PANDEMIC PANIC!

Frosted polycarbonate

Smooth recessed white baffle

Stanpro’s new Universal Commercial Downlight is now available!

You want peace of mind for all your projects?

Whether to illuminate new constructions or to modernize existing spaces, this all-in-one LED downlight is the perfect solution to brighten and improve the lighting of your spaces! With its smooth white recessed baffle and a frosted polycarbonate lens, this downlight is ideal for all types of commercial applications, such as retail, hospitality and offices. The Universal Commercial Downlight comes with a 90 CRI in order to have the best color rendering capacity. It is also ideal to replace existing CFL, HID and incandescent luminaires.

What is its particularity?

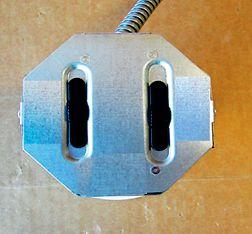

Stanpro Universal Commercial Downlight offers great versatility in a single product due to its switches located on the LED driver box. These switches allow you to select and adjust the amount of light and color temperature required to meet all your lighting needs. The easy access to the LED driver and switches as well as the simplified installation of the module with mounting clips allows you to change the settings at any time.

Key Features :

Spring mounting clips for easy installation

All-in-one integrated 3 color temperature selection : 3 000, 3 500 and 4 000 K

4 power selection per size

4, 6 and 8 inches diameter sizes

High lumen output and color rendering

120-347 V

90+ CRI

Switch on the LED driver box

Beam angle : 75° and 85°

50 000 hours

3

BY McLENNAN ROSS LLP (ERIN LUDWIG, PARTNER AND REBECCA SILVERBERG,

As of March 17, 2020, 424 confirmed cases of COVID-19, a novel coronavirus, have appeared in eight provinces, with the highest number of cases in Alberta, British Columbia, Ontario and Quebec. Although COVID-19 has not yet impacted the day to day lives of most Canadians or the daily operations of Canadian businesses, news headlines remain a constant reminder that there is potential for both individual infection and workplace disruptions to become a tangible and serious risk. Presently, employers should be examining their workplace readiness for COVID-19. Continuity planning is critical. Employer communication with employees about emergency preparedness, workplace expectations, and leave in the event of illness or quarantine should be occurring now. Importantly, in the event of a widespread COVID-19 outbreak in Canada, an employer’s responsibilities under occupational health and safety, employment standards, and human rights legislation will continue as they would with any other illness impacting employees.

This article is meant to provide a

primer on pandemic characteristics and answers to a number of frequently asked questions arising in the context of pandemic planning in the workplace and appropriate business responses to the COVID-19 outbreak. We have also included some immediate actions that employers can take as they begin to plan for an increase in the impact of the COVID-19 outbreak.

Pandemic characteristics

Influenza-type viruses periodically cause worldwide epidemics or pandemics with high rates of illness and/ or death. COVID-19 has been reported in over 110 countries. A pandemic is an epidemic crossing international boundaries. The decision as to whether a pandemic exists is made by the World Health Organization. A high incidence of infection in Canada or a region of Canada could result in the need for extraordinary measures, and those decisions are made by the Chief Public Health Officer and/or local authorities in affected provinces or territories.

A pandemic is not like a physical disaster. A pandemic has unique characteristics when compared with a more “typical” disaster:

Please note, this information was current as of March 17, 2020. The situation continues to evolve day by day.

Widespread impact: The impact of a pandemic is widespread, even global, not localized to a single area. Many business pandemic plans assume some part of an organization is unaffected. That may not be possible in the event of a pandemic.

Duration: A pandemic is likely to exist over an extended period of time. Many business pandemic plans assume a disaster-type event will be short in duration and that recovery can start immediately.

Primary effect is on staffing levels: Unlike a natural disaster, where any disruption to business services is usually tied to property or business assets, business operation disruptions during a pandemic are mainly caused by human-resource related issues. Businesses should be planning for increased levels of staff absenteeism over an extended period of time.

A pandemic may have other impacts on business. For example:

• The provision of essential services like telecommunications, financial services, energy supplies, and logistics may all be disrupted. The news has already reported disruptions to some air travel, increased border security, and disruption in manufacturing and supply chain operations tied to China;

• Supplies or materials needed for ongoing business activities may be disrupted;

• The availability of services from subcontractors may be affected; and

• Demand for business services may be affected.

For updates on COVID-19, information is being regularly provided from the following sources:

• Public Health Agency of Canada website or information hotline: 1-833-784-4397

• World Health Organization

• Government of Canada Travel Advice and Advisories

• Provincial health and safety agencies and Chief Medical Officers of Health.

1. What if my employee(s) contract COVID-19?

Employees who contract COVID-19 should be prohibited from attending the workplace. However, and importantly, these individuals should be treated like any other sick employee. For example, employees who contract COVID-19 may be eligible to claim benefits under a sick leave policy or a disability benefits plan.

Further, most provincial employment standards legislation now provides employees with limited paid or unpaid sick and/or personal days, which could be accessed by an employee in the event s/he, or a family mem-

ber, becomes ill due to COVID-19. In Alberta, the Employment Standards Code provides that employees who have been employed for at least 90 days are entitled to five days of unpaid leave for personal illness or family responsibility, and up to 16 weeks of unpaid job-protected leave for longterm illness.

In the absence of company paid sick leave benefits or disability benefits coverage, employees may be entitled to sickness benefits under the Employment Insurance Act (Canada). Under this Act, employees who face a reduction in normal weekly earnings of at least 40% because of illness, injury, or quarantine are eligible for EI sickness benefits, provided they have accumulated sufficient insurable hours. During the 2003 outbreak of SARS, the federal government implemented special loss of income relief for certain affected employees. A similar extension of EI sickness benefits may be implemented if the coronavirus outbreak becomes widespread in Canada.

Employers should also assess their sick leave or employee absenteeism policies with a view to flexibility. In the event of a widespread COVID-19 outbreak in Canada, obtaining medical certificates for any illness may be difficult or delayed, and place undue pressure on an already overburdened health care system.

2. What if my employee(s) is potentially exposed to COVID-19 and must selfisolate or be quarantined?

Another issue that may arise for employers is the circumstance where an employee is not ill but is unable to attend work due to a potential exposure, a direction to self-isolate, or is quarantined. Generally, there is no legal obligation to pay employees who are unable to attend at or carry out work. For employees who are not sick, employers should review their workplace policies and be prepared to extend paid leave, or allow employees to access vacation or to work remotely. Employers should also consider whether certain sick leave benefits can be provided on a gratuitous basis.

What is important to note is that if employers request that an employee stay away from the workplace, due to recent international travel, sickness, or other reasons, there is arguably an obligation upon the employer to pay these employees. If possible, in this type of circumstance, employers should provide employees with meaningful work to conduct remotely.

So far, a number of events have been postponed or cancelled as a result of the threat of COVID-19, including:

• EFC’S E-VOLVE INDUSTRY CONFERENCE has been rescheduled for September 1-3, 2020.

• IEEE IAS ESTMP 2020 has been postponed until Fall 2020.

• MESSE FRANKFURT’S LIGHT + BUILDING has been rescheduled for September 27 to October 2, 2020.

