Daylighting and artificial lighting combine to drive Joyce Centre’s exceptional energy efficiency

BY ANTHONY CAPKUN

The Joyce Centre for Partnership & Innovation at Mohawk College in Hamilton, Ont., was conceived in early 2016 and, from the outset, the intention was to create a net-zero building; to push the boundaries of what building technologies could achieve, and differentiate the college from its peers.

Around that time, Canada Green Building Council (CaGBC) was developing a pilot program for its new Zero-Carbon Building Program, explains Tony Cupido, Ph.D., P.Eng., who serves at the college as research chair, Sustainable Building Technologies. So Mohawk accepted the challenge, becoming one of 16 facilities across Canada to pilot the ZCB program.

CaGBC’s ZCB-Performance standard certifies that buildings achieve zero-carbon operations year after year.

“What’s important to me—and what was important to Mohawk at the time—was to have third-party validation,” Cupido insists. “It’s easy to say ‘We’ve done this, or we’re doing that’... okay... prove it!”

Which they did. Opening in May 2018, the Joyce Centre became the second project in Canada and the first institutional building to earn

a Zero-Carbon Building-Design certification through CaGBC’s ZCB Program.

“It’s a very ultra-efficient building, and we’re exceeding any performance metrics that we set going in. We’re very proud of that,” says Cupido.

The Joyce Centre features an array of technologies that help it achieve such amazing results, including: a high-performance envelope; solar panels that generate about 730,000 kWh annually (the centre uses no natural gas onsite); low-flow taps, toilets and urinals; and a geothermal system for heating and cooling.

“The mechanical room is roughly a third of what you would typically have for a 100,000-sf building,” says Cupido proudly, “And and we have no boilers, no gas-fired heating equipment for heating or domestic hot water heating—everything is done through solar.”

Designing around an energy budget

Like every construction project, the Joyce Centre set a financial budget, but Mohawk took things further by establishing an Energy Use Intensity (EUI) budget of just over 70 equivalent kWh per square metre, per year.

“And we worked toward that

target on every design component of the building, including the lighting,” Cupido notes. “We had a component of energy use intensity for lighting—which was just under 10 ekWh per m2—and we did that for the heating and cooling, for the plug loads, elevators, and other components of the building.”

“As we went through the design, and then the first year of operation, we were able to show that we could easily live within the target that was set,” Cupido says.

Daylighting and artificial lighting

Of course, a conspicuous energy efficiency tactic is the combination of large, insulated windows that allow sunlight to illuminate classrooms, labs and hallways, alongside sensor-controlled LED lighting.

And, of the artificial lighting, Cupido notes that one of the cornerstones is the use of PIR (passive infrared) and occupancy sensors. On bright days, there is very little need for the lights to be turned on. If not off altogether, the lighting is certainly dimmed low.

“I’m old school,” Cupido chuckles. “I went through entire programs where we were converting T12s to T8 or T5, but the functionality of sensors back then was still limited. They worked in

“The natural daylighting often provides sufficient light for people to learn and work in the building.”

some cases, and didn’t work in others. But with LED lighting, you can get the functionality you need.”

When someone approaches a corridor, the lights come on; if a space is vacant, the lights are off. “For us, it means tweaking and tuning the timing and functionality through our software, but it has worked very, very well—[the lighting] is performing better than we had anticipated, because we’re tweaking and tuning at all times”.

The occupancy sensors were factory-set at 30 min.; meaning, the lights would stay on for a full 30 minutes after a space was vacated. In certain locations, Cupido thinks they’ve got that time delay down to around 5 minutes. That said, safety and security concerns are just as important as energy efficiency, and figure prominently while “tweaking and tuning”.

“We don’t want students to feel that they’re entering an area that is dark, and we don’t want the lights to go off immediately as they leave an area. We want to make sure people feel comfortable and safe,” he says.

The fixtures—which consist of potlights, strips, and pendants—operate wirelessly and are controlled via the

Encelium lighting control system.

“In building automation systems, I know there can be some challenges with software gateways, interoperability but, to my understanding, my team did not have that experience with the lighting packages. They worked fairly well together,” Cupido says.

“And there’s a reasonable simplicity to the concept, right? If you’re not in an area, the lights go off; if you’re in an area, the lights come on. If it’s bright in certain areas, the lighting will be dimmed or actually go off. The natural daylighting often provides sufficient light for people to learn and work in the building.”

