FOOD BEVERAGE

Three technology disruptions that can’t be ignored in 2016

Oven and dryer OEMs benefit from teamwork with suppliers

Simplify sanitation procedures for paper towel dispensers

Three technology disruptions that can’t be ignored in 2016

Oven and dryer OEMs benefit from teamwork with suppliers

Simplify sanitation procedures for paper towel dispensers

The manufacturing industry is a highly competitive one but thanks to NORD Gear’s new sealed surface conversion system, companies can reduce their equipment costs without sacrificing the high quality and durability needed in the harshest of environments.

NSD TupH is a revolutionary surface protection that offers manufacturers an alternative to stainless steel gearmotors at a fraction of the price. Lighter and less costly than stainless steel, the corrosion-resistant, non-flaking surface stands up to acids, alkalis, chemical cleaning, high humidity and other challenging conditions found in industries like food and beverage, pharmaceutical and wastewater. Testing has shown that NSD TupH by NORD is seven times harder than basic aluminum and 1,000 times tougher than paints and lacquers.

Enter NSD TupH. From the tough, corrosive chemicals used to wash down equipment in a meat processing plant to the harshness of saltwater that naturally occurs in fish processing facilities, NSD TupH ensures the drive is well-protected. Manufacturers have soon recognized why NSD TupH’s unique wash down design is so groundbreaking — it can stand up to the rigors of repetitive and intense cleanings without the risk of the surface blistering, flaking , peeling, rusting and any other type of corrosion — and is substantially lower in cost than stainless steel.

The surface protection system works at the molecular level, using

Stainless steel has traditionally been used in manufacturing applications where sanitation and cleanliness are not only preferred but often regulated by government agencies. But its high cost, heavy weight, limited product availability and poor thermal conductivity are reasons why the market has been waiting for an alternative, lower cost option that doesn’t chip, corrode, flake, peel or scratch like paint, nickel and nickel Teflon.

an electrically catalyzed process that bonds the base layer to the aluminum alloy housing material. Followed up with a sealer, the final result is a nonporous, long-lasting, durable piece of equipment that boasts the corrosive resistant properties of stainless steel without the hefty price tag. Stainless steel hardware, optionally available stainless steel shafts and smooth TupH motors combine with optional food grade lubricants to make NORD’s NSD TupH the ideal choice for many applications. Gearmotors and NEMA input reducers protected with NSD TupH are known to be as tough and long-lasting as their stainless steel counterparts, but are they safe? Each is rated in accordance with NEMA MG1 for voltage spike resistance, has a minimum IP66 ingress protection rating (it’s dust-tight and protected against powerful water jets), and features inverter/vector duty wiring and insulation for additional protection. Four continuous duty, premium efficient (IE3) motor sizes

ranging from 0.5 to 1.5 hp with an IEC B14 flange mount are available in common 50 Hz and 60 Hz voltages with many motor options available. NSD TupH gearmotors also provide for a significant weight advantage. Since aluminum alloy is much lighter than stainless steel, mounting and maintaining either new or replacement parts becomes much easier and safer. What makes NSD TupH gearmotors and NEMA input reducers so unique are the qualities that allow them to not only survive but thrive in today’s toughest manufacturing environments. Gearmotors and NEMA input reducers protected by NSD TupH are sold and supported worldwide and free freight shipping is available across Canada. All customers, locally and globally, can take advantage of NORD’s product versatility and on-time delivery.

To learn more about NSD TupH and discover a revolutionary option in gearmotors, visit nord.com.

