EDITOR

Kirstyn Brown

kbrown@annexbusinessmedia.com (519) 429-5205

BRAND SALES MANAGER

Pat Lorusso

plorusso@annexbusinessmedia.com (416) 518-5509

ACCOUNT CO-ORDINATOR

Debbie Smith

dsmith@annexbusinessmedia.com (416) 510-5107

MEDIA DESIGNER

Graham Jeffrey

Beata Olechnowicz bolechnowicz@ annexbusinessmedia.com

Anne Beswick

abeswick@annexbusinessmedia.com (416) 510-5248

PRESIDENT & CEO

Scott Jamieson sjamieson@ annexbusinessmedia.com

JP Giroux • jp.giroux@emccanada.org

VICE PRESIDENT AND GENERAL MANAGER

Amanda Doman • adoman@emccanada.org

VICE PRESIDENT, MANUFACTURING SECTOR PERFORMANCE

Scott McNeil-Smith • smcneilsmith@emccanada.org

MARKETING & COMMUNICATIONS MANAGER

Tiffany Robbins • trobbins@emccanada.org

A new study highlights a need for modernization in F&B supply chains.

8 FOOD SECURITY

Canadian food manufacturers could play a pivotal role in sustainable food production.

10 SAFETY

Preventing unsafe energization with lockout/tagout procedures.

12 TURNING FOOD WASTE INTO BIODEGRADABLE PLASTIC Research from Virgina Tech aims to turn discarded materials into eco-friendly alternatives.

15 FROM SILOS TO SYNERGY: EXPERT Q&A

Advice for implementing maintenance and production toward common goals.

Hello, and welcome to my first issue of Food & Beverage as the recently appointed editor of MRO.

As I put this issue to bed, it’s mid-October, a month synonymous with harvest and abundance in Canada, and I find myself reflecting on the vital role this industry plays in bringing nourishment to millions of Canadians this time of year. Thanksgiving is a reminder of the importance of food—and its production, preservation and distribution—and the responsibility we share in ensuring that all Canadians have access to it.

A recent economics report by Farm Credit Canada (FCC) highlighted the role of Canadian food manufacturers in addressing food sustainability and insecurity. In the article on page 8, representatives from the FCC emphasize the need for innovation and cross-sector investment to enhance productivity to meet the challenges of feeding a growing population.

Then there’s the pressing issue of food waste, which presents its own unique challenges and opportunities for food and beverage manufacturers. Globally, an estimated one-third of all the food that’s produced ends up in landfills, with Canada being one of the worst offenders. This issue of F&B features a thought-provoking article on page 12, which sheds light on researchers from

Virginia Tech and their efforts to turn food waste into biodegradable plastics, potentially addressing both the problems of food waste and plastic pollution. Which brings us to our main feature, page 15, which examines the necessity for effective maintenance and production integration within operations. While maintenance might initially seem disconnected from the broader challenges of sustainability and waste, it is, in reality, deeply intertwined with the industry’s capacity for innovation and growth. In this Q&A with leadership and manufacturing consultant Kim Wolf, you’ll learn strategies for aligning maintenance efforts with production goals to create world-class maintenance and maximum efficiency—all of which contributes to a better industry, and ultimately, a better world.

I hope you enjoy the issue. Have a beautiful and healthy autumn!

EDITOR

Kirstyn Brown kbrown@annexbusinessmedia.com

Atlantic Packaging Products, Ltd., headquartered in Scarborough, Ont., has opened a new manufacturing plant in Hamilton, Ont. The facility was developed in response to customer needs, allowing the company to increase its ability to provide sustainable packaging solutions and support customer growth.

The new plant will also create new job opportunities in the community, as the company is actively hiring.

“We are excited to start our new site in Hamilton and to be part of the city’s

growth. This facility will help us better serve our customers, and we look forward to working here for years to come,” says Sean Weir, President of Atlantic Packaging.

