VTE4-L with Occupancy Sensor

LED vapor tight luminaire with microwave technology for accurate detection of application occupancy

Features:

• Easy to clean and service

• Stainless steel mounting hardware for wall, ceiling or suspended mounting

• 0-10V dimming driver is standard

• UV stabilized polycarbonate housing and lens

• Color temperature 4000K, 5000K

• CRI 80+

PETER SAUNDERS

CSA’s culture of outreach

When Mary Cianchetti, CSA Group’s president of standards, was first given an opportunity to work with the organization in 2004, as a project manager in its nuclear power program, she says it took her a while to figure out who she’d be working for.

“It was all a bit cloak-and-dagger,” she recalls. “I don’t know how they found me!”

Fittingly, then, in her current role—which she took on three years ago—Cianchetti is trying to increase the organization’s transparency through active outreach efforts. By way of example, CSA made a commitment last year to provide ‘free view’ online access to all of its standards (similar to an initiative by UL, which has encouraged other organizations to do the same).

When Cianchetti was growing up, she wanted to be an aerospace engineer. She got her aerospace experience at 16 as a pilot in air cadets, but ended up studying mechanical engineering instead, at the University of Toronto (U of T), before working in wire and cable manufacturing.

“My studies were very theoretical,” she recalls. “I didn’t really learn hands-on until I got into the field.”

With that disconnect between school and career in mind, another recent CSA initiative has been the academic challenge, which gets students involved in standards development. It is important to draw them to the process because, while CSA membership has grown steadily over the years, it has done so primarily through the addition of new categories of standards to its portfolio, rather than through the inclusion of younger generations of professionals.

“Our average member is now 55 years old,” Cianchetti says.

In addition to drawing in new members, who volunteer their time, Cianchetti explains CSA is hiring project managers right out of school.

“I was drawn to this organization as a project manager myself by the chance to merge my technical skills with communications, but I stayed because of the passion here,” she says. “Everyone wants to leave a legacy and make the world better. Our mandate really focuses on the core goal of the social good through standards development.”

And with the CE Code a significant part of CSA’s legacy, the involvement of contractors is vital.

“My message to the electrical industry is we will stay ahead of the curve as the world changes and we want to make sure end users are heard,” she says, “So, don’t be afraid to get involved!”

14

A new standard in smoke detection Soon, a new UL standard will help electrical contractors improve smoke detector reliability.

What is energized electrical work?

By prioritizing arc flash hazards, we risk neglecting shock hazards altogether.

Updating power control systems with minimal disruption

ATS controllers and switchgear systems require different types of maintenance and upgrades.

