PRODUCTIVITY DOESN’T

HAVE TO BE COMPLICATED

Compact and nimble Hy-Brid Lifts are designed to help you move quickly from one project to the next. With lifting capacities up to 750 pounds and 30-inch slide out deck extensions users have more room, can load more supplies and get more done. The industry leading low floor loading pressures allow them to access green concrete weeks before heavier lifts, and the non-marking wheels won’t cause damage to finished floors so they can be on the job from start to finish.

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

(800) 265-2827 or (519) 429-3966 Fax: (519) 429-3094

EDITOR I Patrick Flannery pflannery@annexweb.com (226) 931-0545

SALES MANAGER I Ed Cosman ecosman@annexweb.com (519) 429-5199, (888) 599-2228, ext 276

ACCOUNT COORDINATOR I Barb Comer bcomer@annexweb.com (519) 429-5176, (888) 599-2228, ext 235

MEDIA DESIGNER I Gerry Wiebe

CIRCULATION MANAGER I Urszula Grzyb ugrzyb@annexbizmedia.com 416-442-5600 ext 3537

GROUP PUBLISHER I Martin McAnulty mmcanulty@annexweb.com

DIRECTOR OF SOUL/COO Sue Fredericks

Publication Mail Agreement #40065710.

Printed in Canada ISSN 0383-7920

email: rthava@annexbizmedia.com Tel: 416-442-5600 ext. 3555 Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

Subscription Rates

Canada- 1 Year $42.00 (plus 5% GST - $44.10) U.S.A. - 1 Year $60.00

Occasionally, Canadian Rental Service will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request.

Serving the Canadian rental industry for 40 years.

www.canadianrentalservice.com

4

EDITORIAL

We keep hearing that housing prices are overheating. Is there cause for concern?

