ARE MICROGRIDS A KEY TO GRID RESILIENCY?

When

the main grid falls short, the right mix of renewables offers local, low-carbon power /

BY KELSEY ADKISSON

The aging energy grid is being pushed to the breaking point. Power outages from extreme weather alone cost anywhere from $2 billion to $77 billion per year. And some isolated communities still rely on diesel generators for electricity, since powerlines don’t reach them. Grid expansion isn’t an option—in most cases, the economics don’t make sense.

Where the main grid falls short, such as in isolated communities or when the lights go out from extreme weather, microgrids are a solution for more resilient power. These decentralized, self-sufficient energy hubs can run independently or connect to the larger grid. Yet one lingering hurdle is

“It’s hard to put a price tag on resiliency.”

microgrid design. Getting the mix of power sources right involves complex trade-offs between risk tolerance, cost, and going green.

New research from a team at Pacific Northwest National Laboratory (PNNL) shows that resilient, “hyper-local” microgrids provide economic value when designed with the right mix of power sources. In a series of studies and a presentation at the European Wave & Tidal Energy Conference, the PNNL team predicted the role that both large and small microgrids can play in the drive toward renewable and resilient power.

Lessons from a tiny Hawaiian island

Spurred by a state mandate, the Hawaiian island of Moloka’i is grappling with transitioning to 100% renewables by 2045. Without access to a larger grid and relying on imported diesel, residents pay nearly three times more than the U.S. average cost of electricity. Less than a third of that power comes from renewables, while the rest comes from fuel-powered generators.

Yet the things that make the Hawaiian Islands special—the ocean breeze, sun, and waves—all bode well for a microgrid test case. Moloka’i’s aim to kick the fuel-burning habit is something with which many other island or rural communities grapple.

A solar array at Energy Northwest’s Horn Rapids Solar, Storage & Training Project in Richland, Wash. This facility combines solar generation with battery storage.

“Microgrid design is complicated. A lot of communities aren’t set up to develop something like that,” said Dhruv Bhatnagar, a PNNL mechanical engineer who was part of the research team focused on Moloka’i as part of a larger evaluation of marine energy resources.

Like the reduced risk that comes from a diversified investment portfolio, a variety of power sources helps reduce risk of a microgrid not being able to cover the energy demand. Typically, microgrids include solar and/or wind, which charge batteries, plus a diesel generator for backup.

Since Moloka’i’s goal was zero emissions, researchers predicted what would happen if existing diesel generators were swapped with marine energy. When added to the mix of wind and solar, marine energy not only ramps up resiliency, but also slashes reliance on fuel.

To meet the zero emissions goal, the research team found that using marine energy can cut the need to build solar and wind up to 50% compared to not including marine energy in the portfolio, plus less battery storage is needed. That’s good news for communities since batteries are expensive. Also, less emphasis on solar means a reduced land-use footprint.

And space is a big deal on a small island.

Resilient microgrids to rebound faster, longer

When Hurricane Sandy slammed into the Eastern Seaboard in 2012, the damage was so significant that parts of New York and New Jersey were without power for months afterward. Meantime, a microgrid at Princeton University in New Jersey kept the lights on for emergency workers and at key facilities.

There is growing interest in designing microgrids to power things like hospitals, shelters, or police stations during emergencies. Yet microgrid design tends to focus on minimizing cost rather than enhancing resiliency, which means rebounding quickly when

Battery storage at Energy Northwest’s solar array. Batteries are a critical component of microgrids, which also often include backup generators to withstand emergency outages during a range of weather conditions.

“Getting the mix of power sources right involves complex tradeoffs between risk tolerance, cost, and going green.”

the power goes off. But the cheapest solution isn’t always the best.

“It’s hard to put a price tag on resiliency,” said Sarah Newman, a PNNL data scientist who led a study evaluating microgrid design for U.S. Army posts, which need to be self-sufficient for longer durations. For example, a hospital will place more value on reliable, resilient energy during disasters as opposed to a homeowner who might be able to go a few hours without power.

Solar microgrids are typically powered by solar paired with batteries, with fuel-powered generators for reliable backup. Generators are critical in bridging gaps when batteries aren’t fully charged (e.g. cloudy days), or when energy demand is high and excess can’t be saved.

Newman and her team predicted everything from optimal generator sizes and how much fuel they would need to store for energy use in different types of buildings... and even solar patterns and weather in different states.

They found that, in some cases, the generators aren’t big enough for the

microgrid to be resilient during a variety of outage situations. Plus, the generators need up to 30% more fuel than previously predicted when extreme weather is not accounted for during design. When that extra fuel isn’t planned for, then the microgrid won’t be able to meet the energy demand.

“Stopping after a week and a half may not be an option when a microgrid is the backup for critical facilities,” said Newman. “This underscores how important designing microgrids around resiliency actually is.”

Microgrid modelling

The modeling work being done by PNNL can help decision-makers weigh trade-offs and, ultimately, design microgrids that are more likely to keep the lights on during an emergency or power areas without access to a main grid. With extreme weather events expected to climb, designing resilient microgrids will likely continue to be pertinent in the future.

Science communicator Kelsey Adkisson has specialized in environmental science, policy, science writing, and social media for the past 15 years. At PNNL, she primarily writes about energy and the environment. Founded in 1965, PNNL is operated by Battelle for the Department of Energy’s Office of Science—the single-largest supporter of basic research in the physical sciences in the United States.

PRINCIPLES OF GAS STATION LIGHTING

Safety, convenience... and marketing / BY STAFF

During the light of day, one could be forgiven for thinking one gas station looks the same as another (corporate branding aside, that is).

It’s at night, however, when a gas station with a well-designed and properly executed lighting scheme really shines. It can make all the difference when a driver is deciding where to pull in for gas, and maybe pick up a drink and some snacks.

Gas station lighting design should consider the following areas:

• Canopy lighting

• Convenience store lighting

• Auxiliary area lighting (vacuum station, BBQ tank exchange, etc.)

• Sign lighting

• Outdoor lighting

For all of these areas, the lighting should serve the employees who work there, and ensure a satisfying customer experience—or the promise of a good experience—from a distance. In essence, it’s a

combination of both functional lighting, supplemented by decorative lighting.