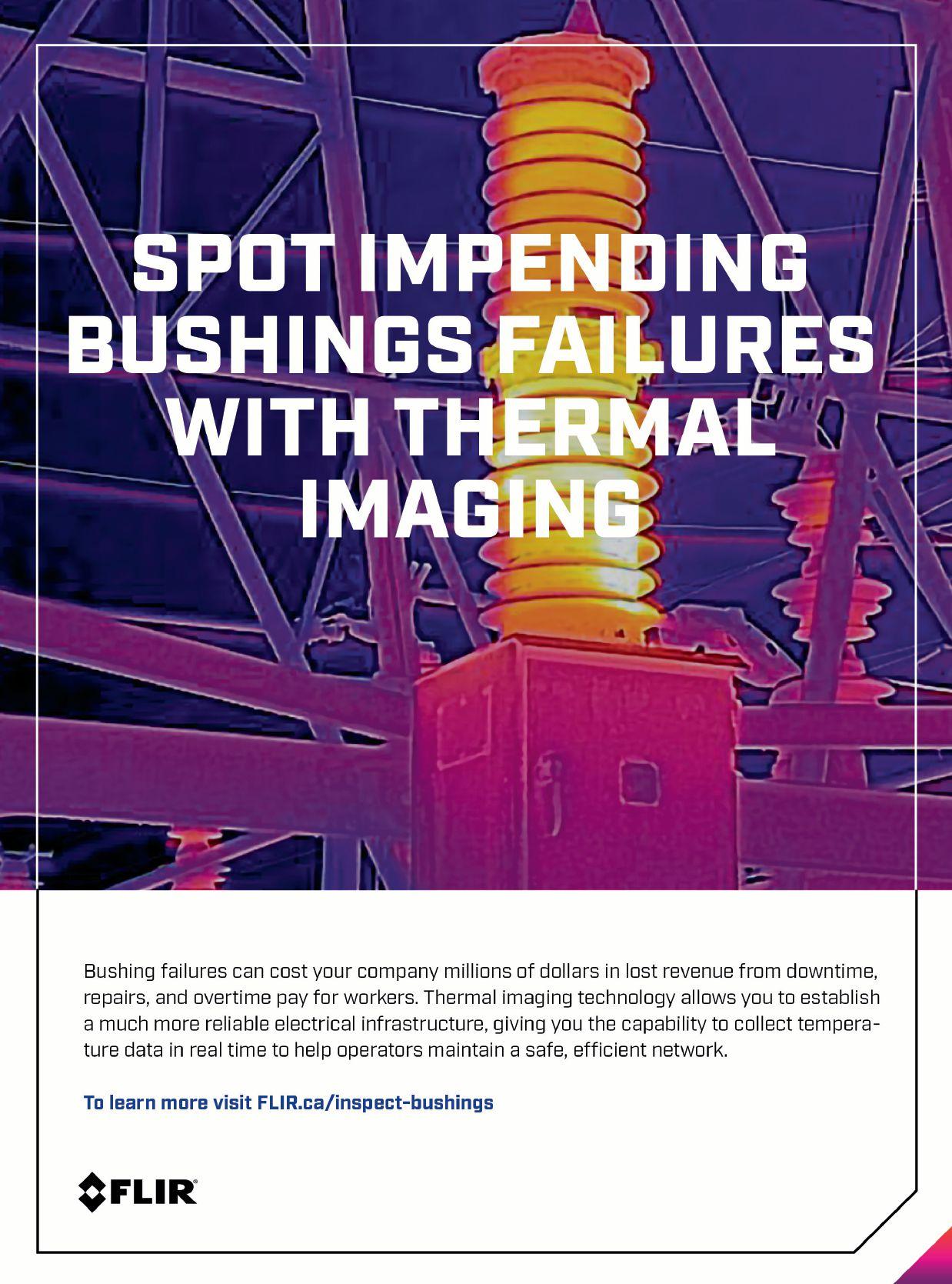

A systematic approach for inspecting transformers

CBM technologies can spot warning signs in transformers before failure.

Parking garage lighting: Le Sanctuaire

For a parking garage in Montreal, switching to LEDs increased brightness and reduced maintenance.

Sealing and insulation for parking fixtures

Electrical contractors can profit by sourcing components for parking lot lighting. 14 20 18

TABLE 1

• temperature at bolted connections.

• oil tank temperature scan, for hot and cold spots indicating possible problems.

• load tap changer tank temperature (differential to main tank).

Contact ultrasound—also known as structure-borne ultrasound—can detect loose windings and other mechanical issues. This type of inspection checks decibel values at defined test points and conducts waveform analysis for fault type determination.

Airborne ultrasound can detect arcing, tracking and corona, all of which emit high-frequency signals in the ultrasound spectrum above 20 kHz. Similar to the structure-borne approach, the inspection checks decibel values at predetermined test points and analyzes waveforms based on time and frequency to determine the nature of partial discharge (PD).

Ultraviolet (UV) cameras can help confirm the exact location of a corona event, while a visual inspection is useful for detecting dust, water or pest ingress,

corrosion, signs of PD, oil leakage, soiled bushings, fan operation issues and stains from previously standing water.