PUBLISHER

Jim Petsis

jpetsis@mromagazine.com (416) 510-6842

SALES MANAGER

Jay Armstrong jarmstrong@ mromagazine.com (416) 510-6803

PRESIDENT & CEO

Mike Fredericks

VICE-PRESIDENT

Tim Dimopoulos tdimopoulos@ canadianmanufacturing.com

In Co-operation with

Rehana Begg

rbegg@annexweb.com (416) 510-6851

ART DIRECTOR

Stewart Thomas sthomas@annexbizmedia.com

ACCOUNT CO-ORDINATOR

Tracey Hanson thanson@annexbizmedia.com (416) 510-6762

CIRCULATION MANAGER

Beata Olechnowicz colechnowicz@ annexbizmedia.com (519) 376-0470 (866) 323-4362

PRESIDENT & GENERAL MANAGER

Al Diggins • adiggins@emccanada.org

DIRECTOR OF STRATEGIC PLANNING & COMMUNICATIONS

Scott McNeil-Smith • smcneilsmith@emccanada.org

SENIOR COMMUNITY DEVELOPMENT MANAGER Bren de Leeuw • bdeleeuw@emccanada.org EDITOR

In a tentative step, Canada’s international trade minister, Chrystia Freeland, signed the TransPacific Partnership (TPP) deal in a ceremony in New Zealand in February, marking the beginning of a two-year ratification phase.

The TPP trading block represents 800 million people and encompasses 40 per cent of the world’s economy or a combined GDP of $28.5 trillion. Being left on the sidelines of the deal would jeopardize Canadian agriculture and agri-food exports to the region and can have potentially devastating effects for our sectors.

From 2012 to 2014, Canada’s agricultural and agri-food exports to TPP countries were worth, on average, $31.2 billion annually. The TPP Agreement benefits the entire sector, from producers to processors. While the deal gives Canadian products preferential market access to all TPP countries, it bolsters Canada’s competitive advantage over competitors outside of the TPP. In fact, 81 per cent of Canada’s total exports already go to TPP members.

The TPP, which covers all sectors of the economy, includes 12 Pacific Rim countries, including Canada, Japan, Australia and the United States. In export-oriented agricultural sectors – including

pork, beef, grains and oilseeds – the opportunity would create a level-playing field for Canadian producers competing with their U.S. and Australian counterparts and result in access to markets such as Japan, Vietnam and Malaysia.

But for some, the deal fell short. Canada’s sugar beet producers drew a short straw in securing access to U.S. markets.

During TPP negotiations, a key focus was on supply-managed sectors. There were new market access concessions for Canada’s dairy, poultry and egg producers. Making an effort to moderate negative impacts that Canadian dairy, poultry and egg producers may encounter as result of this increased market access, the Government of Canada announced a $4.3-billion compensation program prior to the 2015 general election.

Under the TPP and Canada-EU Trade Agreement, three pillars of the supply management system would remain protected. The following programs will be implemented:

• The Income Guarantee Program will keep producers whole by providing 100 per cent income protection to producers for a full 10 years from the day TPP comes into force. Income

support assistance will continue on a tapered basis for an additional five years, for a total of 15 years. $2.4 billion is available for this program.

• The Quota Value Guarantee Program will protect producers against reduction in quota value when the quota is sold following the implementation of TPP. $1.5 billion has been set aside for this demanddriven program, which will be in place for 10 years. More than 246,000 Canadians employed in the sector work in the processing end of the industry and opens new markets for the food processing and beverage industry.

Download the text of the Trans-Pacific Partnership.

Rehana Begg Editor, Food & Beverage Engineering & Maintenance rbegg@annexweb.com

Three disruptions the food and beverage sector can’t ignore in 2016.

BY JAKOB BJÖRKLUND

Disruptive technology has shaken up the manufacturing industry over the past few years and has reached a point of ubiquity that can no longer be ignored. Following are three ways in which the food and beverage industry will be affected this year.

ADD THE INTERNET OF THINGS INTO THE MIX

We will see a significant increase in process manufacturing companies collecting transactional data and exploring Internet of Things to increase traceability. None more so than the food & beverage industry, where customers are demanding visibility into every step of the supply chain to see exactly where

their purchases came from.

