Recently, my eight-year-old daughter began to show an interest in helping me cook. Nothing major, mind you, but I am happy anytime she wants to help. Right now, “cooking” usually means baking cupcakes or cookies, making egg salad for breakfast, doing a pizza from scratch or preparing everything for tacos.

Tacos are clearly the most labour intensive and the closest to the kind of food preparation you would see at an average food manufacturing facility. We get all of our ingredients together, from the vegetables, to the ground beef or turkey, to seasonings, cheese, and so on. All the while making sure everything is still fresh to use. Next, we wash and cut the vegetables, cook the meat, and grate the cheese. Throughout, having to make sure that after the meat is handled, we wash our hands, making sure there is no cross contamination between ingredients.

My daughter loves to help cook, but I have to keep reminding her of the steps and processes, especially the washing of hands. (Isn’t that an issue with every kid?) She just wants to do things and get it done.

While my kitchen can look similar to the chaos seen in restaurant kitchens, it is a much smaller scale and with a lot less traffic. However, the principles of what to do to make sure food is handled properly, cooked properly, and is safe to eat remain the same.

The one main difference from my own kitchen and a food manufacturing facility is that workers are trained on safe food handling processes unlike my daughter who needs constant reminding.

You can invest large amounts of money in having the most high-tech refrigerators, machines, maintenance plans, and so on, however, if kitchen staff are not following the fundamentals of safe food handling, everything else becomes moot. If staff are constantly changing, it may be a good idea to hold training or refresher sessions periodically to go over the fundamentals of food handling.

Proper food handing is the last line of defense from having the public (or in the case of my daughter and I cooking, our family) from getting some sort of food borne illness. Machines are cleaned at high temperature to make them sterile, fruits and vegetables are washed at the industrial farm level to make them as fresh/clean as possible, the items are refrigerated when they are transported to make sure they are fresh when they reach their destination.

The link in the chain breaks anytime something is not done properly, so making sure food is handled correctly at all steps, especially the cooking phase, is of utmost importance.

