FOOD BEVERAGE

PRODUCTIVITY SELF - DIAGNOSTIC TOOL

Sustainable environments

The food & beverage sector is not unlike any other when it comes to being affected by the megatrends of climate change, sustainability and environmental impacts.

When it comes to solving the equation of exceeding bottom-line results while simultaneously meeting customer needs and delivering social good and reducing their environmental footprint, we’re all in the same boat.

In today’s socially responsible organization, serving up products that are produced with environmentally responsible systems and processes are just as important as profitability, particularly when the rate of return meets hurdle rates.

According to a Nielson Global Corporate Sustainability report, 60 per cent of consumers say they are willing to pay more for sustainable brands, up from 55 per cent in 2014 and 50 per cent in 2013. Coors Brewing Company provides a good example of how being sustainable can support a brand. n 2016, Coors Light cut its aluminum usage by 3.8 million pounds. They built the most powerful U.S. solar array at any one brewery, in Irwindale, Calif., which can produce the equivalent of 22 million beers per year powered by the sun. This summer, in its most recent

upcycling and waste reduction ploy, Coors rolled out a campaign (EveryOneCan), in partnership with TerraCycle, by converting its billboards into beer coolers and its kegs into barbeque grills. The list goes on.

To ensure sustainability for industry, companies need to ensure sustainability on two fronts: the environment, as well as the supply chain. In sectors like food & beverage, plants need to look at the entire lifecycle to address short- and long-term health.

Oftentimes that means finding cost savings and efficiency in hygienic design, safeguarding environmental compliance in operations and maintenance processes, and improving availability.

In practical terms, here’s what maintenance practitioners can do: review the reliability of components, consider whether there are energy recapture opportunities, and ask obvious questions.

What is the cost and benefit of installing a new boiler that produces full steam in a matter of minutes? How much water can a brewery expect to save by retrofitting its keg line with dry-running technology (no lubrication or water required)? What’s the intended use of environmentally friendly lubricants?

Not all plants are equally equipped to meet gamechanging expectations. Some may even choose to

ignore opportunities that elevate their competitive advantage. But if you’re looking for ways to control operating costs and increase uptime, take the time to browse through this issue of Food & Beverage Engineering & Maintenance.

From environmentally friendly lubricants, fuel and water savings, and improved efficiency and reliability through better equipment and component selection, to best-in-class inventions and products that meet your HVACR requirements, this edition is packed with information that steers maintenance and reliability practitioners toward practical solutions.

Begg Editor, Food & Beverage Engineering & Maintenance

CLEAN OIL

Shopping for an environmentally friendly lubricant.

BY KEN BANNISTER

In these days of heightened eco awareness, the search for an “environmentally friendly lubricant” or EFL has become a common quest. The search results however, can differ greatly depending on your understanding of the term and how the lubricant is to be used. There are many user interpretations of the term “environmentally friendly lubricant,” the following five being the most common:

1.The lubricant is friendly or non-toxic to the natural environment when in use, and will quickly biodegrade without harm if spilled or disposed of (the most common interpretation used by oil companies);

2. When exhausted of its additive packages through extended use,

the lubricant base stock is renewable and is therefore a sustainable resource based on reduced oil consumption;

3. The lubricant is capable of extended drain intervals – long a claim of synthetic versus mineral based lubricants – and is therefore more friendly to the environment, again based on reduced oil consumption;

4. Lubricants used to reduce energy and a user’s carbon footprint. Due to their lubricity and performance under extreme operating condition many synthetic lubricants play an active role in efficiently reducing machine energy consumption whilst delivering a correlative CO2 emission saving – great for the environment!

5. Specialty lubricants designed specifically to address issues related to specific “working” environments. For example, an automotive assembly paint line overhead conveyor chain lube designed with tactifier additives that ensure the lubricant that does not drip on to the newly painted automobile surface, or a food manufacturing / processing plant’s requirement for specialty lubricants that will not cause harm to humans or significantly degrade its products if they come into contact with the product.

CHOOSING THE RIGHT LUBRICANT PRODUCT TO FIT YOUR NEEDS

Lubricants offered for sale and

marketed as “environmentally friendly” will vary in their base oil and additive combination and may fit one to all of the above interpretations. Making the correct lubricant choice requires the purchaser to provide the prospective lubricant vendor with some basic information on its intended use that should include:

• WHAT is the reason for your choice to move toward an environmentally friendly product? Are you looking to implement or comply with a legislative, corporate or department mandate/program?

• WHERE do you intend to use the product(s)? You will need to explain the type of equipment being lubricated and its

manufactured product, e.g. is it a conveyor system for painted products; is it a bake oven drive system or is it a release agent for baking pans, etc.? At this time, you should also describe the working environment/conditions the lubricant must operate in, e.g. extreme hot or cold (oven/freezer, indoor/outdoor), or continual or occasional water presence (process water, wash down water, humidity); The lube supplier will also want to know if the intention is to apply the EFL product on a single machine, production line or plant wide and the current products you are intended to substitute;

• HOW the lubricant is to be dispensed to the bearing surface or point will determine if it is to be oil or grease and if it can contaminate the product. You will need to answer if the lubricant will reside in a closed reservoir? Will it be delivered through a total loss automated distribution system? Will it be misted? Will it be manually applied?

Traditionally, when searching for an environmentally friendly lubricant, many will commence their search with lubricants used by the food and beverage or pharmaceutical industry in the belief that a food grade lubricant is an environmentally safe product. Beware, as this is

is not automatically the case!