“We’ve had very few issues with the functionality and performance of these [sensors] other than, you know, replace the batteries on an annual basis,” Cupido notes.

“Our Facility Services team has continued to excel in the ongoing maintenance, calibration and monitoring of this impressive facility,” said Ron McKerlie, president & CEO of the college, when the Joyce Centre received confirmation that it had surpassed the required building performance standards for a third consecutive year.

Built for learning, and learning about

Mohawk College is understandably proud of the Joyce Centre. As one of the largest net-zero institutional buildings in Canada, it offers a “living lab” for students, where they have hands-on access to the monitoring and operations of a ZCB-certified building.

Students are able to explore building information modelling, a process of gathering and grouping data from the building’s performance to understand and optimize the design and maintenance during the life of the building.

Both visitors and students can take what they’ve learned about building systems and use that knowledge in other projects—even their own homes. And this may be what excites Cupido the most; besides reducing greenhouse gases and energy consumption, the Joyce Centre is helping occupants and visitors better understand how a building works.

“A lot of occupants don’t really understand something like the mechanical side, but they’ll understand the lighting side because it’s straightforward and in your face.”

CHOOSE LEDVANCE FOR YOUR NEXT OUTDOOR LIGHTING PROJECT

LEDVANCE Performance Class Wattage Selectable Sports Light, Performance Class Dual Selectable Slim Wall Pack, Performance Class Dual Selectable Bullet Flood, Superior Class Area Flood 4A, Superior Class Non-Cutoff Wall Pack 6A, and Performance Class Dual Selectable Post Top Luminaires are environmentally preferable LED alternatives to conventional luminaires. Available in several wattage/lumen packages, these outdoor luminaires offer up to 80% energy savings. Ideal for building exteriors, outdoor corridors, walkways, stairwells and parking lots. All backed by a 5-year warranty.

Introducing LEDVANCE tapTronic™

Industry First Robust Portfolio of FieldProgrammable LED Drivers with NFC Technology

LEDVANCE is proud to present tapTronic Field-Programmable NFC LED Drivers. A series of drivers that are field-programmable via our free smartphone app. These are constant current, dimmable programable power supplies. Available in the most demanding wattages within linear, compact and outdoor categories.

Contractors and distributors will appreciate the convenience of using their smartphones as personal programming tools, eliminating the need for additional wiring and tools, as well as the requirement to carry multiple SKUs. These drivers can also be programmed in the field, at any time, without the need for a laptop or power source.

Looking for an easier and more efficient way to program LED drivers?

Look no further than LEDVANCE tapTronic Field-Programmable LED Drivers!

Here are just a few reasons why these drivers are perfect for contractors:

1. The free app turns your smartphone into a personal programming tool. Simply set the parameters for the driver on the app and tap the driver with your phone to program it. It’s that simple!

2. With the ability to custom program the drivers, you can replace a wide variety of driver types with just one. This means contractors and distributors don’t have to carry a lot of different SKUs.

3. The app allows you to program the drivers without the need for additional wires, tools, labels, or laptops. You can program these drivers in the field, anywhere, anytime.

4. These LED drivers don’t need to be powered to be programmed, so contractors can easily customize as many as they need before installing, without having to climb a ladder.

Scan QR code to learn more about tapTronic.

EV BATTERIES AND THE POSSIBLE RISK OF ARC FLASH

BY SCOTT FRANCIS

Electric vehicles (EVs) are gaining in popularity as a sustainable alternative to gasoline-powered cars, and they’re quickly being seen as a key player in helping the governments achieve their nearand long-term environmental goals.

According to Transport Canada (tinyurl.com/yck8728y), reducing emissions from on-road vehicles is key to achieving Canada’s goal of net-zero emissions by 2050, which leads to investments in purchasing decisions, charging stations and regulations to support the sale of electric vehicles.

While the number of EVs on Canadian roads is still lower than in some other developing countries (just 168,000 of the 25 million registered vehicles in 2019 were EVs, according to Inside EVs), purchases of electric vehicles went up 30% in the first half of 2022—which indicates consumer purchasing behaviour could be shifting in the near future, and longer term (tinyurl.com/2s48uk4d).

One often-overlooked consideration in the conversation around EVs is how the high-voltage batteries they employ present unique safety challenges to the people who build and maintain these vehicles, particularly in the context of arc flash incidents.

