120 min standalone unit 2 x 2.4W LED heads Uses

Working in the electrical business is often a highly localized profession. Contractors, electricians and powerline technicians all tend to service infrastructure relatively close to where they are already living. And with that in mind, you may well wonder if you are charging enough for your services, compared to your counterparts across the rest of the country. If you are an employee, is your boss paying you enough for the job you’re doing?

To help answer these questions in a cross-Canada context, we are proud to be launching the first survey of its type and scale. And hopefully, by the time you read these words, you’ve already heard about it.

For what we believe is the first time in the country’s electrical industry, we are endeavouring to learn about and compare salaries and charge-out rates throughout Canada, including those for commercial, industrial, residential and high-voltage construction and service. We also want to hear about your financial successes and frustrations.

At the same time, we are highly sensitive to your privacy. While your responses will be highly valuable in clarifying the state of the industry, they will be kept entirely anonymous. We are conducting this survey for the big picture, not for your personal details.

And to help encourage your participation, we are also holding a draw for a $500 VISA gift card. Everyone who takes part in the survey can enter. (This is the only place where we’ll need your contact details, so we can send the prize to the lucky winner. But with privacy in mind, we will not even tell anyone else if you win, unless you would like them to know!)

By now, you should have received an email with a link to the survey, but if not, please be sure to visit bit.ly/2LM5sYt today to spend four minutes of your time (estimated) filling it out. And then keep an eye out for our August issue, where we will be publishing the data from this exciting new project.

Thanks in advance for your help! We really appreciate it. And if you ever want to send any other thoughts or feedback, as always, my email address is below.

10 14 18 20 24 27

The benefits of solid-state construction are still being discovered for both portable and permanent lighting installations.

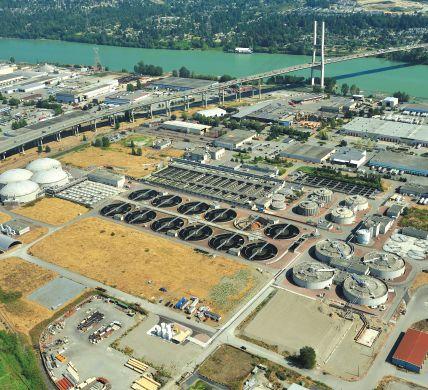

Aging on-site variable-frequency drives (VFDs) called for an upgrade with no downtime.

Electricians require fine motor skills for many common tasks. Without healthy hands, it would be difficult to continue working.

As new projects are designed around the users of a space, rather than the space itself, the ‘trend’ is really a shift in mindset.

Safety and security throughout a large building can be improved by integrating lighting and controls.

There are areas of concern when trying to control both speed and cost in the electrical apparatus service sector.

Daylight harvesting sensors can adjust brightness levels of artificial lighting to account for incoming natural light.

By way of example, adjusting office lighting to simulate changes in outdoor sunlight levels, based on the time of day, has been proven to enhance productivity. The dynamism of the effect helps people get into a better headspace and generally makes them more comfortable.

At the same time, however, another change is happening that also needs to be accounted for in lighting design: office spaces are not only being used in traditional ways. That is to say, many people are not just sitting at their desks all day. Instead, they are moving around to different spaces, participating in meetings and organizing social gatherings. There are many variables to consider, which lighting systems need to be able to accommodate.

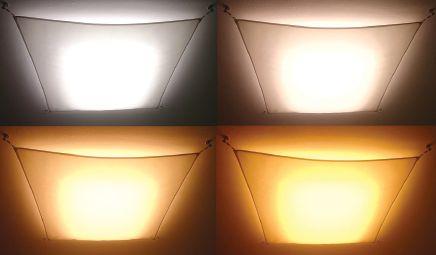

Colours and levels of lighting can be adjusted over time.