For oil-filled transformers, periodic analyses can detect degradation, leaks and excessive acidity (due to insulation breakdown). Dissolved gas analysis of oil can further detect signs of thermal faults and PD activity inside the transformer chamber. Oil pressure and temperature can be checked by reading gauges. Sampling is important for checking oil quality, including moisture content, dielectric properties and dissolved levels

Stylus™ Linear Series Design Versatility Meets Installation Simplicity

Electrical maintenance

Among the important reasons for visual inspections, pests and their predators can be attracted to the warm, dry spaces inside transformers!

of atmospheric gases, oxides of carbon, hydrocarbons and hydrogen.

Finally, transient earth voltage (TEV) detection—addressing another form of PD event—can find hidden defects inside a transformer’s insulating components. Like ultrasound, it checks decibel levels at predetermined test points. It also plots phase-resolved PDs for comparative analysis.

Accounting for safety

Most of these CBM techniques require the equipment to be energized and operating under normal load conditions to provide useful quantitative data. This creates some safety issues that must be accounted for, especially under the scrutiny of new guidelines in the CE Code and the 2018 edition of NFPA 70E, Standard for Electrical Safety in the Workplace

If any inspection tasks require opening the doors or covers of the transformer, then there is an elevated risk of an arc flash or electrocution to the personnel involved. With this in mind, workers must be qualified and wear an appropriate level of personal protective equipment (PPE) for the arc flash incident energy available.

At the transformer, this arc flash risk can be significant and a barrier to performing inspection and data collection tasks altogether. Furthermore, the ‘hierarchy of control’ mandates other alternatives to open-panel work must be deployed if possible and practical,

including the substitution of non-hazardous for hazardous tasks.

Fortunately, there are practical solutions for virtually all of these types of inspection issues, which substitute safer methods of data collection through a ‘safety-by-design’ approach and the use of electrical maintenance safety devices (EMSDs).

Practical systems

Maintenance inspection systems can be installed on virtually any transformer to allow users to perform visual, IR and UV inspections. A single unit can be used for low-voltage (LV) connections and another for high-voltage (HV) connections.

When the large, rectangular inspection window’s cover is being manipulated, the equipment stays in a closed and guarded condition and technicians do not violate the restricted approach boundary. So, they do not need to wear any special PPE, as there is no increased likelihood of an arc flash occurrence.

Oil sampling ports can also be brought outside of the transformer cable compartment. Some vendors offer retrofit kits that permit safe sampling and provide an optional external gauge and nitrogen insert to relieve vacuum pressure.

(Contact ultrasound, PD and TEV detections are performed on the external ‘skin’ of the equipment in a closed condition, so no special EMSD is normally required in these situations.)

Classifying assets

The optimal frequency of different inspection techniques depends on the importance of the assets in question.

Following a failure modes and effects analysis (FMEA) approach by a cross-functional team, each facility should attempt to classify its assets based on replacement cost, lead time, average repair cost, mean time to repair (MTTR), the potential safety and environmental impacts of failure and cost of downtime.

Assets can then be classified, using agreed-upon point system, as (a) critical to the operation of the facility, (b) important to the operation of the facility or (c) supportive but with limited impact to the facility. See Table 1 for inspection frequency examples for different CBM technologies, based on the importance of different assets.

To enable accurate assessments of asset ‘health,’ data must be collected at regular intervals, so long-term trends can be compared. For many of the measured parameters, a baseline can be set for ‘normal’ operation shortly after the transformer goes into service.

The EMSD advantage

In these ways, the use of EMSDs—such as maintenance inspection windows and external oil sampling ports—with transformers can take the danger out of CBM data collection tasks, by eliminating the need to work on energized open panels. With the related safety risks eliminated, inspections become feasible for a single technician, with no cumbersome arc flash PPE. This means data can be collected much more efficiently.

Then, with increased frequency of inspections, problems that could lead to unexpected failures of transformers can be detected earlier and preventative intervention can be initiated. Not only does this ensure regulatory compliance, but it also makes economic sense for the monitoring and protection of important electrical assets.