Mario Cywinski, Editor Food & Beverage Engineering & Maintenance

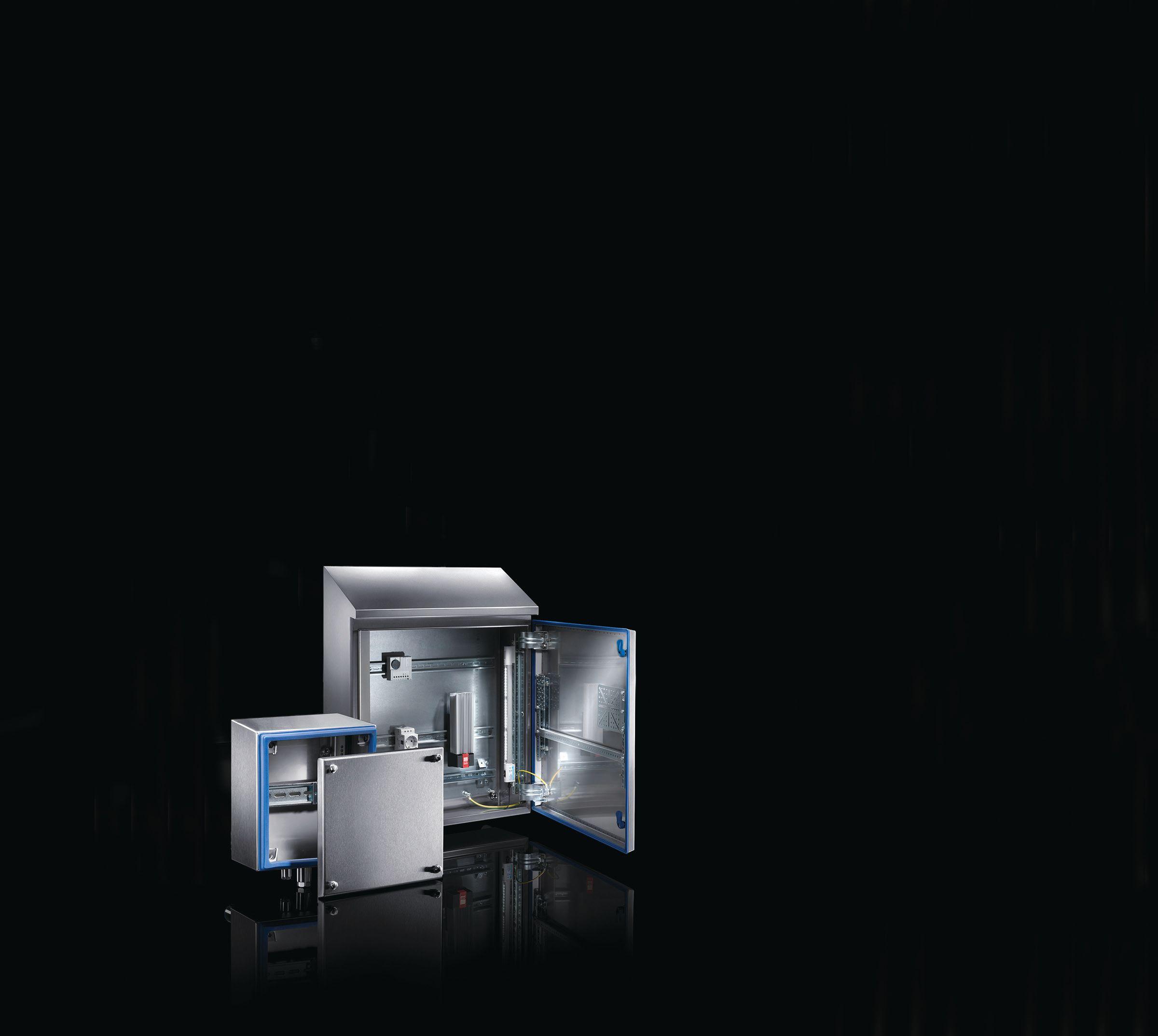

IP 66/69K, cUL approved!

Specially designed to handle the unique hygiene needs of the Food & Beverage industry, when traditional enclosures may fail to provide required levels of protection!

• 30˚ forward sloping and overhanging roof repels water, bacteria & objects

• Joint-free exterior blue gasket is easy to see, clean, replace

• Stainless steel construction and no dead zones for material and bacteria to accumulate

• Hinges are completely internal, so cleaning is not an issue

*Visit rittal.ca/hd for your F & B Guide, or contact marketing@rittal.ca for more information

Rittal Systems Ltd., has been named to the 2019 list of Best Workplaces in Manufacturing in Canada, from Great Place to Work.

“To be declared as one of the Best Manufacturing Workplaces in Canada by GPTW is a testament to the great support offered by our global teams in Germany and the US, as well as to our own Canadian Modification team that ensures that every product is customerready when it reaches Canada,” said Tim Rourke, President, Rittal. “Thanks to the fantastic work ethic, dedication and commitment of our entire team to our customers and to our goal of being the very best workplace when it comes to overall excellence from Engineering to System to Automation! “ To be eligible, organizations must

be Great Place to Work Certified in the past year and work primarily in the manufacturing Industry. The best are ranked based on employee responses to the Trust Index survey.

Consulting company Mallot Creek Group is celebrating its 20th year of consulting on business development and engineering projects across Canada.

“We have grown our company expertise to address the evolving industry and our founding values,” said Tito Guglielmi, Co-founder.

“It has always been about bringing actionable, executable solutions to address real challenges in the food industry.”

The company addresses food safety, strategic business development planning, and engineering and

process design.

“Both of us worked at one of the largest food manufacturers in Canada and finding strategic advice was difficult,” said Bruce Cowper, Co-founder. “We saw that the real opportunity was to listen to our clients’ needs and provide the expertise to get the job done.”

Mallot Creek Group has over 50 employees and is planning to grow “Bruce and I want to thank all of our clients over the years for allowing Mallot Creek the privilege of partnering on their projects” said Tito, “We are respectful of the trust that we have earned and we will continue to provide expertise and value to our clients for many years to come.”

Rittal Systems Ltd., was an award winner during the Great Canadian Data Centre Symposium held recently at McMaster Innovation Park in Hamilton.

