Well, it’s safe to say that since the last issue of Electrical Business, a lot has changed in the world.

As of the writing of this editor’s note, I’ve now been working from home for the last five weeks. While I am grateful for the fact that our governments and employers are taking the threat of COVID-19 seriously, I’m sure I’m not the only one finding it slightly difficult to adjust to our “new normal”.

While in most parts of Canada, electrical industry workers are considered essential and continue to work as usual, the risk of infection remains. That’s why I encourage everyone to take the government’s stance on social distancing and personal protection seriously, especially if you continue to work around others amid the pandemic. Your safety is paramount.

As many of us continue to be in lockdown mode, what better way to pass the time than paging through this issue of the magazine?

For this issue, I had the pleasure of speaking with a number of industry associations to discuss how COVID-19 is impacting business across the country, the fears contractors may be facing, and how employers plan to bounce back. You can find that article on page 10.

This issue also includes an article on unsafe electrical products, such as lighting that doesn’t meet the CE Code, still being available in some big-box stores on page 18, and information on the risk of contracting COVID-19 when sharing arc flash personal protective equipment (PPE) on page 20.

Also, this is where we say goodbye. Effective May 1, I’m moving onto another publication within Annex Business Media’s family. But fear not! You’re in good hands, as Anthony Capkun will be donning his editor hat once more to lead the magazine from the front lines as Publisher-Editor.

It was a pleasure providing you with news and information on this fascinating industry for the past several months. Thank you for reading each issue, writing to me with your thoughts and comments and, in general, being a fantastic audience.

Wishing you all well!

Associations respond to COVID-19

How associations are faring across the country amid the ongoing threat of COVID-19.

Smart home wiring

Introducing consumers to a world of convenience, security and comfort.

When downtime is not an option

Driving Canada’s healthcare facilities with an uninterruptible power supply system.

A smart standard for smart lighting

Providing opportunities to optimize the implementation of wireless controls in facilities.

When lighting doesn’t meet Code

An update on retail sales of light fixtures that don’t meet the CE Code.

Sharing is not caring… when it comes to arc flash PPE

Workers who share PPE are at a higher risk of being exposed to the virus that causes COVID-19.

your estimator making this mistake?

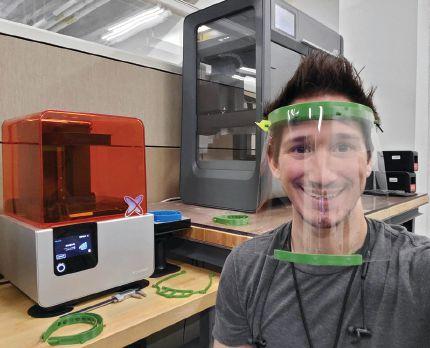

Ontario Power Generation’s 3D printers produce face shields to protect health-care workers.

OPG contributes PPE to healthcare facilities amid COVID-19

Ontario Power Generation (OPG) is using 3D printing technology to produce plastic face shields to address the growing need for personal protective equipment (PPE) for frontline healthcare workers amid the COVID-19 pandemic. OPG has partnered with Ontario Tech University in Oshawa to fast-track the production of face shields. OPG received approval from Health Canada to produce the shields.

“We have a lot of innovative and passionate people on our X-Lab team and I want to thank them for thinking outside of the box in anticipation of a medical supply shortage in the province,” said Ken Hartwick, OPG’s president & CEO.

OPG’s X-Lab innovation hub is now producing the headband piece used in the assembly of the face shields, and has secured materials for the plastic visor and adjustable elastic strap through OPG’s vendor partners.

Following the province’s request to innovate, businesses such as Protagon Display Inc. and Filaments.ca supplied material to develop the face shield.

The first batch of 200 face shields was expected to be shipped to Ontario’s Ministry of Health on April 8, with a plan to increase production to 500 units per week. The ministry will then distribute the shields to hospitals, long-term care homes and any other

essential healthcare providers in the most-needed areas of the province.

In addition, OPG has committed to donate 17,500 Tyvek protective suits to the province, which were part of its inventory for nuclear workers, and 500,000 surgical masks and 75,000 N95 masks that the OPG donated to the province in early April, in response to the growing shortage of PPE in hospitals and healthcare facilities across the province.

RESCON releases best practices for construction sites amid COVID-19

In response to the COVID-19 pandemic, the construction industry released a best practice guide and urges all employers to follow it during this time so construction sites can continue to operate safely.

