COBOTS IN THE SHOP

Why you should consider this technology, and how to take the first steps / BY TREENA HEIN

If you haven’t put much thought into why you might purchase a cobot for your prefab shop, now is a very good time to do so. Designed to work alongside human operators—where they collaborate on part of the overall manufacturing process—collaborative robots (cobots) have never been more versatile and safe, and provide so many benefits, including an ROI that has never been faster.

Putting cobots in a recent historical context, Nicolas Durand explains that, in the past, leaders of smaller manufacturing companies who looked at using robots likely had conversations about completely automating a task. For them, this was (and still is, in many cases) not feasible due to task complexity and high costs.

“Those discussions are now long gone,” says Durand, who is vice-president and general manager at ABB Robotics Canada. “Now the conversation is about which tasks in a given part of the production process require a human for whatever reason, and which repetitive—and even punishing—tasks can be removed from that worker.”

“It’s about examining which part of the process involves monotonous or physically demanding tasks,” Durand continues. “Those [tasks] that are not only difficult to sustain mentally but cause repetitive strain injuries might be done by a robot, making work more rewarding and enjoyable, and increasing throughput at the same time.”

These are the broad advantages of today’s cobots. For smaller manufacturers, their presence

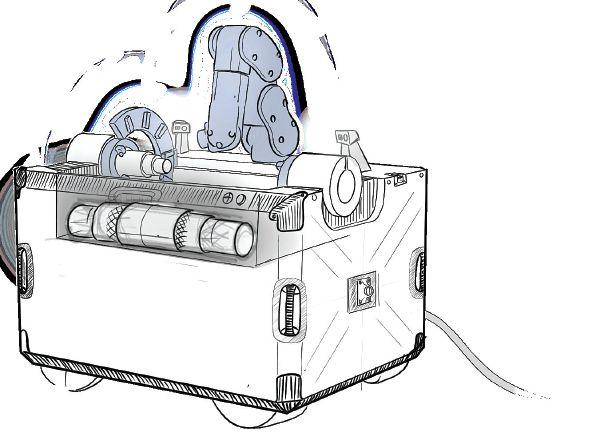

Designed with speed, safety, and ease of use in mind, GoFa continuously shares workspaces with people, performing various applications, such as material handling.

Source: ABB Robotics.

makes it easier to attract/retain employees, and boost productivity in a safe and reliable way.

Choosing among the different programmed actions that make up a finished task is simpler than people might think.

Source: Kinova.

Let’s look at an example where the main task of one of your employees can be broken down into three parts. A cobot is introduced to take over two of those parts, carrying them out quickly and consistently (maybe selecting two different parts from two bins and bringing them together in the correct orientation). The human does the third task of attaching those parts correctly. As the worker does this, the cobot is already fetching and bringing together the next set of parts.

Throughput increases dramatically and the job is easier and much more rewarding for that worker. Employees only carry out tasks that require their skills, skipping the menial, repetitive ones. The same level of production that used to take days can be achieved in just one.

Possibilities in prefab

In an electrical shop, a cobot could manipulate a part into the correct orientation for the final torquing of all screws for example, or it could bring wires together for a worker to crimp the connectors.

(Note: there are cobots available in the market equipped with vision

“Which repetitive— and even punishing— tasks can be removed from that worker?”

systems and dexterous grippers that can accomplish delicate tasks like crimping, and also carry out many types of inspection, but these applications may well be unaffordable for a smaller shop, especially when the shop does short runs. Also, while robots can certainly resupply employees with raw materials and transport finished pieces to other areas, these are not truly collaborative scenarios.)

In looking at how fast a cobot pays for itself, there are estimates that as many as half of many manufacturing tasks can be carried out by cobots, and productivity could be increased by the same percent-

age. Of course, this would vary by scenario. The current lower costs of cobots compared to years ago also make ROI swift.

Will Healy III, global industry manager at Universal Robots, says that when working with a collaborative robot solution provider or system integrator, an organization can typically realize their ROI in a year, depending on the complexity of the application.

Another large ROI factor for the electrical prefab shop owner is the flexibility of cobots. They can easily be equipped with different attachments and their programming changed to carry out different small runs. They might also be modified to take part in two different parts of a manufacturing process during different hours each day or on different days of the week.

On the programming front, Jason Bowen, national business development lead for robotics at Westburne, notes that choosing among the different programmed actions that make up a finished task is simpler than people might think.

“Cobots from Kinova, whom we represent, do not require advanced programming in many cases,” he says. “In these scenarios, through a no-code visual programming environment, you click on a desired function—such as Move, Open Gripper, and so on—hand-guide the attachment into the correct position, and so on. This makes their implementation very simple for any user.”

And with workforce challenges the way they are right now, Healy encourages shop leaders to consider factors beyond the financial ROI and how the cobot investment has a positive impact on worker engagement and employee retention.

“By eliminating the dull, dirty and dangerous tasks, cobots are bringing a powerful ‘ROE’ or ‘Return of Engagement’,” he explains. “This ROE reduces costs due to worker compensation, attracting workers, onboarding and more.”

Safety and worker training

As with any other new piece of equipment, cobot implementation requires worker training to ensure safe interaction. On the regulatory

side in Ontario, cobot implementation requires a Pre-Start Health & Safety Review while, across Canada, implementation of standard national safety requirements.