Food-grade lubricants are classified according to how they are to be used in the plant environment. For example, H1 classified lubricants (the only true food grade lubricant) are used when there is potential for incidental food contact. If the

allowable trace contact amount of 10 parts per million, or 0,001 per cent is exceeded, the food is deemed unsafe for human consumption. H2 lubricants are general lubricants that can be used where there is no possibility of contact with food, and H3 lubricants are generally edible oils used to clean and prevent rust on hooks, trolleys, racks, etc.

Although an H1 food grade lubricant is designed to meet defined toxicity requirements for human beings, it may be toxic to animal and marine life. True EFLs are designed to degrade quickly and naturally with non-toxic decomposed fractions and are generally based on renewable sources. If you are looking for a guaranteed non-toxic lubricant you are best to start your search with a USDA certified biobased products. These lubricants are formulated with base products that originate from renewable biological sources such as vegetable oils or organoclay, and are readily biodegradable and free from heavy metals and other toxic ingredients.

Performance-wise, ESLs formulated with vegetable oils can offer features such as high high viscosity index and high flash points, and offer a high degree of friction and wear protection due to the natural lubricity of the vegetable based oil. On the down side, these lubricants may not work well in adverse temperatures and may have a shorter shelf life than standard or synthetic lubricants.

Working with a reputable lubricant supplier is the best course to ensure you choose the right product for your application and needs. Ensuring your environmentally friendly product stays that way in service

Purchasing the right environmentally friendly lubricant that meets your needs is only the first step of your journey. Your environmentally friendliness is only as good as your lubrication program. The following application tips will ensure your environmentally friendly products stay that way throughout their service life!

Tip 1: When changing from a less environmentally friendly

product, work with the lube supplier to correctly purge all old (previous) product out of the lube system reservoir, lines, bearings, etc. This will usually require the use of an interim flushing or cleaning product;

Tip 2: Review your receiving practices to ensure your environmentally friendly lubricants are stored correctly and separate from other lubricants in your plant;

Tip 3: Use only new and dedicated transfer equipment for each new

lubricant introduced into the plant to ensure cross contamination with other lubricants does not occur;

Tip 4: Ensure all reservoirs and transfer equipment is product labeled with the correct lubricant type and viscosity to ensure the right lubricant is being used in the right place;

Tip 6: Follow all the manufacturer’s recommendations for spillage and lubricant disposal.

Purchasing and using environmentally friendly lubricants is not only good for a healthy environment, but also provides a good reason to update and modernize your lubrication program and ensure machine health by placing the right lubricant, in the right place, at the right time, in the right amount!

Ken Bannister is the author of the bestselling Lubrication for Industry , (Industrial Press, 2005) and co-author of the new Practical Lubrication for Industrial Facilities, (Heinz P. Bloch and Kenneth E. Bannister, Fairmont Press, 2016). Bannister is an asset management consultant who specializes in lubrication program reviews to ISO 55001 standards and lubrication certification training for all industries. Reach him at Engtech Industries Inc., at 519-469-9173, or by email kbannnister@engtechindustries.com.

Tip 5: Do not over lubricate! Over lubricating not only overheats and reduces the life of both bearing and lubricant, it increases lubricant use and exposes the lubricant to the environment unnecessarily.

SET IT AND FORGET IT

Paper-based packaging solutions supplier equips first fully aseptic filling machine for gable top packaging with robust pneumatics.

Machines for filling milk or juice must work around the clock. With an output of up to 12,000 cartons an hour, disruptions and downtime are not at all welcome. For this reason, availability plays a major role in selecting machine components. Elopak’s motto here is “set it then forget it.”

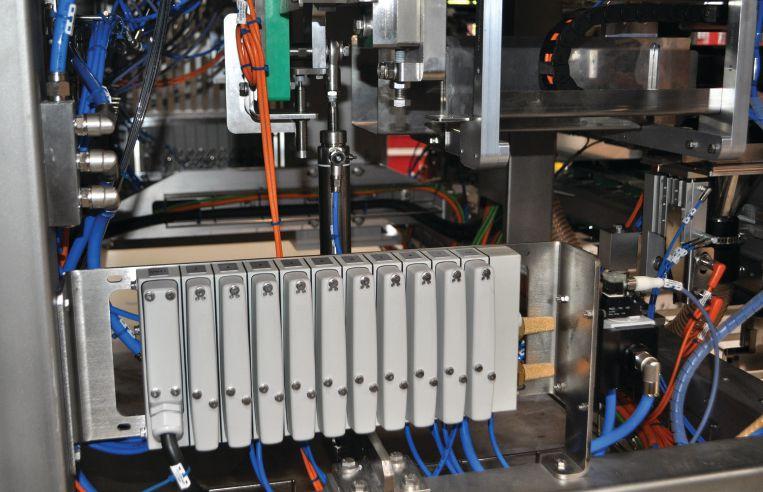

Their E-PS120A is the first fully aseptic filling machine for gable top packaging. This efficient, powerful solution presented by the packaging specialist ensures high reliability owing in part to robust, food-compliant pneumatics.

