WETLANDS REDUCE NITRATES IN THE LONG RUN

Wetlands created 20 years ago between tile-drained agricultural fields and the Embarras River were recently revisited for a new two-year University of Illinois research project. Results show an overall 62 percent nitrate removal rate and little emission of nitrous oxide, a potent greenhouse gas.

“Slowing down the rate of flow of the water by intercepting it in the wetland is what helps to remove the nitrate,” said Mark David, a University of Illinois biogeochemist in the college of agricultural, consumer and environmental sciences. “The vegetation that grows in the wetland doesn’t make much of a difference because the grasses don’t take up much nitrogen. It’s just about slowing the water down and allowing the microbes in the sediment to eliminate the nitrate. It goes back into the air as harmless nitrogen gas.”

David was involved with research on these same wetlands from 1994-98 but didn’t take any measurements after that. He has spent much of his career studying the runoff from tile-drained fields and methods to reduce losses of nitrate and phosphorus. The runoff, particularly nitrate, from fields in the upper Mississippi River basin is believed to be the major cause of the hypoxia in

the Gulf of Mexico.

“The USDA requested proposals on the effectiveness of wetlands and woodchip bioreactors to reduce nitrate losses from fields, but was also concerned about greenhouse gas emissions,” David said. Working with graduate student and lead author Tyler Groh, the research found that greenhouse gas emissions were “really quite low.”

“Nitrous oxide was not a problem,” David said. “The other good news is that this research confirms that wetlands really do work to reduce nitrate runoff, and they work long term.”

David noted that, along with fertilizer management, cover crops, and bioreactors, wetlands are an integral part of the Illinois Nutrient Loss Reduction Strategy. Building a wetland costs about the same as installing a bioreactor. One of the reasons David prefers wetlands to help solve the nitrogen pollution problem is that they work reasonably well in the winter when the water temperatures are low.

What’s the drawback?

“Farmland along the river may be flood prone, but depending upon the landscape, it could be farmable land,” said Lowell Gentry, senior research

specialist and co-principal investigator on the project. “In this case, it was pasture so the wetlands didn’t reduce the row-crop acreage, and the landowner was able to use it as hunting grounds. Our project included funds to build new wetlands, but we couldn’t convince anyone to do it. Wetlands have been a hard sell.”

“Farmers generally prefer to install bioreactors because they don’t take up much space,” Gentry added. “A wetland requires about three to four percent of the drainage area. So, for a 100-acre field, you’d need about four acres in wetland. Although bioreactors don’t use up much land, they also don’t slow the water enough during high flows. Research on their performance is still underway. Because water tends to be in the wetlands for a much longer time period, they are more effective.”

David explained environmental groups have been pushing for years to build more wetlands to help lower nitrate levels. There are already a few in the Lake Bloomington watershed but none have yet been built in the Embarras River watershed.

The findings were published in the May/June issue of the Journal of Environmental Quality

NEW HOLLAND APPOINTS NEW VP FOR NORTH AMERICA

New Holland has appointed Bret Lieberman as vice-president of North America. The appointment, announced in July, was effective immediately.

Lieberman has built an accomplished resumé at CNH Industrial and New Holland spanning 25 years in various roles. He will bring a multi-faceted perspective and a passion from within to the brand’s top leadership position.

Most recently, Lieberman held the position of head of North America manufacturing, where he was responsible for all agricultural and construction manufacturing plants.

“Bret has brought strong leadership to each role he has held and has a deep understanding and passion for New Holland and the equipment that makes us a world-class leader in agriculture and construction,” said Brad Crews, chief operations officer with CNH Industrial NAFTA. “We are focused on the future and given Bret’s proven ability we see a great opportunity for continued growth through close

partnerships with our dealers and customers.”

Lieberman joined the company in 1990 with a position in service parts. He continued to expand his experience with various roles in purchasing, human resources, quality management and hay tools production.

“I am excited for this new opportunity to lead the brand as I have spent a significant portion of my career here on the New Holland campus,” Lieberman said. “I deeply understand the importance of the quality and performance of the equipment that our dealers and customers rely on everyday for their success.”

Lieberman holds a master’s degree in business management from Saint Francis College in Loretto, Pa., and received his bachelor’s degree in business, management and administration from Bloomsburg University in Bloomsburg, Pa. He currently resides in Lititz, Pa. where he enjoys spending time with his three children.

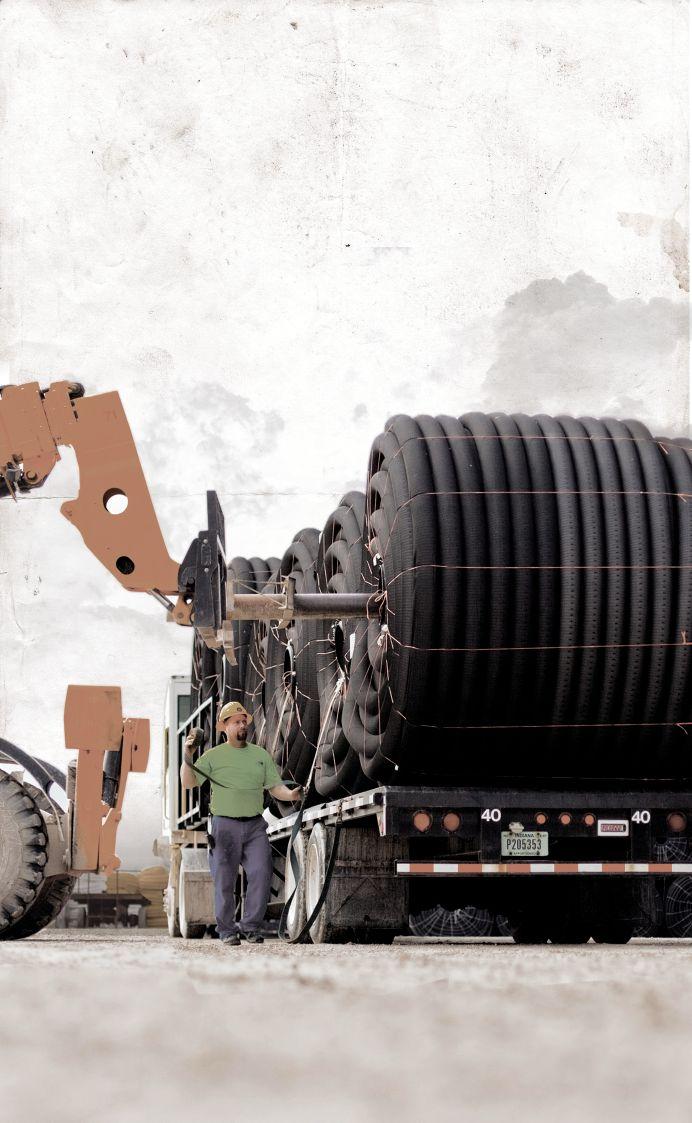

ADS OPENS NEW DISTRIBUTION CENTRE IN B.C.

In August, Advanced Drainage Systems, Inc. (ADS) opened a new distribution center in Abbotsford, BC. The Abbotsford location is the company’s first in British Columbia and ninth in Canada. The new location will increase the local supply of the company’s products and improve customer service.

“The need for storm water drainage products continues to grow in many applications and in many regions,” said Bob Klein, executive vice-president of

ARMTEC CLOSES

BROOKFIELD TRANSACTION

Over the summer Armtec Infrastructure Inc. closed the sale of substantially all of its assets to Armtec LP, or “New Armtec”, an affiliate of Brookfield Capital Partners Fund III LP.

The Brookfield transaction was approved by the Ontario Superior Court of Justice in Armtec’s proceedings under the Companies’ Creditors Arrangement Act (CCAA) proceedings.

Pursuant to the Brookfield transaction, New Armtec acquired substantially all of the company’s assets on a going-concern basis, assumed substantially all of the company’s obligations to trade creditors and all employee obligations, and assumed the company’s revolving credit facility with its operating lenders and the company’s bonding agreement with Trisura Guarantee Insurance Company.

New Armtec did not assume any of the company’s obligations under its 8.875 percent senior notes due 2017 or its 6.50 percent convertible unsecured subordinated debentures due 2017.

The Brookfield transaction did not provide any recovery for the holders of the senior notes, convertible debentures or the company’s common shares.

Ernst & Young Inc. served as the courtappointed monitor as part of the CCAA proceedings. Documents relating to the CCAA proceedings are available on the monitor’s website at www.ey.com/ca/armtec.

A copy of the Brookfield purchase agreement will be available at www.sedar.com.

sales for ADS. “This new yard is another example of our commitment to having local inventory to meet our customers’ water management needs wherever they might need it.”

ADS water management solutions are used in a diverse range of construction projects. The company’s more than 3,800 employees support a network of 61 manufacturing locations and 29 distribution centers in strategic locations across the globe.

PPI ANNOUNCES NEW BOARD OF DIRECTORS

The Plastics Pipe Institute, Inc. (PPI) installed a new board of directors at its annual membership meeting this past summer.