The Canadian Data Centre

Excellence Awards (CDCXA) were presented, with Rittal winning the Excellence Award for Data Centre Facility Infrastructure (which spanned three categories: Edge Deployment, Racks and Cooling Systems.

“Rittal is pleased to be a part of this integral Data Centre Community in Canada, and contribute to Industry 4.0 with our ‘Discover the Edge’ data centre solutions,“ said Tim Rourke, President, Rittal. “We are delighted that our world-leading range of IT racks, cooling, security and monitoring systems and software can benefit the industrial as well as IT sectors!“

BY JOHN CARNEVALE

On the world food manufacturing industry stage, food safety has always been a primary concern. Canada’s Safe Food for Canadians Act, adopted in 2012, maintains a quality oversight over foods traded inter-provincially and internationally.

D uring NAFTA 2.0 talks held in Ottawa in 2017, a “joint risk assessment organization” between Canada and the U.S. was proposed for food safety. An eight-page discussion paper Risk and Reward: Food Safety and NAFTA 2.0 by Rory McAlpine, the senior vice president for government relations at Maple Leaf Foods Inc., and Mike Robach, vice

president for corporate food safety and regulatory affairs, Cargill Inc., outlined a bilateral commitment.

This Canada-U.S. proposal would jointly:

• A ssess and prevent emerging foodborne threats (microbiological, chemical and physical, including, where relevant, those linked to animal and plant health);

• R ecommend food safety risk thresholds for pathogens, chemical residues, allergens, etc.;

• C onduct risk-assessment modeling for various pathogen-food combinations and potential interventions;

• Approve food safety interventions,

technologies and analytical test methods;

• V alidate food safety best practices at all levels of food production, processing, distribution and preparation;

• S hare and interpret food safety testing and surveillance data gathered across North America and globally;

• E xamine emerging risks, establish relationships between prevalence and levels of contamination and update risk assessment models accordingly;

• R ecommend innovative, outcome-based food safety inspection practices and compliance promotion strategies;

• Help the International Food Protection Training Institute and Safe Food Canada to build a North American competencebased learning framework for standardized, certifies food safety education and training;

• B uild harmonized systems for traceability of meat,

poultry and other food products throughout the supply chain, from origin to consumer.

I n 2016, the Canadian Food Inspection Agency (CFIA), and the Department of Health Canada signed an agreement with the U.S. Food and Drug Administration (FDA) recognizing each other’s food safety systems as comparable.

W ithin the United States, under their own passage of the Food Safety Modernization Act (FSMA) in 2011, brands and their suppliers are still struggling to meet the demands of that regulation. Often, the need for high-speed processing and efficiency are at odds with sanitation guidelines and inspections.

Understanding how the law applies to equipment design and purchase considerations

is vital to the success of any OEM. Food safety governs every step of the harvesting, processing, packaging, storing and shipping process. OEMs must be aware of how the rules and regulations affect their brand customers. Some of the rules put in place by the FSMA have only recently been finalized, so implementation and compliance are a concern. Furthermore,

2017 marked the first full year of compliance for many U.S. food manufacturers. Canada and the U.S. support this collaboration of the sharing of modernized regulatory and systems recognition. The food industry is bigger, more global, and the push is more proactive rather than reactive. Data- and science-driven policy are more important than ever.

A lthough the regulatory environment of Canada is not as microencompassing as the U.S., reviewing the standard and challenges set forth there may offer a cautionary tale. Some manufacturers in Canada have begun to implement FSMA-compliant standards, since pundits predict Safe Foods for Canadians Act will eventually have similar requirements as FSMA.

A n understanding of the FSMA rules and guidelines may provide a roadmap in Canadian production. The FSMA has rules and guidelines in place for nearly every step involved in the harvesting and production of food. For instance, OEMs involved in dealing with fresh fruit and vegetable companies, small farms, and foreign suppliers should pay particular

recalled, the FDA will cite the brand, which requires the food manufacturer to examine the machine that created the contamination and recall. If a particular OEM’s equipment is found to be at fault, the supplier will find it hard to continue to service its brand customers without significant improvements in its sanitary procedures and manufacturing processes.