“The latest technical features are not our main concern when selecting components.” With this

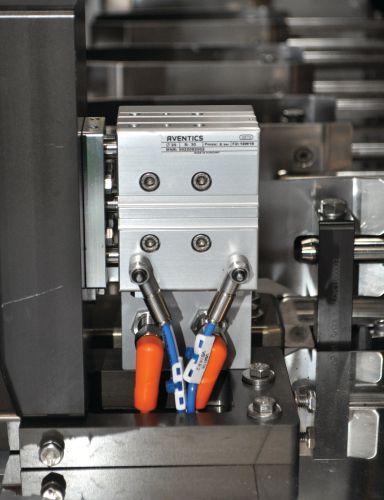

Proven design: Used in many Elopak machines, the Aventics HF03 series valve systems will be gradually replaced with the new AV valve series by the packaging specialist.

statement, Wolfgang Buchkremer, senior manager Research & Engineering at Elopak EQS GmbH in Mönchengladbach, Norway, has astonished some system suppliers. His greatest requirement focuses much more on reliability: “We need components that play their part without standing out – we want to be able to install and then forget them. And that isn’t possible with just any component.”

In developing the first fully aseptic gable top system, Elopak is pursuing its strategy of ultrafunctional packaging concepts, becoming a real trendsetter in the area of aseptics with its new PurePak Advanced filling concept. It meets both increasing expectations

Optimized, energy-efficient solution: The varying pressure when moving the packaging is precisely and dynamically controlled by Aventics ED02 electropneumatic pressure regulators.

of consumers regarding product design, functionality and quality, and industry requirements regarding maximum efficiency and machine availability. This makes the aseptic machine the next generation of the over 100-year-old

tradition of the Pure-Pak principle of Elopak, whose gable top packaging is known worldwide with around 13 billion cartons sold.

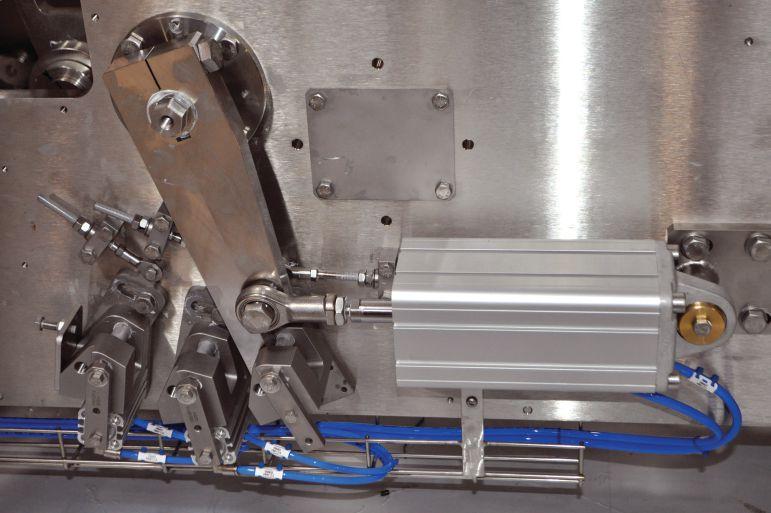

Based on this expertise, the E-PS120A aseptic filling machine offers top-class automation technology and is divided into six modules. The inserted packaging material is recorded, set upright and pre-folded. The sealing cap is then applied via ultrasound welding and the bottom is heated and pressed to seal the carton. In a separate chamber, the packaging is sterilized with hydrogen peroxide, and the product is then filled with a single shot. Finally, the packaging is induction-welded and transported out of the machine. With this system, users can choose from three packaging sizes of 500 ml, 750 ml, and 1 L. Since all machine processes are geared to the packaging height, the only adjustment required to switch between them is the height of the bottom of the carton. Performed by a cylinder,

this movement takes just a few minutes and provides a major advantage compared to competitor machines.

The design and construction of such a modern filling machine are complex tasks. A sterile environment and aseptic packaging are vital to maintain product quality for the long-term at room temperature without cooling the products or using other methods. This means the ultra-sensitive drinks, dairy products and liquid foods have

MROECDRives-2017.pdf 1 06/09/2017 1:43:16 PM

to be filled hygienically and securely while the machine components are subjected to extreme environmental conditions such as cold, humidity and splashes.

Elopak owes its success to technical expertise and decades of experience. “Frequently, permanent reliability comes down to the details,” emphasizes Wolfgang Buchkremer, referring to the close collaboration with pneumatic engineering company Aventics:

“Even though the pneumatic components installed here at first appear insignificant, they are crucial to machine availability and aseptics. In addition to reliable components, we also need close contact and collaboration with suppliers based on partnership to detect optimization potentials in good time and drive improvements forward together.”

INDUSTRY EXPERTISE TRANSFORMED INTO PERFECTION

Taking cylinders as an example: An Aventics SSI series compact cylinder isolates sealing caps by moving them from one side to another. It sounds like a simple task, but it has to function precisely, around one million times a week in day-to-day operations. Based on concrete application data supplied by Elopak, the cylinder experts at Aventics reinforced the piston package, extending the cylinder’s service life, which in turn has a positive effect on machine availability. Other cylinders move packaging forward up to the next processing step. Pressure varies

The system has been optimized by Elopak so that it can easily be adjusted to accommodate different carton sizes. Since all machine processes are geared to the top height of the packaging, the user simply has to adjust the bottom height using the Aventics CCI compact cylinder when switching products.

depending on the position and amount of packaging on a rail. Here, the Aventics ED02 electropneumatic pressure regulator ensures precise, dynamically controlled pressure,

enabling an optimized, energy-efficient process.

Taking throttles as an example : Hydrogen peroxide (H2O2) is used to sterilize the packaging, but has

an effect on all reactive components, including sealing materials and grease, which are standard for throttles. Here, choosing the wrong material poses a risk to the entire sterilization process in the long run.

“We worked with Aventics to find a suitable solution, and now use a throttle that has been cleaned on the inside, with a special sealing ring on the sterilization system’s vaporizer. These design details allow us to achieve higher stability,” states Johannes Platen, responsible for engineering and mechanical design at Elopak EQS.