• NEDCO’S ELECTRIFEST 2020 has been rescheduled for September 21, 2020.

• LEDUCATION has been rescheduled for August 18 to 19, 2020.

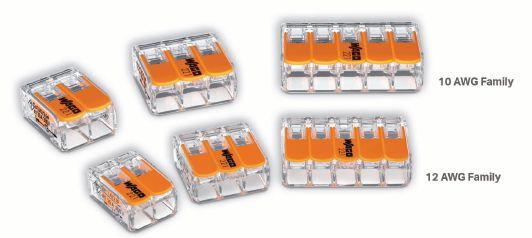

Pull the lever up, insert the stripped conductor, and push the lever back down –done. WAGO’s 221 Series compact splicing connectors let you connect any combination of solid, stranded and flexible copper wires quickly and reliably. Visually inspect for proper strip length and complete wire insertion through its transparent housing.

its transparent housing.

• 10 AWG family: 20 – 10 AWG

• 10 AWG family: 20 – 10 AWG

• 12 AWG family: 24 – 12 AWG

• 12 AWG family: 24 – 12 AWG

For even greater application flexibility, transform the 221 Series connectors into a fixed terminal block solution for DIN or chassis mount applications with the optional mounting carrier.

For even greater application flexibility, transform the 221 Series connectors into a fixed terminal block solution for DIN or chassis mount applications with the optional mounting carrier.

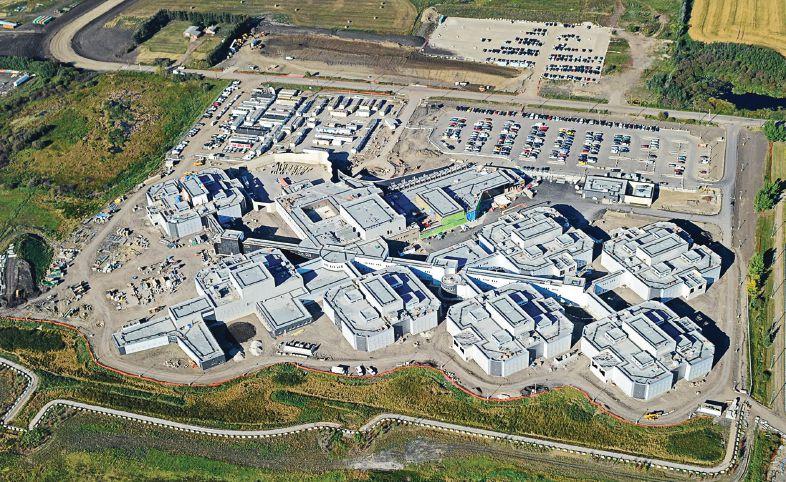

The lighting at the Edmonton Remand Centre was selected to achieve LEED Silver certification

At a time before LED lighting was as widespread and affordable as it is now, how was a facility to reduce energy costs without sacrificing safety and security?

This was a problem faced by the Edmonton Remand Centre during its construction. The LEED Silver-certified, 609,000sq.ft. building was the largest public building project ever undertaken by the Government of Alberta and cost about $568 million to construct.

The facility, which has a capacity of about 2,000 inmates, is

known as the largest, most technologically-advanced remand facility in Canada.

The Centre contains all necessary electrical and security systems segregated to one campus-style site, with all mission-critical systems backed up for full redundancy operation.

As the Edmonton Remand Centre was being built, the project members were challenged to achieve LEED Silver certification and energy savings, without sacrificing safety. At the time of lighting specification,

Almost 1,200 of the surface ceilingmounted fixtures installed have an LED night light, which combines energy efficiency with reduced maintenance costs.

LED luminaires were not an option for the entirety of the project, as they were very early in development, not readily available in a detention luminaire, and the price point was still very high.

The electrical contractor, British Columbia-based Canem Systems, solved this challenge by installing over 5,000 fluorescent luminaires – many with LED night lights – in inmate access areas including cells, corridors, program areas and the facility’s full-service medical treatment centre. This solution reduced

maintenance and energy costs and achieved the goal of LEED certification within budget.

“The luminaires’ superior performance is allowing us to install fewer fluorescent tubes, reducing the watts per square meter usage, while still maintaining equivalent lighting levels when compared to other options,” said Matt Strickland, project manager at Canem Systems, in a Kenall case study.

The luminaires the contractor chose were selected for many reasons. For example, the luminaires’ power tray was easily removed and replaced with a spare assembly, reducing the amount of time spent in an inmate cell. If a repair

A flyover shot of the Edmonton Remand Centre.

did become necessary, the nature of the luminaire allowed the maintenance to be completed elsewhere, rather than in the cell.

Almost 1,200 of the surface ceiling-mounted fixtures installed have an LED night light, which combines energy efficiency

with reduced maintenance costs. The LED night light is adjustable, minimizing inmate vandalism due to excessive brightness while they are trying to sleep. In addition, the night lights are dimmable to 20 per cent and may be adjusted up to full brightness for

safer bed checks.

Integrating energy efficiency into a construction project via a one-time investment will achieve ongoing financial savings for years to come — benefitting staff and taxpayers alike.

— With files from Kenall.

imprimé et numérique qui mobilise l’ensemble des professionnels du marché de l’électricité au Québec et qui offre une variété de produits numériques.

Veuillez remplir le formulaire ci-dessous pour recevoir votre magazine gratuitement par la poste. Veuillez faire parvenir ce coupon-réponse par courriel à l’adresse : redaction@annexbusinessmedia.com

Nom Titre

Compagnie

Adresse Ville Code postal

Téléphone

Télécopieur

Courriel

électrique

Date

Technological advances in “all-in-one” communication and automation processors / BY JEFF ELLIOTT

Utility substation automation schemes are typically complex, involving a variety of intelligent electronic devices (IEDs), microprocessor-based relays, meters and monitoring devices. The information collected is then sent to communication processors or RTUs, before being passed on to proprietary HMI interfaces, SCADA Master Stations, Energy Management Systems (EMS) and/or enterprise networks.

Within this scheme, the component parts are often cobbled together by utility automation groups from a multitude of competitor options with varying protocols (some proprietary), configuration options, wireless transmission bands and interconnections.

Given that utilities may have hundreds of substations and even more pole-tops to monitor and control remotely, the complexity of distribution automation has traditionally been staggering. Fortunately, over the past two decades, substation automation has evolved and changed.

“In the past, the design of the substation was a patchwork of many different devices,” says Russ Fanning, a principal engineer. “Once you finally got the patchwork figured out, you could replicate that pattern but when you went to the next substation and you wanted to bring in something new, you were starting from scratch again and trying to patch that new piece in.”

Today, Fanning says the focus is on stripping out as much of the complexity associated with substation automation as possible.

Technological advances over the past several years have reduced the need for the same amount of hardware in favour of “all-in-one” communication and automation processor units that can interpret and distribute information in many protocols while performing sophisticated logic functions and alarm annunciation without the need for PLCs and racks of RTUs. These all-in-one devices even eliminate the need for security-risk PCs and proprietary HMI interfaces.

The communication and automation processor can connect to nearly any substation device in its native protocol, perform advanced math and logic, and securely present the source or calculated data to any number of clients in their preferred protocol.