Batteries and their cells

An arc flash is a dangerous electrical phenomenon that occurs when an electric current travels through the air between conductors instead of through the intended path. This can cause an electrical explosion and the release of a large amount

of energy in the form of heat, light, sound, and pressure.

According to Oak Ridge National Laboratory, the heat generated by an arc flash can be intense, reaching temperatures as high as 35,000 C, which is hot enough to vaporize metal and cause serious burns (tinyurl.com/54fuwenr).

The risks of arc flash are particularly significant when handling electric vehicle batteries, which can contain hundreds of volts of electricity. One of the main reasons for the increased risk is the use of high-voltage lithium-ion batteries, which are commonly used because to their high energy density and long life span.

Lithium-ion batteries are made up of a number of individual cells, each of which has its own low voltage but, collectively, provide enough voltage to propel a vehicle. The lithium-ion batteries in EVs have a number of these cells

Electric vehicles employ highvoltage batteries that present unique safety challenges

connected together. For example, according to engineering.com (tinyurl.com/mry8arzf), a powerful EV like the Tesla Model S has 7104 battery cells!

At times, these batteries can produce voltages approaching 1000 VDC or more. DC voltages well above 100V and arc flash currents of thousands of amps indicate potential arc flash and shock hazards, as per CSA Z462 “Workplace electrical safety” and NFPA 70E “Standard for electrical safety in the workplace”.

Electrical complexity

Another factor contributing to the risk of arc flash in EVs is the complexity of the electrical systems used in these vehicles. Unlike their internal combustion engine (ICE) counterparts, EVs have multiple high-voltage components, including the battery pack, the electric motor, and the charging system—

all areas that could present potential opportunities for arc flash incidents to occur when energized.

Approach with best practices

There are multiple ways a battery manufacturer or maintenance worker could be exposed to battery arc flash, including: when connecting cables into battery-fed systems; changing components; handling, moving and repairing batteries; working on associated battery systems; replacing electric motors; and when working with batteries after a collision.

Workers handling electric vehicle batteries should be properly trained and equipped to perform their tasks safely, including wearing personal protective equipment (PPE) designed to protect against possible arc flash. CSA-Z462 includes requirements for selecting appropriate arc-rated FR apparel for workers exposed to electric arcs or flames based on the DC arc flash risk assessment.

It is important to follow safe work procedures and

ADDITIONAL READING

PPE best practices when working with EVs and their batteries. This may include procedures for isolating the electrical system, disconnecting battery links to reduce incident energy, performing electrical safety tests, and properly utilizing PPE; for example, insulating the worker from shock hazards via voltage-rated gloves/ leather protectors, and protecting them from arc flash by outfitting workers in appropriate arc-rated, FR clothing, balaclava and face shield before commencing work on EV batteries.

The risks of arc flash when handling electric vehicle batteries are significant and should not be taken lightly. By following proper safety procedures, manufacturers and individuals can help mitigate these risks and ensure that EVs are used safely and responsibly.

Scott Francis is technical sales manager at Westex: A Milliken Brand, and frequently addresses trade associations and companies. He has been involved with the safety industry since 1991 and has extensive experience with protective apparel fabrics and PPE, and knowledge of thermal hazards related to NFPA/ CSA standards.

To ensure a worker is properly trained, review training requirements in CSA Z462 and/or NFPA 70E. Visit csagroup.org and catalog.nfpa.org.

Read Saf-T-Guard’s blog (tinyurl.com/3arud5zm) for information on specific PPE requirements when servicing EVs, and google EINTAC’s Knowledge Hub.

For additional training on safely maintaining and working on EV batteries, find accredited courses to certify your safety managers and labourers.

Also check out “Safety norms for working on highvoltage electric vehicles” (tinyurl.com/ycyw89x7).

PERSONALITIES

Bob Holman has moved up from vice-president and sales manager to president at D.A.D. Sales (dadsales.com)—an electrical manufacturer sales agent in Alberta and Saskatchewan. “Bob Holman has always been a leader and mentor to the D.A.D. Sales team, and we value his continued leadership in his new role,” said Bonnie Youngs, vice-president.

Source: D.A.D. Sales

Stelpro Group (stelpro.com) has named a new CEO, Pierre Huard, who has held several management positions at companies such as Rolls-Royce, Pratt & Whitney and, most recently, Meubles Foliot (top left photo). Patrick Charest will now lead the marketing department as vice-president, Sales & Marketing, for Groupe Stelpro (top right photo). Étienne Guay will focus on his role as vice-president, Innovation & Product Development. Jérôme Potvin has been appointed sales director, Electrical Distribution for Quebec (bottom left photo).