The Internet of Things is still relatively new to process manufacturing so things aren’t going to happen overnight. This year will be another year for businesses in the process industry to watch and learn. There are companies out there that are leading the charge, particularly in the pharmaceutical industry, which needs to prepare for the EU Falsified Medicines Directive that is expected to go live in 2018. In the Food & Bev industry, the upcoming sanitary transportation rule is set to be finalized in the Spring, requiring companies to make sure food distributed and consumed in the U.S. doesn’t get contaminated during the supply chain. The technologies that will

enable food and beverage manufacturers to meet such directives are crucial, particularly around traceability, and 2016 will be the year that they study and acquire these technologies to ensure that they can be rolled out across the global supply chain in time.

The collection of data via sensors and scales is not new to the process industry – in fact, companies that run asset-intensive processes at really large-scale have been doing it for decades. But, historically, this ability to collect data has come with a big price tag. The Internet of Things heralds a new age for an increased level of traceability, one that is no longer the realm of larger companies but opens the door for smaller businesses. Now everything has some sort of sensor and can be traced, from forklift trucks to storage locations, pallets to trucks. Roughly 25 per cent of our customers are

collecting transactional data today. This number will increase to around 80 per cent in the next five years because of the increase in availability of this technology and a decreased entry cost.

The Robot Revolution will impact the process manufacturing industry Smart machines, or robots as they’re more commonly known, are increasingly working their way into the process industry, expected to perform many routine tasks in manufacturing and warehousing. Gartner predicts that by 2018, 50 per cent of the fastest growing companies will have fewer employees than smart machines. We’re not just talking about the machines that build cars in commercials. We’re talking about smart machines that are highly autonomous and able to make their own decisions. For example, a robot that picks customer orders will decide on the most efficient route

and make product allocation priorities in the case of a shortage. Today, these decisions are carried out by humans, often on the basis of a recommendation from the WMS or ERP system. Companies are already starting to experiment and we will see wider adoption of smart machines in 2016. This adoption will also lead to changes in ERP solutions as well – interfaces will change, they will need to deal with more transactional data and, above all, they will provide information necessary to make decisions rather than making the decisions within the ERP. With widespread adoption continuing to grow, 2016 will be a year where process manufacturers increase their investment in smart machines to achieve efficiencies. However, the complexity of supply chains and manufacturing processes mean that widespread adoption across the value chain will take longer than 12 months. Customers will demand highlevel product traceability in a

growing number of industries

I have a particular interest in the rise of adoption in public cloud services as a platform to manage the data produced by traceability.

By this I mean providing consumers with the ability to scan the barcode on their sirloin steak at the supermarket and track its journey from the farm to the supermarket shelf.

This is only possible through traceability in the supply chain – from the manufacturer who will register the goods, which are then picked up by the transport company that can log weight, kilometres driven and even the temperature of the vehicle, to the shop that registers arrival and logs into its system and so on.

This level of traceability is becoming increasingly important for food manufacturers that view brand reliability as absolutely crucial. Ever since the well-known horse-meat scandal that impacted the food industry a few years ago, these companies will do everything to ensure that the product they sell is absolutely perfect. Widespread roll out of this level of traceability is still a little way off, but not by a million miles, so companies will need to spend 2016 putting a strategy in place for the deployment of this technology. This article was submitted by Jakob Björklund, Industry Director for Process Manufacturing at www.ifsworld.com.

Oven and dryer OEMs can benefit significantly by teaming with suppliers to specify infrared elements

Infrared heating technology has become prevalent among industrial ovens, dryers and heaters used by a multitude of industries ranging from metalworking, thermoforming and printing, to the manufacture of adhesives or pulp and paper. The OEMs who manufacture these ovens and heaters use infrared heating elements, which are more energy efficient, cheaper to operate, provide controllable heat and are significantly more environmentally friendly.