For utilities installing equipment in new greenfield substations, upgrading aging legacy technology, or concerned over support, this is a welcome development.

Interpreting communications and protocols

Fanning, who worked at a Wisconsin-based utility for 38 years, started his career as protection technician. After getting his engineering degree in 1990, he worked in substation engineering as a protection engineer, then

R&D engineer and, in 2007, became a principal engineer in the substation automation group.

“In my last five to six years at the utility, I was responsible for distribution automation and substation integration to interface with all the IEDs that were inside the substation and at the poletops. I integrated pole-top device IEDs into the distribution automation systems when they were enabled with communication capabilities,” says Fanning.

According to Fanning, the distribution automation system he installed at the time was designed to automate the switching of substation breakers and pole-top devices to restore power and/or to avoid power outages and equipment damage. The challenge at the time was having to work around ways to retrieve the data from the IEDs and other devices, says Fanning. Multiple protocols are often used for distribution automation, including proprietary protocols with custom communication links.

“In a typical substation set-up at the time, there was often different software in each device and I would have to manipulate the data just to be able to share it,” notes Fanning. “For one system I worked on, I needed a proprietary protocol and software just to communicate to the device.”

In most modern substations, microprocessor-based relays involve a proprietary protocol, so the com-

“Hiring Mohawk graduates is par t of our plan for success.”

Gerrie Electric has strong ties with Mohawk College, sharing a common goal to train and develop a skilled workforce for tomorrow.

Mohawk offers a wide range of opportunities for small, medium and large businesses. Connect with us at our Industry and Employer website! mohawkcollege.ca/employers

munications processors must be able to retrieve real-time fault event data and records by speaking to the relays in their native protocol.

Another standard protocol is DNP (Distributed Network Protocol), which is often used by SCADA Master Stations, RTUs, IEDs and also for relays. To promote interoperation of IEDs from different vendors, the IEC 61850 is an international standard defining communication protocols for IEDs.

Older IEDs may still use Modbus or other legacy protocols.

“There is a wealth of information that is being created inside newer IEDs, microprocessor-based relays and meters that, until recently, has been left behind because it was too challenging to collect and distribute it,” adds Fanning. “Today you can drill down into those IEDs from a remote location using a secure connection.”

Reducing the driving time to remote sites was one of the biggest drivers in automating the substations, as well.

“I could access the IEDs in the sub-

station and get a clear picture of what was happening,” says Fanning. “Knowing what the situation was, I could drive there knowing what I had to do or I could delegate that work to someone in the area – depending on what it was.”

Today, open-source web-based SCADA and HMI solutions eliminate the need for a substation PC and its inherent software and cybersecurity concerns, at a fraction of the cost.

In this approach, engineers can build interactive screens accessible from standard web browsers. For example, a browser can be used to view data from connected IEDs and RTUs. The software comes with pre-configured pages for data archiving, sequence of events recording, alarm annunciation, alarms, trending and communications diagnostics. Customized screens can easily be built for one-line diagrams, IED faceplates, and control screens.

As for HMIs, web-based systems provide a direct-to-touchscreen connection out of the box without a PC as an intermediary. Information can also

Back in 1979 Oceans and Fisheries Canada was funding new Marinas throughout Ontario. Our electrical contracting company was asked to install one of the first electrical systems on this new style of pier. Our company had an extensive marine experience as we had a local dry-dock. A customer for 50 years.

We purchased the specified power pedestal for the job but it wasn’t suitable for Marine applications so we rebuilt the posts and had them approved. Eventually we had more of these projects to do so instead of rebuilding we would manufacture our own. The result was a big success and we have recently decided to separate the manufacturing from the contracting company. So we are very proud to introduce to all “Vickery Electric Manufacturing”.

be accessed by smartphone, which will bring up a substation and graphically show the faceplate of each device with push buttons as if the technicians was physically there.

“The HMI is served up through webpages that are easily constructed with graphic software. It’s all integrated in one package, so building an HMI is so much simpler than it used to be,” adds Fanning.

If there is a physical manifestation of the reduction in complexity, Fanning points to the substation. In many substations he has worked in, there were racks or cabinets of devices with hundreds of wires and blinking lights.

“Today, substation layout is much cleaner. You can probably eliminate entire writing racks and cabinets – or at least make it much smaller – depending on how you are handling your I/Os to the IEDs,” says Fanning.

Jeff Elliott is a Torrance, Calif.-based technical writer. He has researched and written about industrial technologies and issues for the past 15 years.

in providing quick turnaround, fully customizable power posts for numerous applications, including marinas,

Why we must look beyond the traditional grid to distributed energy resources / BY KALIYUR SRIDHARAN

In the last decade, the world has become increasingly connected. Barriers such as language, reach and time no longer present the challenges they once did. The dissolution of these barriers can largely be attributed to the adoption of the Internet and the use of interconnected devices like smartphones, tablets, GPS systems, sensors and virtual assistance, to name a few. As we begin a new decade, there are more opportunities to connect and stay connected than ever before—but these opportunities can offer unprecedented challenges.

The number of Internet of Things (IoT) devices has skyrocketed in the last 10 years, and it’s only going to go up. Globally, we’re projected to reach 50 billion IoT devices by 2030 and these products will be a part of every aspect

of our society. Personal cell phones are just the beginning – everything from traffic controls and transportation to healthcare and manufacturing will rely on these connected devices and electricity to power them. The result of our infrastructure and industries adopting smart technology like IoT is the smart city, a trend we are rapidly moving towards in Canada and around the world.

But successful smart cities cannot be realized without the acknowledgement of the importance of data and power, and the intrinsic link between them.

Our society’s devices put constant pressure and demand on traditional data centres. While data centres used to be able to go offline or reroute traffic for maintenance and upgrades, this is no longer an option. In today’s age, our

devices never stop—they are constantly running and delivering data—so our data centres can’t afford to stop, either. As the world’s population and, subsequently, the number of connected devices continues to rise, we need data centres to be massive, agile, available and flexible.

Unfortunately, this demand can come at a price. Globally, data centers consume roughly three per cent of all generated power and account for approximately two per cent of greenhouse gas emissions—a carbon footprint equivalent to the airline industry. Given recent trends, we could require three to four times more energy to power data centres in the coming decades. We must consider how to build and optimize infrastructure to provide data centres with the reliability and

AimLite has always been a pioneer in emergency lighting. Today, we are expanding our indoor and outdoor general lighting offering by developing a multitude of new products to meet today’s market needs and requirements. Our expertise allows us to design innovative products to set ourselves ahead of our competition while maintaining industry standards.

Designers have always believed that emergency lighting, in general, is unattractive and obtrusive. AimLite’s new Bridge technology is a CSA certified (C22.2 141-15) Emergency component installed in general lighting fixtures and connected to a battery unit so it can power the lights.

Aesthetics are no longer compromised all the while providing better luminosity than traditional emergency remote heads during a power failure.

bandwidth they require to keep our smart devices, smart homes and smart cities running.

The answer comes from rethinking how required power gets to these facilities in the first place; it comes to rethinking our energy grid.

