FOOD BEVERAGE

Looking in your refrigerator, how much of the food ends up being thrown away, and never used. Either because it goes bad, too much was bought, or any number of other reasons. Even with grocery prices going up, food is the one thing we will still pay for no matter the cost.

Unlike things we want (tablets, phones, computers, etc), food is something we need, so we usually buy more than we will consume, and end up getting rid of the rest. This is true for both consumer and commercial food buying. While many municipalities have green bin programs that are meant to divert food waste from landfills, as is human nature, some people use them, and some simply put the food waste in the garbage bin. I’ve always tried to do the former and put as much food waste in the green bin as possible, if nothing else, doing my part for the environment.

However, that brings me to a study done by Second Harvest and Value Chain Management International titled The Avoidable Crisis of Food Waste. It states that 60 per cent of food produced in Canada is lost or wasted every year.

Thinking about that for a minute, that is over half of all food that is not used, even at a time when not everyone has access to a regular meal.

Jennifer Elliott-Cropper looks deeper into the topic and what commercial kitchens can do to reduce their food waste on page 8.

While some of the wasted food has just been in the refrigerator too long, some goes bad as a result of faulty equipment. It is important to make sure any piece of equipment used for food storage is regularly checked, making sure it is working at ideal temperatures and any repairs are done in a timely manner. Technology exists today that provides maintenance professionals with the tools they need to have no excuse for food going bad. Sensors can alert when temperatures are off, while specifications need to be followed for where the unit should be placed, how far away from walls and other equipment, and what unit is the best for the job.

At the end of the day, food waste is not just a problem at home, as a lot of waste comes from commercial kitchens, at restaurants, hospitals, and other places of business.

It is up to food industry professionals to make sure they follow maintenance schedules on their equipment, and in turn use equipment that is the right fit for the job.

