Your

Your

Excellence in Manufacturing Consortium’s Manufacturing Essentials Certification programs are an initiative designed to help manufacturers increase their workforce productivity and become more competitive in a growing global marketplace. Manufacturing Essentials Certificate delivers learning material in training cluster groups, providing up to 40 hours of skills training, using industry validated learning programs. Programming is provided using live workshops, facilitated online learning with on-going support from professional trainers and a workplace action-based learning project.

Paul Burton

pburton@annexbusinessmedia.com (416) 510-6756 EDITOR

Mario Cywinski mcywinski@ annexbusinessmedia.com (226) 931-4194

ASSOCIATE EDITOR

Monica Ferguson mferguson@ annexbusinessmedia.com (416) 510-5206

NATIONAL ACCOUNT MANAGER

Ilana Fawcett

ifawcett@annexbusinessmedia.com (416) 829-1221 Supplement of

Brand Sales Manager

Chander Verma

cverma@annexbusinessmedia.com

(416) 510-6797

ACCOUNT CO-ORDINATOR

Catherine Giles

cgiles@annexbusinessmedia.com (416) 510-5232

MEDIA DESIGNER

Graham Jeffrey CIRCULATION MANAGER

Beata Olechnowicz bolechnowicz@ annexbusinessmedia.com

COO

Scott Jamieson sjamieson@ annexbusinessmedia.com

PRESIDENT

JP Giroux • jp.giroux@emccanada.org

(519) 376-0470 (866) 323-4362

VICE PRESIDENT AND GENERAL MANAGER

Amanda Doman • adoman@emccanada.org

VICE PRESIDENT, MANUFACTURING SECTOR PERFORMANCE

Scott McNeil-Smith • smcneilsmith@emccanada.org

MARKETING & COMMUNICATIONS MANAGER

Tiffany Robbins • trobbins@emccanada.org

In our June 2022 issue, we compared food prices (Spring 2022 to Fall 2021), we saw that prices in many cases were plateauing.

For the last comparison, we used Statistics Canada “Canada’s Monthly average retail prices for food and other selected products” for March 2022. However, this time we are using Statscan’s Monthly average retail prices for selected products, which gives the same information just in a different chart. The latest version available is for July 2022.

Looking at the items we used in our June issue (with some minor changes), staple items that are bought often look like this:

• Milk (four litres) was $5.99 in July 2022 and was $5.98 in February 2022. Milk did go up to $6.04 in April 2022 but has gone back down a little bit.

• Butter, 454 grams ($5.72 vs. $5.36), peak of $6.11 in June 2022.

• Eggs, dozen ($4.29 vs. $4.07), price is on the way up.

• White bread, 675 grams ($3.50 vs. $3.19), price is on the way up.

• Flour, 2.5 kg ($5.51 vs. $4.94), price is on the way up.

• Vegetable oil, three litres ($12.29 vs. $10.62), price is on the way up.

• Ground beef, per kg ($10.64 vs. $10.29), peak of $10.82 in April 2022.

• Whole chicken, per kg ($5.85 vs. $5.65), peak of $5.93 in June 2022.

What we see in the comparison is that while prices looked to be plateauing for the March 2022 numbers, prices have not gone down, and in most cases have gone up or stayed about the same. H owever, the news is not all negative, while some fruits and vegetable are up (apples, oranges, pears, potatoes, and onions), many are down in price (grapes, tomatoes, cucumbers, romaine and iceberg lettuce, broccoli, and peppers).

Why do food prices continue to increase? The biggest change since we did this exercise in June is that the war in Ukraine has intensified and a quick resolution does not look likely. This has increased oil prices through the summer months. While oil prices are on their way down (as of Labour Day) but as is often the case, prices could increase at any time. Further, supply chain issues continue to plague just about every industry in Canada, including the food and beverage industry.

Mario Cywinski

Food & Beverage Engineering & Maintenance

mcywinski@annexbusinessmedia.com www.mromagazine.com

FOODITIVE IS INCREASING PRODUCTION

Fooditive is scaling up its production to make its existing products and introducing their latest developments: LowSalt and Bee-free-Honey. LowSalt is made by modifying

potassium chloride by adding citric acid and mixing it with a carrier to result in an end-product salt to be twice as salty compared to natural salt, while protecting the consumer from a rise in blood pressure and weight gain.

Fooditive uses fermentation enzymes and the same system applied to its casein, the DNA of honey is copied to create a product that performs like traditional honey. Texture, taste, colour and health benefits can be mimicked to provide a plant-based honey, with first trails planned for early 2023.

Fooditive new phase of development will include products that fit its vision and planning towards 2030.

The Very Good Food Company announced plans to expand in the Eastern U.S. retail environment with Weis Markets. Weis owns and operates 196 supermarkets throughout Pennsylvania, Delaware, Maryland, New York, New Jersey, Virginia, and West Virginia and offers online shopping and delivery to Pennsylvania. Weis selected the flippin good burger, mmm meatballs, a cut above pork, and very good steak from the Very Good Butchers plant-based meat brand, expected to become

available at 150 store locations.