Experience has shown protecting transformers with fuses alone is not adequate to prevent fires in the event of a short circuit. Instead, the warning signs and possible causes of a short circuit should be detected early on, through CBM techniques. With files from FLIR.

level up

ANDREW HOUSTON

Quoting profitably

Do you quote jobs day after day but never stop to think, “Is this actually going to be profitable? How much money should I make?” And then the bid gets sent, the client accepts it, time moves on, materials change, you get called back to the jobsite multiple times and of course you still need to pay your suppliers. Does this sound familiar?

It’s important to avoid ending up like those contractors who never earn the profits they expect. And the key to knowing whether or not you will be profitable is all about leveraging the numbers.

Are you making enough profit to cover your fixed expenses? These business expenses, including leases, taxes, salaries and utilities, are not determined by your sales, but always need to be more than covered by them, to avoid bankruptcy.

What sales targets do you need to hit, to become profitable? It is essential to ensure you are bringing in enough work at the right margins.

What formula do you use? Out of 100 contractors I talked to, more than 95 of them were not calculating their margins correctly and it wound up costing them their shirts.

Out of 100 contractors

I talked to, more than 95 of them were not calculating their margins correctly and it wound up costing them their shirts.

All of the information you need can be found in your profit and loss (P&L) statement with your accountant or bookkeeper. The simple formula you need to know is for your break-even point (BEP), as follows:

Fixed annual costs / (Estimated annual sales – variable costs) = BEP

Breaking even is defined as the point where sales or revenues equal fixed expenses. There is no profit made nor loss incurred at this point.

Now that you know how much of a margin you need to earn to break even and exceed to make a profit, here are your next steps.

1. Filter fast.

Prioritize your sales leads based on ‘classes.’ Class A refers to clients you

want to work with, whereas Class D encompasses those you would avoid at all costs. Once you’ve made this list, work with your sales team to develop a process and script for addressing each class of leads with bids and estimates.

2. Put up a sales board.

Every opportunity that comes into your business is not the same, so again, prioritize them. Include their contact information, related notes and what ‘phase’ of the sales process they are currently in. This will help you know what’s coming in and plan your estimates accordingly.

3. Separate your quotes.

This is another chance to prioritize items, but separate items according to level of difficulty—e.g. guesstimate to estimate to detailed final quote.

Andrew Houston is owner and founder of Profit for Contractors (PFC), an industrial controls licensed electrician and an electronics engineering technologist. He helps entrepreneurs in the skilled trades improve their business skills, so they can enjoy more control, freedom and money. To register for his free ‘cash flow mastery’ webinar, which discusses cash-flow issues and strategies to improve your business, visit www. contractorprofitmastery.com/opt-in. You can also join PFC’s Facebook group, ‘Contractor Tips.’

RETROFITTING LE SANCTUAIRE

New lighting improves visibility and safety.

BY TRACY JOHNSTONE

Le Sanctuaire is a large residential condominium development in the heart of Montreal’s Cote-des-Neiges neighbourhood. It surrounds a courtyard with two low-rise commercial buildings. One of these is L’Atrium du Sanctuaire, a 38,000-square-foot structure, operated by FCR Management Services, that is home to medical and professional offices, a Jean Coutu pharmacy and a branch of the Banque Nationale du Canada. The other building contains Midtown Le Sporting Club Sanctuaire. The two share an underground parking garage, also managed by FCR.

Given the mixed uses of the buildings, both pedestrian and vehicular traffic volumes are high at all times of day and night. Last year, when FCR sought a new lighting system that would improve visibility and safety for people passing through the garage, while also enhancing esthetics and reducing energy costs, it turned to Concept Illumination for a site evaluation before choosing a specific course of action.

“They are reliable, on budget and on time,“ says Ginette Longpré, senior property manager with FCR, which has worked with Concept Illumination’s team on other commercial lighting retrofits. “There are no surprises!”

Time for an upgrade

Upgrading the lighting was important for multiple reasons.

While the existing fluorescent lights were doing an adequate job of illuminating the garage’s laneways, they did not project sufficient light over the parking spaces for people accessing their vehicles.

Further, the fixtures were deteriorating and maintenance costs were high. As the T12 tubes were an aging technology, replacement parts were expensive and very difficult to find.

