LEDs not only save energy, but also broaden effects. / BY PETER SAUNDERS

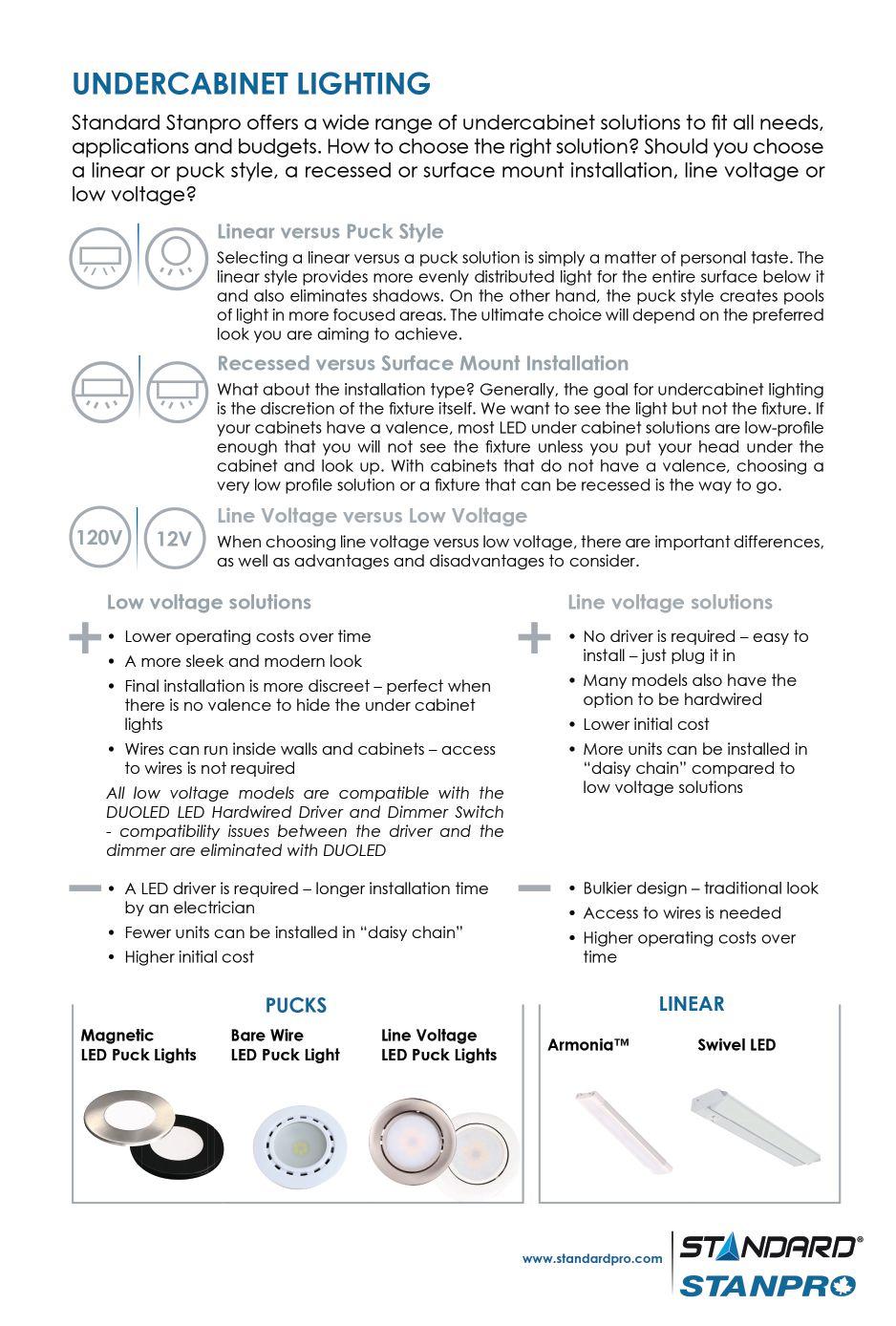

Outdoor lighting can visually transform an existing physical site. By way of example, downtown Winnipeg’s 100-yearold Metropolitan Theatre was recently upgraded with high-output accent lighting. Located across from Bell MTS Place, the historic landmark—now a conference, banquet and meeting facility named the Metropolitan Entertainment Centre, but colloquially known simply as ‘The Met’—served as ‘party central’ during the Winnipeg Jets’ National Hockey League (NHL) playoff run in 2018.

“The new system enables the Met to switch colours for holidays and other special events.”

- Gary Sywake, Christie Lites

The Met was designed by architect C. Howard Crane, built in 1919 and opened in 1920 as a movie theatre. After closing in 1987, it was restored by Canad Inns and reopened in 2012—but while its interior was once again opulent, plans for exterior lighting stalled.

Only with the heightened excitement of the Jets’ playoff games was sufficient interest generated in hosting fan events at The Met and, in turn, in updating its outdoor illumination. According to Economic Development Winnipeg, 120,500

fans attended nine street parties over six weeks. Christie Lites Sales spotted an opportunity to better show off the façade as it became a backdrop for national TV coverage with commentator Don Cherry.

