobile device.

7. Live view feed/outdoor streaming: outdoor line-ups are a way of life at the moment. Food and beverage processors can benefit from a live camera feed interfaced to a website that shows waiting lines or overcrowding at entrances or docking stations.

8. Cross line detection – hygiene reminder: facilities can set reminders for staff to follow hygiene protocols or set them for delivery personnel to follow hygiene recommendations upon arriving or returning to their home. Consider a camera with cross line detection, IP speaker or audio and a bridge that allows the creation of an event where an audio clip can play “please remember to wash your hands”.

9. Audio bridge – intercom messaging: an audio bridge, speakers and audio clip played at a pre-determined internal such as every 5-10 minutes can share a consistent, regular message reminding the team to adhere to physical distancing regulations.

10. Loitering alert or keyless entry: open the

door to the back office or back of the building without having to touch handles. This can be accommodated with a door station and camera, then a staff member can unlock the doors to authorized personnel.

11. Heatmapping – employee flow: know which areas in the building have the most traffic to understand where the possible infection areas may be in the facility with a camera and heat map application.

12. Blocked exits: increase staff safety as well as compliance to authority regulations by alerting them when critical paths or fire exits are blocked, thus causing insufficient safety.

13. Sound detection: Surveillance can assist managers in emergency situations when faced with aggressive employee behaviour or danger with camera analytics and audio.

14. Monitor change/washroom cleaning needs: know when a washroom needs to be cleaned with automated alerts that signal when a certain number of people have used it and cleaning is required. A camera and people counter can make this possible.

There are many locations in a food-and-beverage manufacturing plant where intelligent

surveillance technology can play a valuable role. That is why it is important to consider solutions that can be adapted for other means. Security and safety start from the outside, where protecting the perimeter of the property is foundational. IP network cameras can monitor gates and fences along the boundary of the facility and record vehicles using license-plate recognition if deemed necessary. This can facilitate virus contact tracing and help with intruder trespassing. Surveillance also lends itself to post-incident investigation and can identify where an unsafe work situation occurred. This way the facility can take action and ensure that it does not happen again through measures such as additional signage or sanitation, protective barriers or new equipment.

When working with trusted integrators and suppliers, intelligent surveillance provides tangible solutions to keep food and beverage operations moving. They bring a level of safety and efficiency that are beneficial today and that go beyond into the future to address other needs.

Gavin Daly is the Architect and Engineering Manager at Axis Communications, providing technical expertise and personalized advice for both internal and external customers.

Despite all that has transpired with the pandemic, our spirit for improvement, growth and innovation continues. This season is appropriate to cultivate ideas and sow that accumulated knowledge - and those valuable lessons learned over the cold winter months - into a thriving maintenance and continuous improvement “garden of opportunity”.

With the interests of industry at the core of all we do, the Excellence in Manufacturing Consortium (EMC); a not-for-profit association of manufacturers across Canada, provides opportunities for members to grow through ongoing professional development, peer networking, knowledge sharing, best practice experiences and plant tours. We also serve as a conduit for community partner support, resources and the delivery of timely subject matter expertise when required or requested.

With a family of over 60 consortiums across Canada, meeting EMC members, especially in these virtual times, is an easy task.

The ability to make meaningful connections with others in similar roles and journeys represents just one element in our amazing toolbox to help you grow.

Other aspects include special member programming, training and funding initiatives that can lead to an abundance of opportunities to help you enable business competitiveness.

With plans laid out for upcoming Food, Beverage, Bio and Ag Sector activities, I took a moment to reflect on the incredible array of EMC events that

have taken place over the last decade, which included topics of food safety, maintenance and supply chain management. Maintenance is engaged in each of these identified areas, as it ties us altogether – weaving in out of direct projects, to health and safety, leadership and so forth. Maintenance is an integral part of every company’s “garden of opportunity.”

The entire list of course demonstrates the tremendous amount of knowledge shared over the years, not to mention insight on improvement possibilities – whether from a development standpoint, a plant improvement, investment or leadership.

• How many of these issues resonate with you? May impact your next project or your role at large?

• What would enhance your skills and your knowledge?

• Are there some that would be of particular interest to network with peers on?

• Perhaps you are on a similar journey, have a best practice to share related to the topics listed, or are curious about those who have connected on the same aspect of business?

• What is on your wish list to learn? What are we missing and what can we tackle next?

We would be very interested to hear from you, and if you have ideas to share, please reach out.