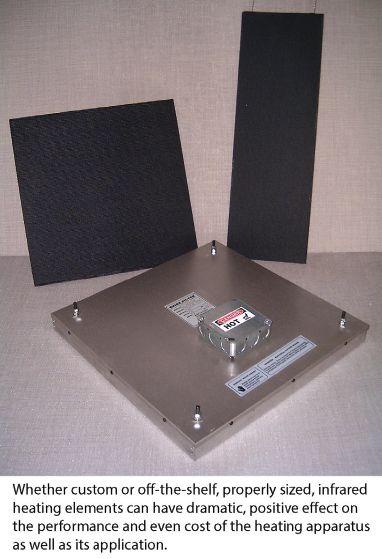

Infrared heating elements are available in standard, off-the-shelf designs such as flat panel models, but there is a host of custom infrared elements that have been developed by OEM suppliers to meet the unique requirements of specific applications.

Whether custom or off-the-shelf, properly sized, infrared heating elements can have dramatic, positive effects on the performance and even cost of the heating apparatus as well as its application. So, it benefits the OEM to collaborate with its supplier before settling on element design parameters and specifications.

Oven/heater applications can vary widely among market segments, even within the same industry. For example, within the printing industry, different heaters or elements are used by screen-printing, paper, and 3D-printing industries.

“There may be some standard specifications within the OEM models available for some specific applications, but in many cases the

OEMs don’t have the in-house technical resources to determine exactly whether an off-the-shelf element is suitable or if a custom design is required,” says Jesse Stricker, founder of INTEK Corporation (Union, MO).

“Or they may not have the experience to consider all of the intricacies of heat transfer, reflection and controls.”

INTEK is a manufacturer of heaters and elements for industrial ovens and dryers used in continuous process heating for production automation and material handling in a wide range of industries.

Stricker, who has been involved with the industrial heating field for over 40 years, says that in many cases it is quite practical to tailor infrared heating elements to provide the exacting performance necessary for the heater/oven to provide optimum productivity and minimum downtime in a given application.

“To say the least, the specifications

should be confirmed with the heating element supplier,” Stricker says.

Whether standard or custom element design is anticipated, certain design criteria should be established with the element supplier at the outset.

“OEM designers sometimes use different terminology, so the first question we usually ask is, ‘Do you need a filament, element or heater,’”

says Stricker.

Basically, a filament is the bare heating wire (usually nichrome) that generally requires some sort of additional construction to provide a finished, usable element. An element generally consists of a filament wire encapsulated in a ceramic body or suspended by ceramic bushings and includes terminal wires necessary for connecting to supply power. Heaters generally consist of a heating element and insulation contained in a sheet metal housing suitable for installation using brackets or structural framework of some design. Next, what is the desired size of the element, which is determined

by the actual heating surface needed for your application? What are the dimensions of the heater frame? Where will this be installed?

What are the electrical specifications: watts, volts, amps, ohms? Does it require single-phase or three-phase operation?

The next thing to be considered is how the filament, element or heater is connected to supply power and what the location is of each element lead wire, as well as the method of attachment or termination required.

“The element supplier should be able to resolve all of these (above) requirements,” says Stricker.

that you get a personal response, and get to talk with someone who has experience with the application in question,” says Stricker. “I feel that the most effective way to provide support is through face-to-face meetings with the OEM’s design group. That may be a little bit more time consuming, and may involve flying or driving some distance, but we feel it is important.

Of course, in some instances Skype might be as effective as meeting the people in person.”

Stricker says INTEK also provides its OEM customers with an approval drawing for each new element design.

“Expect thoroughness from your supplier and good response time,” Stricker advises. When his company completes a design they offer to stock the element so customers won’t have delivery problems. This service is performed in several different stages: raw materials, work in progress and finished goods are all kept on hand. This type of service enables OEM customers to meet their delivery requirements just in time when they are in short supply.

Stricker adds that it is important to OEMs that suppliers maintain strict confidentiality.

Whatever the element design specifications, they should be discussed and confirmed with the supplier whenever possible.

“I believe it is important that a supplier is willing and able to provide support from design to completion,

“The digital drawing illustrates our design discussions and how we understand the requirements of the application,” he explains. “It is an important tool that helps us obtain customer approval before going into production.”

