LICO VISITS THE HOLLAND MARSH

On July 15, 36 participants joined the LICO-sponsored summer tour to see the Holland Marsh Drainage System Canal Improvement Project.

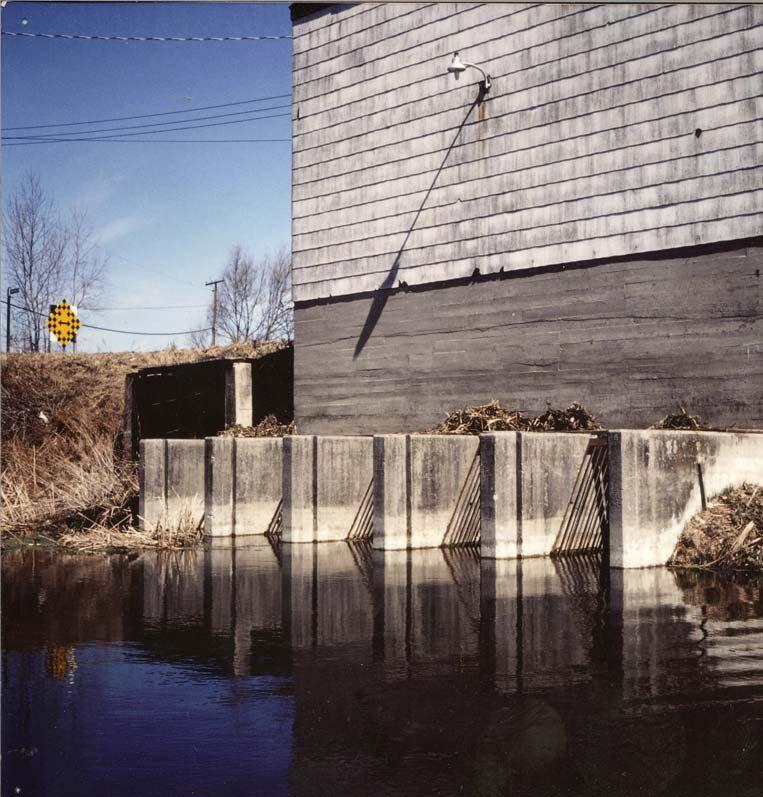

The tour by bus was hosted by Frank Jonkman, drainage superintendent for Bradford-West Gwillimbury. Frank started with a history of the Holland Marsh, explaining how the 28 kilometres of canals and dykes were first built around the perimeter of the marsh in the 1920s to allow for the reclaiming of 3,000 hectares of marshlands for farming and to protect the area from flooding from the surrounding watershed. In 1954, the heavy rains of Hurricane Hazel breached the dykes and flooded the entire area to a depth of up to 10 metres. Following the flooding, a major cleanout was completed and the dykes were rebuilt and raised.

Over the next 50 years, the system steadily deteriorated. The canal filled in and was only providing protection for a 25-year return storm. The dykes, which were built of the high organic spoil taken from the canals, subsided as much as one meter, leaving the road on top very rough. Finally, with little separation between the canal and the road, many accidents and several drownings occurred as cars drove into the canal.

A cleanout was proposed to address these problems, as well as to enhance the habitat for the fish, animals and plants living in and next to the canal. Starting with the engineers’ report in 2003, it has become the largest project under the Drainage Act at an estimated cost of $26 million, with assessments made to 9,000 landowners on 25,000 hectares of land in the watershed.

We were able to se how the canal was deepened but also relocated to leave a wide buffer area between it and the road. The

cross-section had a shallow bench on one side (littoral shelf) to allow for the establishment of aquatic plants and animal life. Gravel beds, root masses and tree trunks were included for fish habitat and spawning. The new roadbed was made of excavated materials from Toronto construction sites to reduce the subsidence problems. The canal or road or both were moved and separated to provide better protection for vehicular traffic.

We learned of a creative approach to the tethering process. Because of the unknowns for both the engineers and the contractors as to what the cleanout costs would be, the estimates in the report were set very high. Rather than go to

tender with these unknowns, it was decided to complete a pilot project involving 650 meters of canal. Four contractors were hired to each clean out a short section on a time and materials basis. It turned out that the construction difficulties were fewer than anticipated. With this experience, these contractors were able to submit bids 75 percent less than the engineer’s estimates, saving several million dollars. Furthermore, the project will be completed three years ahead of schedule.

LICO very much appreciates the time and efforts of Frank Jonkman and Sarah Murray for their time and effort in setting up and hosting the tour.

EDITORIAL FLASHBACK

History does repeat itself!

by Peter Lewington

Editor’s note: This article was originally published in the 1973 edition of Drainage Contractor, written by founding editor Peter Lewington.

Drainage technology has come of age with more innovations in recent years than in all previous history. Many astute farmers, having acquired additional land, ensure that the land drainage is good before they plant a crop. But, some farmers have yet to appreciate the profit that drainage can bring; The Ontario Select Committee On Land Drainage even found it necessary in 1973 to advocate additional drainage demonstrations. Despite instant electronic communications, the good news about drainage has taken a long time to percolate.

The Mesopotamians of 9,000 years ago were probably the first farmers to appreciate the value of water management.

The Romans, before the birth of Chris, knew that poor drainage meant poor crops; they left behind them evidence of open and covered stone and clay tile drains.

But somehow, the world forgot about drainage benefits until the subject was revived by the initiative of the British parliament in the 18th century.

The “Rudimentary Treatise On The Drainage Of Lands” published in 1854 describes drainage as “A new branch of practical art, based upon principles of science and essential to the health, life and morality of our race.”

The author well understood the relationship of drainage affected, not only root development but also crop yields. He warned that vermin could destroy drain outlets and recorded the essential specifications for successful drainage systems.

“The Canadian Home, Farm and Business Cyclopedia,” published long before the prairie provinces became a part of Canada, had sound advice which is relevant today. The authors, writing when only a fraction of Canada had been developed for agriculture, advocated environmentcontrolled livestock buildings, hospital pens for sick animals and even advice on handling liquid manure.

The authors noted the depth and intervals between tile drains that are desirable in various soil types; they dwelt on the function of laterals, mains and drainage outlets.

And if you have wasted time hunting for a drain, remember this advice, given the better part of a century ago: “On the completion of every kind of drainage works, means should at once be taken to have the lines of drains accurately laid down upon a plan, having a scale of not less than 100 feet to the inch. The plans connected with each farm ought to be bound up as a book of reference.”

The Cycolopedia’s “Practical benefits due to land drainage” are so appropriate today they could have been written yesterday. Effective drainage means not only an earlier harvest but a more abundant harvest. Good drainage makes it possible for timely tillage and the spreading of manure without compacting the land. Well-drained soils produce better quality crops and give a wider choice of crops.

The way in which drainage improves soil aeration and the ways in which this benefits crops in diverse seasons were included in this formidable list of drainage benefits. These benefits also included better germination, which reduced the amount of seed required.

Your own checklist of drainage benefits might include aeration of the soil, the paradox that drains are beneficial in both wet and dry years, the relationship of drains to tillage, evenripening and winter survival of such crops as alfalfa.

History does indeed repeat itself; the world learned the lessons of drainage, forgot them – only to learn them afresh. With the delicate balance between population and food supplies, the world of the latter part of the 20th century must seize all of the benefits that drainage brings to both productive soils – and some currently unprofitable soils. DC

ONTARIO DRAINAGE CONTRACTORS LICENCED

1973 – On April 2, 1973, tile drainage installation moved a big step closer to becoming a professional, highly regulated business.

The Agricultural Tile Drainage Installation Act, 1972, states that licences are required to install drainage work or operate a machine used in installation. The Act is administered by the Director of the Agricultural and Horticultural Societies Branch of the Ontario Ministry of Agriculture and Food, Parliament Buildings, Toronto, Ontario M7A 1A9.

The legislation was developed on the initiative of the Ontario Farm Drainage Association; the association’s secretary, Bill Amos, says, “There were isolated instances of workmanship which was below par.

“Earlier, we found it was unsatisfactory for members to endeavour to enforce standards; we would become subject to lawsuits, without accomplishing our objectives.

With the big increase in drainage work, there had been an influx of unqualified contractors. The Act provides protection for farmers and will benefit the entire industry.

While Ontario is the only province that requires contractor licencing, the Act does not break entirely new ground. In 1919 the Ontario Government announced a program of certifying operators of drainage equipment. Subsequently, some 30 certificates were issued before certification scheme lapsed in 1931.

The current legislation is sprinkled with words like “inspector,” “licencing,” “review board,” “offense” and “summary conviction.” But for all that, it is not a restrictive piece of legislation.

Any contractor now in business is given an opportunity to complete a series of three licence

SENSOR FOR MACHINE CONTROL

applications. These are for a licence to install drainage works, a licence for the machine or machines to be used and a licence for each operator.

The licence fee for an operator is $5; contractors’ licences range from $35 for annual installations of not more than 300,000 feet and $50 for installations in excess of that amount. Most machine licences are $100. Fees of $5 are chargers for operators’ examinations or for changes in licences or operators’ categories.

There are three categories for operators. Class A rating is for people with practical experience and appropriate education who exhibit competence. Class B operators have less rigorous qualifications, while the Class C operators are trainees.

Licences can be refused on several grounds, including a lack of competence, the applicant’s record of performance or a lack of satisfactory equipment.