Patrick Collings of Lane Enterprises was named chairman of the board on a two-year appointment. Collings is an engineer by training and holds several patents. He is also an accomplished businessman. In his role as president and general manager of Lane Enterprises, he has led the company through steady growth for nearly a decade.

“We look forward to Pat’s guidance and direction for PPI’s positive future and to ongoing broadening value for members, as well as enhanced benefit and service to our industry,” said Tony Radoszewski, president of PPI.

The board also includes David Fink of WL Plastics (vice-chair); Michael Pluimer of Crossroads Engineering Services (advisory council chair); and Peter Zut of Krauss Maffei (treasurer).

Past chair is George Zagorski of Blue Diamond Industries, LLC.

Working with division chairs, the association’s president and legal counsel, the board of directors governs the institute, overseeing its business.

“Our association is member run and member led,” Radoszewski said. “These individuals and their companies have been strong partners of PPI for many years. Their diligent work on various committees and task groups has supported PPI’s significant contributions to industry advancements. The caliber and talent of these executives, with their technical, operational and leadership expertise, ensures forward-moving momentum. It’s an extremely exciting time to be involved at PPI. Progress and innovation are occurring throughout the organization at an all time high. We are especially fortunate that our new chairman is a seasoned patron and has been a front-runner in much of this development.”

The chairs of the five PPI divisions participating on the board are: Gary Morgan of Viega (building and construction); Michael Tribble of Southwire (conduit); Jeremy Duininck of Prinsco (corrugated plastic pipe); Douglas Keller of LyondellBasell (energy piping systems); and Lawrence Norris of Wolseley Industrial Group (municipal and industrial).

Company on the move Optimize Field Surfaces for Better Drainage

Drainage contractors are well aware of the need to optimize subsurface drainage in order to maximize a field’s yield potential. However, what many contractors may not yet realize is that by also optimizing the field’s surface for drainage, they are ensuring the best possible outcome for crop yield.

Surface Optimization

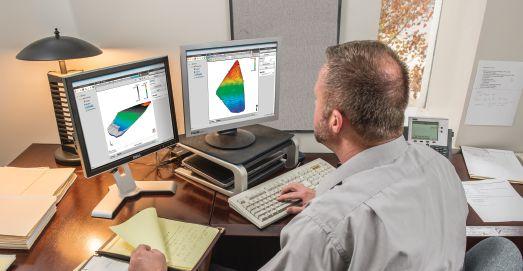

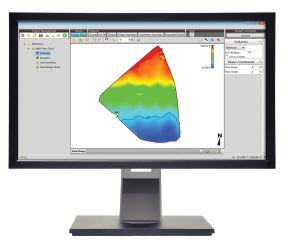

Trimble now offers a solution to optimize field surfaces for better drainage—the WM-Form™ land forming solution for leveling, surface drainage, and irrigation. WM-Form is an end-to-end agriculture solution for field survey, topography analysis, design creation, reporting and cost estimation, land forming, and verification. With easy-to-use surface design tools and flexible parameters, growers and contractors can use the WM-Form solution to repair underperforming areas and extend the amount of productive farmable land. It can reduce the volume and cost of earthworks and minimize disturbance to valuable topsoil. Growers can use the solution to optimize water distribution and drainage, reduce erosion and flooding by effectively directing waterflow, and create more uniform crop production which can lead to increased yield.

Contractors can use the WM-Form solution from survey to verification. They can collect 3D field data using the Trimble® WM-Topo™ survey system, or the FmX® integrated or TMX-2050™ displays. Users can then analyze topographic data in the WM-Form software to identify surface problems that are limiting yield potential and use the software’s flexible design tools to create a design that optimizes their field’s surface. The software also provides reports for volume, area and constraints, providing contractors and growers with an accurate quote on the total cost of the project. Users can leverage the 3D design to conduct land forming operations using the Trimble FieldLevel™ II system, and then verify that the design has been accurately completed using the Trimble WM-Topo survey system.

The WM-Form software provides flexibility, allowing users to design variable-shaped fields based on existing topography, the water needs of individual crops, and individual farming practices. It allows users to:

• Drain water in any direction or to a linear feature such as a ditch or existing drainage system

• Create surface designs for furrow irrigation

• Split a field into sections and create designs for each section individually

• Generate multiple design variations for the field, then compare them in 3D view against the original topography

• Produce 2D cut/fill estimates and reports

• Interact with Connected Farm™ for license and acreage management

• Level fields with custom/best-fit single or multiple planes

The WM-Form solution enables growers and contractors to turn their fields into optimal surfaces, even in areas that were unable to be leveled before. With more farmable land that is optimized for water management and more uniform production, growers can experience increased yield.

Subsurface Drainage

In some cases, however, surface optimization is only half of the equation. The other half is subsurface drainage. Trimble also offers the WM-Drain® farm drainage solution which enables contractors to quickly and easily manage drainage system designs and installation and to be more efficient throughout their operation. WM-Form streamlines the survey, analysis, design, installation, and mapping steps of subsurface drainage. It ensures optimal 3D drain placement, which improves crop yields by controlling ponding, optimizing root depth, maximizing planting seasons, and minimizing nutrient loss.

So What’s the Benefit for the Farmer?

Too much water on the field can lead to crop disease and lower yield, which is a detriment to a farmer’s bottom line. By installing a subsurface drainage system while also optimizing the field’s surface for water distribution and drainage, farmers can ensure their crops are not getting too much water on the surface or at the root zone. This allows farmers to maximize their yield.

For more information on the WM-Form solution, visit: http://www.trimble.com/Agriculture/WM-Form.aspx. For more information on the WM-Drain solution, visit http://www.trimble.com/Agriculture/WM-Drain.aspx.

Drainage Water Management Evolved.

The Trimble ® WM-Drain ® farm drainage solution is a concept to completion toolset that streamlines the survey, analysis, design, installation, and mapping steps of surface and subsurface drainage—making your drainage water management jobs more efficient than ever before. The WM-Drain solution ensures optimal drain placement, which results in increased yields, earlier planting seasons, and more efficient water table control. For more information, visit www.trimble.com/agriculture or see your dealer.

© 2013–2015, Trimble Navigation Limited. All rights reserved. Trimble, the Globe & Triangle logo, and WM-Drain are trademarks of Trimble Navigation Limited, registered in the United States and in other countries. Connected Farm, Farm Works, and TMX-2050 are trademarks of Trimble Navigation. All other trademarks are the property of their respective owners.

INDUSTRY NEWS

STEEL BYPRODUCTS TRAP PHOSPHOROUS IN AGRICULTURAL DRAINAGE WATER

At South Dakota State University (SDSU), an assistant professor of civil and environmental engineering, is using steel byproducts to trap phosphates in simulated tile drainage water.

Guanghui Hua is collaborating with Chris Hay, associate professor of agricultural and biosystems engineering and SDSU Extension water management engineer, who has been testing woodchip bioreactors since 2011.

“This research is very timely,” said Jay Gilbertson, manager of the East Dakota Water Development District. Though drainage water looks clear and clean, it often has elevated nitrogen and phosphorous levels. “Doing something to address this nutrient-loading issue will help offset some of the negatives,” he said.

“Phosphates are the leading cause for algae growth in natural water bodies,” Hua noted. Because dissolved phosphorous is readily available, algae can use it easily.

In addition to consuming oxygen, some algae species release toxic substances into the water, Hua explained.

In the last decade, more South Dakota farmers have installed tile drainage to increase crop production, particularly in the last five years. Tile drainage generally reduces total phosphorous losses from farmland, which helps reduce phosphorous loading to lakes and streams. However, the drains can still be a source of dissolved phosphorous.

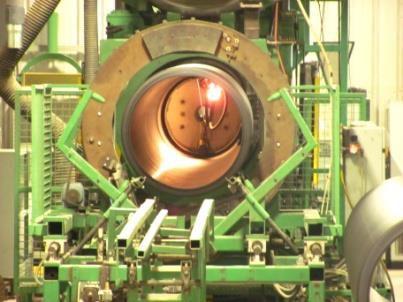

Hua and graduate student Morgan Salo are testing four types of steel byproducts from Sioux Falls, SD, machine shops to determine their phosphate removal capacity. When the steel shavings rust, the iron oxides that form on their surfaces react chemically, binding with phosphate ions and thus removing phosphates from the drainage water.

The researchers performed batch

adsorption tests to determine the maximum capacity on a per mass basis for each type of steel material.

The iron oxide on the surface of this mixture of small and large carbon steel shavings is highly reactive with phosphates. Carbon steel works better than stainless steel, Hua pointed out, noting that the iron oxide on carbon steel surfaces is highly reactive with phosphates.

The researchers selected a steel mixture containing small and large pieces for subsequent reactor experiments.

They are now optimizing the procedure by pumping simulated drainage water first through a column filled with wood chips and then one filled with steel byproduct in an upflow reactor. The researchers are evaluating a 24-hour flow time through the wood chips and eight hours through the steel byproduct. The system contains three times more woodchips than steel.

During three months of continuous operation, the column reactors consistently exhibited 100 percent removal of nitrates and phosphates.