At this Schneider Electric plant in Bulgaria, they focus on the assembly of industrial and home electrical devices. Collaborative robots empower staff to take on creative tasks by automating repetitive processes. Source: Universal Robots.

In Healy’s view, the best and easiest way to ensure compliance is to work with a cobot solution provider or local cobot system integrator. Bowen emphasizes the critical importance of assessing potential impact forces and physical zones of cobot operation.

“Cobots have features for safe usage around humans, such as collision detection, guards, and pre-set programming parameters, but all the risks must be identified and mitigated, with risk level depending on the application and implementation,” he says. “For example, a cobot with a camera poses very low safety risk if stationary and not at the height of a human head, but those that move in that height zone pose much more risk.”

Indeed, with cobot popularity increasing each year, cobot makers have developed standardized advanced safety motion control features over the last two to three years, including safe limited speed and positioning, along with advanced safety sensors. Durand explains that “for an application such as screw driving, an appropriate level of force is set for the task—only that which is required. If resistance beyond a given preset parameter is detected, the cobot will halt operation”.

Rise of the machines

Reaching out to an established robotics company for a feasibility assessment is the first step in cobot implementation.

“You’ll discuss what is driving the desired change: whether that’s health and safety, cost, or other factors,” Durand explains. “When

Cobots can easily be adapted to high-mix, low-volume production, like this screw driving example at Darex in Oregon. Source: Universal Robots.

you truly understand the capabilities of cobots and walk through a shop with their use in mind, you can see quickly where a cobot can be inserted to make a worker’s experience a lot better, speed up production, provide better consistency, and so on.”

At that point, ABB uses its Robot Studio software to simulate how the cobot would assume certain tasks, analyze process speed, changes to raw material placement, and the like.

“Our Robot Studio program is not an animation but the actual software that controls our cobot, and the simulation is very effective to look at performance, identify space requirements, and look at all the other pertinent aspects,” says Durand. “This is done at our Brampton, Ont., facility. Once that’s complete, we can do actual scenarios there with the customer’s part to validate.”

This also helps determines whether an integrator is needed onsite for implementation or the customer can do it on their own, says Durand. “We also have training courses, and hold open-house events in Brampton, Toronto and Montreal, where manufacturers typically bring their parts.”

Durand says these levels of education and support, along with the capabilities and flexibility of today’s cobots, make them very accessible for small manufacturers such as electrical prefab shops.

“The ease with which the cobot can be redeployed to another task, and how its programming and attachments can be changed to add more value is really amazing,” he says. “Cobots are not looked at as hardware anymore—as machines—but as an opportunity to achieve different applications. There’s never been a better time to consider them.”

“Cobots can easily be equipped with different attachments and their programming changed to carry out different small runs.”

Potential cobot uses by electrical contractors

• Assembly of electrical components

• Wiring of panels and systems

• Cable cutting and stripping

• Pick-and-place, transporting components or finished products between workstations, and other material handing tasks.

• Testing and inspection for quality control (when cobot is equipped with appropriate sensors and cameras)

• Applying labels, painting, cleaning

• Loading/unloading material and components into/ from CNC, wire-bending machines, or other processing equipment.

Personalities

ABB’s Emergency Lighting Business has welcomed Bruno R. Ardito to the position of sales specialist, Central Canada. Ardito is approaching 30 years of experience in the lighting and emergency lighting markets, starting with Juno Lighting, followed by nearly two decades with BeLuce. His new role falls within the Smart Buildings-Electrification, division. Sandra Pedro has joined the company as director, Sales & Marketing, Utility Market, Electrification, Canada. She joins ABB from Electro-Federation Canada (EFC), where she served as vice-president, Membership & Corporate Partners. Prior to EFC, she spent over 20 years at Schneider Electric in various positions, including director of Global Offer Management, Global Digital Energy Division.

SourceS: SUPPLIED, File photo

Cristiano Konofal has returned to Ledvance, this time in the role of national account manager. He has been involved in the lighting industry with various companies for about 20 years, including several with Ledvance. Meantime, Lynnette Schaeffer was welcomed as Ledvance’s new director of training, where she will oversee the company’s Lightpoint training program. Schaeffer has over two decades of lighting and electrical experience under her belt; her career began in 1998 at Van Meter Industrial, then moved through positions at global lighting firms. She transitioned to training in 2020.

Source: Ledvance

Steve Boccadoro, senior vice-president and general manager of Eaton’s electrical business in Canada (top), is retiring after nearly four decades with the company. He joined Eaton in 1987 as an internal auditor and, among many roles, served as senior

vice-president, Corporate Sales and Marketing, Eaton, before moving back to Canada in 2014 to assume the role of senior vice-president and general manager. His successor is Chris Fluit (bottom) who has been with the company for over 20 years. Most recently, he served as the business unit manager for Eaton’s Electrical Engineering Services and Critical Power and Digital Infrastructure businesses in Canada.

Source: Eaton

Angelo Miceli has been named sales leader, Central Canada, at Signify. He possesses over 40 years of experience with Canlyte, Lumec, Philips, and Signify, and has held numerous positions over the years, including sales leader of Philips direct sales in Ontario, spec sales lead for Canada and, most recently, leading the company’s end user and CSI partners.