As we consider improved ways of planning, using and maintaining electricity grids, Distributed Energy Resources (DERs)—such as solar panels, wind turbines, microgrids and natural gas-fueled generators—have the potential to address these challenges and help offset the dependency and pressure placed on traditional utilities.

Installing DERs can not only prepare cities for a smart future, but it can also provide consumers with greater control of their electricity usage. From offering a flexible and reliable power supply to reducing environmental impact and offsetting energy costs, DERs are spearheading the shift we’re currently experiencing.

Supporting the grid

As a society, we all depend on electricity to live, work and play. As traditional utilities encounter greater demands, DERs can offset pressure placed on the grid. By generating or storing power, DERs can respond quickly to the grid’s needs to ramp generation up or down, store over-generation and control frequency changes and voltage fluctuations. DERs such as microgrids can easily be connected to the larger grid in times of need, improving grid efficiencies and electric reliability. Unlike traditional models, where electricity flows in one direction, DERs are located closer to where the energy they produce is required. This prevents the loss of energy as it travels from where it’s generated to where it’s needed—leading to Energy Proximity.

The adoption of DERs helps lessen the burden placed on the grid, reducing the amount of greenhouse gas emissions released from power generation. The ability for DERs to provide a resistant, reliable system relies on the diversity of the energy mix—solar, wind and storage, for example, and renewable energy sources have less environmental impact.

A common challenge facing renewable energy is that it’s largely dependent on factors outside of our control, including the amount of sunlight or wind received. To offset this unreliability, energy storage devices release energy as needed, whether during a period of high demand or when wind and solar aren’t available to ensure a reliable energy supply.

Uncontrollable events like severe weather can cause long and widespread outages. In emergencies, we depend on our IoT devices to keep us connected—from receiving critical updates to GPS navigation to communicating with loved ones. Microgrids offer the benefit of being operated in a grid-tied or island mode, meaning they can easily be connected or disconnected from the larger network. DERs can help manage energy flow and provide support to the main grid, so if an outage does occur, it prevents the whole region from being impacted and ensures the delivery of reliable and consistent power.

In a state of emergency, it can be nearly impossible to get fuel deliveries to traditional backup generators. DERs are imperative to keep critical

infrastructure and emergency services running. As the number of natural disasters increases, cities must look towards microgrids to keep critical facilities up and running while also supporting the needs of the larger utility distribution network.

Demands on electricity are not going anywhere, but it’s important we have a forward-looking mindset when looking at utility infrastructure. As demand on the grid continues to grow, we must look at alternative ways to support electricity requirements today, but also for future generations. DERs are changing the way the utility landscape operates—they are environmentally friendly, cost effective, reliable and have the potential to provide new streams of revenue.

A smart city is the sum of its smart entities—and the grid is at the forefront of this imminent transition. It’s hard to predict what the future has in store, but we must look to an integrated smart grid and DERs as the path forward to intelligent, sustainable and smart cities.

Slice launches EDC Folding Knife with finger-friendly blade

The Slice 10495 EDC (Every Day Carry) Folding Knife is a compact, weighted folding knife with a finger-friendly blade that was ground by hand on a diamond wheel. The ceramic blade lasts up to 11 times longer than a comparable metal blade and never rusts.

Made from high-grade, heat-treated steel and coated with heavy-duty black oxide, the compact, portable knife’s frame features spring-assist deployment and a locking liner. The knife features an integrated lanyard hole and allows for a no-tool blade change.

New SolaHD Mini-Tower LineInteractive UPS designed for cabinet installations

Emerson’s SolaHD SSW Series Mini-Tower Line-Interactive UPS provides an economical choice for users requiring the performance of a sinewave output, line interactive UPS in a mini-tower shape for cabinet installations. Utility power is continually protected by this series and internal battery life is optimized. Other features of the SSW Series Mini-Tower include automatic voltage regulation (AVR) topology, sine wave output, user replaceable, “hot swappable” batteries, USB communications port, built-in surge protection, cold start capability and 50/60 HZ auto sensing.

Brady makes printing easier, faster and more efficient for all of your identification needs.

From handheld and portable to high volume and high resolution colour, Brady offers a full line of printers to suit all of your on-demand identification needs. The difference of a Brady printer can be found in the customer experience from start to print. Each feature is designed for a reliable, simple and fast printing experience with minimal input, so that you get a safe, compliant and productive workplace for the long run.

Stanpro’s LED Gimbal High

Output features small aperture without compromise

Stanpro’s LED Gimbal High Output

Downlight features a sleek design with a small aperture that helps prevent glare. With up to 950 lumens and a CRI of 90, this downlight provides high performance lighting that suits both residential and commercial applications, including wet locations.

DeWalt expands Xtreme Subcompact tool series

DeWalt has launched the Xtreme Subcompact Series 12V Max Brushless One-Handed Reciprocating Saw (DCS312). This tool is optimized for one-handed use across a wide range of applications, such as cutting PVC, Your one-stop shop for mobile printing

• On-the-job durability

• Industry tested materials

• Brady Workstation Express Labels Mobile App makes mobile printing convenient and simple

JUNE 9

VAUGHAN, ON

OF AN IOT SOLUTION

Nidal Qwasmi, IBM Canada

CONNECTIVITY FOR “DIGITAL BUILDINGS”: WHAT, WHY AND HOW

William MacGowan, Cisco Canada

BOOT CAMP – BASIC STEPS TO SECURE CONTROL SYSTEMS

metal pipe, wood, conduit and EMT. The compact saw weighs 3.04 pounds (bare tool) and is 12.12 inches in length. It features an efficient brushless motor that delivers up to 2,800 SPM. That is combined with a 5/8-inch stroke length that offers fast and efficient cutting. The saw includes an LED light, a variable-speed trigger and a tool-free blade release for quick and easy blade changes.

Mersen launches HP10M and HP15M

Dual Fuse series

Mersen has announced the availability of the new HP10M and HP15M Dual Fuse series. The products’ precision resistance matched fuse construction ensures balanced load sharing, making them well-suited for continuous temperature and current cycling withstanding.

The 1000VDC-rated HP10M and 1500VDC-rated HP15M were designed for low minimum breaking capacity capabilities of 1.35 times the fuse rated current value. These dual fuses allow for safe circuit interruption under typical low fault current conditions produced by PV arrays. Featuring tin-plated Crimp Cap (CC) wirecrimpable and solderable terminals that accept #8 AWG stranded copper PV wire.

Giant safety

Andy Schonberger, Intelligent Buildings, LLC Optimize

Chaussures Régence, a Canadian company founded in 1979, has just launched the Giant, the widest safety shoe on the Canadian market. This shoe, from the company’s Acton brand, is specifically designed for workers who require safety shoes.

The Giant is the only CSA Z195-certified very-wide fit safety shoe, at WWW (5E), available in Canada. Until now, the only widths available for Canadian workers for a CSA-certified safety shoe were W (3E) and (4E).

The Giant features a steel protective cap, lightweight anti-puncture composite sole resistant to electric shocks, anti-skid rubber sole on dry and wet surfaces, resistant to oils and acids, and a waterproof full grain leather upper with sealed seams and leather lining with antimicrobial treatment.