“Our existing exterior lighting fixtures were out of date,” says Vance Masters, Jr., Canad Inns’ director of entertainment technologies. “They were not projecting enough to wash our building and there was not enough focus to show the true heritage of The Met’s architecture.”

Masters worked with Gary Sywake, Winnipeg sales and integration representative for Christie Lites, which by that point had supplied temporary street lighting for the street parties.

“Our task was to bring back a vibrant look representative of the movie-palace era by highlighting the front and top portion of the architecture,” Sywake explains, “to help position the Met as a showpiece for events and hockey games.”

The design and specification phase started in April 2018. To illuminate the architecture as desired, the fixtures had to

provide precise beam angles, at least 400 lumens per foot and changeable colours—and this being Winnipeg, of course, they had to be able to perform at very low temperatures.

After investigating several options, Sywake specified two types of accent illumination fixtures from Acclaim Lighting: a high-power LED floodlight for the brick façade portions and a low-profile linear LED fixture to highlight the windows.

The 35-W floodlight reportedly provides more than 1,400 lumens, can be wirelessly controlled and operates at temperatures as low as -40 C. The linear fixture reportedly consumes 9 W per foot and delivers nearly 420 lumens per foot.

Once these specifications were complete, Mark Ectovich, president of Rite Lites in Saint-Laurent, Que., came on board to review the design and scope of the project. His company was able to offer local representation for technical support and service.

“The system enables the Met to quickly switch colours to reflect holidays and other special events, without jeopardizing the

historic beauty of the building,” says Sywake.

“We have received a lot of fanfare and positive comments,” adds Masters. “Now we are ready for another playoff run from the Jets!”

From gaudy to gorgeous

The capabilities of the Acclaim Lighting products specified for the Met are becoming more and more common with the increasing trend of urban façade illumination, which often ties in with seasonal themes and events.

“Dynamic outdoor lighting used to be considered flashy, showy or gaudy,” says David Brooks, general manger (GM) of Traxon Technologies, an Osram business specializing in ‘intelligent’ solid-state lighting (SSL) systems for architectural, entertainment, hospitality and retail environments. “Today, we’re beginning to see colour changing and colour tuning become more widely accepted. As more projects are done tastefully, without switching colours too quickly or aggressively, the public sees how beautiful the technology can be.”

Indeed, lighting technologies once considered solely commer-

“We’re beginning to see colour changing and colour tuning become more widely accepted by the public.”

- David Brooks, Traxon Technologies

cial are now being specified for city beautification projects and public art.

Also fuelling the trend is affordability. Now that almost every lighting application can be handled with LEDs, dynamic effects are feasible even with moderate budgets.

“There is no need to relamp or service the ballasts as frequently as in the old days,” says Brooks. “Luminaire maintenance is hardly required when LEDs can last thousands of hours.”

For the electrical contractors who install and service such projects, the long-term value can come instead from selling ‘lighting as a service.’

“You can manage your customer’s lighting for them over time just as you would with a maintenance contract,” Brooks says. “In many cases, the client wants dynamic illumination programming without having to touch it themselves. So, there is an opportunity for you to update the programming over time. The technology can let you store and ‘dial up’ the exact colour or colour temperature you want, whenever you want it.”

LEDs for landscapes

Beyond historic properties, public art projects and downtown cores, one of the areas with the most untapped potential for new outdoor lighting is the residential landscape market. Not only has the affordability of the technology brought it within reach for many homeowners, but the cold-weather performance of LEDs also makes them particularly well-suited for Canadian yards.

“LEDs love the cold,” says Todd Goers, national sales manager for WAC Lighting, who visited Winnipeg in February to speak at Grow 19, the Manitoba Nursery Landscape Association’s (MBNLA’s) industry conference. “Everything that used to be done with halogen lighting can now find an equivalent solution in LEDs. You can even retrofit halogen fixtures with LEDs and save 75% in energy.”

WAC Lighting, however, specializes in integrated—rather than ‘drop-in’—landscape lighting products.

“One fixture can now offer different brightness levels, beam angles and even colour temperatures.”

–Todd Goers, WAC Lighting

“That way, we manufacture the fixtures, have full control over the system and can provide a longterm warranty,” Goers explains. “An integrated product offers better thermal management to survive a huge range of temperatures. Where a drop-in might have to be replaced after a few years, an integrated solution will require a lot less maintenance.”

Another important value-add is adjustability, which now means one type of fixture can replace a multitude of older ones, making it easier for contractors to source inventory to meet their customers’ specific needs.

“A lot of people aren’t really aware of such features,” says Goers. “One fixture can now offer different brightness levels, beam angles and even colour temperatures.”

Of course, there are still local factors to keep in mind. Homes near the ocean, for example need brass fixtures, not aluminum, to thrive in the salt air.