The ribbon-cutting ceremony for Atlantic Packaging’s new manufacturing plant in Hamilton took place on October 10th, 2024, and featured the attendance of Andrea Horwath, the Mayor of Hamilton.

On Sept. 19, Food Processing Skills Canada announced a new funding commitment of $5.5 million from the Government of Canada’s Skills for Success Program for Skills Training Across Canada and other workforce initiatives.

In acknowledgement of the key skills needed to succeed in learning, work and life, Food Processing Skills

Canada honours Skills for Success Day with the launch of Skills Training

Across Canada — a initiative with an expanded mandate to support frontline workers, new hires and jobseekers preparing for work in Canada’s food and beverage manufacturing industry.

The Canadian food and beverage manufacturing industry contributes $35.2 billion to Canada’s GDP and is a top employer with over 310,000 people in the workforce in 2023. However, Food Processing Skills Canada’s Industry Growth and Outlook Report from December 2023 found the average annual hiring requirement for this industry is significant with approximately 11,500 new people required per year driven primarily by the need to replace an estimated 66,800 retirements and age-related exits while considering projected industry growth and labour productivity gains.

The new Skills Training Across Program has been designed to improve foundational and transferable skills to 800 industry frontline workers and 1500 jobseekers nationally through training, webinars and resources in

English and French. The curriculum is aligned to the Government of Canada’s Skills for Success model and the industry’s Learning and Recognition Framework.

Training for new hires and frontline workers will provide comprehensive, online training to transform employees into confident digital learners through a blended approach that includes onboarding, goal-driven content, coaching, gamification, and self-directed skills development. This program will be available in French in January 2025.

CELEBRATES 10 YEARS IN LONDON, ONT.

Dr. Oetker Canada Ltd., the maker of frozen pizza brands, desserts and dry baking products, is marking the 10-year-anniversary of its pizza manufacturing facility, in London, Ont. The company says this location has been a hub for North American pizza operations for the last decade, making an average of 400,000 pizzas per day and employing 430 people in the province. At an anniversary event held on

Sept. 12, diplomats were offered a tour of the plant. All guests were able to hear from and engage with Dr. Oetker executives, who discussed achievements from the last decade, ongoing activities within Canada, and a commitment to excellence in the future.

who visited from Dr. Oetker’s headquarters in Germany, and Koundoutsikos, as well as Valery Henle, Executive Vice President – North America, and Tobias Bauer, Senior Executive Manager, Pizza Production Unit.

The origins of the plant began in 2011, when the business made a pivotal decision to shift from importing products internationally to Canada and the U.S. and instead establish a North American pizza production hub in London, Ont. Since opening in 2014, Dr. Oetker Canada has doubled in size and become the market leader in the thin crust pizza category in Canada and number two in the overall pizza meal market in Canada. Special guests at the Thursday event included Dr. Christian von Twickel,

Dr. Oetker Canada has operated since 1960 and ranks as one of the top five subsidiaries for the food organization, which operates in more than 39 countries. The company’s Canadian operation includes manufacturing and R&D fa cilities located in London and Mississauga that produce over 190 products.

Rustica Foods Inc. has received a $1,000,000 refundable contri bution from the Canada Eco nomic Development (CED) for Quebec Regions. This support will allow the Montréal-based SME to acquire digital produc tion equipment to help boost its productivity and competi tiveness.

Rustica Foods is a commercial bakery that specializes in ready-to-eat pizzas, frozen pizzas and pre-baked pizza crusts. With the help of CED’s funding, the business, which operates primarily in the wholesale, food services and private-label co-production sectors, will be able to build on its success and create jobs in the east end of Montréal. The funds have been granted under

CED’s Regional Economic Growth through Innovation program. This program targets entrepreneurs leveraging innovation to grow their businesses and enhance their competitiveness, as well as regional economic stakeholders helping to create an entrepreneurial environment conducive to innovation and growth for all, across all regions.