22

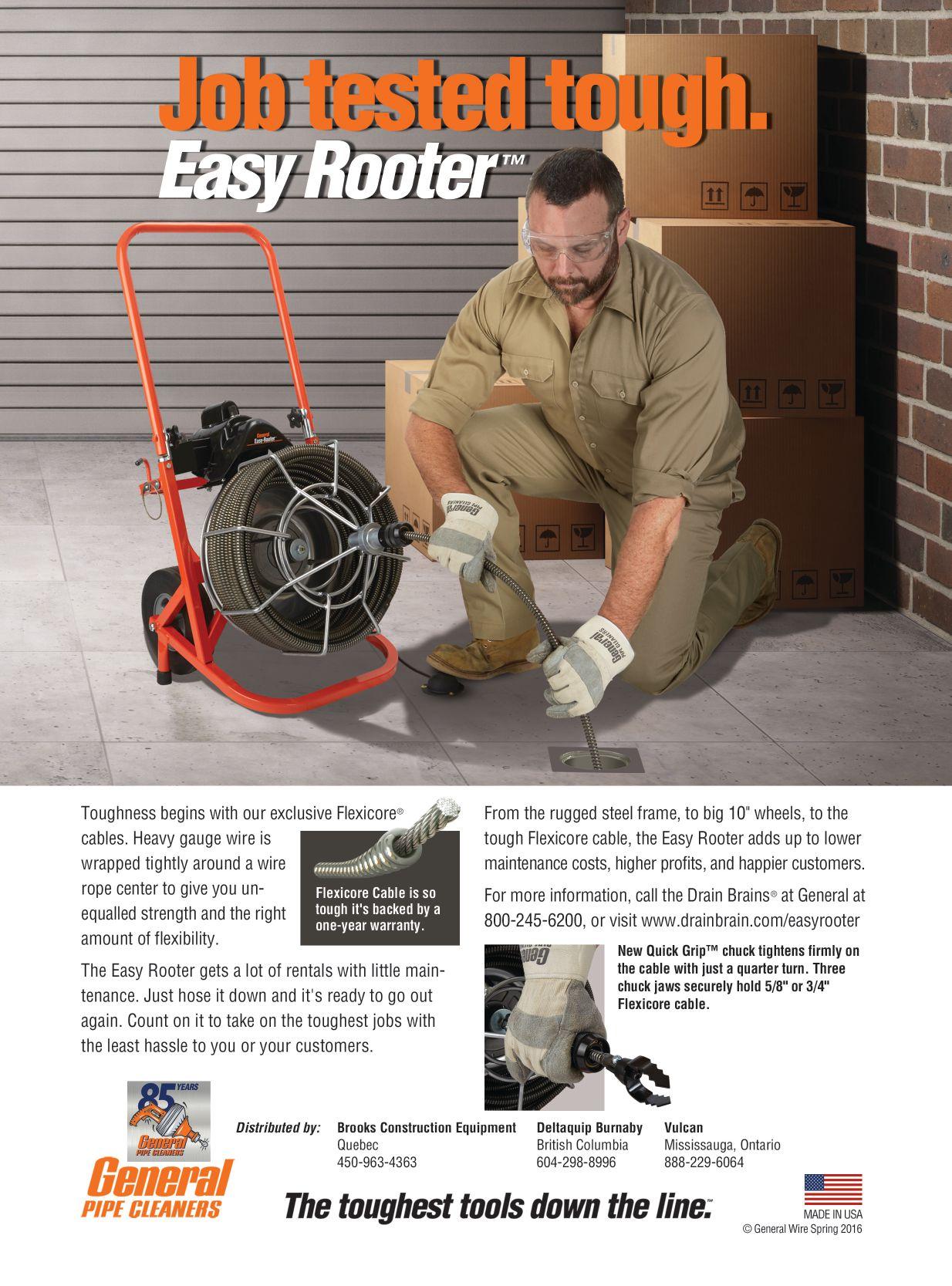

EXPLOSIVE RISK

What you need to know about new rules for transporting propane and other dangerous goods.

12

PRESIDENT’S MESSAGE

Keeping summer students safe needs to be a priority for every rental store. by Tim Ranson

6

INDUSTRY NEWS

Quebexpo introduces new players, Georgian Bay has great rental stores, Berry reps Perkins...

28

AERIAL EQUIPMENT SHOWCASE

AWPs, boom lifts, scissors and more...

14 LEGALESE

Progressive discipline is the correct way to manage employee behaviour without getting sued. by Deryk Coward