DAN BERESFORD & JOHN F. WIESEL

Meet “Joe.” Joe is an electrical contractor. He is running a business and has a small crew working for him. His business is growing but he knows he needs to quote more jobs to keep doing well. Joe does most of his estimates after hours because he is on the go from 7:30 a.m. until 7:00 p.m.

Joe was working through a set of specs and drawings one evening when his phone rang. Joe kept working while he talked on the phone about a job his crew were working on the next day. After getting everything worked out, Joe went back to his estimate. Happy with his quote, he submitted his bid. Joe got the job.

The first day on the jobsite, Joe’s crew found there were two LED fixtures missing. That night Joe went through his quote and checked his count. He had missed two fixtures. No big deal, right? Wrong! Joe now has to eat the cost of the two fixtures. It gets worse...

Joe also has to eat the cost of the missing conduit, conduit connectors, straps, elbows, wire, junction boxes, box covers and wire connectors.

And now the real cost... LABOUR!

The cost of the labour to install the conduit, wire, connectors, straps, elbows, wire, junction boxes, covers and wire connectors will come out of Joe’s pocket. And don’t forget Profit and Overhead. Let’s add it up.

Material missed

missed

Lost profit 5% – $1,384.00 x 5%

$200.00

$1,663.20

How many jobs will Joe have to do to cover the loss on this job?

Let’s think about what just happened to Joe. He made a small mistake. He missed two light fixtures in his count. Then Joe made another mistake. He didn’t have someone else check his work.

Whether you do your estimates by hand or using software, we’re only human and we make mistakes. When estimating an electrical job, even small mistakes can add up to big losses. Check your work and have it checked by someone else.

John F. Wiesel is the president of Suderman Estimating Systems Inc., and has been estimating and teaching estimating since the early 1980s. Dan Beresford served as an electrician in the Canadian Navy, then worked in various roles in business and the electrical sector before joining Suderman as training & development coordinator and business development manager. Suderman’s courses are Gold Seal Accredited by the Canadian Construction Association. Visit www.sudermanestimating.com.

Power Related Fluctuations Cost North American Companies More Than $80 Billion A Year

You have expensive equipment you rely on every day to meet your customers’ needs. Down machines cost you time, money, and resources to get back on line. With a minimal investment, you can protect your sensitive control equipment or your entire facility from surge events. Mersen’s Surge-Trap® product line offers a world-class suite of surge protection products designed to protect your facility from harmful and preventable surge damage.

Most surge spikes originate from within a customer’s own facility. In fact, nearly 80% of all surge problems are directly attributed to power disturbances from within the facilities own equipment.

Any facility with motors stopping and starting, light load panels being turned on and off frequently, and other potential power disturbances is at risk for damage caused by a surge spike.

Of course, surges in electrical power can also originate outside of a facility, accounting for roughly 20% of facility transient problems. These surges may be caused by utility grid switching, lightning strikes, switching of capacitor banks, and electrical accidents.

Although many transients are not predictable, damage to a facility is preventable with a proven and tested surge protective device.

What types of damage can a surge cause to a facility?

• Disruptive: A surge enters an electronic component which interprets the valid logic command. The result: system lock-up, machine malfunction leading to faulty output, or corrupted files.

• Dissipative: A repetitive pulsing of short duration energy. The result: Long-term machine or system degradation leading to system replacement at earlier intervals.

• Destructive: A high-level energy surge that immediately results in equipment failure or destruction.

Metal Oxide Varistors (MOVs) are the most common and efficient technology used to protect equipment against damaging voltage spikes. However, while MOVs are efficient, they also degrade over time and possibly fail catastrophically when they reach end of life. In response, UL wrote standards to prevent fire risk while using MOVs. In 2009, UL 1449 3rd Edition was published (UL 1449 4th Edition, effective March 2016, has superseded 3rd Edition, furthering the surge protection standards), and it transformed the way SPD manufacturers designed and manufactured their devices.

This is when Mersen’s TPMOV® became essential. This Mersen-patented invention was the first fail-safe Thermally Protected MOV (TPMOV) able to pass all UL 1449 3rd Edition tests as well as even more stringent tests applied by our customers. A few years later, Mersen TPMOVs are often imitated, but there is still no match to Mersen’s technology. Almost all Mersen SPDs feature our Thermally Protected MOV (TPMOV) technology, a fail-safe surge protection solution without the need for additional upstream protection. As a result, the Surge-Trap® product line offers the lowest cost, safest, and most reliable surge protection products on the market.

MERSEN SURGE-TRAP ® SURGE PROTECTIVE DEVICES

With a minimal investment, you can protect your entire facility from surge events. Mersen’s Surge-Trap product line offers a world-class suite of surge protection products designed to protect your facility from harmful and preventable surge damage.

• Designed with the industry leading Mersen TPMOV® Technology

• For use in ANSI/UL/CSA Type 1 SPD installations

Desdowd has named Luc Lajeunesse to its team as a sales representative, effective immediately. Luc will be responsible for the South Shore of Montreal, Monteregie and Eastern Townships, and will report to Denis Dumouchel.

Stelpro has named Simon FitzGeorge its new national sales director – USA, effective March 9, 2020. Simon will be tasked with leading and implementing solutions that enable Stelpro to achieve its strategic objectives in the U.S. market.

Alexandre Lafrance has also joined Stelpro as national retail sales manager, effective March 23, 2020. Alexandre has over 20 years of experience in sales and business development across a variety of industries.

Both new members of the team will report to Pierre-Yves Martin, vice president of sales and business development.

Southwire has appointed Maria Sial to the position of manager, communications & digital strategy. In this role, Maria will lead Southwire Canada’s communications and digital strategy initiatives and support its business development and marketing initiatives.

Graybar Canada recently announced the retirement of Brian Thomas, its executive vice president and general manager, effective March 1, 2020. Thomas joined Harris & Roome, Graybar Canada’s predecessor, in 1987. Throughout his 39-year career in the electrical industry, Thomas occupied a variety of sales and senior management positions before being promoted to executive vice president and general manager in 2016.

Thomas will be succeeded by Jason Taylor upon his retirement. Taylor joined Graybar Canada in 1996 and has held many positions at the company, including customer service, finance, operations and VP Central Canada before being named VP Atlantic Canada in 2017.

Magic Lite has announced the appointment of Greg Sideris as outside sales representative for southern Ontario. In his new role, Greg will be reaching out to distributors, contractors and specifiers.

Brenda Mintzberg has joined Viscor in the role of business development, health care western region, effective January 27th, 2020. In this role, Brenda will focus on managing and developing networks in the Western Region for Certolux lighting solutions.

Brenda has over 22 years of experience in the Canadian electrical and lighting industry, and was previously the vice president of end user sales at Signify.

Kevin Wyatt has been named Gerrie Electric’s new director of industrial sales for the central region.

