from the Editor

ANTHONY CAPKUN

ANTHONY CAPKUN

Mid-March... that’s roughly when our entire world got turned upside-down.

Industry events began cancelling/ postponing like a long row of dominoes. (For my part, I was very nearly in Edmonton for an IEEE workshop, but I never made it. My tradeshow booth graphics did, however, make it to Edmonton. They’re still there... somewhere.)

My province went into lockdown around that time, and so my colleagues and I were told to work from home. That was two months ago (even longer by the time you read this), but I was feeling profoundly disconnected from our electrical community by the end of the first week. It was lonely.

And I imagine many of you were feeling the same way; all of our usual routines were completely obsolete, and everyone was busily sorting themselves out. There was much confusion, not to mention anxiety (if not outright panic), feelings of helplessness... and everyone was wondering “What’s next?”.

It was against this backdrop that I conceived the video series “Canadians Standing Up to COVID”. Essentially, COVID-19 is the schoolyard bully, and we’ve decided—both as individuals and as a collective—not to be pushed around.

My aim was to connect with our electrical community and share stories of how its members—through actions both great and small—are doing what they can to get us through our coronavirus struggle. I wanted to share stories of giving, of inspiration, of hope... and of defiance in the face of Goliath.

I invite you to learn more about these short videos on page 12, and let me know if I hit the mark. (I like to think they got better over time.)

Meantime, I close out each video with the same question “Have you got a story to share?”. If you do, don’t be shy: call me at 416-510-5216 or email acapkun@ebmag.com.

I love sharing these stories, and I want to hear from all corners of Canada.

That said, I eagerly await the day when this video series becomes unnecessary and obsolete. Until then, be patient. Stay safe. We will overcome.

12

14 16

18

12 18 16

“Canadians Standing Up to COVID” video features

Through our unique video series, Electrical Business Magazine shares stories from Canada’s electrical industry community.

All construction in Ontario resumes... is this good news, or bad?

We speak with ECAO’s Graeme Aitken, EFC’s Carol McGlogan and OEL’s Stephen Sell.

The convergence of smart commercial lighting and biophilia

Turning to smart lighting, biophilic design—that is, incorporating nature into indoor settings—is having something of a moment right now in interiors.

Both Ryerson’s largest residence, Pitman Hall, and the new-build Daphne Cockwell Complex Residence required communications infrastructure that is flexible, financially and environmentally sustainable.

21 Estimating 101 The impact of COVID-19 on non-productive labour

Code file

or less transformer bonding and grounding

CODE conundrum

RAY YOUSEF

TACKLE THE CODE CONUNDRUM IF YOU DARE!

Answers to this month’s questions will appear in the September 2020 edition of Electrical Business Magazine.

A consumer’s service conductors entering a service box that is not equipped with a barrier between the line and load sides shall:

A) enter the service box as close as possible to the line terminals of the main switch or circuit breaker.

B) enter the service box from the bottom.

C) not come into contact with nor cross conductors connected to the load terminals of the main switch or circuit breaker.

D) all of the above.

E) A and C.

Non-locking 15A receptacles in a hospital shall be “hospitalgrade” in:

A) Critical care areas only

B) Intermediate and critical care areas only

C) Basic, intermediate and critical care areas

D) The whole building

Solid-state devices are permitted to be used as isolating switches, but not as disconnecting means.

A) True

B) False

ANSWERS Electrical Business, May 2020 ed.

Q-1: Which Appendix in the CE Code provides guidance on the creation of the Descriptive System Document?

B) F. Rule 18-002.

Q-2: Cables containing both Class 2 and power and lighting circuits must be:

D) All of the above. Rule 16-212 5).

Q-3: No point of an ungrounded systems is grounded; instead, the non-current-carrying conductive parts (equipment) of the ungrounded system are grounded.

A) True. Rule 10-400.

HOW DID YOU DO?

3 • Seasoned journeyman 2 • Need refresher training 1 • Apprentice 0 • Just here for fun!

Ray Yousef is a code engineer with Ontario’s Electrical Safety Authority, esasafe.com.

DAN BERESFORD AND JOHN F. WIESEL

Before COVID-19, non-productive labour was calculated at 12.5% of a workday, under the best conditions.

Working within COVID-19 guidelines and restrictions, however, has the potential to increase non-productive labour on every jobsite. Consider...

COVID-19 safety guidelines include the need for physical distancing while working and moving through a building, for wearing PPE, for cleaning tools and equipment, and so on. All of this will have a major impact on non-productive labour.

Your crew must be screened at the entry to the jobsite, slowing down entry for everyone. Your crew will have to maintain physical distancing, which will result in waiting to enter work areas, stairwells or elevators.

At times, the stairwells for going up or down a floor will be on the opposite sides of the building. Crossing the floor to the stairs while observing physical distancing will add to the time it takes to get to those stairs.

Your crew must wipe down tools and equipment before starting work and when leaving the jobsite. This will increase delays when starting and quitting work.

Putting on PPE and removing it safely takes time. When receiving deliveries, your crew will don their PPE. This could slow down unloading job materials and moving them to the work area.