All supplemented foods will have a standardized supplemented food facts table, which includes information on the amount of each supplemental ingredient added. This table is similar to the nutrition facts table currently on Canadian packaging. Scientific studies have shown that the ingredients added to supplemented foods can be harmful if consumed by vulnerable populations, such as children or pregnant people or if overconsumed by the general population. Supplemented foods that contain specific ingredients will also require labels to provide information for consumers on the cautions and directions for use related to the supplemented food to see if it is appropriate for them.

McDonald’s Canada plans to source

100 per cent of primary guest packaging from renewable, recycled, or certified sources by the end of 2025 to achieve net-zero greenhouse gas emissions by 2050.

In 2019, McDonald’s Canada eliminated more than 1,300 tonnes of paper from the Canadian system annually by introducing new McWrap packaging, and 20 per cent smaller, 100 per cent recycled fibre napkins.

Maple Leaf Foods completed an extension of its $2 billion sustainabilitylinked credit facility with its existing. The credit facility consists of a CAD $1.3 billion unsecured committed revolving line of credit maturing in June 2027 and two unsecured committed term facilities in the amounts of US $265 million and CAD $350

million, maturing in June 2027 and June 2026.

The sustainability-linked targets include greenhouse gas emissions, electricity usage, water usage, and solid waste generated.

The facility bears interest based on short-term interest rates and is intended to meet the remaining funding for the completion of its poultry facility in London, Ontario.

Agrilait S.E.C. in Saint-Guil laume, Quebec, will receive up to $859,833 through the Dairy Processing Invest ment Fund. This investment will help the company in crease cheese production at Fromagerie St-Guillau me, reduce its produc tion costs and strengthen food security.

The investment will help install automated equip

ment, including an ultrafiltration system and milk separation system. This equipment will allow Fromagerie St-Guillaume to recover by-products of the cheese-making process and incorporate them into different products. The funding is expected to increase processing capacity by 35 per cent a year.

Toppits Foods is getting an investment from the Government of Canada of $6 million through FedDev Ontario, to help expand food processing capabilities and create 60 jobs in Brampton. With this investment, the company will expand production through the

purchase and installation of new, automated, seafood processing and freezing equipment at its newly acquired facility in Brampton. This support will enable Toppits Foods to integrate the manufacturing process of its seafood products, double domestic production capacity, grow revenues and expand its customer base in both Canadian and U.S. markets.

New nutrition labelling regulations for packaged foods to encourage informed food choices was announced by The Government of Canada. These regulations will require a new symbol to be displayed on the front of packaged foods that are high in saturated fat, sugars and/or sodium.

Manufactures will have until January 1, 2026 to comply with the new requirement.

The nutrition symbol includes a magnifying glass and text to draw attention to certain ingredients. The symbol will complement the nutrition facts table displayed on the back

of food packages.

Front-of-package nutrition labelling is a part of Health Canada’s Healthy Eating Strategy, which aims to improve the food environment in Canada and lower the risk of dietrelated chronic diseases.

Baskin-Robbins announces plans for an expansion of 25 new shops in the Vancouver and Calgary markets in a franchise development agreement signed with McMaster Group Holdings.

The new locations will be designed according to Baskin-Robbins’ new ‘moments’ design, which includes dipping cabinets, flexible and comfortable seating, and modernized digital menu boards.

Toppits Foods is getting an investment from the Government of Canada of $6 million through FedDev

Ontario, to help expand food processing capabilities and create 60 jobs in Brampton.

With this investment, the company will expand production through the purchase and installation of new, automated, seafood processing and freezing equipment at its newly acquired facility in Brampton. This support will enable Toppits Foods to integrate the manufacturing process of its seafood products, double domestic production capacity, grow revenues

and expand its customer base in both Canadian and U.S. markets.

Scotia Investments, CKF and UFP Technologies reached an agreement that CKF will acquire UFP’s Molded Fiber Technology. The new corporate entity will be known as MFT-CKF. MFT’s industry stature together with the growing demand for recyclable packaging.

Maximizing capacity and capability with integrated data management adds value at every stage of manufacturing to improve profitability despite notoriously razor-thin margins.

BY STEVEN BURTON

According to a 2022 report, data-driven organizations show a 30 per cent increase in annual growth in addition to being profitable and acquiring and retaining new customers. How can this metric be explained? Research shows that quick and confident decision-making relies heavily upon available data. The most important business decisions in today’s global market require

maximum data visibility – a business strategy that characterizes the largest and most successful industry leaders.

Data-driven decision-making is even more crucial for food and beverage manufacturers, who are operating in a complex global supply chain with thin margins and plenty of risk.

According to CSIMarket, the gross profit margin for the food processing industry in 2022 currently rests at 19.2 per cent, which is lower than other industries (averaging 49.4 per cent). In such an environment, the advantages of quality, workable data for business success is difficult to understate, yielding valuable analytics to drive business agility and providing the means to build capacity in a scalable way for the future marketplace.