Lumen Exhibition

April 21, 23, Quebec City, Montreal Visit lumen.ca

Energizing Efficiency Conference 2020

May 12-13, Saint John Visit efficiencyconference.com

InfraCanada and InfraQuebec FLIR

May 26-October 30, various cities Visit prod.flir.ca

2020 IEEE PES General Meeting

August 2-6, Montreal Visit pes-gm.org/2020/

LEDucation 2020

Designers Lighting Forum of New York

August 18-19, New York Visit leducation.org

Smart Energy Event 2020

Designers Lighting Forum of New York

August 18-19, Halifax Visit smartenergyevent.ca

EFC 2020 e-VOLVE Industry Conference

Electro-Federation Canada

September 1-3, Banff Visit electrofed.com

Electrifest XII: The 2020 Nedco Games

Nedco

September 21, Mississauga Visit electrifest.com

In his new role, Kevin is responsible for providing the strategic sales direction to the branches, account managers and automation group within the region. Amy Carter has also been promoted into the role of technical solutions manager for the central region. In this role, Amy will be responsible for managing the company’s product managers and process group within the central region.

Visit EBMAG.COM for the latest news, stories, products, videos, photo galleries and industry events.

Indicates EB will be there.

Visit EBMAG.COM for an extensive list of upcoming industry events.

Editor’s note

Please note that these event dates were accurate at the time of printing, but schedules are changing all the time due to the threat of COVID-19. We encourage you to visit an event’s website or reach out to organizers to get the most updated information.

The Pluraluce® surface mounted battery unit has a minimalist design to coordinate with any décor.

The optical design allows the Pluraluce® to have a high lumen output with lower wattage consumption. Under any operation, the Pluraluce® delivers between 826 lm - 845 lm. Each pair of LEDs are laid out in parallel on the LED module so if one pair fails, the other will remain illuminated.

Each unit is shipped with 3 custom designed optical lenses which are interchangeable for wall mount, ceiling mount symmetric and ceiling mount asymmetric

distributions. By optimizing the light output, the Pluraluce® can provide up to 55´ spacing on centre.

The Pluraluce® housing acts as a large heat sink ensuring efficient thermal management and provides the LEDs with 100,000 hour lamp life.

The Pluraluce® series is configured with two-wire 120-347VAC 60 Hz input. Solid state microprocessor controlled circuitry also includes line latch, brownout protection, battery and charge circuit monitoring, LED failure detection and reverse polarity protection.

The Pluraluce® is available in indoor, NEMA 4X, hazardous, recessed mounting and remote versions.

SID RIDGLEY

According to Statistics Canada, the poverty rate has declined to a new low of 8.7 per cent in 2018, or 3.2 million people, which is down from 4.2 million reported in 2015. However, poverty numbers are not the same as low-income numbers.

UtilityPULSE’s 21st Annual National Customer Satisfaction Survey for Residential and Small Commercial customers shows six per cent of respondents say they often have a problem paying their electricity bill, while 28 per cent say they sometimes worry about being able to pay their bill. These numbers mean over 2.2 million households and small businesses have difficulty paying their bill, and millions more sometimes worry about paying their bill – those are not small numbers. The issue is the ability to pay as one survey respondent told us: “Power is a need, not a luxury. One to two dollars may not seem like much, but to someone on a fixed income, it can mean the difference between staying warm in the winter or freezing to death.”

In every province and territory across Canada, concern about the costs of electricity remains high. Nonetheless, when we listen to residential and small business customers across Canada talk about their satisfaction with their electric utility, we can make the statement that the relationship between the customer and their electric utility is very strong. The UtilityPULSE survey shows that 85 per cent of electric utility customers interviewed would say their utility is credible and trusted.

rising rates we’ve received:

• “I am a senior – the thought of escalating rates makes us fearful!”

• “As a single person living alone, it is important to keep costs low. Some months my delivery charge is more than my usage fees.”

• “As a single mother, I’ve, on occasion, had to decide between paying my bills and getting groceries. Instead of completely sucking us dry, why don’t you lower the costs of hydro and help people out in these tough times?”

Six per cent of respondents say they often have a problem paying their electricity bill, while 28 per cent say they sometimes worry about being able to pay their bill.

Sorry to the provincial government entities, regulators, commissions, electricity system operators throughout Canada, you don’t get the same level of trustworthiness as the electric utility. Why? You are not the people on the front lines. After all, when the lights go out, when service is needed, or assistance is required to understand the bill or the industry, customers turn to their utility.

Customers rely on their electric utility to be an efficient, effective and trustworthy operating entity. The truth is, every entity, each provincial government, regulator, commission, and electricity system operator, has a substantive role to play in ensuring the electricity system is delivering the benefits of an electrified world to all Canadians.

How does this impact low-income electricity customers?

increased 8.9 per cent in November 2019 over the same 12-month period the previous year. They go on to report, “the number of people struggling with debt in November is just the tip of the iceberg.”

Every utility will say they offer programs of support for low-income people. The problem is some of those programs are run by provincial bodies, or regulators, or other entities. Some programs have nothing to do with helping customers pay their bills, e.g., spend money on items to reduce consumption and receive a rebate/ incentive. Variances in eligibility requirements and the need to contact multiple organizations to get some assistance adds to the confusion as to what role each entity has in safely and reliably delivering electricity to homes or businesses.

Maybe if we simplified the industry so that the electric utility, who is the most credible and trusted entity to customers, administered all the payment support and energy reduction incentive programs, more customers would know that relief or help is available.

What a novel idea – let the provincial government bodies, regulators, commissions and electricity system operators do the heavy lifting of defining policies (and stay out of operations). Those policies need to be less about auditing and more about supporting the electric utility’s ability to help customers pay their bills, become more energy-efficient while being focused on the safe, reliable, cost-effective delivery of electricity to homes and businesses.

Typical comments about costs and

The economy is moving along at a reasonable pace, and unemployment rates are low. Yet, according to the Canadian Association of Insolvency and Restructuring Professionals, the number of personal insolvencies will grow in 2020 after the rate of filings

Sid Ridgley is a business leader and researcher with expertise in helping electricity industry leaders capture information, insights, feedback, and wisdom from their customers and other stakeholders. He can be reached at 905-8957900 or sidridgley@utilitypulse.com. You can also find Sid on LinkedIn and follow him on Twitter @sidridgley.

The WSIB’s Health and Safety Excellence Program aims to improve the province’s businesses /

BY ROD COOK

When it comes to accidents in the workplace, hindsight is always 20/20.

Now, with the Workplace Safety and Insurance Board’s (WSIB) new Health and Safety Excellence program, there is a clear path to help businesses make workplaces healthier and safer. The program provides a roadmap for businesses in Ontario to develop health and safety systems based on best practice, and it makes health and safety accessible to businesses of all sizes.

Some businesses may be looking to build a new system, while others want to improve what’s already in place – the Health and Safety Excellence program can be tailored to individual business needs to help boost health and safety outcomes and culture. Success in the program can also earn premium rebates as well as non-financial recognition.

The program is built on 36 topics spread across three levels – foundation, intermediate and advanced – to help develop and integrate health and safety management systems into workplaces

and take a business from awareness to excellence.

The WSIB has made it easy to get started.

First, a business can register with a WSIB-approved health and safety provider listed on the program’s website at wsib.ca/healthandsafety. Providers offer different supports to meet business needs, including support through in-person coaching, online, or over the phone.

The second step is to complete an online health and safety assessment. The assessment helps to evaluate what’s already in place and what may be missing and suggests program topics that address each business’ unique needs. These topics can be completed at a pace and time that works best for each business - there is no time limitation.