The director has sweeping powers to refuse renewal of licences or revoke existing licences. The Act gives the minister authority to appoint one or more inspectors; contravention of provisions of either the Act or the Regulations on the Act could lead to fines of $25 for first offences and up to $100 for subsequent offences.

So far, anyone who applied for a licence received one, one inspector has been appointed and no charges have been laid. This moderate approach appears to have been taken to give the industry an opportunity to police itself. However, the system of licensing and the incentive for operators to acquire an A or B licence, in preference to a C licence, should upgrade expertise.

If Ontario farmers suspect that they have received substandard drainage work, a mechanism now exists for objective investigation by an independent third party, backed by the authority of the provincial government.

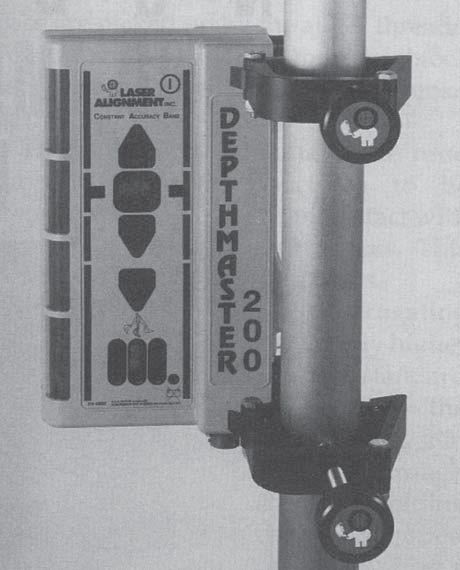

1996 – Laser Alignment has launched a new machine control sensor, the DepthMaster-200. This new sensor is lightweight, portable and is battery operated. CAB, or Constant Accuracy Band, is Laser Alignment’s method of assuring constant accuracy with changes in distance, environment and laser transmitter or rotation speed. The Depth-Master-CAB technology averages the laser spot size and assures consistent accuracy in all conditions. Additional features include: over 48 hours of on-board rechargeable Ni-Cad battery operation; low battery light indication when six hours remain in battery life, shake to wake function, where the unit shuts down all nonessential electronics after five minutes of non-use. The movement of the machine restarts the DepthMaster. Additionally, after one and a half hours of non-use, the unit shuts off completely, saving battery life; and front and back display allows for easy viewing from all angles.

DRAINAGE CONTRACTOR WORKSHOP NUMBERS RISE

June 1980 – The 1979 Drainage Contractor Workshop proved to be more successful still than the previous year, with more than 250 delegates attending the event last December in Indianapolis. Unusually good digging conditions at the time prevented many other contractors, some of whom had pre-registered, from attending. But those who came were not disappointed and found that lost work more than compensated for new ideas to increase business and profitability.

Once again, the contractors came from all over North America, and one contractor came all the way from France. Most delegates were from the Midwest states and Ontario, however, with a large proportion returning for the second year. Further growth is expected for the 1980 event.

A highlight at the second workshop was again Gordon Spoor, who returned by popular demand following his down-to-earth approach in discussing soils. A very interesting panel discussion was held on the role of drainage as a pollution control measure, and inspirational speaker Chris Christianson was well received by the group at dinner.

As this issue goes to press, plans for the 1980 Drainage Contractor Workshop are well advanced; a brochure has already been produced and mailed and already the bookings have started to come in. Over 350 delegates are expected at the third Drainage Contractor workshop, which will be held at the Sheraton West Hotel in Indianapolis from Dec. 14 through Dec. 16.

At this year’s event, the keynote speaker will be a contractor, Len Frey. The presentation will feature theoretical and practical seminars on trenchless plows of all types, a panel discussion of licensing and certification in the United States and Canada and, very topical, a top-grade drainage oriented talk entitled “Knowing your costs and setting your prices.”

FULL MARKS TO MICHIGAN LICA

1977 – Efficiency was the keynote at St. Charles, Mich., where more than 2,000 visitors saw 30,000 feet of tile installed on the 30-acre demonstration site.

The event was organized by the Michigan chapter of LICA, with Orville Howe of St. Charles as work superintendent and his wife Rose playing a prominent

From France, Dan Andries represented Fournier Drainage S/A, one of the world’s biggest contractors.

role in the background. Professor E. Kidder, of Michigan State University, introduced each of the 20 machines and explained their major features before each run.

Working demonstrations have certainly become big attractions and the considerable organizational ability of Michigan LICA in running the St. Charles show is to be highly commended.

Company on the move

Since 1984 the name Tesmec has been synonymous with quality in the high performance oil & gas pipeline trenching industry. After achieving market leadership, diversification of the product line was important to continue to grow the company. The expertise and quality associated with its high performance trenchers lent Tesmec the opportunity to enter the Farm Drainage segment.

How does a manufacturer from Texas decide to enter the Farm Drainage market, you ask? Hiring a National Sales Manager from the heart of the Corn Belt in Indiana was a start. Also, having expertise in designing durable, highly productive, easy-to-use, trenching machines capable of handling rugged material was imperative. With those qualifications in check and a familiarity with the market, Tesmec launched into the business with their first Farm Drainage specific machines. The new 775DT series

terrains. Jobsite reports have indicated productivity rates up to 55 ft/min. The significant strength of its frame makes the 775DT suitable to be utilized in highly fractured loose materials, highly compacted soils, and permafrost. Both 775DTs weigh less than 47,000 lbs. The all new 775DT Chainsaw is designed for a maximum dig depth of 8’ with a maximum cut width of 24”, while the all new 775DT Bucket Wheel is designed for a maximum dig depth of 6’ 6” with a maximum cut width of 30”.

Both machines feature a CAT 6.6L 225 H.P. diesel engine and are designed around Tesmec’s Trench Tronic control system, providing maximum productivity whether your operator has 15 years or 15 days of experience. The closed loop hydraulic transmission and the exclusive Tesmec flywheel gearbox allow the 775DT to transmit the full power delivered by the CAT engine.

To complement the DT series machines, Tesmec is proud to announce the Gallmac TG series multipurpose wheeled excavator. Gallmac is available in three models with corresponding weights of 22,000-24,000-28,000 lbs.

These machines bring a whole new meaning to the term maneuverability. They are road capable and cruise at speeds above 20 mph, allowing the operator to save time and money moving among various jobsites without having to load and transport the machine via truck. They also have three steering modes (Rear Wheel, Four Wheel, and Crab) allowing the operator to work in tight areas and also move laterally.

Along with being highly maneuverable, the Gallmac has unlimited attachments available, giving this machine the ability to replace several machines by performing multiple tasks. The hydraulic coupler allows the operator to change attachments without leaving the cab. Hydraulic downriggers increase the stability of the machine while performing heavy load tasks.

The DT series trenchers and the Gallmac TG series excavators are big steps forward in offering drainage contractors a complete line of solutions to their everyday challenges; however, there is more to come. Currently Tesmec has in production an FBK Ladder Trenching Machine. This machine will reach digging depths of 14’ 60” wide! This is being built specifically for contractors needing to install main lines at extreme depths. A selfcontained plow will round out the product line in 2014.

is available in both a Chainsaw and a Bucket Wheel configuration.

Due to its low ground pressure and high floatation, the 775DT yields high performance and productivity in various

Tesmec is a proud National Associate Member of LICA, Indiana LICA, and Illinois LICA and looks forward to serving this exciting industry.

The 775 DT farm drainage series features these advantages:

High performance and productivity in both soft and wet terrains (up to 55 ft/min)

Reduced weight (below 47,000 lb-21,000 kg), thus ease of transport

Max cut depth of 8’ (Chain) and 6’6’’ (Bucket)

Max cut width of 24’’ (Chain) and 30’’ (Bucket)

High floatation 31.5’’ tracks

Shiftable conveyors

ROPS cabs

Flywheel gearbox can deploy a peak torque up to three times the torque delivered by a hydraulic motor.

For more information, please contact:

Nate Miller - 775DT/GALLMAC Regional Sales Manager nmiller@tesmec.com or (817)666-9150

Bryan Blankenship - National Sales Manager bblankenship@tesmec.com or (817)559-2958

Where do we go from here?

Predicting the future of the drainage industry.

by Lowell Kraft Editor’s note:

This article was originally published in the 1977 edition of Drainage Contractor magazine.

Forecasting is a risky business and more than a few reputations have been tarnished while looking into the future. Nevertheless, I’ve been asked to give my views in answer to the question, “Where do we go from here in regard to drainage machinery?”

I feel that the question should be answered in two steps. The first addressing the near future, and the second step covering some time down the road.

In the near future, all drainage machines will be equipped with roll-over protection devices for operator safety. Very few are today. In addition, the roll-over protection devices will incorporate enclosed air-conditioned cabs and other operator conveniences, such as a public address system to enable the operator to give directions to the ground support personnel.

Hydrostatics are going to play an important part in the future design of drainage machines. Already incorporated on many machines, their use is going to be expanded even more. Today, few manufacturers attempt to use them for the power train to the digging mechanism, partly because they are unable to cope with shock loads.

I believe engineers will soon overcome this problem, and when they do, there will be a marriage between the digging and traction hydrostatics.