A TraceGains report reveals that almost half of global suppliers rely on spreadsheets for daily tasks.

BY KIRSTYN BROWN

Arecent report from TraceGains, a Colorado-based provider of networked compliance, quality and innovation solutions in the food and beverage (F&B) industry, has revealed that 48 per cent of suppliers still use manual spreadsheets for daily operations, processes and document exchanges.

Published on Sept. 13, 2024, the report, Old Habits, New Challenges: The Critical Need for Modernization in Food and Beverage Supply Chains, evaluates how prepared suppliers are to navigate regulatory changes and market pressures. Based on insights from over 450 global F&B suppliers, the study indicates that outdated practices are a significant barrier, leaving many suppliers ill-equipped for impending disruptions, regulatory shifts and the rising demand for sustainable products. The findings show that 71 per cent of suppliers recognize that outdated processes

contribute to workflow issues, with 60 per cent citing time-consuming tasks, 39 per cent pointing to data entry errors, and 32 per cent identifying miscommunication as frequent problems. The lag in modernization is partly due to a lack of awareness; 25 per cent of respondents reported being unfamiliar with available technologies to enhance

customer relationship management in the F&B sector. The push for modernization is primarily driven by the need to comply with regulatory changes. Notably, the forthcoming FSMA Rule for Traceability (204), which will take effect in January 2026, mandates lotlevel traceability for specific food items in the U.S.

Among those familiar with technological solutions, 65 per cent cited “keeping up with regulatory changes” as their main motivation for updating internal software. Other significant factors include the need to quickly adapt to consumer preferences (58 per cent), manage supply chain disruptions (42 per cent), and integrate emerging technologies such as artificial intelligence (33 per cent).

Furthermore, the study found that nearly half (44 per cent) of suppliers acknowledge that changing consumer behaviors—particularly a preference for sustainable products and online delivery—are significantly impacting their operations.

Paul Bradley, Senior Director of Product Marketing at TraceGains, stresses the importance of adopting digital solutions. “This new research underscores the urgent need for suppliers to update their operations,” he says. “With increasing regulatory pressures and shifting consumer demands, widely used, outdated methods are putting companies at risk. Embracing digital solutions is essential not just for staying competitive, but for meeting compliance, sustainability, and market demands.”

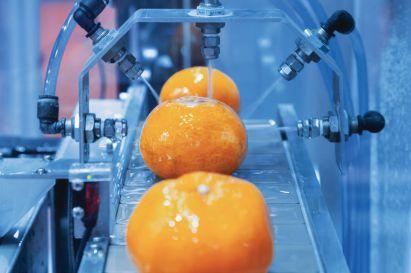

As the world faces population growth and climate challenges, a recent FCC report highlights Canada’s food manufacturing sector as a pivotal player in sustainable food production.

BY JILL MCALISTER AND SARAH MAZENC, FCC

Canadian food manufacturing plays a crucial role in addressing the need to sustainably feed a growing global population, according to a recent Farm Credit Canada (FCC) Economics report.

Food is the largest manufacturing sector in Canada by both employment and sales. With abundant natural resources and a strong global reputation for safe and high-quality food,

the sector is poised to be a world leader in sustainable food production.

“If we’re going to tackle some of the most pressing challenges facing our planet like hunger, global health, climate change and stagnant economic growth, we need to build new and

{

ambitious partnerships with key sectors like food manufacturing,” says Krishen Rangasamy, FCC manager economic insights. “To fully capitalize on this opportunity, we also need to engage investment and innovation by those in our industry and beyond.”

With the world’s population expected to exceed 9 billion by 2050, the Food and Agriculture Organization (FAO) estimates that agricultural production needs to increase by 60 per cent over 2005 levels. This challenge requires

“Productivity growth is not a one-size-fits-all solution; it requires a blend of efficiency, economies of scale, and innovation,” says Amanda Norris, FCC senior economist.

producing more food with the same or fewer inputs—a task that Canadian food manufacturing is well-positioned to tackle as it makes the most of the potential created through smart manufacturing and digitization.