Bright and easily recognizable signage—especially at a distance—helps establish both a sense of security and trust, thereby attracting customers to one gas station over another. Of course, this also strengthens the gas station’s brand, ensuring customers will seek out that brand for future visits.

Tips and tricks

One should consider several important elements with regard to lighting a gas station.

Ensure the overall lighting provides proper horizontal and vertical illuminance. Good horizontal illuminance helps ensure a safer driver experience, while good vertical illuminance helps aid refuelling operations. The lighting should be pleasant, evenly distributed, and avoid creating distracting glare.

Ultimately, the right lighting atmosphere means vehicles can enter and exit without glare, signage is clear and easy to follow, and activities such as refuel-

ling, wiper fluid top-up, payment, etc., are easily executed.

The gas station canopy demands high-quality lighting so that drivers can clearly see fuel information when entering the gas station, avoid obstacles, and enter/exit safely. Rather than lighting that only focuses light on the ground, consider solutions that also help light vertical surfaces (e.g. sides of the vehicle, other vehicles and people).

The light should not interfere with digital screens on the pumps.

Convenience store lighting

The lighting in the gas station’s convenience store serves double-duty: besides providing required illumination, it serves to stimulate the consumer’s desire to buy and to make it easy for them to do so.

Lighting in the shopping area should employ bright lighting to make the customer feel comfortable and safe, establishing the notion that this is a good place to spend some time and buy a few things.

Continues on page 21

RENEWABLES OR NUCLEAR ENERGY... WHY NOT BOTH?

BY KEN DARLINGTON

According to a 2021 Abacus Data report commissioned by Canada’s leading electricity associations, Canadians across the country are concerned about climate change and believe we should invest in clean energy technology.

As we work to identify the energy generation options that are most viable for Canada—sustainably, economically, reliably, and politically—it would seem we are compelled to find a single answer.

But there is no single perfect solution.

Instead, we need to implement multiple, complementary systems that will better enable us to meet our collective energy and climate goals. The most viable zero-carbon energy mix is a hybrid approach that leverages multiple clean energy technologies, including renewables such as wind and solar, and next-generation nuclear technologies.

The primary benefit of renewable solutions is clear: zero-carbon power. But while renewable energy generation has advanced and become more economically viable, it is not without limitations; the most notable being the fact that adequate environmental conditions (the right weather, position of the sun, and other environmental factors) must exist to generate power.

Even with battery storage, these limitations preclude renewables’ effectiveness at meeting load demands in certain environments.

However, the benefits of renewables can be realized in just about any scenario when they are complemented by reliable, baseload power. That’s where nuclear becomes an essential companion to renewables.

For off-grid applications, such as remote communities and mines, a new generation of very small modular reactors (known as microreactors) is capable of providing

We need to implement multiple, complementary systems that will better enable us to meet our collective energy and climate goals.

reliable, scalable power production, regardless of environmental conditions. When deployed as a hybrid system, the microreactor acts as a carbon-free peaker plant providing reliable power to complement insufficient renewable supply.

Continued advancement led us here

Several advanced nuclear technologies and applications, including microreactors, have been developed in recent years. Fourth generation (Gen IV) reactors offer many game-changing features for nuclear energy generation, including inherent safety, efficiency, cost-effective modular construction methods, scalability, and repeatable designs.

These new nuclear technologies are the result of a research and development effort not unlike that which resulted in the large conventional CANDU reactors that have served Canada and other countries for decades.

Small modular reactors can be built in a factory setting and shipped to power generation sites no larger than a few football fields. The nuclear industry has also advanced nuclear fuel design and developed radically simpler reactors to create passively safe systems and improve fuel utilization to reduce waste.

Balancing energy needs, slashing emissions

Availability of zero-carbon Gen IV reactors is in our immediate future. Released in 2020, Canada’s Small Modular Reactor (SMR) Action Plan

is the country’s official strategy for the development, demonstration, and deployment of SMRs for multiple applications, and the safe management of fuel and waste. Innovative companies are making great strides in helping us meet our federal, provincial, and territorial emissions targets (smractionplan.ca).

Among the world’s microreactor developers, USNC continues to progress toward demonstrating the technical and financial viability of its Micro Modular Reactor (MMR) and unique fuel designs, including applications in hybrid environments. USNC’s proprietary fully ceramic microencapsulated (FCM) fuel provides safety at the fuel level, rather than requiring complex and extensive safety systems.

The deployment of USNC’s first MMR in Canada achieved an important milestone in 2020 with the signing of a Project Host Agreement for the initial deployment site at Chalk River, Ontario.

The project, which will be constructed and operated by Global First Power—a joint venture between USNC and Ontario Power Generation—is currently the first and only SMR project to enter the formal licensing phase with the Canadian Nuclear Safety Commission (CNSC) and is on track to be the first commercial microreactor deployment in Canada.The project Environmental Assessment (EA) is underway, as is the Licence to Prepare Site—the initial phase of the CNSC licensing process. The start of operations is planned for 2026.

Not this or that, but both

The MMR addresses the primary challenge of integration with renewables— providing reliability and matching supply with demand—and can be deployed as part of hybrid energy systems, addressing inherent power-demand limitations. The nature of USNC’s design allows utilities and power purchasers to effect-

Retail Lighting

Continued from page 18

It’s official – Canada confirms nuclear is “clean” energy

On November 3, the Government of Canada released a fiscal update that introduces an investment tax credit of up to 30% for clean energy technologies, including small modular reactors (SMRs), reports the Canadian Nuclear Association.

The government has also indicated that it will consult on additional technologies, including large-scale nuclear. This inclusion of nuclear in this tax credit sends a clear signal that the Canadian government considers nuclear power to be “clean energy”—on par with all other low-carbon technologies, including renewables, CNA says.

“Including nuclear in the investment tax credit for clean energy technologies is a major step forward for the industry and great news for our climate and economy,” said John Gorman, CNA president & CEO. “It confirms what we at the CNA have been saying for years: that nuclear is clean energy, and must be a key part of Canada’s strategy to maintain energy security while reducing emissions on the path to net-zero.”