Sensors are also integral components, as they enable ‘smart’ lighting. By way of example, daylight harvesting sensors can adjust brightness levels of artificial lighting to account for incoming natural light. Motion sensors can automatically dim or turn off lights when a space is not being used. They can also be tied into plug loads, so as to reduce power to plugs and associated hardware.

These types of hardware can be added easily to existing fixtures to create a ‘smart lighting’ infrastructure and future-proof an office building’s systems. The groundwork is laid for centralized building management systems, the capability for office managers to control lighting from their

In large facilities, especially, it is important for reasons of energy efficiency to enable control over various lighting systems based on occupants’ changing requirements, as opposed to simply leaving all of the lights on all of the time. As such, office lighting—in an overall sense—needs to become more versatile.

The technology for HCL applications already exists, primarily through the use of LEDs, where standard colour temperatures in environments like these are shifting to a more comforting mix between 3,500 kelvins (creamy white) and 4,100 kelvins (neutral white).

Vickery Electric specializes in providing quick turnaround, fully customizable power posts for numerous applications, including

Design-oriented fixtures can make an office space more inviting, appealing and comfortable for longer periods.

smartphones and even integration with specialized building software, such as for security sign-in and facial recognition.

Another method for achieving HCL is indirect lighting, which allows for an overall reduction in harshness. Potlights and recessed troffers are excellent go-to options to maintain consistent lighting patterns.

There is also a movement toward task and decorative lighting in office environments. Task lighting, such as desk and floor lamps, provides individual control, so users only illuminate the space they need, as opposed to flooding the entire floor with light.

Motion sensors can be tied into plug loads, so as to reduce associated hardware.

Decorative and design-oriented fixtures, meanwhile, can both be functional and make an office space more inviting, appealing and comfortable for longer periods. A diversity of interesting fixtures, including pendant lighting and even chandeliers, is becoming increasingly popular for today’s workspaces.

Another important method is allowing for greater forethought in the design stage. This may involve facilitating a discussion between the electrical contractor, the property manager, the lighting designer and other relevant players early on, so as to understand the space before working from there.

Commercial lighting experts also have opportunities to teach clients about updating lighting in pre-existing spaces, where new hardware and wireless controls can be added to the infrastructure. There may be many options to consider.

For that matter, new lighting systems are very scalable. There is a chance to implement them first in small test

areas, one at a time, to get used to them and to learn more about what works for the space, before expanding them throughout a facility.

The overall positive effect of HCL on office workers’ well-being has been scientifically proven. It is also a benefit for their employers, since happier employees are more productive and more likely to stay in an organization.

As for property owners, better-designed lighting systems can help attract high-quality tenants and help retain existing ones. By differentiating a space, it may increase its value.

For most electrical contractors across Canada, HCL represents a new offering to their clients. The current knowledge base is still low, so there is a significant opportunity to educate their clients, increase—and add value to—their services and get to handle more projects.

More ‘thoughtful’ lighting is also more efficient lighting, contributing to an overall reduction of energy consumption, prolonging the useful life of hardware and reducing maintenance costs. It is important to convey this benefit to customers.

It is not a matter of if office building managers switch to HCL, but of when. Electrical contractors who get a head start on learning more about this field and delving into designing systems accordingly will benefit the most in the long run.

Latif Jamani is the president and Karim Panjwani is the general manager (GM) of Calgary Lighting Products. For further information, please visit www.calgarylightingproducts.com.

With all the noise and confusion in cyberspace today, it’s more important than ever to ensure your presence and visibility in Electrical Business Magazine’s long-running, easily-accessed buyers’ guide for electrical contractors... the EB Bluebook!

The Bluebook buyers’ guide is being published in August as a stand-alone magazine, but will feature our first-ever national survey of Salaries for electrical contractors and electricians, PLUS their Charge-out Rates.

As a manufacturer, distributor or service provider, this is an opportunity you don’t want to miss.

Promote your organization’s solutions with a FREE basic listing in the 2019, which also resides all year long at EBmag.com as a searchable online directory.