Taking valve systems as an example : HO-impregnated air also resulted in an application-specific development here. To extend the valves’ service life, valve specialists at Aventics combined a standard valve system with an aluminum corner strip including an all-round seal. Now, the valve pilots engage directly in the closed cable conduit within the machine, while the outlets exit the machine. This effectively prevents problematic contact

between valves and hydrogen peroxide, contributing to optimized reliability.

Taking quick exhaust and soft start valves as an example : The special unit consists of three Aventics components mainly aiming for machine safety to meet the required performance level. Combined with a soft-start and a blocking valve, an AS series maintenance unit offers an array of functions. After a safety cut-out and when the system is depressurized, for example by opening the doors, the valve systems should not be subjected to the full six bars of pressure immediately upon restart. The application-specific design now ensures the valve systems are slowly filled with compressed air.

HYGIENIC SAFETY FOR SERIES PRODUCTION

Aventics realizes such detailed solutions thanks to its many years of experience in designing hygienic components. This is reflected in numerous properties of the

Depending on the requirement, Elopak combines shut-off and ventilation valves to create the perfect solution, optimizing the compressed air system’s energy efficiency. Compressed air treatment steps such as filtering, regulating, and dehydrating are already integrated in the AS maintenance units from Aventics and ensure high compressed air quality.

Designed for high demands: Cylinders in Elopak’s aseptic filling machines have to function precisely around one million times per week in day-to-day operations.

“best-in-class” components customized specifically for utmost food safety. In plain terms, this means no recesses or sharp edges, easy cleaning and disinfection as well as the

use of food-compliant materials and lubricants and resistance to chemicals.

“Aventics provided Elopak EQS with support right from the start and knows what it means to monitor a near-series machine in development. The pneumatic components made a major contribution in the reliability and low-maintenance requirements of our innovative aseptic filling machine, not least for these reasons. This all boosts machine availability,” emphasizes Buchkremer. “Furthermore, Aventics and Elopak support the VDMA initiative to standardize consumption measurement so we are on the same level when it comes to determining energy efficiency, able to implement this together to the user’s advantage.”

Elopak will soon also use the Aventics Advanced Valve series, which is optimized for future requirements for continuous data exchange from the control to the lowest field level. “This meets our desire to continue driving fieldbus

High reliability despite hydrogen peroxide: A corner strip with an all-round seal prevents the valves from coming into direct contact with H2O2 -impregnated air in a standard valve system. The valve outlets exit the machine.

technology forward, also in pneumatics,” says Johannes Platen. “This development, too, will be realized in close collaboration with Aventics.”

This article was submitted by Aventics, a leading manufacturer of pneumatic components, systems and customer-specific applications. The pneumatic engineering company provides products and services for industrial automation, additionally focusing on the sectors of commercial vehicles, food and beverage, railway technology, life sciences, energy, and marine technology. For more information, visit www.aventics.com/us.

FULL STEAM AHEAD

Compact size, ease-of-use and maintenance were factors in deciding which boilers would best suit the Yee-Haw Brewing Company.

Yee -Haw Brewing Company has been heading in the right direction since opening in a renovated train depot in Johnson City, Tennessee in the first half of 2015 and choosing a Miura LX-200 Boiler as its “steam engine.” Since then, the company has expanded distribution to Nashville and picked up the Bronze Award for their European-Style Dark/Muenchner Dunkel beer at the 2016 World Beer Cup, a global beer competition that evaluates beers from around the world and recognizes the most outstanding brewers and beers.

“You can credit our success from doing things right from the very beginning,” notes Cris Ellenbecker, the company’s Brewmaster. “Yee-Haw takes a lot of pride in what it makes and where it’s located, and that extends to making smart decisions throughout the facility, including which steam boiler to use.”

After doing their homework, there were a number of reasons why YeeHaw chose Miura.

“While planning for the brewery, it was quickly evident that space would be at a premium,” notes Ellenbecker. “The Miura LX-200 that was chosen would require less space than a traditional boiler (it can fit through an average doorway), and provide additional capacity beyond the initial steam load.

The brewery would be able to grow without adding additional boilers.”

The ease of use was also an important consideration.

“Without trained boiler operators, the Miura boiler is easy to operate, a task that can be accomplished by many of our people,” adds Ellenbecker.

Life-Lube® Bearings

NSK offers a wide range of highly-specialized, high performance products to meet the rigorous demands of the food and beverage industry, from chemical exposure and contamination to continuous washdowns and fluctuating temperatures. Featuring special / sanitary materials and advanced food-grade lubricants, NSK products are designed to deliver reliability, reduced maintenance, and hygienic compliance.

877.994.6675 www.nskamericas.com

“Plus, the ability to turn the boiler on in the morning and have steam in less than five minutes negates the need to have personnel come in hours earlier.

“The boilers ability to produce full steam in a matter of minutes was a huge advantage, because I can just come in the morning, fire the boiler up, and start mashing in and heating up my mash right away,” said Ellenbecker. “There’s no wait time. I can just start work. We can start cleaning our tanks and brewing right away. That’s an amazing benefit.”

It wasn’t always that way for Cris, who came to Yee-Haw from another brewery that didn’t have Miura. It gave him a unique perspective, allowing him to appreciate Miura’a features and benefits even more.

“We worked with another boiler when I was in Milwaukee, Wisconsin,” explained Ellenbecker. “It took forever to get started in the morning. We’d have our first shift guys come in at 6:00 a.m. and we were maybe starting our day by eight or nine o’clock. There were huge wait times and the shutdown procedures were insanely lengthy. You

had to make sure you didn’t miss any detail. Otherwise, something could go wrong when you started it up again.