Value-added services can in some cases be vital to the success of a customer-supplier relationship. For example, they can include extra services or assurances that supplies will be available when required.

“These days virtually all products and processes have some proprietary aspects”, he says. “That is why we share design concepts – not proprietary information. This is an important distinction that allows us to help our OEM customers achieve their goals in a unique manner, and yet protect their product and process information at the same time.”

For more information, contact INTEK Corporation at sales@intekcorp.com; or visit the website at www.intekcorp.com.

A paper towel dispenser that doesn’t need to be covered during high-pressure water spray downs.

BY TOM BERGIN

Health and safety will always be one of the most crucial elements within a workplace, and even more so in food processing environments, where employee and consumer safety are of the utmost importance. To help mitigate risk, staff and visitors alike must adhere to strict hygiene practices including handwashing and high-pressure water spray downs. Hand washing stations are often located in processing areas and can be subjected to overspray from washdown procedures. Given the risks of bacteria growth and crosscontamination associated with wet environments and the requirement for frequent hand washing by staff, it is important to provide food processors with tools that operate

efficiently under these conditions.

SCA, producer of the Tork brand of AfH professional hygiene products, commissioned an independent research firm to fully understand the paper towel dispenser needs of hand washing stations in food processing facility environments. The study found that, in addition to a certification from HACCP International, an ideal dispenser would offer increased durability and ease of refill, accommodate more paper, have improved safety and contamination deterrents, as well as be available in modern and sleek design. Based on these findings, SCA recently unveiled the Tork Washstation Dispenser, a purpose-built paper towel dispenser designed to meet the rigorous standards of industry governance

and offer the high performance and efficiency demanded by facility managers.

Unlike traditional dispensers, the Tork Washstation Dispenser is water-resistant, thus does not need to be covered or removed from walls during routine sanitation procedures such as common high-pressure water spray downs. Furthermore, this dispenser was designed to channel water off the housing and away from

the refills inside. This means less time wasted by employees on water spray down preparation, and more time spent on actual cleaning.

The Tork Washstation Dispenser’s water resistance not only helps prevent water pooling, which can lead to bacteria growth, but also reduces waste when refills get wet during clean-up. In addition to saving time and reducing waste, the high capacity of the Tork Washstation Dispenser

improves plant floor efficiency –staying stocked longer means less downtime for refilling.

In addition to best-in-class water resistance to higher capacity roll system, the new Tork Washstation Dispenser was specifically designed for food processing facility environments with features such as hands-free dispensing, which limits the risk of cross contamination as employees only touch the towel they take. It is also the only dispenser certified by HACCP International, making it the most secure bet for processors seeking to strengthen their HACCP plans. And finally, facility managers can add a touch of design to processing areas thanks to the modern functional design and Tork performance dispenser colours (Aqua/White or Smoke/Red). The Tork Washstation Dispenser has been officially unveiled at the 2016 International Production & Processing Expo in Atlanta, Georgia, in January, and will be available for all North American food-processing facilities in April.

Remember: safety and risk management is an all hands effort, which is why those hands deserve the best tools.

Tom Bergin is the marketing director for Away-from-Home (AfH) Professional Hygiene business, SCA North America. Learn more about the Tork Washstation Dispenser at www.tork.ca/en/washstation.

“Give ‘em the razor, sell ‘em the blades,” a quote attributed to King Camp Gillette of the Gillette razor company, is perhaps the best-known example of a strategy driven by revenue through the sale of consumables. But there are numerous other examples from inkjet printers, to mobile phones, to coffee K-Cups.

While this is a legitimate strategy, it is most profitable when the company supplying the consumable can remain the sole source provider. When that is the case, prices and profit margin can be kept artificially high and the end user has no choice but to keep coming back for more.

Invariably, however, alternatives sprout up. Be it generic options or third-party suppliers, it is impossible to keep the lid on a consumable for too long.