Visit ebmag.com/bluebook, or contact:

Anthony Capkun

Publisher

acapkun@ebmag.com

905-717-6421

Jennifer

DiIorio

Account Manager

jdiiorio@ebmag.com 416-510-5230

Regulations also call for monthly and annual testing, with the results recorded in a log. This testing must include verifying battery operations by simulating a failure to ensure the luminaire is working properly.

The regulations for annual testing involve the same procedure as those for monthly testing, except the emergency lights need to be operated for their full rated duration (normally three hours) to confirm the batteries work properly. Upon completion of this testing, all of the lights need to return to their ‘readiness state,’ once power is restored and the results are logged.

To become truly automated and go beyond minimal safety requirements, emergency lighting needs more capabilities, such as:

• Testing from anywhere at anytime, including function tests, duration tests, automatic logging and automated failure alerts.

• Real-time emergency monitoring of current status and incidents.

• Remote maintenance monitoring, including alerts for end-of-life of products, as well as lamp, LED and battery failures.

• Greater integration of emergency lighting with security and access systems.

• Analytics to determine building occupancy rates and traffic patterns.

With added capabilities like these, while maintaining ease of use, new emergency lighting systems can make buildings even safer. Consider, for example, the potential for intelligent building evacuation. With sensors embedded in emergency light fixtures, it would become easier to identify parts of a building that pose a danger, such as fire. Those same sensors could then be used to activate lighting to help direct occupants to a safe exit point, rather than inadvertently leading them through or into danger.

over Ethernet (PoE), whereby the same cabling provides both power for lighting and data for communications.

New construction, however, comprises only a small fraction of the commercial building space. In most cases, building owners are instead looking to retrofit existing lights with LEDs to save on their operating costs.

One of the advantages of LEDs over traditional lighting is they are dynamically ‘tunable’ in terms of both intensity and hue. Built around semiconductors, LEDs offer embedded programmability.

Since emergency lights are installed at strategic locations throughout a facility, they provide an ideal set of end points for a building-wide management and control infrastructure. All you need to do is add the programmable sensors to the luminaires.

As the sensors are connected, they will form a communications network. The two basic options for such a network are wired or wireless.

Wired connections may make sense in new construction, where you can plan out the network in advance. Some luminaire manufacturers have even experimented with Power

In such situations, hard-wiring luminaires into a single system can be cost-prohibitive and impractical. Enter wireless communications. By equipping emergency LED lighting with built-in support for wireless communications, such as Bluetooth mesh networking, you can develop a building-wide lighting control infrastructure without having to rip out or replace any existing wiring.

While Bluetooth is a mature standard for device-to-device communications, Bluetooth mesh is newer—conceived in 2015 and introduced in 2017—and can establish a broadcasting grid to reliably link multiple devices to each other. Like Bluetooth, it is an open, manufacturer-independent standard, so any vendor can create interoperable products.

Unlike other types of data networks that require hubs and routers, Bluetooth mesh is a low-energy, radio-based protocol where each device broadcasts the same data to all other devices within range. The beauty of this approach is it is extremely reliable and scalable. Since the connection points (or nodes) in the mesh network relay all of the messages, if one node fails, then the data is sent through adjacent connection points, so there is never a failure. Also, devices can be added to or removed from the mesh without causing disruptions.

For emergency lighting testing, Bluetooth mesh makes it easy to initiate and log the tests from a central console, saving time and resources while ensuring regulatory compliance.

With data delivered to a central control console, you now have an interactive system that can be extended for building automation purposes. The sensors in the emergency luminaires, after all, can also be used to monitor and report other conditions.

Sensors can be deployed to detect fire, smoke, carbon monoxide, sounds ( e.g. gunshots) and other hazards. Collecting this data can support ma-

chine learning, so as to identify secure paths to safety and to activate specific emergency lights to light the way. The same sensors can even detect room occupancy, to determine if and where people may be trapped.