“With Miura, shutdown is basically two valves and a button,” added Ellenbecker. “It’s that simple and you’re done. Anybody can shut it down. Anybody can start it up and if we did have any minor issues, the customer support is phenomenal.”

Miura’s outstanding reliability and efficiency didn’t go unnoticed, and Cris wasn’t surprised to hear that Miura boiler customers who switched from a competitors boiler to Miura were saving around 20 per cent in fuel costs.

“Because it starts up so quickly and shuts down so easily, there’s no question about the efficiency and the savings on fuel and water,” adds Ellenbecker. In terms of reliability and maintenance, we’ve seen no problems on over two-plus

years.

“Reliability has been a big key and has eliminated downtime and costly repairs,” notes Ellenbecker. “The old boiler at my previous employer resulted in absurd repair bills. That’s an expense no one wants. With Miura, as long as you do your regular maintenance, which is easy, you’ll be way ahead of the game.”

Doing things better has allowed Yee-Haw to grow rapidly.

“In the short time we’ve been around, we’re already surpassing about 12,000 production barrels a year, which is insane for a craft beer,” notes Ellenbecker. “It’s a really exciting time to be on board and to be in charge

boilers and he knew how easy they were to operate,” added Ellenbecker. “But also, the fact that we had one, said a lot about our brewery to him.”

LX-200 SG LX Gas/Low NOx Series, Low and High Pressure Steam

Boiler use natural gas or propane and are available in a range of steam options (300 MAWP, 170 MAWP or 15 MAWP). Their compact size allows them to fit through a standard doorway, while their naturally low NOx (nitrogen oxides) ratings are as low as 9ppm depending on model. Hot water boilers are available depending on models.

The Miura LX Series design (available in boilers from 50-300HP) consists of rows of vertical tubes sandwiched between two rectangular headers. Both headers are encased in a castable refractory with only the tubes exposed to flame and/or combustion gases. The upper header is attached

“The old boiler at my previous employer resulted in absurd repair bills.

That’s an expense no one wants. With Miura, as long as you do your regular maintenance, which is easy, you’ll be way ahead of the game.”

of all these great guys helping to keep this place running so well.”

Having a Miura boiler has not only helped to “fuel the growth,” but to make a statement about the company to potential new employees.

“We just promoted someone to brewery supervisor, who came to us from a brewery in Asheville, North Carolina,” explains Ellenbecker. “That company also had a Miura boiler, and just bought a second one about the time he was leaving. At his old company, he was the one doing all the maintenance at that facility, so when he came here for his job interview and saw that we also had Miura, he was like, ‘Yeah, this is a place I can work.’

“It was very reassuring for him because he had worked on Miura

RELIABILITY

to the lower header only by the tubes. As the tubes expand and contract, the headers float up and down accordingly.

This “floating header” concept greatly reduces stress and allows for the use of cold feedwater without the fear of significant thermal shock. The “leaky tube” problems associated with firetube and bent watertube designs have been eliminated.

Miura boilers have a range of impressive benefits that are attracting a growing number of customers in a range of industries. Among these are: improved efficiency (fuel savings average about 20 per cent based on customer comments); enhanced reliability through their modular design; advanced controls and advanced monitoring; and a best-in-industry safety record with zero catastrophic vessel failures resulting in casualty.

Yee-Haw’s boiler system design, installation, training and ongoing support is handled by Combustion & Control Solutions of Chattanooga, represented by David Flowers.

“Combustion & Control Solutions has been awesome for us, noted Ellenbecker. “They’re actually the ones who come and help us do our yearly permit inspections for the city. They’re super helpful. They really know what they’re talking about.”

Asked whether he would consider recommending Miura to another brewer, Ellenbecker responded without hesitation:

“Oh, I would absolutely recommend the Miura boiler,” he said. “One of the things that I would say, is we’ve been running steam all over the brewery with it; and then just added another line onto it, and it hasn’t skipped a beat. It’s taken the full workload and then some.”

This article was submitted by Miura Boiler, an industrial steam boiler manufacturer with its manufacturing facility in Rockmart, Georgia. For more information visit www.miuraboiler.com.

WATER RESTRICTIONS

Dry conveyor system installation amounts to big water savings.

Regal Beloit installed a dry-running conveyor system made with System Plast NG Evo technology at a Sierra Nevada Brewery in Chico, Calf. The brewery can now save 750,000 gallons of water annually on its keg line.

Sierra Nevada Brewery retrofitted its keg line 16 months ago and has already saved approximately 1 million gallons of water through the use of the System Plast NG Evo dry-running technology, which runs without lubrication or water.

“We already picked a lot of the low-hanging fruit when it comes to sustainability. But, we were able to achieve both productivity requirements and support California’s need to reduce water usage on the keg line with the System Plast dry running conveyor technology,” said Pat Young, project manager at Sierra Nevada. “It was something no one had done before.”

Regal Beloit’s System Plast NG Evo dry-running conveyor system was installed at the Sierra Nevada Brewery.

“The line runs without the use of water, soap or dry lubricants, which has also helped to reduce component maintenance,” said Stephen

eliminate or greatly reduce wasteful water-andsoap lubrication; slip hazards; and premature failure of bearings, gearboxes and other conveyor components typically seen in washdown conveyors. The conveyor chain accomplishes this all while helping users meet their productivity goals.