Traction governors will be installed that will automatically advance or retard the tractive speed to match the best digging speed, the best grade control ability and move the most dirt in the shortest period of time. Other improvements, such as the cleaning of the digging equipment, will also be developed to work more efficiently.

With the advent of hydrostatics in the power train for wheel and chain machines, it seems to me it would be a natural development to incorporate automatic sensing devices to change the wheel or chain travel speed to

match the variables of hard or soft ground, clay or sand, and dry or wet conditions.

To date, most contractors have experience based around a constant speed wheel or chain variable only by a full gear either faster or slower. Safety will be a major area for change. With the construction industry’s heavy emphasis on safety, legislation will call for all danger points, such as open chains and/or belt drives to be shielded. On wheel machines that are currently driven by partially guarded or exposed chains, there will be new designs to incorporate hydrostatics or designs will include power shafts that can be guarded adequately.

Taking a longer-range view of the safety efforts, I predict that the cutting equipment also will be shielded. This is not going to be an easy problem to solve. The safety ideas must also remain practical for the user. Think about the variable depths to which either a wheel or a chain machine digs, then picture some shielding that would protect the operator from the cutting equipment at all times. The shielding will have to be flexible and quickly removable. It will also have to be made so that it cannot be removed or retracted unless the cutting equipment is shut down. In other words, it has to be foolproof.

I don’t relish the thought of the consequences. Just imagine a machine hitting a rock and bringing it up to the surface and the operator not being able to see it. Or how about a root that gets trapped and continues to rotate with the wheel?

Safety committees have already discussed safety measures at length and pressures have been applies to include these items in drainage machine safety standards.

Conveyors and augers are two items used on the wheel and chain machines to discharge spoils. Neither are very efficient, and their many moving parts make them costly to maintain.

I feel there will be a tendency to see more machines with discharge chutes like that on the

Continued on page

Non-owned auto exposure

Do your employees use their own vehicles? Beware the risks.

by CNA Financial Corporation

Many companies know that there are risks associated with managing a fleet of vehicles for company use. But a business owner may also be liable for accidents that occur in vehicles not owned by the company. Do any of your employees use his or her personal vehicle to run errands for the company? Do your salespeople use their own vehicles for company business? Are any employees reimbursed for driving his or her own vehicle to pick up supplies or parts?

Anytime someone uses a personal vehicle on behalf of a company, the company has a nonowned auto exposure. If an employee causes an accident in his or her own vehicle, the liability insurance policy on the vehicle is the first line for liability coverage. After the limits of liability on the employee’s personal automobile are exhausted, the injured party may look to the company to pay damages. Your company could be put in this situation under the theories of negligence or vicarious liability. There are steps you can take to protect your company from non-owned automobile exposure.

If possible, implement a requirement that employees must use company vehicles for business-related tasks. Allow only designated employees to conduct business with personal vehicles. Review your employees’ motor vehicle record (MVR) before they start driving. Follow up with annual MVR reviews. Require that each employee driving his or her own personal vehicle for business must provide proof of insurance.

For employees who regularly drive on company business, require the company be named as an additional insured on the employee’s personal auto policy.

• Regularly inspect the vehicle to ensure it is properly maintained and safe.

• Investigate all accidents and provide training to prevent future accidents.

• Keep written records of everything you do to control the non-owned auto exposure.

Here are some suggested criteria to help determine what to look for when reviewing your employees’ motor vehicle records. The following violations are classified as guidelines from CNA only. Use discretion when checking your employees’ motor vehicle records.

Class A violations

• DUI (alcohol or drugs)

• Reckless or careless driving

• Hit and run

• Vehicular assault

• Racing/speed contest

• Driving on suspended or revoked license

Class B violations

• Moving violations, including speeding

• improper lane change

• failure to yield/obey traffic sign or signal

• suspended license related to moving violations

Consider implementing guidelines, such as prohibiting anywho who has received a class A violation within the last five years from driving for your company. drive for your company if they have received a class A violation within the past five years. Or, perhaps drivers with two type B violations or one at-fault accident in the past three years should be put on warning.

Familiarize yourself with these tips on how to manage non-owned automobile exposure to avoid being held liable for accidents that occur in vehicles your company doesn’t own. DC

The information, examples and suggestions presented in this material have been developed from sources believed to be reliable, but they should not be construed as legal or other professional advice.

meet the incr ina rs p 4" info meet in plastic dra Corrugato For more

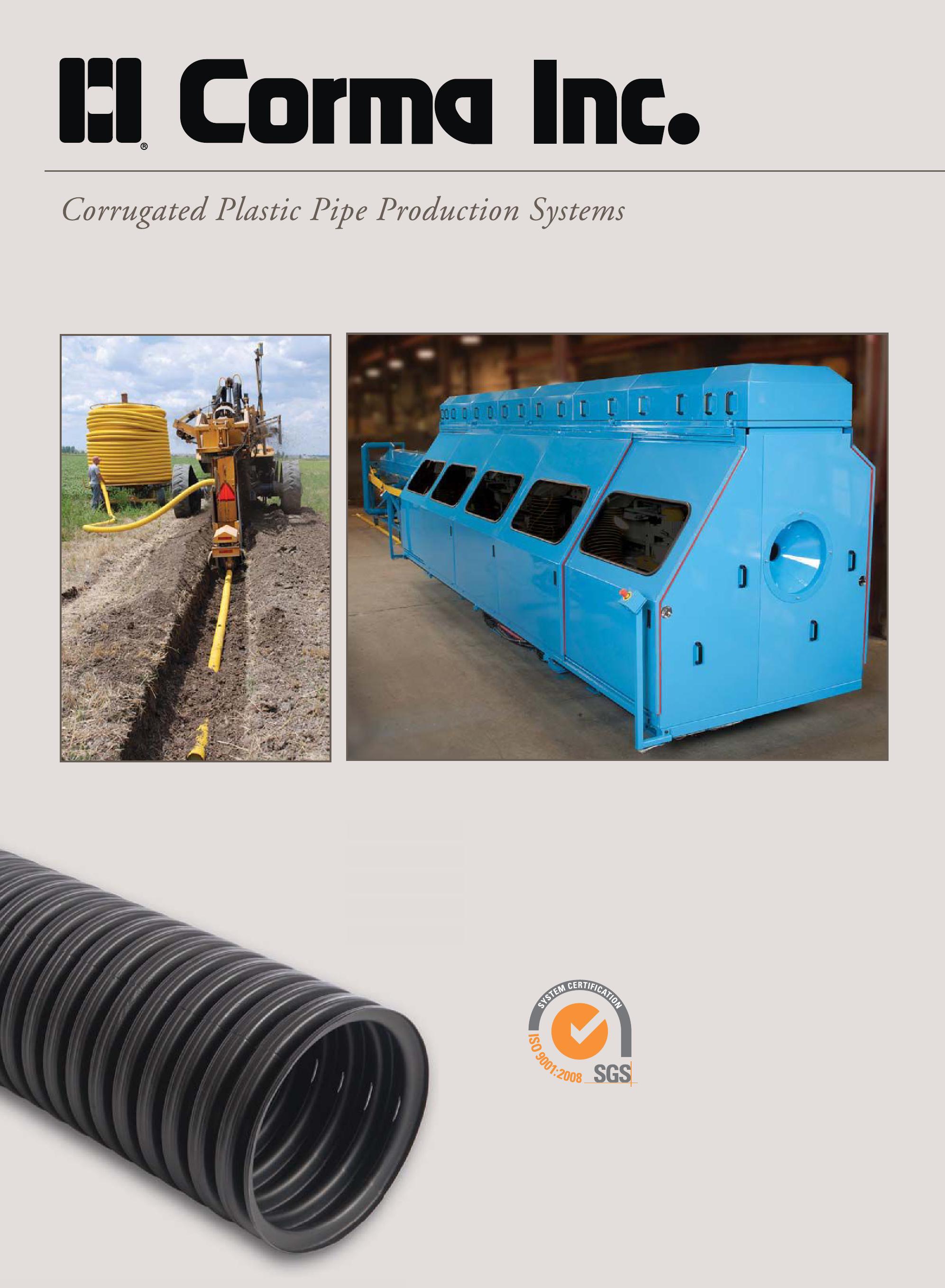

Corma Inc. introduces our High Speed Corrugators to meet the increasing demand for agricultural corrugated plastic drainage pipes. The 630-12 and 830-12 High Speed Corrugators provide output capacities of 1800-2000 lbs/hr., producing 4" single wall HDPE pipes at 100' per minute. For more information, contact: 830-12 Corrugator 2" (50 mm) I.D. to 12" (300 mm) O.D.

669-9397 info@corma.com www.corma.com

DECADES IN THE DITCH

Reflecting on the rise of the drainage industry.

Water, we’re told, is one of the few things we cannot live without. But apart from the human body’s constitution and water’s importance to sustaining life, to most people, that’s the end of the discussion.

by PETER DARBISHIRE

For me, however, it has meant much more. There’s a fascination about water that has been part of my life since I was a small boy. I’d often play in the stream, damming it up, watching the water overflow and eroding the dam. Then there was the curiosity of poking into the tile to watch the orange-colored water falling into the ditch and seeing workers clearing ditch bottoms, then laying tile and covering them with straw – the traditional way of “blinding the ditch.”