The Canadian Government’s support for nuclear has increased steadily over the past year, CNA recounts, and has included funding announcements for small modular reactors (SMRs) under the Strategic Innovation Fund, budgetary commitments for Natural Resources Canada to promote the development of SMRs and, most recently, a $970-million loan from Canada Infrastructure Bank for the development of new nuclear at Darlington (Ontario).

Provincial governments have also “signalled strong commitment to nuclear”, CNA continues, including the release of a Strategic Roadmap for SMRs by Ontario, New Brunswick, Saskatchewan, and Alberta; the announcement by SaskPower that it is exploring the potential to build an SMR in the 2030s; and a lifetime extension of Pickering Nuclear Generating Station (to be followed by a study into possible refurbishment).

The benefits of renewables can be realized in just about any scenario when they are complemented by reliable, baseload power.

ively address their power generation needs, including spikes in demand, with no carbon emissions.

The MMR operates as a nuclear battery, dispatching its energy as needed, thereby ensuring a stable energy supply.

Additionally, the MMR is set to achieve the goal of zero-carbon power generation in settings that typically rely on diesel for electricity generation. For example, a single MMR system producing 5 MW of electricity can replace over 200 million litres of diesel during its 20-year fuel cycle.

When we consider a mining operation (a potential use case for MMRs) that requires 20 MW of energy, the MMR

represents a displacement of over 800 million litres of diesel—the equivalent of 9000 rail tankers. This works out to 40 million litres per year, the same volume as 16 Olympic-size swimming pools of diesel every single year.

Advancements in Gen IV nuclear, together with the support of Canada’s federal and provincial governments, means Canada is maintaining a leadership position in developing solutions to meet our power and net zero goals. That solution needs to leverage all viable technologies at our disposal, including approaches that combine sustainable, renewable technologies with Gen IV nuclear.

Ken Darlington is vice-president, Corporate Development, at Ultra Safe Nuclear Corporation (USNC). USNC-Power—the Canadian subsidiary of USNC—is partnered with Ontario Power Generation to build, own and operate the Micro Modular Reactor (MMR) Project at Chalk River in Ontario. This guest post was first published May 2022 at EBMag.com.

PRINCIPLES OF GAS STATION LIGHTING

The lighting on the shelves, coffee station, etc., typically adopt warm colours, which makes them stand out from the overall illumination scheme and appear more inviting.

For the cashier area, a warm light is also suggested, as this creates a welcoming atmosphere for customers when they engage with staff.

Also a hazardous location

Don’t forget that a gas station is also classified as a hazardous location (to varying degrees, depending on the area). In looking at CSA Group’s notes about North America’s transition from the Class/Division system to the 3-Zone system for hazardous locations, you can see how a simple gas station easily includes all three zones:

• Zone 0 – An area in which an explosive gas atmosphere is continuously present for a long period of time.

• Zone 1 – An area in which an explosive atmosphere is likely to occur in normal operation.

• Zone 2 – An area in which an explosive gas atmosphere does not normally exist.

So while good lighting is crucial for practicality and safety, it could also inadvertently become an ignition source if not specified correctly. This is why it is so important to ensure the hazardous locations are properly classified, and that the fixtures specified and purchased meet those location requirements.

— With files from Tachyon Lighting, NJZ Lighting, CSA Group

MOVING FROM DEI TARGETS TO COMMITMENTS

Reflections from EHRC’s Agents of Change / BY

ANTHONY CAPKUN

Agents of Change is Electricity Human Resources Canada’s (EHRC) annual flagship event on diversity, equity and inclusion (DEI), and EBMag caught some of the action across the national two-day forum (electricityhr.ca).

The event’s theme this year was “The Power of Change”. Like all Agents events, the ultimate goal is “to create workplaces where all employees feel valued, respected and heard”.

To that end, EHRC lined up a powerful roster of speakers and presenters on topics such as:

• Gender expression, gender identity, and sexual orientation.

• Supporting reconciliation and strengthening relationships with Indigenous peoples.

• Becoming a DEI ally and champion, and making DEI an enterprise priority.

• Supporting people with disabilities (not “disabled people”) with accessible workplaces.

Considering all the delegates assembled, I imagine some discussions from Agents will stick out more than others. For me, there were two: 1) mental health and 2) anti-DEI behaviour in the construction sector.

1. Mental health by the numbers

During his keynote, Dr. Ryan Todd stated 81% of employees reported feeling they were at risk of burnout—an 18% increase

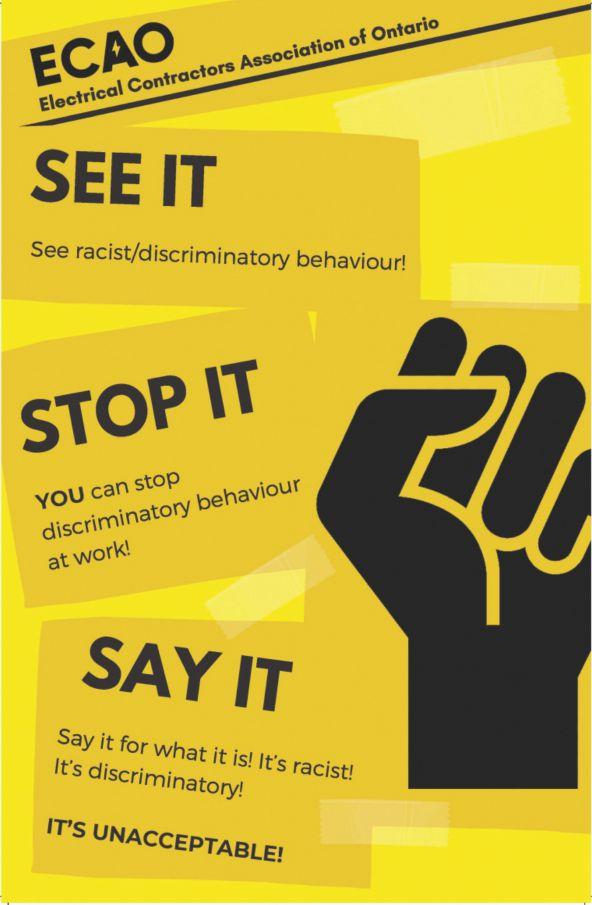

ECAO’s campaign to combat racist/ discriminatory acts and behaviour.

