FOOD BEVERAGE

PRODUCTIVITY SELF - DIAGNOSTIC TOOL

ART DIRECTOR

Mark Ryan mryan@annexbizmedia.com

ACCOUNT CO-ORDINATOR

Barb Vowles bvowles@annexbizmedia.com (416) 510-5103

CIRCULATION MANAGER

Beata Olechnowicz colechnowicz@ annexbizmedia.com (519) 376-0470 (866) 323-4362

Fatal errors

My thoughts are with the family of Amina Diaby, a 23-year-old temporary worker originally from Guinea, who died in a tragic incident after her headscarf got stuck in a conveyor belt at a North York, Ont., industrial baked goods facility.

The incident took place on September 2, 2016. At the time, Diaby was not wearing a lab coat and her hijab became entangled under a guard covering the chain drive of a conveyor, according to the Ontario Ministry of Labour court bulletin.

Unfortunately, Diaby was unable to reach for an emergency stop button because it was not accessible from the location of the entanglement.

The Ontario Ministry of Labour determined that her employer, Fiera Foods Company, had failed to ensure that a worker near a source of entanglement secured all loose clothing. The Ontario Ministry of Labour reports that the Fiera Foods Company pleaded guilty and was fined $300,000.

Section 83(2) of the Industrial Regulation stipulates that “jewellery or clothing that is loose or dangling or rings shall not be worn near any rotating shaft, spindle, gear, belt or other source of entanglement” (R.R.O. 1990, Reg. 851, s. 83.). The industrial bakery

is in violation of section 25 (1)(c) of the Occupational Health and Safety Act.

Diaby’s story is embroiled in a much broader scheme of exploitation of temp workers, which cannot be ignored. She was hired by Fiera Foods through OLA Staffing, a temporary help agency based in Woodbridge, Ont. The hiring arrangement has exposed a dubious workaround practice for limiting a company’s liability for accidents on the job. However, the Workplace Safety and Insurance Board hasn’t laid charges against the agency.

Which begs the quesion: Does paying a $300,000 fine clear the way for resuming business as usual?

News reports on the case have stirred up controversy about the ensuing Diaby investigation.

According to one report, a lawyer representing Fiera Foods said that the company has invested $500,000 in health and safety initiatives over the past two years.

In contrast, a Toronto journalist, who recently spent 30 days undercover at Fiera Foods, reports a slew of safety infractions she encountered on the job.

It is not the first time the industrial bakery has been associated with slipshod occupational health and safety practices related to temporary workers. In 1999 a Toronto teen was crushed to death when a dough

machine he was cleaning was accidentally activated by a co-worker. And in 2011, another employee was crushed by a transport truck outside Marmora Freezing Corp., a contractor of Fiera Foods.

For each of these incidents, Fiera Foods was convicted under the Occupational Health and Safety Act and fined a mere $150,000.

I can’t think of any reason to reduce an employer’s responsibility for making sure conditions of employment – temporary or full-time – are up to par and that employees’ legal rights are respected.

It remains to be seen how the baked goods facility will make amends.

Rehana

COMPRESSED AIR

A major factor in increasing service life of machines and components is the compressed air supply.

BY REHANA BEGG

From food-filling machines and packaging to fluid pumps and air knives, compressed air permeates the food and beverage industry. But despite the demand for this utility, good manufacturing standards, along with costs and potential hazards can be nebulous to wade through. To gain insight, Food & Beverage Engineering & Maintenance reached out to an authority on compressed air solutions. To our delight, Festo, a manufacturer of pneumatic and electromechanical systems, components and controls, responded by having three industry segment specialists answer our questions.

Food & Beverage: What is compressed air and how is it used in the food and beverage industry? Where does compressed air contact food?

FESTO’S SUBJECT MATTER EXPERTS:

John Wilson, Industry Segment Specialist – Food & Pharma, Central Canada (Ontario)

Marcus Koenigs, Industry Segment Specialist – Food & Pharma

Luc Roberge, Industry Segment Specialist – Food & Pharma, Eastern Canada (Quebec)

John Wilson: Air that is compressed above atmospheric pressure (14.7 pounds per square inch

gauge) is called compressed air. It’s an important medium for transfer of energy. It is sometimes referred to as the “pneumatic muscle.” Typically, manufacturing plants generate compressed air and store it in reservoirs at pressures between 90 and 110 psi. Many food manufacturing plants use compressed air to do a variety of functions. In food processing, compressed air can be used to power pumps and mixers, fill pies and cakes and blow crumbs off and reject product from conveyors. In food packaging, compressed air powers valves that control air cylinders,

pneumatic grippers, rotary actuators and air motors. Because compressed air can come in direct contact with food, special considerations or good manufacturing practices need to be followed and reviewed to ensure a safe condition.

Air quality is an example.

Food & Beverage: What are the advantages of using compressed air?

John Wilson: Compressed air is a clean medium that can be prepared or filtered to an industry

*Qualified sites receive no-obligation HD enclosure for test installation.

Specially designed and built to handle the unique hygiene needs and challenges of the Food & Beverage industry!

In harsh environments, traditional enclosures may fail to provide the required levels of protection, so we have the perfect solution for you.

*Demo units are limited in quantity!

“Today’s manufacturers of compressed air components design them to run unlubricated – an advantage by itself.”

standard. Still, compressed air generates oil vapours and moisture. Festo manufactures filters with different levels of particulate and moisture retention characteristics. Our job is to recommend solutions to meet industry standards, based on how the compressed air is being used. For example, air that comes in direct contact with the food we ingest requires a high level of filtration, and meet a specific ISO classification. In years gone by, lubricators were used to keep the mechanical components operational. Today’s manufacturers of compressed air components design them to run unlubricated – an advantage by itself. In addition to clean design solutions for sanitary wipedown applications, FESTO utilizes industry standard grease, known as NSF-H1 and FDA-approved materials in the products we deem suitable for the food industry. Due to the ambient conditions found in a food processing plant, moisture created from washdown and sanitization procedures, components need to be of a clean design, high-corrosion resistance materials and a higher electrical degree of protection. Our jobs, as industry specialists at Festo, require specific industry training. It provides customers with confidence in our suggestions and that the right product is recommended to provide trouble-free, safe operation.