Source: STELPRO

Muktha Tumkur is the new executive director of Technology Accreditation Canada (technologyaccreditation.ca), which delivers accreditation services for the engineering technology and applied science profession. She comes to TAC with experience in accreditations, standards development, strategy and business development, having worked for many years at CSA Standards.

Source: Supplied

Schneider Electric (se.com) has appointed Shitiz Agarwal as vice-president, Power Systems, Sales and Operations, in Canada. Under Agarwal, the national sales, operations and Power Systems teams have been linked to form one centralized execution/solutions centre. Agarwal possesses over 18 years of experience in strategic planning, business transformation and operations management in the energy and digital automation market.

Source: Schneider Electric

Ihor Cap, program development officer and training standards coordinator at Apprenticeship Manitoba, was selected by the Canadian Council of Directors of Apprenticeship (CCDA, red-seal.ca) as recipient of the 2022 Red Seal Award of Excellence. The award is bestowed annually to one apprenticeship authority staff member who “demonstrates inspiring leadership in the development of and promotion of apprenticeship and skilled trades certification” (gov.mb.ca/aesi/apprenticeship).

We’re limited by space here, but have plenty of room online! Learn more about these individuals by visiting EBMag.com. Click “News”, then click “Personalities”.

WHAT DO CAT RATINGS MEAN?

Comprehending safety ratings for electrical tools, test & measurement equipment

The International Electrotechnical Commission develops and distributes international standards for electrical technologies, including for devices used to identify, test and measure live electrical circuits (iec.ch).

Known as the “measurement category”, this method of classification examines the total potential continuous energy available at any point within a circuit, including the potential for transient voltages that can spike voltages well beyond normal levels.

Transient voltages can be caused by lightning strikes, arcing, or other naturally occurring electrical phenomena, which can pose significant danger to personnel working on or around electrical equipment—from fixing a copy machine through to examining power utility infrastructure.

Measurement categories are divided into four parts, known individually as category (CAT) ratings: CAT I, CAT II, CAT III, and CAT IV. Understanding what each of these categories means is vital for choosing the right equipment for the job to avoid exposure to unnecessary risk.

In short, the rating system will inform anyone working with electrical equipment about the right tool for a job; whether a basic multimeter will suffice through to selecting the right devices for industrial utility infrastructure inspection.

Understanding voltage ratings In the CAT rating system, the Roman numerals I through IV refer to the location of a circuit in relation to the power source, defined in terms of the total potential transient voltage danger.

CAT I

describes secondary circuits not intended to be connected to the mains electricity supply, such as electronics (including a typical laptop) and circuits powered by regulated low-voltage sources.

CAT II

is defined as local-level electrical distribution, such as a standard mains socket and plug-in loads. This category includes household appliances, such as washing machines, and portable plug-in power tools.

CAT III

references a building’s electrical installations, including circuit breakers, wiring, switches and industrial equipment.

CAT IV

involves the source of the low-voltage power installation; essentially, the power grid infrastructure, such as underground utility vaults or outdoor powerlines.

However, determining the appropriate voltage category is only half the story. Simply matching the presumed voltage to the test & measurement device will not provide adequate safety assurance. Failed electrical units can experience impulse or transient voltages on the order of many times a particular electrical tool’s rating.

For example, a line may normally have a voltage of 120 or 240, but a lightning strike can create transient voltage—perhaps several thousand volts—that can cause a short-circuit and arcing, which could severely injure personnel testing the power infrastructure with inadequate equipment.

In essence, then, not only must the tool have the appropriate CAT rating for the application, the device must also have a voltage rating higher than the maximum voltage of the given environment to withstand potentially dangerous surges in voltage.

Thankfully, IEC supplies a quick-reference chart to determine whether a given electrical tool is appropriate for the task at hand (see chart, page 22).

Matching the right electrical tools for the job

If a given specification requires a tool to be rated for CAT III 600V and CAT II 1000V, then the module can withstand up to 6000V of impulse or transient voltage. This type of spec would additionally inform the user that the device must not be used with mains CAT III circuits with the potential for voltage to rise above 6000V.

Conversely, the tool or device rated in this manner should not be used with CAT IV circuits under any circumstances, even when a particular scenario does not require more than 6000V. Ultimately, the purpose of the CAT rating system is to provide a quick and easy-to-understand method for selecting the right tool for the job; to know if a given tool is designed for a particular application/scenario or not. A quick check adds an additional level of safety, helping to prevent serious injury—or even death—that could result from severe shock, fires or explosions.