In addition, the researchers are exploring factors such as varying flow-through time and influent nutrient concentrations. They will also conduct batch experiments to determine the impact of pH, temperature and reaction time on adsorption.

Hay explained that once in the bioreactor, water will flow through a bed of woodchips first and then a steel-loaded barrel before entering the last control structure. An underground bioreactor in the neighborhood of 15 to 20 feet wide and 100 to 120 feet long can handle the runoff from a 30to 40-acre field.

The researchers plan to add a phosphorous unit to a woodchip bioreactor at Baltic this fall through funding from the South Dakota Soybean Research and Promotion Council.

GULF OF MEXICO DEAD ZONE ‘ABOVE AVERAGE’

Scientists report this year’s Gulf of Mexico dead zone – an area of low to no oxygen that can kill fish and marine life – is above average at 6,474 square miles.

Dead zones, also called hypoxia areas, are caused by nutrient runoff from agricultural and other human activities in the watershed. They are highly affected by river discharge and nitrogen loads. These nutrients stimulate an overgrowth of algae that sinks, decomposes, and consumes the oxygen needed to support life in the Gulf.

This year’s dead zone is larger than the 5,052 square miles measured last year, indicating that nutrients from the Mississippi River watershed are continuing to affect coastal resources and habitats in the Gulf.

A suite of National Oceanic and Atmospheric Administration (NOAA) sponsored models forecasted a dead zone in the range of 4,633 to 5,985 square miles, based on May nitrogen loading data provided by the United States Geological Survey (USGS).

“An average area was expected because the Mississippi River discharge levels and associated nutrient data from May indicated an average delivery of nutrients during this critical month, which stimulates the fuel for the mid-summer dead zone,” said Nancy Rabalais, executive director of the Louisiana Universities Marine Consortium (LUMCON). Rabalais led the survey cruise, which sailed from July 28 to Aug. 3.

“Since the models are based largely on the May nitrogen loads from the Mississippi River, the heavy rains that came in June with additional nitrogen and even higher river discharges in July are the possible explanations for the larger size,” Rabalais added.

The average size of the dead zone over the past five years has been about 5,500 square miles – nearly three times the 1,900 square mile goal set by the Hypoxia Task Force in 2001.

Ready to work?

New rules are poised to change the game for contractors.

by Steven Anderson, president, LICA National

Water: the single most important substance in the world. Water: the most available substance in the world. On the surface of those statements it would seem that all is well; we all know there is a “but” lurking within them.

Without water, life ceases to exist. It is the basis of all cellular structure. While a person can exist without food for weeks, the period of life without water is about three days. If you paid attention in biology class, you already know this. And, as we have spent many days in the trenches up to the top of our boots (or higher) in water, we also know that most of the water we come in contact with is not water we would drink. Therein lies the problem the world faces today: we have a thirsty population looking for a cool, clear glass of ice water on a hot day.

Looking at this from our first world point of view, we tend to miss something about water. In the past, many of the minerals our bodies needed were found in the water we drank. As our supplies have been cleaned and purified, many of those minerals are now removed. Contamination is measured in parts per billion – sort of like trying to find 10 soybeans in a 30,000-bushel bin of corn. Yet look at all the animals that seem to do just fine on water in streams, ponds, lakes and rivers. It all comes down to immunities built up over generations and passed along the tree of life. Life is a very adaptable enterprise and finds a way to survive changes in the environment.

This all brings us to the point where it may be good to mention the huge mule in the room: the new interpretation of what are considered “Waters of the United States” or “WOTUS.”

(I use mule as opposed to elephant due to the political party that is the genesis of this new interpretation.) As president of LICA, much information about these crusades comes to my

attention, as well as all the efforts to bring reality to bear against them.

While the House has passed a “no you don’t” bill, and the Senate now has one in committee that will most likely be acted on (and hopefully passed) this fall, there probably won’t be enough support to override an almost certain presidential veto. So what was supposedly a clarification of what constitutes “waters of the U.S.” is now an overreach to include just about every drop of water that will “flow” somewhere into a navigable river. Taken to extremes, a homeowner could need an Environmental Protection Agency (EPA) permit to change the gutters on his house since that water very often does flow into a significant “nexus.” And for drainage contractors, while the subsurface water in a field is not labeled “waters of the United States,” that changes as soon as the water flows out of a tile – unless that tile empties into a landlocked lake. We all know how often that happens on a drainage project.

The implications of this new “understanding” of WOTUS are clear. There will be a wave of regulation and permitting that will delay and add to the cost of every job you do. No longer will you be able to pop over and do that short run next to the job you are finishing up, because nobody will be able to afford the fine for doing it without a permit. And that’s assuming you can even get a permit to begin with.

As I mentioned earlier, it’s about those parts per billion. Does anyone 55 or older think the environment is less clean than when we were young? And just think how many more people will be needed to handle those permit requests and inspections.

So join with LICA and other groups fighting this overreach. Support those elected officials that oppose this plan. Tell them about what is happening in the real world. Help us be a voice of reason and progress. DC

DRIVEN TO DISTRACTION?

Employers can be liable for employees’ cell phone use.

AUniversity of North Carolina

Highway

Safety

Research

Center study found an estimated 284,000 distracted drivers are involved in serious vehicle accidents every year. One of the contributing factors is cell phone use.

More than 80 percent of the 94 million cell phone owners in the United States use their phones while driving, at least sometimes. Many states have legislation to regulate cell phone use in moving vehicles. At least 13 nations, including England, Germany and Japan, have banned the use of cell phones in cars.

In the past few years, cell phone usage has been an issue in several lawsuits, and employers are being held responsible if a worker causes an accident while talking on the phone. Cell phone usage is a distraction while driving, like a lot of other things. So why are employers worried? Cell phone records can be subpoenaed to prove the employee was on the phone. Other distractions cannot be identified down to a specific time, and many drivers don’t want to say they were distracted and not driving safely.

Here are several examples of liability cases against employers resulting from cell phone use by employees:

In 2000, a lawyer struck and killed a teenaged girl in Virginia. The attorney, who was returning from a work meeting, was allegedly talking on her cell phone with a client at the time of the accident. The deceased’s family filed a $30 million lawsuit against the employer. In October 2004, the jury awarded $2 million in damages to the girl’s family. The plaintiff’s lawyer filed suits against both the driver and the driver’s employer after an

examination of phone records revealed that the driver had been talking to a client when she hit the girl.

The driver was also convicted of criminal charges and sent to prison for two months for punitive and compensatory damages. In his suit against the employer, the plaintiff’s lawyer argued the case on the grounds of common law negligence, since the employer required drivers to be available to clients via cell phone and use their driving time productively, and that an employer is responsible for bad acts committed by an employee on the job.

The suit against the employer was settled for an undisclosed amount.

There are other examples too. In December 2001 a Miami jury awarded $21 million to a woman who was hit and severely injured by a lumber industries salesman while he was on his cell phone. That same year, an appeals court ordered the State of Hawaii to pay $1.5 million in damages after a state teacher, who had just completed a cell phone call, struck a pedestrian while driving to work.

Employer liability in these types of cases is based on a legal doctrine called respondeat superior. Under this doctrine, an employer may be responsible for the harm caused by its employee if that employee was acting within the course and scope of his or her employment at the time the accident occurred. In addition to arguing that an employer is liable for the harm

by CNA FINANCIAL

caused by one of its employees, some plaintiffs have argued that the employer is directly liable for its own negligent conduct in failing to provide adequate training or instructions on safe cell phone use, or failing to restrict usage.

With the risk of employer liability associated with employee use of cell phones while driving, society’s growing dependence on cell phones, and the new laws restricting cell phone use while driving, it is time for employers to consider adopting or adapting comprehensive policies and practices concerning employee cell phone use. Considerations include adopting cell phone policies prohibiting employees from using cell phones while driving for business purposes and while driving to and from work. The restrictions should include the use of hands-free headsets, (cell phone distraction involves all types of driver distractions: visual, manual and cognitive) since studies indicate it’s the conversation (cognitive) not the physical act of holding the phone that contributes to accidents.

While there is no guaranteed defense to liability, developing appropriate policies, training and enforcement mechanisms can help limit potential liability. DC

The information, examples and suggestions presented in this material have been developed from sources believed to be reliable, but they should not be construed as legal or other professional advice.

DRAINAGE MANAGEMENT

ADAPTIVE DESIGN

Changing climate conditions could require new drainage system designs.