In addition to such emergency-related purposes, the network can help automate everyday building management systems. Heating, ventilation and air conditioning (HVAC) systems can respond to changing temperatures on a localized basis. Luminaires can be dimmed in response to ambient light levels, but also, window blinds can be activated. A tenant’s smartphone can issue commands to open doors for specific areas. ‘Tagging’ can help track assets throughout the building. And Bluetooth-enabled ‘beacons’ can assist in wayfinding.

To consolidate all of these building controls, however, you need a common language to enable interoperability between devices. A building might use Digital Addressable Lighting Interface (DALI) for dimming its lights, but a separate system for managing HVAC.

IoT is proving a viable ‘lingua franca’ for all types of devices, but you still need a common control interface. One example is Elitedali, which is based on Tridium’s Niagara framework.

A common platform that integrates lighting with other building features makes it easier to automate advanced functions, such as using smoke sensors to trigger lights, doors and alarms to help direct occupants to safety in case of fire.

In these ways, what was once a nuisance for building managers can now offer advanced diagnostics and analytics. Indeed, emergency lighting retrofits can lay the foundation for a new era of building automation.

Russ Sharer is vice-president (VP) of global marketing for Fulham, a supplier of commercial lighting components. This article is based on a seminar the company presented at the 2018 LED Professional Symposium (LPS) in Bregenz, Austria. For more information, visit www.fulham.com.

Expose yourself online! EBMag.com boasts over well 28,000 page views per month. That’s a whole lot of good online exposure for very reasonable rates! Visit EBMAG.com/advertise

There are areas of concern when trying to control both speed and cost./

BY MIKE HOWELL

End users desiring speed and/or torque control often buy variable-frequency drives (VFDs) to modify existing applications where a standard induction motor is in place. Frequently, they try to control costs by using that existing standard induction motor. Before taking that path, however, it is best to consider a few areas of concern with the approach.

Motors designed for use with VFDs must meet the requirements of National Electrical Manufacturers Association (NEMA) standard MG 1, Part 31. These requirements include defined speed-torque characteristics, such as are shown in Figure 1. Additionally, motors that meet the requirements of Part 30 of the same standard may be suitable for inverter duty if appropriate measures are taken (e.g. line conditioning).

Figure 2 shows a typical speed-torque curve for an induction motor with some fixed voltage applied to the machine terminals that results in acceleration according to the machine dynamics.

Point 3 in Figure 2 represents the speed at rated or full-load torque and corresponds to Point 3 in Figure 1. Using a standard induction motor with a VFD without proper evaluation to determine Points 1, 2 and 4 from Figure 1 introduces the potential for overheating in the lower speed range (i.e. below Point 3) and mechanical damage from overspeeding (i.e. beyond Point 3).

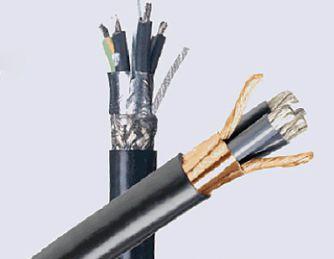

Shaft currents are another major concern. The high switching frequency associated with inverter operation produces a capacitive coupling between the rotor and the stator that can lead to shaft currents and, as a result, damage to the bearings and lubricant. Motors designed for operation on

VFDs usually have insulated bearings and shaft grounding brushes. These modifications can often be made to standard motors.

Standard induction motor stator windings are usually not insulated for use in VFD applications. Most machines designed for inverter duty use a modified magnet wire. They also may have enhanced ground insulation and more robust coil bracing.

Among other installation details to consider for VFD applications, it is important to establish a low-impedance common ground for the motor, drive and electrical system. Cable manufacturers have developed products specifically for this purpose, as shown in Figure 3.