Selecting luminaires

The retrofit they decided upon involved the installation of 105 new architectural LED fixtures, selected to reflect the upscale nature of the buildings’ surroundings. Each 70-W luminaire featured a colour temperature of 5,000 K to complement the natural light coming into the garage from various skylights.

For the most part, the fixtures were replaced one-forone, but several were eliminated altogether, thanks to the superior coverage of the new lights. The retrofit dramatically improved visibility in building entrances from the garage, as well as a service corridor, through the installation of linear LED strips.

Addressing challenges

The garage’s ceiling posed a design challenge because of its substantial ductwork and piping. Some of the old fixtures were nestled in the midst of these obstructions, so while they were still producing light, it was not distributed to where it should have been. Concept Illumination’s team decided to lower these particular fixtures by approximately two feet, while keeping them within the required height clearance.

“We attached the base of each fixture to the ceiling with a ball joint that had some give, so in the event they are nudged by

Before After

pedestrians or larger vehicles, they will be protected,” explains Daniel Herz, director of sales for Concept Illumination.

The single biggest challenge while completing the retrofit, however, was managing traffic. The management company’s goal was to keep the garage open during the work, allowing for regular operations and minimizing disruptions to the pedestrians and drivers who access the space. Accordingly, Herz co-ordinated the lighting installation so only one lane would be shut down at a time.

Another planning challenge was the fact the old fixtures were set in concrete. As a result, removal and installation were particularly labour-intensive.

Visible (and invisible) improvements

Despite these challenges, the retrofit was successfully completed within one week, transforming the look of the parking garage.

Most visibly to the tenants, the new architectural fixtures distribute bright and clean lighting uniformly across the garage’s laneways, parking spaces and walkways. There are no apparent ‘hot spots’ under individual lights.

“The garage is so much brighter and the lighting is uniform,” says Longpré. “The tenants’ comments have been positive. They feel much more secure now.”

What the garage’s users cannot see are the significant anticipated energy savings. The 70-W LED fixtures replaced 175-W four-tube T12 fluorescent lights, representing a 60% reduction in energy consumption. As a result, FCR can budget for substantial reductions in its operating costs in the months and years to come.

SEALING AND INSULATION FOR PARKING LOT FIXTURES

Outsourcing presents an opportunity for electrical contractors.

BY ROBERTO NACCARATO

Parking lot lights must provide adequate outdoor illumination for areas used by both pedestrians and drivers. They are usually pole-mounted and only accessible by bucket truck or lift. Most older parking lot lights use high-intensity discharge (HID) lamps, with ballasts that regulate the voltage supplied to gas-filled capsules. Newer parking lot lights often use LEDs instead. Built with semiconductor chips, these lights last longer, but are more expensive to purchase.

As such, today’s electrical contractors need to know how to install and maintain both types of lighting. While some parking lot owners have their own crews for such work, others outsource it, which provides an opportunity for independent contractors.

And it’s not just new installations and maintenance contracts that can be profitable. LEDs are installed in many retrofits of existing parking lots, even if just a few lights at a time. For electrical contractors, then, it’s important to

Electrical contractors need to align gaskets with the lights’ internal parts and features.

know what to look for when sourcing the right components.

Rubber gaskets

The surfaces of machined parts might look smooth, but small irregularities can create tiny gaps that admit wind-blown dust and water. With this in mind, the lamps for parking lot lights are housed in enclosures that are designed to prevent the entry of dust and water. These enclosures may meet specific Ingress Protection (IP) standards,

such as IP64, IP65, or IP66. Rubber gaskets—i.e. mechanical seals that fill the space between two or more mating surfaces—help keep out contaminants. Since they are installed outdoors, parking lot lights are exposed to sunlight and must withstand a range of temperatures, so it is essential to choose gasket materials that will provide the appropriate level of environmental resistance. Otherwise, seal failure could occur and lead to unwanted costs. Parking lot owners do not want to field complaints about lights that do not work, particularly due to avoidable problems like corrosion, and renting a bucket truck or lift to fix a lighting enclosure can be expensive—in some cases, thousands of dollars a day.