At the third and final step, a business will submit simple documentation to the WSIB to show that a topic was completed. Once validated, the business will be eligible for financial and other incentives for every topic completed.

Success in the program means saving money, paying lower premiums and receiving rebates on WSIB premiums. For example, depending on its size, a business could receive a 1.4 to 2 per cent rebate per topic. Most importantly, investments in health and safety prevent future workplace accidents and the costs associated with such events.

The Health and Safety Excellence program can also help businesses achieve a best practice standard, such as COR2020 or ISO 45001, and can also help businesses meet the Ministry of Labour, Training and Skills Development’s Supporting Ontario’s Safe Employers accreditation standard. Once a business has completed the Health and Safety Excellence program, and implemented and maintained a strong health and safety management system within their business, they should be ready for the third-party audit required to verify they meet one of the approved accreditation standards under the Ministry of Labour, Training, and Skills Development’s Supporting Ontario’s Safe Employers program, including ISO, COR, CSA, or OHSAS.

In 2020, we look forward to working with businesses to create healthier and safer workplaces, and a healthier and safer Ontario. Let’s turn hindsight into foresight, together.

For more information, please visit our website at wsib.ca/healthandsafety.

Rod Cook is WSIB’s Vice President of Workplace Health and Safety Services.

continued from page 24

Employers should also consider and review temporary layoff provisions under provincial or federal employment standards legislation, which allow employers to temporarily lay off employees for up to 60 days within a 120-day period. In Alberta, for example, temporary layoff notices must be given to employees in writing and specifically detail sections 62 to 64 of the Alberta Employment Standards Code. Furthermore, one to two weeks’ advance notice must be given to the employee (depending on length of service). Employees who have been temporarily laid off for more than 60 days within a 120-day period are deemed to be terminated.

All employers should be taking proactive steps to ensure the protection of its workplace and the safety of its employees. We suggest employers take the following actions as they flesh out their COVID-19 response plans: Employers should prepare a comprehensive pandemic plan.

The employer should designate an individual or form a team to monitor COVID-19 in the workplace and to coordinate prevention efforts.

The employer should provide information about COVID-19 to employees and outline symptoms and criteria to watch for.

The employer should clearly communicate what steps an employee is required to take if s/he begins to experience symptoms.

ABB Electrification Canada SRI 1, 5

Affiliated Distributors 48

AimLite 33

Beghelli Canada 41

BIoT Forum 36, 37

Brady Canada 35

Bridgeport Fittings 10, 11

FLIR Systems Canada 29

Ford Motor Company 46, 47

Hubbell Canada 7

IPEX Electrical Inc 2, 3

TO ADVERTISE CONTACT

Employees should be advised of the circumstances in which the employer will require an employee to self-isolate or be quarantined, and what effect that self-isolation or quarantine period will have on their compensation.

Employers should consider their policy and response to a circumstance in which a symptomatic employee, or an employee who has contracted COVID-19 but has not reported symptoms, has attended to work and where the site or facility at large may have been exposed to COVID-19.

Employees should be encouraged to wash their hands frequently. Signs should be posted in appropriate areas in this regard. Employers can also consider offering hand sanitation supplies.

Employees should be required to advise their local HR/Office Manager of his or her vacation plans, providing the names of all cities s/he will be visiting or connecting through, particularly if traveling to “hot zones.”

Depending on the progress of the virus within Canada, employers ought to consider revising their travel and travel-reporting policies with respect to “hot zone” areas. Employers should also confirm with their benefits and disability providers whether employees who have travelled to one of these zones will have coverage if they contract COVID-19.

Contingency plans should be developed to limit possible work interruptions for those who perform essential duties in the workplace

For more information, please visit https://mross.com/law/COVID-19 or email covid19@mross.com.

BY RAY YOUSEF, CODE ENGINEER

Ontario’s Electrical Safety Authority esasafe.com

TACKLE THE CODE CONUNDRUM IF YOU DARE! Answers to this month’s questions will appear in the May issue of Electrical Business

QUESTION 1

When only four conductors of an eightconductor cable, not marked LP, are used for power, the ampacities obtained from Table 60 must be multiplied by: a) 0.5 d) 2 b) 1 e) None of the above c) 1.4

QUESTION 2

The ampacity of an approved cable bus assembly is determined from: b) A section 4 ampacity calculation b) The ampacity on the product label c) A certified test report from the cable bus manufacturer d) a) and c) e) a) and b)

QUESTION 3

A bonding connection is required for any device having a bonding terminal and mounted on a non-metallic outlet box.

A) True B) False

ANSWERS Electrical Business, February 2020

Question 1

A totally enclosed no-ventilated Class B motor requires conductors rated at 38 A. The minimum size copper multiconductor cable can be used is:

b) No. 8 AWG TECK90

Ref. 28-104, Table 37 & Table 2

Corp. 8 Mersen USA 38, 39 Mohawk College of Applied Arts & Technology 30 Northern Cables Inc. 1, 9 STANPRO 20, 21 United Wire & Cable 12, 13

Vickery Electric Ltd. 31

WAGO Canada Inc. 25

Anthony Capkun • acapkun@ebmag.com Jennifer Dilorio • jdiiorio@ebmag.com Ledvance Ltd. 19 L’Industrie Électrique 27

Question 2

A disconnect for luminaires with double ended lamps operating at 120 volts is required for:

E) None of the above. Ref. 30-308

Question 3

For a single dwelling unit with 100 A breaker using No. 3 AWG Copper service conductors, is the marking required based on Rule 4-004 22) and Table 39?

b) No. Ref. Rule 4-004 22) and Table 39

DAVID PILON

With the arrival of warmer weather comes water sports: swimming, boating, waterskiing, sailing and even fishing! People are starting to get their boats ready, and soon they’ll head out to the cabin to get it all ready to go. Boats will be launched, docks and boat houses will be built, and pumps will be installed in the lakes to water the yards.

So how does this affect us when it comes to electrical safety? For some, the term Electrical Shock Drowning will be new. The reason is that it looks like drowning and is often only detected long after the fact with system testing or through multiple incidents or multiple victims. In the U.S., they have created an advocacy group known as the ESDPA or the Electric Shock Drowning Prevention Association. They are very concerned with the use of electricity on or around water and are continuing to promote the changes coming with the 2020 National Electrical Code as well as barring swimming in harbours supplying shore power to boats.

In Canada, we may be wondering what the issue is. As far as many of us know, we don’t have these concerns; but in fact, we do, and the changes that took place in the 2018 CE Code are meant to address these concerns as well as create a safer environment for our families to enjoy water sports.

The first and most notable is the requirement that feeders to panels or distribution equipment which may supply power to locations near or on the water, or to equipment which may extend into the water, must be GFI protected at 30ma. This would include boat houses, docks, wharves and fixed or floating piers providing shore power to boats.

While it takes only 10ma to disable a person and prevent their ability to swim, call out or self-rescue, at 30ma, they would need to be relatively close to the point where the fault is implied onto the water and hopefully the 30ma will be exceeded and cause the protection to trip and effectively

prevent injury or death. Therefore, in the U.S., they have made it mandatory to post warnings about electric shock around docks with power distribution for shore power.