While service centres can often modify the bearing and stator winding insulation to address potential issues with VFD applications, defining a speed-torque curve to a standard motor as shown in Figure 1 is not easy. Variable-torque loads, such as fans and centrifugal pumps, are less risky candidates for such modifications, providing the maximum operating speed does not exceed the motor’s base speed. Constant-torque loads like conveyor belts would be more susceptible to overheating in the low speed range. The most conservative approach for adding speed and/or torque control is to buy an inverter duty motor that is appropriate for the application. If the goal is just to limit starting current, using a variable-voltage, fixed-frequency soft starter is much simpler.

Mike Howell is a technical support specialist for the Electrical Apparatus Service Association (EASA), an international trade organization representing more than 1,800 firms that sell and service electromechanical apparatus offerings in approximately 80 countries. For more information, visit www.easa.com.

need help prospecting? Has Canadian Anti-Spam Legislation reduced your email prospects list? EBMag’s newsletter reaches 12,900 CASL-compliant subscribers, and it does so every week! Visit EBMAG.com/advertise

MIKE DOHERTY

The two most evident electrical hazards in a workplace, i.e. shock and arc flash, can be extremely dangerous to people, infrastructure, profits and business concerns. As such, there are moral, social and economic costs involved, to varying degrees, with the consequences of a significant electrical incident in the workplace.

The first rule for workers within the scope of CSA Z462-18 (Clauses 1.1 and 1.2) for the electrical trades is to only do work in the de-energized state, if feasible, as per the documented procedures in place. This rule requires strict, rigid procedural adherence to what is most often described as a documented lockout/tagout (LO/TO) program, as defined by the individual business unit executing the work. Another relatively common term is a Control of Hazardous Energy (COHE) program.

Electrical contractors may use their own program or a similar program from their client, if agreed upon beforehand. Employees must be trained and competent in the use of these programs. Documented audits need to be completed on a regular basis to ensure accountability at all levels.

TO program is highly recommended, to ensure it is equal to or greater than CSA Z460-13. This opportunity for improvement cannot be overstated in terms of its value on many levels, including but not limited to safety.

The first rule is to only do work in the de-energized state.

CSA Z460-13 (R2018) is the go-to standard in Canada for all LO considerations, within the scope requirements of CSA Z462-18 or as appropriate to the requirements of the specific electrical sector. (Note: CSA does not use the term ‘tagout’ in Z460.)

Regulators across the country fully expect comprehensive due diligence, with business units’ managed systems using the standard as an integral tool to ensure a safer workplace. During an incident investigation, they often look for where LO/TO considerations may have been less than adequate.

With this in mind, a deep-dive, fully documented audit of your current LO/

It is important to note CSA Z462-18, Clause 3, includes a whole section of definitions that have been reviewed and improved over the past 12 years and four editions; it is an outstanding reference section that is closely aligned with other best-case standards from around the word, reduces murkiness and vagueness in the electrical industry and is definitely helpful when planning work. Clause 4.2, meanwhile, features eight detailed steps for ‘establishing an electrically safe work condition.’

By way of example, ‘de-energized’ is defined as ‘free from an electrical connection to a source of potential difference and from electrical charge, i.e. not having a potential different from that of the earth.’ This is a critically important definition for the fundamental requirement to establish and verify an electrically safe work condition as per Clause 4.2.5. It is simply not adequate or acceptable to use

jargon like “we’ve turned off the power” or “it’s dead” in an LO/TO work program, which communicates very serious interactions between professionals in the electrical trades.

Clause 3 defines an electrically safe work condition as ‘a state in which an electrical conductor or circuit part has been disconnected from energized parts, locked out in accordance with established standards, tested to verify the absence of voltage and, if necessary, temporarily grounded for personnel protection.’ This is a professional and accurate description of the true goal of an LO/TO or COHE procedure in ensuring extreme clarity and safety for electrical workers.

Words are important. Jargon will not suffice.

Mike Doherty is president and owner of Blue Arc Electrical Safety Technologies and an electrical safety subject-matter expert. His specialties include electrical safety management, consulting, training, auditing and incident investigations. He is an independent electrical safety consultant/trainer contractor for eHazard in Canada, an independent technical advisor contractor for eWorkSAFE in Canada, a licensed electrician and an IEEE senior member. He chaired the Technical Committee for CSA Z462 from 2006 to 2018 and continues to serve on the committee. For more information, contact him via email at mike.doherty@e-hazard.com.