Becoming the editor of a magazine that dealt with water moving down grade was a natural fit. I had graduated in mechanical engineering in the United Kingdom and worked for a while in diesel engineering. I ventured to the United States to work with Laserplane, and later moved to Canada and hitched my ride to drainage forever.

In 1974, lasers were leading edge technology

and they had begun to revolutionize the farm drainage industry. North American agriculture was still in the throes of massive increases in production capacity of growing corn; new hybrid seed, commercial fertilizer and weed control chemicals were pushing the farmers’ production to the point that they were limited by the capacity of the soil and its moisture holding abilities. Farm machinery was getting bigger and tillage methods were becoming more intense. This led to new problems: soil compaction and soil erosion were lending their own pressures on farm production capacities. Progressive farmers realized that the most significant limiting factor was tile drainage in their fields. So a boom in drainage began, but it was stifled initially by a lack of capacity for clay and concrete tile production and installation techniques to keep

up with demand. At this point, most clay tile was still being laid out alongside the trench and put into place in the trench bottom by hand.

The rotating laser was part of a three-part solution. Combined with the introduction of corrugated plastic drainage pipe in the late 1960s, and faster installation capabilities of chain trenchers and trenchless drainage plows in the early 1970s, a surge of enormous proportions was underway. Between 1967 and 1977, the production and installation of drainage pipe in North American fields – mostly the Midwestern United States, plus southern Ontario and Quebec – went through a boom period.

The stories of success in the 1970s are almost legendary. Some contractors at industry meetings vied for the rights of ownership

for the trophy of who had installed the most tile in a day or a year. In the back of the room, there would always be another who had a different opinion, or a quiet fellow who was content to count the revenue. Not every contractor jumped into the new wave immediately, but most did eventually. In fact, there was an impact on the traditional North American machinery manufacturers, which were mostly producing wheel trenchers based on Buckeye’s design from the turn of the 20th century. They knew they had to increase the production and output of their machines to compete with the newcomers: Speicher, Buckeye and the then formative Port Industries with its HydraTandem began a 25-year (or longer) campaign to design and produce ever larger and more powerful trenchers.

prinsco: your technical partner

As you plan for your upcoming drainage projects, remember that Prinsco is your technical partner and available to address all of your questions. With over 35 years of experience serving the Midwest, Prinsco offers valuable insight into the selection of the best products for water table control in a variety of soil conditions. If you’ve got technical questions about drainage, Prinsco has answers. Call 800.992.1725 today!

800.992.1725 | www.prinsco.com | agblog.prinsco.com

Who were these newcomers? Hoes and Eberhardt from Germany, and Barth, Draiente, Drainmaster and Hollanddrain from the Netherlands brought the major introductions of chain trenchers in the early and mid-1970s. By late in the 1970s, Hoes of America reportedly sold more than 100 machines into the U.S. Midwest in one year. In Europe, new breeds were spawned: Mastenbroek in the United Kingdom and Inter-Drain (initially in the United Kingdom, then in the Netherlands) set up their new manufacturing operations. Older names either faded out or trended to the construction industry, like Vermeer, Ditchwitch, Cleveland, Barber Green, Parsons in the United States, and Howard, Caley and others in the U.K. Some made the trans-Atlantic journey and others, like the U.K.’s Bruff, which produced one of the world’s first self-propelled drainage plows, stayed home. Most of the European makes sold many machines for use on Middle-Eastern projects.

Drainage plows, while originally developed in the U.K. as installation tools, became widely popular in the mid to late 1970s. In some regions of the United States, they were poorly operated and left an unfavorable image that was to take more than 20 years to overcome. In other areas, they quickly became the norm and we soon saw contractors scaling up to operate several plow crews. The first commercial plow seen in North America was Badger’s roller linkage plow, introduced by Daymond, a pipe manufacturer in Ontario. Then, Canadian companies such as Zor, Eddy Oxford (Link Plow), Krac, Canteco (Wedge) and

RWF followed with double link plows. Tait began producing its heavy-duty self-propelled plow. Self-propelled plows with various linkage designs were first introduced by Hoes, Draiente and Barth. Most of the linkage plows followed basic design concepts formed by Dr. Ainsley Ede in the United Kingdom and Dr. Jim Fouss at the Agricultural Research Service of the United States Department of Agriculture at Columbus, Ohio, in the 1960s, while Barth and Draiente followed mechanisms borrowed from shallow angle chain trenchers.

Interestingly, during the massive 1970s expansion in the industry, there was not a great deal of animosity shown towards those who advanced and adopted new technology early. Most of these contractors willingly shared their experiences and helped later adopters to learn the technology and how to become more productive. Drainage Contractor magazine itself held workshops in Indianapolis in 1978 and 1979 that promoted these ideas as well as business management methods.

Information transfer was also happening from the drainage research community during this period, and the proceeds of that work are still being used today. University- and government-sponsored research and extension bodies were disseminating the benefits of drainage, while new research tackled things like plastic pipe integrity in manufacturing and installation, how to reduce or avoid installation problems like pipe stretch, trench-wall smear and pipe collapse after

installation. Open discussion of these topics led to innovations, most often by contractors themselves, of tools and methods that have become universal, like power feeders and, more recently, automatic crushers and shears to chop the end of the pipe before installation.

Informally in most regions of the world, but directed only in Ontario through a licensing program, installation quality has been a priority of most drainage organizations and associations. It is a testament to this that so many millions of feet, meters or miles of drainage tile has been installed over the past 40 years and is still functioning to improve food production output from farms.

By the 1990s, the industry had settled into something of a lull before a new wave hit, thanks to global positioning satellite (GPS) technology. It did not hit the drainage industry directly as the laser had 30 years before, but obliquely. Farmers were checking their GPS-based yield maps and discovered they needed more drain tile and in more intensive systems. Once more, the installation side of the industry could not keep up with demand, and farmers started to take the work on themselves, using the so-called pull-behind plow.

Now, many years later, many contractors have upgraded their machinery capacity to meet demand and GPS-based grade control and guidance systems have become widespread. Meanwhile, many farmers have parked their DIY machines because they found the work was more complex and time-consuming than they had thought – but some have become today’s contractors, a great boost for the industry.

Current research in drainage is still delivering ideas, with concepts of denitrification and controlled drainage. It’s impressive to see how contractors can continue to fine-tune their field operations to squeeze the extra money out of more efficient machinery. Now that GPS technology and on-the-go computerized installation design has become the norm, it’s hard to predict what will happen in the next 40 years. DC

from 1978 to 2008.

www.fratco.com/drainage-done-right

Company on the move

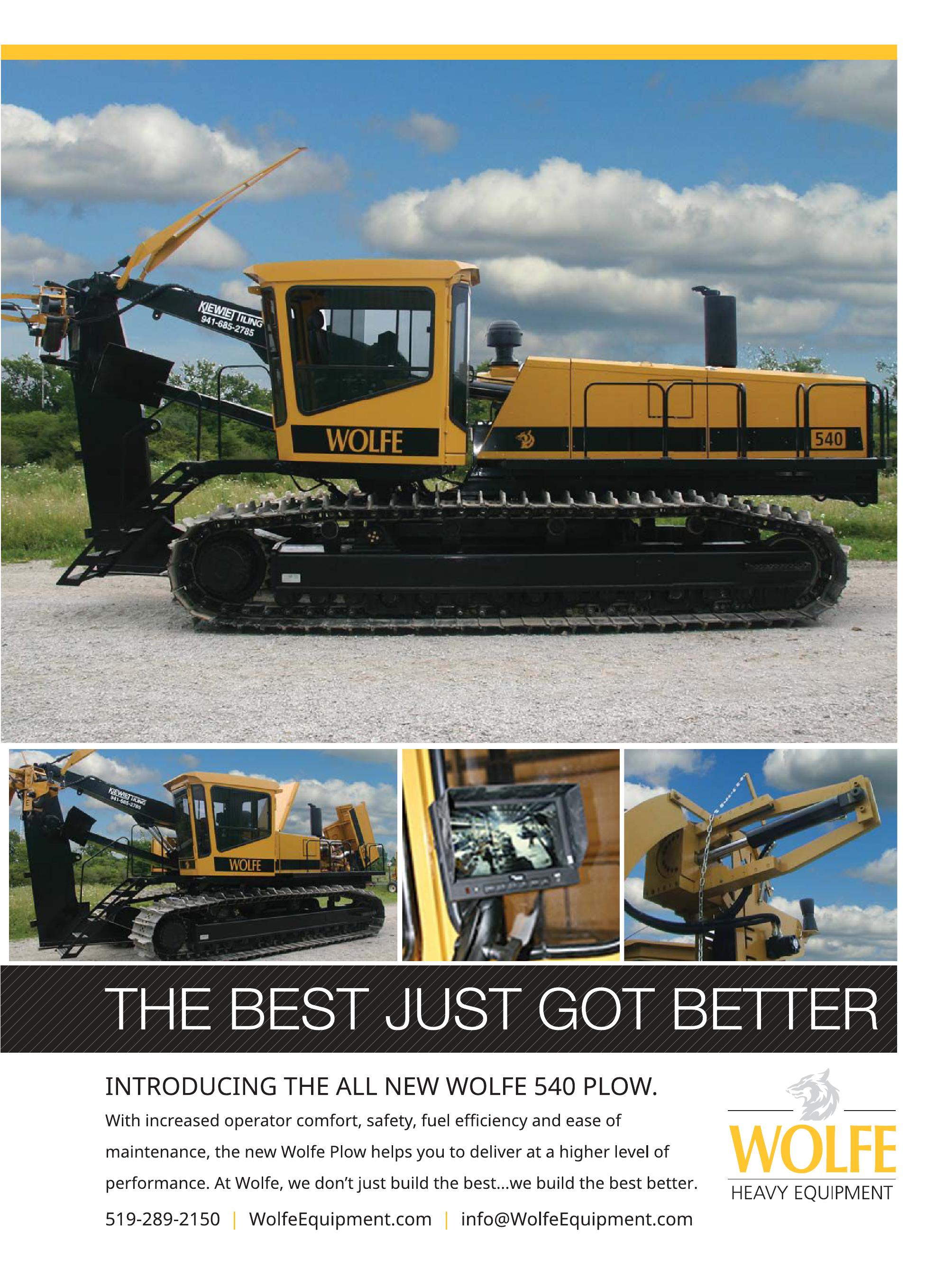

Introducing the All New Wolfe 540 Drainage Plow

You asked and we answered. Introducing the newly redesigned Wolfe 540 Drainage Plow.