Fortunately, most OEMs are ahead of the curve when it comes to safety and sanitation. Most Canadian companies use Hazard Analysis and Critical Control Points (HACCP) as a part of their design principles. As a result, many OEMs do not anticipate major changes or large orders of new equipment because of their

attention to new regulations, as handling and processing equipment are drastically affected by the FSMA. Smaller companies may have trouble handling the costs and overhead that the FSMA introduces, and new regulations on interactions with foreign suppliers could be expensive to implement.

While not directly under the authority of the FSMA, U.S. OEMs are still a part of compliance. For example, if a food manufacturer has a product

progressive approach and best practices. They may need to adapt equipment to meet evolving regulations, but a drastic overhaul is not on the horizon.

Consider the regular cleaning and sanitizing process a food manufacturer goes through. Equipment must be shut down while being cleaned. Many manufacturers used to clean equipment approximately every 24 hours, but now the FSMA requires science-backed processes and proof that cleaning operations are effective, which could necessitate more regular wash-downs.

A lso, cleaning occurs for a number of reasons when lines are switched, including meat to non-meat foods, different species of animals, processing common allergens and different spices and seasonings. Specialty manufacturers, nonGMO and organic labels may

customize their production lines even further. Cleaning takes an immense amount of time out of the day that could otherwise be used for production. The easier an OEM makes it to clean equipment and get back to production, the greater market advantage they have.

C ompliant cleaning is not just wiping down a stainlesssteel surface. Workers must disassemble equipment, and every part, gasket and knob must be thoroughly cleaned and sanitized. The easier an OEM’s equipment facilitates this process, the more marketable it is to brands. Any part of an OEM’s equipment that is concave, hollow or otherwise non-linear can trap moisture and is considered a liability.

F ood manufacturers often use powerful super-hot jets of water and chemicals to clean equipment. If this water gets trapped anywhere, it can be a mold and contamination

hazard. Remember that the FSMA is proactive, so such situations should be prevented from the outset by thoughtful equipment design whenever possible.

Equipment that self-cleans with programmable and customizable options is another time and labour-saving option OEMs can implement.

T he jets of super-hot chemical filled

water are a concern in a different way as well. Consider that food manufacturers often use chemicals like bleach, powerful detergents, ammonia, phosphates, acids and alkalis to clean equipment. If the FSMA does end up leading to more frequent cleaning, this can be a primary concern for the durability of equipment. OEMs must ensure equipment

and surface materials can stand up to this abuse and protect sensitive electronics.

T hat same sensitive electronic equipment that allows food companies to collect all the required data by the FSMA, and allows equipment to link and work together, faces its own set of concerns. Ideally, control

panels should be easy to hose down, but this is likely unrealistic. Instead, the panels should make it easy to shield sensitive electronics from such conditions and then make it easy to spot that they need special cleaning. This could mean bright, visible covers, loud verbal notifications and alarms, and frequent reminders. The

FSMA is proactive, and making the control panels, switches, buttons and related parts of equipment easy to clean is a vital part of this.

W hile wet cleaning may seem more obvious, that is not all there is to it. Before food manufacturers even reach that step, they must remove large debris, soils and the like. The same general guidelines apply here, too. Make it easy to reach and clean all parts of machines. Equipment should disassemble easily, and any parts that could trap dust and debris should be minimized or eliminated entirely.

B eyond hot water cleaning, the FDA has a long list of chemicals approved to sanitize equipment. These chemicals include iodine, calcium hypochlorite, ammonium chloride, ethyl alcohol, isopropyl alcohol and sodium dichloroisocyanurate. Equipment should withstand repeated use of these chemicals. Milk handling operations cannot use certain chemicals, including trichloromelamine and either sodium lauryl sulfate or

dodecyl-benzene sulfonic acid, but other operations you serve may use them, which is something else to keep in mind.

Remember that organic and nonGMO labels may wish to use other cleaning chemicals, and have to balance this with FSMA regulations. When working with a particular industry, be sure to know these requirements. What you are doing as an OEM should line up with FSMA requirements and your customers’ operations to best suit their needs. Drying time is another concern. Once the equipment is clean, how quickly can it get back up and running? If it takes hours to dry and is out of operation, that is valuable production time wasted.