Source: Signify Canada

Greg Stephenson, senior vice-president, Electrical, at Bartle & Gibson has been elected AD Electrical Canada’s new board chair, replacing outgoing chair Peter Dalton. Stephenson has served on this board for three years, but his industry involvement extends further; he also participates as a director and board president of the Alberta Electrical Alliance, and as a member of Electro-Federation Canada’s national board.

Source: File photo

Danfoss has appointed Hannes Leichtfried head of Sales and Marketing for the Drives business segment in North America. He began his career at Danfoss in 1994 as a technical support engineer, and most recently held the role of

head, Sales and Marketing, for Danfoss Drives in Central Europe.

Source: Danfoss

Electrical manufacturers rep Intralec Electrical Products introduced outside sales reps Nathan Roberts and Brent Kozuh. Roberts (top) joined the agency to serve the Southwest Ontario region, while Kozuh (bottom) joined Intralec to serve the Golden Horseshoe region.

Source: Intralec

Marie-France

Patenaude is the new Eastern Region sales manager for Leviton Lighting Canada (LLC). Her territory includes the Atlantic Provinces, Quebec, and Ottawa. Meantime, Leviton Canada’s Jason Denstedt—who serves as sales director, Ontario, since May 2023—will now additionally serve as lead for the National Accounts team.

Source: Leviton Lighting Canada

Source: Leviton Canada

Westburne has appointed Jason Bowen to the position of business development manager, Robotics. He started with Westburne in 1995 as an automation specialist; his most recent position was that of sales manager, Northeastern Ontario. Bowen reports to Andrew Thurlow, director, Automation.

Hydrostor has appointed Chris Phebus and Tom Duckett to lead its technology and development teams, respectively. Phebus joins the company as chief technology officer, while Duckett joins the company as chief development officer.

We’re limited by space here, but have plenty of room online! Read the news behind the news Visit EBMag.com and click “News”.

Is your aluminum clean?

It’s not something most people think about when trying to make an eco-conscious choice, but approximately 3% of the world’s CO2 emissions come from the production of primary aluminum. The “Dirty” Truth is that most aluminum utilizes coal or gas to generate the electricity required for production. Aluminum requires anywhere from 13,000 to 18,000 Kilowatt hours to manufacture one tonne of product, leading to a high carbon footprint just to produce the base product.

100% of Canada’s primary aluminum production utilizes power generated from clean, renewable hydroelectricity, having a third of the CO2 emissions when compared to coal and gas. Globally, only 20% of the primary aluminum produced is made utilizing clean hydroelectric power. When you compare this to Canada’s availability of clean, renewable hydroelectric aluminum, why would you choose any other product?

Northern Cables supports the “ON-SHORING” movement that is fundamental to a well-rounded North American Economy. Our raw material supply chain consists of Canadian and American supply partners, which all metals, plastics, and packaging materials are sourced from.

Reduce your carbon footprint and support sustainable practices with Northern Cables. Why?

• Approximately 3% of CO2 emissions are a direct result of aluminum production. Where you source it matters!

• Foreign aluminum is made using power generated from dirty, carbon-rich coal or gas.

• Overseas shipping further adds to carbon emissions.

• Foreign aluminum is NOT subject to ANY carbon taxes in Canada.

• 100% of the aluminum in Northern Cables products is produced using power generated from CLEAN and RENEWABLE hydroelectricity.

• Our aluminum manufacturing partners are all within 700KM of our factories.

• It’s a fact: Canadian-made aluminum significantly lowers CO2 emissions.

SCAN TO LEARN MORE

USING GOPHURRS TO BURY POWERLINES?

Initiative to enhance grid reliability by going underground

Con Edison employee works underground on cable repairs.

In the United States, an initiative under the Department of Energy’s Advanced Research Projects AgencyEnergy (ARPA-E) seeks to simplify the construction of underground medium-voltage (5-kV to 46-kV) grids in urban and suburban areas by adopting a concurrent drilling and conduit installation method of construction that reduces inefficiencies associated with horizontal drilling and conduit installation operations.

“We know that, by undergrounding our grid, we can create a more resilient and reliable U.S. power grid,” said Dr. Evelyn N. Wang, director, ARPA-E.

There’s just one problem: that concurrent drilling and conduit installation method needs to leave the surface nearly untouched. How do you do that in built-up urban and suburban areas?

Call in the gophers, er, GOPHURRS

Enter the GOPHURRS program, which stands for “Grid overhaul with proactive, high-speed undergrounding for reliability, resilience, and security”, which aims to strengthen and modernize the country’s aging power grid.

“Undergrounding powerlines is a proven way of improving the system reliability for both transmission and distribution grids, as weather events are less likely to interfere with systems that are protected below ground,” say program proponents. However:

Despite the reliability, resilience, and security benefits, today’s methods of undergrounding powerlines are disruptive to surface and environments, slow in construction, unsafe for workers, and consequently make an undergrounding project too expensive to afford.

The GOPHURRS program aims to tackle these problems headon, added Wang, “by developing new technology solutions that allow for reducing costs, increasing speed, and improving the reliability and safety of undergrounding the grid”.

Projects involved in GOPHURRS, therefore, will focus on “advancing transformative autonomous utility installation technologies, such as automated and rapid subsurface drilling along the terrain and concurrent conduit installation, while also avoiding hidden underground obstacles with advanced look-ahead sensors”.