— Contributed by Teledyne-FLIR

Distributed drive system

Source: Siemens

Designed for horizontal conveyor applications, the G115D comprises the motor, drive and gearbox in one unit, and is offered in wall- and motor-mounted versions. The system is rated UL Type 4X and up to IP66, with an operating temperature range of -30 C to 55 C (siemens.com).

Custom power resiliency

Source: Trystar

Trystar sees an increased demand for resilient power systems. To that end, the company offers to help design and specify a load bank, docking station, and cabling package that is “harmonized and tailored to their permanent or rental generator backup power system” (trystar.com).

Non-contact voltage detector

This water-resistant detector features static discriminator technology to provide reliable detection in low voltage ranges. Weighing less than 1 lb, the unit incorporates an all-in-one

universal attachment and shotgun adapter in the handle (hfgp.com).

Wireless mobile IR camera

Source: Teledyne FLIR

The FLIR One Edge Pro doesn’t need to be physically connected to its companion mobile device. Users can operate the device up to 30 metres away. The unit features a 160x120 thermal imaging camera paired with a visible camera (flir.ca).

Utility fencing stapler

Source: Milwaukee Tool

Milwaukee aims to improve copper ground wiring and fencing installation with its M18 Fuel stapler and 9-ga. galvanized staples. The system allows linemen and fence installers to staple up to 6X faster than with a hammer. When paired with an M18 RedLithium high-output CP 3.0Ah battery—the tool can drive up to 600 staples per charge (milwaukeetool.ca).

We’re limited by space here, but have plenty of room online! Check out more products and solutions at EBMag.com, under “Products”.

CALENDAR

MCEE Expo

April 19-20, Montreal

mcee.ca

Thrive Summit

BC Electrical Association

April 20, Langley, B.C. bcea.bc.ca

OEL Electrical Industry Conference

Ontario Electrical League

May 3-6, Brantford, Ont. oel.org

ECAA Annual Conference

Electrical Contractors Association of Alberta

May 11-14, Jasper, Alta. ecaa.ab.ca

LightFair

May 21-25, New York, N.Y. lightfair.com

EDIST

Electricity Distributors Association

May 30-June 1, Markham, Ont. eda-on.ca/EVENTS/EDIST

EFC Annual Conference

Electro-Federation Canada

May 30-June 1, Charlevoix, Que. electrofed.com

ADVERTISER INDEX

ABB Electrification Canada ULC 1 ,4 , 5

Acuity Brands Lighting Canada 15

Adrian Steel Company 9

Association of Equipment Manufacturers 13

Canadian Standards Association 27

Eaton Canada 2 , 3

EFC Electro-Federation Canada 25

Ledvance Ltd. 18 , 19

Mersen Canada Toronto Inc. 30, 31

Northern Cables Inc. 1 , 23

Satco Products of Canada 29

Uline Canada Corporation 8

Zip Cable Tray Systems Inc. 32

TO ADVERTISE CONTACT

Leslie Osborne losborne@annexbusinessmedia.com

DAN LEDUC

Subcontracts that come after close of tender

Since at least 1980, the process of tendering in Canada has been premised in contract law. Typically, an owner’s invitation to tender is treated as an offer, and your compliant bid submission is considered acceptance. That offer and acceptance forms what the Supreme Court of Canada considers Contract A.

(Acceptance must match the offer. Qualifying your bid submission is not acceptance, but rather a counter-offer. Hence, no Contract A.)

In a typical situation, the owner chooses from the compliant bid submissions to award what amounts to Contract B—the actual construction contract with the prime or GC then, by derivation, with the subcontractors whose prices the prime or GC incorporated in its overall bid submission.

By all accounts, Contract A and Contract B must match (subject to any negotiated changes).

Where can this become an issue for the electrical contractor (or other subs)?

Let’s say you are handed a set of tender documents, typically through a GC or prime. You do a takeoff based on that set and submit a bid to one or more GCs or primes. You then receive a phone call, followed by a letter of intent or award, advising that you have been chosen as the successful bidder.

When this happens, what is your legal position?

You begin purchasing material, planning labour and mobilizing. In effect, you start work.

After one or more progress draws, the prime/GC hands you a subcontract and tells you the next payment is conditional on you signing that subcontract.