Food & Beverage: What are the challenges associated with compressed air? (Cost of producing? Leakage? Contamination?)

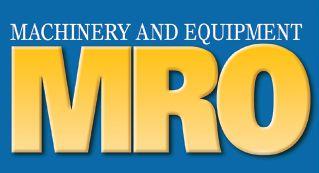

Marcus Koenigs: Properly prepared compressed air is essential to prevent faults on pneumatic components. It ensures trouble-free functioning

Ensure trouble-free functioning of pneumatic components by properly preparing compressed air.

of components, thus reducing failures and downtime. This significantly improves process and reliability and extends the service life of components and systems. The three major challenges are the cost of production of compressed air, leakage and proper filtration. Cost: At Festo, we say an average cost of electricity is 6.4 to 7.4 cents/KWH in Ontario. A ¼ HP compressor consumes 0.207KW to generate 1 scfm of compressed air resulting in energy costs to run this compressor at 100psi approximately $450/year (8,760h/ year). This is a cost that cannot be neglected. More and more customers ask us how we can help to reduce energy consumption. Leakage: Once produced, the user’s challenge is to maintain his compressed air circuit as leakage can possibly occur on every piece of equipment, such as fittings, tubing and valves. Just one leak with a hole of 1/16 (1.5mm) at 100psi causes an air loss of 9,345 ft3/day. This calculates to roughly $80 in Ontario. Contamination/filtration: Oil from a leaking compressor and humidity could potentially contaminate the air. Compressor oil not only is bad for the equipment down the line, but it could also contaminate the product while being processed and packaged. Therefore, it is important to use proper filtration at the point of use to catch a contaminant where it could harm the product or equipment.

Compressor oil can damage equipment and potentially contaminate product being processed.

Food & Beverage: What are the potential risks and hazards that compressed air systems can introduce to food products?

Luc Roberge: The potential hazards associated with this are not obvious and apparent. Untreated compressed air contains many potentially harmful or dangerous contaminants, which must be removed or reduced to acceptable levels in order

“When conducting a Hazard Analysis Critical Control Point (HACCP) analysis any point-of-use contact between the compressed air and food should be considered a potential risk point.”

to protect the consumer and provide a safe and cost-effective production facility. Along with moisture and particulate matter, inlet air to a compressor generally carries 5 to 50 bacteria per ft³. Working surfaces like counters and conveyors are obvious and manageable contact points. The air is invisible. It leaves no visible trace where it contacts the food, other food contact surfaces, or the packaging. When conducting a Hazard Analysis Critical Control Point (HACCP) analysis any point-of-use contact between the compressed air and food should be considered a potential risk point. Identifying the risk and potential hazards with compressed air in a food plant is the easy part. Determining Good Manufacturing Practices for cleaning up the air is not so straightforward.

Food & Beverage: In Canada, which compliance standards or policies define a minimum acceptable level of cleanliness when using compressed air in food facilities?

Luc Roberge: Legislation places the responsibility on the food manufacturer. Many businesses often develop their own internal air quality standards.

Food & Beverage: Are there new products or techniques that readers should be aware of as they plan their maintenance and reliability programs?

Marcus Koenigs: A proper PM schedule to maintain the compressed air circuit and production of compressed air is the key to save production of food and to savings. Customers can talk to Festo about air audits and filtration. Festo carries preconfigured air prep solutions for every food application from end-of-line packaging to food processing in stock with a very short delivery... To monitor air consumption Festo has engineered the world’s first energy efficient module E2M. It makes saving energy easier than ever before as it helps customers achieve their energy efficiency and sustainability targets. It also improves the efficiency of machinery for OEMs. The intelligent service module rigorously monitors and regulates the compressed air supply in new and existing systems.

Mitigate food contamination from compressed air with timeous PM scheduling, air audits and filtration.

John Wilson, Marcus Koenigs and Luc Roberge are Industry Segment Specialists – Food & Pharma, with Festo, a leading supplier of automation technology and a performance leader in industrial training and education programs. For more information, visit www.festo.com.

Rehana Begg is the editor of Machinery and Equipment MRO magazine. Reach her at rbegg@annexweb.com.

EXTRA CLEANLINESS GUARANTEED

Enclosures offering guaranteed protection for the food industry.

BY NATASCHA TREML AND MANUEL LOTZ

Hygienic production is an absolute must in the food industry. It must be possible for machines, systems and their components to be quickly and easily cleaned, particularly in open processes. The materials used and the geometry of the production plants have a decisive influence on cleanability. Hygienic design enclosures that offer numerous advantages over conventional enclosures have become the standard housing for electrical controls because they permit rapid cleaning and prevent the formation of pockets of dirt. Downtimes during production represent the “worst case” for plant operators. They mean ever-lower

productivity and, consequently, reduced sales. However, in hygienecritical production situations, longer downtimes are unavoidable due to the large amount of cleaning needed. For example, up to 40 per cent of the time is spent at a standstill due to cleaning procedures in meat-processing plants. This time must be kept as short as possible in order to increase productivity –but not at the expense of cleanliness and hygiene, because ultimately the health of final consumer is what counts.