“Water reduction is quickly becoming ubiquitous in the beverage and brewing industry, and we have been working over the past 30 years to steadily reduce our water consumption,” said Stephen Russell, plant manager, Sierra Nevada Brewing Company.

“Water reduction is quickly becoming ubiquitous in the beverage and brewing industry, and we have been working over the past 30 years to steadily reduce our water consumption,” said Stephen Russell, plant manager, Sierra Nevada Brewing Company. “In light of California’s water concerns, it became even more important that we evaluate any and all means of reducing water consumption.”

Regal’s team worked with Sierra Nevada from design through installation, and remained

on-site during startup to ensure the keg line ran smoothly. A dry-running keg line also helps reduce maintenance, because water and soap corrode components such as bearings and gearboxes.

“The team was also able to reduce the clean-in-place frequency, saving water as well as time,” said Young. “Considering all the different areas where we’ve reduced water usage, running a dry keg line translated into approximately 750,000 gallons of water saved annually. The System Plast solution helped turn my dream of a lubeless conveyor system to reduce water usage a reality.”

Despite the drought state of emergency being lifted in April, California Governor Jerry Brown is still encouraging residents and businesses to continue their efforts to conserve water. According to his office, the drought that spanned the years 2012 through 2016 included the driest four-year period of statewide precipitation on record.

This article was submitted by Regal Beloit Corporation, a leading manufacturer of electric motors, electrical motion controls, power generation and power transmission components. For more information, visit RegalBeloit.com.

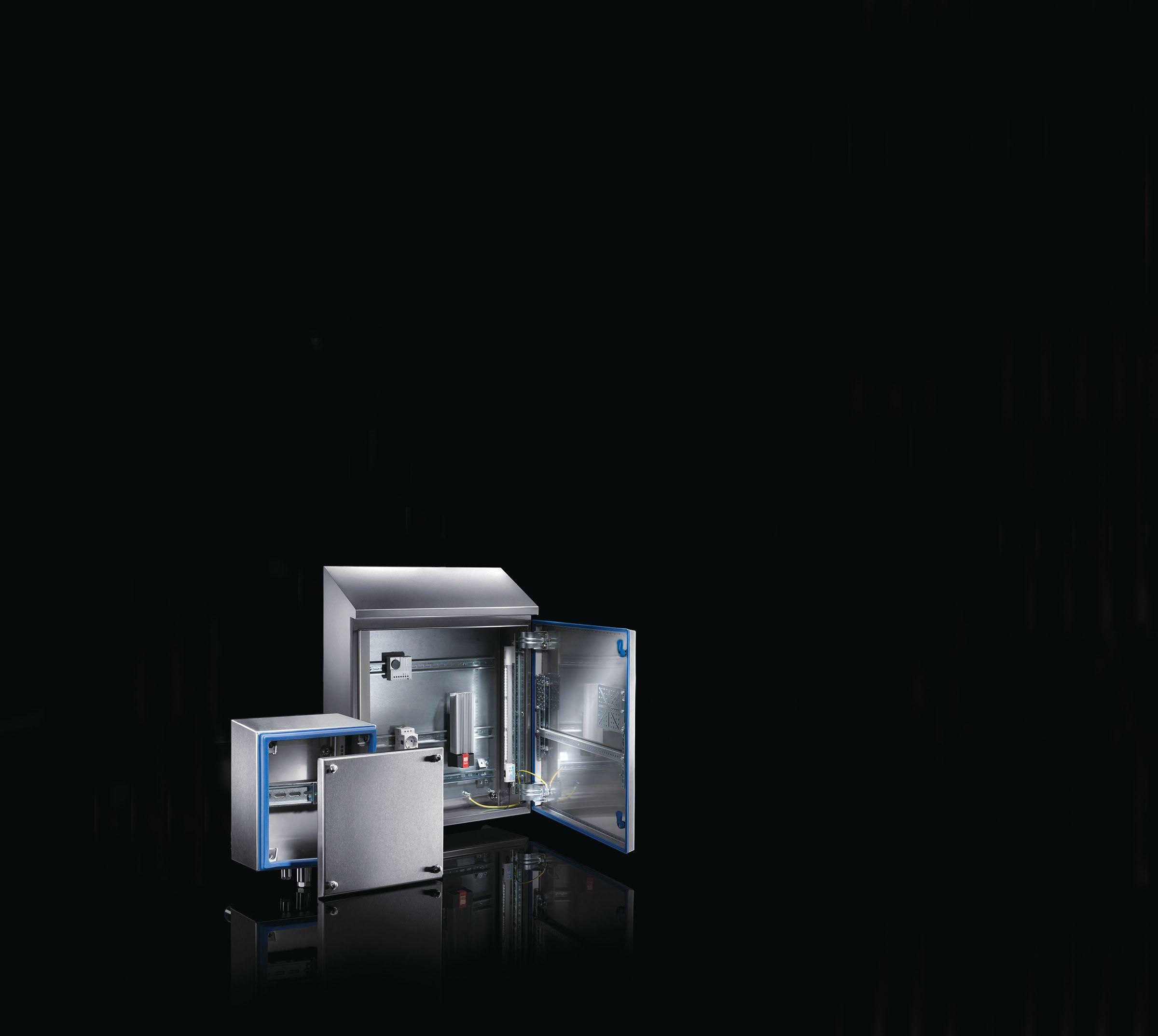

Hygienic

*Get your complimentary HD Enclosure today!

Design

Enclosure

It's on us if you qualify!

Specially designed and built to handle the unique hygiene needs and challenges of the Food & Beverage industry!

In harsh environments, traditional enclosures may fail to provide the required levels of protection, so we have the perfect solution for you. Try it for free if you qualify!