Fruit and vegetable companies are likely to require the most investment in new equipment and should be an area of focus for OEMs in equipment design. The FSMA applies many new standards to the

harvesting, handling and processing of fresh produce. OEMs should keep this in mind when designing equipment for this subset of the food industry.

O ne important development in fruit and vegetable processing is the introduction of new rules governing water quality standards. These regulations mandate no detectable generic E. coli in water that could end up on produce. This includes water for hand washing during and after harvesting, water used to wash surfaces that touch food and water used to irrigate sprouts. Water directly applied to produce other than sprouts can have a geometric mean of 126 or less colony-forming units (CFU) of generic E. coli per 100 mL of water. Additionally, the statistical threshold is 410 or less CFU of generic E. coli per 100 mL of water.

All of these new regulations mean more testing, which means demand for testing equipment, but also possible production delays. Water purification equipment purchases

may also rise if manufacturers find their water supply does not meet requirements with their current setups. Sprouts are especially under tight restrictions, because they have been linked to many historical instances of food poisoning.

E quipment should reduce

contaminants through enhanced filters and metal detectors. Because the FSMA changes food safety from reactive to proactive, thorough data collection should capture information from critical control points and from the preventative controls the FDA has outlined, while also

keeping track of performance. This would allow companies to have both the adequate records required by law and analysis that highlights inefficiencies in production. If an OEM’s equipment data shows where certain parts of production can be improved, while maintaining regulatory compliance, it is likely to be popular in the market.

T he FSMA is based on detailed analysis and one of the notable areas in which OEMs can excel is offering scientific proof that their products meet marketing claims. This includes scientific data on bacteria control and sanitation. For example, OEMs can provide data to show how long bacteria can survive on their product surfaces. Providing ways to keep records and track tests is another method in which OEMs can not only offer equipment that allows companies to meet FSMA requirements, but that also provides a competitive advantage.

Because the FSMA is heavily data driven, communication between various pieces of equipment, shop

computers and office computers should be easy and seamless. That way, all employees — from operators to the CEO, are aware of the details of operations. An OEM that offers a way to manage all of the two years worth of data the FSMA mandates, would have an immense advantage in the marketplace. Larger companies look for many different diagnostic and record-keeping tools. They want critical control points, food processing, sanitation, packaging, downtime and performance, and FSMA operational documentation to be easily captured, viewed and used across a single interface. Downtime is of particular importance, as it cuts into revenue. Providing short training videos allows OEMs to answer concerns about worker safety and preparedness.

F or Canadian production, both OEMs and food manufacturers need to remember that many

newer food safety regulations like the U.S. FSMA are proactive, not reactive. The processes, practices and equipment that ensures food contamination does not happen, and that the food supply is safe from farm to table, requires coordination and communication at every step of the process.

O EMs can provide a key resource through sanitationfocused products, interconnected data-driven processes and consultations. Responsible global food production is a goal without boundaries. Forecasting the convergence of productivity and compliance will enable equipment manufacturers to deliver highly marketable products that future-proof brands against regulations and improve their bottom lines.

John Carnevale, Market Manager, Food and Beverage, Rittal Corporation. Article was provided by Rittal Corporation.

Select options that handle wide flow range and maintain tight temperature requirements.

BY JASON CARPENTER

Food and beverage applications must meet a variety of process temperature and pressure control requirements to maintain tight temperatures that help ensure product quality and safety. Selecting the right steam control system and using best practices for piping and installation can have a huge effect on production, downtime, and health and safety of end users. Implementing a rotary globe valve with a 100 to one turndown to simplify the process and allow tight performance control and shut off for the application, should be considered.

Steam control systems, which include control valves, steam traps, and condensate recovery

equipment, are critical in many food and beverage applications. Key applications include clean in place (CIP) processes and HTST (high temperature/short time) pasteurization used in dairy, cheese, milk, and ice cream manufacturing. Other widely used steam processes include retort sterilization in canning operations; bottle washers; tempered hot water systems; condensate of whey (COW) water; poultry scalders; flash steam peelers, blanchers; evaporators; direct steam injection processes; and hot air dryer systems.