EASE OF MAINTENANCE

catwalk.

An overall updated and improved look with increased operator comfort, safety, fuel efficiency and ease of maintenance.

NEW CAB UPGRADES

hands-free.

Interior light.

Bulkhead for all switches and controls for HVAC. easy access.

The hydraulic tank has for easier access to the lines. Redesigned hoods to -

NEW CHARGE AIR, OIL AND ENGINE COOLERS

Larger engine and charge air coolers. Fuel coolers are now standard.

DISTRIBUTED BY:

SHAPING THE FUTURE

Educational workshops, shows and social events have helped the drainage industry develop.

The drainage industry experienced a vibrant period of expansion and a boom of new technology during the 1970s and 1980s.

by PETER DARBISHIRE

This was a time for education and promotion of the industry. During these years, demonstrations and events, such as knowledge transfer workshops and ctonventions run by associations, were numerous and well-attended, drawing in crowds from all over North America to network and engage in the drainage community.

In the United States, the Land Improvement Contractors of America (LICA) held its annual national convention, and state chapters also held annual winter and summer meetings as they still do. The former “Buckeye Days” in Ontario were replaced by

the annual winter meeting of the Ontario Farm Drainage Association, which later became the Land Improvement Contractors of Ontario (LICO). Besides hosting vibrant social activities, the association was known for its technology transfer with practical sessions, which helped spread the word on new ideas and techniques in the field.

Every six years, the American Society of Agricultural Engineers held the Drainage Symposium, usually in those days in Chicago. This was where drainage researchers spoke of their latest findings and advances in research techniques. Of particular note was Dr. Wayne Skaggs’ development of a

The Land Improvement Contractors of America

LICA has been serving contractors for over 60 years, providing members with the benefits they need to work “Smarter not Harder”.

Below is a list of the programs available to members.

Petrocon Commodities Program. This program will generate savings for LICA members. They receive a minimum savings of 10% on their oil, tires and possibly more.

Universal Premium Fuel Program. The LICA Universal Premium Fuel Program can save you up to 15% on fuel and fleet expenses.

Hotel Savings Card. The LICA Hotel Savings Card Program from CLC Lodging simplifies lodging administration while saving 20-40% off hotel rates.

Contractor Safety Manual. Designed to be your company’s safety program. It is free to contractor members.

National Equipment Register. Preferred pricing for LICA members. You can register up to 400 pieces of equipment for two years for ONLY $300.

Dental Insurance. Under LICA Dental, we combine choice and affordability to create long-term satisfaction.

For more information or membership application contact…

National LICA

3080 Ogden Ave., Suite 300, Lisle IL 60532

Website: www.LICANational.org

In the U.K., Farmers’ Weekly magazine staged an annual event until this last one in 1985. Land and Water Service engineer, John Page of Yorkshire, showed how it used to be done! He used a grade of ¾ of an inch per seven yards of run, or 0.3 percent slope, measured by pouring water into the trench until it flowed over the lip of the last tile (3/4-inch wall thickness).

computerized system of predicting drain performance using the Drainmod calculation model. This, in a more updated version, is still used to simplify drainage performance research and design. Meanwhile, the plastic pipe industry held its own annual convention, as the Corrugated Plastic Tubing Association, which eventually became the Corrugated Plastic Pipe association and then part of the Plastic Pipe Institute. The organization was the sponsor of many research projects on plastic pipe structural integrity in manufacturing and in installation.

Also during the 1970s and 1980s, suppliers provided learning opportunities for contractors. Drainage Contractor magazine helped Daymond present workshops in Ontario and Alberta. In 1978 and 1979, Drainage Contractor invited contractors to a two-day workshop in Indianapolis. This was a highly successful, though intense, session. The workshop featured speakers like Ed Walsh from Ohio, who provided some insight into good business practices, and Gordon Spoor from Silsoe College in the United Kingdom, who presented lectures to

The Ontario Farm Drainage Association (now LICO), raised money for drainage education through this drainage machinery auction in 1983, held at Grand Bend. Many serviceable wheel trenchers were sold to Ohio, where they found new life in the hands of farmers wishing to install their own drainage systems.

help contractors in their understanding of the soil. Spoor also introduced concepts to help contractors avoid trench smear when using plows, another top-of-mind subject of the time. These workshops were attended by 400 contractors from the United States and Canada.

In the United Kindom, a publication titled Farmers’ Weekly staged demonstrations of drainage installation annually for a period of about 10 years when drainage was booming on the back of a 50 percent grant offered by the British Ministry of Agriculture, Fisheries and Food. Drainage Contractor magazine led groups of contractors, sponsored by The Big ‘O’ Drain Tile Company, in 1974 and 1975.

Events – past and future – certainly help the industry grow and thrive, and drive innovation on and off the field. DC

WHEN IT’S YOUR REPUTATION ON THE LINE, CAN YOU AFFORD LESS THAN 100% VIRGIN RESIN IN YOUR DRAINAGE PIPE?

At Springfield Plastics, we use only 100% virgin resin, which means you get a consistently strong pipe at every single inch. If we didn’t use 100% virgin material, weak spots could occur in your pipe leaving it vulnerable to cracks. Why spend money to fix what wasn’t done right the first time?

CONTRACTOR AT WORK

PRIDE OF OWNERSHIP

Kafer Tiling and Excavating is celebrating 65 years.

It was a few short years after the Second World War came to an end – 65 years ago to be exact – that Ben Kafer started his family on its journey in the tile drainage business.

by TREENA HEIN

“It was 1948 and he was a foreman on the railroad at the time,” explains Ben’s grandson, also named Ben Kafer, who is a current co-owner of Kafer Tiling and Excavating in Fairbury, Ill. “A railroad strike happened and he needed to provide for his family of eight children, so he started digging drainage by hand.”

The elder Ben’s son Duane was 19 at this point and pitched in to help his father. Duane then joined the army, and when he finished his military career a few years later in 1953, he used his savings to purchase a Jeep trencher.

“My grandfather Ben and my father Duane used it to work jobs together, using a string for grade,” notes the younger Kafer. “In 1962, Dad also purchased a Speicher wheel trencher as well as a backhoe, one of the first in the

area.” Kafer himself started working full time in the family business in 1979, and in 1983, he purchased the business (which was then known as Kafer Tiling & Ditching) from his father, who continued as an active part of the company for many years. Kafer says he enjoys the drainage business because he gets to see firsthand the difference it can make in a farmer’s field. “It’s amazing what the impact can be when an existing tile quits draining and is repaired to start working again,” he explains. In 1990, Kafer made the move to purchase a Port Industries Hydratandem II wheel trencher, and used it for many years to install mostly clay tiles from Diller Tile in Chatsworth, Ill. “In 2011, we added a Hydramaxx 2500 chain trencher for easier backfilling,” he says. “And as more

Water Management Systems for Pros

Our powerful Water Management products make going from design to jobsite with RTK-GPS a snap!

Designed with the convenience of the touchscreen in mind, AGPS’s intuitive interface is interfac interfa easy to learn and use asy arn an se n !

AGPS offers many S great entry-level Water Management products that can be upgraded to Pro level later!

ile ile nstallation nsttaallllaatitioon that is th t s asy and a asy sy and an ccurate ccuraratte te

ile esign that is essigign th that is hat t is ast and recise and orming o orming ng that t oves s ess irt r

S 1-A-AGGPS

www..agpsinnc.coom agpgpsisininc c

Rust S Sales, Innc st Saaleleses, , s, Inc 800-4478-78001 80000-0-4-4747878-8-7780 8 801 wwww.rustsalles.com wwwww.rusustststsa coaleleses. om Distribuutor for ND, SDD, MN, MB B & SK

Soil and Water Management oil

customers wanted system drainage on their farmers, we purchased a Hydramaxx 3500 plow in order to be able to offer the installation of plastic tubing (made in Chatsworth by Prinsco).”