Prysmian Group, too, is involved with the program, receiving $4.5 million in funding from ARPA-E to develop a hands-free power cable splicing machine to operate in underground vaults, with the goal of reducing the share of splicing-caused medium-voltage network failures from 60%80% to less than 5%, and “dramatically improve workforce safety by reducing the time the underground cable splicing crews spend in underground vaults”.

Prysmian’s development of the machine is being done in collaboration with Con Edison and Exelon—two investor-owned utilities in the U.S.

“Safety is a top priority for Con Edison,” said Patrick McHugh, senior VP, Operations. “That’s why we are proud to partner with Prysmian, Exelon, and the DoE to develop a tool that will improve worker safety, efficiency, accuracy and, ultimately, the reliability of the nation’s grid.”

“Exelon is committed to being a leader in the energy transformation, and this means nurturing a culture of continuous innovation,” added Sunny Elebua, senior VP and Chief Strategy & Sustainability Officer.

According to GOPHURRS, over 90% of powerline failures happen on the MV distribution grid; in the U.S., this system comprises over 5.5 million line-miles and over 180 million power poles. These are all susceptible to damage by weather and tree-related incidents, which account for 62% of all power outages every year.

Other GOPHURRS participants and projects

• Arcbyt: Integrated thermal spallation drill for heterogeneous ground conditions.

• Arizona State University: High-speed installation of buried medium-voltage electrical distribution lines using a single-pass system.

• Case Western Reserve University: Peristaltic conduit with stiff structure and compliant skin.

• Cornell University, Mini-Mole: Combustion-powered tip fracturing and undulatory locomotion robot.

• GE Vernova Advanced Research, SPEEDWORM: Swift, portable, and efficient electrical undergrounding using a water-free, compact, and reliable machine.

• Melni Technologies: Enhancing reliability and resilience of underground distribution systems using innovative splicing.

• Oceanit: Artificial intelligence and unmanned aerial vehicle real-time advanced look-ahead subsurface sensor (AURALSS).

• Pacific Northwest National Laboratory: Subsurface intelligence for undergrounding operations; rapid AIbased geophysical imaging and advanced visualization.

• RTX Technology Research Center, UnIQue: Underground imaging with quantum sensors.

• Sandia National Laboratories: Advancing horizontal directional drilling for rapid undergrounding of electrical utilities.

• Virginia Polytechnic Institute and State University: Multi-physics, intelligent sensing system (MISS) for real-time, look-ahead while drilling.

Sketch of hands-free power cable splicing machine.

Source: Con Edison, Exelon, Prysmian Group

Besides improving the security of its current power infrastructure through new undergrounding technologies and advanced underground obstacle sensors, proponents believe GOPHURRS technologies could reduce the cost of undergrounding electric power grids by at least 50%.

OVER 275 LADDERS TO CHOOSE FROM 24_001484_Electrical_Business_APR_CN Mod: February 29, 2024 12:10 PM Print: 03/01/24 1:53:21 PM page 1 v7

SMALL MODULAR REACTORS... AND YOU

A conversation with Hatch’s Mario Pieries

/ BY ANTHONY CAPKUN

It was roughly seven years ago when Electrical Business Magazine first started reporting on a new paradigm for baseload power called small modular reactors.

The president & CEO of the Canadian Nuclear Association, John Gorman, told us that these innovative reactors are designed to be built economically under factory conditions and, because they are modular, they can be custom-designed for the application at hand.

Those applications can range from serving Canada’s remote and smaller communities that are not easily connected to the grid, to resource industries, such as mining and oil extraction. Plus, SMRs promise more than just electricity, as they could also be used to produce heat, and possibly hydrogen.

That was then. We were curious to learn the status of SMR deployment across Canada today, and where electrical pros fit into that scenario.

For answers, we turned to Mario Pieries, global director, Nuclear, at Hatch. He prefaced our conversation with a clarification: SMRs are actually not new technologies.

“People might say that SMRs are new technologies—and there are advanced reactors that we would call emerging but a lot of Gen 3 nuclear reactors, like

the BWRX-300, are scaled down to a smaller footprint. They’re based on proven technology,” Pieries says.

“And just think about what nuclear submarines use... small modular reactors, right? And they have pedigree; six, seven decades-worth of deployments, and industry continues to build on that intellectual property.”

Pieries points out that small modular reactors are being deployed in other parts of the world, so it is just a matter of our regulatory environment “going through the right steps and adopting these technologies for deployment within Canada, which is part of the path toward commercialization”.

He pointed to current projects underway (OPG, Chalk River, etc.), adding that “I envision that, by 2030-ish, you

CNA’s John Gorman weighs in

When it comes to the electrification of our economy, the grid will need a lot of work. No matter how much new clean generation we build, we’re not investing enough in the grid. (At the same time, more nuclear on our grids will require far less investment in transmission, distribution, and storage than variable resources.)

The clean energy transition represents big opportunities for electrical professionals, and we’re excited about what it means for our economy. We’re expecting that Canada needs to double or even triple power generation by 2050, and that will create jobs across the full electricity system.

There are also going to be new jobs, with specialists working to integrate SMRs into the grid or creating microgrids in remote communities.

will see a lot more of these construction projects going on”.

Room for electrical pros?

So will electrical professionals be shut out of all this SMR excitement? Pieries sees opportunities for any number of skilled professionals, including Electrical. The big question is whether we have enough of them.