Mario Cywinski, Editor Food & Beverage Engineering & Maintenance

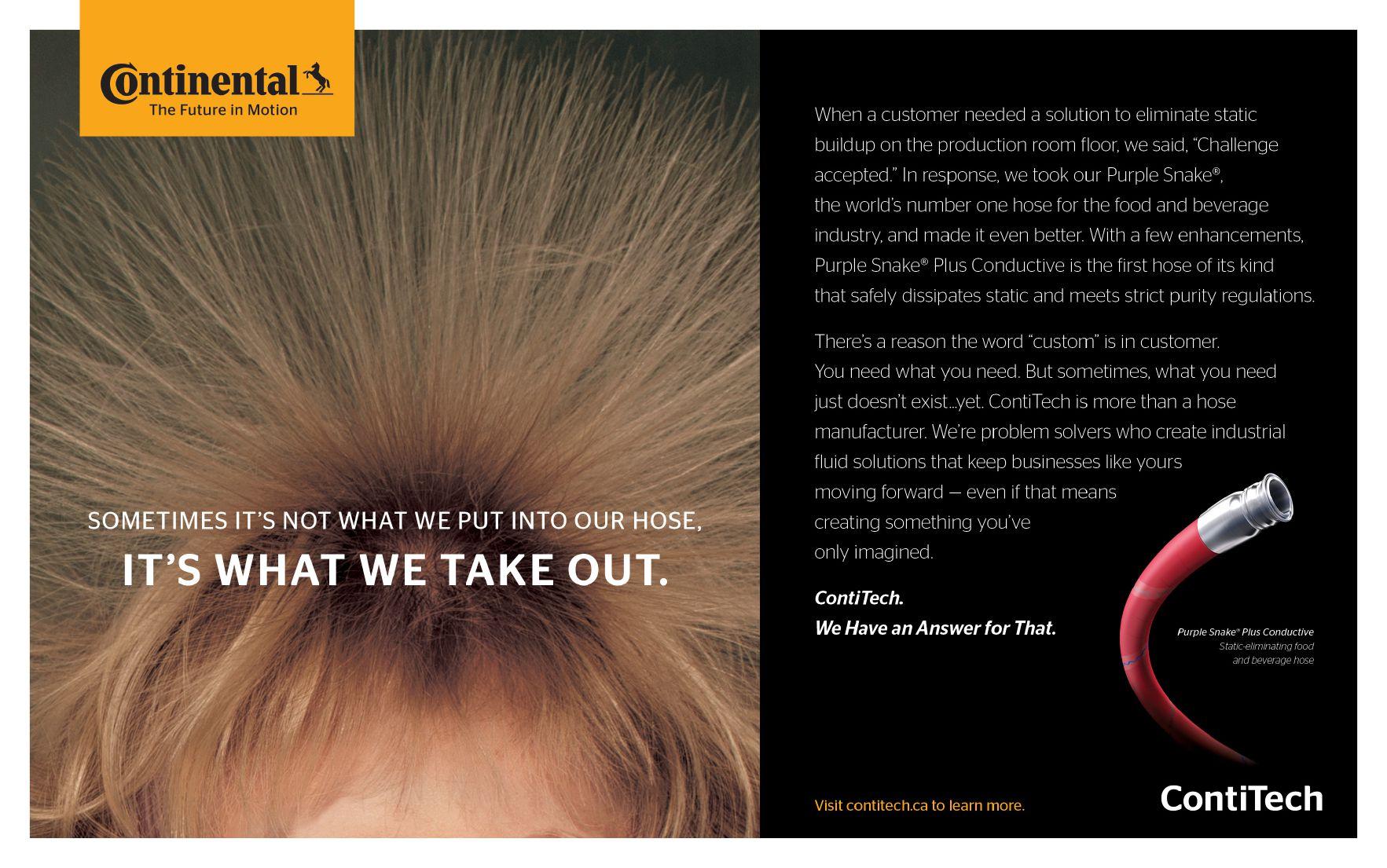

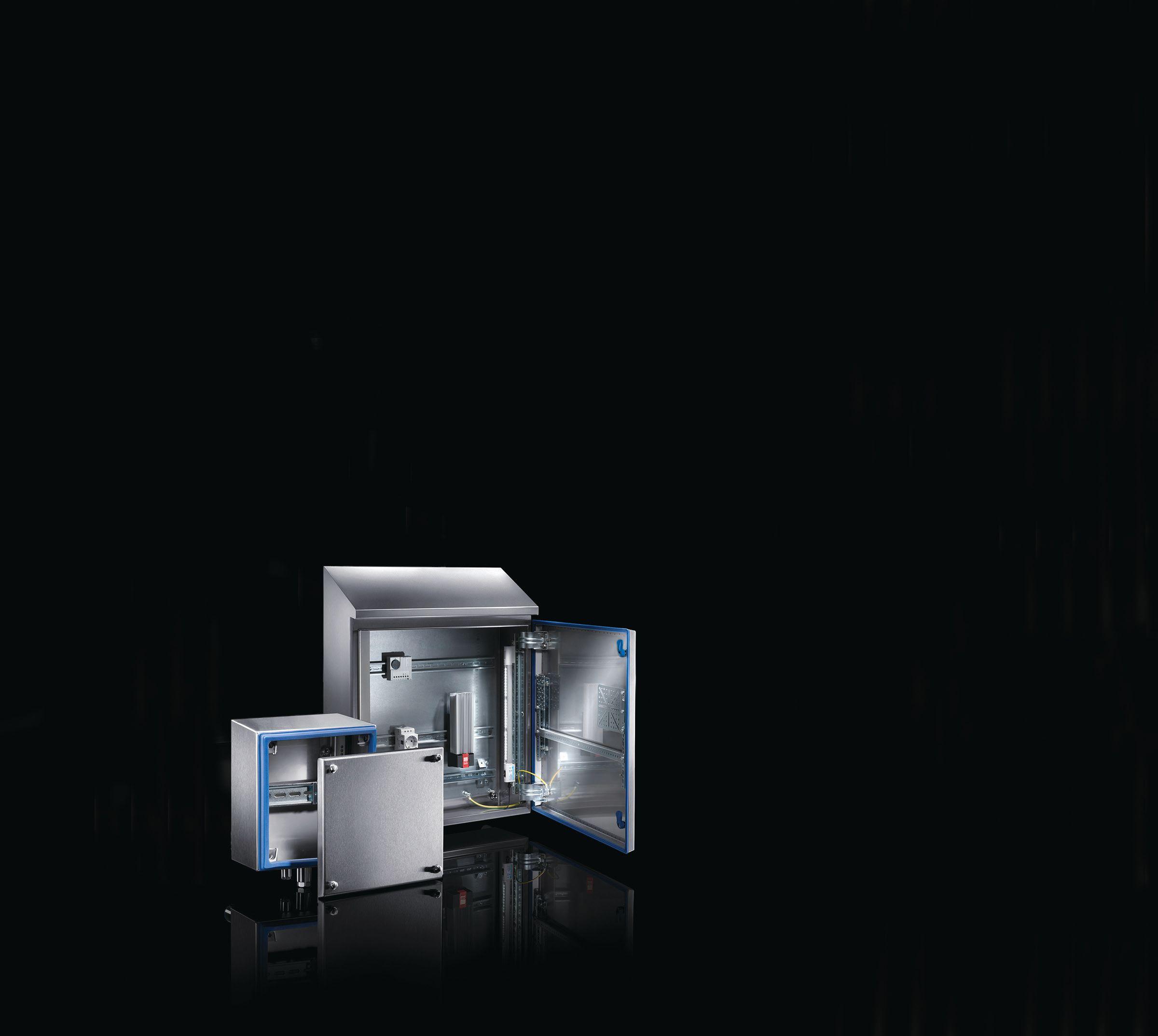

IP 66/69K, cUL approved!

Specially designed to handle the unique hygiene needs of the Food & Beverage industry, when traditional enclosures may fail to provide required levels of protection!

• 30˚ forward sloping and overhanging roof repels water, bacteria & objects

• Joint-free exterior blue gasket is easy to see, clean, replace

• Stainless steel construction and no dead zones for material and bacteria to accumulate

• Hinges are completely internal, so cleaning is not an issue

*Visit rittal.ca/hd for your F & B Guide, or contact marketing@rittal.ca for more information

BY MARIO CYWINSKI

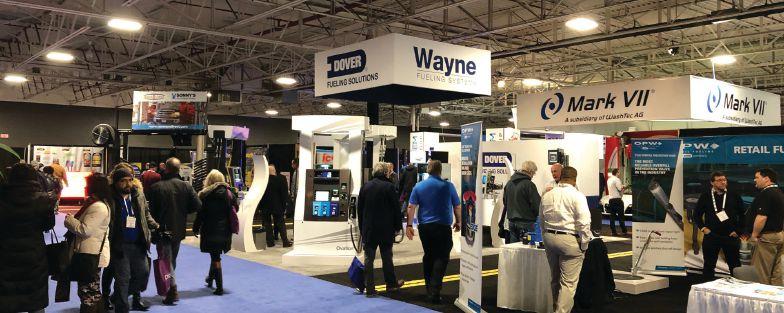

The 16th annual Convenience U CARWACS show was recently held at the Toronto Congress Centre in Toronto, Ontario. The show is touted as Canada’s largest convenience, gas, and wash industry event. While the main part of the show is the trade show floor, it also offers keynotes and informative sessions for visitors.

This year the keynote topic was “From the place to buy to the place

to be: Staying relevant in a hyper competitive industry” presented by Tony Chapman, a leading communications expert.

Other sessions included “Cannabis is now legal. So what Now” presented by Constable Amy Boudreau with the Peel Regional Police and Larry Masotti, Director, Strategic Relationships, at the Workplace Safety and Prevention Services; A great workplace culture is good for your business by George

Anastasopoulos, Chief Outcomes Engineer, Leadership Fundamentals; Hiring the right people for the right job by Gail Green, Owner and President, Emergenetics Ontario; and Leveraging OLG innovations to create excitement and drive customers to your store. The trade show floor was filled with companies in the food and beverage industry, convenience industry, car wash and gas industry, as well as companies who provide machines to those industries. Examples include Duro-Last Roofing, Eurovac, Hamilton

Manufacturing, Kleen-Rite Krown Rust Control, RDM Industrial Electronics, STI Conveyor Systems, Western Refrigeration and Beverage Equipment, and many others.