“Local electrical contractors really have an opportunity to

As LEDs do not emit UV light, they do not attract mosquitoes and other insects.

pitch systems to new customers,” Goers says. “Too many homeowners don’t do enough due diligence. You need to set yourself apart from your competition through proficiency and craftsmanship.”

Indeed, there are many benefits of landscape lighting, from home beautification to nighttime safety. One of the lesser-known advantages of LEDs is they do not emit any ultraviolet (UV) light, so they do not attract mosquitoes or other insects.

“So, in addition to less maintenance, there are no dead bugs on the glass to clean up!” says Goers. Finally, there is the potential of connected lighting. While still more novelty than practicality for the residential market at this point, one could easily foresee homeowners adjusting their backyard lighting with a tap of a smartphone screen.

With files from Acclaim Lighting, Traxon Technologies and WAC Lighting. For more information, visit www.acclaimlighting. com, www.traxontechnologies.com and www.waclighting.com.

Decora Smart™ Wi-Fi™ turns any home into a Smart Home. Leviton offers an exciting selection of automated dimmers, switches and plugin products for automated control of lights, motor loads, appliances and more. Schedule lights and connected loads to turn on/off at specific times or based on sunrise/sunset, easily group smart devices into rooms, and create scenes to activate multiple lights at once. Enjoy remote access from anywhere, No Hub Required!

All products universally support LED, CFL, incandescent and halogen bulbs, as well as coordinate with our popular line of Decora™ devices. Easily matches any style with six different color options.

The products are backed with an impressive warranty and feature the latest technology with scheduling, full range dimming and adjustable fade rates.

Devices are compatible with Apple and Android mobile devices using either Amazon Alexa or Google Assistant voice controls. Devices work with Nest and can be integrated with IFTTT to expand control.

Control up to 99 smart devices per residence and up to 20 residences per account.

To help its electricians in work trucks service everything “from plugs in walls to shopping malls” in an efficient and adaptable manner, Olson Electric—a residential, industrial and commercial contractor based in Sechelt, B.C., that has been in business since 1990—relies on fleet management technology and telematics software to save time and fuel.

Electrical Business recently interviewed project manager Tom Lund about the company’s experiences to date.

Q: How did you find out about this technology and what was involved?

A: We did some research on the Internet about the best fleet technologies on the market, spoke with a few different companies and then ultimately chose Verizon Connect.

Q: When did you begin?

A: We began using it in May 2017.

Q: Why were you interested in implementing it?

A: We do residential, industrial and commercial electric projects and we realize there are a lot of moving parts when it comes to ensuring our electricians work to the highest standards at competitive rates. Our number one reason for implementing fleet management technology was so everyone in the company could know where everyone else was, in case help was needed on a job.

For example, if one of our electricians is missing a $5 part, they can now easily look and see if another of our electricians working down the street has it on hand, rather than having to drive all the way back to the distributor to buy it.

Similarly, if someone is doing a job and ends up needing an additional set of hands, they can use Verizon Connect to quickly find who else is nearby and can get them to come over to help.

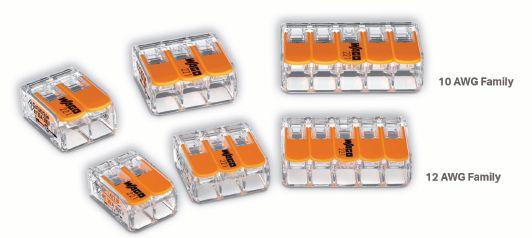

Pull the lever up, insert the stripped conductor, and push the lever back down –done. WAGO’s 221 Series compact splicing connectors let you connect any combination of solid, stranded and flexible copper wires quickly and reliably. Visually inspect for proper strip length and complete wire insertion through its transparent housing.

• 10 AWG family: 20 – 10 AWG

• 12 AWG family: 24 – 12 AWG

For even greater application flexibility, transform the 221 Series connectors into a fixed terminal block solution for DIN or chassis mount applications with the optional mounting carrier.

Q: Were there any challenges in changing the way you managed your fleet?

A: The biggest challenge was getting our team’s buy-in and reassuring them this would not be about ‘Big Brother’ watching over their shoulders. To get everyone on-board, we had to communicate clearly about why we were doing it and to show them how we would be using the technology and how it would be beneficial to their work.

Q: What were the benefits to your business?

A: It has made a huge difference when our team members are seeking help or materials. In addition to the previous examples, being able to see if someone is already heading to a distributor and being able to ask them, “Hey, can you get me this item, as well?” saves both time and the extra fuel of going there separately. So, we continue to use it and are happy with it.

Q: What are your future plans with regard to managing your fleet of work trucks?

A: Our future plans are to add more vehicles to our fleet. One of the reasons we chose Verizon Connect is it was developed with enterprise-grade application programming interfaced (APIs) that allow us to easily scale up our telematics software as we grow our fleet.

TACKLE THE CODE CONUNDRUM IF YOU DARE!