These applications all use a temperature controller with a valve to maintain a separate temperature. The valve is critical, because operators must maintain very tight temperature control to avoid issues that would otherwise occur, like bacteria growth or loss of product.

The challenge faced by many food and beverage applications is that they often do not have a set flow range. This variation of flow ranges is especially true for plants that run different products at different times. For example, at many plants the HTST pasteurized flow range can range from 10,000 pounds per hour to 2,000 pounds per hour. To maintain proper temperature control in the face of changes in flow, operators must use a control valve with varying rangeability and excellent shutoff characteristics.

Unfortunately, too often operators use a cookie cutter approach for steam isolation on modulating process steam equipment. For example, many systems today incorporate a pneumatically activated quarter turn ball valve to assist in shutting off the steam to the heat exchanger. They typically select the ball valve due to the standard globe valve applications in the market that have leaked. Using an actuated ball valve for isolation on the steam train to the process can lead to water hammer, pressure spikes, loss of product, or bacteria growth. By contrast, a rotary valve has good shutoff and can meet FCI ANSI Class V shutoff on steam for these process applications. This eliminates the need for the actuated ball valves for isolation on the steam train to the process. Some rotary globe valves incorporate cam action, low friction plug operation that provides tight shutoff over long

best practice setup was developed by Kevin Rasmussen, President, KEI Steam Solutions, Inc.

“The setups commonly used today typically require a lot more service and maintenance because they are not laid out or selected correctly and lack best practice piping, which can cause equipment to fail,” said Rasmussen. “Use of

the suggested best practices increases productivity, reduces down time, and allows for equipment reliability on the systems. In addition to the best practice implementation shown, plant operators should always conduct an annual evaluation of steam and condensate equipment to make sure the equipment is running at optimal levels.”

Figure 1 shows an example of a best practice installation for a CIP process that performs to high level expectations. The

service life in a wide variety of flow control applications. Their rangeability is 100:1, allowing precise control over a wide range of flows. This enables the plant to utilize the same control valve for all the facility’s steam and fluid control applications. There can be quite an advantage to using one valve style for many applications, because it allows for plant standardization and minimal stocking requirements.

CIP systems for the food and beverage industry utilize steam to heat water in the process through non-contact heating of a heat exchanger or through direct injection of the steam into the CIP tanks. The rotary globe control valve shown can be used for heat exchanger temperature control. The turndown allows for maximum temperature and pressure control across a wide range of flow variations. This is critical in CIP heating, where load variations are constant and the application requires consistent temperature control. The application requires very tight shutoff when the system is not in operation, so there is no steam and condensate losses and degradation of the heat exchanger.

Another issue in food and beverage applications is the steam trap and condensate return system, which should remove condensate quickly to allow heat transfer to occur and eliminate the stall point. The best practice solution shown includes condensate elimination for the CIP heat exchanger. The use of a free float steam trap allows for the continuous removal of condensate from the heat transfer surface, allowing for proper heat transfer to the product. Unlike standard float and thermostatic (F&T) traps, this free-floating steam trap does not have any mechanical linkage, and has a variable orifice that will modulate with the continuous condensate load for fast efficient condensate removal and process temperature control.

In addition, the best practices set up also eliminates condensate from stalling or stacking condensate into heat transfer surfaces by utilization of a steam motor or a steam pump and trap combination. When using a modulating control valve, all condensate lines must be drained by gravity or pumped back to the boiler room. The ideal setup also includes a main pressure reducing valve for reducing the steam pressure to the CIP system from main plant pressure.

It should be noted that the best practice implementation also positions plants to take advantage of energy savings from recovering condensate, which can be like “liquid gold” to a process. This type of setup helps plant meet the required balance between energy recovery and food product performance. It helps answer the question, “How can I maintain my control without having to install costly extra bells and whistles?”

To illustrate the benefits of a steam control system designed in accordance with the best practices discussed, here is an example of a large cheese manufacturing facility that recently overhauled its set up from an automated ball valve to the rotary valve set up.

Figure 2. Midwestern cheese manufacturing plant using automated ball valve.

