The Land Improvement Contractors of Ontario (LICO) met recently in London, ON, for their 60th anniversary convention. Franklin Kains, convention co-ordinator, opened the event with some introductory comments. This was followed by a comprehensive educational session with talks on phosphorus loss, managing phragmites, workplace fraud, soil compaction and machinery lubrication needs, among other topics. There were breaks in both the morning and afternoon sessions, giving 179 registered delegates the opportunity to walk the sold-out trade show portion of the event where 28 companies showcased the latest products and services for the agricultural drainage industry.

The annual banquet and awards evening was held on the first night. The room was at capacity with 250 delegates and guests enjoying the buffet-style dinner of roast beef, chicken, pasta, rice, salads and desserts. A 60th anniversary cake along with a chocolate fountain rounded out the dinner with a live band providing entertainment for the evening, and attendees enjoyed posing for keepsake pictures at the photo booth.

The second day of the convention included additional education opportunities on Internet security and the use of drones in drainage work, along with the LICO annual general meeting. In the afternoon, some 40 people participated on the tour of Coldstream Concrete – a supplier of precast concrete products as well as concrete pipe and municipal drainage products.

Plans are already underway for next year’s event, which will again be held in London in January 2019.

Agricultural Drainage Management Coalition (ADMC) member companies and Dan Jaynes with the National Laboratory for Agriculture and the Environment collaborated to quantify the effectiveness of installing saturated buffers on buffers enrolled in the conservation reserve program to reduce nutrient loading from tile drainage waters. This demonstration program builds upon this same group of collaborators’ findings from the 2012-2015 project that evaluated the ability for saturated buffers at field scale to reduce nitrate and phosphorus from field drainage systems.

With many of the row-crop agriculture fields in the Midwest being located adjacent to ditches, streams, rivers and lakes, it is no surprise that nutrient transport from agriculture lands is a major concern. Large areas of the Midwest are intensively tile drained and it is assumed that many of the vegetated buffers adjacent to waterways are being under utilized, because the tile outlets quickly move large amounts of subsurface flow past the buffer and into the receiving waterway without any opportunity for treatment by the buffer.

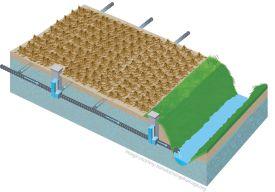

The project collaborators sought to demonstrate and evaluate the effectiveness of a new conservation practice commonly referred to as a saturated buffer. The goal of a saturated buffer system is to hydrologically reconnect a subsurface drainage outlet with an edge-of-field buffer. This practice takes advantage of both the denitrification and plant nutrient uptake opportunities that are known to exist in buffers with perennial vegetation.

This project monitored nine saturated buffers in Iowa, Illinois, and Minnesota. These sites intentionally included a of soil types, buffer vegetation, surface topographies, and ditch/stream channel depths. The monitoring timeline included a period from September 2016 through February 2017, yielding six months of flow and nutrient samples.

All nine sites were consistent in showing nitrate concentration reductions from the main line of the drainage system to the stream side test well. This reinforces data from the previous study, where 27 out of 28 field years indicated the same reductions. Current data collection techniques heavily support the use of saturated buffers as a credible nitrate load reduction practice. The cost per pound of nitrate removed is low compared to other nitrate removal practices.

To view the full research report and find additional information and videos pertaining to saturated buffer systems, please visit www.saturatedbufferstrips.com.

Ontario is helping Thunder Bay area farmers improve their agricultural land, diversify crops and expand their businesses.

The Northern Ontario Heritage Fund Corporation (NOHFC) has announced funding to install tile drainage on 1,390 acres of land and to undertake land clearing on 354 acres, a project led by the Thunder Bay Agricultural Research Association in partnership with 23 local farms.

This partnership between the Thunder Bay Agricultural Research Association and the farm businesses is ensuring the longterm sustainability of area farms. The new tile drainage system and clearing will help farmers increase their crop yields by providing more available land for production and will help reduce soil erosion, which will extend the growing season.

For more industry news, visit us online at www. drainagecontractor.com

by Mike Cook

Iam excited to assume the position of National Land Improvement Contractors of America (LICA) President for 2018. This is the same position my father John held in 1999. Much is the same, but a great deal has changed since then. LICA is growing rapidly, largely through the benefits secured by Jerry Biuso, our CEO, and our close ties to government agencies through John Peterson, our director of government relations. Here’s a look at a few of the projects happening at the moment.

Many y ears a go, w e h ad a M emorandum of Understanding (MOU) with the Natural Resources Conservation Service (NRCS). It has since expired and the executive committee would like to create a new MOU representing LICA and NRCS today. We have established a steering committee to work on a rewrite. The relationship between our two organizations has been very productive since we have similar goals.

LICA is growing rapidly, largely through the benefits secured by our CEO and our close ties to government agencies.

LICA has embarked on a comprehensive project to publish “The History of Farm Drainage.” America feeds the world and the development of farm drainage systems has been vital to that effort. LICA believes it is important to have a recorded history of the drainage industry in which many of our members work.

B ob C lark, p resident o f C lark F arm Drainage, Inc. and past-president of LICA, is serving as the project chairman, with a goal of collecting relevant information from every aspect of the industry, reviewing and co-ordinating that data, and publishing the results in a leather-bound book which will be available through LICA.

We are reaching out to anyone involved in the drainage industry – researchers, producers, contractors, manufacturers, educators – and asking them to provide any history they may have relating to the drainage industry in America, as well as where they see the industry heading tomorrow.

All editorial submission should include the follow four items:

1. Date: The publication will follow a time line.

2. What: Describe the action, product or service.

3. Impact: Describe the positive impact it had on the industry.

4. Source: Identify the source.

Please submit all editorial to the designated email: LICAHISTORYOFDRAINAGE@gmail. com.

If you have some history you would like to share, please contact either Jerry Biuso, National LICA CEO (908-996-7979 or email: gb iusosr@earthlink.net) or Bo b Cl ark, project chairman (317-694-9167 or email: bob2@clarkfarmdrainage.com).

The Michigan LICA state chapter will host the 2018 National Sumer Meeting, July 10 to 15, 2018 in Grand Rapids. We will be staying at the beautiful Amway Grand Plaza, and offer tours the first two days. I am proud to be reviving a children’s program at the summer meeting and we will have trips and activities planned for everyone. Look for details coming soon on our national website at www.licanational.com. I hope to see you there.

Work safe and best wishes for a prosperous year. DC

Mike Cook is the current president of the Land Improvement Contractors of America. Visit www.licanational.com for more updates from LICA.

by Warren Formo F

ew

innovations have contributed as much to the rise of agricultural productivity across the Northern Great Plains as the ability to remove excess water. Drainage, through a combination of underground tile and ditches, has made development for crop production, urban growth and transportation possible in conditions where it would not otherwise be feasible.

Much of our oldest drainage infrastructure needs repair. In addition, modern technology, coupled with advances in water quality research, has introduced changes in drainage design and layout that improve crop productivity and address environmental concerns. In my view, one of the biggest environmental success stories of the past quarter century is simply the practice of installing tile drains to follow field contours, often referred to as pattern tiling.

Unfortunately, critics of pattern tiling use the visual of rolls of plastic pipe to raise alarms about alleged loss of wetlands, increased downstream flooding and water pollution. These concerns have become the key talking points of those calling for even more regulation of drainage, usually relying on a combination of inaccurate, incomplete and conflicting information.