Answers to this month’s questions will appear in the May 2019 issue of Electrical Business

Compiled by Ray Yousef, code engineer Ontario’s Electrical Safety Authority • esasafe.com

QUESTION 1

TC-ER cables may transition exposed between cable trays:

a) For any length needed.

b) Up to 1.5 m when not supported.

c) Up to 7.5 m when supported.

d) B & C.

e) None of the above; ‘ER’ indicates Emergency Runs only.

QUESTION 2

When metal enclosed high-voltage equipment is installed in an electrical room, which of the following—within the room—is to be grounded to the station ground electrode?

a) Metal doors and door frames.

b) Metal pipe works.

c) Metal ventilation ductwork.

d) Metal window grills.

e) None of the above.

QUESTION 3

True or false: An identified conductor is required at a switch controlling a receptacle used for lighting in a living or sleeping room.

a) True b) False

ANSWERS Electrical Business, February 2019

Question 1

Receptacles in CSA configurations 5-15R or 5-20R, installed in buildings under construction, .

d) All of the above (i.e. shall be protected by GFCI Class A; can be wired by NMSC according to Rules 12-500 to 12-526; and shall be kept entirely separate from lighting branch circuits). Rules 76-012 and 76-016, CE Code 2018.

Question 2

True or false: the CE Code allows the use of non-metallic sheathed cable in a building of combustible construction.

a) True. Rule 12-504, CE Code 2018.

Question 3

For a mobile home, the minimum permitted size conductor for the power supply cord is:

c) #6 AWG. Rule 70-108(4)(a), CE Code 2018.

How did YOU do?

3 • Seasoned journeyman 2 •Need refresher training

1 • Apprentice

0 • Just here for fun!

April 24 & 25, 2019

Canada’s largest plumbing, HVACR, hydronics, electrical and lighting expo

• Attend free seminars, many of which will offer continuing education credits

• see more than 400 exhibitors and thousands of products

• Visit the new Product showcase to see innovative energy and water efficient products

Free r egistr Ation up to April 23, 2019

IEEE has published a new standard. / BY PETER SAUNDERS

On Nov. 30, 2018, the Institute of Electrical and Electronics Engineers (IEEE) and its standards association (IEEE-SA) published a new technical guide for performing arc-flash hazard calculations to help reduce burn injuries suffered by qualified workers due to equipment failure or less-thanadequate work practices.

IEEE 1584-2018, Guide for Performing Arc-Flash Hazard Calculations , provides mathematical models for engineers to apply in determining (a) the arc-flash hazard incident energy at an assumed working distance and (b) the arc flash boundary distance for electrical equipment. The new standard is based on the collaborative efforts of IEEE and the National Fire Protection Association (NFPA), which formed a research and testing planning committee (RTPC) in 2005 in Baltimore, Md., to investigate arc flash

phenomena. Hence, this undertaking became known as the Arc Flash Phenomena Research Project.

“Our work has resulted in a standard that dramatically improves the prediction of hazards associated with arc faults and accompanying arc blasts,” says Konstantinos Karachalios, managing director of IEEE-SA. “Contractors and facility owners will be able to more thoroughly analyze power systems to calculate the incident energy to which their employees could be exposed during operations and maintenance work, allowing them to provide appropriate protection in accordance with the requirements of applicable electrical workplace safety standards.”

IEEE 1584-2018 also outlines processes covering the collection of field data, the consideration of power system operating scenarios and calculation parameters. Applications include

electrical equipment and conductors for three-phase AC voltages from 208 V to 15 kV.

Only one Canadian was involved in the RPTC working group in Baltimore: Electrical Business columnist Mike Doherty, president and owner of Blue Arc Electrical Safety Technologies, who is an IEEE senior member. Doherty was the working group’s chair responsible for writing an initial report and estimating the timeline to completion. And as he explains, due to challenges with the requiring funding and getting world-class technical experts to lead the project, the guide’s release was a long time coming in response to industry demand.

“When I was a young electrician, we didn’t wear any arc-rated garments,” he recalls. “I did wear specially supplied coveralls, undergarments and socks when working at the Bruce Nuclear Generating Station in Tiverton, Ont., but those were designed to deal with the radiation hazards. If they had caught on fire from an arc flash, they could have burned into my skin, as they were just a cotton-polyester blend. Ontario Hydro electricians instinctively started to use welders’ flame-resistant garments, as we felt they would be better.”

After a significant safety audit in 1999, a new electrical safety program was developed and rolled out, with management support at the Darlington Nuclear Generating Station in Bowmanville, Ont.The program built on the foundation of the NFPA 70E standard of the day and, most importantly, IEEE Industry Applications Society (IAS) electrical safety workshops, which helped establish Darlington as a leading nuclear power plant for electrical safety knowledge over the next few years.

“A lot changed because we established knowledge and facts,” says Doherty. “We got arc-rated garments into facilities

like Darlington, which was a critical improvement of worker safety.”