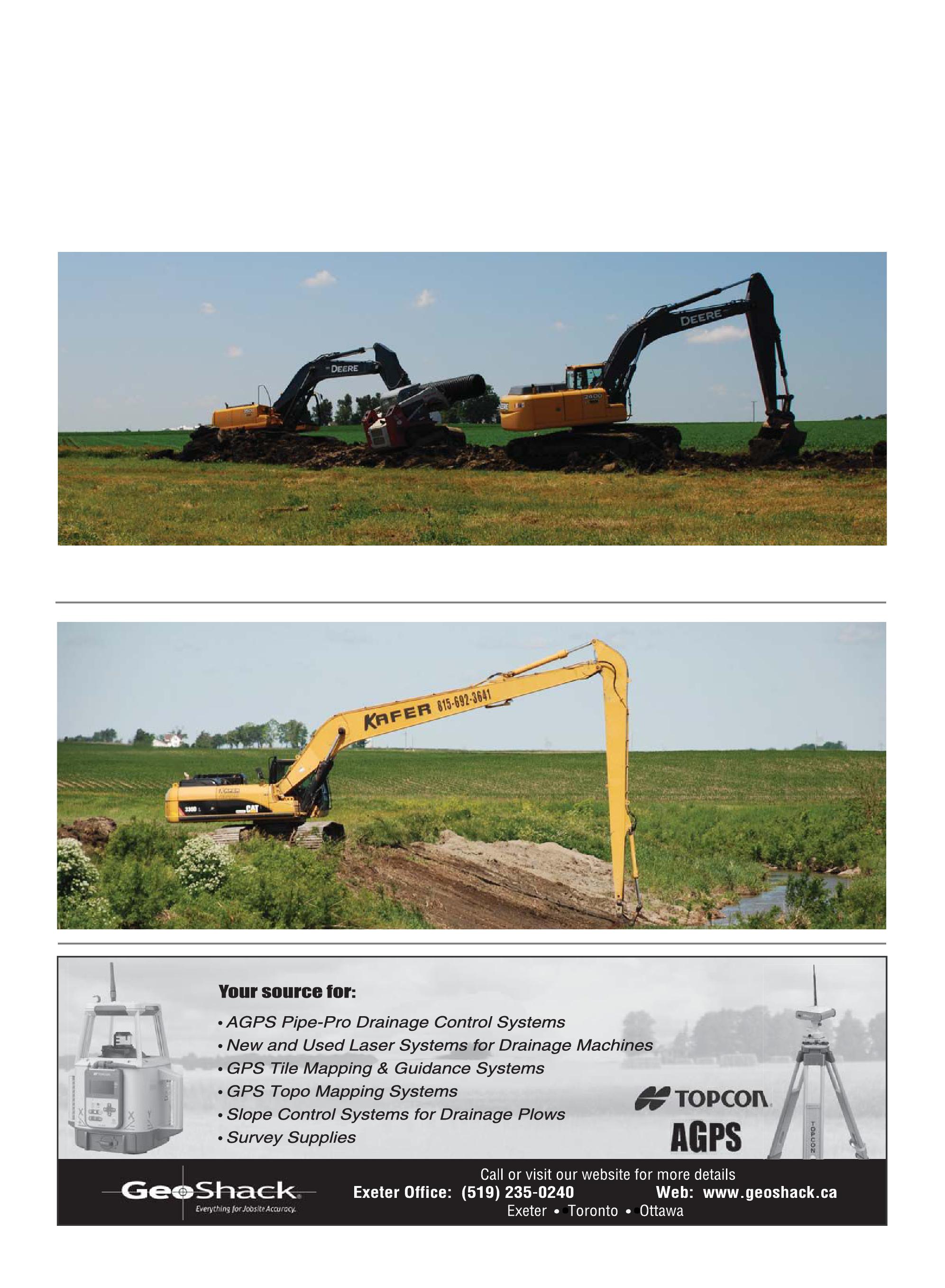

The company also installs large-diameter tiles with its excavators, all John Deere and CAT. “We choose these brands because they allow us to provide our customers with what they desire, and because they and their dealers offer dependable service and available parts,” Kafer says.

A member of the fourth generation – Kafer’s son Chris – started full-time work in the family business in 2002. “He enjoys the ditching and began a business called Kafer Excavating in 2006,” notes Kafer. “In 2009, we changed Kafer Tiling and Ditching to Kafer Tiling and Excavating Inc. to merge the two businesses and allow the sale of stock.” The move also brought in Kafer’s cousin Josh Kafer, who had worked for the company on and off since 1992, as a part owner. “We three are the current owners of the corporation and my wife Carol continues to run the office,” Kafer says. “I believe this will help in the continuance of this business for years to come.”

Kafer Tiling and Excavating now designs and installs drainage systems (main tiles shared by neighbors and random tile lines) and handles tile repair, downspouts, septic systems, waterways, ditch cleaning, pond creation, tree grinding, directional boring, terraces and demolition. Chris manages the excavating side of the business. Carol handles payroll, invoicing, payables, advertising and all other office management tasks. Kafer works in sales and purchasing of materials, and assists where needed. Josh designs drainage systems and dispatches the company’s eight employees each day. And with such a strong family involvement, Kafer says

treating employees the way he and his family would like to be treated is so important. “We greatly appreciate the work our employees do and recognize that they are a very important part of our business.”

INDUSTRY PROGRESS

Looking back over the years, Kafer says the use of laser on trenching machines was probably the first large industry change that affected the family business. His father Duane added laser to replace the targets he was using at the time in 1972. “The change from laying clay tile to plastic tubing was another big step,” Kafer observes. “In recent time, I would say the biggest change in the industry is the use of GPS, not only for mapping but also machine control.”

In terms of memorable jobs, Kafer recalls one that involved a long-term tenant farmer customer. “The land he worked had been sold to an owner who had tile plowing done by a competitor,” he says. “They had plowed through a neighbor’s eight-inch main and caused him to have a pond full of water for a year. This tenant then asked us to repair about 400 feet of it because the other company would not come back evidently for such a small job and planting was already started.” Kafer says the landowner was so pleased with their work that he later had Kafer system tile more than 700 acres for him in three locations. “I believe it pays to offer a full-service business of both new installation and repair of old,” Ben says. “If a customer has a wet spot, no matter what size the job, it is important to us to satisfy him.”

Another memorable job involved the opportunity to install a 30-inch tile for a 2,000-acre watershed. “The neighbors had worked together to replace a failing 21-inch clay main,” Kafer remembers. “It was a joy to see everyone co-operating

Dealers:

Illinois: Midwest Auger-Aerator Phone: 815-844-6400 Fax: 815-844-7469 Toll Free: 800-232-7008

financially and otherwise, with most of the people involved not getting a tile on their farm but understanding that their tiles connected to this main. Most of the owners involved were our customers and trusted us to design and install this main.” He adds, “Our customers told us this project was very helpful in draining the excess water from the spring rains of 2013.”

Kafer says the company has plans to build an office close to the shop, as the company has outgrown the office in his and Carol’s home.

When asked about the secrets to success and longevity for a business such as theirs, Kafer recognizes the value of learning from the past.

“I believe everyone can and does make mistakes. It’s the way you handle them that makes the difference,” he says. “To stay in business for years and have repeat business, we must provide our customers with a quality product at a competitive rate. We try to treat people the way we would want to be treated.” DC

HYDRAMAXX

LESSONS LEARNED

Ten things you may not have known about drainage.

Attendees of the 2013 LICO and DSAO Drainage Convention, which took place in January in London, Ont., saw several speakers and presentations offering tricks of the trade.

by STEFANIE CROLEY

One such presentation that caught the eye of Drainage Contractor magazine was by Sid Vander Veen, drainage co-ordinator with the Ontario Ministry of Agriculture and Food. It was entitled 10 Things You Did Not Know About Drainage.

In a room full of industry professionals, Vander Veen’s presentation was bravely named, but as he explained, the presentation was originally intended for a different audience. “I am Canadian, and, therefore, I start out with an apology,” Vander Veen joked, explaining that his talk was originally given to a crowd of people involved in conservation and resource management. However, Vander Veen had several interesting facts about agricultural drainage to share with the folks in attendance at the LICO convention. In case you missed it,

here’s a recap of Vander Veen’s 10 points.

10. Subsurface drainage functions comparably to the holes in the bottom of a flower pot.

Subsurface drainage drains the water out of the top layer of the soil, leaving the soil moist, but not saturated and drowning the crop roots. “Many in the resource management crowd view tile drainage as a bad practice,” Vander Veen explained. “I want to show that tile drainage functions no different than the holes in the bottom of a flower pot – it is a fundamental means of providing the proper growing conditions for crops.”

9. Subsurface drainage dates back as early as the second century B.C.

As Vander Veen explained, there has been a long-recognized need for subsurface drainage, and a huge increase in drainage

in the late 1960s and early ’70s. But rolling the clock back even further, to the late 1800s and early 1900s, clay tile was installed with a wheel machine – a very labour-intensive process. “Each clay tile was individually put into a chute and laid at the bottom of the trench. The trench would then have to be backfilled . . . The practice of tile drainage was slower back then,” Vander Veen said.

In the early to mid-1800s, anything that could form a conduit where water could flow through, including rocks, chunks of wood or clay tile, was used for drainage. Tile drainage in North America was largely attributed to John Johnston, a Scottish immigrant to New York State who embraced drainage in 1835. Prior to Johnston, there were sporadic references to tile drainage: in France in the 1600s and in Scotland in the 1400s. Palladius, a Roman agriculture writer in the third or fourth century, wrote on drainage, and Lucius Columella wrote on agricultural drainage at the time of Christ. And the very earliest reference to drainage was Marcus Porcius Cato, 239-149 BC, who wrote that if the land is wet, it should be drained with trough shaped ditches. “It’s important to realize that subsurface drainage has been recognized as a necessary component of agriculture for a very long time,” Vander Veen said.