One starting point is to design machines and plants and the housings and enclosures that accommodate controls so that they are easier to clean. However, industrial

wall-mounted enclosures and standard enclosures for machines and plants are not the prerequisite for fast, simple and hygienic cleaning. This is because open cavities make cleaning more difficult; they are dirt traps and thus a breeding ground for germs. Horizontal surfaces, where water cannot run off properly, also create the conditions for contamination.

INTERNATIONAL STANDARDS

The high hygienic standards involved in food and beverage production, in cleanrooms or in the chemical industry pose great challenges for plant constructors and production planners. Guidelines can be found, for example, in the Hygienic Design enclosure in use in a food plant.

Machinery Directive 2006/42/ EC, which came into force in Europe in January 2006, and in supplementary standards on the hygienic requirements to be met by machinery and equipment such as EN 1672-2 and EN ISO14159. For processors of foodstuffs, the European regulation EU 852/2004 on food hygiene is one of the binding regulations. These regulations define the requirements of the machinery used with foodstuffs, as well as providing guidelines for the design of hygienic machines. Parallel to these regulations, the so-called European Hygienic Engineering and Design Group (“EHEDG”) was founded in 1989 with the principal goal of promoting hygiene measures during the processing and packing of food products. The group is a consortium of equipment manufacturers, food processing companies, research institutes and public health authorities. Rittal has been a sponsor of this organization since 2008. Rittal’s

USE WATER TO DISSIPATE HEAT

Enclosure climate control with water cooling is highly efficient, especially if a central cold water supply is already available in the production plant. The new Rittal Hygienic Design air/water heat exchangers are ideally suited to the food industry, where hygiene requirements are exceptionally stringent.

Liquid cooling of enclosures offers a number of benefits: because water has a higher thermal capacity than air, liquid cooling can dissipate even large quantities of heat. What is more, industrial environments often already have a central cooling water supply available that can be used for enclosure cooling. All that is left to do is to mount suitable air/water heat exchangers on the enclosure. With Hygienic Design, it is particularly important that no air exchange takes place between the enclosure and the environment.

HD air/water heat exchangers best suited to the food and beverage industry.

with a brushed grain size of 400, producing a surface roughness Ra of less than 0.8 μm. The smooth surface finish is easy to clean and disinfect. There are no hard-to-clean gaps where contamination could collect.

The silicone seal between the enclosure and the case prevents the transfer of colorants, flavourings and unwanted odours. The seal eliminates gaps between the air/water heat exchanger and the enclosure which would be difficult to clean. The seals are available as spare parts, and are easily replaced in the event of mechanical damage.

Rittal has revamped its air/water heat exchangers, and can now offer its customers in the food industry two variants of Hygienic Design. Air/water heat exchangers for wall mounting can supply cooling outputs of either 0.65 kW or 1.2 kW.

For Hygienic Design, Rittal has modified the design of the heat exchangers in a number of respects. For example, the attachment to the enclosure wall using threaded bolts and nuts has been designed so that the screw fastening is not visible from the outside. The enclosure is made from stainless steel

The top of the enclosure tilts forwards by 30 degrees. This typical Hygienic Design feature prevents objects from being deposited on top of the enclosure, while at the same time ensuring that liquids, such as detergents and disinfectants, run off quickly. With protection categories of IP56/59, air/water heat exchangers meet the demanding requirements of pressure washing and steam cleaning.

The air/water heat exchangers have C-UR and CSA approval, making them suitable for international use. The Hygienic Design was tested by the DGUV Food department testing and certification agency in accordance with GS-NV 6 (test principles for hygiene). The systems comply with standard DIN EN ISO 14159:2008 and are suitable for use in the food industry in conformity with DIN EN 1672-2:2009.

HD range also meets stringent CSA guidelines and carry protection ratings of NEMA 4X and up to IP 66/69K.

HYGIENE AND HYGIENIC DESIGN

However, despite all these standards and guidelines, hygienic design means one thing above all: Provisions for the simple and thorough cleaning of everything that could come into contact with foods – from the machine to its enclosure. Here, it is especially important to avoid dead spaces,

roof: The 30° tilt of the compact enclosures allows liquids to run off quickly, prevents objects being stored on the roof and ensures it can be easily checked.

undercuts of any kind, as well as joints without radius, since such points are particularly prone to product residue accumulations, which in turn represent an ideal substrate for microbial contamination. For the same reason, surfaces with recesses such as the uncovered threads of screw connections, or screw heads with internal hexagons (Allen screws) or Torx screws are not allowed. Corners and joints must be smooth, gapless and cleanly rounded. To ensure that sprayed water is able to run off the surfaces of housings and enclosures in spray and wet zones, appropriately angled drain slopes must be provided.

The specially designed Rittal Hygienic Design (HD) enclosures meet these tough hygienic requirements in full. In addition to terminal boxes and compact enclosures in common sizes, which are available ex-stock, Rittal also has a comprehensive product portfolio that ranges from enclosures to operating

housings for safely accommodating electrical equipment.

Rittal also offers a hygienic protective enclosure for the storage of fire extinguishers in these areas. A relatively new addition is the hygienically designed air/water heat exchanger as a climate control solution, which Rittal now offers for the complete hygienic enclosure product range. They have been meticulously designed to meet the requirements,

MROECDRives-2017.pdf 1 06/09/2017 1:43:16 PM

regulations and guidelines of the food and beverage industry. All the external parts are made entirely of stainless steel, which means a high resistance to chemicals, cleaning agents and disinfectants.

The roof of the HD compact enclosures, which tilts forward by 30° in accordance with the EHEDG guideline, reliably prevents objects being stored, allows liquids to run off quickly and also ensures good

Tilted

visibility, even with enclosures that have been mounted higher. Thanks to the roof projection with its drip edge, water is guided away from the enclosure safely and the upper area of the door seal is protected. In addition, the door edge fold has a 10° tilt. This way, no residues that are washed off during cleaning adhere to the enclosure and no pockets of dirt can form.