Nitrate loss through tile drainage systems has been a water quality concern in the Midwest for many years. Reducing concentration from current values to a maximum level of 10 mg N L-1 has been adopted as a goal in many nutrient reduction plans.

by ZHIMING QI

But, as changes in precipitation, temperature, and other climate components have been measured in Iowa, and changing CO2 concentration in the atmosphere is recorded, it’s unclear if these changes affect nitrate concentration in tile drainage. This uncertainty is due to the complicated water and nitrogen dynamics in a drained agricultural system. Because drainage experimental plots are relatively large, it is difficult to conduct field experiments at a plot scale under controlled climate variables, such as the Free-Air CO2 Enrichment (FACE) program. Agricultural systems models, equipped with newly updated scientific findings, can be used as a tool to mimic field situations under a changing climate. Therefore, by employing an agricultural system model emphasising water quality – known as the Root Zone Water Quality Model (RZWQM2) – I, along with my colleagues, Zhaozhi Wang, Lulin Xue, Melissa Bukovsky and Matthew J. Helmers, investigated climate change impacts on nitrate leaching and crop yield. Our work, which was published in the March edition of the journal Climatic Change studied a drainage site near Gilmore City, Iowa, as an example. The site is managed by Helmers, my PhD supervisor. RZWQM2 was used because the response of water and nitrogen dynamics, as well as crop growth, to key climate components are taken into account by the model. These include: atmospheric CO2 concentration; air temperature; rainfall amount and intensity; solar radiation;

wind speed; and relative humidity. A successful calibration and validation of the model is the cornerstone of modeling work. In this study, calibration and validation of RZWQM2 in Iowa’s subsurface drained agricultural fields can be traced back many years. Based on the work of Allah Bakhsh et al. (2001 and 2004) and Kelly Thorp et al. (2007) who have conducted the RZWQM model test under the lead of Ramesh Kanwar, Dan Jaynes, and Robert Malone, I further calibrated and validated the RZWQM2 model in 2011 using five years of observed data at Gilmore City. The model was subsequently tested again in 2012 using 16 years of observed drainage flow and nitrate loss data at the same site. Ranvir Singh et al. (2006) calibrated and validated the DRAINMOD computer simulation model at this site and some verified parameters were adopted by my RZWQM2 simulation.

Without those explorations by earlier researchers, this work (which was mainly conducted by Wang, a postdoctoral fellow on my team) would not have been possible. Although climate change is a sensitive topic, we are confident conducting climate change impact research using the RZWQM2 model because of these previous consolidate works.

To predict climate change impacts, we ran the RZWQM2 model under historical observed (1990-2009) and future predicted (2045-2064) climate data and subsequently compared the output of drainage flow, N loss in tile drainage, and crop yield under these two scenarios.

The future climate data was created by superimposing the predicted monthly change to the observed 20-year historical weather data. The predicted climate change data was provided by Xue and Bukovsky at the National Center for Atmospheric Research in Boulder, Colo. They used six sets of different global and regional climate models to establish their prediction data.

The projected climate change from 1990-2009 to 20452064 suggested more significant changes in air temperature and precipitation than other climate components. Compared to historical weather, mean annual air temperature is projected to increase by 2.2C (3.96F) (that’s 26.9 percent greater than the historical value of 8.1C (46.6F), and mean annual precipitation is projected to increase from a baseline value of 76.9 to 81.3 cm (30.3 to 32 inches) (suggesting an increase of 5.6 percent).

The simulation showed that, compared to drainage flows under historical climate conditions, the annual drainage flow and annual NO3-N loss are projected to increase by 4.2 cm (1.7 inches) and 11.6 kg (25.6 pounds) N ha-1, respectively. The annual flow-weighted average annual nitrate-N concentration is also projected to increase by 2.0 mg N L-1 under forecasted future climate conditions. The percentages of those increases were 14.5 percent, 33.7 percent, and 16.4 percent, respectively. The yield of soybean increased by 28 percent mostly due to CO2 enrichment but increased temperature showed negligible effect. However, the yield of corn decreased by 15 percent because of fewer days to physiological maturity due to increased temperature and limited benefit of CO2 to corn yield and water conservation under a subhumid climate.

What does all this mean for drainage contractors? In order to drain more water under future climate conditions, I think that drainage spacing will have to be narrower or the depth of tile installations will have to go deeper. Additionally, I think that under projected future climate conditions the drainage coefficient used to design drainage systems should be slightly higher to accommodate anticipated increases in drainage requirements. In other words, the frequency of flooding affecting drainage systems designed with the current drainage coefficient may increase under the future climate conditions. Moreover, nitrogen loss and its concentration, which is one of the major factors in eutrophication, will probably tend to be higher. Developing a more environment-friendly drainage design would allow contractors to capture a bigger share of the market.

In terms of future work, my research team at McGill University is now applying this RZWQM2 model in Quebec and Ontario to simulate climate change impact on nitrate loss through tile drainage, through a collaboration with McGill professor Chandra Madramootoo, and Agriculture and Agri-Food Canada scientists Chin S. Tan and Tiequan Zhang. And, since phosphorus is another major concern on tile drained fields amended with manure, we are developing a phosphorus module for the RZWQM2 model through a close collaboration with Lajpat R. Ahuja and Liwang Ma, soil scientists with the United States Department of Agriculture Agricultural Research Service (USDA-ARS). Hopefully we can further evaluate climate change impact on the fate and transport of phosphorus after a P module is linked to RZWQM2. DC

Dr. Zhiming Qi is an assistant professor with McGill University’s department of bioresource engineering. He holds a B.S. in irrigation and drainage engineering and an M.S. in soil and water engineering from China Agricultural University in Beijing. He earned his Ph.D. in agricultural engineering and environmental science

• No

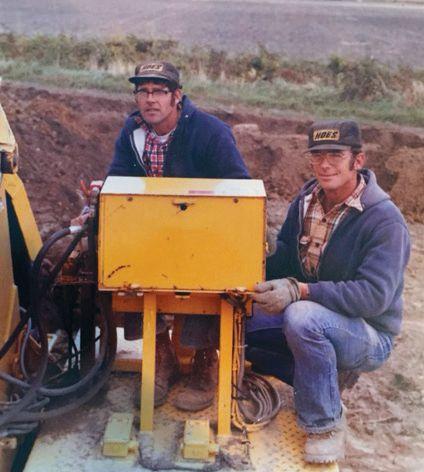

TESMEC’S LADDER TRENCHER CONQUERS MINNESOTA FARM DRAINAGE MARKET

Wilmont, MN The overcast sky and rain-filled clouds in a warm early summer morning are common in this part of the country and the local farming community is well aware of the problems that an overabundance of rain may cause to the crops. Wilmont-based contractor, LooCon Inc. is one of the main farm drainage/ water mains contractors who successfully addresses the issue of lack of water mains or replacement of them. The increasing need of water mains in the Upper Mid-West and lack of specialized equipment to expedite the completion of the project led the Loosbrock Brothers (owners of LooCon Inc.) to come up with newer, more effective solutions. That’s when they approached Tesmec USA, Inc., an international leader in the engineering, manu -

facturing, and marketing of large track trenchers.

In 2013, Tesmec USA, Inc. decided to take on a new challenge: introduce its line of agricultural trenchers to the Farm Drainage market. At first, Tesmec’s agricultural line was made up of two models, the 775 DT Chainsaw and the 775DT Bucket Wheel, but it would soon include one more machine. During the same year, LooCon Inc. and Tesmec started discussing the potential design and production of a machine capable of digging water mains and the TLM 60/60 was born.

Tesmec’s TLM 60/60 is highly unique and satisfies many required features, especially: weight, depth, width, track width, cab size, operator comfort, ease-ofuse, discharging system and many others. Its weight at 131,000 lbs facilitates

transport operations and, together with its 31.5’’ track pad and high center of gravity, allows for digging operations in extremely wet terrains. With max digging width at 60’’ and max depth at 14’, the TLM 60/60 is the optimal piece of equipment for the installation and replacement of water mains throughout the Upper Midwest.

Brian Loosbrock, coowner of LooCon Inc. and its crew are highly satisfied with the TLM 60/60 and are achieving production results never achieved before via traditional methods (excavators). The TLM 60/60 was engineered and manufactured with operator’s comfort and ease-of-use in mind. The spacious, 18 sq. ft., elevating cab is equipped with Heat and A/C to face the oppressing humidity of the summer and the harsh

Midwestern winters. In order to facilitate operations and increase user-friendliness, the TLM 60/60 is equipped with both automatic grade control and TrenchTronic 3.0. The former allows for automatic control of the slope/ grade at which the machine is digging, while the latter is Tesmec’s very own electronic control system. TrenchTronic 3.0 sets optimal chain speed, track speed, and digging pressure and also allows for remote monitoring and diagnostic.

The TLM 60/60 is also not short of power for the 540 HP, CAT C15 ACERT engine delivers plenty of power to meet expectations.

After a highly successful Farm Progress Show, Tesmec USA, Inc. is looking forward to the potential that this new machine represents and is looking forward to helping contractors all over the world reach their excavation goals, no matter the challenge.

CHANGING HANDS

A new generation takes the reins at Bower Tiling Service.

It was an eventful summer for the folks at Bower Tiling Service Inc. Drainage Contractor first introduced readers to the company three years ago, when we profiled the then 112-year-old business in our Spring 2012 issue.

by BRANDI COWEN

Now, after an exciting few months that saw two retirements and two successions transferring ownership of established businesses from one generation to the next, we’re checking back in with Bower Tiling Service to find out what’s new with this fourth-generation family business.