By all accounts, Contract A and Contract B must match

When this happens, what is your legal position? Is this subcontract even valid?

Consider the situation using a linear approach—a timeline. The act of submitting your bid (acceptance) locks in the applicable terms and conditions of any subcontract (which are part of the offer). The obligations and allocation of risks in the tender documents against which you were asked to submit a price should be identical to those found in your subcontract. Again, Contract B should match Contract A.

From a legal perspective, you are not required to sign a subcontract that differs from your tender documents. Instead, you can advise the prime/GC that your submission was against the terms and conditions of the offer. (You may have commercial reasons for taking a different position, but this is your legal position.) Conversely, if you received that subcontract during the tender process, it becomes part of the offer. If you proceed to submit a bid (acceptance), you will be bound to the subcontract’s terms and conditions, and there is little legal leverage available to you.

The next time you receive a subcontract after the close of tender, always check whether it was part of the tender documents, and respond accordingly.

This column is not legal advice, nor should it be taken as such

Dan Leduc is a partner at Soloway Wright LLP, and specializes in construction law. He is always happy to take on new clients from anywhere in Canada, and can be reached at dleduc@ solowaywright.com.

CODE conundrum

RAY YOUSEF

Ray is a code engineer with Ontario’s Electrical Safety Authority

TACKLE THE CODE CONUNDRUM IF YOU DARE!

Welcome to the newest round of questions that test your knowledge of the CE Code-Part I. Answers will appear in our June 2023 edition, and online at EBMag.com under Features.

QUESTION 1

When a two-conductor NMS cable is used for a switch loop, does the Code require you to tape the white wire with Black tape at the switch, if the connections are made so that the actual Black wire is the return conductor from the switch to the outlet?

a) Yes b) No

QUESTION 2

All space within 6 metres horizontally in any direction from dip tanks and

their drain boards, with the space extending to a height of 1 m above the dip tank and drain board, is considered:

a) Zone 1 c) Category 1

b) Zone 2 d) Category 2

QUESTION 3

Conductors in the high-voltage circuits of X-ray equipment shall be of the ___ type.

a) TC c) Shockproof

b) RW d) Extra-hard usage

How did YOU do?

3 • Seasoned journeyman

2 • Need refresher training

1 • Apprentice

0 • Just here for fun!

ANSWERS

Electrical Business, Winter 2023 ed.

Q-1: It is permitted to use electrical non-metallic tubing (ENT) underground and in concealed locations; however, it is not permitted in exposed locations.

b) False. Rule 12-1500.

Q-2: Which of the following CSA receptacle configurations is required for an electric range, having a calculated demand of 50A or less, in a dwelling unit?

c) 14-50R. Rule 26-744(4).

Q-3: For a mobile home, the minimum length of #6AWG power supply cord measured from the attachment plug to the point of entrance to the unit is:

d) 7.5 m. Rule 70-108(1)(e).

NANSY HANNA, P.ENG.

Adjustable electric vehicle supply equipment

Different levels of government continue to support the adoption of zero-emission vehicles, with electric vehicles being the most common ZEV. If trends continue, our electrical systems must continue to evolve at every level of distribution— from the electrical grid to a home’s service panel—to meet this higher demand.

That continued evolution could involve adjustable EVSE (EV supply equipment).

Whether connecting via Ethernet or Wi-Fi, software- and app-based chargers provide the user with a greater amount of control over the charging of their EV (e.g. charging time and rate of charge), along with additional functions that allow the user to manage the load and energy consumption.

Authorities having jurisdiction (AHJs) continue to receive questions regarding software-adjustable amperage ratings of EVSE, and whether the de-rated rating can be used when determining service, feeder and branch circuit ratings.

Given that it is not directly addressed in the CE Code, let’s discuss some of the nuances of adjustable EVSE.

Based on Electrical Safety Authority Bulletin 86-1-*, it is permitted to base the rating of the EVSE on the charger’s field settings for the purposes of maximum circuit loading, disconnect requirements, or overcurrent protection—provided the adjustable settings are not accessible; meaning, a tool would be required for access.

Allowing software-adjustable settings provides advantages but, at the same time, poses some challenges. The greatest advantage is allowing the installation of the EVSE without having to incur the additional cost of upgrading the service and main panel for houses and buildings with limited loading capacities. The greatest challenge is ensuring users cannot inadvertently increase the charge rate settings, which could result in the potential hazard of a circuit overload.