When it comes to cabins at the lake, we must not only be aware of our dock, but what about our neighbours’? If you have ever seen a cord run on the dock out to the boat to charge the battery, operate the boat lift or run a thruster, then you may well have seen a potential for Electric Shock Drowning. Often the cords at the cabin are the ones that don’t work as well at home anymore, or they are worn from age and exposure. They are often looped around the metal piers of the dock and around the metal boat lift; all of which, if energized, present a hazard to Electric Shock Drowning.

The CE Code 78-050 now requires that any 15A or 20A receptacles located on the exterior of a boat house, fixed or floating piers, docking facilities or wharves be protected by a Class A GFI. Note that the code is stating that the receptacles must be protected, not that they must provide GFI protection. That means that the feed to the receptacle must be protected as well. So, in most cases, this means the protection

will either be a faceless device near the panel or breakers mounted directly in the panel.

There are also several changes to the wiring methods in 78-056 for corrosion protection, including an increase in the bonding conductor minimum size if installed around salt water (Ref. 78-058).

Remember, if you see a cord running down a dock, you may want to speak to people about the use and condition of the cords and the necessity for ground fault protection, and potentially save a life or two. Enjoy the summer and be safe, not only on the water, but in and around your docks.

For more information, visit the Electric Shock Drowning Prevention Association’s website at https://www. electricshockdrowning.org.

Always consult your AHJ for more specific interpretations.

David Pilon is an electrical inspector with SaskPower, the utility’s training co-ordinator for electrical inspectors and vice-chair of the Canadian Certified Electrical Inspector (CCEI) committee of the International Association of Electrical Inspectors (IAEI), Canadian section. He can be reached at dpilon@saskpower.com.

Looking for big power for your business? Look to the 2020 Ford Super Duty – now with more power, more capability and more technology than ever. Our dedication to Built Ford Tough® has produced this: the strongest Super Duty ever. It was worth it, earning us Best-In-Class claims across multiple categories, including Best-InClass Available Diesel HorsePower & Torque at 475hp & 1,050 ft.-lbs¥, Max Available Payload of 7,850lbs◊ and Max Available Diesel Towing of 37,000lbs^. But that’s only the start of its mighty capability.

You can confidently power through your workday with an all-new available 7.3L gas V8 engine and a heavy-duty TorqShift 10speed transmission with selectable drive modes (Normal, Tow/ Haul, Eco, Slippery, Deep Sand/Snow), joining a next generation 6.7L Power Stroke V8 Turbo Diesel in the powertrain lineup. Top-rated gas and diesel power ratings combined with rugged frame and chassis engineering, enable Super Duty to achieve best-in-class numbers in hauling (Max Available Payload 7,850lbs◊) and towing (Max Available Diesel Towing 37,000lbs^).

Ford engineers are constantly pushing the envelope and the 2020 F-Series Super Duty offers its highest conventional (Max Available Diesel

24,200lbs^^), gooseneck (Max Available Diesel 37,000lbs^), fifth-wheel towing (Max 32,500lbs.) and payload (Max Available 7,850lbs. ◊) ratings ever(2).

Brains and brawn, all in one heavy duty package. If we’re talking tough, we’d have to mention the category-defining innovation of the fully-boxed frame, built from 95% high-strength steel. This frame minimizes flexing and twisting, while maximizing strength and torsional rigidity, serving as the foundation for achieving the highest payload and tow ratings in its class^,◊

Speaking of payload, our combination of high-strength steel and military-grade‡ aluminum alloy reduces overall vehicle weight enabling us to reinvest this weight savings where it counts. The 7,850-lb.◊ Max Available Payload rating and solidaxle front suspension on all 4x4 models provides the weight-bearing capability ideal for aftermarket snowplow upfits. There’s no buckling under pressure for this pickup.

Smarter than ever, this Super Duty comes packed with new features to help maximize your productivity. Stay connected with FordPass Connect†† 4G LTE Wi-Fi hotspot , available wireless charging pad and smart-charging

ports.

Stay safe on and off the road with DriverAssist technologies such as the Available Pre-Collision Assist with Automatic Emergency Braking (AEB)**. This feature scans the road ahead and alerts you to potential collisions, taking corrective action if you don’t. Audible Lane Departure Warning† is now available on vehicles with a pickup box delete option and available Hill Descent Control™† uses traction control technology with anti-lock brakes to maintain a constant speed going down a steep grade.

Effortlessly maneuver any load with the available Ultimate Trailer Tow Camera System**, which includes Pro Trailer Backup Assist‡‡ and Trailer Reverse Guidance‡‡ functions with all trailers, including gooseneck and fifth-wheel applications. Enhanced visibility gives you a clear rear view of where your trailer is going, making precision an easy feat.

remote features (see FordPass Terms for details). Connected service is now complimentary for remote features excluding Wi-Fi hotspot. Connected service and features depend on compatible Bell network availability. Evolving technology/cellular networks/vehicle capability may limit functionality and prevent operation of connected features. Certain restrictions, 3rd-party terms or message/data rates may apply.

At purchase, the FordPass Connect modem in some models is connected and sending vehicle data (e.g., diagnostics) to Ford. Vehicle data is stored by Ford Motor Company in the United States and may be accessible by US governmental authorities. To disable, or for more information, see in-vehicle connectivity settings. Learn more at www.FordConnected.com.

Wi-Fi hotspot includes wireless data trial that begins upon Bell activation and expires at the end of 3 months or when 3GB of data is used, whichever comes first, but cannot extend beyond the trial subscription period for remote features. To activate, go to www.bell.ca/ connectedcar.

Some mobile devices require a special adaptable sleeve for compatibility. See your owner’s manual for a complete list of compatible devices.

‡‡ Some driver input required. Driver-assist features are supplemental and do not replace the driver’s attention, judgment and need to control the vehicle.

** Driver-assist features are supplemental and do not replace the driver’s attention, judgment and need to control the vehicle. While Pre-Collision Assist with Automatic Emergency Braking may be especially helpful in unexpected situations, and can assist to detect walking pedestrians, it does not replace the driver and has limitations, including nighttime, low and harsh lighting conditions, vehicles moving in a different direction and certain weather conditions. Pedestrian Detection is active at speeds between approximately 5km/h and 80km/h. Automatic Emergency Braking is active at speeds between approximately 5km/h and 120km/h. †Driver-assist features are supplemental and do not replace the driver’s attention, judgment and need to control the vehicle.

Whatever your business needs from a vehicle, Ford F-Series trucks have what it takes. The 2020 Super Duty has available class-exclusive Pro Trailer Backup Assist TM^ and a Military-Grade † Aluminum Alloy body. It can help take your business to the next level.

• BEST-IN-CLASS Max. Available Payload of 7,850 lbs*

• BEST-IN-CLASS Max. Available Diesel Towing of 37,000 lbs**.

• BEST-IN-CLASS Available Diesel Torque of 1,050 lbs.-ft.^^

With more ways to earn loyalty points and redeem great prizes, the new and improved AD Rewards program allows you to capitalize on the power of your purchases from AD distributors like never before.

With over 6,000 valuable merchandise and travel rewards, your relationship with your AD distributor has never been more powerful…or lucrative.

Join today at any of these participating AD distributors.