But first, a quick re-cap: George W. Bower founded the Clyde, Ohio, based company in 1900 with a steam-powered Buckeye Trencher. In time his sons, Richard and William, formed a partnership with their father. All three worked together until approximately 1955, when Richard bought William’s share of the business. When George retired in 1958, Richard was left to run the company. Six years later, another partnership was formed – this time

with Richard’s sons, Jack and Tom. In 1976 it was Richard’s turn to retire, leaving the family business safely in the hands of a third generation of Bowers. By 1980, the company had grown into one of the largest agricultural drainage contractors in the United States, installing more than four million feet of tile every year.

To those in the drainage contracting world, the story so far – of family working with family and a business being passed down from one generation to the next – may sound familiar. But under Jack and Tom’s leadership, the Bower Tiling Service story unfolded a little differently. In 1985, the brothers formed Great Lakes InterDrain Inc. – the first Inter-Drain distributor in the United States. A decade later, Tom left

Continued on page 28

MANY BENEFITS OF DWM

Bioreactor benefits controlled drainage system.

It’s a short jump to change many drainage systems into drainage subirrigation systems, says Mark Nussbaum, an area engineer at the United States Department of Agriculture - Natural Resources Conservation Service (USDA-NRCS). Add a bioreactor intended to eliminate water pollution and it equals good news for farmers and the environment.

by TRUDY KELLY FORSYTHE

“The bioreactor was installed with the purpose of treating the drainage water for excess nitrogen in an economical manner,” says Mark Nussbaum, an area engineer at USDANRCS.

Nussbaum should know. He is involved in a project at Southeast Missouri State University’s David M. Barton Agriculture Research Center in Missouri where researchers monitor how a wood chip denitrification bioreactor installed in May 2014 works with the centre’s controlled, subsurface drainage and irrigation system.

The university installed the drain management system in 2007 on a 100-acre piece of land consisting of bottomland soils that were historically wetter than desired, but were not wet enough to be classified as wetlands. “We always check to ensure that potential project areas are not mapped as

wetlands,” Nussbaum says.

The question then was “What can be done to improve the land?”

The consistently low yields were usually due to waterlogged soils, but sometimes due to lack of sufficient rainfall during the growing season. Accordingly, the project’s goal became removing surplus water from the soil during wet periods and supplying water to the soil during dry periods. Enter the above-mentioned controlled, subsurface drainage and irrigation system, which consists of a series of parallel four-inch subsurface conduits spaced 30 feet apart collecting into eight-inch conduits to transport surplus

water to field ditches. This provides the system with the capability to maintain a water table beneath the entire installation.

These improvements take the system beyond a typical drainage project and to a drainage water management (DWM) system.

“Drainage water management is a growing field,” Nussbaum says, explaining that with DWM, the focus isn’t just on drainage. “A well-designed DWM system gives producers the ability to manage their soil’s water table to increase yields, reduce off-site nutrient losses, grow more vigorous cover crops and even subirrigate in some cases.”

DWM systems typically cost more during installation, but they pay dividends for the entire life of the system.

At the Barton Center, conduits were placed 30 feet apart, as compared to

50 to 60 feet apart for a drainage-only system. Stop log boxes are arranged to permit the restriction of water flow, monitor irrigation and allow well water to be added and dispersed throughout the system by gravity flow. The centrepiece of the irrigation pumping system is a solar panel array having the capacity to pump 70 gal min-1 (265 liter min-1) during the daytime, with additional conventional wells added to provide water when solar pumping alone doesn’t fully supply crop water needs.

“The site is managed with a dormant season cover crop with controlled drainage during the winter and subsurface irrigation during the growing season,” Nussbaum says, adding that in most years, managers add an average of five inches of subirrigation water, representing a 50 percent water savings when compared to typical surface irrigation in the

region.

“The issue with surface irrigation is that you have some water loss during the application process as well as more evaporation from the wet soil surface over the next couple of days,” Nussbaum says. “In our conventional irrigation, typically just over half of applied water is lost to evaporation; the rest is actually used by the plant.”

However, when producers irrigate from below, the surface remains dry, while at 18 to 24 inches, the plant has all the water it needs. “There is zero percent water loss during application to run off and evaporation,” Nussbaum says.

The next step for researchers was to see how much they could reduce nutrient losses, particularly nitrogen, with various practices. Practices being tested include precision fertilizer application, cover crops and adding a bioreactor to the DWM system.

“The bioreactor was installed with the purpose of treating the drainage water for excess nitrogen in an economical manner,” Nussbaum says. He explains that a total of 27 acres drains through the wood chip denitrification bioreactor.

“The bioreactor is connected to tile drainage outlets,” says Dr. Michael Aide, chair of the university’s department of agriculture. “The denitrification bioreactor receives discharge water containing nitrates. In the denitrification bioreactor, bacteria convert the nitrate into nitrogen gas, thus water

A second bioreactor is planned. It will be a mirror image of the existing one and will provide additional research opportunities.

leaving the denitrification bioreactor has typically much less than 10 ppm NO3-N.”

That is exciting news considering the U.S. Public Health Service suggests 10 ppm, or 10 milligrams per litre, of nitrate-nitrogen as the maximum for safe human drinking water.

“The denitrification bioreactor has received a year’s worth of drainage water wherein approximately 70 to 90 percent of the nitrate load has been converted to harmless nitrogen gas,” Aide says. “We are planning on construction of a second bioreactor.”

The second bioreactor will be a mirror image of the existing one and will provide researchers with an opportunity to see how cover crops and precision application of nitrogen, combined with DWM and bioreactors, can reduce nitrogen losses even further in a variety of crops and settings.

Other emerging research explores the water savings subirrigators experience compared to typical surface irrigation. To this end, another project slated for this year at the university is the construction of a water storage reservoir to store dormant excess season drainage water from a 20-acre portion of the research farm. The excess water will be used to subirrigate the same area the following year.

The combination of the DWM and reservoir will provide full irrigation without ever using aquifer or surface water. “It will be a self-contained loop,” Nussbaum says.

This has major implications for the environment.

“Nitrogen losses via drainage water will be drastically reduced because most years little tile water will leave the field, and the field will no longer draw upon aquifer water for subirrigation.”

“When the economics of the total drainage management system, including subirrigation, are better quantified here and elsewhere, I believe it will show that there is a great opportunity for the installation of similar systems and that is a big plus for the drainage industry,” Nussbaum says.

“There is tremendous opportunity in DWM to add cover crop management, subirrigation and reduced off-site nutrient losses to traditional aspects of drainage.”

Aide says this edge-of-field technology has the potential to substantially reduce agriculture nitrate migration to surface fresh water supplies.

“This technology, where appropriately applied, may become a large piece of the North American environmental issue associated with fresh water eutrophication,” Aide says, explaining that when combined with appropriate fertilization practices, riparian buffers and cover crops, this technology, “will likely solve, to a compelling extent, water quality issues across North America.”

The drainage industry can be an important part of the

process.

“More and more farmers want to drain, but they also want to see if they can irrigate in the summertime,” Nussbaum says. “They want quality drainage, subirrigation capabilities and to raise better crops on wet soils. If they install a DWM system, they are better able to do all three.”

From a business perspective, it’s good news for drainage contractors as well.

“It is almost the same process to drain as to add water,” Nussbaum says. “On many sites, it’s a short jump to change a drainage system into DWM and the odds are very high in those flatter areas that if they design with drainage and subirrigation it is going to be very profitable.”

He estimates that using one system for two compatible purposes – drainage and irrigation – will need about 30 to 50 percent more drain tile per acre.

“If drainage contractors install more product, that improves the economics of their businesses,” Nussbaum says. “At the same time, it gets more DWM systems installed, meaning producers can reduce nitrogen losses over more acres. Drainage water management works.” DC

DRAINAGE MANAGEMENT

CLOSED-LOOP MANAGEMENT

System combines tile drainage, reservoirs and controlled drainage with irrigation for effective water management.

Researchers at Agriculture and Agri-Food Canada (AAFC) have developed an innovative closed-loop water management recycling system that can offer farmers many benefits, including improved crop yields – but it may very well be another business opportunity for drainage contractors as well.

by TONY PALERMO

The system was developed at AAFC’s Greenhouse and Processing Crops Research Centre in Harrow, ON, and combines tile drainage, reservoir and controlled drainage with irrigation. It works by using strategically placed riser pipes, which can be installed on existing tile drainage systems, to prevent water from leaving the tile until it reaches a pre-determined level controlled by the farmer. The system is attached to a reservoir or artificial wetland to store excess water, which can then be returned to the field by using subsurface irrigation and/or drip irrigation during dry periods.

As Chin Tan, a water management and quality specialist with AAFC and the lead researcher for the system says, this new closed-loop water management system may very well be “a secret weapon for crop farmers.”

The team has also designed and developed a water quantity and quality data acquisition system for automated and remote monitoring of all surface and sub-surface tile drainage water in the fields.

“As water moves through the automated system, runoff volume, crop nutrient content and leached agrochemicals are continuously measured so that farmers can see — and, more importantly, explain — the differences

between water management practices and resulting yields,” Tan explains, adding that year round, 24 hours a day, seven days a week, every drop is captured and measured.