• Operations overview and lean journey

• Project management for the office

• Identifying process improvement ideas

• Improving shop floor execution and measurement through the adoption of digital technology

• Continuous improvement strategies

• Production and scheduling

• Five-S and decision-mapping

• Rapid improvement team – improving efficiencies

• Implementing technology on the plant floor

• Maintenance

• Conveyor and line control solutions

• Emergency evacuation planning

• Safety walk and best practices on health and safety

• Evaluating your personal protective equipment

• Building a healthy workplace with ergonomics

• Corrective actions – internally and with suppliers

• Food traceability

• Food safety and food labelling

• Building a culture of food safety and traceability

• World class food safety best practices

• Food safety/SQF Certification

• Striving for excellence in food safety

• Food safety traceability and KPI tracking

• Packaging, labelling and innovation

• Positive impact of digitalization on food safety

• Supply chain management 1

• Supply chain management 2 – getting your suppliers on board

• Leadership and supply chain management

• Logistics, transportation and border issues

• Literacy and multiculturalism

• Attendance management

• Coaching as an HR tool

• Ministry of Labour and Legal Updates

• Reward and recognition programs

• Surviving an MOL fine – lessons learned

• Aging workforce and duty to accommodate – retirement and severance

• Accountability and consequences – policies and procedures

• Institute of Food Processing Technology Trades and Apprenticeship Programs

• Mental stress and accommodation

• Attendance management

• Change management

• Assessing employee performance

• Talent attraction and retention best practices

• Talent review and building performance

• People involving people

• Utilizing engineering students

• Generational workplace issues

• Leveraging opportunities through apprenticeships

• EAP programs – measuring cost effectiveness and benefit analysis

• Turnaround interviews

• Skills management using learning technologies

• Culture development

• Helping you fund and plan the growth of your business

• Foreign exchange opportunities

• Dealing with rapid growth

• Retail management and merchandising

• Food export workshop

• Business growth, development, expansion and innovation

• Business growth and ERP implementation

• Creating opportunities for business growth in the food sector

• Remaining competitive in the food sector today

• Funding opportunities

• Dealing with rapid growth

• First steps in exporting

• Business growth through encouraging learning and empowering your people

• How to leverage digitalization in the food and beverage processing industry

• Why we need to be looking at automation

• Future of manufacturing in the food industry

• Risk management

• Business continuity planning

• Reducing your carbon footprint

• Environmental issues

• The road to net Zero waste

• Sustainability: a business strategy

• Lean and green initiatives

• The road to net zero waste

• Sustainability

• Energy management

• Environmental monitoring

• Building positive employee relations

• Developing employee engagement and accountability

• Teambuilding

• High performance work teams on the shop floor

• Shaping your company’s culture and developing leaders for the future

• How to lead a good company to greatness

• Developing supervisory leadership skills

• Getting back to basics

• Leadership development and employee engagement

• Leadership in manufacturing

• Change management – overcoming resistance, building buy-in and getting real results

MC Food, Beverage & Bio Sector ZOOM Webinar Networking Event

03-Jun-21 – Laura Lee Blake Change Management - Overcoming Resistance, Building Buy-In and Getting Real Results

As outlined earlier, our efforts are all designed to enable competitiveness in the industry, to assist where we can, address challenges as they unfold, and look to the future and how we can shape our businesses and our teams to be better, stronger and more capable of producing goods we can all be proud of.

We are constantly seeking input from manufacturers and community partners across the country to ensure that your opportunities and challenges are addressed. What keeps you awake at night? How can we help?

Inc. (former Vice-President - Human Resources at Campbell Company of Canada). Mark your calendars for June 3, 2021 and join us!

What’s next for our EMC Food, Beverage, Bio and Ag Sector? First and foremost, a session on Change Management – Overcoming Resistance, Building Buy-In and Getting Real Results with Laura Lee-Blake, Chief People Officer, Pearle Hospitality

If you are interested in learning more about EMC and the Food & Beverage Sector Initiative, please feel free to touch base with Bren de Leeuw, Vice-President, Community Partnerships and Stakeholder Relations, at 519-372-6009 or deleeuw@emccanada.org.

https://www.emccanada.org/event/emc-food ---beverage-sector-event--June%202021

EMC Food, Beverage & Bio Sector ZOOM Webinar Networking Event

02-Dec-21 – Carol Vandenhoek, Lawyer Issues Impacting the Food Industry –Legislative Update

https://www.emccanada.org/event/emc-food-andbeverage-sector-event-legislative-update-food-sector