Data-driven production does not look the same for every kind of product. The complexity of food and beverage processing puts it in another category that has unique needs for data management. Food

processors need a solution that can interact with a range of production workflows, meet compliance and quality standards, bring operations into sync, and equip them for growth.

However, what is true for all kinds of data management systems is that it needs to be collaborative to reflect the real way your business is running. Connecting all departments in your food manufacturing business with an ERP improves transparency and awareness, allowing leaders to show employees what and why things are working, reduce friction between team members, cut cost, and generate more revenue.

A data-driven culture ensures that everyone on your team, from the production floor to head office, can contribute to the quality of information, by adding value at every stage of the process. One way to build a data-driven culture of collaboration is having data champions assigned to each critical area. For smaller com-

panies, only one person may be needed. For larger organizations, it is best to have data champions for each division, and consistent and timely reviews of data to ensure results.

A system that centralizes data creates a single source of truth for your organization. It embeds a culture of transparency and accountability, providing your team with the essential information required for people-centric productivity. To ensure the trustworthiness of your information, it must meet the criteria for quality data, such as:

• Accuracy – reflects reality of production in real-time to ensure compliance and visibility;

• Standardization – systematically collected in a consistent format;

• Uniqueness – organized granularly for traceability precision;

• Completeness – covers all important metrics at the right intervals;

• Validity – meets all requirements for documentation standards; and,

• Visibility – easily transformed into actionable insights for business and auditing purposes.

With these criteria met, collected data can be leveraged for analytics, helping businesses make decisions for the future with clear eyes.

T he more a company uses data for analytics, the more powerful it becomes.

Consider what information you need in the face of a problem. You need to know what happened (descriptive analytics), why it happened (diagnostic analytics), what will likely happen next (predictive analytics), and how to make it happen – or not happen – again (prescriptive analytics). All these analytics play a role in improving your bottom line; by analyzing your results over time, you’ll gain the insight you need to predict what will come next, and make the course corrections you need to achieve more and avoid costly mistakes.

With a data-driven model of your business, food businesses gain the resilience to meet unprecedented challenges that increase risk and damage profitability. Digitized systems offer clear advantages:

• Infectious outbreaks can be controlled by maintaining the highest levels of biosecurity and the ability to rapidly implement new measures when needed, as well as keep critical records for contact tracing and other health and safety measures.

• Cloud-based systems ensure access to all essential business information in the event of an emergency, enabling remote work and eliminating avoidable gaps in production or compliance.

• Documented procedures and automated task management makes it easy to train new employees, keep training records, and simplify transitions. A smart system uses training data to ensure that the right people are being

assigned to the right tasks, and uses performance analytics to optimize operations.

• Supplier management is critical for sustaining productivity and profitability. The ability to look for alternate suppliers and manage alternate formulations and recipes for products provides flexibility for businesses. Data-driven supplier management tracks vendors, monitors supplier audits and qualifications, and helps food businesses sift through information to pinpoint problem areas in their supply chains. As you watch trends in lead time, you can identify your best options and look for alternates during unforeseen disruptions.

• Advanced planning and costing capabilities, using real-time data, allow businesses to become more adaptable to new, difficult or adverse circumstances like supply chain challenges and rising costs. Integrated, smart inventory management systems leverage data to maintain optimal inventory thresholds, maximize production uptime, and lengthen product shelf-life.

In these ways, data-driven approaches to food production provide significant opportunities to weather storms and gain an advantage in a highly competitive industry.

Creating a culture and infrastructure that thrives on data allows companies to do more internally: speed up production, reduce waste, improve systems or processes to optimize resourcing. Leveraging high quality data in decision-making – whether for start-ups or established companies – means that growth can go beyond profits, generating capacity to reach long-term business goals.

Let’s start with compliance, which poses an increasing data management

challenge as traceability systems and requirements become more complex. Data-driven logistics and production operations allow food businesses to achieve the highest levels of productivity while maintaining audit-readiness, translating into less time spent on preparing for and completing audits and more time for specialized staff to improve product safety and quality. With data-driven systems in place, you can leverage that extended capacity to meet regulatory requirements in new markets, whether from governments or third-party certification bodies (like non-GMO or vegan).

Efficiency translates even more concretely into profitability when it comes to production, maintenance, and warehouse management. Efficiencies add up, especially for high volume operations. Process automation, particularly for data capture, gives food production operations the benefit of faster turnaround times, fewer manual processes like data entry, reduction of errors, and increased efficiencies that result in direct cost savings.

Efficiencies add up, especially for high volume operations. Process automation, particularly for data capture, gives food production operations the benefit of faster turnaround times, fewer manual processes like data entry, reduction of errors, and increased efficiencies that result in direct cost savings.

A member of the Icicle user community found that a six second reduction on each order picked from their warehouse yielded over $100,000 in savings over one year. For another, having complete records on production runs revealed a packaging error that could have cost the company over $1.4 million a year, if not corrected. The timely review of data is critical to your bottom line.