And, that’s where the new water management system really starts to show its economic and environmental benefits.

MANY BENEFITS FOR THE GROWER

Tan says part of the beauty of this closedloop water recycling technology is that it collects water from multiple sources and not just from rainfall, which has a higher rate of evaporation from reservoirs. Surface run-off and tile drainage water is added to precipitation already collected during the “off” growing and winter seasons which prevents the wetland-reservoirs from drying up.

Because the wetland-reservoir acts as a sink of sorts, the system also prevents leached agrochemicals, nutrients and even sediments from reaching neighbouring land, in turn preserving wildlife habitats.

This also means that any nutrients captured are kept in the system.

“This is not only good for crops, it is good for the environment,” Tan says. “Nutrients captured in the reservoir are returned to the crops which reduces the farmer’s need for

A Few Key Features:

• 350 HP Cummins QSM11 Engine

• Cab with Heat and Air

• Power Shift Transmission

• 7' Dual Hydrostat Drive, Tapered Digging Wheel

• Self-Leveling Wheel Up to 8 Degrees Left or Right

• Digging Wheel Pivot

A Few Key Features:

• 350 HP Cummins QSM11 Engine

• Power Shift Transmission

• 7' Dual Hydrostatic Drive, Tapered Digging Wheel

• Self-Leveling Wheel Up to 8 Degrees Left or Right

• Digging Wheel Pivot

• 36" Wide Conveyor-Bar Style Dirt Shield

A Few Key Features:

• 400 HP Cummins QSM11 Engine

• 175 Double Link Plow with Auto Self Leveling

• Enlarged Cab Design for Operator Comfort with Heat and Air

• Full Wrap Around Service Deck

• Lower Profile Hoods for Greater Visibilty

• Plow Depth Up to 6' Deep

• Easy Access Catwalk to Tile Feeder

Land Improvement Contractors of America

LICA has been serving contractors across the country for over 60 years, providing our members with the tools they need to “work smarter not harder ” Below are a few of our member benefits.

LICA Safety Management Plan

A comprehensive safety manual providing LICA members with recommended safe operating procedures and to outline techniques that are essential for the protection of the industry’s greatest asset “its people and equipment.”

The LICA Portal

Each LICA Contractor member has access to the Zywave Resource Library Log-in to your personalized LICA Portal & you can search for safety materials as well as a news feed tailored to your business

The LICA Portal Offers:

• OSHA Requirements

• Risk Mgmt Materials

• Property & Casualty Info and so much more

Petrocon Commodities Program

Not only a discount on oil lubricants and tires but a $2,500 savings on membership in the Petrocon Group!

For more information please contact:

National LICA

3080 Ogden Ave, Suite 300; Lisle, IL 60532

Phone: 630-548-1984 • Email: NLICA@aol.com www.LICANational.org

extra fertilizers. We estimate that this will contribute to a 25 to 50 percent reduction in nitrate loss.”

Improved water management results in better crop yields by reducing crop stress brought on by overwatering or drought conditions – so much so that research shows continuous closed-loop water recycling and management improves soybean yields by 50 percent, tomato yields by 40 percent and corn yields up to a whopping 95 percent. As Tan says, these results more than compensate for the land taken out of production for the reservoir.

“By learning how to save water for when it’s really needed, farmers will be able to take some of the guess work out of agriculture,” Tan says, “If farmers have water, they can have crop yield stability.”

Tan points to Dave Epp, a Leamington, ON, based tomato farmer with whom Tan has been working closely for approximately 20 years. He says by incorporating a reservoir closed-loop system, Epp has been able to increase yields to 50 tons per acre, which is significantly higher than the area’s average production level.

SYSTEM HAS BEEN WELL RECEIVED

Tan says the system has been well received when presented at various international conferences, including at the International Conference on Environmental Indicators in Windsor, ON, this past August.

For high-valued cash crops, Tan believes this water management system can achieve both economic and environmental benefits within short periods without government incentive; however, with field crop production, he cautions it would take relatively long periods to achieve economic benefit.

“To ensure large-scale implementation of this new water management system, the initial government incentive and/ or regulatory instruments can definitely help agricultural producers to adopt the new system to achieve both economic and environmental benefits,” Tan explains.

He also says this water management system performs best under relatively flat agricultural drained lands. In high slope areas, more modified control structures are needed to ensure the effectiveness of the water management system, resulting in a greater cost to producers looking to implement the system.

Because drainage contractors are familiar with different soil types and farming and draining practices, Tan says they are well equipped to offer advice to farmers looking to install such a system and improve their operation’s profitability and environmental performance.

TILE PLACEMENT

Tan says the soils in southwestern Ontario are mainly heavy textured clays. Using the Ontario Handbook of Drainage Principles to optimize water removal and determine tile depth, Tan says tiles are generally placed between 0.6 to 0.7 meters (two to 2.3 feet) in Ontario, compared to 1.2 to 1.5 meters (3.9 to 4.9 feet) in areas around the U.S. border in the Great Lakes Regions. As a result, drainage control levels in southwestern Ontario can be raised by only a modest amount, generally up to 0.15 meters (0.49 feet). Tiles around

This controlled drainage sub-irrigation water management system performs best under relatively flat agricultural drained lands.

Researchers at Agriculture and AgriFood Canada (AAFC) have developed an innovative closed-loop water management recycling system that combines tile drainage, reservoir and controlled drainage with irrigation.

the U.S. border in the Great Lakes Regions can raise their drainage control level by up to 0.45 meters (1.5 feet).

Tan says the results of on-farm scale trials in Ontario indicate that drainage control can reduce nitrogen and phosphorus losses between 25 and 45 percent during the non-growing season; in the U.S. border area around the Great Lakes Regions, drainage control can reduce phosphorus losses anywhere from 40 to 65

The Greenhouse and Processing Crops Research Centre’s instrumentation building houses 32 automatic samplers, used for analyzing collected run-off and drainage water.

percent during the winter months.

As long as the agriculture lands rely on the practices of drainage, Tan says the closed-loop water management system can be applied on a large-scale across Canada and the United States. DC

Looking for more on drainage management? Visit www.drainagecontractor.com.

CONTRACTOR AT WORK

Continued from page 18

Bower Tiling Service to head up Great Lakes Inter-Drain; Jack remained at the helm of Bower Tiling Service.

That arrangement stood until earlier this year, when both Jack and Tom decided to retire from their businesses. The brothers have handed the reins of their companies over to Jack’s daughter, Wendy Jett, and her husband, Jim. The Jetts, who were already involved in the day-to-day of Bower Tiling Service, bought Great Lakes Inter-Drain over the summer. They were in the middle of the ownership transition in late August, when they spoke with Drainage Contractor.

Wendy expects the move will be good for both businesses. For Great Lakes Inter-Drain customers, the change in ownership will mean purchasing parts and equipment from a fellow contractor wrestling with the same opportunities and challenges they’re facing in their own businesses – one who’s also in the field working with the same equipment it sells and services.

Merging the two companies is also expected to bring benefits for Bower Tiling. “It will give us something to do in the winter when we’re frozen out,” Wendy says. “We’ll have the parts and the machine sales to focus on.”

“The last two winters and springs have been the worst in a long time, and that affects our business because we can’t get out there and get anything done,” she adds. “That puts our log behind; we’re always playing catch up.”

Purchasing an Inter-Drain 2040 GP a little over a year ago has helped make up lost time when the weather wreaks havoc on their plans. The company also operates an Inter-Drain 2050 GT and an InterDrain 2028 trencher.

Wendy expects this equipment will be put to good use soon, as construction gets underway on three natural gas pipelines planned to be built in Ohio. The Rover, Nexus and Utopia pipelines are expected to disrupt the existing tile systems of a number of landowners in the area. These drainage systems will have to be patched up and re-routed around the new pipelines. With work on the pipelines set to begin next year, Bower Tiling is taking a “wait and see” approach to the anticipated up-tick in demand for their

services.

“We’ll have to see as the work comes in what we’re going to have to do, and whether we’re going to have to hire more people,” Wendy says. Any new staff will very much be getting in on a family affair. Current staff include Wendy’s aunt and uncle, Michelle and Joe Picciuto, and her brother, Jay. As well, a fifth generation, that includes

Wendy’s two teenaged sons and her nephew, work for Bower Tiling. And even though he’s supposed to be enjoying his retirement now, Wendy says her father is still very much a part of the business. In the weeks after the Jetts acquired Great Lakes Inter-Drain, Jack and his daughter continued to work together, getting parts packaged and shipped to customers. DC

DRAINAGE DONE RIGHT. DONE ONCE.

With nearly a century of experience behind them, Fratco products stand the test of time. Our pipe is engineered to a quality level that exceeds specifications. An investment in Fratco pipe means you can tile your field and never think about it again.

Call it “green” or call it “cost effective”, just don’t call it weak. Our highly engineered HDPE pipe is designed and tested to the same high standards.

For less demanding projects consider our 100% recycled TruFlo pipes. Call our expert staff today to see if the TruFlo pipe might be a good fit.

END OF AN ERA

Wideman’s Farm Drainage performs what could be the last clay tile installation in North America.