“That’s been identified as one of our risks and limiting capacities. If we’re going to be building hundreds of SMRs across the globe, it presents an opportunity for professionals, contractors, electricians, apprentices, to enter that supply chain—that labour force—but I don’t think we have enough of those professional resources.”

“And this is where we are going to have to be innovative while building capacity,” Pieries says. “You know, look at building capacity in Indigenous communities, encouraging more people to get into the trades, and so forth.”

He points out that, while SMRs would be designed in the shop, the site needs to be designed for them. “That cannot be done by robots.”

Even though there will be some prefab work, Pieries says pre-construction activities, site prep, transport, hook-up, commissioning, ongoing maintenance, and the like will be carried out by skilled tradespeople, including Electrical.

But despite possible skilled labour shortages, Pieries remains enthusiastic.

Besides the prospect of using SMRs to help decarbonize heavy industry, “What excites me the most is the opportunity to develop professionals organically within Canada, and high-value, high-paying jobs that will contribute to generational wealth,” he says. “And I’m a big proponent of engaging our Indigenous communities and partners to help build capacity while delivering benefits that last seven generations.”

Hatch’s Mario Pieries

LED ROUND HIGH BAY UFOs

FIELD SELECTABLE | 120V-347V

SATCO|NUVO’s Round High Bay Field Selectable fixtures offer an energy efficient and low-maintenance alternative to traditional HID fixtures. These luminaires are field selectable, giving users the flexibility to choose from three wattage and three CCT options during installation. The fixtures are constructed with a durable die-cast aluminum housing and an IK08 impact-rated polycarbonate lens. Featuring 6kV surge protection, 120V-347V range voltage and NEMA 4X (IP65) wet location rating, these high bays are resilient in various commercial environments. Compatible with a wide variety of accessories (sold separately) fixtures can be customized to accommodate a multitude of lighting needs.

EHRC’S ELECTRICITY SECTOR AWARDS

A celebration of human resources excellence

The room was filled with excitement and anticipation, and greetings between friends—new and old—at Electricity Human Resources Canada’s 2023 Awards of Excellence, held in Toronto.

“With a mission to strengthen the Canadian electricity workforce to be safety-focused, innovative, and inclusive, EHRC honours employees, leaders and teams who are making a positive and tangible impact in the industry,” said Michelle Branigan, EHRC’s CEO.

This year, the Leader of the Year honour went to Leslie Gallinger, president & CEO of Ontario’s Independent Electricity System Operator, in recognition “of her exceptional leadership and commitment to cultivating an inclusive and values-based work culture”.

Congratulations to her and the other 2023 honorees. (The award for HR Innovator was accepted on behalf of Lathani Sivakumaran, Ontario Power Generation.)

This Photo Feature showcases award winners (or those accepting on their behalf), as well as candid photos during the networking break.

Leslie Gallinger (left), president & CEO of Ontario’s Independent Electricity System Operator, is named Leader of the Year. At right, Nirav Patel, chair, EHRC.

Workplace Culture Innovator: Jesse Spring, Primary Engineering and Construction.

EHRC is Canada’s leading provider of human resources research and insights for the electricity sector. Its primary mission is to help the sector meet current and future workforce needs.

Workplace Diversity and Inclusion Champion Award (large organization): Manitoba Hydro.

Emerging Leader of the Year award: Oluwafemi Obadeyi, Atura Power.

Workplace Diversity and Inclusion Champion Award (SME): Ontario Energy Board.

Rosana Kemsley, ENWIN Utilities: Workplace Culture Innovator.

DESPITE ADDING 2.3 G OF RENEWABLES/STORAGE

Canada must “increase the pace of build-out

CANADA’S CURRENT INSTALLED WIND, SOLAR AND ENERGY STORAGE CAPACITY

Source: Canadian Renewable Energy Association, December 31, 2023. (This snapshot includes 2023 data for rooftop and behind-the-meter solar.)

Photo: Luisrftc / iStock / Getty Images Plus / Getty Images

Canada’s wind, solar, and energy storage sectors grew by 11.2% in 2023, according to industry data released by the Canadian Renewable Energy Association (CanREA).

The industry added 2.3 GW of new capacity in 2023, including more than 1.7 GW of utility-scale wind, nearly 360 MW of utility-scale solar, 86 MW of onsite (rooftop and behind-the-meter) solar, and 140 MW/190 MWh of energy storage. While that sounds impressive, it’s not impressive enough for CanREA:

Canada’s wind, solar, and energy storage industry had a relatively good year in 2023, but it fell short of the trajectory needed to meet net-zero targets. What is needed is more geographic diversity. We need to increase the pace of build-out, and we need to see deployment in all provinces and territories. (Vittoria Bellissimo, president & CEO, CanREA)

This year’s greatest success stories were found in Atlantic Canada, the North, and Alberta. Other provinces saw no growth in their wind, solar, or energy storage sectors in 2023. CanREA says this is due to their lack of centralized procurements and corporate power purchase agreement (PPA) offerings.

The regional breakdown

Alberta accounted for 92% of Canada’s overall growth in renewables and energy storage capacity in 2023. The province added 1.7 GW of installed capacity, and now has a total of 5.8 GW of renewable energy generation, as well as 212 MW/260 MWh energy storage capacity.