Similarly, maintaining optimal levels of equipment uptime yields direct benefits to food manufacturers working with thin margins from the getgo. Automated, data-driven systems ensure that maintenance activities are properly scheduled and monitored, and help your staff uncover and avoid costly problems through analytics on productivity, preventative and corrective maintenance logs, and schedules.

Today’s food industry presents a challenging landscape for small and medium sized businesses, and they need a competitive edge. Growing companies can expand their distribution and export markets simply by freeing up the capacity to manage additional compliance requirements. Companies now required by law to implement highly data-driven traceability systems are leveraging that same information to reduce waste and improve efficiencies. Manufacturers and distributors are automating production and logistics processes to enhance quality – of data and of products – with IoT sensors and other forms of automated monitoring technology. Crucially, even small startups are

using data-driven systems to design their operations for scalability and adaptability for tomorrow’s challenges, entering the market with the intelligence and awareness more often characteristic of large corporations with decades of experience and expertise behind them. These startups are taking advantage of precise planning and costing capabilities that used to be unaffordable even a decade ago. Having sustainable accurate data will help you meet targets you know you need to meet and discover targets you didn’t know you could reach. With larger clientele that require industry leading price points, managing margins with high precision ensures your profitability and business success. This can only be achieved through an integrated data-driven approach to warehouse operations that keeps quality and team performance at its highest and builds a strong workforce culture which is the best way to have true competitive advantage.

Article provided by Icicle.

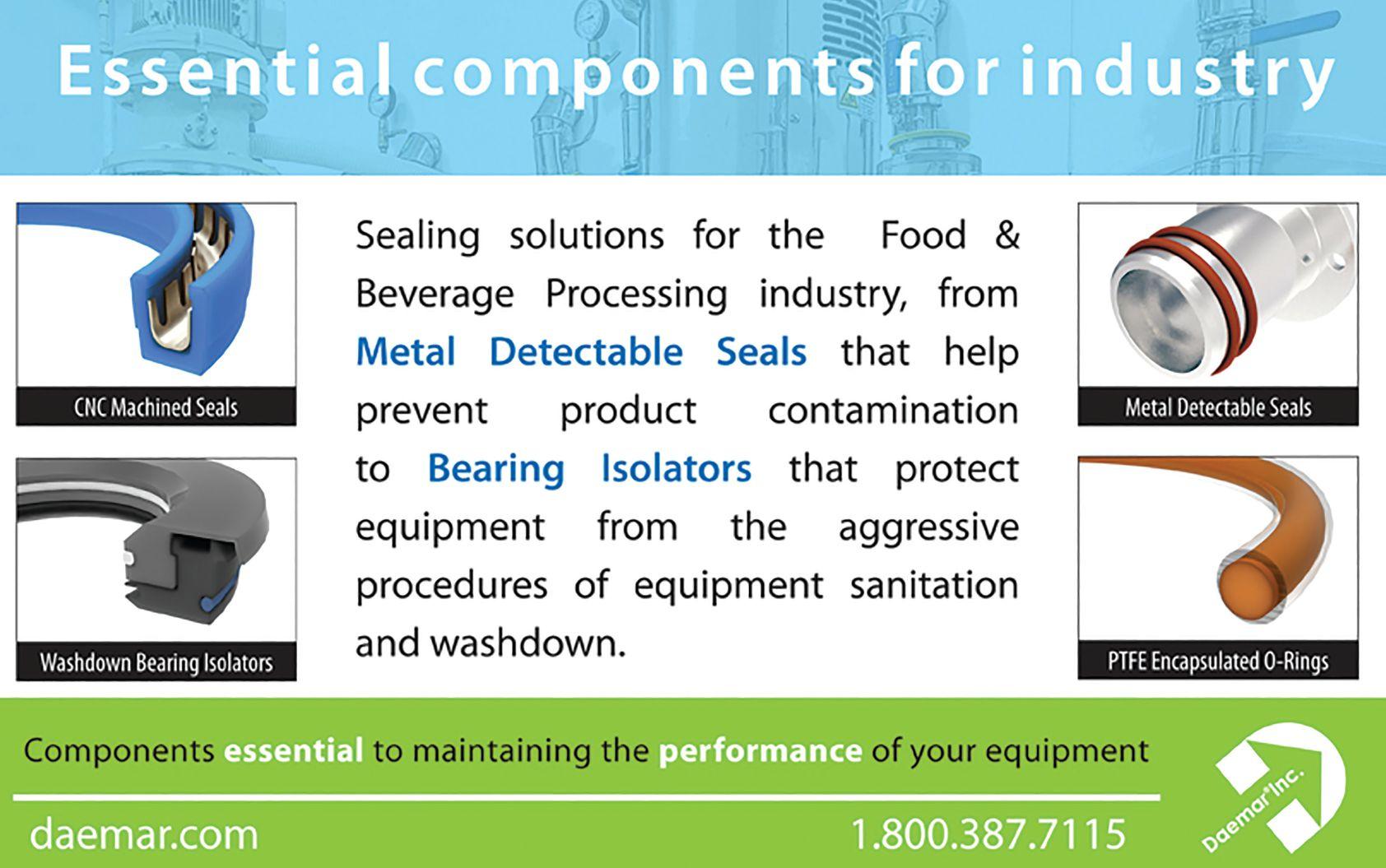

Parker’s Hose & Fittings Division is your largest selection of fluid connector products. World renown for its quality, safety & integrity in helping you with your product requirements, Parker makes sure you optimize your run time & remain profitable.