“Just as steam, electricity and the internet propelled us to produce more with fewer inputs during previous industrial revolutions, automation, robotics, artificial intelligence and blockchain are shaping up to do the same in food manufacturing in the fourth industrial revolution,” says Amanda Norris, FCC senior economist. “These technologies can improve output and labour efficiency, manage inventory, prevent unplanned downtime, fore-

cast demand, track production and ensure quality control—all opportunities to help improve productivity in Canadian food manufacturing.”

Productivity increases when output grows faster than working hours, a trend that has been evident in Canadian food manufacturing over the past two decades. Despite challenges between 2008 and 2012, the industry has rebounded, demonstrating resilience and the ability to produce more food in less time.

“Food manufacturing in Canada has already proven its resilience and adaptability. After a period of decline, the industry rebounded by investing in new technologies and consolidating operations, leading to an 11 per cent productivity growth between 2013 and 2017,” Norris explains. “Now, with productivity growth remaining relatively flat, it’s time for a renewed focus on innovation to drive the next wave of growth.”

Rangasamy also underscores the importance of attracting investment from sectors outside of agriculture and food. “To truly harness the poten-

tial of the fourth industrial revolution, we need greater investment from those who may not traditionally see themselves as part of the ag and food industry,” he notes. “This will help us scale up and innovate, ensuring that Canada not only meets the food demands of tomorrow but does so in a way that benefits all Canadians.”

B y embracing new technologies and fostering crosssector investment, the industry can continue to lead in sustainable food production, ensuring a stable food supply and contributing to the global effort to feed the world.

“ Productivity growth is not a one-size-fits-all solution; it requires a blend of efficiency, economies of scale, and innovation,” Norris says. “By embracing new technologies and supporting a qualified labour force, Canada’s food manufacturing sector can help sustainably feed the global population and maintain a competitive edge in the

international market.”

FCC is proud to be 100 per cent invested in Canadian agriculture and food. The organization’s employees are committed to the long-standing success of those who produce and process Canadian food. FCC provides flexible financing and capital solutions, while creating value through data,

knowledge, relationships and expertise. FCC offers a complement of financial and non-financial products and services designed to support the complex and evolving needs of the industry. As a commercial Crown corporation, FCC is a stable partner that reinvests profits back into the industry and communities it serves. For more information, visit fcc.ca.

Realize your vision with Festo‘s approach to smart automation for food processing and packaging. Partner with Festo today.

Industry Leadership

Superior Quality Products

Global Training & Support

www.festo.ca

Implementing lockout/tagout procedures is crucial in safeguarding workers from the dangers of uncontrolled energy during maintenance tasks.

BY EMC, CANADA’S LARGEST MANUFACTURING CONSORTIUM

Ensuring that a piece of equipment is de-energized before any cleaning, oiling, adjusting, repair or maintenance work is performed is an essential safety element. Uncontrolled energies (including stored energies) and uncontrolled motion pose a high risk to workers, equipment and sometimes the work environment. To prevent incidents, employers have an obligation to ensure that an adequate lockout/ tagout and de-energization program is in place and functioning across their operations.

IS THE LEADING WORKPLACE

SAFETY RISK IN ONTARIO’S FOOD MANUFACTURING INDUSTRY.