Those in attendance who wished to participate also had the opportunity to partake in the Canadian Carwash Association semi-annual car wash tour.

Mario Cywinski is Editor of Machinery and Equipment MRO magazine, a member of AJAC and a judge for CTKC. He has more than 15 years’ automobile industry experience.

BY JENNIFER ELLIOTT

Earlier this year, Second Harvest, a Toronto-based organization that connects suppliers and distributors with non-profit organizations to help divert food from landfills, partnered with Value Chain Management International (VCMI).

The partnership produced “The Avoidable Crisis of Food Waste,” a study aimed at increasing awareness around Canada’s food waste crisis. It found that nearly 60 per cent of food produced in this country is lost or wasted each year. Further, when food waste ends up in landfills, it creates methane gas (which is 25 per cent more dangerous to the environment than carbon dioxide), which adversely affects the environment in Canada.

The findings in the study suggest that approximately 30 per cent of our country’s food waste can (and should) be rescued, leaving 70 per cent. Although much waste occurs before it ever reaches the consumer, hospitals, restaurants and institutions account for approximately 13 per cent of overall food waste in Canada.

Though this may not, at first glance, seem egregious, when combined with the accumulative associated costs like energy, water and labour (which, studies suggest, may be 2.5 times higher than the face value of the food waste itself), it is significant.

Not only is reducing food waste a best practice from a social/environmental perspective, a well-managed institutional food-waste program

may have the added benefit of having a positive impact on an organization’s culture and it’s bottom line, both of which help support positive impact to the top line.

What steps can restaurants and institutional kitchen operators take to help minimize their foodprints?

There is an old adage

identify and address obvious and quick fixes first. A tip-to-toe walkthrough of the kitchen and storage areas, with a view to evaluating inventory levels, state of repair of equipment and maximizing shelf life, is also in order.

Operators of kitchens in franchised businesses must blend efforts to minimize waste with their contractual obligations to remain in compliance with brand

standards around menu offerings. This often means they are essentially required to prepare more food in a day than they will sell. In these situations, it’s essential for operators to work closely with restaurant leaders and production staff to maintain minimum levels in non-peak periods and to maintain detailed records throughout the course of the business day. Where food waste is unavoidable, and

suggesting we can’t manage what we don’t measure, so the first step in the process is to figure out how much, and what is being wasted in kitchen(s) by conducting an audit of both raw and retail foods. This may be done manually or by embracing advancements in technology waste-tracking systems, and by working closely with teams to

where possible, retail food-service operators should strive to collaborate with local organizations to redirect waste through donations to help address issues of food insecurity in our communities. If that’s not an option, it might also be worth considering donating scraps as animal feed. If both of these streams of food rescue are inaccessible, efforts should be made to compost food that is not sold through at the restaurant level.

Operators of unique, one-off restaurants have the luxury of creating their own menus, which gives them a leg up when it comes to managing food waste, as they have more flexibility around maximizing food use (ensuring foods that appear on menus, and are therefore maintained in inventory, work in more than just one recipe), by being able to choose their vendors (local) and adjusting menus seasonally.

Adjusting storage practices to extend freshness and implementing standards around portion calculations and control also helps. Of course, daily and weekly specials

Did you know? Only five foods expire and should not be eaten after a best-before date: meal replacements, baby formula, protein bars and a couple of prescriptions. Best-before dates identify “key freshness” and do not speak to safety.

were originally designed, and have long served, to help operators deal with surplus foods, and taking time to create menus, and stock kitchens, with ingredients that serve more than one purpose is helpful. As is a movement towards “nose-to-tail” cooking, a practice emphasizing using every part of a food source in a recipe or

recipes. Independent operators, and their production teams, may also exercise their creative muscles to make the most of scraps.

Leaders in both types of foodservice operations will benefit by embracing the following best-practices: adhering to first-in, first-out (FIFO) rotation, storing all foods

properly, putting a stop to over-prepping, investing in, and monitoring, high-end, energy-efficient equipment, conducting regular inventories to help minimize over-ordering, and eliminating any “niche” or nonrequired ingredients. Both types of food-service operations should be smart with working to extend the shelf life of cooking oils by skimming and cleaning regularly, and disposing responsibly.