The fact is, drainage is highly regulated already, and the chief objective of current regulations is to prevent wetland loss. In Minnesota, state wetland regulations require review of drainage projects by a drainage authority, usually the county or watershed district, as outlined by the Wetland Conservation Act. Only after it is determined that there are no wetland impacts, or that any unavoidable wetland impacts are being mitigated through the creation of replacement wetlands, is the project allowed to proceed. As many as seven different federal and state agencies are involved in this process. Statistics available from state agencies show that the primary goal of the Act is being achieved, as wetland area is increasing in Minnesota, not decreasing, as is often claimed by drainage critics.

Peak flows and water quality are more complicated issues. Anecdotally, critics attempt

to connect rapid jumps in water level following large rains to tile drainage, without noting that these jumps are largely driven by surface runoff, which is conveyed in the same channels as tile drainage but flow virtually without limits. In short, it takes rain to make floods. One can easily find numerous examples of drainage projects coupling modest storage basins with more underground tile that actually reduce peak flows.

State regulators also recognize the value of storing water in soils to reduce peak flows and help reduce sediment and nutrient pollution. This realization has moved them to join the soil health discussion, which is a good thing, but they have not yet widely credited the value of tiling in improving soil health.

Healthy soils contain both water and oxygen. Many of our most productive soils do not have the ability to drain naturally, starving the microorganisms in the soil of oxygen. This in turn affects nutrient cycling in the soil and can reduce crop productivity, which is important in returning organic matter to the soil to continue the cycle. Yields continue to set records due to many factors including better genetics, improved nutrient application practices, and improved drainage design that contributes to improved soil health.

B eyond s oil h ealth, d rainage h as m any benefits, but these aren’t communicated as often as they should be. The entire agricultural c ommunity – f armers, l and i mprovement contractors and conservation authorities included – has a role in fixing this. I encourage you to promote productive discussions about drainage practices when given the opportunity. DC

Warren Formo is the executive director of the Minnesota Agricultural Water Resource Center, a coalition of agricultural organizations formed to help farmers evaluate and address water resource concerns.

Word of mouth and social media spread the word for this successful drainage company.

Like many successful businesses, Bedolli Excavating and Tiling, Inc. in Buffalo, IL, grew out of necessity. Andy and Brittany Bedolli, a husband-and-wife team, started with a backhoe, a bulldozer and an excavator in 2006 when they needed to make improvements to their family’s farm and soon found themselves on neighboring farms repairing tile holes.

by TRUDY KELLY FORSYTHE

One recent project included building a block chute through the natural resource service to stop erosion into an open ditch on a large watershed. Photos courtesy of Bedolli Excavating and Tiling, Inc.

In 2007, quickly recognizing the need for more equipment, they upgraded the excavator to a newer machine and began doing tree line removals, small drainage repairs and maintenance on neighboring farms. Three years later, they purchased their first Port Industries wheel trencher machine to do their own drainage. From there, word of mouth spread the news and they were open for business. They incorporated in 2012, bought a pull-type plow they could haul with their 850K bulldozer and never looked back.

As the need for tiling increased in the region, so did the Bedollis’ needs for additional

equipment. In 2013, they purchased a new wheel trencher that gave them the ability to install tile up to 24 inches, important for those larger main projects. In 2015, they added a Bron self-propelled tile plow with special boots that allows them to install tile from four inches up to 18-inch dual-wall tile.

“We have continued to upgrade equipment through the years,” says Brittany, explaining they now have a full fleet of equipment and employ three full-time and two parttime employees to meet all of their tiling and excavating needs. “When we are not putting in field drainage, we are working

on drainage district projects, bridge projects, waterway construction, pond construction and various site demolitions.”

Married in 2007, Andy and Brittany have grown Bedolli Excavating and Tiling together. Because it is a small business they both wear many hats while also juggling raising a family (the couple have three boys in elementary school) and other jobs (Brittany works full-time for a local auction company and they also farm with Andy’s uncle). Andy is the primary planner and organizer/ operator with Bedolli Excavating and Tiling while Brittany works more behind the scenes to keep the day-to-day operations running smoothly.

“I try to help Andy as much as I can,” says Brittany. “The days that I am not at the office or on the road at an auction, I am usually on the job site.”

That can mean operating bulldozers to help backfill dirt, driving the tile stringer cart, flying the company’s drone, taking pictures or riding along with Andy.

“During the busy season, that is the only time we really see each other,” she says. “Our date nights usually include parts runs or looking at the next job. We never really leave the tiling business at the end of the day.”

The couple also shares a love for antique equipment. They collect antique tractors, and turn-of-the-century tractors have become Andy’s hobby.

“I buy them from people, get them running and use them all summer at tractor shows,” says Andy, explaining that he completely disassembles some of the tractors and rebuilds them to free up parts that have seized or rusted past being repaired. “I recently found a 1944 Buckeye trencher that had been sitting for many years, they thought since the 1980s, and I am working on getting it going to do demonstrations at old tractor shows.”

The kids are following in their parents’ footsteps. They attend various plow days in the early fall with their dad, and each of their children has learned to operate their own small tractor.

Over the years, the company has developed a successful social media

presence, starting with Facebook, then adding Instagram and Twitter as they saw how popular those platforms were becoming. Twitter has been particularly successful for them as Brittany has built up a following of more than 2,000 people since joining the platform in 2013.

That said, the Bedollis don’t use social media to just gain followers and likes. Their main goal is to help educate people about field drainage, and drainage in general. They do this primarily by using pictures and videos describing the different projects they are working on. They also offer a behind-the-scenes look at the business, as they’ve discovered that’s what their customers and other followers like to see.

Brittany believes social media is a powerful tool that drainage contactors should consider using, especially since it is free.

“With a little marketing budget – or no budget at all – you can create a great platform to tell your story and introduce people to your products,” she says. “If you want to market your business or to increase information about your product or service, social media is a great outlet.”

It’s also a good way to meet other individuals in the industry.

“A few weeks ago, we had a fellow Twitter friend come from Canada to our job to see how we installed our drainage products . . . so social media

can be used to help each other out as well,” Brittany says.

She does warn against Internet trolls or individuals who do not understand the product or service and can spread fear or fake information, but as a free marketing tool, it can be worth the risk.

While a love of what they do is part of their success, the Bedollis also credit customer loyalty and doing the job right.

“In the 10 years with our business we have not traveled very far from our shop,” Brittany says. “We have been very fortunate with repeat customers and building trusting relationships within our own community.

“Some customers use us every year for various tiling or excavating projects,” she adds. “These same customers, we have found, have helped our business just by spreading the word about us at the local coffee shop.”

One reason for this is because the Bedollis strive to do the job right.

“We don’t want the customer to ever worry if their job was done correctly or if they have a question that they can’t call us,” says Brittany. “We work very closely with the landowners and tenants throughout the entire process.”

To see what the Bedollis are up to on social media visit the Bedolli Excavating & Tiling, Inc Facebook page, or follow betilinginc on Instagram and @TileBride on Twitter. DC

Crops grown on fine-textured and poorly drained soils require artificial drainage for optimum crop production. A dual-purpose subsurface drainage system can drain away excess water in wet periods and hold water for crop use in dry periods. Additionally, holding water in the soil profile can help keep some nutrients from escaping through the tile system.