The need for lockout/tagout isn’t limited to the food and beverage industry. All manufacturing environments with equipment that could pose an energization safety risk are included. Historically, the types of injuries sustained by workers have included the following:

• Mechanical crushing

• Entanglement in moving machinery parts

• Cuts and lacerations (in some cases, even amputation)

• Electrical injuries such as shock, burns, and even electrocution

The main CSA standards for lockout tagout are:

• CSA Z460 - Control of Hazardous Energy: Lockout and Other Methods

• CSA Z462 - Workplace Electrical Safety

Provincial occupational health and safety regulations include specific provisions for lockout/tagout. In general,

employers are responsible for:

• Having written lockout procedures

• Providing lockout devices and tags

• Training workers so that they know lockout/tagout safety procedures

• Auditing lockout/tagout practices and procedures on a regular basis

The CCOHS2 defines de-energization as “a process that is used to disconnect and isolate a system from a source of energy to prevent the release of that energy. By de-energizing the system, the risk that the system could inad-

vertently, accidentally, or unintentionally cause harm to a person through the release of hazardous energy is eliminated.” For safe de-energization, all sources of energy in each piece of equipment or machinery must be identified, and a means to control or release each energy type must be implemented. Ensuring that the energy sources cannot be restored inadvertently is where the concept of locking out comes in.

Lockout is the physical component of preventing unsafe energization. According to CCOHS , lockout is the isolation of energy from the system (machine equipment or process) that physically locks the system in a safe mode. Many different lockout devices are available for compliance with lockout regulations. Examples of locking devices include:

• Safety padlocks that require a key to unlock

• Circuit breaker lockout clamps that keep circuit breakers in the off position

• Lockable cables

• Pneumatic and hydraulic valve lockouts for compressed air and other pressurized systems

• Switch lockouts to secure switches in the off position

Tagout is visual communication to help prevent unsafe startup and energization of equipment. Tagout procedures will vary for different situations, but generally require attaching a warning tag with a clear message such as “Do not operate” to the circuit breaker or energy isolating device. The tag is meant to supplement physical lockout protection by providing a clear visual warning.

The forms of energy that need to be considered will vary depending on the design and operation of a particular piece of equipment, machinery or process. Examples include the following:

• Electrical (mains, auxiliary & control voltage, batteries, capacitors)

• Kinetic/mechanical (items that may continue or be able to move even after the controls are locked out)

• Stored (pneumatic/air, hydraulics, spring tension, gravity, capacitor banks)

• Chemical (equipment, machinery and process in which a chemical process is used to create an action or function)

• Thermal/heat (items that radiate heat or that may burn on contact with the body)

• Radiation (non-ionizing radiation such as lasers and UV light sources as well as ionizing radiation such as X-rays)

There are five main phases of a lockout/tagout safety process:

1. Preparation – in this phase, all equipment, machinery, and processes that could pose a re-energization safety risk are identified. Lockout/tagout devices and processes are defined for each piece of equipment.

2. Awareness and training – in this phase, employees are notified about the safety risks, and trained on proper lockout/tagout procedures.

3. Implementation – lockout/tagout devices are installed so that equipment can be isolated from energy sources when it is powered off.

4. Enforcement – this phase is critical in order for the lockout/tagout to reduce risk. Employers need to ensure that employees are verifying that equipment is fully de-energized and isolated before doing any maintenance, repair or other work that could be hazardous if the equipment re-energized.

5. Review and audit – For a lockout/ tagout program to be effective, it must be kept up to date and audited periodically to ensure its effectiveness and the degree of implementation and practice throughout your operations.

Additional information about lockout/tagout is available from the Canadian Centre for Occupational Health and Safety.

New research out of Virginia Tech aims to transform discarded materials into eco-friendly alternatives, potentially reshaping the world’s approach to sustainability.

BY MARK STEPHEN

Extraordinary amounts of energy, water and capital are put into food systems throughout the world—and far too much of that is wasted. Globally, an estimated one-third of all the food that’s produced ends up in landfills; and in Canada it’s even worse, with approximately 58 per cent of the food we produce ultimately going to landfills. All of which begs the question: What if there was a way to convert this wasted food into something that people can use every day?

Researchers in Virginia Tech’s College of Agriculture and Life Sciences, in Blacksburg, Va., are attempting to do just that by developing biodegradable bioplastics from food waste to give those materials a new—and useful—life.