One of the very best ways to fix problems in food-service operations is to increase awareness, that is, to start talking more about it, keeping eyes, ears and minds open to embracing innovations in equipment, technology and other initiatives designed to minimize food waste.

Jennifer Elliott Cropper is a writer and part-time Professor with the School of Hospitality, Tourism and Culinary Arts at Centennial College in Toronto. Elliott blends her teaching and writing with her full-time work in QSR operations with Tim Hortons. She may be reached at jenniferelliottcropper@gmail.com.

Keeping cool when it comes to maintenance and repairs of commercial refrigeration units

BY ZACHARY ATTREE

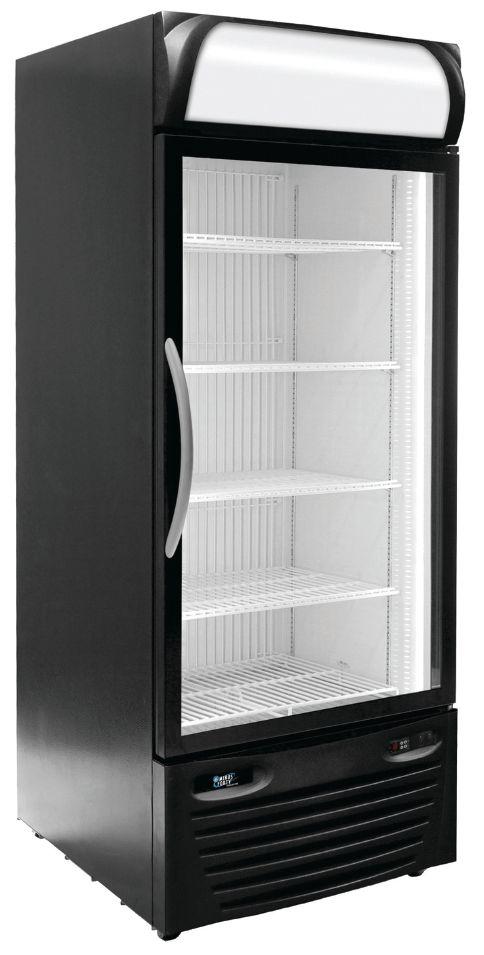

All along the cold chain, from the processing plant to the retail display cabinets (where some food manufacturers have to maintain their own branded coolers or freezers), frozen and refrigerated foods need to be preserved and monitored constantly, as do the refrigeration units they are kept in, to ensure food protocols and safe storage temperatures are maintained.

Given the innovations in the latest generation of commercial freezers and refrigerators, this is easier than ever. Environmentally friendly refrigerants, smart engineering features and design choices all combine to make maintenance and repairs as simple and straightforward as possible. For optimal operation, it’s important to look at everything from how the units are installed, to

how to properly load units to ensure they operate efficiently and experience fewer breakdowns.

The smooth operation of food and beverage merchandisers and display units depends on a regular maintenance schedule. Follow the manufacturer’s instructions and all other technical considerations. Beyond regular cleaning and maintenance, here are other issues, often overlooked, to keep units in top condition for a longer working life.

To keep food products fresh, it’s vital to keep the cold chain intact from factory to retail shop, and even temperature across all products stored.

This can affect the quality and shelf life of the product, depending on how long it is stored. If your business requires lengthy storage times for frozen products, ensure freezers have forced air functionality.

Refrigeration units need to have adequate airspace to allow for airflow, since hot air needs to move out of that critical area. Most units have a minimum tolerance for clearance at the back, so you are not starving the unit of airflow. Often a manufacturer will specify a six-inch gap behind the unit, this is often ignored, and units are pushed right up against the wall to save space.