With controlled drainage, water control structures installed on the main pipe allow the water in the field to be raised or lowered. Boards, or stoplogs, in water control structures are removed (water table is lowered) one to two weeks prior to planting, so the field dries for spring field operations. The boards (stoplogs) are re-installed (water table is raised) as the crop grows during the growing season to create a potential storage of water for the crop, especially important if there is limited rainfall throughout the summer. The boards are again removed about a week prior to harvest and remain out during fall field operations. The boards are again installed after fall field operations, and remain in the structure (water table is raised) throughout late fall and winter.

When the water level is kept high in the field through controlled drainage, water and the nutrients carried with it are forced through the preferred path of the soil via seepage. A high water table can also promote denitrification, thus reducing the loss of nitrate through the water. Although controlled drainage has also been documented to reduce phosphorus transport from of the field, research for dissolved reactive phosphorus (highly bioavailable for organisms) reduction with controlled drainage is scarce.

For this purpose, Michigan State University, led by Ehsan Ghane, is investigating the effectiveness of controlled drainage in Lenawee County at two on-farm sites with varying soil types. This research will determine the effectiveness of this practice in reducing nutrient load from the field.

For controlled drainage to work well, field topography must be nearly flat, 0.5 – 1.0 percent, typically. Operating a controlled drainage system also requires initial installation costs and a moderate level of management. However, if a landowner or operator has flat fields and is willing to meet the cost and management obligations, controlled drainage can help meet production and environmental protection objectives.

Unpredictable Canadian weather makes managing excess groundwater a challenge. A Big O drainage system improves farm profitability by increasing crop yields, lowering production costs and extending the growing season.

The Thames River Phosphorus Reduction Collaborative (PRC) is moving into the next phase in developing practical ways to reduce the amount of phosphorus getting into local waterways from agricultural and municipal drains.

"We have involved a lot of skilled people who are eager to do their part to improve local water quality and help resolve this issue," said Randy Hope, mayor of Chatham-Kent, ON, and the project's co-chair.

The PRC steering committee met in Woodstock, ON, on Feb. 23, to determine the project's priorities. They approved the proposed implementation plan, budget and financing strategy. Most notably, the PRC will proceed with nine demonstration projects, subject to financing, including three edge-of-field phosphorus removal projects, three in-field blind inlet phosphorus removal projects, and three treatment technologies in the municipal drain system.

Phosphorus in stormwater collected in municipal drains from agricultural lands, contributes to the growth of toxic algal blooms in downstream water bodies. The western basin of Lake Erie has experienced several algal bloom incidents in recent years, disrupting the ecosystem, causing the closure of beaches and even, in Toledo, OH, a ban on city drinking water for two days. Lake St. Clair, which is an indirect pathway, has also been experiencing

problems with near-shore algal blooms, and last year, they were discovered in the Thames River at Chatham.

The Canada-U.S. International Joint Commission recently released a report urging bold action to identify and implement approaches to restore the health of Lake Erie.

The PRC is among the principal voluntary initiatives included in the Canada-Ontario Action Plan released yesterday. The action plan is aimed at meeting the 2016 commitment between Canada and the U.S. to a 40 percent reduction in the total phosphorus entering Lake Erie. There is also a commitment among Ohio, Michigan and Ontario to reduce phosphorus to the western basin by 40 percent by 2025.

"As farmers, our commitment to taking care of the land and water is strong, which is why we're working collaboratively to find and use the best, most affordable and practical drainage and water management solutions," said Mark Reusser, co-chair of the PRC and vicepresident of the Ontario Federation of Agriculture.

The PRC represents agricultural organizations, municipalities, conservation authorities, First Nations, drainage professionals, and environmental nongovernmental organizations. It is dedicated to developing a suite of effective land management and drainage solutions for agriculture, in cooperation with partners, for reducing phosphorus and improving water quality in the Thames River. For more details, visit thamesriverprc.com.

Anew project by researchers at the University of Minnesota could eventually have implications for phosphorus removal from tile drainage systems on both sides of the border.

by JULIENNE ISAACS

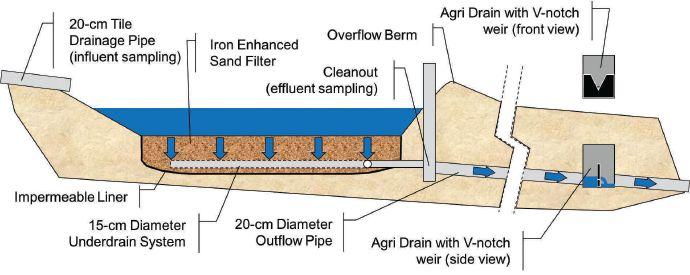

John Gulliver, a professor in the department of civil, environmental and geo-engineering and resident fellow of the Institute of the Environment at the University of Minnesota, was the lead on a four-year project that examined the efficacy of iron-enhanced sand filtration (IESF) in removing dissolved and particulate phosphorus from tile drained water.

Gulliver’s team installed the filter below drain tile for 18.4 acres of agricultural land (90 percent corn and soybean crops and 10 percent pasture) in Wright County, MN.

Filters like these are already used around Minnesota for urban drainage as a best management practice for storm water runoff, Gulliver says. This is the first time such a system has been tested for use on agricultural land.

Phosphorus can be in two forms –particulate or soluble (dissolved). Methods typically used in storm water control are sedimentation, in wet or dry ponds, or filtration, in sand filters. But neither method captures soluble phosphorus (typically phosphate).

That’s where the iron comes in, explains Gulliver. When iron filings are added to sand filter media, the iron rusts and the negatively charged phosphate is attracted to the rusted iron’s positively charged ferric ions. “The phosphate binds to the filings,” he says.

The system has advantages over the use of constructed wetlands for phosphate removal, which adsorb phosphate for a limited time but not permanently, says Gulliver.

“After a while the plants start degrading

Years

When land improvement contractors need innovative drainage and complete earthworks solutions, they come to Trimble. Why? Because we listen to our customers.

Most of our best ideas come from our users. Laser grade control, levee design systems, field leveling and 3D GPS‑based grade control all came out of talks with growers and contractors.

and the wetland can release more phosphorus than comes into it. It can work for a while but then you have to dig it up and start over.”

What the IESF does is pull phosphate out of the water column –for good.

At year four of the project, the team saw a total of 66 percent phosphate removal from the site – an impressive achievement rivaling that of newly constructed wetlands.

The study’s main objective was to evaluate how effectively the IESF could remove phosphate from tile drained water.

The IESF was designed so the filter media surface lay about 30 centimeters below the natural topography; drain tile water was intercepted to flow over the surface of the IESF, with berms installed around the edges to provide storage volume.

The media bed measured 6.1 meters

Iron-enhanced sand filter schematic with relative location of agri-drain and V-notch weir (not to scale).

wide by 15.2 meters long and 30 centimeters thick. Below that was a layer of pea gravel (15 centimeters thick) surrounding a PVC perforated pipe underdrain system to collect water after filtration.

After passing through the underdrain system water was discharged into a nearby ditch.

Monitoring equipment recorded rainfall-induced tile drainage events

beginning in June 2015 and continuing until November of that year. The monitoring equipment was reinstalled for the following summer and fall.

For these monitoring periods, flow rate data was separated into two categories – rainfall event and baseflow, with baseflow defined as periods with a flow rate less than .28 liters per second.

Roughly 90 percent of the measured

tile drainage corresponded to rainfallinduced events and approximately 10 percent corresponded to baseflow. Thirty-three rainfall events were recorded during the study’s duration.