The fasteners can be cleaned easily and safely thanks to their special external contours with minimum radii, and this also prevents the ingress of water. Internal hinges allow a very easily cleanable exterior design with an all-round silicone door seal that is free of gaps. One special aspect of the HD enclosure is the seal. Made of silicone instead of polyurethane (PU foam), it is more resistant to all kinds of detergents. The HD seal is dyed blue, which makes it stand out clearly from foodstuffs. Thus, in the worst case, they are immediately visible as foreign objects in the foodprocessing environment in the event

of mechanical damage. The easily replaceable (but securely inserted) one-piece gaskets, which are safely fitted on the insides of the doors and panels to the outside, guarantee an unbroken seal. Unlike rolls of seals that are bought by the metre, they do not need to be pulled stretched during assembly, which means that no gaps appear at the ends. Experience shows that a reliable seal is rarely achieved with a butt-jointed strip or four mitre-cut sections: the seal is unintentionally pulled and comes apart to some extent, or else a gap is formed at abutting or mitre edges due to aging. In the case of continuous HD sealing frames, the original degree of protection is quickly ensured, even after changing the seal.

The enclosures meet the IP 66 protection category in accordance with IEC 60 529, as well as the NEMA 4X protection class, and they are thus protected against splashing and water jets. They can easily be cleaned with a high-pressure cleaner. Of course, in order to clean a

production plant quickly and easily, every single part of the system has to meet the hygiene requirements. That is why Rittal offers an extensive range of HD accessories that meets these high requirements.

HD cable glands with smooth exterior surfaces prevent the desposit of harmful micro-organisms.

A COMPREHENSIVE RANGE OF ACCESSORIES

In accordance with the current guidelines, it is permissible to bolt an enclosure directly to the wall if a corresponding gasket is provided. But how durable is such a seal? In case of only minor damage to the top section of the seal, it may be some time before any contaminated liquid becomes visible or, worse still, impairments are registered in the production process or products. Finding a way to permanently and securely seal the enclosure against the wall remains a problem. With this in mind, we recommend that you leave sufficient space to clean behind the enclosure. The special HD wall spacer brackets from Rittal can provide the answer. They provide sufficient room behind the enclosure to allow all the contamination to be regularly removed with a cleaning device.

The floors of such production areas often have a slight incline to allow the water used for cleaning to drain off. The hygienic attachment

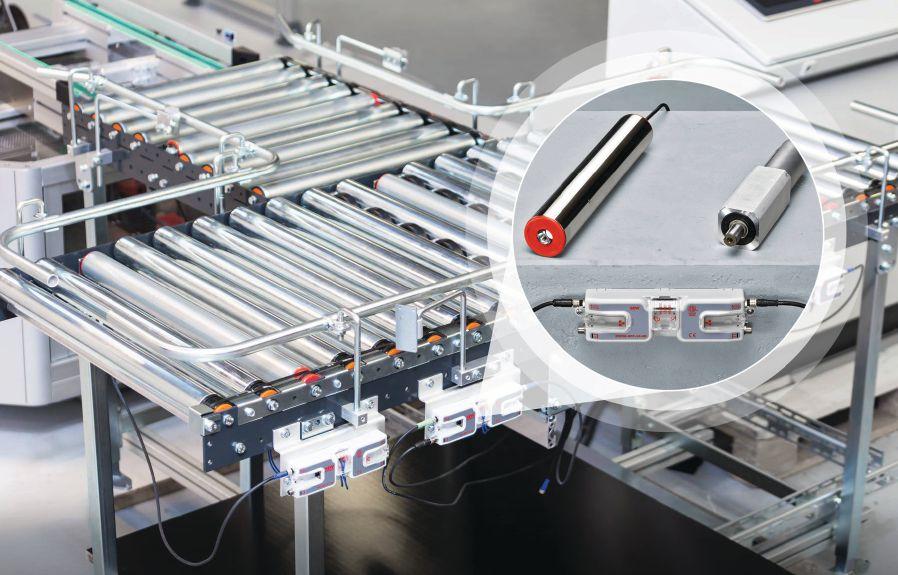

Different areas of the food industry require different hygiene standards. The Rittal portfolio ranges from enclosures to power distribution through to climate control and the IT infrastructure.

of enclosures on such inclinations in the ground then requires a little adjustment. Floor angles of up to 10° can be easily compensated for by using HD levelling feet, which have a levelling range of 55 mm. Here too, the cleaning time has been minimized by the use of fully covered, permanently sealed threads. HD cable glands permit much easier (and therefore less expensive) cleaning than conventional ones, even with high-pressure cleaners. Their smooth, solid exterior surfaces effectively prevent the depositing of harmful micro-organisms. They can be inserted anywhere in the enclosure and are available for cable diameters ranging from 3 to 17mm.

WHERE COOLING IS REQUIRED

Where waste heat loads need to be dissipated due to the power losses of the components installed, Rittal offers liquid cooling systems for its enclosures that comply with strict hygiene requirements. The most hygienic cooling solution is enclosure climate control with air/water

heat exchangers. If no cooling water system is available, the cooling water supply needed for the individual heat exchangers, either decentralized or centralized, can be provided via chillers, which may be installed outside of the open process. For smaller systems, the one-off procurement costs for heat exchangers, chillers and piping are generally slightly higher than the costs of classic wall-mounted cooling units. A heat exchanger is the system of choice for hygiene-relevant applications, however, and quickly pays back the investment through reduced maintenance requirements and lower energy costs. In addition to air/water heat exchangers with stainless steel enclosures, Rittal offers special Hygienic Design versions in the 650 and 1250-watt output classes. The design for hygiene and the high protection category simplify cleaning procedures and guarantee food safety.