Des-Case offers products & solutions to maximize every minute of uptime available. Combining unique services, a wide array of products & solid support, Des-Case can help increase uptime, reduce costs & gain greater efficiencies for your equipment.

Product reliability begins with the design, but the manufacturability of that design is critically important to produce a quality product repeatedly. The proven reliability of Clippard’s product design, paired with the quality of manufacturing processes, delivers unmatched performance.

Destaco’s products are engineered for reliability & long life to ensure maximum production uptime. These products are designed & machined for precise repeatability with minimal maintenance.

Technology that provides food producers with real-time data analytics enables them to optimize the use of energy and raw materials, reduce food and energy waste, and achieve higher production capacities.

BY DANA MCCAULEY

The Canadian food industry is facing numerous challenges, from labour shortages and supply chain disruptions, to increasing input costs and changing consumer expectations. Many of these challenges can be addressed by automating processes so they can be made faster, safer, and more reliable.

W hile the shift to automation has been slower in the food industry

than in other industries, the use of automation, robotics and data analytics has the potential to transform Canada’s food and beverage industry. By investing in technology, the industry could become more agile, traceable, and transparent, while growing capacity and ensuring our food supply chain remains strong, safe, sustainable, and competitive in the world market. Automation also has the potential to help with labour attraction and retention, since it can make work safer for employees, can

boost profitability for businesses, and even help them expand into nontraditional areas such as in airports, hotels, and conferences.

T he Canadian Food Innovation

Network (CFIN) is a not-for-profit organization with a mandate to help grow Canada’s economy by helping to accelerate innovation in the food industry through connections, col-

laborations, and investments across Canada’s food ecosystem. CFIN offers funding programs and services that help food businesses, and their partners bring innovative ideas to life.

This past spring CFIN presented Robotics in Action: Seeing is Believing, a virtual event hosted by Jim Beretta, president of Customer Attraction, which focuses on robotics, automation and applications. Beretta spoke with several Canadian entrepreneurs whose companies are leading technological change in the food industry, and demonstrated automation solutions at Western University, including Mycionics, Ghost Kitchen Brands and 168 Sushi, and robotic systems from SJW Robotics, Anubis 3D, Gastronomous Technologies, JMP Solutions, Armo Tool and Tiny Mile Robotics. Beretta was also a speaker at Food and Beverage Magazine’s recent Max Uptime event, where he presented How Robotics is Changing Food.

Some key takeaways from the presentations are:

Robots and automatic systems are designed to do the tasks that are dangerous, dirty, or repetitive, and are a solution to current labour shortages in the industry. While robots perform tasks such as picking and packing, employees are freed up to complete more value-added and skilled duties. Collaborative robotic systems are designed with added safeguards so they work side-byside with their human counterparts.

In the last decade, costs of implementing automatic systems or robotics have fallen, while performance and consistency have increased dramatically. There are also many new advancements in gripping technology, resolving older robotic challenges such as distinguishing between different-sized and shaped products or boxes.

Automation systems and robotics are now easier to integrate into food operations and are often designed so that companies can add one piece of technology at a time, ensuring success and worker comfort. Working together with technology companies, food businesses can integrate plug-and-play components or create unique, custom-designed system featuring different technology modified to fit their needs.

Technology that provides food producers with real-time data analytics enables them to optimize the use of energy and raw materials, reduce food and energy waste, and achieve higher production capacities. Data analytics can also be used to predict preventative maintenance in

the system and prevent drops in throughput. Many companies rely on robotics that target sanitary compliance to assemble foods safely and reliably such as protein and uncooked ready-to-eat meals for retail or healthcare, where safe food handling is crucial.

Quick-service kiosks that offer a wide range of hot and cold food choices like salad, pizza and cooked noodles are appearing on campuses, in malls, and in other public spaces. Far beyond vending machines, the kiosks offer made-to-order meals prepared while you watch in just minutes, with a variety of customizations and payment options available. With a low carbon footprint and minimal labour needs, the kiosks have the potential of replacing QSR units in some locations.

Dana McCauley is the Chief Experience Officer at the Canadian Food Innovation Network.

Piezo technology is taking compressed air technology to a technological level that is resource-saving, energyefficient and sustainable.

BY DAVID GERSOVITZ

In the marketplace of automation technologies, both pneumatic and electromechanical products are available. Often, the best choice may be a combination of both, like an electric Z axis for positioning a pneumatic gripper, or vice-versa.