However, the pause on approvals announced by the Alberta government in August—alongside the investor uncertainty it creates—will have impacts into 2025 and beyond. CanREA is tracking 8.3 GW of projects under development in Alberta. Of these, 3.9 GW of projects had the potential to come online in 2025, along with a further 4.4 GW of proposed projects with later commissioning dates, which are all now at risk.

Wind made gains in Yukon, moving from 0.2 MW to 4 MW total. The Northwest Territories added 3.2 MW in Inuvik.

In Saskatchewan, CanREA is tracking 200 MW of projects under construction, 800 MW of wind and solar projects, and a single 20-MW battery site with 20 MWh capacity (all currently in advanced stages of development), as well as 350 MW of wind projects in the proposal stage.

Saskatchewan’s longer-term procurement outlook includes 600 MW of wind and solar in south-central Saskatchewan, expected to be in service by 2027, up to 1 GW wind and solar in the southwest by 2030, and 1 GW of wind and solar for 2030-2035.

At this time, the current total installed capacity in Saskatchewan remains the same as last year.

Ontario’s installed capacity is still the largest in Canada, at more than 7.5 GW (5.5 wind, nearly 2 GW solar, more than 100 MW storage). This total is expected to increase, as the province invests in energy storage.

CanREA is tracking 429 MW of storage projects that are already in advanced

development, and another 407 MW in proposed energy storage projects.

There is no new wind or solar development expected in the short term (20242025) in Ontario, but the longer-term outlook includes up to 2 GW of new wind and solar by 2030-2031, and up to 3 GW of additional new wind and solar by 2034.

Quebec currently has the third-highest installed capacity of wind and solar energy and energy storage in Canada, at more than 4 GW (nearly all wind, though). While this total did not increase in 2023, there is opportunity for growth in the long term.

Hydro-Quebec intends to triple windpower generation by integrating more than 8 GW of wind capacity into the grid by 2030, and two more by 2035.

It also intends to establish the province’s first pumped-storage facility with a 1-GW capacity, and to facilitate the installation of solar panels on the homes of more than 125,000 customers by 2035.

British Columbia currently has 746 MW of capacity (742 MW wind, 2 MW solar, 2 MW storage) and, in future, BC Hydro plans to acquire 3,000 GWh of renewable energy per year.

Parts of Atlantic Canada saw growth in 2023, with New Brunswick adding 42 MW of wind and Prince Edward Island adding 31 MW of utility-scale solar, as well as some energy storage.

CanREA is tracking a total of 296 MW of projects in advanced development across the Atlantic region (280 MW onshore wind, while the rest includes both utility-scale solar and energy storage).

New Brunswick aims to increase renewables five-fold by 2035, adding 1.4 GW of new windpower, 0.2 GW of grid-scale solar power, an additional 0.1 GW of energy storage, and 0.3 GW of onsite solar.

Nova Scotia aims to add more than 1 GW of new wind capacity, more than 300 MW of solar, and 300 MW to 400 MW of battery storage by 2030, with the potential for offshore wind post-2030.

State of the nation

Canada now has a total installed capacity of more than 21.9 GW, including 20.4 GW of utility-scale wind and solar energy, 1.2 GW of onsite solar, and 356 MW/539 MWh of energy storage nationwide.

products and solutions

Mersen STP-50 DIN-rail SPDs with Surge-Trap

The latest addition to Mersen’s line of DIN-rail surge protective devices is the Surge-Trap pluggable STP-50 series SPD—a no-fuse, fail-safe SPD with a 50kA short-circuit rating, suitable for most industrial control panels. The SPD is designed to provide safe and reliable performance in high-risk environments. It features an enhanced base with a tool-less DIN-rail clip for easy installation. The STP-50 series comes with a 5-year warranty and is intended for use on a range of low-voltage applications inside appropriate enclosures (ep-ca.mersen.com).

Source: Mersen

Bi-directional IPSC15MC network horn

TOA Canada Corp.’s horn speaker delivers “rich extended speech range” with the added feature of a built-in microphone for speech talkback and external environment monitoring. The device is IP66-rated and can withstand temperatures as low as -45 C, making it ideal for outdoor use. Powered by PoE/PoE+, the horn hosts audio file stored

for playback, and provides an external dry-contact out for external device control (toacanada.com).

Source: TOA Canada Corp.

Hubbell ScrubSwitch sealed switches

ScrubSwitch devices help reduce bacteria transmission in high-touch areas, making them suitable for healthcare facilities, or other applications with strict cleaning and disinfection procedures. The switch module is completely sealed against liquids and installs in a standard electrical box. Proximity sensing allows users to simply tap on/off, and it works just as well for latex gloved hand, or an elbow in a shirt sleeve. The devices’ design limits accidental activation from vibration, walking past, or standing nearby (hubbell.ca).

Source: Hubbell Canada

Ranger composite aluminum shelving solution

Ranger Design’s composite aluminum shelving line provides the same load capacity as the company’s steel shelving, but with a 25% reduction in weight. The aluminum-alloy end panels are coated with a protective finish that

improves resistance to smudge and abrasion. Each shelf combines Ranger’s aluminum extrusions with a honeycomb composite, providing improved noise mitigation and protection against a range of chemicals (rangerdesign.com).