Samples were collected from within the inlet pipe (influent samples) and where the underdrain pipe connected to the discharge pipe (effluent samples).

“Routine and non-routine maintenance performed since installation of the IESF resulted in a reduction between influent and effluent total phosphorus and phosphate loads on the receiving water body for all rainfall-induced events measured during this study,” writes Gulliver and colleague Andy Erickson, a research associate at the University of Minnesota, in the study’s publication in the journal Water . The total phosphorus load reduction for each event ranged between 42 percent and 95 percent, with an overall total phosphorus load reduction of 66.3 percent –similar to the phosphate load reduction (63.9

percent), because both particulate and solublephosphorus were captured.

Gulliver says the system cost roughly US$30,000 to install, of which the iron filings, sourced from junkyards specializing in turning old machinery into filings, cost between US$3,000 and US$6,000.

The team did not consult or work with drainage contractors on the project – the IESF was installed using a front-end loader. Another contractor brought in sand, and the team mixed the media with a rototiller.

In Minneapolis’ urban storm water control context, the city generally makes deals with landowners to maintain the system for two years, after which the landowner takes over the responsibility. But maintenance requirements are minimal, says Gulliver: all that’s really required is weeding.

As this is the first time such a system has been tested in an agricultural context, there is no precedentfor tile

drainage contractors on either side of the border for designing or installing IESFs. But IESFs could theoretically join the ranks of other water treatment systems already in contractors’ arsenal. DC

IESF DESIGN CONSIDERATIONS

• The IESF must be allowed to drain; therefore the outlet of the underdrain system must be placed above the high-water elevation of the downstream conveyance system.

• The IESF must be designed with eight percent or less of iron by weight; iron content greater than eight percent may cause clogging.

• Iron used in the IESF must be high purity to avoid leaching contaminants into runoff water.

(Adapted from “Phosphate removal from agricultural tile drainage with iron enhanced sand” published in Water on Sept. 6, 2017).

Wolfe Heavy Equipment continues to set the tone for powerful agricultural and commercial trenching equipment. Wolfe’s versatility, superior manufacturing and expert service along with reduced fuel consumption provides increased profitability.

Learning the trade of farm drainage is often a handed-down, hands-on experience from one generation to the next. In one instance though, it has also included a transfer of knowledge and practical experience internationally.

by PETER DARBISHIRE

RIGHT: Being able to show customers how he severs existing tile systems effectively provides them with confidence in his techniques.

What transpired was an apprenticeship beyond the home-learned variety, which was eventually taken back home.

Curious about the tile drainage business in North America and specifically in Canada, Tom Whittemore, a U.K. contractor, decided to learn more. The industry in the U.K. was almost at a standstill and he was eager to continue in the business his father had started in the 1960s near Chester in northwest England. What followed was a whirlwind trip to Ontario and Michigan to see the latest technology contractors were using.

Interestingly, at that time several contractors were looking at their succession plans and Whittemore learned there might be opportunity to emigrate and work in the industry, and perhaps find himself in an equity position

after a few years. He was encouraged by a few discussions with contractors and personnel from the Ontario Ministry of Agriculture and Food, which oversees the land drainage business. He decided to take a plunge, uproot his young family, and apply for immigration to Canada with a promise of employment from an Ontario contractor.

One of his first commitments was to enroll in the series of drainage courses provided by OMAFRA. The courses are operated to ensure that all tile installation complies with the Drainage guide for Ontario, within Regulation 18 of the Agricultural Tile Drainage Installation Act. There are primary and secondary courses for machine operators and a third course to qualify for contractor status. Individuals passing these courses are awarded certificates.

FASTER AND EASIER INSTALLS

With a flexible liner, FlexCorr greatly cuts down on the complexity and time required for dual-wall installations.

The smooth interior of FlexCorr provides a resistance free flow for high capacity drainage. (Verified Manning’s “n”<.012)

RIGOROUSLY FIELD TESTED

It took years of R&D to get the formula right for FlexCorr. But we didn’t stop there. We continue to test all of our pipe and look for new ways to innovate.

The program is the only such program offered in the world, following passage of legislation in 1973, though contractor ‘short courses’ have been offered for about 100 years in Ontario (more information on the courses and the licensing program for operators, contractors and drainage installation machines is available at www.omafra.gov.on.ca/english/engineer/facts/01-063.htm).

Whittemore worked with a couple of contractors over the following two years, then while awaiting his final immigration papers to arrive, set up what was to be a promising relationship with a contractor who was planning to retire. In the intervening period, he had a Class ‘C’ license, was on his way to achieving his Class ‘B’ and ‘A’ licenses, which require accumulating 250 hours and 500 hours of machine operating experience and was signed up for the advanced course. His attendance at the annual meeting of LICO (Land Improvement Contractors of Ontario) also helped gain understanding of the business.

As time was nearing for the final papers to arrive, bureaucratic bungling came into play. His immigration application papers had been misplaced and he was instructed that he would need to re-apply at his own cost. Appeals to authorities, members of Parliament and assistance from staff at OMAFRA achieved nothing, So Whittemore reluctantly, and at great cost, decided to head back to England with his family. A last minute call from Immigration Canada after officials had

located his application came too late.

What was Canada’s loss in accepting an immigrant with the desire and drive to succeed has turned out to be the U.K.’s gain. Whittemore Land Drainage is now a viable and thriving contracting business, operating out of Oakham, Rutland, England. At first, the business used a leased self-propelled Mastenbroek 35/20 trenchless machine and now is in the final stages of trading his Mastenbroek 20/15 chain trencher for a larger model, a used Mastenbroek 30/30 chain trencher.

Importantly, the Ontario experience has given Whittemore the knowledge that enables him to show U.K. farmers there is another way to drain farmland, “with more pipe per acre and better drainage performance,” he says. His projects now feature 3.2 inch (80 millimeter) pipe laid at 35-foot (10 meter) spacing. This compares with recent traditional spacing in the U.K. of 140 feet (40 meters), with stone backfill to within 12 inches (30 centimeters) of the surface. The landowner would normally cross drain the field with a mole drainer every few years to improve water flow to the wide spaced drains (see sidebar). Closer-spaced drains will allow the user to eliminate this pass with additional equipment, which fits with modern field management in the U.K.

The costs of draining with closer spacing works also. Whittemore is able to work a two-man crew: himself operating the trencher and another man to make connections, bring tile to the machine and backfill the trenches. “An operation

installing with stone backfill, needs a much larger crew, a specialized stone backfiller, stone delivery equipment and extra loaders and tractors, all of which contribute to soil compaction and site damage that needs remediation,” Whittemore explains.

As the concept of closer spaced drain lines is getting more discussion, Whittemore can see where he might need to invest in a trenchless machine. “I have already had a positive reaction to the idea of trenchless drainage,” he says. Customers realize how using a trenchless system reduces soil compaction at work sites. While using a trencher, they have been able to see how he is ensuring all existing tile are connected to new systems and he can illustrate how using trenchless machine will eliminate old tile systems by altering the layout direction of laterals. He tries to place drains slightly deeper than existing tile for this purpose. Mostly, he uses the layout he learned in Ontario of trenching diagonally to fencelines to sever existing tile frequently, thus decommissioning them. He emphasizes to clients that a diagonal layout also improves trafficability of farm operations.