Source: ECAO.

81% of employees reported feeling they were at risk of burnout— an 18% increase since 2019.

since 2019. Furthermore, 50% of employees who left their jobs last year did so for mental health reasons.

Noticing this trend, 42% of companies redesigned their Employee Assistance Program (EAP) in 2021, realizing the status

quo just wasn’t cutting it. Rather than an EAP, Todd suggests companies adopt what he calls a “Pre-AP” a.k.a. Pre-Assistance Program. This way, companies have a better chance at getting ahead of potential issues that could befall their employees.

CALENDAR

2. Anti-DEI behaviour in construction

“We are all agents of change... at least we can be,” said Graeme Aitken, executive director of Electrical Contractors Association of Ontario (ecao.org).

While he only spoke for a few minutes, Aitken shared some statistics (via Alex Willis of Leadership Surge) that should give us all pause:

• 63% of women who experienced harassment did not file a complaint, and 79% of men kept issues to themselves.

• Nearly 3 in 4 sexual harassment claims in the workplace go unreported.

• 55% of victims experience retaliation after speaking up or making a claim.

• According to victims who have reported harassment, 95% of the men go unpunished.

• 72% of victims were harassed by someone more senior in their workplace.

• 77% of respondents said that nothing was done to address the incidents they witnessed.

“Very few in our industry feel such behaviour, these actions, are acceptable,” said Aitken, “yet even fewer take action—even the seemingly simple act of reporting such basic violations of their fellow workers.”

How can we all be agents of change? “See it. Stop it. Say it,” said Aitken, referring to the simple, straightforward messaging of ECAO’s campaign that was launched to combat racist/discriminatory acts and behaviour.

Aitken added, “we feel strongly that [this message] is a basic call to action for anything unwelcome in the workplace and beyond”.

“Our industry—our community—is striving to be able to loudly and sincerely declare: ‘We welcome all’.”

Don’t set a DEI target, make a commitment

“Building a culture of inclusion and diversity doesn’t happen overnight.”

During the discussion “Getting it done: making DEI an enterprise priority”, Beth Buckmaster explained her company, Hatch, has established a rule that 50% of all new hires have to be women. And, before a final job offer is made to anyone, 1/3 of the finalists must be female. If not, it’s back to the drawing board (except in truly rare circumstances).

Hatch is also reviewing its remuneration scheme, and bringing women up to par with men. Buckmaster noted these kinds of initiatives do not happen overnight; they continue to make progress. Most importantly, progress is being made.

Bruce Power’s Danielle Short perhaps said it best: “We’ve moved from setting [DEI] targets to making commitments”.

The Agent of Change, 2022

CCA Annual Conference

Canadian Construction Association

March 7-10, Tucson, Az. cca-acc.com

NETA PowerTest (hybrid)

InterNational Electrical Testing Association

March 8-12, Orlando, Fla. powertest.org

IEEE IAS Electrical Safety Workshop

March 13-17, Reno, Nev. electricalsafetyworkshop.com

MCEE Expo

April 19-20, Montreal mcee.ca

EFC Annual Conference Electro-Federation Canada May 30-June 1, Charlevoix, Que. electrofed.com

EUFMC

“Our industry— our community— is striving to be able to loudly and sincerely declare: ‘We welcome all’.”

Of course, the event would not be complete without EHRC announcing this year’s Agent of Change, and that distinction falls to Carol Dayment, senior advisor, DEI with Nova Scotia Power. (Although, according to her LinkedIn profile, she is now director of DEI at Emera.)

“My role starts with enabling conversation about diversity and inclusion because, before change can happen, there needs to be a foundation of education and understanding,” Dayment was quoted in a Nova Scotia Power blog.

“Diverse perspectives put us in a better place to be creative, solve problems, and understand our customers—and it’s our job to harness the power of every unique employee. Every person who shows up here deserves to feel supported, included and heard in order to do their best work.”

“Building a culture of inclusion and diversity doesn’t happen overnight,” Dayment was quoted. “It must be driven by leadership, but employees make it happen.”

Electric Utility Fleet Managers Conference June 5-8, Williamsburg, Va. eufmc.com

EASA Convention & Solutions Expo Electrical Apparatus & Service Association

June 24-27, National Harbor, Md. easa.com

IEEE PCIC Petroleum & Chemical Industry Technical Conference

September 11-14, New Orleans, La.

ieeepcic.com

The Utility Expo September 26-28, Louisville, Ky. theutilityexpo.com

Got an event to share? Email the editor at acapkun@ebmag.com. Meantime, scroll through Electrical Business Magazine’s online industry calendar at ebmag.com/events for direct links to these events (and others).