Under overcast September skies, David Wideman of Wideman’s Farm Drainage marked the end of an era, laying what he believes to be the last clay drainage tile to be installed in Canada.

by BRANDI COWEN

Near as Paisley Brick & Tile Co. Ltd.’s J. Doug Seiler can figure, his company manufactured the four-inch tile about six years ago. At the time, Paisley Brick & Tile was the last producer of clay tile in the province; plastic had already risen to dominance in the agricultural drainage market. Seiler says the tile would have been made from shale clay, dug from deep in the earth and trucked from Georgetown, ON to the manufacturing plant in Paisley, ON From there, the tile was purchased by Terence Laird to drain his farm in Thedford, ON.

But after Laird passed away in 2011, 32 pallets of tile were set aside as estate assets. In the intervening years, while Laird’s estate was settled, the tile sat out exposed to the

elements. Then, earlier this year, with the summer’s harvest out of the ground and fall planting set to soon get underway, that tile finally found its way into the soil.

In mid-September, Wideman returned to the same field where he’d last installed clay tile in order to finish the job: installing the remaining tile about 2.5 feet down; mains were laid an extra few inches lower.

“The laws that govern us guys, they want two feet of cover on the tile at all times so that way, to accommodate for four-inch tile, you go two-and-a-half feet deep,” Wideman explains. “With any mains, we set our minimum to at least three feet, if you can, so that it’s out of the way and you can slip over it.”

“In the last 25 to 30 years, we had better facilities to fire the tile, and tighter tolerance on quality control. It’s as simple as that.”

– J. Doug Seiler

Although the installation was a little different because of dealing with clay rather than plastic tile, Wideman adjusted easily. “You need more help with clay, but clay’s fast,” he says. “We usually worked with three to four men and they did everything. You run the machine, you have somebody put tile in and then somebody would bring tile or load tile and he could backfill and do the blinding too.”

There was no shortage of helping hands on the day Drainage Contractor visited the work site. Laird’s son, Robert, who now owns the farm, was very hands-on, loading the tile while Wideman drove.

“Dave is the guy to do the job,” Robert says. “He put in the last tile and he’s got the machine for it. He knows where the tile is in the field better than I do, that’s for sure.”

Robert’s brother and grandson were also on hand to pitch in on the installation. And so was Seiler, who was impressed by how well his product has stood up after so long above ground and exposed to the elements.

“In the last 25 to 30 years, we had better facilities to fire the tile, and tighter tolerance on quality control. It’s as simple as that,” Seiler says.

On the day Drainage Contractor visited the job site, the tile was performing at a 94 percent install rate (that is, 94 percent of the available tile was usable).

Although Wideman and Seiler agree that there’s almost certainly the odd pallet of clay tile stashed here and there, and perhaps some scattered tile stacked in the back corner of someone’s shed, they believe Laird’s farm will be the last in North America to be tiled largely with clay.

“Unless there’s a pallet in Ohio someplace, or some piled in a fence row, this is it,” Wideman says. “And that tile – it depends who made it, whether it survived the weather as well as this tile. That’s just a fact of life.”

Double Link Tile Plows

unfold, the North Dakota judge found that the states were “likely to succeed” in their legal challenge. Specifically, the court found that it was likely that “the EPA” had violated its Congressional grant of authority in issuing the rule and that it was likely that “the EPA” failed to comply with APA requirements when issuing the rule.

District courts in West Virginia and Georgia, although considering similar requests for a preliminary injunction from other states, denied those requests. Those courts did not address the merits of the lawsuits. Instead, the courts found that the federal circuit courts had original jurisdiction for these claims under 33 U.S.C. §1369(b)(1). The State of Georgia and 10 other states have appealed the Georgia district court’s ruling, arguing that the district court (and not the circuit court) is the proper court to consider the lawsuit. These states are asking the United States Court of Appeals for the Eleventh Circuit to send the case back to the district court for a speedy decision on the merits.

Most plaintiffs have also filed petitions for review in their respective circuit courts to preserve their claims if it is ultimately determined that only the circuit courts have jurisdiction to review the claims. All petitions for review

filed in the circuit courts have been consolidated in the United States Court of Appeals for the Sixth Circuit. To add even more complexity to this litigation quagmire, the agencies have sought to have all pending district court lawsuits transferred to the United States District Court for the District of Columbia for consolidated pretrial proceedings. The plaintiffs have argued that this multidistrict consolidation would deprive them of their choice of forum.

On Oct. 9, the United States Court of Appeals for the Sixth Circuit stayed the Clean Water Rule nationwide. This temporary ruling brings uniformity to the patchwork of enforcement that has existed since the rule’s Aug. 28 effective date. In several weeks, the same court will decide whether it has jurisdiction to decide the merits of the case. And on Oct. 13, the United States Judicial Panel on Multidistrict Litigation denied the agencies’ motion to centralize the cases in the United States District Court for the District of Columbia. This means that if the Sixth Circuit determines it does not have jurisdiction to hear these cases, the merits will be decided by the various district courts where the complaints were filed.

Although much uncertainty surrounds

the future of the rule, it is pretty clear that the barrage of litigation will continue into the foreseeable future. Several environmental groups have also challenged the rule in court, arguing that the rule does not go far enough in protecting the nation’s waterways.

Legislative efforts to vacate the rule have also been initiated. In May, the House of Representatives voted to force the agencies to withdraw the rule. A similar bill is pending in the Senate.

On Sept.17, 47 Senators – led by Iowa Senator Joni Ernst – signed a resolution to “disapprove” the rule and block its implementation. Iowa Senator Charles Grassley also signed the resolution. In a statement accompanying the release of the resolution, Ernst said, “This illconceived rule ignores the thoughtful comments and serious concerns raised by farmers, ranchers, manufacturers and small businesses across the country.” The EPA continues to assert that the rule merely eliminates confusion and that “normal farming practices” continue to be exempt.

One thing is certain: the rule has definitely caused waves. “Tsunami” may be the more appropriate description. We will keep you posted. DC

CALT does not provide legal advice. Any information provided in this article is not intended to be a substitute for legal services from a competent professional. CALT’s work is supported by fee-based seminars and generous private gifts. Any opinions, findings, conclusions or recommendations expressed in the material contained in this article do not necessarily reflect the views of Iowa State University. For more information about CALT, visit http://www.calt.iastate.edu/.

•Oscillating tracks

•Wider cab model

•Variable

•Quick change teeth (reversible)

•Tubing chutes up to 16 inch

•GPS or Laser Guidance

Surface Water Intakes

• 8” & 10” riser with patented 8" & 10" combination Tees.

Also 6” square & round risers with patented reducing Tee.

• Constructed of heavy-weight, high-density polyethylene.

• Parts highly adjustable & interchangeable with others on the market

• Orifice plate placed at tee level or at ground level.

• Exclusive locking device on each part. • User Friendly-Priced effectively.

EVENTS

OHIO LICA

Jan. 4-6, 2015

Embassy Suites Dublin, OH

MINNESOTA LICA

Jan. 6-8, 2016

Best Western New Ulm, MN

IOWA LICA

Jan. 10-12, 2016

Airport Holiday Inn Des Moines, IA

SOUTH DAKOTA LICA

Jan. 11-13, 2016

Rushmore Plaza

Holiday Inn Rapid City, SD

LICO

Jan. 20-21, 2016

Best Western Lamplighter Inn London, ON

MISSOURI LICA

Jan. 21-23, 2016

Hilton Garden Inn Columbia, MO

INDIANA

LICA

Jan. 27-29, 2016 Marriott East Indianapolis, IN

KANSAS

LICA

Jan. 31 – Feb. 1, 2016 Capitol Plaza Hotel Topeka, KS

• Adaptor available to repair old metal or broken intakes.

Why inventory 2, when 1 serves both!

“Dealer Inquiries Welcome”

PRECISION INTAKES

Norm & Coretha Rozendaal 2064 Republic Ave West Monroe, IA 50170

(800) 932-7611 (641) 259-2651 (641) 259-3218 Fax

NEW YORK LICA

Jan. 12-14, 2016

Ramada Lakefront Geneva, NY

ILLINOIS

LICA

Jan. 14-16, 2016

Embassy Suites East Peoria, IL

NEBRASKA

LICA

Jan. 19-21, 2016

Holiday Inn Convention Center Kearney, NB

NATIONAL LICA WINTER CONVENTION

March 1-6, 2016

Drury Plaza Hotel Riverwalk San Antonio, TX

NEW JERSEY LICA

March 20-21, 2016 Holiday Inn Clinton, NJ

2016 NATIONAL LICA SUMMER MEETING

July 18-23, 2016

Intercontinental Kansas City at the Plaza Kansas City, MO

SUBMIT YOUR EVENT

Drainage Contractor also welcomes additions to our new online listing of coming events.

To ensure publication at least one month prior to the event, please send your event information at least six weeks in advance to: Drainage Contractor, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON, N3Y 4N5.

You can also submit events via email to scroley@annexweb. com or by fax to 888-404-1129.