Weather-resistant gaskets made of ethylene propylene diene monomer (EPDM) rubber are used for outdoor lighting enclosures. So are silicones with low gassing, since the release of volatile organic compounds (VOCs) can hinder the performance of LED lighting that is hermetically sealed.

Various types of rubber also differ in terms of their durometer, a measure of hardness. To form a long-lasting seal, gaskets need to be just soft enough to support compression but not prevent closure. It is also important to resist ‘compression set,’ the permanent deformation of a gasket.

Liquid caulk can also provide environmental-resistant sealing, but installers may apply it inconsistently or, overall, use too much or too little of it. Pour-in-place gaskets are sometimes used for LED lighting, but this type of sealing is designed for factory installations, rather than field repairs.

Ultimately, rubber gaskets that are cut from sheet or roll materials are easier to install and can accommodate part features, such as angles, notches and holes for fastener heads.

Water-jet cutting is ideal for low- to medium-volume quantities, as there is no tooling to wait for or buy. This equipment’s high-pressure heads direct jets of water toward an x-y axis table with a large cutting surface. This pressurized stream makes fine, fast cuts and minimizes material waste from miscuts, which are a common problem with manual cutting.

Water-jet cutting also supports reverse-engineering projects for hard-

to-find or obsolete gaskets. A computer-aided design (CAD) file from a 3-D scan is used to get the process started.

Vibration dampers

Besides dust, water, sunlight and temperature fluctuations, another environmental issue outdoors is vibration, which can cause noise, loosen fasteners and weaken structures.

When parking lot lights vibrate, it is usually because of the pole’s location. Elevated ramps and parking decks, especially, are problem areas. Light poles that support cameras and other accessories with appendages are also particularly susceptible to wind-induced vibrations. Fortunately, dampers made of rubber can isolate vibrations. They may be moulded onto metal fasteners.

High-temperature insulation

LED lights generate significant amounts of heat. If this heat is not dissipated properly, the level of illumination may decrease.

Mount-style vibration dampers use metal-to-rubber bonding.

Thermal management materials can increase the effectiveness of an integral heat sink, but silicone greases are time-consuming to apply and messy to use. By contrast, water-jet cut gaskets can be installed easily and offer high temperature resistance with low outgassing.

Bonding properties

Sealing and insulation techniques for parking lot lighting also differ in terms of bonding.

Hot splicing requires clean, straight cuts and is used for higher-volume quantities. Vulcanization is more forgiving, since the cuts do not have to be smooth and precise.

Cold bonding is a manual process, performed with a brush and an adhesive or glue. It is ideal for low-volume quantities, but cold-bonded gaskets won’t last as long as hot-spliced ones. Moulding, meanwhile, is the only bonding technique that can create rounded corners.

Right for the job

Electrical contractors who install, maintain and repair parking lot lights need to choose the right rubber products for the job. By understanding what to look for in terms of materials and how they are manufactured, they can make their installations easier and longer-lasting.

Roberto Naccarato is sales manager for Elasto Proxy, which fabricates seals, gaskets, and insulation for the outdoor equipment and lighting industries. For more information, visit www.elastoproxy.com.

CODE conundrum

BY RAY YOUSEF, CODE ENGINEER

Ontario’s Electrical Safety Authority esasafe.com

TACKLE THE CODE CONUNDRUM IF YOU DARE!

Answers to this month’s questions will appear in the December 2019 issue of Electrical Business

QUESTION 1

When a photovoltaic (PV) recombiner is more than 7.5 m from the inverter, the disconnect:

a) shall be rated to interrupt the load.

b) shall be installed within 2 m of the recombiner.

c) may be integral with the recombiner.

d) (all of the above.)

e) is not required.

QUESTION 2

The ampacity of a communication cable marked “-LP” is determined by a) Table 60.

b) the ampacity marked on the cable.

c) a qualified person.

d) any of the above.