Today, in the packaging world, this is playing out in the arena of film and paper banding. Many food and beverage processors use such banding

to secure lids to containers, as a security measure and to replace expensive pressure-sensitive labels. Banding is also used to replace bundling films to secure products packaged in corrugated trays.

Far from a “giveaway” product, banding equipment manufacturing is dominated by overseas companies. Still, those that invest in such equipment continue to purchase from the same source, unaware that less expensive domestic alternatives exist. As a result, the overseas equipment manufacturers hold a virtual monopoly on the pricing of film and paper banding rolls.

Google the word “banding” and the top results are sure to be related to the industrial steel, poly and polyester bands used to secure pallets or other boxed goods for shipping.

Less well known is the “other” type of banding – poly film and paper used to secure lids to containers and products packaged in corrugated trays by food and beverage companies.

These banding film and paper are often used as a more economical, “greener” (less waste) alternative to shrink film and poly bags.

At first glance, rolls of film and paper banding might be considered a commodity product. Available in a variety of roll sizes in clear or coloured poly, or brown and white paper, these consumables appear to be standard items that could be supplied by just about any conventional packaging supply house.

However, this is not the case. Most packaging supply distributors offer conventional packaging materials (stretch film, bubble, foam, corrugated and Jan/San products), but don’t have the converting capabilities to provide these films or paper, so they don’t offer them.

Only a rare combination of paper/ film distributor and converter is qualified to provide this type of material,

one that understands the specific details of the consumables required for the various overseas brands and the requirements such as thickness of the material, width and other key details.

Unlike overseas suppliers, which

can take weeks of lead-time to restock banding supplies, including production and shipping, a domestic source like Pacific Packaging can ship standard stock the same day and most special stock requirements within a few days.

Pacific Packaging, a U.S. film and paper manufacturer, distributor and

converter, offers a variety of banding materials slit to the required widths that work on automatic and selfstanding banding equipment from ATS, Felins, Wexler, Blumer USA, BandAll, PB 110, Polar Auto Cut, Busch, BL Products, MBO, Heidelberg and Akebono, among others.

Pacific is also an authorized distributor of the Akebono line of banding equipment.

that there are suitable domestic, third-party suppliers, Pacific Packaging supplies free banding samples for evaluation on customers’ banding equipment and in many cases will visit customers in person for on-site testing and evaluation.

A domestic supplier has other advantageous programs as well. Stable pricing can be further achieved with contracted blanket orders and dated deliveries for up to one year. This eliminates the extremely high prices of foreign material and ensures meeting budgetary forecasts. Since consumables must be continually ordered, the savings go directly to the bottom line.

Because there tends to be a lack of awareness

One attractive strategy being employed by Pacific Packaging Products, for example, is to offer consignment programs that allow the customer to only pay for the material they use on a monthly basis and also allows inventory and payment to be managed electronically. Consignment allows the customer to have 60-90 day supply in their warehouse. Should they suddenly get busy, the materials are readily available at their disposal. Furthermore, there are considerable transportation savings shipping 60-90 days compared to monthly shipments.

This article was submitted by Pacific Packaging Products. For more information or to request samples, contact Magdi Bichay at 978-808-8827 or visit filmandpaperbandingmaterials.com.

An old piece of equipment in a non-food environment, a

“Ferrari” actually, standing proudly amidst a relatively new, innovatively designed facility, caught my eye right away during a plant tour last week. Not familiar with anything, save the actual motor vehicle, this piece of equipment intrigued me for its name and its ability to continue production in a manner that complemented the newer systems around it.

I thought long and hard about that iconic piece. It seemed to be a testament to perseverance, patience and longevity and – through my limited name association alone –quality, efficiency and speed. It wasn’t so much about the product it produced, as it was from a symbolic standpoint. I considered our businesses in general and how, much

like that Ferrari, our companies are a mix of old and new. A mix of people, processes, equipment, and so forth. We require that mix – we need that old Ferrari as much as we need innovative new elements in our business.