8. Subsurface drainage reduces the overland flow and the movement of sediment, and . . .

7. Subsurface drainage only flows when the water table rises to the bottom of the pipe.

These two points are directly related. When it rains, tile

drainage increases the capacity of the soil to absorb water, which allows the soil to function almost like an urban storm water management pond. As Vander Veen noted, many people know that storm water management ponds are installed to slow down water runoff. “Tile drainage does the exact same thing, using the agricultural soil surface as the storage area,” he noted. “The fact that tile drainage encourages more water to go down is good. When it stops raining, tile are still flowing, and the tile are now doing their job of getting that root zone of the crops in a good condition so that it doesn’t drown the crops.”

6. Subsurface drainage acts as a conduit for water – it does not pollute water.

Vander Veen asked the audience how much air pollution an empty road causes regularly. The answer was zero. He then asked how much air pollution a road with lots of traffic on it causes regularly. The answer was, again, zero. “The cars are creating air pollution, and the road is the conduit for the cars, but the road itself doesn’t create any air pollution,” he explained. “So often, when we look at tile drainage, I hear claims that tile drainage pollutes. It doesn’t – but it can be a conduit for pollution, and we need to continue to work on land management practices to try to minimize that.”

5. Subsurface drainage encourages crops to develop stronger root systems, which help them in dry conditions.

High water levels in the soil tend to cause crops to develop a shallow root system. When dry conditions develop, the crops with the shallow root system are usually the first to suffer. Tile drainage lowers the water level in the crop root zone, which encourages crops to develop healthy, deeper root systems in the soil. These more extensive roots allow these crops to better withstand dry conditions. Tile drainage contractors know that even in dry conditions you see where the tile runs are in the field because the crops are actually better immediately over the tile. Tile drainage improves crop production and crop yield in dry times as well.

4. Ontario is one of the few jurisdictions in the world that require tile drainage contractors to be licensed.

In Ontario, the Agricultural Tile Drainage Installation Act is in place to protect farmers by regulating contractor workmanship. The Act applies to the installation of tile drainage systems on agricultural land only, and licenses are not required when an individual installs tile drainage on their own land using their own tile drainage machine. A business license, a machine license and a machine operator license are all required, and operators must successfully complete a five-day primary drainage course and an eightday advanced drainage course. As Vander Veen said, this is not necessarily the case around the rest of the world.

3. There are benefits to subsurface drainage that extend beyond increased crop productivity.

There are several benefits of subsurface drainage to farmers besides increased crop productivity, Vander Veen explained. “Improved trafficability is one. Drainage reduces the fuel consumption when working the land.” Tile drainage allows farmers to take advantage of optimal planting times. And finally, environmentally conscious methods of farming,

like no till and conservation tillage practices, depend on well-drained land to be effective, he pointed out.

2. Subsurface drainage improves crop productivity, which reduces pressure on land conversion and improves our ability to produce food for a growing population.

As Vander Veen pointed out, the world’s population is continuing to increase, and we’re running out of space for everyone. “We’re not making new agricultural land – and we’re building on what we have,” he said. “There are extra pressures on our agricultural production capability like biofuel production and loss of prime agricultural land due to urban development. These are all good, important things, but at the end of it all, we still have to produce food. How do we do that for a growing population?” His solution is to try to improve production with what land we have using soil moisture management, a combination of drainage and irrigation. “To me, that’s the least intrusive and one of the best ways of trying to continue to improve our food production capabilities.”

1. Conservation goals can coexist with agriculture and subsurface drainage.

Jack Miner was a world-renowned naturalist who was awarded the Order of the British Empire in 1943 for

the greatest achievement in conservation in the British Empire. Miner was born in the United States and his family moved to Canada where his father worked as a clay tile manufacturer. “To make the tile, clay was removed from the ground, which created pits,” Vander Veen explained. “The pits filled up with water and they became some of the very first geese sanctuaries.” During the time that Miner was getting recognition as a world-renowned conservationist, he continued to make drainage tile. He recognized the balance between agriculture drainage and conservation and resource management. Before ending his presentation, Vander Veen recited one of Miner’s poems, which, with verses like the one below, was a hit with the audience. DC

If your land is too wet and you’re burdened with debt And encumbrance begins to accrue, Obey Nature’s laws, by removing the cause, Drain your farm or it will drain you.

John 519-524-9081

Hugo 519-524-5515 Fax 519-524-1849

http://hickenbottom.ca

GOLF COURSE DRAINAGE

SYSTEM SOLUTIONS

Taking action on the golf course drainage front.

Unpredictable and excessive wet weather patterns through 2012 are creating major financial problems for many golf clubs in the

U.K.

by DAVID SHELTON

The drainage project on this fairway is finished and the fairway is ready for play. The scars heal within a few weeks, depending on the growing season. Photo courtesy of David Shelton.

Clubs that have invested in field drainage and are on lighter soils are better off than those on heavier land

In the U.K. we are undoubtedly experiencing changing weather patterns and the majority of meteorologists seem to think that this phenomenon is likely to continue.

A closed course can lead to a fall in income, not only from green fees, but also from fewer sales in the pro shop and restaurants/catering department. Generally speaking, there is a decrease in revenue, but staff expect to be paid as usual.

Unless action is taken on the drainage front, things will go from bad to worse. Now that joining fees have been widely abolished, even longstanding members will consider moving to a drier club nearby.

There is no inexpensive way to drain a course. But a desperate situation calls for desperate measures. Different approaches need to be set out and prices compared. Here is one example:

A club decides it must drain parts of several fairways if it is to keep the course open for play in periods of wet weather, but it has no spare cash. The club owners have approached banks, which are unwilling to loan money, even though the club specifies that this is an investment.

So the club turns to its 700 members and asks for an interest-free loan of $150 each, payable over one year by a payment plan, i.e., approximately $12.50 per month. The $105,000 loan will be repaid by the club when it is in a better financial position.

Working on a tight budget, the club decides on a do-it-yourself approach. It plans to buy a new chain trencher that will fit on

the three-point linkage of one of its own compact tractors. The greenkeepers keep their machinery in top condition so, at the project’s completion, the chain trencher will be sold for 50 percent of its purchase price. Because they will have their own trencher, the club can work at the most convenient time for them.

The chain trencher they purchase costs approximately $28,000. Its digging width can be varied to allow it to install 60-, 80-, 100-, and 110-millimeter-diameter land drainage pipes. It digs to a maximum depth of one meter. The digging blades do wear down, and need to be costed into the equation.

The club devises a plan for its drainage work and gleans information on layouts from the Internet. However, it decides to take professional advice and builds this into its budget. The advice includes layout, depth and width of trenches, pipe sizes, junctions, outfalls and discharge points. Professionals also explain the type and source of backfilling aggregates needed.

The course overall is gently sloping, which has advantages when undertaking drainage works. On flat terrain the use of a hired-in laser should be considered.

It’s important to keep in mind that if greenkeepers undertake the land drainage, they may not have time to carry out their routine maintenance work. One suggestion is to put a senior greenkeeper in charge of drainage operations and seek volunteers from the club membership to help him. This may seem unorthodox, but remember – desperate times call for desperate measures. Basic training would need to be given to each of the temporary greenkeepers.

Good leadership is necessary for this formula to work. Club members and volunteers may develop new friendships, and the club may experiece a boost in morale.

APPROXIMATE COSTS

(Tax is not included)

• 50 percent of the cost of chain trencher and blades: $14,000

• replacement digging blades per set: $350

• 60-millimeter land drainage pipe: $.70 per meter

• 80-millimeter land drainage pipe: $.90 per meter

• 100-millimeter land drainage pipe: $1.50 per meter

• Outfall pipe: $15

• Connector: $11

• Headwall and vermin guard: $84

• Backfilling aggregate per ton: gravel, $32.00; sand, $38 In working out the costs, the club includes a generous contingency figure. Nevertheless, the $105,000 will go a long way to rectifying poor drainage on many fairways and hopefully restore the financial well-being of the club. Upheaval caused by drainage works is no longer a serious problem with today’s precision machinery. The fairway will need to be closed while the actual drainage operations are in progress but can be reopened for play immediately afterwards. DC

David Shelton is managing partner of Shelton Sportsturf Drainage Solutions based in England. The business has 30 years of experience in fine turf drainag and manufactures a wide range of equipment. For more information, phone 01507 578288 or visit www.sheltonsdrainage.com

THE TRIED AND TRUE “LINK”

EVENTS

Ohio LICA

Jan. 6-8, 2014 Dublin, OH

South Dakota LICA

Jan. 6-9, 2014 Sioux Falls, SD

Keystone Farm Show

Jan. 7-9, 2014 York, PA

Illinois LICA

Jan. 9-11, 2014 Decatur, IL

Michigan LICA

Jan. 13-15, 2014 Lansing, MI

Nebraska LICA

Jan. 14-16, 2014 Kearney, NB

New York LICA

Jan. 14-16, 2014 Geneva, NY

Minnesota LICA

Jan. 17-18, 2014 Rochester, MN

Indiana LICA

Jan. 23-24, 2014 Indianapolis, IN LICO

Jan. 23-24, 2014 London, ON

Missouri LICA

Jan. 23-25, 2014 Columbia, MO

Kansas LICA

Jan. 26-27, 2014 Manhattan, KS

International Erosion Control

Feb. 25-28, 2014 Nashville, TN

National LICA

March 1-3, 2014 Las Vegas, NV

China METE

March 1-3, 2014 China

small Radahl wheel machine from Norway. I think it will become common practice on many larger-capacity trenchers.