Please write “Event Submission” in the subject line.

NEW PRODUCTS

WARTHOG FLOATING PUMP FROM AGRI DRAIN

The Agri Drain Warthog floating pump is a rugged, highly efficient pump assembled in the United States. It pumps water at a rate of 850 gallonsper-minute for fast, efficient water removal or retrieval. The pump weighs approximately 85 pounds, allowing for one-person setup and use. With the optional auxiliary fuel tank, you can increase the typical run-time from around one hour up to approximately 12 to 15 hours between refueling intervals. Just set it in the water, roll out the hose, pull the cord, and walk away.

The Warthog floating pump can be used for water removal as well as supplying water from a remote source. The pump’s 400-foot hose can move water from a flooded area or take water from a water source and supply it to an area where it is urgently needed.

The pump can be used in a number of applications including flood relief and irrigation. In agricultural applications, the pump can be used to drain low spots in the spring for earlier planting or to irrigate areas further away from the water source.

The floating design of the pump draws water from just

under the surface, drawing cleaner water, avoiding surface debris, and not stirring up debris underneath the pump. The innovative design of the pump takes in water while keeping large debris out, eliminating the need for a filter. The Warthog floating pump also boasts very low emissions.

www.agridrain.com

DRILL PERFORATORS FROM CORMA

With a highly versatile design and line speeds of up to 115 feet per minute, the Corma HSC Series 2 perforator can be configured for on-line perforation of a variety of corrugated pipes, including: single/double wall; HDPE/ PP/PVC material; and with/ without in-line coupling.

The HSC Series 2 is adjustable for pipe diameters ranging from two to eight inches for the Model 600

and four to 16 inches for the Model 1200, complying with slot perforation requirements under the AASHTO M252 specifications. As an added benefit, a material savings of up to two percent can be recovered by recycling the perforations.

For larger pipes up to 72 inches in diameter, Corma produces the drill perforator to make circular holes instead of slots. Drill cutters can be equipped instead of

NEW PRODUCTS

traditional blades for larger pipe in order to meet the requirements of the AASHTO M294 drainage specifications.

www.corma.com

TR450 WHEEL TRENCHER FROM BRON

The Bron TR450 wheel trencher is designed with the power and strength to easily dig in even the toughest rocky soil types. The TR450 wheel trencher powers through up to 8.5 feet of earth, leaving smooth-walled 40 to 50 inch wide trenches in its wake.

The TR450 is the perfect tool for digging trenches to accommodate simultaneous mechanized laying for the construction of various infrastructures, including drainage, plus

water, gas, sewerage, and telecommunication in rural and urban areas. Trenches will always have the same width and depth, and spoil piles are easily distributed where needed to optimize backfilling post-installation.

The machine is highly ergonomic with wheel controls mounted on the high-back swivel chair, pivoting with the seat as the operator navigates and monitors the job at hand.

www.rwfbron.com

THE SHELTON CT150 AGRICULTURAL CHAIN TRENCHER

The CT150 Agricultural Chain Trencher from Shelton Sportsturf Drainage Ltd. is a tractor mounted chain trencher with the laser grading accuracy of a self-propelled trencher but without the hefty price tag.

The trencher requires a 150-200 hp tractor with vario transmission or a creep speed gearbox for speeds down to 0.3 km per hour. The machine has a maximum digging depth of up to five feet. It can use

laser grading to evenly install drainage tiles on agricultural land to give longevity and efficiency to a drainage system. The machine is easy to operate so you can carry out drainage work during optimum trenching conditions for the best results.

The trench depth is controlled hydraulically from the tractor cab and the tile layer lifts out of the ground for easy setting in at the start of the trench. The tile is placed onto the trench bottom automatically through the tile layer, which is fed from the tile reel. The digging chain is driven from the tractor PTO. Twin augers on either side of the digging chain move the soil to the edge of the

trench so that it can be bladed back in after the addition of aggregate, if required. The augers can be winched out of the way when setting in at ditches to minimize any damage to banks.

A laser control system can be added for greater accuracy of grading and extra tile layers for larger diameter tiles can also be fitted as optional extras as required.

All U.S. sales are through Shelton’s U.S. agents, Port Industries.

www.sheltonsdrainage.com

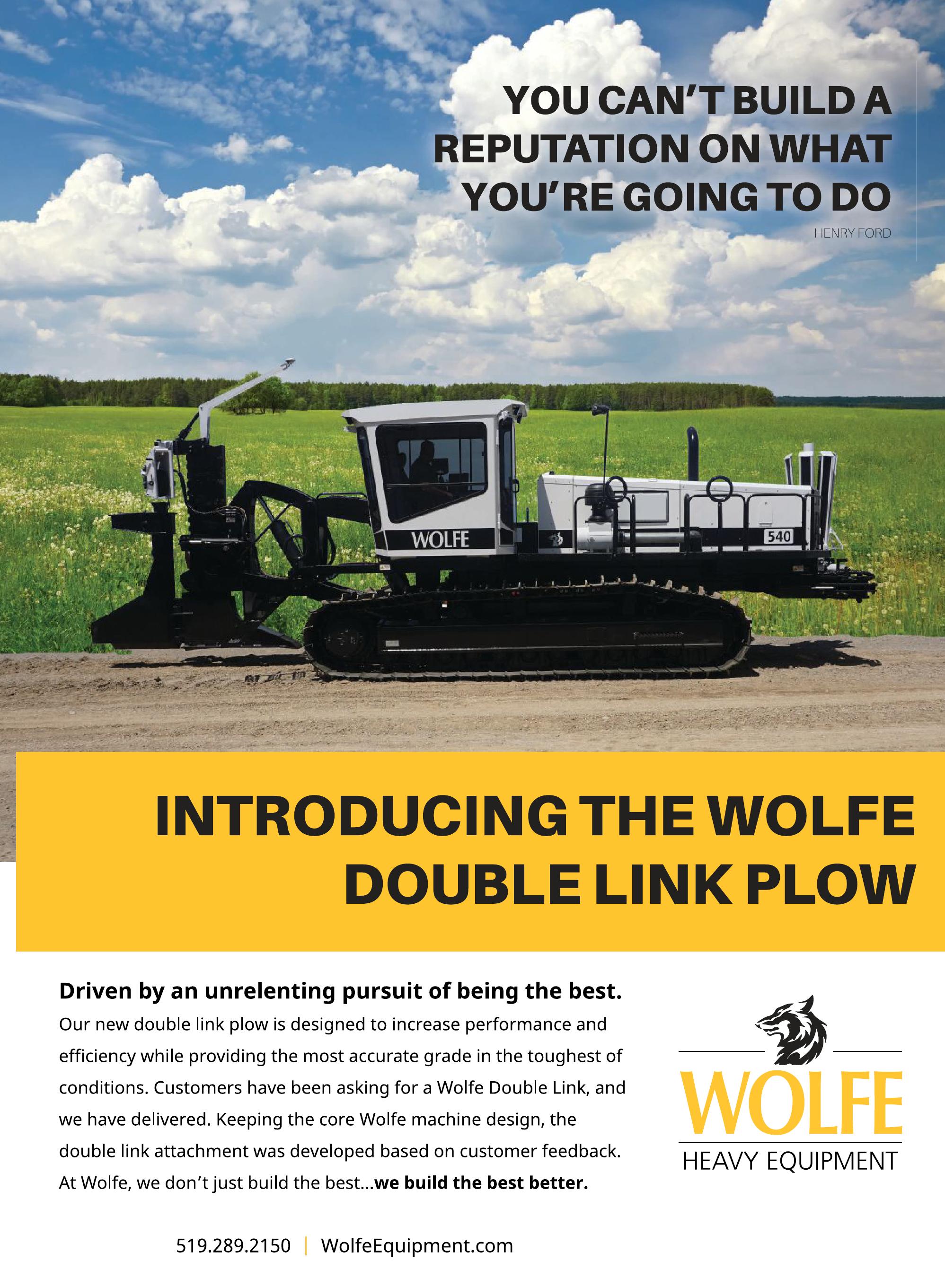

NEW DOUBLE LINK PLOW FROM WOLFE

The Wolfe Double Link Plow is the newest addition to the

company’s line of drainage plows. The plow is designed to increase performance and efficiency while providing the most accurate grade in the toughest conditions.

Wolfe developed the double link plow with engineering enhancements that increase fuel efficiency and machine durability, simplify maintenance and promote operator safety. The plow features the highest ground clearance in the industry with state-of-the art Plus 1 Electronic Over Hydraulic Control System with complete machine monitoring, diagnostics and feedback to protect the machine for the long term.

The double link plow comes pre-wired for GPS

Auto Steer, which allows for the fastest processing time in the industry. This system will quickly, efficiently and accurately control the Auto Steer, as well as the grade and pitch control.

www.wolfeequipment.com

VERSATILE WATER CONTROL STRUCTURE

The Nyloplast Water Control Structure from Advanced Drainage Systems, Inc. (ADS) provides a best management practice (BMP) to manage water levels in many applications.

The structure is designed to allow timely drainage to maximize crop development or wetland control and therefore improves water