TEMPERATURE SPECIFICATIONS

in which their units can operate. For instance, some freezers and coolers are designed to work in 30°C ambient temperatures. Most commercial units are designed for 24°C temperatures, while units intended for outdoor use can operate in temperatures as high as 38°C without compromising the interior temperature. Look at what the manufacturer has specified to ensure the right unit is in the right place in your operation.

cleaning of the interior, a regular check of the condensers is the most critical maintenance task in a commercial freezer. If the condenser is not kept clean, it cannot dissipate heat energy that is necessary for the refrigeration system to function. Prolonged operation in this state will cause the compressor to overheat and fail. In especially dirty environments, where airborne debris can be a problem,

it’s wise to exceed the manufacturer’s recommendations and inspect the condenser more often.

Some condensers are advertised as selfcleaning. They have a different, more innovative design that looks less like a radiator and more like a giant spiral with very big gaps. This design makes it very difficult for anything to get caught and create a blockage. It’s still wise to inspect

Different manufacturers specify different ambient temperatures

In addition to a thorough

them annually, especially if they are operating in challenging environments.

Another timesaving feature to look for is automatic defrost functionality. Defrosting units manually is time-consuming and costly, look for units that have auto-defrost functionality to avoid lengthy downtimes and additional labour costs. Finally, don’t overlook the gaskets that run along the edge of the inner door. Depending on how frequently the unit is loaded and reloaded, these rubber seals can tear, leading to air leaks and inefficient operation.

Gone are the days when freezers and coolers had dials with imprecise temperature controls. Today’s modern units have electronic digital display controllers that will indicate an exact temperature and maintain a much tighter temperature range within your unit. In addition, a Smartlock will issue an alarm and automatically lock the door of a unit whose internal temperature rises above a pre-set safe limit.

If you’re experiencing fluctuating temperatures, it might be because of the load of your unit. Cabinets are better able to maintain a stable temperature when they’re full. This is because

the frozen products inside have a thermal mass that helps maintain the interior temperature, even when warm air is introduced through an open door. If you picture an empty freezer and another unit beside it full of ice cream, open the door on the empty freezer and the temperature will change much faster than the full one for this reason. To mitigate, try to keep all units evenly filled with product, helping to mediate interior temperatures.

Typically, the top part of a commercial unit is where you find the evaporator, which operates with fans that can be blocked when a unit is overloaded with product. This can be as bad for the unit as having a blocked condenser, yet many people aren’t aware of this, and will load a unit

without thinking about air circulation, which is vital to its operation. Many units have “load limit” stickers. These indicate the maximum area of the unit that can be loaded with product. Looking forward, it is likely that with connectivity and the associated costs thereof becoming more and more competitive. You will start to see manufacturers offering units that are always online. Some potential benefits of this will be their ability to send you alerts when the unit is down, and possibly to send preventative alerts indicating that the condenser needs to be cleaned, or to check that the unit is not overfilled.

Zachary Attree is the Innovation Manager at Minus Forty Technologies.

Advanced cooking and chilling technology improves freshness and optimum shelf life without the use of unappealing preservatives.

BY ED SULLIVAN

This just in… Canadians love potatoes.

The headline is a bit like “Dog Bites Man,” not all that surprising. What is surprising is the shear amount of potatoes consumed each year in North America. According to recent reports, the average person consumes over 20 kilograms per year.

For any food processor making a prepared dish utilizing the popular tuber, the only practical way to satisfy regional distribution demands is to make a lot of product (thousands of pounds per hour). Until recently, this often forced food manufacturers to add unappealing preservatives to ensure the massive amount of product stays fresh. However, by using more advanced cooking and chilling technology,

processors can ensure the potato product is fresh and delicious, while offering optimum shelf life without the added preservatives.

Among the more sophisticated cooking systems that are perfect for potato products (such as potato salad) is the vacuum-sealed retort, a vessel used to cook diced potatoes within half an hour, and then chill the product to 35 degrees (Fahrenheit) within 17 minutes, through an evaporative cooling system that uses no refrigeration.

“This type of system enables producers of fresh produce to cook and mix high volumes very quickly with equipment that requires a relatively small footprint compared to linear systems that require refrigeration or mechanical cooling,” said Carl Illiff,

According to Illiff, because the potatoes are cooled and chilled within a sealed retort, the food is not exposed to air when being chilled, which occurs with mechanical systems such as a blast cooler.