In specific, the project tackles the challenge of oceanic plastic pollution that’s becoming even more prevalent with so-called microplastics—defined as plastic debris that are less than five millimeters in length, that result from both commercial product develop-

ment and the breakdown of larger plastics—and which is estimated by agencies such as the World Wildlife Fund to effect nearly 88 per cent of all marine species, primarily by inadvertently swallowing the tiny particles. Because they can quickly biodegrade in sea water, the Virginia Tech bioplastics have the potential to reduce the effect of pollution on marine life across the globe. “By creating cost-effective bioplastics that naturally decompose, we can reduce plastic pollution on

{“By

environmentally sustainable plastics, we hope to benefit people, companies, waste management systems, and communities worldwide,” Zhiwu Wang says.

land and in oceans and address significant issues such as greenhouse gas emissions and economic losses associated with food waste,” says lead researcher Zhiwu “Drew” Wang, associate professor in the Department of Biological Systems Engineering and director of the

Center for Applied Water Research and Innovation.

Said to be the first of its kind, the pilot

project will develop and demonstrate an affordable modular bioprocessing system to produce biodegradable bioplastics from food waste. Researchers will harness microorganisms to convert food waste into fats, which are then processed into bioplastics. This process, akin to fermentation in microbreweries, ensures that the produced bioplastics can be easily com-

posted, mitigating marine pollution caused by microplastics. The project aims to demonstrate the feasibility and scalability of this bioprocessing system on both national and global levels. “By creating environmentally sustainable plastics, we hope to benefit people, companies, waste management systems and communities worldwide,” Wang says.

Collaborating with other experts at Virginia Tech, as well as both undergraduate and graduate students—including Haibo Huang in the Department of Food Science and Technology and Young Kim in the Department of Sustainable Biomaterials—the team led by Wang focuses on the purification of polyhydroxyalkanoates (PHAs) and the creation of high-value bioplastic products.

“While there are many ways to generally improve sustainability in the world, there are two primary methods right now—one is to use more recycling and recyclable material, and the other is to use biodegradable material,” Kim says. “Using bioplastic is a viable option to solve our increased

{“Using bioplastic is a viable option to solve our increased plastic pollution. Our approach is to improve the sustainability using the biodegradable option,” says Young Kim of Virginia Tech.

plastic pollution. Our approach is to improve the sustainability using the biodegradable option.”

These biodegradable products include home compostable packaging, which has become increasingly popular. “Our first step is to make single-layer film to see if it can be utilized

as an actual product,” says Chen Shin, a research team member and senior student in Virginia Tech’s packaging and system design program.

“If it has good oxygen and water vapour barriers and other properties, we can move to the next step. We aim to replace traditional coated paper products with PHA. Current paper products are often coated with polyethylene or polylactic

acid—also known as PLA—which are not fully degradable. PHA is fully biodegradable in nature, even in a

backyard environment.”

Polyethylene or PLA coatings are often found on single-use plastics, which can include disposable coffee mugs, films covering food, or even the ice cream cups enjoyed on a hot summer day.

A US$2.4-million grant from the U.S. Department of Agriculture is funding the Virginia Tech research.

Expert advice for integrating production and maintenance toward common goals in the food and beverage industry.

BY KIRSTYN BROWN

In food and beverage manufacturing, the effective collaboration between production and maintenance can significantly impact overall performance and quality. Kim Wolf, of Kim wolf Leadership Coaching and Manufacturing Consulting, brings a wealth of experience to this challenge, emphasizing the importance of data-driven decision-making and cross-functional collaboration. In a recent conversation with Food & Beverage Engineering and Maintenance, Wolf expains the common obstacles manufacturers face when integrating these two vital areas and offers actionable strategies for fostering a culture of teamwork. With insights drawn from her dual

background in maintenance and operations, Wolf underscores how leaders can facilitate a unified approach that not only enhances efficiency but also supports food safety and quality control. Read on for her advice on creating common goals, utilizing key performance indicators and developing a unified workforce to achieve world class maintenance.