One large dairy operation near Chester, U.K., which milks 1,200 cows, has already noticed the benefit of this. Harvesting 280 tonnes per hour of forage corn (maize), Grosvenor Farms’ field manager, Charlie Steer, appreciates the difference at harvest as well as when planting crops. Others are reporting better soil structure recovery.

As his business grows, Whittemore expects to use GPS more extensively. Currently the trencher is fitted with Trimble laser grade control, but the operation uses a GPS guided

tractor fitted with a sub-soiler leg to mark out parallel lines for trenches once the layout is determined. After finishing each run, the machine is backtracked over the next one to check grade changes. He also expects more farms will realize the benefits of closer spacing and hopes they will look to him as the one with the experience, knowledge and qualifications to do the work. DC

Peter Darbishire was editor of Drainage Contractor from 1978 to 2008. He is an honorary life member of the Land Improvement Contractors of Ontario.

The use of stone backfill material in most U.K. drainage is that there has been a long-held tradition for using mole drainage, especially in very heavy soils. Well-formed mole drains can last for years if created when the subsoil is moist and ‘plastic’. They are made by pulling a blade fitted with a mole expander through the soil at a constant depth. Moles are made at an angle to tile drain trenches, which are backfilled with stone, thus allowing the water to reach the drains.

Following World War 2, the War Ag program in the U.K. provided grants to farmers for installing drainage systems. The grant aid specification called for 40 meter spacing, stone backfill and moling. The program provided aid until 1984 when it was phased out over five years. The business of draining farmland then took a nosedive, but the tradition of using wide spacings and stone backfill remains.

Location, location, location. This old adage used in real estate hints at the fact that not all properties are equal and the characteristics that make up a place will affect the value of that property.

by BY BEN REINHART, DAN JAYNES, MARK TOMER AND DAVID JAMES

LEFT: Conventional drainage (top) allows free drainage to nearby ditches and streams. Controlled drainage (bottom) uses water control structures to manage the depth of the outlet allowing control over the water table in the field.

Images courtesy of Ben Reinhart.

RIGHT: Saturated buffers utilize a water control structure to divert tile drain water into the soil of a riparian buffer where excess nitrogen can be removed before being discharged to a nearby ditch or stream.

This same relationship applies to evaluating the suitability of sites for practices such as controlled drainage and saturated buffers. Two new tools are available that drainage contractors can use in evaluating the suitability of potential sites for these practices.

Controlled drainage is the practice of using water control structures in subsurface tile drains to manage the depth of the drainage system outlet. For example, water control structures that are set at the depth of the tile drain are able to drain freely, similar to an uncontrolled tile drainage system. Water control structures set at shallower depths (i.e. closer to the soil surface) retain tile

drain water in the soil profile and cause the water table rise. The overall result leads to reduced total tile drain flow volumes, which can offer improvements in water quality and water availability to crops in tile-drained agriculture.

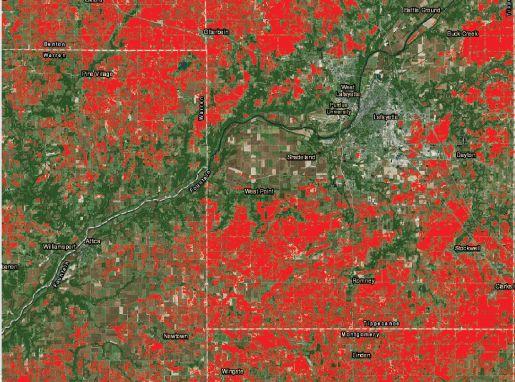

The primary factors in determining suitable agricultural sites are topography and soil type. The more variability that we have in both, the more difficult (and costly) it becomes to not only implement but also manage controlled drainage systems. The first estimates of cropland suitable for the practice of controlled drainage, developed by NRCS soil scientists in 2012, provided valuable information on the regional potential for the practice. In working in collaboration with researchers from the Transforming Drainage

project, NRCS soil scientists have developed new estimates using more recent soils and cropland data and results are now viewable in an online GIS viewer. This online tool allows drainage contractors to take advantage this spatial analysis and to help evaluate the potential for implementing controlled drainage in Midwestern tile-drained agriculture. The tool is accessible at www.transformingdrainage. org/tools/cd-suitability and identifies land in the upperMidwestern United States that has a high probability of being suitable for the practice of controlled drainage. These estimates are based on the following criteria:

• Land use is determined to be cropland (source: 2015 USDA-National Agricultural Statistics Service Cropland Data Layer)

• Field slope is less than or equal to one percent (Source: 2017 USDA-NRCS Gridded Soil Survey Geographic [SSURGO] Database)

• Soil types that naturally have a water table within 18 inches of the surface during the growing season, and thus are likely tile drained (Source: 2017 USDANRCS Gridded Soil Survey Geographic (SSURGO) Database)

• Mapped soil units that are at least 15 acres or larger in size, and thus are considered the most economically cost-effective to control tile drainage with the fewest number of water control structures (Source: 2017 USDA-NRCS Gridded Soil Survey Geographic [SSURGO] Database)

It is important to note that the online viewer does not take into account property or field boundaries. So, as in any project, the project planning should further evaluate any potential impacts on neighboring landowners and land uses. In some cases, areas not identified in the map may actually be suitable for controlled drainage depending on the site-specific topography, drainage system layout, and other factors. This online viewer does not replace the need for field verification by a drainage contractor or engineer. However, this resource provides an easy to use, open-access tool to evaluate quickly potential locations for implementing controlled drainage.

Typically, tile drainage water is discharged to either a county main or to a drainage ditch or stream. When the tile outlets to a ditch or stream, the tile flow bypasses the near-stream (or riparian) soils. Riparian soils are well suited to remove nutrients, especially nitrates, from water. The saturated buffer is a new practice that discharges a portion of the tile drainage water into riparian soils, which reduces nitrate concentrations from drainage water before it enters the stream or ditch. Basically, a saturated buffer consists of a water control structure that is installed into the tile line just upstream of the outlet, within a streamside buffer. The water control structure is used to raise the water height at the outlet and divert some of the tile flow through a perforated pipe installed roughly parallel to the stream and as close to the surface as possible. Some of the tile water (and nitrate) seeps into the buffer and flows as shallow groundwater to the stream. Nitrate is removed within the

Online viewer showing potentially suitable cropland soils for implementing the practice of controlled drainage.

buffer by natural biological activity using carbon stored in the soil and renewed by the growing perennial vegetation within the buffer.

Saturated buffers are fairly inexpensive and easy to install, but to function properly, specific soil and landscape factors need to be satisfied. The USDA Agricultural Research Service has developed a GIS-based toolbox, called the Agricultural Conservation Planning Framework (www. northcentralwater.org/acpf/), which includes a tool that identifies riparian locations that are well suited to the

saturated buffer practice. The tool checks soil survey information to ensure the soils should have organic carbon concentrations sufficient to support nitrate removal, and that the soil hydrology will help keep the discharged tile water at shallow depth where that carbon is found. There are also two topographic criteria that must be satisfied, which are used to reduce the chances of unintended consequences from installing the practice. First, the new USDA-NRCS standard for this practice specifies that bank heights should be less than eight feet, so that the risk of bank collapse is minimized. Second, the slope of the riparian zone above the stream bank is also important. If the slopes are less than two percent, there is a risk that the practice may inundate some of the crop above the buffer. If the slopes are greater than eight percent, there is a risk that the tile water may seep out and flow over the soil surface, leading to erosion. Therefore, the tool checks that a substantial portion of the riparian zone is comprised of two to eight percent slopes. By default, a “substantial portion” is defined as 35 percent of the riparian zone, but a planner familiar with soils in the area is able to adjust that criteria to be either more or less restrictive. A preliminary statewide analysis for Iowa found more than 14,000 miles of streambanks that met all suitability criteria for saturated buffers (note: one mile of stream has two miles of stream bank).