Four years ago, Festo captured the virtues of both technologies in digitalizing pneumatics –where flow, motion, pressure regulation are managed digitally by software apps controlling piezo valves in the Motion Terminal VTEM.

As a cyberphysical solution, the motion terminal enables complex movements and various speed profiles or positioning tasks that used to be possible only with servo-pneumatic or electrical automation.

The development of piezo valve technology is displaying versatility, from performing microdosing in medical and laboratory equipment, sachet filling of spices and condiments and other filling functions, to proportional flow control in heavy industry. It’s reaching far afield, as part of VTEM installations doing critical assignments on oil rigs and fish farms.

In the case of a Norwegian open ocean fish farm, for example, the motion terminal manages the supply air for aeration for each of eight pens, replacing manual functions such as reading sensors to determine the oxygen content of the water, then adjusting the supply with manually operated

ball valves. Too much oxygen is just as harmful to the fish as too little. When all adjustments are done manually – measure, adjust, measure again to be certain and readjust again if necessary

aquaculture is vulnerable to errors.

With VTEM and piezo pilot control, the oxygen supply is automated to regulate the air supply to the optimum value. Data from the oxygen sensors is transmitted to the farm’s control centre and displayed on dashboards. If the values approach a critical range, an operator can intervene immediately via remote control to maintain good fish health.

Each VTEM is housed in a control cabinet and has four valves and piezo pilot control to precisely control the air flow for the fish farm’s eight pens.

There are 11 available apps for VTEM: in this case, the app ‘Flow Control’ suits all the fish farm’s needs. In food and beverage applications, VTEM units are being used in pick and place functions in secondary packaging, and in precise mini-filling and dosing applications.

Part of the appeal of digitalizing pneumatics is how VTEM dis-

penses with many of the mechanical components required in a conventional pneumatic operation, also how it enables fast product and packaging format changeovers via software apps.

Piezo valves are featured in a new product identifier: controlled pneumatics – an expanding class of devices, which combine proportional technology, sensors, and control algorithms to form a control loop. These are mechatronic, pneumatic systems that enable digital influence in conjunction with closed-loop control based on a sensor variable.

The piezoelectric characteristics of certain ceramics that mechanically de-

In the case of a Norwegian open ocean fish farm, for example, the motion terminal manages the supply air for aeration for each of eight pens, replacing manual functions such as reading sensors to determine the oxygen content of the water, then adjusting the supply with manually operated ball valves.

form when a voltage is applied, are used. Whereas a standard two-position valve has only two positions and is always in one of two states, piezo valves can attain an infinite number of conditions. Since the control electronics and sensors are integrated in most of piezo valves, they can be opened continuously, and pressure and flow can be regulated by comparing the setpoint/ actuator values. As such, piezo valves are highly accurate, and quick to reach the specified pressure and setpoints.

In the Motion Terminal, four 2/2-way valves with piezo pilot control are connected, forming a bridge circuit within the valve body. This enables a wide range of directional control valve functions at each valve position, assignable by the controller and changeable during operation.

Each can perform the functions of a:

• 2 x 2/2-way valve;

• 2 x 3/2-way valve;

• 4/2-way valve;

• 4/3-way valve;

• Proportional pressure regulator; and,

• Proportional directional control valve.

The benefits of piezo valves for pilot control also include very long service

life, minimum energy consumption and low leakage when acting as a proportional pressure regulator.

Piezo valves can be especially small and lightweight because they have no solenoid or electrical coils. They generate no heat. Piezo valves are also virtually noiseless – the bender/actuator moves freely with no impact noise.

The Motion App ‘Leakage diagnostics’ can also be used. It can pinpoint leaks down to the specific actuator requiring attention by using diagnostic cycles and defined threshold values.

It can even close off the faulty air duct. Piezo technology is taking compressed air technology to a technological level that is resource-saving, energy-efficient and sustainable.

Article provided by Festo.

Your

BY JACOB VENTRESCA

Waste is an unavoidable byproduct of the manufacturing process – to refine resources into something of value to a consumer, certain elements of that resource need to be stripped away. For many manufacturers, this means generating piles upon piles of unusable, non-renewable refuse that must be discarded.

Food and beverage (F&B) manufacturers are in an interesting position, as processors of edible goods, the waste generated by their activities isn’t unusable or non-renewable, and consumers aren’t typically averse to it. The repurposing of excess materials created by food processing certainly isn’t a new idea; however,, in today’s age of sustainability and environmental awareness, the practice is now being given serious recon-

sideration by a diverse variety of manufacturers. Let’s examine the use of food waste as a manufacturing resource and determine whether it can serve as an asset to our businesses.

For F&B manufacturing, as defined by the Harvard School of Public Health, food waste is excess material that occurs as a result of processing and is still viable for usage by consumers in some form. Food waste is not excess that is toxic, hazardous, or otherwise non-consumable. Discarded coffee grounds are food waste, for example, but moldy banana skins are not. It’s important to recognize what the ‘waste’ in ‘food waste’ implies: food that could be consumed (or otherwise utilized), but willfully isn’t. Under these criteria, food waste remains a viable resource to its manufacturing entity, even after being stripped of its other components. Remember that, in F&B man-

ufacturing, ‘waste’ means ‘an unused surplus’, not ‘garbage’, and you may begin to realize this resource’s potential.