ONE-STOP SOLUTION FOR OPTIMUM PROCESSES

With its Hygienic Design range,

Rittal offers enclosures and enclosure accessories, as well as climate control components specifically developed for applications in areas where hygiene is important. HD products are resistant to environmental influences such as dirt or cleaning agents, and they can be cleaned easily and quickly, thus directly increasing manufacturing productivity. In addition, Rittal also offers an extensive range of accessories for internal installation in HD enclosures, as well as busbar systems for different current ranges to ensure safe and standard-compliant power distribution in the HD enclosures. The new HD brochure from Rittal has the details for the hygienic design of housings and enclosures and outlines the Hygienic Design range the company has to offer.

This article was submitted by Natascha Treml, team leader, Product Management Enclosures, Rittal, and Manuel Lotz, team leader, Product Manager Compact Enclosures, Rittal. For more information, visit www.rittal.ca.

Hygienic accommodation of the fire extinguishers, protected from water jets.

FIRE EXTINGUISHERS MUST ALSO BE HYGIENICALLY HOUSED

Fire protection is also required in food and beverage production, so any fire extinguisher in that area must be quickly accessible. That is why Rittal offers a protective enclosure that meets the hygienic requirements, but which also allows a fire extinguisher to be quickly removed. Due to its large viewing window, the fire extinguisher is visible from the outside for everyone while the T handle allows quick opening and removal.

OVEN BEARING SOLUTION

How plane bearings can cut costs and help plants run more efficiently.

Given the daily demands of food- and beverageprocessing facilities, bearings may be the last thing an owner or operator considers on an average day. Decision makers can agree, however, it’s often the small things that eventually have the biggest impact on operations. And with increasingly stringent food safety regulations across the board, even minor missteps can have major consequences for today’s manufacturers.

The Timken Company helps customers in virtually all industries ensure more reliable operations by improving the performance of bearings in critical machines. And EDT by Timken, a Timken

company, especially understands the demands of the food and beverage industry, with nearly 40 years specializing in bearings for severe service environments.

As Michael Thrailkill, technical product and applications manager for EDT, explains, a safer, more productive food processing plant starts with getting to know your bearings better.

“The biggest demand on bearings comes from the very aggressive cleaning agents and degreasers that are being used more frequently today,” Thrailkill says. “As companies try to eliminate contamination and bacteria that cause foodborne illnesses, they are forced to use harsher and harsher chemicals.”

Bearings that are not designed for frequent washings will corrode, perform poorly and suffer reduced service life.

Thrailkill says that bearings that are not specifically designed to deal with frequent washings and caustic substances can be compromised by the early onset of corrosion, and that debris and contamination can easily damage a bearing’s highly finished surfaces, resulting in poor performance and shorter service life.

At the same time, bearings that are not specially engineered for extreme hot or cold environments can prove problematic for other reasons.

“Ovens present some of the biggest challenges to bearings,” says Thrailkill. “These tend to be ball bearings that see a lot of stress as they heat up and cool down, and most are not designed to accommodate this repetitive thermal expansion of the shaft and bearing, so again the life of the bearing is reduced.”

Thrailkill recalls one such instance involving an international snack manufacturer that

had grown weary of frequently replacing the ball bearings supporting its oven rollers. A changeout was required every 90 days, which, over a two-year period, was costing the company over $3,200 per roller including parts, labour, lubrication and journal repair. With 54 rollers per oven, this amounted to a total repair bill of over $141,000.

EDT showed the snack maker an upgraded bearing solution that would eliminate shaft damage and significantly reduce associated expenses and downtime (each change-out required three personnel three hours to complete). EDT’s Poly-Round plane bearings – which operate without rolling elements, unlike ball bearings – are made from special non-corrosive, non-contaminating polymers (the bearings have USDA acceptance) and are designed to move as the roller shaft expands (thereby minimizing harmful thrust loads). And unlike conventional

Plane bearings made from special polymers can offer many advantages over conventional bearings in food and beverage processing plants.

bearings, polymer plane bearing inserts can be rotated 180 degrees when they eventually become too worn in one direction, further extending the life of the bearing.

Since adopting EDT’s oven bearing solution, the snack manufacturer has reduced its bearing spending by over 80 per cent per oven roller – a total savings in excess of $141,000 over a two-year period as the cost comparison in the table shows.

Another benefit EDT’s customer now enjoys is that the plane bearings are self-lubricating, which means there is no grease or oil to pose sanitation concerns.

“The original bearings were not designed to account for the temperatures the oven was operating at,” says Thrailkill. “And because it had always been that way with the machine, our customer was surprised to learn there was a better answer out there. In fact, management’s top priority was to eliminate the grease that was melting out of their bearings and

running down the side of the oven, which can lead to serious food safety issues.”

Most customers, says Thrailkill, are accustomed to specifying and maintaining the same type of bearings that originally came with their machines (up to 20 years ago in many cases) and a little grease escaping may not seem like a serious concern to plant operators who have never run into a problem before.

However, with new regulations from the U.S. Food Safety Modernization Act (FSMA) now firmly in effect, there are many practices that were acceptable as little as three years ago that are no longer permitted, says Thrailkill.

Among these is failing to address the very real hazards a bearing can present, such as the risk of crosscontamination. For instance, even a small spot of grease, hidden on the underside of a housing that’s already hard to see, can become a breeding ground for bacteria should the problem go unattended.

Thrailkill says that the practice of over-lubricating bearings can be just as detrimental to keeping a clean facility. Following the manufacturer’s exact steps for bearing relubrication is a good place to start when it comes to avoiding complications.

“The tendency for personnel who haven’t been taught better is to pack more grease into bearings, as opposed to less, ‘just to be safe,’” Thrailkill explains. “The truth is, this can be more harmful than under-lubricating, because now your bearing has to work harder and the grease starts to churn inside it, meaning the bearing can no longer operate in the manner it was intended.”