16

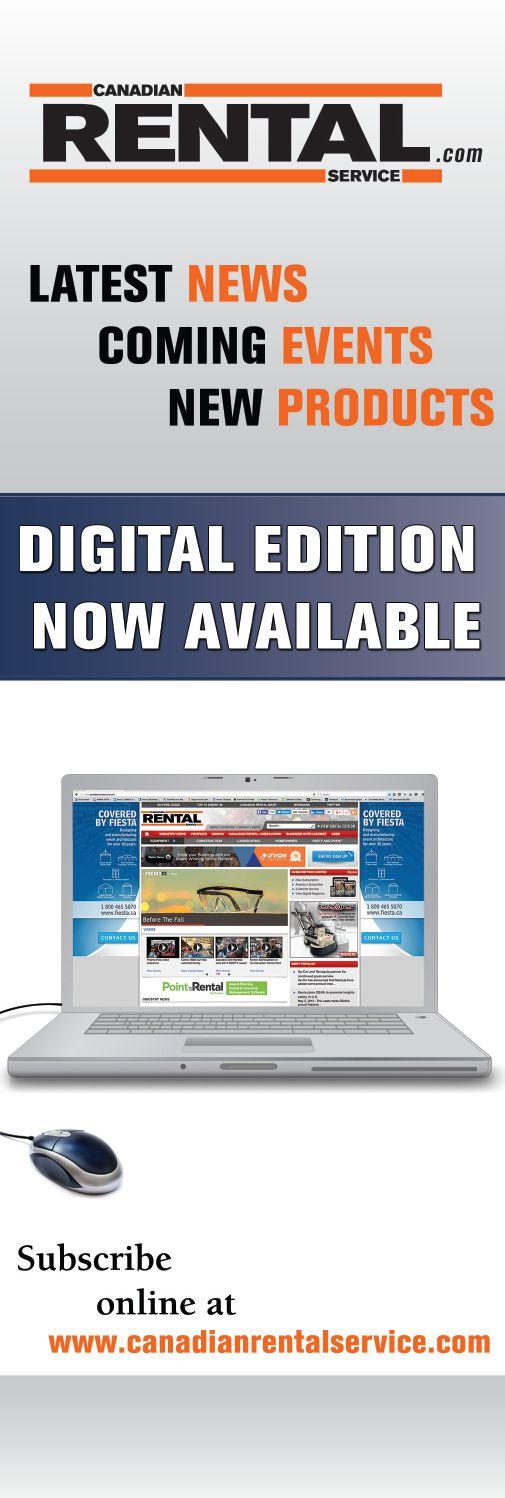

SMART STYLE

NJS Designs is attracting attention with a mix of creativity and business savvy.

34

SAFETY FIRST AND LAST Training is more effective when expertly planned. by Jeff Thorne

Blowing bubbles

Overvalued

The Canada Mortgage and Housing Corporation released a study re cently saying housing may be overvalued in as many as nine of Canada’s top 15 housing markets. Now places like Hamilton, Ont., and Saskatoon, Sask., have been added to the familiar big cities like Toronto, Vancouver, Montreal and Calgary as places where the price of housing is exceeding what we would expect to see according to their history and the financial, economic and demographic conditions in the economy.

We have been hearing about the house price “bubble” for some time, though now that bubble appears to be expanding to cover more of the Canadian bathtub. For at least 10 years, economists have been wringing their hands about the unsustainable acceleration of prices in the big markets and the inevitable crash it predicts. About five years ago, economist speakers at industry events started admitting that the predicted crash was taking a long time to come. About three years ago they started wondering if it was ever going to come and admitted puzzlement as to what is going on. Maybe Canadians are so resigned to debt now that we will continue to pay anything for housing as long as the mortgage rates stay low.

If housing prices are in for a correction across the board,

ON THE WEB:

Counter Talks recording available online

Canadian Rental Service hosted its first educational Counter Talks webinar on May 10 and the session was a big success. John Adcock of Leavitt Machinery discussed best practices for buying and selling aerial equipment and answered your questions online. Thanks to our sponsor, Point of Rental Software. To access a recording of the talk, visit canadianrentalservice.com > webinars.

Canadian Rental Association donates to Fort McMurray relief

Details of how to join the national CRA initiative to donate to the Red Cross for Fort McMurray relief are online in our Canadian Rental Association section.

by Patrick Flannery

it’s not good news for the rental industry. Residential construction is a $15-billion industry in this country employing close to a million people. The value of houses drives investment in that industry, and most equipment rental stores depend heavily on custom from its contractors. Housing prices tell an economic story on the other side as well. When people are employed and making money, they pay more for houses. When they aren’t, they don’t and prices collapse. A bursting price bubble and the sharp reduction in the value of a family’s primary asset will put a freeze on spending that will send a chill across the entire economy.

Diversifying your business away from one-dimensional reliance on housing contractors and homeowners is one way to avoid this risk. Opportunities may exist in local factories and municipal governments – when is the last time you knocked on their doors? Another way to mitigate risk from fluctuations in the fat middle of the market is to move up the market. I remember doing a story on a custom furniture manufacturer back in 2008, just as the Great Recession was starting to bite in the U.S. and Canadians were wondering if we were going to catch the same disease. This man made dining room chairs that cost $10,000 each. The economy was going into recession and other furniture manufacturers were shutting down or fleeing to China, but this company couldn’t keep up with demand. Seems the “one per cent” are not affected by recessions the same as the rest of us. Perhaps there are opportunities in luxury custom homes and recreational properties that don’t go away when price bubbles burst.