Answers to this month’s questions will appear in the August 2019 issue of Electrical Business

Compiled by Ray Yousef, code engineer

Ontario’s Electrical Safety Authority • esasafe.com

QUESTION 1

For a disconnect switch fused at 400 A and fed with multi-conductor 600-kcmil copper in a raceway, marking is required beside it to state the maximum permitted continuous load.

a) True. b) False.

QUESTION 2

The consumer’s service head or equivalent shall be installed in such a position that the point of emergence of the conductors from it is a maximum distance of horizontally from the support for attachment of the overhead service conductors.

a) 150 mm d) 750 mm

b) 300 mm e) none of the above

c) 600 mm

QUESTION 3

When feeding building B from building A:

a) The system shall not be grounded at Building B.

b) A bonding conductor is required to be installed from Building A to Building B.

c) A system bonding jumper is required to be installed in the panel of building B.

d) All of the above.

e) A & B.

ANSWERS Electrical Business, May 2019

Question 1

Each vehicle space in a carport or garage is required to have:

b) One receptacle for each vehicle space, readily accessible. Rule 26-726, CE Code 2018.

Question 2

Rapid shutdown is required for PV systems on or in buildings where the PV source or output conductors are:

d) More than 1 m from the array with shutdown within 30 seconds. Rule 64-218, CE Code 2018.

Question 3

Equipment marked Ex ia Gb is suitable for installation in a Zone 0 location.

b) False. Rule 18-090, Table 18, CE Code 2018

How did YOU do?

3 • Seasoned journeyman 2 •Need refresher training

1 • Apprentice 0 • Just here for fun!

DeWalt is expanding its 20V Max system with the Atomic compact series of six new tools, which will be rolled out throughout 2019 and 2020. Designed for electricians working in tight spaces, overhead and/or for long periods, the line launched this spring with the 20V Max compact drill/driver and impact driver, kitted with two compact batteries or available bare (i.e. without batteries) and featuring brushless motors, LED worklights, variable speed triggers and adjustable belt hooks for left or right attachment. This fall, they will be joined by the 20V Max compact hammer drill/driver, circular saw and oscillating multi-tool. Finally, in early 2020, DeWalt will release the 20V max compact reciprocating saw. dewalt.ca

Arlington cable connectors install with the push of a button

Arlington’s White Button non-metallic (NM) cable connectors can be installed from inside or outside an electrical box, with push-in functionality. Listed by both CSA and UL, they allow one or two cables to be inserted through a single opening. Models include the NM94X for 0.5-in. and NM95X for 0.75-in. knockout (KO). Arlington reports the new connectors cost the same as its earlier NM94 and NM95 models. aifittings.com

Legrand’s Wattstopper wireless digital lighting management (DLM) system includes a variety of IPv6 mesh-based wireless control products, such as dimming room controllers and wall switches, ceiling- and corner-mounted passive infrared (PIR) occupancy sensors, digital photosensors and five-button scene switches, complemented by a custom configuration app for Bluetooth commissioning and a new version of Wattstopper LMCS software for project design and advanced programming. legrand.us

FLIR’s non-contact

FLIR Systems has designed its new VP40 non-contact voltage detector with a built-in flashlight for preliminary jobsite checks on live and neutral wiring in sockets and junction boxes. The pen-sized tester verifies the presence of AC voltage in residential, commercial and industrial electrical installations without having to contact the wires. Carrying a CAT IV safety rating, it uses multi-colour LEDs and vibrations to alert electrical contractors of live voltage, so inspectors do not miss such notifications in loud or dark locations. Its anti-roll case body can reportedly withstand a 3-m drop onto concrete. flir.com

DAVID PILON

When an authority having jurisdiction (AHJ) such as myself asks, “What is your area classification or designation?’ what are we really asking? Most people assume we are looking at a section 18 requirement for a hazardous location. There are, however, several sections in which a determination from a third party is required and, in most instances, it must be in writing.