An idea recently gaining traction in F&B manufacturing is ‘upcycling’: the practice of re-using food waste for various processes. Upcycling has become a popular concept for several reasons. In addition to being eco-friendly, the re-use of waste eliminates costly disposal fees, and maximizes the value of F&B manufacturers’ resources. Through events like Anthesis Provision’s annual Upcycled Food Fest, consumers are rapidly becoming aware of upcycling as well. Judging by the success that this event and others like it have seen, upcycling food waste may become the sector’s next big trend.

Many organizations have also chosen to use their participation in upcycling processes as promotional material, as upcycling demonstrates a businesses’ willingness to reduce food waste

as much as possible, and positions them as responsible, environmentally aware organizations. If upcycling activities are marketed effectively to manufacturers’ consumer bases, they can serve as critical competitive advantages in a culture of environmental preservation.

Consider the parts of food that are typically discarded during the manufacturing process. F&B manufacturers tend to exclude elements that are traditionally unpalatable, visually unappealing, or nutritionally hazardous from our products. Things like fruit cores, animal bones, and hard shells usually can’t be incorporated into processed foods for various reasons: consumer preferences, health and safety legislation, and established formulas, make these parts of food unsuitable for products meant to be ingested. Today’s F&B processing machinery automatically removes these items from the production line. If they are not re-introduced at a later part of the process or used as input materials by another business for other

types of products, they go entirely unused, thereby becoming waste.

According to a 2019 article from The Globe and Mail citing the most recent study on the subject, Canadian manufacturers generate about 4.63 million tonnes of food waste per year, which is about 13 per cent of the national total. This makes F&B manufacturers the third-largest generator of food waste in the country, direly harming Canada’s environment — and these businesses’ bottom lines.

Food waste is typically comprised of rinds, peels, shells, bones, cores, and stems. Interestingly, these different forms of waste have several

components in common, which allows us to make certain generalizations. Overall, food waste is relatively hard, rough, and dry, whereas the parts of food that can be easily processed are relatively soft, smooth, and moist, making them ideal for human consumption through eating and drinking. Many foodstuffs with the qualities of food waste are typically consumed, but only after further processing. For example, rinds and peels can become zests and flavourings, shells and bones have long been used to create gelatin, and cores and stems are common ingredients in natural oils.

A wide variety of processed food

products that use items typically thought of as waste exists in the Canadian marketplace today, and many of them (seasonings, condiments, sauces), belong to multi-billion-dollar industries. F&B manufacturers likely already have the equipment and processes needed to enter these industries — and, by utilizing their food waste, they have the resources to do so as well.

There’s no need to limit one’s utilization of food waste to foodstuffs themselves, many kinds of food waste are exceptionally useful as elements of non-consumable goods. Foods are a common ingredient in various household items (soaps, medicines, aromatics), and consumers are already familiar with their inclusion in contexts outside of dining. While F&B manufacturers may not have the capabilities to process food waste into non-consumable items, a wide range of manufacturing businesses in other industries certainly do. Approaching these organizations with partnership opportunities based on food waste is

an excellent way to develop vital insector connections.

While not all food waste can be repurposed for products targeted to humans, there is another market that’s more than happy to consume waste as-is: livestock. A steady source of animal feed is necessary for prosperity in meat and produce farming, and Canadian F&B manufacturers generate high-quality meals for farm animals on a gigantic scale. The World Wildlife Fund has identified food waste as a valid source of sustenance for several species of farm animals and as long as farmers’ demands for healthfulness in this waste are met, F&B manufacturers will have a sustainable method of eliminating excess foodstuffs in a mutually beneficial way. This method of disposing food waste is exceptionally efficient for F&B manufacturers, many businesses in this industry already have strong working relationships with the agricultural sector and can use this contribution of potential animal feed to strengthen their shared bonds.

Farmers are an essential part of the F&B ecosystem, by supporting them in procuring a critical resource, F&B manufacturers can showcase their own businesses’ value.

It’s true that certain kinds of food waste cannot reasonably be re-utilized, upcycled, or integrated into other products. As biological materials, most forms of foodstuff eventually rot, solidify, or degenerate to the point of toxicity. If all else fails, though, there is one final use for food waste that is no longer safe for human or animal usage: compost. Even if food waste isn’t fit for consumption or further production, the inherent biodegradability of all foodstuffs makes using them for compost an ideal disposal method.

Compost — a natural fertilizer necessary for the continued growth of healthy plant life — can be created from most forms of food waste. By generating it on a facility-sized scale, F&B manufacturers will be able to display their dedication to the environment in a tangible, quantifiable way. The Government of

Canada offers several resources that F&B manufacturers can use to begin integrating composting processes into their activities and provides various tools and programs to these businesses for making these operations easier.