*Complimentary units - limited in quantity!

*Visit rittal.ca for HD F & B promo or contact marketing@rittal.ca rittal.ca

WINNER’S CIRCLE

The AHR Expo recognizes some of the most inventive products, systems and technology.

BY REHANA BEGG

Keeping processing rooms properly cooled and clean is a basic requirement for food production. So it’s a good idea to keep a close eye on the tools and techniques that keep commercial and industrial heating, cooling and ventilation systems in top form. A great place to keep up with innovation is at 2018 AHR Expo.

Winners of the 2018 AHR Expo Innovation Awards, the annual competition recognizing some of the most inventive HVACR products, systems and technologies, were selected by a panel of thirdparty ASHRAE member judges who evaluated all award entries based on innovative design, creativity,

application, value and market impact. The winners will be recognized in a formal ceremony during the 2018 AHR Expo, which takes place Jan. 22-24, 2018, at McCormick Place in Chicago.

Congratulations to all the winners and finalists! Meanwhile, we salute the innovative products and solutions from five categories – cooling, green building, refrigeration, tools and instruments, and software.

COOLING Company: Emerson

Innovation: Copeland Scroll

The latest generation of Copeland Scroll two-stage compressors from 1-10 tons was redesigned for improved performance and reliability in commercial air conditioning systems. The third-generation technology is optimized for mid-tier

comfort and efficiency rebates with improved full-load and part-load performance up to 5 per cent. www.emersonclimate.com

GREEN BUILDING

Company: Danfoss

Innovation: Danfoss Turbocor TTH/ TGH High Lift Compressor

The Danfoss Turbocor TTH/TGH

High Lift Compressor is a compressor optimized for air-cooled chiller and heat recovery applications. Engineered for high-lift applications, including air-cooled chillers and heat recovery, Danfoss Turbocor TTH/TGH models feature oil-free, variable speed, magnetic bearing operation for outstanding full- and part-load efficiency, low vibration and sound, a small footprint, and reduced maintenance—while providing an expanded operating map suitable for air-cooled chiller and heat recovery applications. www.danfoss.us

REFRIGERATION

Company: Chemours

Innovation: Opteon XP44 Refrigerant (R-452A)

Opteon XP44 Refrigerant (R-452A), a non-ozone depleting, low GWP, HFO-based refrigerant replacement for R-404A/507. It offers about 50 per cent reduction in global warming potential compared to R-404A/R-507, while providing

the closest match to the compressor discharge temperature of any other low GWP solution on the market.

With the regulations addressing high GWP refrigerants such as R-404A/R-507 in commercial refrigeration applications, Opteon XP44 uniquely provides equipment manufacturers and end-users an option to cost effectively cut the environmental impact of their refrigerant choice in half, without sacrificing performance or equipment reliability. www.chemours.com

TOOLS & INSTRUMENTS

Company: Fluke Corporation

Innovation: Fluke T6 Electrical Tester

The Fluke T6 Electrical Tester is an electrical tester that takes simultaneous voltage and current measurements without test leads. The T6 testers now make it possible to take reliable true-rms measurements in crowded junction boxes or along conductors with inaccessible endpoints, saving time, minimizing potential errors and greatly reducing the possibility of arc flash. www.fluke.com

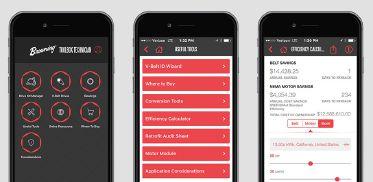

SOFTWARE

Company: Regal

Innovation: Browning Toolbox Technician Motor Efficiency Calculator

The Browning Toolbox Technician Motor Efficiency Calculator is a mobile app for Apple and Android platforms. The app calculator module allows a user to identify efficiency differences between different generations of integral horsepower electric motors. This app not only identifies the potential efficiency gain, but it allows the user to tailor the motor usage parameters to mirror their application or overall facility usage so a projected Return On Investment (ROI) can be displayed. www.regalpts.com

For more information, visit https:// ahrexpo.com/awards-winners-2018/

The Excellence In Manufacturing Consortium (EMC) began many years ago in Owen Sound, Ont., with a group of dedicated manufacturers who were keen to learn and share experiences to improve their businesses. This year marks our 20th Anniversary and we are so grateful to our members and community partners across Canada who have enabled us to provide those same grassroots networking

opportunities for companies of all sizes and sectors.

Over the years, we have brought many key function areas within the manufacturing setting together to address business challenges and areas of interest. Our perspectives were broadened through a myriad of plant tours representing the food, plastics, automotive, furniture, décor and printed material sectors. We call these sessions

“Strategic Interest Groups” (SIGs)

and they truly are “events with a purpose.” Relationships grew and transcended beyond our boardroom and plant tour gatherings. We came to know each other’s buildings well enough so that when one company had a breakdown they could borrow a motor from a neighbour to keep them running until the necessary parts came in. As you can imagine, massive delays were avoided in this instance and production continued.

Recognizing the value in

connecting peers, the SIGs, together with our GF2 (Growing Forward 2) Food Sector Networking Events, continue to include activities with Senior Managers, Continuous Improvement, Human Resources, Health and Safety, Food Safety, Sales and Marketing, Purchasing and Logistics, IT and, of course, Engineering and Maintenance. Through all of this, there remains a deep respect for the interconnectedness of the roles within our companies and a recognition that ideas can be generated for improvement, regardless of the position we hold.