While Doherty praises the resulting standard update for significantly reducing potential injuries to qualified electrical workers through the proper selection of personal protective equipment (PPE), he cautions against a false sense of safety.

“The numbers based on the latest version of IEEE 1584-18 are harder now, verifiable, repeatable and as good as we can get at this time, adding greater credibility to the standard as the electrical engineering community demands,” he says, “but these values are just one component of the knowledge required to execute a comprehensive job safety plan as per CSA Z462-18, Clause 4.1.6.9.2.”

The fear factor

Another Canadian electrical safety specialist, consultant Terry Becker, also expresses concern with how the guide will be received.

“The new edition of IEEE 1584

will have a significant impact on the completion of new and existing arc flash hazard incident energy analysis studies,” he says. “My concern is with a resulting negative impact for the industry, with engineering consultants misinterpreting the standard and being too conservative with the new requirements when completing their calculations.”

To address his concerns, Becker has prepared a summary of the key changes represented by the new guide and presented it to his clients and other contacts.

“The calculations are for incident energy at an assumed working distance and, separately, for the arc flash boundary distance, e.g. where incident energy is calculated at 1.2 cal/cm2,” he says. “Some of the updated requirements that must be assessed by an electrical engineer with suitable power system study experience and competency are: system operating modes and determining the available bolted fault current and arcing fault current; protection and co-ordination; fault clearing

Back in 1979 Oceans and Fisheries Canada was funding new Marinas throughout Ontario. Our electrical contracting company was asked to install one of the first electrical systems on this new style of pier. Our company had an extensive marine experience as we had a local dry-dock. A customer for 50 years.

We purchased the specified power pedestal for the job but it wasn’t suitable for Marine applications so we rebuilt the posts and had them approved. Eventually we had more of these projects to do so instead of rebuilding we would manufacture our own. The result was a big success and we have recently decided to separate the manufacturing from the contracting company. So we are very proud to introduce to all “Vickery Electric Manufacturing”.

times and the use of the two-second guideline; voltage level considerations for arcing fault sustainability; gaps between conductors; enclosure sizes; and box and electrode configurations.”

Becker particularly emphasizes this last point.

“One of the most significant changes, which will need to be assessed appropriately, is to box and electrode configurations for specific electrical equipment relating to specific energized work tasks,” he says. “If conservatively assessed, incident energy values could increase by up to 200%. I am concerned that with some of the issues I have reviewed with arc flash hazard incident energy analysis studies that have already been completed, the 2018 changes will create additional issues.”

With this in mind, Becker suggests engineering associations across Canada should establish a professional practice guide for such studies and issue it to all professional electrical engineers throughout the country.

in providing quick turnaround, fully customizable power posts for numerous applications,

DAN LEDUC

Given recent changes to Ontario’s Construction Act and a series of decisions across Canada involving ‘pay when paid’ clauses, this column will try to provide a dashboard of how such clauses are being interpreted in various jurisdictions.

This type of clause—sometimes characterized as a ‘paid if paid’ clause— typically manifests itself in the contract between (a) a general contractor or construction manager and (b) a subcontractor or trade contractor. In very general terms, it means the subcontractor is not entitled to payment until the general contractor or construction manager is paid by the customer. It is, in a sense, a condition-precedent clause.

For further context on the status of ‘pay when paid’ clauses in Canada, consider the following three recent legal decisions:

In 2013, A&B Mechanical, a subcontractor, sued Canotech Consultants, a general contractor, for monies owing on a project and brought a motion for summary judgment.

The trial court awarded the summary judgment on the basis that the ‘pay when paid’ clause was more logically interpreted as a timing mechanism for payment to A&B, rather than as a condition precedent to payment. The decision was upheld on appeal in 2014, generally applying the reasoning that, in accepting such a clause, the intentions of the subcontractor could not be interpreted as agreeing to never be paid for the work it had performed. This reasoning has gained traction in other jurisdictions, as well, with the interpretation of the clause going straight to the intention of the parties. It would be very difficult to understand why any subcontractor would accept the full-blown risk of performing work without payment.

EOS Pipeline & Facilities sued Sprague Rosser Contracting and brought a motion for summary judgment in 2016. The Court of Queen’s Bench of

Alberta granted this judgment to EOS, despite an argument by Sprague-Rosser that the ‘pay when paid’ clause in the subcontract relieved it of its obligation to pay EOS.

There is a risk of nonpayment.

Similar to the approach in Manitoba, the court found the clause was not a condition precedent to payment, but rather dealt with timing of payment; it did not affect entitlement to payment. This rationale carries more weight when the clause is not sufficiently clear in the complete allocation of risk to the subcontractor. It is worth noting the wording in ‘pay when paid’ clauses can vary widely and there is no single, particular rule for interpreting the intentions of the parties.

In 1988, the Ontario Court of Appeal decision in Timbro Developments v Grimsby Diesel Motors held that agreeing to a ‘pay when paid’ clause did in fact mean a subcontractor assumed the risk of non-payment. Today, it could be argued the law has shifted somewhat, thanks to a 2016 Ontario Divisional Court decision.