NEMA 1 = UL TYPE 1, YET UL TYPE 1 = NEMA 1

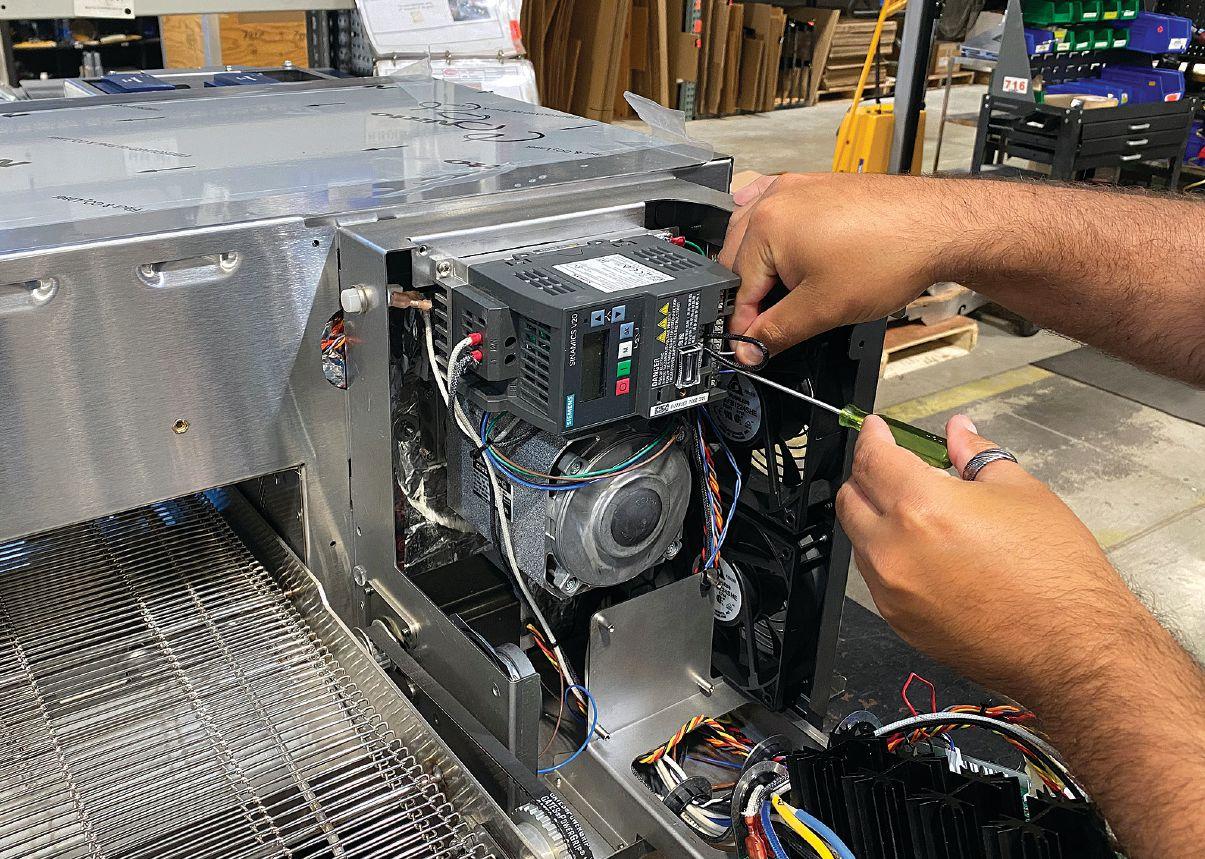

An enclosed drive market overview / BY NIKUNJ SHAH

Enclosed drives are estimated to represent between 45-55% of the total drives market worldwide.

While NEMA 1 (IP21) drives constitute the majority, others include NEMA 12 (IP54), NEMA 4 (IP65) and NEMA 3R (IP27) versions. Many are for new installations, but many others are used in retrofit installations ranging from across-the-line start to VFD (variable-frequency drive) control.

NEMA 1 and UL Type 1 are the enclosure ratings according to NEMA 250 and UL 50/50E standards, respectively, for the indoor use of an electrical equipment—in our case, enclosed adjustable-speed drives.

The NEMA rating is selfcertifying, which means the rating hinges upon the manufacturer’s compliance with published standards for enclosure protection.

NEMA 250 is an ANSI standard used for self-declaration of enclosure Type ratings e.g. NEMA 1. UL 50/50E are UL and CSA harmonized ANSI standards. However, unlike NEMA enclosure ratings according to NEMA 250, testing and certification by UL (or similar certification agency) is required

to mark electrical equipment with an enclosure rating of, say, UL Type 1 (according to UL 50/50E).

To ensure electrical and fire safety, UL-listed electrical equipment intended to be used indoors requires a minimum enclosure rating of UL Type 1 to comply with listing requirements and ensure acceptability by the authority having jurisdiction (AHJ), according to the CE Code or local applicable electrical codes and regulations.

The NEMA rating is self-certifying, which means the rating hinges upon the manufacturer’s compliance with published standards for enclosure protection.

By contrast, for “UL Type 1” listings, rigorous certification/compliance testing must be conducted against a rigid protocol of protection testing by the third party, whether for indoor or outdoor application.

In short, this is why the NEMA enclosure rating does not equate to the apparently similar UL enclosure rating, whereas products with the UL rating do, in fact, meet or exceed all relevant requirements of the NEMA specification for use in North American industrial and building markets.

The testing is performed not only to UL enclosure standards (UL 50/50E), but also the new standard UL 618005-1, which recently replaced UL 508C for variable frequency drives with respect to electrical, thermal and energy safety considerations.

Such drives are typically found on centrifugal pumps, radial/axial fans, compressors, screw pumps, hydraulic pumps, dosing pumps, and all manner of conveying equipment—plus hoists and cranes, printing presses, and so much more—in both continuous and discontinuous motion applications.

Commercial building applications for UL-listed drives and enclosures are also numerous, ranging from high-rise motor control centres (MCCs) to plenums for HVAC and lighting control.

Why is an enclosure/kit required for open drives?

For an open-type (IP20) drive, protection must be provided against direct or indirect contact of hazardous parts—as well as electrical, thermal and energy hazards in use—to ensure product and personnel safety, and avoid property damage from a potential fire hazard. Manufacturers routinely provide either a standard approved enclosure or an adapter kit for the attachment of conduit, connectors and other hardware.

In retrofit applications, there is typically no space in an existing enclosure for the additional hardware required. This additional hardware depends on the end application requirements, and could include control components such as terminal blocks, relays, DC power supplies, PLC, etc. This is especially germane when, as part of the retrofit, traditional electromechanical controls are being replaced with VFDs,

Manufacturers routinely provide either a standard approved enclosure or an adapter kit for the attachment of conduit, connectors and other hardware.

where something must be mounted external to the enclosure or MCC. In such cases, a new rating distinction must be considered essential.

Whether the enclosure is stationary or portable (as might be found in a process industry location, such as oil field operations), it is often necessary to mount the drive separately (from the other controls, power supply, PLC) in a new machine or mobile electrical power unit. This facilitates easier maintenance but, in such cases, the additional protection level of the UL Type 1 standard becomes critical.

Kits are provided to comply with relevant electrical codes and regulations for the installation and wiring of IP20 open-type drives. These UL enclosure/ kit ratings (UL Type 1, 12, 3R, etc.) guide the construction and performance in accordance with UL 50/50E + End Product Standard.