The chance to meet with others in a peer-to-peer environment and to participate in roundtable discussion and plant floor learning opportunities has remained a fundamental element of EMC initiatives. As I reflect specifically on peer

interaction as it relates to those representing Maintenance and Engineering, a major component of our business, one must appreciate the lens with which they embrace and approach a challenge – a necessary skill set in a dynamically changing environment. At a recent peer networking event, we listened to an Engineering Manager share ideas as we problem-solved an issue relating to ergonomics. Building on experience in his current and past positions and putting those outside sets of eyes to use, was a perfect example of the continuous improvement grassroots spirit this type of interaction can bring. An unfamiliar business and unfamiliar processes that yielded our host some wonderful ideas on next steps. Around the table, Engineering, Health and Safety, Plant Management, Human

Resources, all worked together to help another business bolster their journey to provide a healthier and safer work environment.

It is easy to recognize that our equipment and production efficiencies could never be obtained without people committed to understanding the dynamics of our operations. A good Maintenance and Engineering team building on experience and equipment knowledge can help us innovate and plan for the future. Engaging peers around the table to enhance labour productivity, equipment efficiency and improved processes can lead to some interesting discussions that focus on a variety of areas, such as:

• CMMS Reviews

• Ergonomics and Equipment

Adaptability

• Lean Management

• Innovation and Automation

• TPM (Total Productive Maintenance)

• Preventative and Predictive Maintenance

• Improving System Reliability

• KPIs and Traceability

• SR&ED

• Health and Safety

• Continuous Improvement

Just a few of the topics embraced in at these EMC events!

Quite some time ago, a speaker shared a chart that highlighted the exponential rate of change. It was astounding at that time – how much more change could there possibly be? Considering our 20th Anniversary and reflecting specifically on activities and increasing demands for those in Maintenance and Engineering since our inception, it leaves one in awe and again we are left

wondering what the future has in store. Some of those major changes enabling us to improve production and capacity and health and safety in our working environments:

• The evolution of IT and technology in general on the plant floor and equipment

• Utilization of Maintenance Programs

• Easier and faster accessibility to materials, required components and supplies both online and delivered

• Ongoing preventative and predictive maintenance techniques

• The implementation of lean methodologies

• Valued input on continuous improvement opportunities and innovation

• Integration

• Exposure and development of

various approaches to problem solving drilling down to real root cause discovery

• Movements to team-oriented tasks with Production and Operations shortening downtime and changeovers

It has been a privilege to have toured facilities where the Maintenance and Engineering Teams have embraced the challenge of continuous improvement and who willingly share their journey. The culture is engaging and Maintenance, like other key function areas, recognizes its impact on organizational success and customer satisfaction.

I recall marvelling at the creativity of one team in particular. The plant manager recognized that his people spent the majority of the day at work and he allowed each team to paint their area a colour of their choosing.

The maintenance team took it one step farther, and each of their bolts in the mezzanine area was painted a different colour demonstrating their connection to each of the departments on the plant floor. A simple illustration of the interconnectedness of our roles and the importance of production to maintenance and maintenance to production.

EMC, through networking activity and GF2 (Growing Forward 2) initiatives such as our public and in-house Productivity Events and Self-Diagnostic Tool, have helped and continue to help companies interested in embracing lean thinking. One of our Food Processors decided that the area they would most like to focus on was their maintenance department. They were having issues finding things when they needed them and ordering

items they already had because they couldn’t be found. The team in this department began with a 5-S initiative. During a subsequent peer networking event, participants were excited by the transformation and the team’s pride was evident! Other parts of the facility wanted to engage in this same type of activity for their areas. Showcasing these types of journeys allows people to learn about the concepts, best processes and what may not work as well as planned. It opens the door for all to see what the possibilities may be in our own maintenance departments or other areas of our plants – where to start, who to involve, how to sustain advances, etc. This type of tour, with outside eyes, often exposes other opportunities worth considering! With an aging population, finding

qualified and enthusiastic people to fill these roles is a growing industry challenge. The job itself has evolved so much so that many companies can now provide opportunities in highly automated and innovative settings. The position calls for those with good communication skills, decision-making abilities and problem-solving talents and, above all, the capacity to work in a team setting that embraces continuous improvement opportunities.

This fall there have been Manufacturing Day celebrations across the province, bus tours with students to plants, and of course, the “Take Your Child to Work Day” opportunities. We need to celebrate the various positions in our manufacturing environments, including maintenance and engineering, to engage the youth of today in a

future career opportunity in the Food, Beverage, Bio and Ag Sector. We need to share our stories, get excited about the possibilities, and connect with peers to look at ways in which we can continue to attract and retain talent in one of the largest Sectors of our economy.

As we embrace our 20th Anniversary and celebrate the incredible and wonderful dynamics of an everchanging Sector, we look forward to welcoming you to an upcoming GF2 Food Sector Networking Event and Member SIG activity. These sessions are developed and formed with your needs and challenges in mind and offer the perfect forum to share and learn, to take in a plant tour, to connect with others within your discipline and beyond, and to seek continuous improvement opportunities for your

company. The topics are always interesting, our hosts extremely accommodating, and your peers very interested to learn about your company, products and processes and your role in enabling manufacturing competitiveness today.

Please consider joining in on any of our upcoming EMC Food & Beverage Sector Peer Networking Events: How do you get involved? If you are interested in learning more about EMC (Excellence in Manufacturing Consortium) and the Food Sector Initiative, please feel free to touch base with Bren de Leeuw, Director – Field Operations Canada and EMC Food, Beverage and Bio Sector Program (bdeleeuw@emccanada.org) anytime!