“By the time you see grease passing around the seal, it’s too late; the bearing is already 100 per cent full of grease. As the temperatures increases, the bearing will self-regulate and purge the excess lubricant, which is what you frequently see running down the side of the oven.

It’s a common occurrence that deserves more attention than it typically gets.”

Thrailkill points out that price pressure plays a big part in an OEM’s decision when it comes to specifying bearings for their machines, and often these bearings are designed only to meet the minimum requirements of the equipment.

“In a lot of cases there’s considerable cost savings and reduction of labour associated with upgrading your bearings or improving your maintenance practices,” he says. “And with the requirements within the FSMA, it’s a good time to find out if your current bearings meet all of the new standards.”

This article was submitted by EDT Corp., a Timken company specializing in bearings for all areas of the process floor, particularly food processing environments. For more information, visit www.timken.com and www.edtcorp.com.

Lubricant that escapes the bearing can elevate the risk of food safety violations.

Molded-Oil TM Bearings

NSK’s patented Molded-Oil grease is specifically developed for situations requiring high levels of hygiene, such as in the food and beverage industries. As such, the Molded-Oil lubricant is transported by a substance that releases the lubricant gradually. This way, the required amount of lubrication is provided to the bearing over a long period of time. At the same time, the risk of oil leakages is minimized making the bearings outstandingly smooth running. Optionally, lubricants with USDA H1 certification can be used.

877.994.6675 www.nskamericas.com

GOING DIGITAL

Delete non-value-added tasks through digital transformation in food manufacturing.

BY JERRY BROWNING

Food and beverage manufacturers are under more pressure than ever to get products to market quickly, while squeezing cost out of ongoing operations. Historically, new food products that required additional or reconfigured processes took months or even years to plan, with the management of these projects dominating the time and bandwidth of plant management, maintenance and operations personnel. But with just a few smart moves toward better asset management, food and beverage manufacturers can control the playbook on the road to digital transformation.

GETTING UP TO SPEED

Reconfiguring manufacturing processes at companies that offer limited edition or short

lifecycle products, for example, can be an extremely difficult task. It can also be a challenge for manufacturers experiencing rapid growth or ones involved in the acquisition and integration of new product lines into an existing portfolio.

Each time a new product or new capacity is added, there are several steps plant and senior managers must take:

• Identify the scope, specifications and cost of the new manufacturing line

• Let bids for relevant work

• Accept bids

• Manage the project through to hand-off and startup

Create asset structures in enterprise asset management (EAM) software to support ongoing operations and maintenance of the equipment. In many cases, there is no single software platform that encompasses or streamlines this entire process – just coming up with a reliable price for new productive assets can be time-consuming and daunting.

POTENTIAL FOR A BUMPY START

Once a capital project proposal is started by management, that proposal or bid document must be

operationalized and turned into a project structure, bids for work and subcontracts must be let and the project executed through to handoff to operations.

But the system used to generate that quote and execute on the project may not be integrated

directly with the project management software used to perform the work once the quote is accepted. Project management software may also be unable to drive finished project data directly into asset and equipment structures in EAM software. This is vital, as this is the data that will

dictate maintenance activities and provide management visibility into the status, serviceability and projected cost of operating the asset over its entire lifecycle.

In most asset management processes, all of these steps are disconnected, resulting in substantial non-value-added work. But in some cases, EAM software, which includes key modules of ERP software can provide the same type of configuration capability to asset-intensive environments as it does with lean improvements in manufacturing.

DIGITALLY TRANSFORMING FOOD AND BEVERAGE ASSET MANAGEMENT

In order to become leaner and more competitive, food manufacturers must apply the concepts of digital transformation to their asset management program, specifically the configuration and installation of new assets, so they can move faster and eliminate non-value-added work.

Compatible unit functionality adds powerful asset configuration functionality to EAM, allowing users to build a reusable object structure that can be tied into an asset management project. They can build this project to include details on materials, labour, contractors or subcontractor scopes, rental equipment and other elements necessary to calculate the costs for the entire project.

For decades, discrete manufacturers have relied on specialized ERP functionality that can streamline configure-to-order manufacturing processes. This has allowed the user to repurpose existing product structures and change key variables to

configure a product to meet specific requirements. Sizes, capacities, inclusion or exclusion of various components could be selected, but there was no need to design the product from scratch. The same functionality can also be used to automate asset management projects in these enterprise systems.

PRIOR PLANNING

For example, as you set up this system to streamline your asset management projects, you can enter information on the different variables of a work cell or manufacturing line so that as each individual project is planned, users will be prompted with questions that configure the design. To what extent can the requirements of a new line or work cell be defined by existing equipment and assets? How must the speed, capacity or capabilities differ based on the product to be manufactured? Does the environment the asset will be housed in influence the requirements?

So, if you are that plant manager and the CFO comes to you and wants pricing on how much it will cost to add additional capacity or support a new planned product, you can turn around an accurate cost proposal almost instantaneously. Once the proposal is approved by corporate, the software can send out the requisite work orders,

send requests for quotations to contractors and enable maintenance department staff to put their time against the project as required. The system can also capture the cost of materials out of inventory to complete the project, without additional administrative overheads or duplicate efforts.

“In order to become leaner and more competitive, food manufacturers must apply the concepts of digital transformation to their asset management program... so they can move faster and eliminate non-value-added work.”