The certification process requires that the design be thoroughly evaluated and additionally tested by a third party. When a kit is deemed to be UL Type 1, it provides users the following:

• Design per UL 50 and UL 50E, plus UL 61800-5-1 for drives.

• Comprehensive independent thirdparty testing.

• UL Listed “Open/IP20” drive and UL Type 1 Kit compliance.

What to look out for in available kits

Most of the enclosure kits currently available in the market are rated “NEMA Type 1 or NEMA 1” only and are not “UL Type 1,” meaning they do not comply with UL/NEC specifications. It is suggested that checking the drives supplier is advisable to determine the UL listings applicable on their kits and NEC compliant installation.

Also, some kits available on the market are tested and listed according

to the old UL standard for drives, namely UL508C; however, they are not rated according to the latest and current drive standard UL61800-5-1. For future installations, specifiers and contractors should look to assure that the components they are installing will meet these new standards and allow for better compliance to the new testing requirements and regulations.

Why is there a new drive standard UL 61800-5-1?

The new standard calls out more stringent construction and performance (testing) requirements as compared to UL 508C, which have been imposed by the UL to ensure a higher level of product safety.

Short-circuit (SC) tests are now done at standardized amperages (5, 10, 18, 42 kA, etc.) as well as high fault currents (65 kA, 100 kA, etc.) on all output terminals—including DC terminals available to the customer (not just motor terminals).

Various breakdown-of-component tests by simulating component failures within the drive are also conducted to standard, as well as high fault currents to assure these enclosures meet the higher product safety requirements.

Not

synonymous

For the maximum protection of property, equipment and personnel, it is highly advisable to consider the differences between the NEMA 1 and UL Type 1 enclosures for low-voltage electric drives. These ratings are not synonymous, and the independent lab testing done by a third-party to UL standards has substantial merit when sourcing products for a variety of new construction, new equipment and retrofit upgrades—both indoor and outdoor, stationary and mobile.

A senior member of IEEE, Nikunj Shah is responsible for the development and certification of low-voltage drive products, as well as product management for Sinamics G120X drives. He is actively involved in the development and maintenance of various national and international standards, and represents Siemens in various standards technical panels, as well as many IEC and NEMA technical committees. He holds a Master’s Degree in Electrical and Computer Engineering, and has over 20 years of experience in the design, development and certification of converters and drives, and in their application.

Mersen Modulostar fuse holders

Source: Mersen

Now available in North America, Mersen’s Modulostar fuse holders are available from 1 to 4 poles for cylindrical fuses with a 600VAC/DC voltage rating as per class, and CC fuses up to 800VAC/1000VDC voltage rating as per midget fuses. Changing a fuse is easy thanks to the fuse carrier’s wider opening angle, says Mersen, adding the fuse holder can be opened and closed quickly with a clear audible confirmation (ep-ca.mersen.com).

Centurion D1 dV/dT filter

Source: Hammond Power Solutions Hammond Power Solutions’ Centurion D1 dV/dT filter is designed for use between variable frequency drives and motors when long lead lengths are used. It combines an inductor and parallel resistor network to mitigate both high frequency components and voltage spikes between the VFD and motor. Typical applications include oil & gas pumps, wastewater treatment plants, HVAC systems, pulp & paper, and irrigation fields (hammondpowersolutions.com).

Wieland podis MS 5HP motor starter

Wieland Electric says its starter reduces the complexity of installation and improves the safety of conveyor systems. The podis MS 5HP is a drive component with an integrated STO (Safe Torque Off) function, which disconnects the power supply from the emergency stop circuits. The starter covers motors with a power range from 0.3 hp to 5 hp. Installation and commissioning are simple, says Wieland, as DIP switches, for example, can be programmed on the device or with a web tool (wieland-americas.com).

Greenlee ratchet cable and ACSR cutters

Conduit and fittings for sanitary and washdown

Littelfuse SB5000 industrial Shock Block GFCI

Source: Littelfuse Inc.

Available in various models, Littelfuse’s SB5000 industrial Shock Block ground-fault circuit interrupter detects leakage current and interrupts the circuit for loads up to 60 A. In addition, the SB5000’s ground check protection functionality monitors the ground wire for continuity—from the Shock Block to the load—to interrupt power or prevent energization of equipment, if compromised. It is suitable for harsh industries, outdoors, or in wet environments (littelfuse.com).

Source: Greenlee/Emerson Greenlee says its line of ratchet cable and ACSR cutters includes five cutters, and comes in both open jaw and flip-top designs. Together the ratchet cutters provide a solution for copper up to 600 MCM, aluminum up to 750 MCM, and ACSR up to 336 MCM. The ratcheting mechanism holds cable tight to allow for rapid advance cuts, says Greenlee, “while material-specific blade design gives clean cuts and robust durability” (greenlee.com).

Hammond NEMA 4X HYJ enclosures

Hammond

Hammond Manufacturing’s HYJ Series 304 stainless steel enclosures are designed for use in areas where maintaining hygiene standards and avoiding contamination build-up are critical. The enclosures meet UL 508A Type 3R, 12, 4 and 4X, NSF – ANSI 169 and IEC 60529 IP69/ IP69K, and withstand regular high-temperature, high-pressure washdown. The family is currently available in five sizes, and all units can be mounted either vertically or horizontally (hammfg.com).

Source: Atkore Calbrite Atkore Calbrite has incorporated a fiber laser marking process to apply product information and labelling to its stainless-steel conduit and fittings. “The fiber laser creates precise, durable markings that avoid fading regardless of time, environments, high temperatures, or repeated abrasions due to harsh cleaning,” says the company, adding that this process is an improvement over paper labels, engraving or stamping (calbrite.com).

Rittal Blue e+ S cooling units cUL approved

Source: Rittal GmbH & Co. KG

Rittal Blue e+ S cooling units boast cooling outputs of 300W, 500W, and 1000W, and additional “smart” capabilities. The S series combines a heat pipe with inverter-controlled components. The heat pipe works without a compressor, expansion valve, or other regulating elements, meaning no additional electrical energy is required (except to operate the fan). The units come with a fully integrated IoT interface as standard (rittal.ca).

Source:

Mfg. Co. Ltd.