A: I think one thing is if there’s no data available. Once you get data of some kind—that could be everything from an Excel spreadsheet to fully integrated and automated downtime tracking systems and everything in

between—you can use that to make cross functional decisions that make more sense. If you start getting into opinions that people have, that’s when you can start the finger pointing. So, one person may say, ‘This is an operator training issue,’ and production says, ‘No, that’s an equipment issue or a mechanic training issue.’ If you’re not using data to really drive those discussions, it’s very difficult to try to reach some kind of objective strategy. I think the other thing is not having

processes in place. If you have downtime and you say, ‘What process is missing that potentially caused that downtime?’ if you don’t have a standard operating procedure, an SOP, written on a changeover from one product to another, then you get into the finger pointing.

I also think organizations that are focused so much on firefighting also can really struggle with that maintenance-versus-operations mentality a little bit. Because when you’re firefighting so much, everything is chaotic

and so the first thing you do is just start to blame. And it’s very easy to blame somebody in another another function than it is to blame internally. So, when you start implementing world class maintenance programs, it ultimately will help drive that relationship between maintenance and production because you’re reducing the chaos in your organization.

A: Certainly, having common goals. I think if all of the goals that are developed in a company below the plant goals, if those are siloed, then typically you will also get that finger pointing. Where, if you’ve got common KPIs, then you’re all working toward the same goal. So, I think that’s one thing. And again, the objective data. So, for example OEE. Using objective data to develop those goals, develop those KPIs, not using somebody’s opinion of where the issues are.

And I’d say the last thing is to change the lingo. I think you need to create a culture where it’s acceptable to call somebody out, saying, ‘That sounds like blaming as opposed to working together toward a common solution.’ Creating that type of a culture where you’re able to respectfully call one another out when you start having conversations like that. It’s just saying, ‘Nope, it’s not helpful for us to be blaming another department, another function. Remember, we’re all in this together.” When you’re using the data and making that conversation more objective, then people really start to get it.

A: I would say the data is one place. And, there are lots of companies out there that have really good, simple and easily integrated downtime collection systems. But if you don’t have that, or you’re a smaller company that may not have those types of resources, doing a simple Excel spreadsheet, where you’re just

For the food and beverage industry, lubrication is vital to the performance of rotating equipment; when over 40% of maintenance cost are related to poor lubrication, proper management is crucial.

No matter where in the lubrication management journey you are, with SKF Lincoln, you can boost the performance that matters to your business.

keeping track of anything that’s over 15 minutes or half an hour, wherever you need to start and then just try and keep track of that. How many cases should we have gotten? Should we have gotten? How many did we actually get? And then, what were the causes of that?

And then I would say the second thing is having a solid CMMS system, where you’re keeping track of not just maintenance activities, but I like to use the CMMS system also for sanitation activities as well as production. So, if production is doing CILs (cleaning, inspection, lubrication procedures), put all of that into one CMMS system. It’s easier to make sure that those activities are coordinated, especially if you’ve got a maintenance planner. Again, if you’ve got them all collected in one place, it’s much easier to say, ‘This is our cleaning plan,’ or ‘This is our equipment maintenance plan,’ because it’s all part of one system.

A: Don’t allow the finger pointing to happen. You’re responsible as a leader for creating that culture. If you’re allowing any function, not just maintenance and production, but even if it’s supply chain planning, or warehouse and logistics, anytime you start to allow that finger pointing to

happen, you’re creating that culture. So as a leader, I think that’s one thing that we need to say, ‘OK, I hear you, but let’s take that back to the process. Do we have a process that’s documented? Do we have documented checklists of exactly what’s supposed to be done?’ If not, that’s where your attention should be.