We know in today’s environment that our companies have to be flexible, adaptable and innovative. This big old green machine represents a starting point and shows how old technology can open doors to creative thought – in essence becoming somewhat of a perfect stepping stone as we continually improve our machines and processes – it gives us the opportunity to set goals that lead to more efficiency with better systems, methodologies and opportunities to grow the business. Looking ahead, one thing we can all count on is change. There will be

new equipment, new processes, new computer programs, new people, new products, new customers, and new ideas for our companies in general. No matter how you look at it, we can all be sure that five years from now, business will be entirely different. Hopefully, with good maintenance and attention to detail, your Ferrari (whatever that may represent to you) will continue to produce and hold its own or spark your next innovative steps to be that much more flexible, adaptable and innovative to meet your customer demands!

EMC (Excellence In Manufacturing Consortium) has a plethora of resources available in our toolbox for keeping our businesses in peak condition! For the past 25 years we have striven to provide the latest information, connecting you with those who can enable your business growth,

and sourcing programs to keep you poised and ready to be competitive the year through. With a combined collective work experience of 217 years, our team is ready to assist manufacturers as best we can. Sharing best practices and providing plant tours are among the ways we transfer knowledge. With all things food, beverage, bio and ag processing in mind, we invite you to take part in our 2016 GF2 EMC Food Sector Networking Events. Upcoming sessions are listed below together with two excellent summit opportunities. A Food Sector Calendar is also available on the EMC Website (www. emccanada.org), which has the latest in event information.

EMC is also very excited to continue its series of GF2 Funded Productivity Training courses. Beginning in May across Ontario, these free Workshops,

those who directly support the industry.

A few topics to select from:

-Introduction to Lean Productivity (Lean 101)

which focus on lean and lean methodologies, are available to all food-, beverage-, bio- and ag-sector manufacturers and those who directly support the industry.

-Introduction to Lean Management Systems

-Productivity Action Plan Development

-Introduction to Value Stream Mapping

-Leadership and Culture for Productivity Improvement

-Productivity Lean Tools

Each of these sessions – whether peer-to-peer exercises, best practice sharing, plant tours, online webinars, subject matter expert case studies or formidable workshops as above, are an excellent way to ensure ongoing business success!

Each of our sessions – whether peer-to-peer exercises, best practice sharing, plant tours, online webinars, subject matter expert case studies or formidable workshops – are an excellent way to ensure ongoing business success!

05-Apr-16

Descon Conveyors, Newmarket, ON

Conveyor and Line Control Systems and Plant Tour

12th Annual North American Food Safety Summit Toronto, ON www.foodsafetycanada.com

20-Apr-16

To 21-Apr-16

17-May-16

To 18-May-16

An interactive Summit hosted by the Strategy Institute that examines a variety of topics including: Government Regulations, Contamination Prevention, Audit Preparation, Risk Management Improvement, Supply Chain Management and Traceability, Pathogen Detection and Microbiology.

EMC & NRCAN Energy Summit 2016 Sheraton on the Falls, Niagara Falls, ON www.energy2016.ca

Energy Summit 2016

02-Jun-16 Institute of Food Processing Technology - Conestoga College Cambridge, ON www.ifpt.ca

Wal-Mart Canada Corp. – Risk Management Best Practices and IFPT Overview of Food and Beverage Apprenticeship Programs and Pilot Plant Tour

13-Sep-16 Campbell Company of Canada Toronto, ON

A Journey in Energy Management Best Practices and Plant Tour

How do you get involved? If you are interested in learning more about EMC ( Excellence in Manufacturing Consortium ) and the Food Sector Initiative, please feel free to touch base with Bren de Leeuw, Director – Field Operations Canada and EMC Food, Beverage and Bio Sector Program (bdeleeuw@emccanada.org) anytime!

Everyday, thousands of Canadian manufacturers are connecting through EMC ... to skills and training, vital programs and resources, & EACH OTHER

Reduce costs | Connect to Peers and SME’s | Access resources | Grow your business