Source: Wieland Electric

3RD ANNUAL EVENT

As the owner of a construction business, what are you doing to increase the representation of women in your organization?

Do you even know how to get started?

Make plans to attend Women in Construction 2023 on March 8, a virtual event geared toward business owners in the construction industry.

Our experts and panelists will provide you with helpful advice and actionable insights for starting—or further advancing—your pursuit of greater female representation in the workforce.

Teledyne FLIR VS80 videoscope

Source: Teledyne FLIR

The VS80 high-performance videoscope series is outfitted with a 1024×600 resolution (HD) 7-in. touchscreen display, and is available for purchase in seven different kits, with the option to purchase waterproof, ultra-slim probes. Probe options include a 4.5-mm diameter 2-way articulating; a 4-way articulating; a plumbing spool with a 25-m cable; single HD and dual HD visible camera; a standard definition; and a general-purpose thermal camera (flir.ca).

TSOC

SmartConnect network cabling solution

Source: TSOC

TSOC’s Smart-Connect engineered system is designed to simplify network cabling installations, and includes a 25-year warranty. The company offers design services and manufactured cable bundles to customer-required lengths. These bundles are fully terminated, labelled and tested before shipment to site. The plug-and-play nature of the solution can reduce installation time by up to 50%, says TSOC (tsoc.com).

Makita XGT cordless metal-cutting solutions

Source: Makita

Makita has added 19 cordless tools and equipment to its 40V/80V XGT battery system. The 40V max XGT brushless deep cut portable band saw (GBP01) promises up to 2x faster cutting than the 18V LXT model (XBP02), and features a 5 x 5-in. cutting capacity. The 40V max 7-1/4-in. metal cutting saw with electric brake and chip collector (GSC01) boasts up to 2x faster cutting than a comparable corded saw, says the toolmaker (makitatools.com).

Nidec SynRA

synchronous motor]

Source: Nidec Corp.

When paired with the ID300 PerfectSpeed integrated drive, Nidec Motor says its new SynRA synchronous motor offers “one of the highest efficiencies available” for today’s industrial and commercial pumping systems, and HVAC equipment. It provides the starting benefit of an induction motor, the operating benefit of a pure synchronous reluctance motor, and suitability benefit from the simple volts/Hz drive (acim.nidec.com).

20V Max cordless electrician cable stapler

Source: Dewalt Dewalt says its 20V Max cable stapler replaces manual cable-fastening methods, and is twice as fast as manual hammer stapling. It is designed primarily for fastening NM-B (i.e. Romex) wires and cables, but can also be used for low-voltage applications. The tool is compatible with Dewalt DRS1800 1-in. insulated cable staples (sold separately), and the included belt clip offers left or right placement (dewalt.ca).

Cummins vegetable oil fuel gensets

Cummins’ entire line of diesel generator sets has been approved for use with paraffinic fuels (EN15940), including hydrotreated vegetable oil. HVO is not prone to bacterial growth, making it suitable for applications requiring extended fuel storage,

ADVERTISER INDEX

Source: Cummins

including back-up power standby applications. HVO is also compatible—and can be blended in any proportion—with diesel (cummins.com).

Hilti Nuron 22V platform

Source: Hilti Group

Connectivity is at the core of Hilti’s new 22V cordless battery platform. As Nuron tools are used, the data they generate is stored in the battery pack before being uploaded to the cloud during charging—no operator interaction required. The data collected includes things such as usage, utilization, charging location, and battery health. This information can then be used to alert individuals if action is required (hilti.ca).

DAN LEDUC

Indemnity provisions: more trick than treat

It seems appropriate that I penned this column on Hallowe’en. I am often asked to review contracts and, predominately, subcontracts, and the one item that keeps rearing its ugly head—that no one can identify as an inappropriate allocation risk—is indemnities.

The extent of the indemnities to which you are agreeing will be found in the particular contract clause providing for them. They are typically loosely worded so that you end up covering off and indemnifying, not only the party with whom you contracted, but others as well, thereby effectively protecting them from any losses or claims.

The one item that keeps rearing its ugly head [...] is indemnities

The wording of these indemnity clauses is almost always misunderstood and, because of that, largely ignored. An indemnity clause is essentially your agreement to protect another party or group of parties from any losses incurred because of something you may have done, or not done—even when your improper action or failure to act is only proportionally allocated to you.

One reason to start paying more attention to these clauses is to understand what has occurred in the United States, where nearly half of the states have passed anti-indemnity legislation, prohibiting the enforcement of provisions that purport to indemnify the indemnitee for losses resulting from the their “sole negligence” or “willful misconduct”.

So why is it that half of the United States—typically a bulwark against government intervention—has anti-indemnity legislation and we do not? Obviously, there was sufficient concern to pass such legislation in the States... yet Canada has no equivalent legislation that I know of.

If half of American states believe indemnity provisions inappropriately allocated risks in contracts, then perhaps we—and more importantly, you—should regard them as problematic, and spend more time reviewing them as they arise in your tender documents, contracts and subcontracts.

This column is not legal advice, nor should it be taken as such

Dan Leduc is a partner in the law firm of Norton Rose Fulbright LLP, and practices exclusively in the area of construction law. He is always happy to take on new clients from anywhere in Canada. Contact Dan at dan.leduc@nortonrosefulbright.com.

CODE conundrum

RAY YOUSEF

Ray is engineering manager with Ontario’s Electrical Safety Authority

TACKLE THE CODE CONUNDRUM IF YOU DARE! Welcome to the newest round of questions that test your knowledge of the CE Code-Part I. Answers will appear in the Winter 2023 edition of Electrical Business Magazine, and online at EBMag.com under Features.

QUESTION 1

Overload protection shall not be required for a manually started motor rated at ___ hp or less that is continuously attended while in operation, and that is on a branch circuit having overcurrent protection rated or set at not more than 15 A, or on an individual branch circuit having overcurrent protection as required by Table 29 when it may be readily determined from the starting location that the motor is running.

a) 1/2 hp c) 2 hp

b) 1 hp d) 5 hp

QUESTION 2

The interior of a storage tank that is vented to atmosphere, and contains flammable liquids stored above their flash point, is typically classified as:

a) Zone 0 c) Zone 2

b) Zone 1 d) Zone 20

QUESTION 3

Class H fuses are permitted to be used for overcurrent protection where circuit overload protection is provided by other means.

a) True. b) False.