The Transforming Drainage project is an eight-state project of 15 leading agricultural engineers, soil scientists, agronomists, economists, social scientists, and database and GIS specialists with a common vision to transform the way we implement drainage across the agricultural landscape. Our team works to bring together people, data, and tools to learn from each other and explore new ways to increase water storage in tile-drained areas as a way forward in improving water quality and water availability in Midwestern agriculture. The network of drainage professionals, engineers, and farmers involved in the Transforming Drainage project continues to grow across the region. If you are interested in finding out more about the project, tools, and resources go to www. transformingdrainage.org and stay tuned for future tools from the project. DC

Ben Reinhart is the project manager for the Transforming Drainage project and staff in the Agricultural and Biological Engineering Department at Purdue University. You can contact him at 765-496-6331 or breinhar@purdue.edu.

Dan Jaynes and Mark Tomer are research soil scientists and David James is a geographic information specialist at the USDA National Laboratory for Agriculture and the Environment in Ames, IA.

Port Industries traces it roots back to Mercer County, OH, before 1900, when Harvey Shimp was laying clay field tile. His son, Nathan Shimp, helped Harvey through his years growing up while he was in school, and then also after he returned from WWII. In 1950, Nathan wanted a better ditching machine than the 1911 model he was running, so he designed a new machine. He hired a local welding shop to build it for him and others quickly wanted one of the new Tandem Traction Trenches. In the early 1960s, Nathan sold his interest in this venture to Karl and Mark Speicher. He then incorporated Port Industries, and in 1967 Port Industries completed it's first machine. This was an auger backfiller, and it was followed by the HydraTandem Trencher in 1968.

The Hydra-Tandem was the first completely hydrostatically driven trencher. All other ditchers being built at that time were driven with gear boxes and exposed drive chains. Nathan used the machines he built through Port Industries to build a successful drainage contracting business in northeast Missouri and westcentral Illinois. He continued to build machines through the ’70s and ’80s, and if a machine wasn’t sold, Nathan and the Port Industries employees would use it to install drain tile themselves until it did sell.

Port Industries introduced the Hydra-Tandem II in 1987. This was the first rubber-tired trencher capable of digging seven feet deep. In 1991, the Hydramaxx 2400 became the first four-wheel drive trencher offered by Port Industries. By 2002, Port Industries’ product line included the Hydramaxx 2600 (rubber tire wheel trencher), the Hydramaxx 2500 (rubber tire chain trencher), and the Hydramaxx 3300 (self-contained plow).

Port Industries moved to its current location in 2000. In 2015, Port Industries added on again to include office space, and in 2016 added a new service building, featuring three independent service bays.

This year, Port Industries has introduced an interchangeable V-Plow attachment, and a selfcontained full-size V-Plow, the Hydramaxx 3320 V-Plow, manufactured in the USA. Hydramaxx equipment is used in a variety of markets, including agriculture, renewable energy, pipeline and gas. The Hydramaxx brand can be found in Canada and across the United States.

Today, 50 years after the launch of the first trencher, Port Industries is still growing and changing to keep up with technology, customer demand, and service. Port Industries now also specializes in setting up machinery, from back-fillers to tractors, with Trimble products for machine control for steering and elevation control offering both laser and GPS.

On July 27, 2018, Port Industries will be hosting a field day to celebrate its 50th anniversary and to showcase its newest models of trenchers and plows. Visit www.portindustries.com for more information.

It is our pleasure to introduce you to the all-new BRON 585 Drainage Plow. Field tested with many new features, the BRON 585 is once again raising the bar for plowing performance and accuracy.

Performance & durability improvements come on all fronts, from the dual-auxiliary circuits to the available Heavy-Duty drive package. The plow valve now has a dedicated pump providing on-demand fl ow for those fast grade corrections, without interruptions from other functions. Custom confi gured to improve effi ciency, all plow functions are not integrated into one valve assembly. To improve drive component durability and travel speeds, the new HD drive package can plow in excess of 4mph while maintaining cooler gearbox temperatures driven by effi cient motors and pumps.

The newly reconfi gured operators’ station is considerably quieter and ergonomically equipped for best in class operator comfort, in part due to the felt-lined headliner. Convenience is brought to a new level in the front dash with cup holders and a dual USB charging port next to a pocket to store a phone or media player. The integrated peak over the rear window makes it easier to see out back in inclement weather.

Our new and improved 5-core cooling package is best in class with a continuous duty rating of 50˚C in ambient conditions. This cooling package exceeds the performance demands of

the new Tier-4f engines prolonging major component life. A dedicated fan designed for fast response keeps the hot intake air within limits in the most extreme operating conditions, while allowing the main fan to remain at a consistent speed, reducing noise and eliminating wasted power/fuel.

Servicing the BRON 585 has never been easier. An access door allows the operator to check the engine oil without opening the hood, which is accessible from the ground or the catwalks. The side opening hood gives you premium access to the engine while the new front opening hood allows for great entry to our new cooling package.

The higher-rated pump drive gearbox includes increased oil capacity for better cooling, improving gear and bearing life, providing piece-of-mind for the high-production requirements of seasonal equipment. An oil level dipstick is now standard equipment to simplify daily inspections.

The BRON DL850 plow comes standard on the 585. Out in the fi eld since January 2016, the DL850 is fi eld proven and sets the standard for performance and grading accuracy.

To match the performance, the machine looks the part with a larger 6" chrome exhaust stack, powder-coated honey-comb grilles, and ‘bright-as-the-sun’ LED light bar.

The all new BRON 585. Purpose built with the Power to Perform.

www.rwfbron.com

■ Five Core Cooling System exceeds cooling for Tier 4 engine standards

■ Quieter Reconfigured Cab Interior for Operator comfort

■ Standard DL 850 Drainage Plow increased strength & durability

■ LED Light Package for increased visibility for those long days in the field

■ Improved swing mechanism for the Onboard Reel for smoother reel speeds & consistent torque

■ Optional hydraulic rear step raises out of the way when plowing and lowers when required.

■ Standard oscillating track frames.

■ Fluid Samples for All Fluids

■ 150 Point Machine Inspection

■ Internal Inspection All Drivetrain Components

■ Required Factory Repairs

■ New & Used Equipment Sales

■ Parts & Service all BRON Products

■ Selected All Makes Parts for Construction Equipment

■ Certified Rebuilds on BRON Products

■ Custom Fabrication

■ New Paint

■ Factory Tested

■ New Certified Serial Number Assigned

■ 6 Month Warranty Assigned

■ Repairs on all Drainage Plows & selected Construction Equipment

■ Parts Facility in Marine City Michigan

■ Road Service for all BRON Products & other selected Equipment

■ Parts Facilities in Woodstock ON and Marine City MI.

by Jacqui Empson Laporte

TSomehow we need to find a way to address a risk-averse society if we want to encourage innovation in drainage.

here has been a lot of work in Ontario to establish relationships and partnerships between the drainage community, local agricultural groups and conservation authorities. The intended goals of these partnerships have been to dispel myths about drainage, promote the adoption of innovative drainage techniques, and to use the knowledge and skills of tile drainage and erosion control contractors in achieving improved water quality and soil health. For example, municipal drainage superintendents and environmental specialists presented on innovative drainage topics at the Latornell Conservation Symposium. LICO and the Drainage Superintendents Association annual conferences always include an environmental component. Larry Brown, a professor and drainage water management researcher at Ohio State University, spoke to representatives from local conservation authorities, engineers from the Ontario M inistry o f A griculture, F ood and Rural Affairs, certified c rop a dvisers a nd r esearchers in January. And in March, a meeting was held at a 40-acre demonstration farm in Clinton, ON, as a collaborative effort between the County of Huron, lakeshore residents and the Huron Soil and Crop Improvement Association.