By way of example: is there a hazard due to the equipment you are installing? More specifically, is there a hazard to people due to both the type of equipment and how it interacts with them? Is the process you are planning to perform creating an atmosphere that may interact with people, equipment or other process and lead to the failure of a piece of equipment?

We are asking what your process entails and what type of research and background information have you obtained regarding it. If you hired an electrical engineer, did they do their due diligence to ensure the process and the wiring methods are compatible?

If your customer is designing a health care facility, have they been in contact with the health authority or made a ‘determination of area’ in accordance with CSA Z32? Have they been made aware of the maintenance requirements under the choice of processes or wiring methods? As an inspector, if I don’t have the determination of areas in writing from the owner or health authority describing

the patient care environment, then I must assume the worst-case scenario, which can be a disadvantage to the customer in terms of higher costs, especially if after the fact.

What about the installation of lighting in an area where, say, they have always done the painting this way and it hasn’t been a problem? Does this make it okay for the contractor to assume the area is normal?

This is the type of scenario where the contractor needs to look closely at the CE Code, get an engineer involved or call the inspector for a site visit. The intent is to save the customer money in the long term. Maybe it is a normal area, but if the contractor is questioning it, then there is a good chance the inspector will be questioning it as well. Replacing equipment and wiring after the fact will always be costlier, especially when paint lines get shut down, processes get backed up and more expensive equipment needs to be ordered and installed.

rosive location, wet location or patient care area.

Often, the answer is clear-cut in the code and no further questions need be asked. Examples include service stations, bulk storage plants and automotive paint mixing rooms.

Other times, however, there may be methods for mitigating hazards, such as poor ventilation, in which case the areas are no longer classified. And unless it is in writing that the hazard has been removed, inspectors will keep on the safe side and call it a hazardous location.

If I don’t have the determination of areas in writing, I must assume the worst-case scenario.

What we need to understand is to which section of the code the area would be referenced. If it falls under section 18 to 24, then we have specific rules that come into effect and we should immediately check if the area has been designated as a hazardous location, flammable liquid, propane, or gasoline dispensing location, paint booth, repair garage, bulk storage, cor-

When engaging the services of an engineer, it is also important to ensure they understand what the process involves. The code is not a design document, but an installation document. With this is mind, Appendix L was added to provide guidelines engineers would require in performing hazardous area classifications. This section has been beneficial to many people who have wondered, “How do I do this? Where do I find the relevant information?’

Remember, if you are not sure, a quick call to your local AHJ could save you time and your customer money.

Always consult your AHJ for more specific interpretations.

David Pilon is an electrical inspector with SaskPower, the utility’s training co-ordinator for electrical inspectors and vice-chair of the Canadian Certified Electrical Inspector (CCEI) committee of the International Association of Electrical Inspectors (IAEI), Canadian section. He can be reached at dpilon@saskpower.com.

Gutenberg would be proud! Electrical Business Magazine is published by Canada’s largest B2B publisher, Annex Business Media... and we have our own presses! Talk to us about your custom publishing needs. Visit EBMAG.com/advertise

The FLIR C3 is an affordable, pocket sized, professional thermal camera made for any job site. Easily troubleshoot electrical issues such as:

• Overheating circuit breakers

• Miswired connections

FREE VOLTAGE DETECTOR WITH FLIR C3 PURCHASE FOR A LIMITED TIME

Learn more at www.flir.ca/c3-vp50-promo

With AD Rewards, you can be rewarded for purchasing participating products from AD Canada Distributors. Earn one point for every dollar spent(1) at any AD Rewards Distributor(2) across Canada. You may already have points and not even know it. It’s the best rewards program in the industry. Isn’t it time you started rewarding yourself?