In this case, a subcontractor made a claim against Bluelime Enterprises for monies owing. The divisional court upheld a trial judge’s finding that a contractor has a duty of good faith, when relying on a ‘pay when paid’ clause, to make its ‘best efforts’ to seek payment from a customer. And indeed, the court held Bluelime had fulfilled this duty by making many attempts to get an explanation from the customer, Alberta Justice, for the non-payment (which

followed a termination of the subcontractor’s services after discovering the latter had failed to disclose insider trading convictions against its principal).

This case is notable for confirming the duty and obligation of a general contractor relying on a ‘pay when paid’ clause to pursue the monies owed on behalf of the subcontractor. Clearly and simply drafted clauses have remained enforceable in Ontario.

This brings to the aforementioned changes to Ontario’s Construction Act, which include ‘prompt payment’ provisions that will come into force on Oct. 1, 2019. They essentially represent a statutory ‘pay when paid’ regime, reflecting earlier case law to some degree.

Under the new rules, if there is non-payment by the owner to the general contractor, then a notice must be provided to the general contractor within 14 days of that contractor’s proper invoice; and a similar notice must be provided to the subcontractor, along with an undertaking from the general contractor to commence an adjudication process (and potentially other proceedings) to pursue the monies owing—i.e. the ‘best efforts’ duty.

Given the diverse interpretations across Canada, for ‘pay when paid’ clauses to be legally enforceable, an unequivocal acknowledgment of the risk of non-payment is likely required by the subcontractor.

Dan Leduc is a partner in the law firm of Norton Rose Fulbright LLP, practising exclusively in construction law. For more information, contact him at dan.leduc@nortonrosefulbright.com.

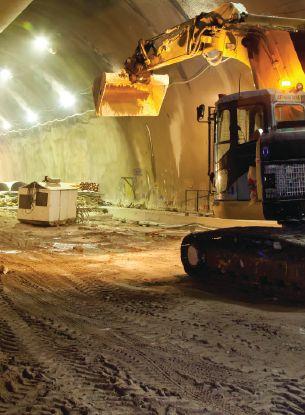

The BoxLED® line of flood and high bay fixtures has a new addition to the family, the compact BoxLED® MIDI. With reliability and performance in mind, the BoxLED® MIDI can deliver between 6,100lm - 11,700lm and an efficacy of up to 130 lm/W. This IP66 and NEMA 4X rated fixture is rated for wet locations and provides protection against dust and corrosion. The BoxLED® MIDI has a 4mm microprismatic tempered glass diffuser, and precision reflectors, which provide optimized glare control.

The BoxLED® MIDI is 3G and IK09 rated, making it suitable for indoor or outdoor applications with high impact and vibration. With an ambient temperature of -40°C to +40°C, the BoxLED® MIDI is ideal for flood lighting, accent lighting, building façades, monuments, security, tunnels and signage.

The BoxLED® MIDI is available in 9 mounting options, including the standard 180° adjustable yoke mount, surface mount, aviation cable, chain, hook, pendant, swivel pendant, twin post top mount and quad post top mount.

Fast-charging stations are set to become a lot more common.

/

BY GREG LARY

As you spot more and more electric vehicles (EVs) on the road and plugged in at parking lots, what might not be quite as obvious are the abundant new opportunities for electrical contractors.The demand for charging stations to keep EVs on the move is growing fast, with everyone from fleet managers to utilities striving to develop relationships with specialists in this field. With just a few easy-to-obtain additions to your current skill set, you can start increasing revenue now. Indeed, early adopters who

are ready to repair EV charging stations could end up locking in the lion’s share of such work needed by site owners, capitalizing on a significant opportunity without having to travel far.

Revving up

As charging stations become more common, more drivers are buying EVs, as they are less worried about running out of power. In turn, a larger number of EVs on the road leads to more demand for chargers. In Canada alone, the number of EV chargers sold annually is

Early adopters could end up winning the lion’s share of the work.

forecast to grow from around 10,000 at the end of 2016 to approximately 80,000 in 2026, according to Navigant Research. Further, the prices of EVs are dropping while their feasible ranges grow—which in turn will drive the need for more charging stations, as EV drivers venture farther afield than they could in the past. The Chevrolet Bolt, by way of example, carries a manufacturer’s suggested retail price (MSRP) of $44,000 and an estimated range of up to 383 km. Soon, similar models will offer a 500-km range at a slightly lower

price. And they will take high-speed charges, which only fast 50-kW and ultra-fast 150 to 475-kW DC chargers can provide.

Fast-charging stations will soon become much more common in Canada: In early 2019, for example, Volkswagen will launch Electrify Canada, an ultra-fast DC charging network spanning the country. In addition, a $6.7-million project funded by Natural Resources Canada will place 100 curbside charging stations in Ontario, Alberta and British Columbia. Tritium, for its part, has clustered 30 active DC fast chargers in British Columbia, Ontario and Quebec, mostly within Vancouver and Toronto.