The point of these meetings was to c hallenge e xisting b eliefs a bout d rainage, explore innovative drainage ideas and discuss how organizations can balance agricultural productivity and the need for improved water management. Yet, discussions about tile and communal drainage are polarized as ever. At any event and you will hear comments from

both ends of the spectrum, from “tile drainage is essential for agricultural productivity and improving soil health” to “tile drainage is responsible for degraded water quality in the Great Lakes.” In reality, the answer is not at the ends but somewhere in the middle.

Perhaps these opposing views of drainage impact the adoption of innovative drainage designs that would benefit agriculture and the environment. Could entrenched beliefs contribute to a lack of innovation and adoption? What else is preventing research and development into innovative drainage technology?

First, risk management is a huge barrier. Farmers don’t want to take the risks of unpred ictable produc tion in fluctuati ng economic systems. Contractors want to be associated with “innovation” but not the project that “fails” in the eyes of the agricultural community. Municipalities and regulatory agencies don’t want to take risks on innovative projects with taxpayer funds, when predictability of the outcomes are demanded. Grant programs rarely fund innovation, when the success of receiving the grant money i s d ependent o n pr edictable e ffectiveness; for example, the amount of kilograms of phosphorus removed.

S omehow, we – f armers, c ontractors, designers, engineers, and regulatory agencies – need to find a way to address a risk-averse society if we want to encourage innovation in drainage. Can we affordably use technology to improve efficient use of the system (for example, to measure soil moisture levels a nd a nticipated w eather e vents t o c ontrol water levels in real time and use of remote operation)?

Second, the upstream and downstream practices of adjacent farmers can pose both challenges and opportunities for innovative

drainage projects. In Huron County, Ausable Bayfield Conservation and Maitland Conservation have been successful in encouraging farmers in two priority watersheds to implement a series of best-management practices such as biofilters, windbreaks, water and sediment control basins (WASCoBs) and cover crops. Positive results include reduced erosion, improved water management during storm events and collaborative projects among landowners. Innovative drainage must be a component of a watershedbased drainage and erosion control design, in order to achieve cumulative benefits.

Third, agricultural economics and precision agriculture could play a role. While drainage can improve the productivity of farm or increase the value of a field, it will not be the complete answer to farm finances. Precision agriculture may assist us in determining more accurate costs of production and find a balance between agricultural production and those areas that can be used for water retention and storage. Innovative drainage must be part of a whole-field stewardship design involving cropping practices, erosion control and overall water management.

Fourth, the options for innovative practices must be based on the local conditions. Ontario has not consistently experienced drought to an extent that would influence the economic necessity and feasibility of controlled drainage. The complex topography may affect the success of contoured drainage techniques, but broad implementation would have to address existing drainage systems.

Technology can address some of the barriers, but we have to move away from entrenched beliefs and be willing to invest in it. We have focused on partnerships with agricultural and stewardship groups to improve water quality, but we need to invite LICO members to the table. While they have been part of project construction and design, we need to make sure they are part of broader discussions about water quality and soil health. Finally, while agriculture is inherently a competitive business environment, perhaps it’s time to return to our rural community society and work together to find solutions to problems of poor water quality.

Jacqui Empson Laporte is an environmental specialist and a member of the drainage team for the Ontario Ministry of Agriculture, Food and Rural Affairs. She is also a director on the board of Innovative Farmers Association of Ontario, and is responsible for managing projects related to Lake Huron water quality. Her interest is the design of environmental programs.

• Environmentally friendly

• Self levels spoil

• Direct Drive

• Reach and precision of an excavator

Haviland Drainage Products has added SmoothFlex to its catalogue of drainage products. SmoothFlex is a flexible dual-wall pipe ideal for those areas where the water table elevation is an issue and contractors are unable to trench. With its smooth inner wall, this pipe allows for significantly higher flow rates, while still maintaining its flexibility. The flexibility of this product allows it to be installed in the same manner as single-wall pipe, cutting installation costs while increasing jobsite safety.

Haviland also recently added short and long Spin In tap tees to its lineup. Spin In tap tees allow users to simply cut a hole, push and spin, thus locking the tap tee in place. For more information, visit www. havilanddrainage.com.

Advanced Drainage Systems Inc. has launched the ADS Installation Guides mobile application, offering

everyday installation instructions for its thermoplastic pipe products. The app is a resource to provide guidance on the installation of ADS pipe used in both stormwater management and sanitary sewer applications.

With specific instructions from jobsite handling and receiving, to in-field testing recommendations, the app is designed to be an easily accessible handbook for on-the-go contractors. Installation instructions are provided for N-12, SaniTite HP and HP Storm pipe products.

The app provides information on a variety of topics, including product handling, storage, joint assembly and installation. The app is available in English and Spanish and is free to download via the App Store and Google Play. For more information about the app, ADS SaniTite HP, HP Storm, N-12 pipe and all ADS water management system products and support tools, go to www.ads-pipe.com.

Little Beaver Inc. offers its D-Series augers for extended drilling depths. The series features a secure drive pin connection,

allowing operators to drill deeper than 15 feet during geotechnical and environmental testing and foundation repair. Augers in the series range from four to 18 inches in diameter.

The D-Series augers and extensions are available in 36-, 48- and 60-inch lengths with standard tips and blades, arbide blades or heavy-duty tips. The tips and blades exchange easily to accommodate varying soil types, allowing the operator to quickly switch on the jobsite.

Visit www.littlebeaver.com for more information.

A new rotary attachment is now available from DitchDoctor. Developed to work in dry conditions, the attachment does not require water to work at cleaning out various forms of infrastructure, including agricultural drainage. The DitchDoctor rotary attachment requires only one excavator and one operator. Visit www. ditchdoctor.ca for more information.

Sentera LLC, a Minneapolisbased supplier of remote sensing and drone technology to the agriculture industry, has

added elevation maps to its FieldAgent software platform. Formerly known as AgVault, FieldAgent offers a broad range of precision agriculture capabilities and analytics. The addition of elevation variance maps provides topography and elevation data to ag professionals. The data can be used to increase operating efficiencies in building variable rate prescriptions, create drainage or land-leveling plans and design subsurface drainage. Visit www.sentera. com for more information.

Elmer’s Manufacturing has acquired Dynamic Ditchers Inc., the manufacturer of the Wolverine Extreme Rotary Ditcher, closing June 1, 2018. The Wolverine Extreme Rotary Ditcher will complement the current offerings from Elmer's Manufacturing. Dynamic Ditchers started in 1999 with a farmer wanting to close a gap in the current equipment market that provided an improved finish over a scraper and excellent performance. After constant testing and modification on their current farm, they released the first Wolverine Ditcher in 2008. The Wolverine Extreme Rotary Ditcher will continue to be available at existing dealers as well as being available at all Elmer’s dealers. Visit elmersmfg.com for more information.