CATALYST FOR CHANGE

The ability of EAM software to deliver lean improvements to key steps in the asset lifecycle depend on the inclusion of, and tight integration with, select ERP functionality – in this case, configure-to-order processes, contract management, inventory and human resources. A third-party configurator tool sold as an add-on or white labelled functionality will not be adequate as these usually rely on point-to-point integrations that will invariably fail to encompass all of the data points required to streamline the process. When choosing your EAM software, it’s important to get a demonstration of how the system

would facilitate all of your asset workflows and not just a select few. You will also want to ascertain how much vendor or third-party consulting time is necessary to configure the system, now and in the future as your needs change over time, as even the slightest amount of downtime in the food and beverage industry can significantly

harm business.

As Senior Advisor, Jerry Browning assists IFS’s North American customers in asset intensive industries with knowledge transfer and consulting on enterprise asset management (EAM) software. For more information, visit www.ifsworld.com.

THE GOOD OIL

Food-grade lubricants can improve efficiency and help maintain high sanitary practices.

BY REHANA BEGG

Contamination of processing equipment and food products occur at every level in the plant. So a big challenge for plants to avoid contamination from inadequately designed processing equipment and improving food safety without raising operating costs from production hygiene is an ongoing challenge. One aspect that cannot be ignored in this regard is the use of lubricants. In fact, the use of food-grade lubricants can be used to minimize contamination during processing, as a preventive measure against unplanned shutdowns, as well as to prolong the service life of the equipment.

In upholding quality assurance/

quality control processes, food and beverage facilities that are commit ted to good maintenance practices perform reliability assessments before deciding to convert to foodgrade lubricants where it makes sense to do so. The conversion has proven to be valuable in consolidat ing a facility’s logistical needs with large amounts of inventory from various suppliers.

In one example, The Hershey Company, one of the largest choc olate manufacturers in North America, enlisted the services of lubricant specialist, Petro-Canada, to assist in a complete conversion of Hershey’s manufacturing facil ity in Stuarts Draft, Virginia. After a comprehensive plant analysis,

perform the same tribological and lubrication functions as any other lubricant, including protect against wear, rust, friction and corrosion, transfer power, seal components, provide oxidation stability and good pumpability. But what makes it truly food-grade is its clearance to be in contact with food processing equipment and other applications in food-processing plants.

The USDA categorizes food-grade lubricants under the designations H1, H2 and H3. A lubricant’s approval is based on its list of ingredients and the likelihood that the lubricant will contact food.

H1 lubricants may be used in food-processing applications where incidental food contact may occur, but contact must be limited to trace amounts. It must not exceed 10 parts per million (that is, 0.001 per cent). This category is generally referred to as “food-grade.”

H2 lubricants are used on equipment and machine parts in areas where there is no possibility of contact with food. These lubricants do

Food-grade lubricants are contingent on the likelihood that the lubricant will contact food.

not have a defined list of acceptable ingredients, however, they cannot contain heavy metals, such as antimony, arsenic, cadmium, lead, mercury or selenium. H2 lubricants

must not contain substances that are carcinogenic, mutagens, teratogens or mineral acids.

H3 lubricants – also known as soluble or edible oils – are used to

prevent rust on hooks, trolleys and similar equipment.

PICK AND CHOOSE

Food-grade lubricants lubricate all

types of food processing equipment, from bearings and compressors, to hydraulics, gearboxes and conveyor systems. The ideal practice in food facilities is to prevent serious consequences, including accidental contamination due to spatter, leaks or human error.

Facilities can reinforce continuous improvement programs by converting to food-grade lubricants that meet the following criteria:

Third-party certification : Look for lubricant suppliers that have had an independent organization review the manufacturing process as a way to determine that products produced in food facilities comply with standards of safety, quality and performance, and that an impartial review has been conducted. Products that carry the NSF certification mark is an assurance that the certifying agency conducts periodic facility audits and product testing to verify that the facility complies with and continues to uphold standards.

Registered NSF H1: These lubricants use non-toxic base stocks, such

as white mineral oils, vegetable oils and certain esters (as opposed to petroleum-based stocks) and carry a set of credentials for incidental food contact. H1 lubricants have come a long way from its reputation for inferior performance when compared to non-H1 lubricants.

supports continuous improvement as products are audited annually if they are to remain certified.

“Products that carry the NSF certification mark is an assurance that the certifying agency conducts periodic facility audits and product testing to verify that the facility complies with and continues to uphold standards.”

Non-H1 lubricants are historically reputed for being cheaper, but given the choice of available products and technological advancement, this is not necessarily the case.

ISO 21469 certification : Introduced in 2006, this internationally recognized standard is a voluntary certification standard. The standard

GMO free and allergen free: This guarantees that the product does not contain natural products derived from genetically modified organisms (GMO) and are allergen free of animal origin.

Selecting the right lubricant can be challenging; a conveyor running over a food line will need H1-category lubrication, whereas, it may or may not be safe to use an H2category lubrication on a conveyor running underneath the food line. These decisions are best left to subject matter experts who can apply Hazard Analysis and Critical Control Point (HACCP) requirements and evaluate where contamination might occur. Lubricant suppliers can assist with making these assessments.

Rehana Begg is the editor of Machinery and Equipment MRO magazine. Reach her at rbegg@annexweb.com or visit mro-mag.com.

There is something about Fall that brings with it a fresh enthusiasm for projects and possibilities. It’s the perfect time to reflect on yearto-date accomplishments and give thought to next-quarter endeavours. As I take a moment to reflect, this year has been a particularly memorable one at EMC (Excellence In Manufacturing Consortium) as we celebrate a very special anniversary. It’s been 20 years of bringing

manufacturers together, building partnerships, facilitating growth through networking, best-practice sharing, and the development of countless programs and services all designed to improve our processes and grow our businesses. Together with the passion and commitment of a fabulous team, engaged community partners and manufacturers keen on improving their operations, we look forward to continuing our enthusiastic efforts in the years ahead.

We are excited about the next few months as we roll out a variety of interesting networking opportunities. This Fall, we also look forward to participating in supporting activities that help manufacturers across the provinces harvest ideas that enable business competitiveness.