As these stations’ numbers grow by the week, so too does demand for trusted service partners. The future of transportation is here—and it could put a new skill on your business card.

There is more than one way to extend your earning potential from installing and servicing EV chargers. The following are a few areas of specializations that can bring customers to your doorstep.

First, when a customer buys a charger, they must engage an internal or external specialist to install the system on the ground, with wiring and cabling. Since most site owners and network developers do not have their own electricians on staff, the chargers’ manufacturers will usually refer someone who knows how to handle their technology.

Next, over the longer term, Murphy’s Law dictates even the most reliable chargers will sometimes need servicing. This is an opportunity for electrical contractors to be on ‘speed dial’ for charger owners and manufacturers alike.

Finally, another emerging opportunity for electrical contractors is the reselling of EV chargers. Indeed, manufacturers are already positioned to engage a network of resale partners who can serve as an extension of their sales force, both to handle used chargers and to sell more new ones.

Developing the right skills to service EV chargers need not be daunting. You just have to know where to look.

Today, the playing field is open for electrical contractors who are willing

to learn. Any professional can view a demonstration or induction video by contacting charger manufacturers. Early adopters have the chance to learn their skills for free, before paid certifications become common practice. (ChargePoint, which operates commercial and residential chargers in Canada and the U.S., already offers paid certifications.)

As networks of charging stations grow, standards will be developed and implemented, so as to ensure contractors have expert knowledge of the systems. Many of those who have already gone through training, however, will be ‘grandfathered’ in, with the option to re-certify if necessary.

This trend will follow the example of the information technology (IT) industry. Early on, for example, any skilled computer technician could repair a touer, but eventually, companies like Cisco and Microsoft rolled out their own paid certification programs, to ensure consistent quality of service.

Currently, the most technologically advanced EV chargers have durable cases that enclose liquid cooling cables. Learning how to fix these types of systems now will set you up for success in the future. The more comfortable you become, the easier it will be to diversify in terms of the companies with which you work.

In the near future, standards will be developed to certify trained specialists. more comfortable working with residential charging stations, where they are dealing with up to 240 V. As far as safety goes, however, working with higher voltages will not be an issue for contractors who follow standard precautions, such as discharging the equipment before working on it.

The EVs of the future will be able to take ever-faster charging speeds, which drivers will rely on to keep on par with fill-up stops at traditional gas stations. In turn, this will spur utilities and charging networks to invest in DC fast charging stations in public spaces.

Once you have learned how to work with EV chargers, the next question is how to find jobs. The easiest answer today is to be the first to get out in your field. If you can get certified, solve problems quickly and not let issues idle, you will be referred for work time and again.

The biggest growth opportunities are likely to be commercial and with the aforementioned upper range of 150 to 475 kW, where fast chargers will first appear in truly significant numbers. So, to future-proof revenues from installations and repairs, electrical contractors will need to learn how to service these chargers. At this point, those who can work with ultra-fast chargers are in particularly short supply.

Many contractors so far have been

Electric fleets are on the rise, too. In June 2018, for example, the Toronto Transit Commission (TTC) welcomed 10 Proterra Catalyst E2 buses, part of a plan to convert its entire fleet to zero-emission vehicles by 2040. As more transit agencies across Canada move to buy or lease EVs, they will need service partners, including electrical contractors.

This is a ‘tip-of-the-spear’ moment, when the chargers that are currently installed offer only a glimpse of the market’s larger potential. It is time to get well-versed as quickly as possible, since opportunity favours those who step up early.

Greg Lary is Australia-based Tritium’s vice-president (VP) of sales for the Americas and installed his own EV charging station at home. For more information, visit www.tritium.com.au.

DAVID PILON

Section 64-112 of the CE Code tells us a utility interactive point of connection for a solar project must meet the requirements of the supply authority and Section 84, based on predetermined safety factors. So, even though most utilities (i.e. supply authorities) are not required to conform to Section 84, the installation must do so, as a minimum.

Meanwhile, a utility may have further requirements. Thus, it is important for electrical contractors to understand how the installation and connection of a solar project is a two-part process involving multiple jurisdictions. This may mean sending drawings to the utility, municipality and authority-having jurisdiction (AHJ) for review prior to starting the work. (Of course, contacting the local AHJ and becoming aware of local codes, utility standards and building code requirements is very important before starting any project.)

Section 84 addresses the need to ensure the customer’s power production equipment is suitable for interconnection with the supply authority system, so as to achieve synchronization without adverse effects on the interconnected system, and can disconnect immediately in the event of failure of any one phase of the supply source.

It also requires a disconnecting means from the supply authority, where the disconnect can be energized from both sides, as well as indicate whether it is open or closed. It must disconnect all electric power production sources from the supply authority system simultaneously. This means if the customer has more than one type of renewable power production, they must all be able to be disconnected with one means.

on utility regulations, utility capacity, the customer’s own equipment and service capacity and the location of the interactive point of connection. An electrical inspection of the installation will be based on comparing the available input from the utility with the equipment ratings and the interactive point of connection.