Source: Ranger Design

Megger MCT105 detects hidden cables

Megger’s MCT105 is designed to detect and trace cables and metallic conductors located in walls or buried underground. It can also identify fuses and breakers on electrical circuits, locate breaks or short circuits in cables and electrical underfloor heating systems, as well as trace hidden metal water and heating pipes. The locater works on both live and dead cables and conductors, and comes equipped test leads, crocodile clips, test probes, and carrying case (us.megger.com).

Source: Megger

Greenlee “dual-shoe design” bender

Greenlee’s hand bender with patent-pending “dual-shoe design” promises precise bends on 1/2-in. and 3/4-in. EMT and 1/2-in. rigid and IMC conduits with one tool. The bender features a large foot pedal and wider base to provide stability and

leverage. New inner shoe markings, meantime, make it easier to see measurements when bending shoe-up, while the Site-Rite sighting system enhances visibility in lowlight settings (greenlee.com).

Source: Greenlee

Track crawler carriers for difficult terrain

When paired with a Terex 4047 digger derrick, the Terramac RT7U provides an all-in-one tool for digging holes, setting utility poles, lifting heavy equipment (or line workers) to perform maintenance on distribution lines. The RT9U with a Versalift 9500 aerial lift provides a 100-ft working height for challenging ground conditions. When paired with a hooklift, Terramac says the RT9’s hauling options are endless (terramac.com).

Source: Terramac

Baffin extends size range for Titan boots

Baffin has extended the size range of its industrial Titan boot, bringing the full range from Size 7-14 (Women’s 9-16) to Size 5-14 (Women’s 7-16). Titan STP contains a steel safety toe and plate, is CSA/ASTM approved and ESR/EH rated, and is finished with an oil- and acid-resistant Oarprene compound (baffin.com).

Source: Baffin

We’re limited by space here, but have plenty of room online! Check out more products and solutions at EBMag.com, under “Products”.

DAN LEDUC

Focus on value in change order negotiations

In the dynamic landscape of change order negotiations, it is not uncommon to encounter objections based solely on a perceived high price, leading to a defensive stance from contractors. However, when you shift the conversation from price to value, you have a greater chance at a better outcome.

Here is a common scenario: an owner or consultant expresses discontent with a quoted price.

“You are charging two times what others charge for that same change,” they might say. “We’re not paying that much!”

A hasty

readiness to adjust your price undermines the value of the change order.

In such instances, it is crucial that you resist the temptation to apologize for the pricing structure and acquiesce, as a hasty readiness to adjust your price undermines the value of the change order.

Justifying the offer without compromising on price is paramount, and the key lies in redirecting the focus of the negotiation. Move the discussion away from price and toward value. You could say, for example:

“We both know that you are not paying for this change yourself, and no one will pay more for something than it’s worth. Let’s instead discuss the value we bring, and I will help you demonstrate that value to the actual payor.”

Repositioning the discussion encourages a deeper understanding of the intricacies behind the change, and how the corresponding benefits (e.g. unique features, quality assurances, expertise) serve the client’s needs better than price alone.

By fostering a productive and mutually beneficial exchange, change order negotiations can transcend mere price considerations. This not only reinforces confidence in the proffered services, but empowers clients to make truly informed decisions. It also fosters a collaborative environment where mutual understanding and alignment on value propositions can lead to favourable outcomes for all involved.

This column is not legal advice, nor should it be taken as such

Dan Leduc is a partner at Soloway Wright LLP, and specializes in construction law. He is always happy to take on new clients from anywhere in Canada, and can be reached at dleduc@solowaywright.com.

RAY YOUSEF

Ray is a code engineer with Ontario’s Electrical Safety Authority

TACKLE THE CODE CONUNDRUM... IF YOU DARE!

Welcome to the newest round of questions that test your knowledge of the CE Code-Part I. Answers will appear in the June 2024 edition of Electrical Business Magazine, and online at EBMag.com under Features.

QUESTION 1

What size of copper tap conductor is required to connect a metal fence around an outdoor substation to the station ground electrode?

a) 6 AWG c) 3/0 AWG

b) 2/0 AWG d) 4/0 AWG

QUESTION 2

Receptacles having CSA configurations 5-15R or 5-20R installed in buildings under construction:

a) Shall be protected by GFCI Class A

b) Can be wired by NMSC

c) Shall be kept entirely separate from lighting branch circuits

d) All of the above

QUESTION 3

Class H fuses are permitted to be used for overcurrent protection where circuit overload protection is provided by other means.

a) True b) False

ANSWERS

Electrical Business, February 2024 ed.

Question 1

What is the maximum allowable ampacity for a #6AWG T90 Nylon run in conduit containing 6 #6AWG T90 Nylon, 12 #14AWG TWU75 and 7 #12AWG TW75?

d) 33 A. Rule 4-004(13)(14).

Question 2

Areas where paint finishes are regularly applied by spraying and there is adequate ventilation, the interior of spray booths—and their exhaust ducts—are considered:

b) Zone 1. Rule 20-302(1).

Question 3

When receptacles in a trailer park are mounted vertically, the CE Code requires the U-ground slot to be:

a) At the top. Rule 72-110(3).

How did YOU do?

3 • Seasoned journeyman 1 • Apprentice

2 • Need refresher training 0 • Just here for fun!