“If a producer were to chill the diced potatoes in a blast cooler, it would take 18 to 20 hours to cool it,” said Illiff. “And in the process, it will be exposed to the bacteria, mold and yeast that is being circulated through these fans on the cooler.”

Illiff adds that when food is exposed to such biological organisms, shelf life will be compromised unless the processor adds preservatives, something that consumers don’t want to see on the labels of fresh foods.

The diced potato retort, is used by some food processors to cook chickpeas and other vegetables, The main part of the system, a cylindrical chamber loaded with carts and trays, is all stainless steel and capable of a holding a vacuum of over 30 inches. The retort is normally between 12’ and 22’ long, and about 5’ in diameter, depending on customer specifications. Smaller

models can cook and cool 2,000 lbs of potatoes per hour; the largest can cook up to 8,000 lbs per hour.

Contained inside an upper chamber in the retort are a shell-and-tube condenser and a liquid-ring vacuum pump, which are, in turn, connected to a cooling tower. The shell-and-tube condenser provides evaporative cooling under high vacuum pressure created by the pump. Evaporated water is circulated from the condenser to the cooling tower and back to provide a continuous chilling effect.

“This cooling processing is amazing,” said Illiff. “When you remove the diced potatoes, they are nice and cold, and ready to mix with the potato salad dressing, then packaged and shipped to the customer, all with hardly any exposure to air.”

When you have 4,000 kg of potatoes steaming with heat, you can’t afford to have anything less than a reliable cooling system. Otherwise you’ll end up with four tonnes of mashed potatoes.

When Illiff first looked for a complete solution to cool his tots for potato

salad, he understood that incorporating a cooling tower was the key to creating a seamless, effective process. However, sourcing one that met his criteria turned out to be tougher than expected.

“We were very concerned about the reliability, service requirements, and lifespan of the cooling tower,” said Illiff. “Our cooling system is very demanding, and dependent on the tower working efficiently for a long period of time.”

In exploring the cooling options available, he found that the majority of models were traditional, galvanized metal-clad design. Due to the inherent weaknesses of traditional metal cooling towers, he was not satisfied with the engineering, which promised

to be maintenance intensive with frequent periods of downtime.

Eventually he found a fit for his operation, an alternative to a traditional cooling tower, which had durability and performance characteristics. The design featured a high-density polyethylene (HDPE) shell and enclosed direct-drive motor assembly that provided highly reliable operation with very low maintenance.

HDPE cooling tower shells are virtually impermeable to corrosive elements, including water treatment chemicals such as chlorine and UV rays.

“We found an HDPE cooling tower at Delta Cooling Towers, the manufacturer that originally developed the “plastic” design, and has installed industrial, commercial and institutional systems nationwide since the 1970s.”

Benefits of the cooling tower technology include the variable-speed, direct-drive motors that run the system fans and have proven to be far more efficient than belt-driven or gear drives, which are subject to failure over time. The cooling tower design also requires considerably less horsepower therefore consuming less energy and providing some users up to an 80 per cent savings in electric power. Also, the HDPE cooling towers were available in a wide range of sizes from 10 up to 2,500 tons.

“These cooling towers are also lighter in weight,” said Illiff. “Only a relatively simple stand is required to support it. We installed another one recently and had the entire cooling tower system up and running in half a day.”

Ed Sullivan is a Los Angeles based freelance writer with over 30 years of expertise in the mechanical engineering, HVAC, and process cooling industries.

Enhancing knowledge, leveraging expertise, benchmarking, dialoguing with peers and building relationships, it’s shaping up to be an extremely exciting year of learning opportunities.

It really doesn’t seem that long ago since a group of interested like-minded manufacturers came together to learn and share in a peer-topeer setting. It’s been almost 30 years since EMC (Excellence In Manufacturing Consortium) first began in Owen Sound, Ontario. A not-for-profit organization, EMC continues to unite manufacturers of various sizes and sectors across Canada on all aspects of enabling business competitiveness, This includes providing programming and services that build and strengthen our knowledge, capabilities and connections. With enhancing knowledge always in mind, this year we are hosting the fifth EMC National Advantage Through Excellence – Future of Manufacturing Conference on October 8 to 10 at the Universal Event Space in Vaughan, Ontario. Three days of streams featuring best practices, subject

matter experts, industry leaders, exhibitors, plant tours and plenty of opportunities to network with peers, participants and speakers. We will be exploring advanced manufacturing and innovation; export development and growth; operational excellence; and the future state of manufacturing, and more. Information on speakers, sessions and agenda can be found at www.FutureofMFG.ca.