QUESTION 3

For the identification of intrinsically safe wiring, which of the following methods is acceptable?

a) Cables are labelled.

b) Cables are identified blue.

c) Cables are identified light blue, where light blue is not used for any other cabling.

d) A and B.

e) A and C.

need help prospecting?

Has Canadian Anti-Spam Legislation reduced your email prospects list?

EBMag’s newsletter reaches nearly 16,000 CASL-compliant subscribers, and it does so every week!

Visit EBMAG.com/advertise

ITC introduces Sontheimer compact rotary switches

ITC Electrical Components, a master distributor based in Concord, Ont., is offering a new line of Sontheimer compact rotary switches. The line spans a variety of types of operation, switching diagrams and mounting modes, but in terms of dimensions, each contact package is only 30 x 30 mm. The UL and CSA listed switches are rated for thermal current of 10 A, and voltage of 300 V AC. With a single central hole, they carry an ingress protection (IP) rating of 65. itcproducts.com

Reliant LED fixtures designed for light-duty industrial applications

Dialight’s Reliant high-bay industrial LED fixtures are the company’s first intended for light-duty applications, including warehouses, light manufacturing plants and other large indoor spaces. A rectangular, modular design enables both single-unit and tandem installations, configurable on-site, while a lightweight, dust- and moisture-resistant polymeric chassis is intended to help contractors access wiring and mount the LEDs at heights (up to 100 ft) more easily, in comparison to heavier fixtures. Rated for 100,000 hours of performance, the fixtures are supported by a 10-year warranty. They are field-upgradable with optional surge protection up to 10 kV and integrated battery backup, to provide continual illumination in case of a power outage. dialight.com

RSA-97B actuator closes or trips MCCs from safe distance

CBS ArcSafe has introduced the RSA-97B remote switch actuator for the Square D Model 4 motor control centre (MCC). The portable device is designed to allow technicians to close or trip the MCC remotely, from a safe distance of up to 300 ft, while stationed outside the arc-flash boundary. With a magnetic latching system, no modifications to existing electrical equipment are needed for installation or operation. Optional features include a radio remote with a range up to 300 ft, a 24-V DC LED light, a wireless video camera system with an LCD monitor and a rugged protective case assembly. cbsarcsafe.com

Ideal Networks futurereadies LanTek IV cable tester

Ideal Networks’ LanTek IV is a new copper and fibre cable certifier. With its touchscreen and user interface, technicians can reportedly conduct and save a Cat 6A test within seven seconds. A VisiLinq permanent link adapter, with field-replaceable RJ45 tip, allows them to initiate testing and view results without even needing to hold the certifier. The tester can certify links up to Cat 8, including transverse conversion loss (TCL) and resistance unbalance, and will sweep to 3,000 MHz, providing capacity for future International Organization for Standardization (ISO) and Telecommunications Industry Association (TIA) test standards. idealnetworks.net

Repair or Replace?

Sometimes it makes sense to replace your electric motors. Other times, repair is the best option. EASA members can help you make that decision. They understand motors can be repaired or rewound without reducing efficiency or reliability if the work is performed to the industry standard.

ANSI/EASA AR100-2015: Recommended Practice for the Repair of Rotating Electrical Apparatus is the standard for maintaining (or sometimes even improving) AC electric motor efficiency and reliability.

Find a list of EASA members at www.easa.com/find.

For a complimentary download of ANSI/ EASA AR100, go to www.easa.com/ar100.

Does your service center comply with ANSI/EASA AR100?

More than 130 service centers have earned EASA Accreditation. These companies demonstrated via third-party, independent audit that they follow the prescribed practices of ANSI/EASA AR100 to consistently deliver quality repairs that maintain or sometimes improve AC electric motor efficiency and reliability.

Count on an EASA Accredited Service Center for your electric motor repair/service needs!

See a full list of these service centers at www.easa.com/accreditation.