Looking ahead to next issue, we will be revisiting Canadian Rental Service’s 40-year history with news and company profiles from the past. If you have photos and stories from the ’70s, ’80s and ’90s, or want us to remember a special person that was instrumental in building the industry in your area, please let me know. I’m just a button-push away at pflannery@annexweb.com or 226-931-0545. CRS

@CRSmagazine

HY-COR PICKS UP LINES FROM RENTQUIP

Hy-Cor has announced that Rentquip has passed some product lines over to Hy-Cor to provide the ongoing sales and service that Rentquip has provided to its valued customers. Hy-Cor will now be the national supplier for Van Mark brakes, Primatech nail guns and accessories, Erie wheelbarrows, Kraft tools and the TranzSporter platform hoists from Tie Down. Both Rentquip and Hy-Cor have a reputation of providing outstanding service to the rental industry across Canada and hope to provide uninterrupted service to everyone requiring any of these products. Hy-Cor’s head office is located in Komoka, Ont., and its representatives are spread across Canada.

QUEBEXPO OFFERS UNIQUE OPPORTUNITIES

By Carroll McCormick / During March’s two-day Quebexpo show, 200 Canadian Rental Association members and more than 30 non-member rental store owners and representatives dropped in to see the 56 exhibitors’ offerings. This is the third year that the Association de Location du Quebec has held the event in Place Forzani, just off Autoroute 440, just north of Montreal. A 31,500-pound Skyjack SJ 1056 TH teleboom, with a 10,000-pound maximum lift capacity, dominated one booth, while a nearby Genie Z-62/40 articulated boom slashed a blue zigzag toward the exhibition hall’s ceiling. Elsewhere, exhibitors displayed products ranging from saw blades to laser levelers to a teeth-rattling Atlas Copco Dynapac CA 1300 vibratory roller. Christian St-Marseille, sales representative with Action Marketing A.G., based in L’Assomption, offered an impromptu tutorial on cement cutters, cement polishers and cutting blades. He discussed the special blades used to remove epoxy from concrete surface, and diamond drills for drilling holes in cement.

Gauthier Chariots Élévateurs, a specialist in sales, rentals and repairs of forklifts, with offices in Drummondville and Warwick, had a new product on the floor this year: a diesel-powered model 33D-9 Hyundai forklift with a 6,500pound capacity. New features include a rear-facing camera. Toggle a lever on the steering column and the camera image pops up on a little screen. Other features on the screen include lights that begin flashing faster if there is a risk of a rollover. If such a risk is sensed, the clever forklift automatically slows down. Company president Louis Gauthier noted that Gauthier Chariots Élévateurs opened a third location in Quebec City this April. Among this year’s offerings on display from Multiquip are updated pipe frame generators, ranging from 2.5 to 9.7 kilowatts. Dropping in on the Brooks Équipment Construction booth (they have locations in Laval and Mississauga) Benoit Dufresne, territory manager for the Construction Equipment Division, answered questions about a commercial wood chipper made by Wallenstein, a Mennonite manufacturer in St. Clements, Ont. The 35-horsepower, gas-powered machine has an end feed of seven inches by 12 inches, nicely done welds, a heavy-duty frame and a Pintle hitch with a lunette ring. Questioned about this Canadian-made machine, Dufresne answers with a thumbnail history of the trend to buying offshore products and the return to Canadian-made hardware. “The market shifted from high-quality tools to disposable tools. People tried lower-end tools. But they are coming back to quality, and there is good, fast parts availability for Canadian-made products.” Dufresne had a fascinating little story to tell about Wallenstein’s manufacturing setup, and the other exhibitors were wellsprings of expertise they were happy to share.

BERRY COVERING RENTAL ACCOUNTS FOR PERKINS

The appointment of Corey Berry as rental account manager for Perkins has been announced by Leon Hunt, direct sales and rental manager. Berry, an 18-year rental market veteran, will coordinate and manage Perkins’ industry focus.