According to a survey completed by the Greater Toronto ECA, these extra precautions add about 56 minutes (roughly 12% of the work day) of non-productive labour to each person’s work day.

(Read “Set aside 56 minutes of your day for COVID-19 prevention” on page 4.)

When preparing your estimates, strongly consider including time for all of these non-productive labour situations.

John F. Wiesel is the president of Suderman Estimating Systems Inc., and has been estimating and teaching estimating since the early 1980s. Dan Beresford served as an electrician in the Canadian Navy, then worked in various roles in the electrical sector before joining Suderman. Visit www.sudermanestimating.com.

Thanks to Doug G. for pointing out a typo in the Table in the April 2020 ed. The amount used in the lost profit calculation should be $1584.00, not $1384.00.

You will find the entire column, with corrected Table, on EBMag’s website, direct link: tinyurl.com/ya9qpnle

Why did CE Code Section 10 change the methods of bonding and grounding transformers? Why do we not need a #6 AWG ground taken, unbroken, from each transformer to the ground grid? Why is the system bonding jumper so big when the ground is so small? First, we must understand a few important principles via questions such as: Why do we bond? Why do we ground? What makes the transformer different?

The purpose behind grounding is to set a Near 0 ground potential reference (I’m right here, right now analogy) and stabilize the system. It is also about extending that Near 0 reference to other portions of the installation to establish an equipotential plane (equipotential grounding). The #6 AWG is often overkill, as the bonding conductor—which is sized for the available fault current on the primary side— will have no problem establishing the Near 0 reference. At 750V and less, grounding is not about a fault current return path; that is the purpose of bonding.

Bonding is about interconnecting all metallic equipment and objects, thereby establishing a return path for current imposed on a bonding conductor or metallic equipment (electric or non-electric) which may have inadvertently become energized under a fault condition. This interconnection to the bonding path is what creates the fault return path back to the X0 to complete the circuit and trip the overcurrent device. This is known as a short circuit

When we install a primary feed to a transformer, the bonding conductor that’s included with the feeder is sized for any potential fault current on the primary side and is substantial enough to establish the

Near 0 reference and stabilize the new system.

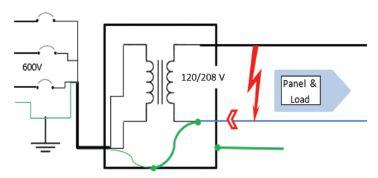

The new system has no electrical reference establishing it as it is not electrically connected but rather magnetically connected. Therefore, any fault on the new system will only see the new

Always

system (Figure 1). Were there a fault on the system prior to the secondary protection, it would cause a magnetically coupled increase in current draw on the primary and trip the primary O/C device, but the fault itself would not be imposed on the bonding conductor of the primary system. The primary system, in fact, only sees an increased current draw that exceeds its capacity. Short circuit to the neutral is shown in Figure 1.

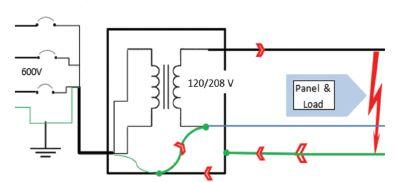

When the fault is to the bonding system, then the system bonding jumper must be sized to conduct the fault on the secondary back to the X0 of the transformer (Figure 2). Here it is shown after the panel, so now the O/C device in the secondary distribution panel will directly see the fault current and trip accordingly. The primary will continue to operate as normal, as it has not had time to magnetically see the rapid increase because the secondary has already dealt with the issue. As such, the rest of the installation continues to operate without issue.

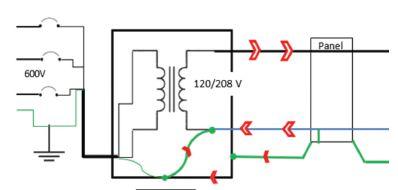

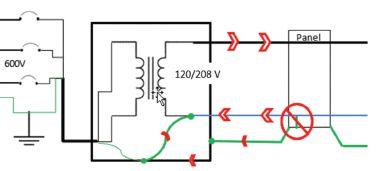

It is also for this reason that we want to ensure single-point grounding. We need to ensure that the neutral is only grounded in one location—as far back as possible—to set the Near 0 reference and ensure the bonding system and equipment never act as a parallel neutral conductor (Figures 3a and 3b). This can be an issue for equipment operation and potential shock hazard when working around equipment, and the bonding system was not designed for this.

David Pilon is an electrical inspector with SaskPower, the utility’s training co-ordinator for electrical inspectors and vice-chair of the Canadian Certified Electrical Inspector (CCEI) committee of the International Association of Electrical Inspectors (IAEI), Canadian Section. He can be reached at dpilon@saskpower.com.

With more ways to earn loyalty points and redeem great prizes, the new and improved AD Rewards program allows you to capitalize on the power of your purchases from AD distributors like never before.

With over 6,000 valuable merchandise and travel rewards, your relationship with your AD distributor has never been more powerful…or lucrative.

Join today at any of these participating AD distributors.