• Exclusive locking device on each part.

• Adaptor available to repair old metal or broken intakes.

How advancements to drain tile have influenced the drainage

Wby JANNEN BELBECK

ith the advent of GPS technology and the development of the newest tile plows, it can be easy to forget about how far the tile industry has come in terms of technology and advancements.

From the beginnings of clay and concrete tile, to the manufacturing of corrugated wall highdensity polyethylene (HDPE) pipe in the 1960s, drainage pipe has continued to advance, offering easier installation, a safer worksite, and costsavings like less labor and time spent in the field.

Clay drainage tile was typically four inches in diameter, installed in one-foot sections laid end to end and buried about three feet deep. While the clay or concrete tile did its job, the installation was labor intensive and required a large crew. Today, customers and contractors would be hard-pressed to find a crew or manufacturer still working with those materials in the realm of agricultural drainage.

High-density polyethylene was discovered in 1951 and first used to make baby bottles. In the 1960s, the owners of Advanced Drainage Systems (ADS), Marty Sixt and Ron Martin, were some of the first to manufacture tiles from the material in long, continuous lengths. Agriculture was one of

the first industries that saw its use.

The first commercially manufactured corrugated HDPE drainage pipes were four inches in diameter (the same as what was manufactured for clay/concrete), before they got larger, moving from four, to six, to eight and in the mid-1970s, some companies began making 12-inch pipe. Twenty years after the first HDPE pipe was manufactured, the ’80s saw the first dual-wall (or double wall) pipe sold.

Instead of water flowing through the uneven surface of corrugation of a single wall pipe, dualwall pipe (DWP) allowed for faster water flow efficiency – a much-needed feature for large rain events at critical times in a crop’s growing cycle.

Manufacturing dual-wall pipe involves a different extrusion process than typical single wall pipe. Today, DWP is manufactured a bit differently than it was in the ’80s – and with better quality, thanks to technological advancements in plastics formulation and manufacturing processes.

“The way it is produced today by the industry

was a mid-90s revolution or change in process,” says Jamie Duininck, co-owner of Prinsco.

He says likely by the early 2000s (or maybe even the late ’90s), most – if not all – pipe companies were manufacturing dual-wall more or less the same way, with similar size options.

Aaron Kassing, vice-president of marketing for Timewell Drainage Products, calls the creation of plastic tile “one of the greatest things that happened to the tiling industry.”

“[Plastic] made it so much easier when we were able to move away from the high labor that was needed to install the clay. I would call the development of dual-wall and flexible dual-wall pipe as enhancements to the industry,” he says. “That is to say that dual wall and max flex dual wall didn’t replace single-wall pipe, but they created a better product for specific applications.”

The last couple of years have seen the release of flexible dual-wall (FDW) HDPE pipe in North America. A product ideal for areas with a high water table, FDW is manufactured to be as flexible as possible, but with enough strength to avoid crushing.

Primarily used for the collector lines, FDW continues to save contractors on labor cost and time spent in the field. For example, data from Prinsco highlights 60 percent faster installation with their version of flexible dual-wall. FDW in general also improves worker safety. When flexible dual-wall products were introduced into the marketplace, it helped with the installation of the mains.

“From a speed standpoint, there are very significant speed increases [with FDW] and from a safety standpoint, there’s no one in the trench box,” Duininck says.

Because of the flexibility needed for the FDW to be coiled into a maxi and run through a boot and installed, the inner wall isn’t as smooth as standard dual-wall pipe, Kassing says, and the flow rate is slightly affected. But Kassing says it’s still very similar – after all, flexible dual-wall may be a slight bit more expensive, but the labor costs and time spent in the field lead to the installation of the main line cheaper for the contractor (and, in turn, the customer).

In order to use this newest pipe technology, FDW often has to be installed with modified equipment, but Kassing says none of

his customers have experienced issues with this.

Research and development in a variety of industries will continue to change how drainage contractors operate – and even what their jobs encompass. It’s not unusual to see contractors doing other excavation jobs, and installing saturated buffers and constructed wetlands to mitigate the environmental effects of nutrient run-off, all in addition to their regular drainage work.

The tile industry may also see advancements in an environmentally friendly manner. For example, recent research from Villanova University found the performance of HDPE pipe made from virgin material was indistinguishable from pipe containing recycled HDPE resin. Pipe manufacturers aligning with drainage sustainability make sense – the majority of the research focus is on sustainability. For example, scientists with Agriculture and Agri-Food Canada presented a study at the International Drainage Symposium in 2016, showing there are optimal combinations of tile depth and spacing to reduce nutrient losses (both surface and subsurface). And, in one of the many research projects by the Illinois Drainage Research and Outreach Program (I-DROP), the team is evaluating dissolved phosphorus in tile drainage to develop a new drain concentration table to answer questions about how and why phosphorus is transported through subsurface drainage.

Drainage research allows contractors to be up to date with best practices, and in turn continue to educate the farmer (and the public) that drainage does more than improve crops yields.

Echoing the directions and considerations of the research, Kassing believes environmentally conscious drainage systems are the future.

“I think we will continue to see a push from the industry, as well as partnering farmers, to look at new and innovative ways they can retain some subsurface moisture and monitor some of the outflows,” he says. “Constructed wetlands, things of that nature will continue to be a growing area in our industry.”

Drain tile and the manufacturers will likely have a role to play. DC

Sharing knowledge and advice benefits everyone.

by Rob Burtonshaw

This year, contractors from the Netherlands, Canada, the United States and even Tasmania have decided to make the effort and visit us here in sunny old England. It’s been quite a conveyer belt of accents, flight times, hire cars and difficulty with navigation, all within the backdrop of different drainage techniques. This has been a pattern for the last couple of years and I hope I have improved as a host. These days, I opt for a warts-and-all policy; whilst the welcome is warm and I give my time generously, I do not arrange special things or try to give the place a spring-clean for our guests. We are what we are: a traditional drainage company trying to improve; we have faults and any decent contractor will spot them anyway, so, in my line of thought, it’s best to be open and ask how they solve them. Most spend a day with us and give a great deal of attention to the gravel backfill we routinely place over our pipework. As far as I can tell, the visits have gone well, and I hope everyone leaves contented.

I’m keen to welcome visitors warmly, in part as repayment for sincere and generous receptions I received whilst travelling the world for my Nuffield Scholarship. But I’m also keen to welcome people because it’s the best way to learn.

I have welcomed some very successful and clearly competent contractors through the doors of our 1970s office/bungalow, and shown machinery far older than they are used to seeing do a job they have done many times before. I hope to show people something new – or at least light fire to their enthusiasm with my own – but I’m under no illusions; often I gain more from their visit than they do. Other people have been faced with the same problems I face and if I can piggyback on their experience and take a shortcut, then I’m keen to do so. If it works, I’ll happily accept advice.

Having read the first two paragraphs you might now understand why I felt a tad envious whilst giving a talk on drainage to a recent Monitor Farm Meeting. For those of you not familiar with British agriculture, the levy board (the Agriculture

miles away, hence my keenness to share and talk to other contractors. I do not have all the answers but I reckon between us all, we have at least some of the answers and by sharing that knowledge we all gain. DC