With engines, speed is proportional to horsepower. Today’s contractors want and demand a lot of speed from their equipment. Therefore, horsepowers are going to increase as they have done with farm tractors. Once again, safety and environmental standards are going to come into play and demand that these engines be quiet enough to meet certain standards. That’s why cabs are going to be necessary.

Cabs will lower noise levels at the operator’s station. Also, noise needs to be reduced for those in the immediate vicinity such as the ground support personnel. Engine manufacturers will have to make efforts to quiet their engines.

As far as long-range predictions are concerned, farmers are becoming more and more aware of the importance of uniform drainage. They want to see the land dry evenly, and not simply over the tile. They are going to demand more tile per acre to establish uniform water tables. But they are going to want to do it at a reasonable cost.

One possibility is the use of smaller-diameter tubing: the costs associated with increased tile densities would be prohibitive. Smaller diameters also will allow for much faster installations, thus reducing installation costs.

Therefore, I predict that there will be continued future design on machines for the trenchless method of installing tubing, especially using the rubber-tired tractor as a prime mover.

We’re likely to see two types of contractors with specialists in both. On one hand, we’re going to see contractors that will install large main drain diameters only, and their equipment will be geared for it. The demand for the very best and most modern equipment for that purpose will, therefore, continue. On the other hand, there will be the contractor that specializes in lateral work only. He’ll probably concentrate on the trenchless method. Of course, there will be some contractors that can finance and manage equipment to specialize in both.

Some people have said that the processes of manufacturing and installing a drainage material and will someday be combined into one operation. If this happens, it is likely to be a new process in conception. This could involve variation of the trenchless method coupled with the simultaneous application of synthetic materials; these might be injected into the soil to form a honeycomb inside drain tube wall, not dissimilar to porous cheese.

In the area of grade control equipment, there will likely be even greater sophistication than is already available. The contractor will probably be able to take their pickup and drive down a particular lateral and record elevations and distance. They will be able to take the resulting punch card and feed it into a hand-held pre-programmed drainage computer, which will produce a punch card of the drain design. This will then be fed into the machine’s control equipment, and the drain will be installed to a perfect grade.

Development of any type is an ongoing procedure: the drainage contractor who thinks they are going to wait for the newest, most reliable and perfect machine, will wait forever. DC Continued from page 14

NEW PRODUCTS

RWF BRON LAUNCHES NEW DRAINAGE MACHINE AND PLOW

RWF BRON introduced the 350 self-propelled drainage machine with a 400 DL plow in May. The machine features a Cummins engine QSM11 at 360 horsepower. The D6 undercarriage comes with 30-inch, 32-inch or 34-inch pads. The estimated weight is 65,000 pounds and the operator’s cab is ROPS/FOPS-certified with air ride seat. The estimated travel speed in high is 3.5 miles per hour.

RWF BRON has also released a 375 add-on drainage plow. This plow requires a 180 to 200-horsepower tractor or dozer, mounted with a back plate or draw bar pull. The plow has a plowing depth of 5.5 feet and weighs 5,000 pounds with a shank. www.bronrwf.com

INTAKES AVAILABLE IN SEVERAL UNIT SIZES

Precision Intakes for tile lines are available in a six-inch or an eight-inch and 10-inch unit, each consisting of the top, middle, and tee section. The six-inch tee offers step-down adjustability for four-inch, five-inch and six-inch tile without the need for additional fittings. The six-inch below-ground unit can be cut in seven places and is adjustable in fourinch increments. The eight-inch and 10-inch unit can be cut in thirds and is adjustable in six-inch increments. Precision tees work well with in-line installations or offset applications. The eight-inch and 10-inch tee is a combination tee that serves for both sizes of intake units. Reducer fittings are molded on each end so additional fittings are not needed. 1-800-932-7611

TESMEC INTRODUCES NEW LINE OF FARM DRAINAGE TRENCHERS

Tesmec recently introduced a new line of farm drainage trenchers.

The 775DT is the first Tesmec trencher specifically developed for the farm drainage tile industry. The close-loop hydraulic transmission and the exclusive Tesmec flywheel gearbox allow the 775DT to transmit the full power delivered by its Cat C6.6 Tier III diesel engine. The 775 DT is available in bucket wheel or chainsaw configurations. The 775DT bucket wheel can dig at widths up to 30 inches with a maximum depth of 6.6 feet. The 775DT chainsaw has the capability of digging widths up to 24 inches and depths up to eight feet. For more information, contact Bryan Blankenship at 817-559-2958 or via e-mail at bblankenship@tesmec.com.

BUSINESS DIRECTORY

K. SMART ASSOCIATES LIMITED

CONSULTING ENGINEERS & PLANNERS

Kitchener Sudbury Delhi New Liskeard Rainy River 519-748-1199 Toll Free 1-800-265-6456 Fax 519-748-6100 info@ksmart.on.ca www.ksmart.on.ca

STRUCTURAL - Bridges, Culverts, Low Rise Buildings

PLANNING - Municipal & Private Development Land Use Planning

MUNICIPAL - Site Plans, Lot Grading, Subdivisions, Servicing DRAINAGE - Municipal Drains, Storm Water Mgt, Storm sewers ENVIRONMENTAL - Water Supply / Wastewater Treatment Plants

Infrastructure Environment Communities Facilities OfficesAcrossCanadaandInternational 202KingSt.W.,Suite300,Chatham,Ontario 519.354.7802 www.dillon.ca

Weather woes

The U.K. drainage industry is battling Mother Nature.

by Rob Burtonshaw

Drainage contractors often have a difficult relationship with the weather, especially in the United Kingdom, where four seasons in one day is the norm rather than the exception. We need bad weather: without excessive rain, no farmer would invest in drainage. However, this very weather also creates some of our most painful headaches. One day we are choking in dust, and the next we are axle deep in mud and sinking fast. Such is the plight of a drainage contractor.

For British contractors, the weather has been a roller-coaster and a subject that has proven impossible to avoid over the last couple of years, hence the reason for writing about it. The 201112 winter season was dry as a bone. Normally, our weather dictates that very little can be done in the field during January and February as it’s simply too wet (by definition any field we enter is a wet field, and in the dank winter months, our plant would sink out of sight if will tried to install drainage). In 2011-2012, we were able work hard throughout the winter; great news, one might think. The problem was that after such a dry time, farmers’ thoughts were not focused on draining. Orders were delayed or cancelled and all contractors were scrapping around trying to find work.

Of course, balance is something that Mother Nature is very keen on: It started raining in April 2012 and the summer was washed away. Still not content, the rain continued into autumn and caused major problems, with farmers unable to drill and plant winter wheat in as many fields as they planned. And even still not content, the rain continued into the winter, although at least such rain is expected at that time. By the end of the year, 2012 had been officially labelled the wettest in England since 1872.

The rain had two major impacts on the drainage industry. The first was positive: demand skyrocketed. The second impact was not so positive. The little work that was available in the summer and autumn was harder to complete and, therefore, less profitable.

This year the weather has been benign and typical. The only deviation from the average was a warmer and sunnier summer than normal –something welcomed by all! It sounds almost unbelievable, but we had a three-week block of solid sunny weather with temperatures reaching over 25 C degrees every day, all very unusual for our damp, mild Isles.

I can say for certain that 2013 is already going to be a good year for British contractors. High demand combined with good summer weather will mean profits for all, which is a very welcome prospect after last year. However, it also makes me ponder a question, which often lurks deep in the edges of my mind: Why does demand for drainage fluctuate depending upon the weather?

I suppose the answer is easy; when the rain is falling it sharpens the mind to the problems it causes. But this perhaps shows a misunderstanding of the time scales involved with drainage. Buried safety in the ground, drainage lasts a long time; the investment is for the long term and should be made following a session spent number-crunching yield data –not when looking out of the window wishing it would stop raining.

I’m convinced that worldwide, but especially in the United Kingdom, we have to be more proactive in selling and promoting drainage. I’m not convinced that our customers and, more importantly, our potential customers, understand drainage and what it can do for them. We need to use the press, shout loudly and explain to farmers the yield advantages. The decision to drain should not be based on last month’s rainfall; it should be part of a long-term investment plan comparable to a new barn or combine harvester. DC

Rob Burtonshaw is a drainage contractor in the United Kingdom.

Chesterville 1-800-449-2806

Comber 1-800-265-1447

Orangeville 1-800-265-2446

Forest 1-800-265-1447

Walkerton 519-392-6929

Dresden 519-683-6231

Armtec provides a complete range of products from steel and plastic pipe to tubing designed to collect and remove subsurface water in various situations. With several different tubing diameters, a variety of perforation patterns, and an extensive range of fittings and accessories, we have the solution for your drainage needs.