Figure 2 shows the “before” state with a variety of improper practices:

• No drip steam trap was installed for condensate removal before the control valve to prevent valve seat wire drawing.

• The installation has an automated ball valve for isolation directly before the control valve, which offers only on/off service. This will likely cause premature failure of the control valve and heat exchanger tube bundle. It will also cause

instability in the process control.

• The control valve is piped too close to the heat exchanger inlet, which does not allow for the velocities to expand out on the pressure reduction through the control valve. The minimum should be 10 pipe diameters of straight pipe run after the control valve of the heat exchanger inlet connection size.

• The heat exchanger should utilize a continuous type steam trap or variable orifice steam trap, which continuously discharges condensate to remove condensate from the heat transfer surface and allow for full latent energy utilization.

• The condensate must be gravity-drained to a condensate pump for full condensate removal. This can be done with a steam/air motive pump or electric condensate pump.

• The setup had no thermostatic air vent for the removal of air on startup of the heat exchanger.

• Without proper air removal, the heat exchanger may experience lagging startup times, improper heat transfer, and air binding of the equipment.

• There is no Y strainer protection before the control valve to allow draining of the piping and removal of scale and debris.

Figure 3 shows the solution designed to follow the best practices outlined.

A rotary control valve provides tight process temperature control and isolation in one valve.

Gravity draining the steam traps to the steam / air motive condensate pump or electric condensate pump provides proper condensate removal from the heat exchanger.

Expanding the piping after the steam trap, the setup includes one pipe diameter for flash allowance from the trap discharge.

There is no need for a ball valve isolation because the rotary globe valve allows for 100:1 turndown for process control rangeability, class V shutoff, and larger CV.

Proper piping layout before and after the control valve to the heat exchanger ensures performance will be optimal.

The new setup features correct use of a thermostatic air vent with vacuum breaker on the heat exchanger.

Correct discharge piping utilizing a variable orifice free float steam trap provides continuous condensate evacuation on the heat transfer surfaces.

Proper drip pockets and Y strainer protects the control valve from wire drawing of valve seat.

Implementation of best practice equipment selection, piping, and procedures will result in reliable long-lasting service and control of equipment and processes. Unfortunately, many food and beverage plant operators do not have the technical expertise to ensure the equipment set up is properly implemented. They may be relying on vendors and process equipment providers for this service. That is why promoting best practices is critical to making the process work correctly.

With nearly 20 years of experience, Jason Carpenter is a skilled Business Program Manager at CIRCOR International. Jason manages the product portfolio of control valves, regulators, steam-fired heaters, and steam straps for steam application solutions for district energy and processing industries such as food and beverage, pharmaceutical, chemical and pulp and paper in the Americas market.

When I was younger, I took pleasure in listening to others recant their summer adventures and couldn’t wait to share mine. In thinking back, our peer sessions then were an early version of “best practices,” depending on how bold the exploit might have been. As always, the summer came and went, and each fall we began another school year full of enthusiasm, confidence and experience to build on, while revelling in lessons learned over what seemed an epic season!

Now older and less adventurous, as adults that same type of “experience sharing” we learned from days gone by continues to bring our teams together. Now rejuvenated from our summer achievements or R&R and ready to engage with fresh perspectives, open mindsets and tackle goals at hand within our business roles. E xcellence In Manufacturing Consortium (EMC) networking events and activities are about learning from each other and this fall is the perfect time to take stock of best practices

that can foster cultures of business improvement, idea generation, and problem solving in our own organizations. They present the perfect forum for companies to review journeys, sharing what is works and looking at how to take businesses to the next level.

I n that “fresh back from summer holidays” spirit, one of the key issues EMC will be addressing this fall is the future of manufacturing. A topic that continues to invite dialogue and perspectives from manufacturers across Canada, and explores the possible impacts industry faces in the years to come and how businesses are adapting.

Years ago, I remember a speaker who included a chart in his presentation detailing the exponential speed of change. It continually reminds me how fast the world is evolving and how quickly our businesses, roles, products, markets, skills, and training need to transition and adapt. Forward-looking companies are casting thought far beyond basic forecasts to focus on what the future of manufacturing entails to all aspects of their business, to industry at large and to our

country in the years to come. The need to be flexible, nimble and adaptable has never been more imperative.