To help mitigate that challenge, perhaps we consider conditions that would permit only those software-adjustable

settings that support their advantages and help manage the risks, such as:

• Permitted for fixed-in-place EVSE only.

• Manufacturer’s instructions are followed.

• EVSE is marked with permanent legible marking when adjusted below the maximum nameplate rating.

• Restricted access to the adjustable settings.

CSA C22.2 No. 280 provides some helpful definitions for fixed-in-place:

• Fixed-in-place is a mounting means for EVSE that requires a tool to remove the equipment from its mounted position.

• Fastened-in-place is a mounting means for EVSE for relocation, interchangeability, maintenance, or repair without the use of a tool.

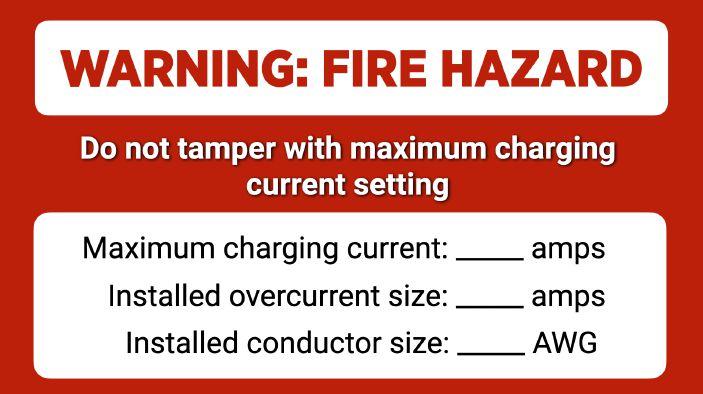

A permanent legible marking can be posted on or adjacent to the EVSE (when set below the nameplate maximum rating) with the minimum information shown in Figure 1.

Restricted access can help prevent a user from gaining unwanted access to the adjusting means, and could be accomplished by one or more of the following:

• A cover or door that requires the use of a tool for access.

• Password-protected commissioning apps or software.

• Other means by which the manufacturer can demonstrate “restricted access” has been achieved.

Some AHJs accept hardware-adjustable settings, such as dip switches but, as yet, none of them accept software-adjustable settings.

With the increase in EV charger installations—coupled with the restrictions and costs of upgrading the service capacity in older neighbourhoods (which are also the areas with the highest EV adoption)—permitting adjustable EVSE could be the obvious solution. However, this needs to be considered with clear conditions and precautions to mitigate any safety hazards to both property and personnel.

Consult your Authority Having Jurisdiction for more specific interpretations

Nansy Hanna, P.Eng., is senior director, Engineering & Regulations, at Ontario’s Electrical Safety Authority (esasafe.com). She is also chair of the Canadian Advisory Council on Electrical Safety (CACES) and a member of the ULC Advisory Council and CSA Technical Committee on CE Code-Part I. Visit esasafe.com.