ANSWERS Electrical Business, October 2022 ed.

Question 1

The CE Code requires a splitter to be installed where two or more conductors are connected to a conductor larger than ___ copper

b) #6 AWG. Rule 12-2000(6).

Question 2

For single dwelling units, the CE Code requires a minimum ___ duplex receptacles to be installed in a 2-door car garage with overhead door openers, a cord-connected central vacuum, and a garbage disposal unit installed.

c) 5. Rules 26-720 and 26-724.

Question 3

Does the CE Code permit a bare neutral in a consumer service when this conductor is made of copper and run in a raceway?

a) Yes. Rule 6-308.

Visit EBMAG.COM for the latest news, stories, products, videos, events and more.

How did YOU do?

3 • Seasoned journeyman 1 • Apprentice

2 • Need refresher training 0

Just here for fun!

NANSY HANNA, P.ENG

Conductors and cables in conduits and tubing

The Canadian Electrical Code’s Tables 6 and 9 have seen some modifications over the last few code cycles. Historically, Table 6 served as a quick reference for determining the number of conductors of the same size in conduit. Now, based on changes to Tables 6 and 9 in the CE Code (2021 ed.), a calculation or comparison may provide a better understanding of the changes.

Our technical team prepared the analysis at right to help us see where we were, and where we are now with the current 2021 edition.

By way of comparison, have a look at the impact on conduit fill using Table 6 over the last few code cycles:

How many No. 10 AWG RW90 unjacketed 600V conductors will fit in a 16-mm (1/2-in.) EMT conduit?

• 5 conductors (2012 code)

• 2 conductors (2015 & 2018 eds.)

• 4 conductors (2021 code)

Here is a process for determining the maximum number of same-size conductors in conduit using Tables 6, 8 and 9:

1. Use Table 8 to determine max percentage conduit fill.

2. Select correct Table 9 based on Table 8 results.

3. Use Tables 9A-9H to find type of conduit and size to be used; record cross-sectional area value.

4. Go to appropriate Table 6 based on type of conductor used.

5. Tables 6A-6K are used to select conductor size. Follow the chart to the right until the area of conductors is less than or equal to the value recorded from Table 9. From this value, the corresponding number of conductors will be at the top of the Table.

6. This value at the top of the chosen Table 6 is the maximum number of same-size conductors permitted in the conduit.

CE Code edition Table 6

2012 “Maximum number of conductors of one size in trade sizes of conduit or tubing”. Single table, sorted by conductor type and how many per generic conduit size.

2015 and 2018

2021 (current)

Broken out into Tables 6A-6K. New tables for each different type of conductor. Tables show the maximum number of conductors for each AWG size in generic conduit or tubing sizes. (Taken per smallest conduit type’s internal cross- sectional area). Changes made to easily select the table based on conductor type.

Tables 6A-6K replaced with new Tables 6A-6K “Dimensions of single conductors and cables for calculating conduit and tubing fill”. New tables for each conductor type, providing the cross-sectional area based on AWG conductor size and number of conductors to be installed in the conduit or tubing. This area value is used in conjunction with Table 8 and Tables 9A-9H. Changes were made to the table to allow a more accurate representation of conductors in conduit instead of a worst case (smallest) cross-sectional area.

This process can also be performed in reverse to determine minimum conduit size when the number of same-size conductors is known. For example:

What is the minimum size EMT conduit in which three (3) No. 10 AWG RW90XLPE 600V unjacketed conductors will fit?

1. Choose Table 6A for RW90XLPE 600V unjacketed conductors

2. Find the area of (3) No. 10 AWG conductors (47.08 mm2).

3. Table 8 for max percentage conduit fill, and see which Table 9 to select.

4. Table 8: three (3) conductors = 40%. Go to appropriate Table 9 at 40% fill (Table 9G).

5. Table 9G: Choose correct conduit type (EMT).

Table 9

“Cross-sectional areas of conduit and tubing”. Single table, showing cross-sectional area at different fill percentages for different sizes of conduit. One table for all types of conduit.

Broken out into Tables 9A-9P. New tables for each type of conduit. Each table shows the cross-sectional area at different fill percentages for the nominal conduit sizes. Changes made to address different cross-sectional areas of different types of conduit or tubing.

Tables 9A-9P replaced with new Tables 9A-9H “Internal diameter and maximum conductor cross-sectional areas allowable fill at % for various trade conduit and tubing used for conductors or multi-conductor cable”. New tables created using the allowable fill percentages per Table 8. They consolidate all conduit types, displaying their internal diameter and cross-sectional area based on the allowable fill percentage of table chosen (100, 53, 31 and 40%).

6. Table 9G: Compare results from Table 6A (47.08 mm2) to cross-sectional areas for different EMT sizes (47.08 mm2 < 72.51 mm2 = 16 mm [1/2-in.] EMT).

So 3(*) x No. 10 AWG RW90XLPE 600V unjacketed will fit in a minimum 1/2-in. EMT conduit. (Based on the above calculation, maximum 4x No. 10 AWG RW90XLPE 600V unjacketed conductors could fit in 1/2-in. EMT conduit, if needed.)

Consult your Authority Having Jurisdiction for more specific interpretations

Nansy Hanna, P.Eng., is senior director, Engineering & Regulations, at Ontario’s Electrical Safety Authority (ESA). She is also chair of the Canadian Advisory Council on Electrical Safety (CACES) and a member of the ULC Advisory Council and CSA Technical Committee on CE Code-Part I. She can be reached at nansy.hanna@electricalsafety.on.ca.

WE’RE TAKING REWARDS TO THE NEXT LEVEL.

With more ways to earn loyalty points and redeem great prizes, the new and improved AD Rewards program allows you to capitalize on the power of your purchases from AD distributors like never before.

With over 6,000 valuable merchandise and travel rewards, your relationship with your AD distributor has never been more powerful…or lucrative.

Join today at any of these participating AD distributors.