As F&B manufacturers, we understand that eliminating waste from our processes entirely will never be a feasible possibility. Fortunately, food waste is one of the most versatile forms of excess in the manufacturing industry and, if we utilize it effectively and proactively, it can reap a vast array of operational and financial benefits to our businesses.

With new legislation surrounding

environmental sustainability being passed every year, the elimination of food waste in an ecologically conscious manner may become mandatory. By putting upcycling procedures in place now, we can gain significant competitive advantages. The usage of food waste isn’t just a smart idea in terms of a business’s environmental impact though — it can open additional revenue streams, strengthen the bonds between manufacturers, and demonstrate an organization’s progressiveness to a consuming public. Start making the most of your business’s food waste and you may find this excess to be one of your greatest resources.

While some manufacturers lack the time or resources necessary to build strong working relationships with their peers. Excellence in Manufacturing Consortium (EMC), which maintains Canada’s largest manufacturer network, is wellsuited to facilitating these connections through access to a team of manufacturing consortium managers experienced in the industry and in establishing mutually beneficial partnerships. Through EMC’s Opportunities Alerts service, manufacturers can even advertise their food waste for purchase by other businesses. Foodstuffs are commonly-used materials in a multitude of manufactured goods, and F&B manufacturers would do well to recognize their value in the greater manufacturing space.

Endress+Hauser’s in-line Teqwave H analyzer monitors fluids in the food and beverage industry. It monitors sugar content in fruit juices and distilled beverages or concentration of cleaning agents.

In soft drink and fruit juice production, measuring product quality is checked through its

determination of sugar content and invert sugar content. For production of distilled beverages, it ensures that the alcohol content remains consistent. When cleaning plants, bottles and kegs, Teqwave H monitors different concentrations and supports dosing of cleaning agents. If the cleaning agent needs to be changed, this can be done without recalibration.

For sanitation purposes, the analyser is designed with a full-bore stainless-steel measuring tube with no places inside the measuring tube where material can accumulate.

Teqwave H measures concentrations at the same time using one sensor. Concentration data sets are pre installed for the most common beverages and cleaning agents.

The analyzer records multiple measured values, and forwards them to the process control systems. Complete access to all measurement data is possible at any time – by using conventional 4–20 mA or digital data transmission via Modbus TCP. www.at.endress.com/en

Emerson launched its Aventics series Servo Profile

Advanced (SPRA) electric actuators, a line of rodstyle cylinders. SPRA actuators offer three screw technologies; including a precision ball screw, a lead screw option, and roller screws. This range of rod-style cylinders lets users in the automotive, food and beverage, packaging and life sciences industries configure electric actuators to meet exacting application requirements. www.emerson.com/en-us

RITTAL BLUE SMART COOLING UNIT APPROVED FOR CANADA

Rittal expanded its smart cooling unit solutions with the Blue e+ S range. It has lower output categories of 300, 500, and 1,000 W and has a smaller footprint and lower costs.

The Blue e+ S range combines a heat pipe with inverter-controlled components. The heat pipe

works without a compressor, expansion valve, or regulating elements, and does not need any electrical energy except to operate the fan.

The additional compressor cooling only operates if a large amount of heat must be dissipated from the enclosure or if the ambient temperature is very high. When it does operate, it is energyefficient because the compressor and fans have an inverter-controlled drive, which adjusts their speeds depending on the requirements.

The new series uses a refrigerant with a global warming potential that is 56 per cent lower than those used in comparable cooling units. Instead of the R-134a previously used, the cooling circuit in the new generation of units now runs with R513A refrigerant.

www.rittal.com

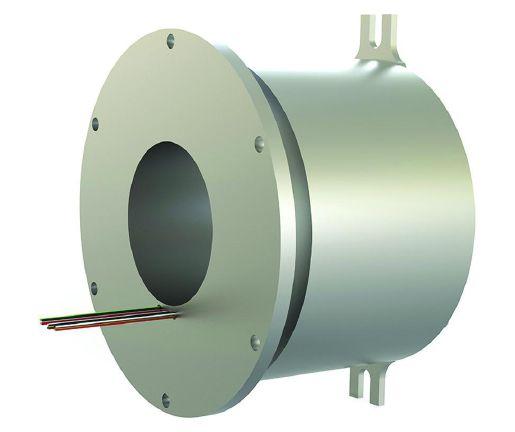

The Orbex Group introduces standard slip rings with an IP65 protection rating, providing washdown tolerance in food and beverage and pharmaceutical manufacturing applications.

Available with short lead times, the slip rings come in stainless steel or aluminum housings,

while their IP65-rated, sealed design enhances component protection in demanding environments. They offer mounting options with through-hole diameters ranging from 25 to 100 millimeters, or capsule style when a throughhole is not required, facilitating installation.

The slip rings support a range of standard industrial network protocols, such as Ethernet/IP, EtherCAT and Profibus.

www.orbexgroup.com