NANSY HANNA, P.ENG

Essential electrical systems in health-care facilities

Life safety systems are defined under Rule 46-002 of the CE Code and required by Articles 3.2.7.4 through 3.2.7.10 of the National Building Code (NBC) to be supported by an emergency power supply, i.e. either a generator or batteries, to ensure continuity of operations. These loads are important for public safety in general and crucial for evacuations during fires and other emergency situations in particular. Examples include exit signs, egress route lighting, fire alarms, elevators and smoke-venting fans.

Under Rule 46-108, the wiring for an emergency power supply and any electrical equipment that is not defined as a life safety system must be kept entirely independent of all other wiring and equipment (except in transfer switches and emergency lights supplied from normal and emergency sources). Separation is required beginning at the first point of distribution for either power source.

An essential electrical system is defined under Rule 24-002 as having “the capability of restoring and sustaining a supply of electrical energy to specified loads in the event of a loss of the normal supply.” In health-care facilities, an interruption of the normal supply can jeopardize the care of patients, as well as the safety of staff and the public.

Essential electrical systems are divided into three categories: vital, delayed vital and conditional branch. CAN/ CSA-Z32 provides guidance as to what loads should be supplied by each.

ADVERTISER INDEX

The vital branch is the portion of the system in which the circuits require power restoration within 10 seconds. Health-care examples include the intensive care unit (ICU) and emergency lights. The delayed vital branch is the portion where circuits require power restoration within two minutes, e.g. blood bank refrigerators.

The conditional branch is the portion where essential loads such as medical records storage may be transferred to the emergency source at a time dictated by the prevailing need. Loads on the conditional branch typically sustain the continued operation of the facility and some additional services, but are not as crucial to patients.

A need to clarify

As both Sections 24 and 46 are amendatory and NBC requirements are also applicable in health-care facilities, there has been a need to clarify how Rule 46-108 can be applied within the scope of Section 24 where there are essential electrical systems. A new version of Rule 24-302 in the 2018 edition of the CE Code provides two options as alternatives to meeting the requirements of Rule 46-108.

The first permits the wiring of vital, delayed vital and conditional branches to be combined with that of life safety systems, provided all overcurrent devices of the essential electrical system are selectively co-ordinated. This ensures a fault in a conditional load does not cause power loss to a vital

load, aligning with Clause 8.7.2 of CSA C282, Emergency Electrical Power Supply for Buildings.

The second permits the wiring of vital and delayed vital (but not conditional) branches to be combined with that of life safety systems without selective co-ordination of all overcurrent devices.

It is important to note it could be impractical to satisfy the first option of providing selective co-ordination down to the branch circuit level. Commentary Clause B.18 of CSA C282 clarifies that while most systems use moulded-case circuit breakers for protection, the ability to achieve selective tripping under short-circuit conditions is extremely limited. The use of air or power circuit breakers with a true short time rating and no instantaneous trips allows a much greater level of co-ordination.

The commentary further clarifies it is generally not possible to ensure selective tripping under short-circuit conditions between downstream panel breakers and those that feed the panels, given the moulded-case breakers. Selective tripping is achieved only when the magnitude of the fault current in the branch circuit is so low, it does not release the instantaneous trip of the breaker that feeds the panel.The cost of air circuit breakers for these applications is prohibitive.

One approach to satisfy the requirements of the new Rule 24-302 is to combine both options—that is, where possible at higher-level distribution, provide selective co-ordination, then start separating the branches when it becomes cost-prohibitive and, with regard to volt/current level, impractical.

The ultimate purposes of these rules are to maintain power to loads for public safety and patient care and to minimize the risk of power interruption to crucial loads due to faults in less crucial loads.

Always consult your AHJ for more specific interpretations.

Nansy Hanna, is director for engineering at Ontario’s Electrical Safety Authority (ESA), chair of the Canadian Advisory Council on Electrical Safety (CACES) and a member of the ULC Advisory Council, CSA Technical Committee on Industrial, Consumer and Commercial Products and CSA CE Code-Part I, Sections 24, 32, and 46. She can be reached at nansy.hanna@electricalsafety.on.ca.