Second, creating an opportunity for cross functional projects. So, whether those projects are very short term and might come from your daily direction setting meeting, which is very short

term, very quick to implement, or whether it’s something more long term like a capital project. Often times you see a capital project that just engineering and maintenance is involved in and then by the time it gets installed out on the floor, the operators are like, ‘Whoa, we’ve never even been asked to be involved with this,’ and now they’re stuck with this piece of equipment that doesn’t meet their needs, or makes changeovers more difficult or makes sanitation more difficult. Instead, have a cross functional project early on and involve all the departments.

And then, the last thing I would say is a root cause failure analysis process. It’s a fundamental foundation tool that I think every company should be using. Insisting that process be used to solve problems takes away the subjectivity.

A: I like OEE because you’re taking into account first-pass quality, the availability of the equipment and then the performance of that line. And so I think that can be a shared KPI between maintenance and production.

I think PM Completion is another KPI, if you’re using your CMMS system for operator tasks, then that’s a good one. It also ensures that when you’re

setting up a production schedule, that you’re looking at it from all the needs across the whole plant. Incorporate in a production schedule all of your preventative maintenance, sanitation needs, team meetings and planned downtime. That shows you that production is no more or less important than maintenance sanitation, they have equal weight. So PM completion I think is a big one.

And lastly, I would encourage companies to use planned work versus unplanned work within the maintenance department because that will reduce the chaos, which then ultimately reduces the finger pointing.

Q: HOW DOES THE INTEGRATION OF PRODUCTION AND MAINTENANCE IMPACT FOOD SAFETY AND QUALITY CONTROL?

A: To me, it’s about consistency of results. Quality really is about consistency. In food and beverage, you’re dealing with product that is organic. It’s grown somewhere. It’s not something that’s built. And, so you’re going to have variations when it comes to quality parameters, so I think if you’ve got the production and maintenance groups tightly working together, you’re going to be able to deliver more consistency of results because you’re going to have less firefighting. You’re going to have less equipment downtime.

In beverage, for example, if you have downtime,

you may not be able to maintain the temperature of the beverage, which could lead to a yield problem. So that would be very easy to say, ‘Oh, it’s the equipment downtime that’s the problem,’ rather than, ‘What happened in that process that caused that beverage to have to sit on the line too long and where the temperature was increased beyond what the specs call for?’ As far as quality goes, that’s really what you would get out of making sure that these cross functional departments are integrated.

WHAT

OF

OR SKILL DEVELOPMENT INITIATIVES WOULD YOU RECOMMEND FOR CREATING A MORE VERSATILE WORKFORCE CAPABLE OF UNDERSTANDING BOTH NEEDS OF PRODUCTION AND MAINTENANCE?

A: I like an autonomous maintenance program, which is sometimes referred to as TPM or Total Productive Maintenance because you’re sharing those maintenance tasks. You’ve got operators who know the equipment better than anyone because they’re standing next to it all day long. They can hear or see if there’s a problem with the equipment probably better than a maintenance person can. So using autonomous maintenance to leverage the information that the operators have then frees up your technical resources to do things that are more technical.

That’s one way that you can really do predic-

tive maintenance without adding any additional sources to your maintenance team. You start autonomous maintenance and you have operators working on cleaning, inspecting and lubrication, and then you have maintenance working on oil analysis and vibration analysis. With some of those predictive maintenance technologies you’re going to get a much more comprehensive program, but you’re also going to have that sharing between cross functional groups in how that equipment performs.

But I think that you have to introduce it to your organization at the right time, because if you introduce it too early it can be a problem if your operators are not ready to be able to perform those tasks and maintenance gets frustrated because they have to come in and do it again, and now you’re creating division as opposed to collaboration.

A: I think if you’re seeing inconsistent results that are not achieving company or plant goals. And you see a lot of the finger pointing going back and forth, in particular between operations and maintenance. That is the time to start asking yourself, “How do we change that culture?”