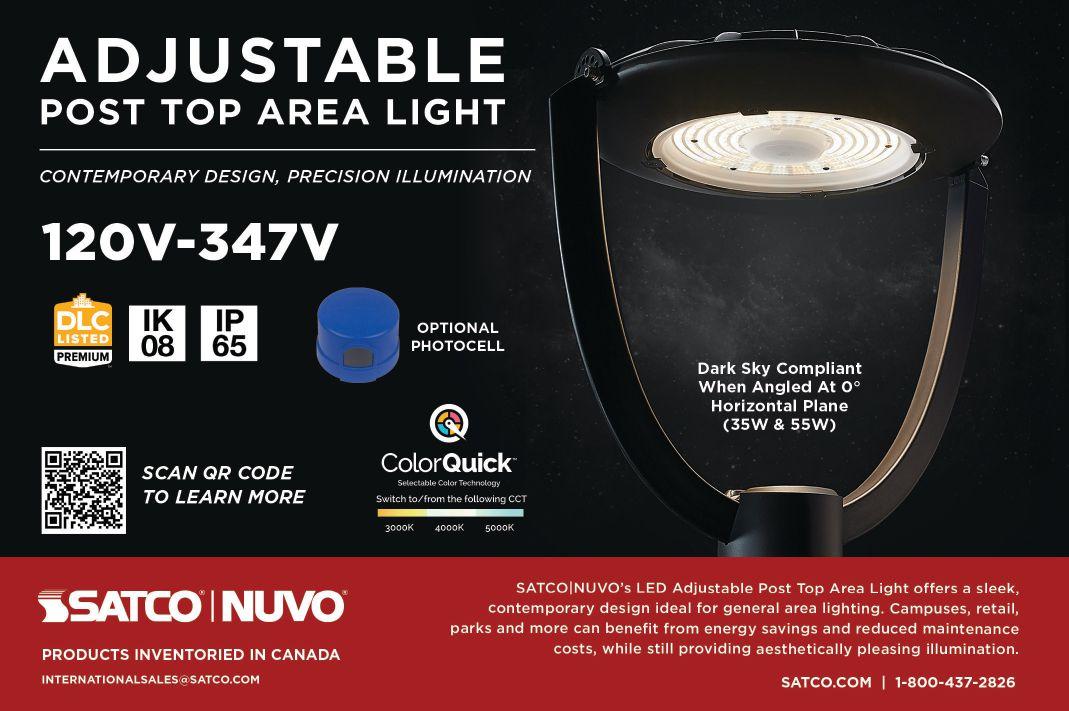

CONTEMPORARY DESIGN, PRECISION ILLUMINATION

Through innovation and design, SATCO responds to today’s changing lighting needs with thousands of products that provide energy efficiency, high quality illumination, value, safety, and solutions. Our Latest LED Adjustable Post Top Area Light offers a sleek, contemporary design ideal for general area lighting requiring a highly efficient architectural light source with precise control.

Unique to this product is the locking articulating head allowing adjustments from 0-90° for directional illumination. Another advantage of the articulating head, noting our 35W and 55W versions in particular, is that it is Dark Sky Compliant when oriented at 0°. Color selectable choices include 3000K/4000K/5000K with 120V-347V input voltage options. These high-performance luminaries are offered in 4 popular wattages to service a variety of lighting applications and feature and integrated NEMA photocell. Not only are these fixtures IK08 impact rated, all models are DLC 5.1 premium complaint, IP65 rated and deliver significant energy savings.

What about DC Distribution?

With DC distribution continuing to evolve and new technologies on the horizon, Mersen’s MDC series helps customers achieve the ultimate protection for today and tomorrow.

There are minimal options available in today’s market for a DC rated fuse which is capable of safely interrupting low level currents (overloads) up to its maximum interrupting capability (faults), making it challenging for system integrators and equipment manufacturers. The MDC series provides unique performance characteristics, allowing customers to safely protect their equipment and the personnel servicing the equipment.

While there are a number of DC rated fuses in the market today, not all DC rated fuses provide the level of protection required for DC systems. For example, there are a number of 1500VDC, 100A rated fuses available; however, these fuses may not have the capability to safely interrupt lower overcurrents or they may fall short of the system’s maximum available fault current. In either case, there will be a concern for safety and system reliability.

The MDC series incorporates proven fuse technologies which provide optimal current limitation while achieving maximum performance. The MDC portfolio is designed to easily allow customers to choose fuses which meet system requirements, ensuring a safe and reliable product.

Applications include:

• DC cabling

• DC bus

• DC auxiliary circuits

• Electrical energy storage (EES)

• Battery module protection

• EV charging

• Critical power

• UPS protection

The MDC series is a solution for applications where a dedicated DC distribution fuse is required. The MDC series offers a complete product range from 600VDC up to 1500VDC, and 1A up to 600A. The MDC series is designed to meet all of today’s requirements, with future requirements in mind.

MERSEN’S NEW MDC SERIES DC DISTRIBUTION FUSES

LOW AND HIGH OVERCURRENT PROTECTION FOR DC SYSTEMS

Mersen’s MDC DC Distribution fuses help customers achieve ultimate protection and let system integrators and OEM manufacturers easily select fuses for the protection of DC distribution in a variety of applications.

MDC06A(1-50)

600VDC/AC up to 50A

• Auxiliary circuits for DC applications

• UPS

• EV Charging

• EES

• DC bus/wire protection

MDC10A(1-30)

1000VDC/700VAC up to 30A

• Auxiliary circuits for DC applications

• UPS

• EV Charging

• EES

• DC bus/wire protection

MDC10M(70-600)

1000VDC/600VAC up to 600A

• Auxiliary circuits for DC applications

• UPS

• EV Charging

• EES

• DC bus/wire protection

• If remote indication needed

MDC15A(4-32)

1500VDC

• Auxiliary circuits for DC applications

• UPS

• EV Charging

• EES

• DC bus/wire protection