The best practice guide includes seven safety recommendations developed by health and safety experts in Ontario’s construction industry and endorsed by labour and management representatives. They come from a document called “COVID-19: What you need to know about Health and Safety and Working On-Site.” The recommendations include:

1. Maintain good personal hygiene: Avoid touching face with unwashed hands. Cough and sneeze into elbow or a tissue and wash hands often.

2. On-site sanitation: Provide access to more hand-wash stations with soap and water, washroom facilities, commonly touched surfaces or areas (hoists, site trailers, door handles, equipment or residential units), and an increased cleaning schedule.

3. Practise physical distancing: Stagger start times, breaks, lunches, total number of people on site and coordinate pinch points, including hoists and site trailers, to keep people safely apart. Limit unnecessary on-site contact between workers and outside service providers.

4. Communicate policies: Employers must ensure everyone on site has a clear understanding of roles and responsibilities in health and safety. Policies must be posted and communicated to all employees, contractors and trades, including

May 2020 || Volume 56 || Issue 3

ELECTRICAL BUSINESS is the #1 Canadian resource for electrical contractors, maintenance and engineering professionals, distributors, manufacturers and their agents and associated stakeholders.

Editor Kavita Sabharwal-Chomiuk ksabharwal-chomiuk@ebmag.com

Associate Publisher/Advertising Sales Anthony Capkun acapkun@ebmag.com

Account Manager Jennifer Dilorio jdiiorio@ebmag.com

Media Designer Andrea M. Smith asmith@annexbusinessmedia.com

Account Coordinator Kathryn Nyenhuis knyenhuis@annexbusinessmedia.com

Audience Development Manager Urszula Grzyb Tel: 416 510 5180 ugrzyb@annexbusinessmedia.com

Executive Publisher & VP Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

President & CEO Mike Fredericks

Published by Annex Business Media 111 Gordon Baker Road, Suite 400 Toronto, ON M2H 3R1 Tel. 416-442-5600 • Fax 416-442-2191

Printed in Canada ISSN 0013-4244

Publication Mail Agreement #40065710

Circulation Costumer Service

Email: ugrzyb@annexbusinessmedia.com Tel: 416 510 5180, Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Road, Suite 400 Toronto, ON M2H 3R1

Subscription rates

Canada: Single issue $7.50 • 7 issues: $38.00

USA: $86.50 (CAD) International: $104.00 (CAD) per year

Annex Privacy Officer Email: privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Electrical Business will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Electrical Business are copyright ©2020 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

continued from page 11

According to Aitkin, ECAO members are focused on preparing for the “new normal” following this pandemic. “The bulk of what we are seeing is training that relates to COVID-19, anticipating a second or third wave, and coming out of this stronger and more prepared as an electrical contractor,” he says.

COVID-19 fears

Some contractors that are still on the job are worried about contracting COVID-19 while at the workplace. Sell notes that “the social distancing requirement affects different workers in different ways. Workers with young families or caring for elderly parents are more reluctant to continue working due to fear of infection.”

“Calls from individual workers to WorkSafeNB seeking guidance have increased dramatically,” adds Ellis. “In most cases, WorkSafeNB has been referring anxious workers back to their employers.”

Electrical workers employed by ECAO members are themselves members of the IBEW, says Aitkin. “Where there may be fear, we work with the IBEW/CCO to ensure that these fears are thoroughly investigated and dealt with. Further, ECAO fully supports the recommendation of the IBEW/CCO to their members that workers should not be put into a position to perform at a site that they do not feel has the proper COVID-19 (and, of course, all health and safety) protection.”

As for how electrical contractors in New Brunswick are faring emotionally, Ellis says most of the ECANB’s members seem to be concerned, but not overly frightened for the short term, and are cautiously optimistic for the longer run. Meanwhile, in Alberta, Barnett says members are uneasy because they’re unsure how long the halt to business will last.

Although the turn of events related to COVID-19 have been shocking, to say the least, Aitkin presents a positive message for the future, one that all contractors can surely relate to.

“I have not been associated with a group as strong, practical, caring and adaptable as the ECAO.Yes, they are facing a threat. However, like all of the threats faced in the seven decades of this association, I am confident that our community will come out of the pandemic even stronger, more united and with greater resolve than when we entered this time,” he says. “As a very resilient community, our members, labour partners and industry partners are collectively ‘rolling up our sleeves’. We’re resolved, not resigned.”

“Long term, there is work on the other side of this,” McMillan adds. “We just need to get through it safely.”

Code file

TATJANA DINIC