We can be sure that the future of manufacturing will incorporate a breadth of changes in the industry centering on issues relating to workforce (shortages/future skills/productivity), and technical impacts (advanced manufacturing and automation/digitization/cybersecurity) and sustainability (energy/carbon/legislative impacts/ strategies).

A recent EMC manufacturers networking event brought representatives from various key function areas to discuss the current and expected impacts on businesses. During that session, those participating were asked to name one thing that might be different 20 to 25 years in manufacturing.

Here are some responses:

• Robotics

• Highly automated

• AI

• Data/cloud management will grow

• Higher skill requirements (such as technical labour)

• Attraction and retention of employees in nonautomated processes

• Ongoing skill shortages

• I ncrease in innovation and reduction of manual labour

• Less waste and more sustainable practices

• More state-of-the art equipment with greater efficiencies

C onsider this for a moment – how might your company or your role within the organization change in this 20 to 25 year time frame? How will your position evolve? What kind of impact will automation have? How will your product or customers change? What will gauge efficiency? How will you be move innovative, competitive, adaptable? How will you attract and retain the talent needed? What kinds of skills will be required?

I n short, these are interesting times for industries. EMC is inviting manufacturers, subject matter experts and community partners from

across Canada to look at change and the impact at the EMC National Advantage Through Excellence – Future of Manufacturing Conference.

Export Development and Growth; Operational Excellence; Future State of Manufacturing and Advanced Manufacturing and Innovation are themes, which will provide participants with the opportunity to learn from a roster of keynotes, industry experts, best practice presentations and panel discussions, lending insight on where industry is at and where it is going.

Keynote speakers at the conference will include:

Peter Hall , EDC, Vice-President and Chief Economist

Dr. Michelle Chretien , Sheridan College, Director, Centre for Advanced Manufacturing and Design Technologies

Jason Myers , NGen – Next Generation Manufacturing Canada, CEO

There are also three plant tours – Transcontinental Printing , Siemens Canada , and Tayco . Finally, a trade show component will afford participants the opportunity to meet service

providers and fellow peers.

I f you would like to join us on October 8th, 9th and 10th in Vaughan, do let me know – we would be delighted to have you or a delegate from your company there! Further programming and registration details can be found by visiting our website at www.futureofmfg.ca. And definitely, definitely remember to bring your business cards or program on your cell phone to carry on connections with those you meet after the Conference ends!

I n addition to the conference, we are hosting an EMC Food and Beverage Sector presentation by HFS – Healthcare Food Services on world class food safety best practices on September 19 in Ottawa. Building robust, manageable, well-thought out programs and developing a positive culture around every aspect of food safety is imperative to those in the food and beverage industry. Staying abreast of changes in legislation, adhering to proper food handling, sanitation and pest control, and nurturing a culture that

understands, engages and continually seeks improvement on current practices is all part of the broader picture of developing an enduring a world class food safety program.

L ooking further ahead, registration is now open for the 10th Annual Food Regulatory and Quality Assurance Summit. It is a forum to garner a wide array of insight on legislative issues and regulation requirements through traceability, compliance, education, training, labelling, exporting, food fraud, blockchain applications, sustainability and consumer demand expectations. This year’s conference will hosted by the Strategy Institute and held at the Old Mill Inn in Toronto on October 29 and 30.

If you are interested in learning more about involvement in EMC’s Programs and Services including Strategic Interest Groups (SIG) or our Special Food and Beverage Sector networking sessions, please feel free to reach out and we would be happy to share information on what is coming up in your region.

How do you get involved? If you are interested in learning more about EMC and the Food Sector Initiative, please feel free to touch base with Bren de Leeuw, National Director – Program Delivery and EMC Food, Beverage and Bio Sector Program (bdeleeuw@emccanada.org) anytime.

A s we reflect on another summer, we look forward to building on our daring feats, taking stock of the lessons learned and engaging with enthusiasm, confidence and new experiences with another season of peer networking, best practice sharing and planning for the future. EMC participants can look forward to a fall that enables learning, development and growth.