SEPTEMBER 2017

We kick off September by looking at one of the key challenges in the Food and Beverage Sector and

industry in general across the country – attracting and retaining talent. People are a fundamental component of any business and talented and skilled employees can considerably enhance a company’s growth prospects. The questions on many of our minds are: How do we retain the trained and skilled workforce we have, and how can we attract new, interested people to work in our manufacturing facilities? Managing today’s workforce certainly presents complexities with its aging population and multi-generational dynamics.

The first Fall EMC GF2 (Growing Forward 2) Food and Beverage Sector Networking Event was held earlier this month.Maple Lodge Farms, located in Brampton, shared their best practices on retention and attraction and Toronto-based

Griffith Foods addressed the opportunities available through involvement in an “employer of choice” program. Supplementing their presentations, we also heard from the Manufacturing GPS Team on the latest LMI (Labour Market Intelligence) Survey Results and areas of greatest need, while Brampton Economic Development highlighted some of their tools and resources. In addition, FBO (Food Beverage Ontario) shared information on their “Taste Your Future” and “Newcomer” programs and the CPG Executive provided perspectives on “Talent through Growth.” A comprehensive event summary is available on the EMC website (www.emccanada.org).

The month ends with our final round of GF2 Productivity Workshops, beginning in Kitchener on

September 25 , followed Brampton on September 26, Belleville on September 27, and Bradford on September 28, and all culminating with the Productivity Action Plan Webinar on September 28. These introductory training courses are open to any company in the Food, Beverage, Bio or Ag Sector, or any business directly supporting that sector, such as packaging, labelling or equipment manufacturers. Our three areas of focus for these events include Root Cause Problem Solving, Leadership and Management of Change, and An Introduction to the Kaizen Process of Implementing Change. Each of these workshops help participants understand the basic concepts and our Productivity Action Plan Webinar is designed to help you consider next steps and answer questions.

OCTOBER 2017

October’s learning can only culminate in a proverbial “horn of plenty” when it comes to opportunities to interact with peers, learn from best practices and participate in plant tours. We have a wonderful EMC GF2 Food and Beverage Sector Networking Session planned and there are also a variety of industry events, including the North American Food Regulatory and Quality Assurance Summit, the Grocery Innovations Show, Meat Industry Expo, Canada’s Baking and Sweets Show and Top 50 Packaging Ideas Expo. Each of these events showcase what’s innovative in industry and are a venue for connecting with peers from supply through production and sales. October is a month that really focuses on manufacturing and companies will host special activities

showcasing our industries, raising awareness of economic and community impacts and the breadth of available career opportunities in the industry today. It is truly exciting to see that many regions have high schools taking part in touring plants and enthusiastic hosts who are looking forward to providing company overviews of products, capabilities and types of positions available. Interestingly, this is also National Ergonomics Month and the theme of our very special GF2 Food and Beverage Sector Networking Event set for October 26 at John O Foods in Wheatley, Ont. They are looking forward to welcoming companies to their facility and sharing their best practices to implement, improve and sustain their Ergonomics Program. In turn, they hope attendees will bring an outside perspective to

some of their ergonomic challenges and through that, open the door to potential improvements.

NOVEMBER 2017

In November, we will embrace a fundamental topic for any company in this industry – Food Safety. Throughout the past several years, there have been engaging discussions and presentations relating to various elements of food safety, including company endeavours to enhance this area of their business, implementation of policies, procedures and processes, and overviews by subject matter experts on certifications and current legislation. Some of our participants were just beginning their journey and seeking input from those with robust programs. Others were looking at improving or enhancing their standard processes. Without

a doubt, staying abreast of the latest in Food Safety regulations can be challenging and having a peer group to engage with is helpful. We are very excited to be visiting with Burnbrae Farms in Lyn on November 14 to learn from their best practices. For those who have never had the chance to tour an egg processing facility, you will come to appreciate the work that goes into ensuring how eggs make it safely from farm to table.

This month also features NSF International’s State of the Industry Forum 2017, an engaging day for Food and Beverage Processors to discuss emerging industry issues.

DECEMBER 2017

Join us on a tour and networking session on December 6 at The Original Cakerie in London, Ont. This will be the perfect event for anyone with a mindset for continuous improvement initiatives. Our host’s Rapid Improvement Team will be sharing their experiences to increase efficiencies through the use of ZBA (Zero-based Analysis). This is a session I am definitely looking forward to! Ending the fall and winter activities with the topic of continuous improvement is a gentle nudge to all to complete the EMC GF2 Self

Diagnostic Tool. This is a free resource that looks at 16 sector specific KPIs (key performance indicators) and allows plants to consider where they feature on the CI continuum. It takes about 20-25 minutes to complete and answers are confidential. The link to register is: https://www.emccanada. org/group_spaces/foodsector/gf2/ self_diagnostic_request

FUTURE POSSIBILITIES

From all of us at EMC, we encourage you to consider the topics you would like to see addressed in 2018:

• What are some of the challenges you are facing, the opportunities you might like to explore?

• What insight might your peers provide to help you be more competitive?

• Are you interested in sharing your experiences?

On behalf of EMC, I would like to convey very special thanks to our hosts, presenters and participants who have so readily opened their doors and supplied their talents so that our learning opportunities might grow and be harvested in a true spirit of continuous improvement!

How do you get involved? If you are interested in learning more about EMC (Excellence in Manufacturing Consortium) and the Food Sector Initiative, please feel free to touch base with Bren de Leeuw, Director - Field Operations Canada and EMC Food, Beverage and Bio Sector Program (bdeleeuw@emccanada.org) anytime!

Follow us on LinkedIn, Twitter (@EMCCanadaMFG) and Facebook!