NANSY HANNA, P.ENG

Energy storage system installations: residential occupancies

Energy storage system (ESS) installations are growing. Consider that, in addition to smaller ESS installations that serve local communities, businesses, and homes, the Independent Electricity System Operator expects to have at least 1217 MW of storage capacity participating in Ontario’s electricity market by 2026.

Recognizing this rapidly evolving and expanding technology, the recently published 2024 CE Code-Part I includes three new subsections (under Section 64) with crucial updates for ESSs: one subsection applies to all ESSs in general terms; one covers ESSs that utilize batteries; and the third applies to the installation of ESSs at residential occupancies.

Let’s look at some of the notable changes that apply to residential occupancies:

Previous Rule 64-918 “Location and separation requirements for ESS” has been deleted and and replaced with:

• New Rule 64-1100 that provides location and separation requirements for ESSs at residential occupancies.

• New Rule 64-926 that provides requirements for separation and egress from buildings for all installations.

The previous Rule 64-918 did not permit ESS installations in dwelling units, which severely curtailed broader adoption of the technology. (Note: “dwelling unit” can be a single dwelling unit, or a dwelling unit in a rowhouse, duplex, triplex, or stacked quadruplex.)

The CE Code-Part I (2024) now permits these installations. The ESS is to be located in an attached garage, an associated detached garage, or other freestanding structure; on the exterior surface of the building; in a dedicated (e.g. utility) room following certain specifications; or in other locations permitted by the authority having jurisdiction.

When an ESS is installed in a dedicated room, a smoke alarm or detector shall be installed in the room in accordance with Section 32.

The same requirements and permissions apply to an ESS installed in a building containing multiple dwelling units; however, the room in which the ESS is located must have a fire resistance rating of not less than one (1) hour.

It is important to note the new rules provide capacity limitations for a single system and, where multiple systems are installed, limitations have been set for the aggregate capacity. (Although the previous CE Code also had capacity limitations, the 2024 edition increases them in some locations.)

Some of the requirements for dwelling units have not changed. For example, ESSs shall not be installed in sleeping areas or rooms opening directly into sleeping areas, and smoke alarms or detectors must still be installed in the room in which the system is located.

This new subsection was developed by a task force that included a diverse representation of manufacturers, regulatory bodies, installers, and certification bodies. They diligently reviewed challenges and concerns from the field, with the overarching goal of aligning the CE Code with UL 9540 “Energy storage systems and equipment”.

The CE Code 2024 contains additional requirements that are important to review before planning or designing new energy storage system installations, and I will explore them in future columns.

Consult your Authority Having Jurisdiction for more specific interpretations

Nansy Hanna, P.Eng., is senior director, Engineering & Regulations, at Ontario’s Electrical Safety Authority (ESA). She is also chair of the Canadian Advisory Council on Electrical Safety (CACES) and a member of the ULC Advisory Council and CSA Technical Committee on CE Code-Part I. She can be reached at nansy.hanna@electricalsafety.on.ca.

Response to Geoff P. enquiry

Thank you for your question about the meter base photo (EB February 2024, p.4). This is from an installation in Ontario, where it is permitted not to provide a separate bonding conductor between the meter base and the panel. It is permitted to have the bonding connection between the meter enclosure and the service box provided by the service neutral conductor (ESA Bulletin 10-15-*).

As always, consult your AHJ for specific interpretations.

ATTENTION CONTRACTORS, WHOLESALERS AND ENGINEERS!

The path forward requires the fostering of diverse, equitable, and inclusive workplaces. Discover the strategic advantages of recruiting and retaining talent from traditionally underrepresented groups, including Indigenous communities and newcomers to Canada.

Industry leaders in the mechanical, electrical, plumbing, and general contracting sectors will lead and participate in crucial discussions, sharing insights on building a workforce that reflects the rich tapestry of Canada’s talent. Explore how embracing inclusivity propels innovation, fosters growth, and positions your organization as an employer of choice, creating a workplace where everyone thrives.

KEYNOTE SPEAKER

Rubiena Duarte

VP of Diversity and Inclusion at Procore NAVIGATING UNCONSCIOUS BIAS

PANEL 1:

BUILDING & MAINTAINING YOUR CULTURE OF INCLUSION

From Intent to Impact: Dive into proven steps to establish an inclusive workplace culture, with practical insights on enforcement for transformative change.

Hosted by Mary Van Buren

President

PANEL 2:

PUTTING YOUR CULTURE OF RECRUITMENT INTO PRACTICE

Elevate Your Team: Explore the undeniable business benefits of recruiting from non-traditional talent pools for enhanced innovation, resilience, and sustainable success.

Hosted by Martin Luymes VP Government and Stakeholder Relations

PANEL 3:

LEVERAGING YOUR INCLUSIVE WORKPLACE AND BECOMING AN EMPLOYER OF CHOICE

Inclusive Excellence: Learn the strategic secrets to transform your workplace into a sought-after employer of choice, attracting top talent with a culture of innovation, belonging, and sustained success.

Hosted by Michelle Branigan

CEO

SPONSORED BY:

NO BURN-THROUGH CHAMPION DUCT® ELBOWS SOLVE PROJECT CHALLENGES

No burn-through eliminates elbow repairs

Lower material and installation costs

Fault resistance makes repairing cables easy

Durable and corrosion-resistant for project longevity

Champion Duct® Electrical Conduit Elbow