Leading up to this is an open Invitation to join us at one of EMC 2019 food and beverage sector networking events. In April, is a visit to Burnbrae Farms Ltd., in Lyn, with the topic Talent Attraction and Retention Best Practices. Reunion Island Coffee will be hosting a May event, titled A Journey of Growth with Reunion Island Coffee, where participants will have a chance to hear about business growth and ERP implementation. Later in the year, HFS – Healthcare Food Services in Ottawa will be sharing their World Class Food Safety Best Practices. All of these sessions are complimented with plant tours and general roundtable networking.

In keeping with the opportunities to learn, our EMC Team is always honoured to participate in

conferences and special events that benefit the manufacturing sector and 2019 promises to be a very interesting year in that regard.

Fresh back from the 2019 RC (Restaurants Canada) show and once again in awe of the breadth of food and beverage products on display. Supplementing the samples and smells, were key components of manufacturing including packaging materials and equipment - all available to industry and restaurateurs.

Sustainability was this year’s theme at the RC Show, which led to interesting discussions with attendees and exhibitors, their goals and achievements. Welcoming the occasion to connect and reconnect with participating manufacturers from across Canada to gain insight on their businesses and current challenges and opportunities

Recently, we attended the Conference Board of Canada’s Canadian Food & Drink Summit 2019 in Toronto and discussed “The Future of Food –What Will the Next Five Years Bring? ” Through interactive sessions, we explored key themes in Canada’s food sector. Those included: The Future

of Grocery Retail; Digital Technology; The Role of Innovation; Shaping the Canadian Food Distributor of the Future; Cultivating the Future of Food Safety while Earning Public Trust in Every Meal; Trading Way Beyond Agri-Food Export Targets by 2025; and Positioning Government and the Food Industry to Feed the Future and Drive Food Ambitions and more.

Strategy Institutes’ Annual North American Summit on Food Safety, celebrated it’s 15th year, recently this year in Toronto. Presentations from the Food & Drug Administration (FDA) and the Canadian Food Inspection Agency (CFIA) started this year’s Summit and over the course of two days learned from industry leaders and best practices on variety of topics, including: global standards; training programs; managing compliance; emergency preparedness approaches; block chain technology in food safety; among many others.

Joining an EMC food and beverage networking event or participating in industry or sectoral conferences and trade shows provides a perfect forum to build new ideas, gain insight on innovative

concepts and the chance to form long lasting relationships with companies on similar journeys.

We enjoy celebrating the triumphs of small business throughout the province and sometimes we do not have to travel far to appreciate a company’s journey, gain insight on their success, best practices and lessons learned.

This month I celebrate a special entrepreneur who has taught me a lot in her four years of business – “The Back Forty Baker.” A winner of the 2019 local Chamber of Commerce Best New Business Award. I applaud her dedication to keeping her business plan relevant and her short and long-term goals achievable. Admiring her spirit for trying new things, creating products, accepting failure as an opportunity to grow, and for her determination to succeed. Her nomination (and win) is more than that, it reminds us of all the companies that EMC has met over the years who have

worked tirelessly creating their products, and the goals achieved in improving them, diversifying where they could, building customer and retail relationships. Above all, we are reminded of those who employ their passion and determination to actively seek new ways to grow their business and give back to the communities they live in.

If you are interested in learning more about involvement in EMC’s SIG (Strategic Interest Groups) or our special food and beverage sector networking sessions, please feel free to reach out and we would be happy to share information on what is coming up in your region.

How do you get involved? If you are interested in learning more about EMC (Excellence in Manufacturing Consortium) and the Food Sector Initiative, please feel free to touch base with Bren de Leeuw, Director - Field Operations Canada and EMC Food, Beverage and Bio Sector Program (bdeleeuw@emccanada.org) anytime.