If the customer has more than one type of renewable power production, they must all be able to be disconnected with one means.

Once we deal with all of the safety equipment and labelling requirements, we need to look at how much solar we want to install. This will depend partly

In the early days of solar energy, it was determined standard testing conditions (STC) of 1,000 W/m2 could be exceeded for three hours per day, if the irradiance and weather were above the STC requirements. This resulted in solar energy being considered a continuous load, even with an output of 0 W/m2 in the evening or during the night.

As for the location of the interactive point of connection, the designer needs to choose where to interconnect the two systems, based on the size for which they have space and capacity. Will it be a load-side or supply-side interconnection, in a rural location, on a commercial structure or at a residence, using micro-inverters or a DC system with one or more larger inverters?

For the average 100-A residential solar panel, the bus rating is generally 125 A. If there is access to the panel, then a load-side connection is possible, with a maximum continuous renewable output circuit at 40 A.

A supply-side connection could involve changing out the meter socket to a double lug socket rated for 200 A, while a 100-A panel is already fed off the system. Due to the ampacity of the bus and the lug size of the socket, a separate input with a utility disconnect could be located outside the dwelling unit, depending largely on the equipment ratings, space requirements, local AHJ, municipality and utility limitations on the amount of solar that can be installed in the location.

With this in mind, be sure to contact your local AHJ and utilities before planning or installing solar panels in any location.

Always consult your AHJ for more specific interpretations.

David Pilon is an electrical inspector with SaskPower, the utility’s training co-ordinator for electrical inspectors and vice-chair of the Canadian Certified Electrical Inspector (CCEI) committee of the International Association of Electrical Inspectors (IAEI), Canadian section. He can be reached at dpilon@saskpower.com.

Power Related Fluctuations Cost North American Companies More Than $80 Billion A Year

You have expensive equipment you rely on every day to meet your customers’ needs. Down machines cost you time, money, and resources to get back on line. With a minimal investment, you can protect your sensitive control equipment or your entire facility from surge events. Mersen’s Surge-Trap® product line offers a world-class suite of surge protection products designed to protect your facility from harmful and preventable surge damage.

Most surge spikes originate from within a customer’s own facility. In fact, nearly 80% of all surge problems are directly attributed to power disturbances from within the facilities own equipment.

Any facility with motors stopping and starting, light load panels being turned on and off frequently, and other potential power disturbances is at risk for damage caused by a surge spike.

Of course, surges in electrical power can also originate outside of a facility, accounting for roughly 20% of facility transient problems. These surges may be caused by utility grid switching, lightning strikes, switching of capacitor banks, and electrical accidents.

Although many transients are not predictable, damage to a facility is preventable with a proven and tested surge protective device.

What types of damage can a surge cause to a facility?

• Disruptive: A surge enters an electronic component which interprets the valid logic command. The result: system lock-up, machine malfunction leading to faulty output, or corrupted files.

• Dissipative: A repetitive pulsing of short duration energy. The result: Long-term machine or system degradation leading to system replacement at earlier intervals.

• Destructive: A high-level energy surge that immediately results in equipment failure or destruction.

Metal Oxide Varistors (MOVs) are the most common and efficient technology used to protect equipment against damaging voltage spikes. However, while MOVs are efficient, they also degrade over time and possibly fail catastrophically when they reach end of life. In response, UL wrote standards to prevent fire risk while using MOVs. In 2009, UL 1449 3rd Edition was published (UL 1449 4th Edition, effective March 2016, has superseded 3rd Edition, furthering the surge protection standards), and it transformed the way SPD manufacturers designed and manufactured their devices.

This is when Mersen’s TPMOV® became essential. This Mersen-patented invention was the first fail-safe Thermally Protected MOV (TPMOV) able to pass all UL 1449 3rd Edition tests as well as even more stringent tests applied by our customers. A few years later, Mersen TPMOVs are often imitated, but there is still no match to Mersen’s technology. Almost all Mersen SPDs feature our Thermally Protected MOV (TPMOV) technology, a fail-safe surge protection solution without the need for additional upstream protection. As a result, the Surge-Trap® product line offers the lowest cost, safest, and most reliable surge protection products on the market.

MERSEN SURGE-TRAP ® SURGE PROTECTIVE DEVICES

With a minimal investment, you can protect your entire facility from surge events. Mersen’s Surge-Trap product line offers a world-class suite of surge protection products designed to protect your facility from harmful and preventable surge damage.

• Designed with the industry leading Mersen TPMOV® Technology

• For use in ANSI/UL/CSA Type 1 SPD installations

With AD Rewards, you can be rewarded for purchasing participating products from AD Canada Distributors. Earn one point for every dollar spent(1) at any AD Rewards Distributor(2) across Canada. You may already have points and not even know it. It’s the best rewards program in the industry. Isn’t it time you started rewarding yourself?