“The rental industry is an important market for Perkins,” Hunt said, “and Corey’s extensive experience makes him uniquely qualified to deliver on the Perkins promise. He knows what it takes to be successful in the rental business and I am confident he will translate that knowledge into solid value for Perkins customers.”

Berry was most recently general manager of H&E Equipment Services in Orlando, Fla. He has held sales and management positions with Nationsrent, Abco Bramer Crane and Equipment, Sunbelt Rentals and Standard Equipment Company. A veteran of the United States Marine Corps, Berry has extensive experience in the design, staffing and implementation of sales operations in addition to his proven administration and management skills.

“I entered the rental industry as a mechanic and now have 18 years in the industry,” Berry said. “That experience is now available to the Perkins rental customers I’ll be serving.

GEORGIAN BAY-AREA STORES IMPRESS CRA ONTARIO

A solid turnout of close to 70 rental people made for a lively evening at the Ontario Canadian Rental Association’s April meeting in Collingwood and Stayner, Ont. Members toured Happenings Party Rentals in Collingwood, Ont., followed by tours, dinner and a presentation at Stayner Rental. Happenings owner Mike Carleton welcomed members to his attractive party and event store in Collingwood. Happenings concentrates on wedding supplies, including tents, chairs, tables, linens, place settings, serving items, food preparation tools, fountains, barbeques, centre pieces and games. Carleton bought out the previous owner, Karen Burland, in 1999 and has found success in Collingwood’s lucrative destination wedding market.

The main event was held at Stayner Rental, home of Paul Van Staveren, CRA Ontario vice-president. Stayner is a very large and impressive equipment rental operation owned and run by the Van Staveren family with the help of about 50 employees.

The store sits on seven acres of land with five massive buildings featuring a distinct, barn-like design that the company built itself. Large compaction equipment, excavators, telehandlers, lifts, generators, loaders and a selection of agricultural machinery are prominent. Van Staveren also runs a groundwater pumping business from the location. Each building is spacious and neatly laid out with lots of storage in second-storey mezzanines. Air and power are conveniently located everywhere and clearly labelled.

Van Staveren is very interested in green power generation, so he invited an old friend, Ken Rounds, to address the meeting. Rounds is a local farmer who is also managing director of the Simcoe County Community Energy Co-operative. Rounds gave a very informative and interesting presentation, going in-depth into the numbers justifying solar power for medium-sized businesses and explaining the incredible amount of red tape from Hydro One that adds tens of thousands of dollars of cost to solar power projects. Based on a 25-year lifespan for the panels and conservative estimates of how much the price of power will go up, Rounds predicts businesses can realize about a 10 per cent return on investment in solar power.

At the end of the meeting, CRA Ontario president Colin Wilson announced that Kim Rixon of Muskoka Party Rentals had been acclaimed as second vice-president of the association

ONLINE EDUCATION FROM TVH

Rental store staff can expand knowledge right from the home or dealership with new industry-specific online classes from TVH University. The courses cover a variety of topics including techniques to increase sales, profits and customer satisfaction, as well as enhancing the customers’ buying experience to increase sales and profit. Courses on offer include:

• Counter-Intelligence

• Value-Added Selling

• Customer Satisfaction

• Enhancing the Customers’ Buying Experience

• Motivating and Compensating

TVH university can be accessed at tvh.com.

GENIE AERIAL PROS AIMS TO EDUCATE

Genie has announce the launch of a new educationfocused website, Genie Aerial Pros (aerialpros.genielift. com), designed to connect customers, operators and key stakeholders with industry experts. Genie Aerial Pros is dedicated to educating the aerial industry on important subjects, such as upcoming changes to ANSI and CSA standards, safety and training, service, product introductions and new applications. The website also gives customers’ insights on sales and marketing best practices, company news, as well as upcoming industry and company events. Content featured on Genie Aerial Pros includes tips and trends articles, product bulletins and videos, industry alerts, customer success stories, testimonials and more.

“Our goal with Genie Aerial Pros is to provide customers, operators and key stakeholders in the aerial market with a platform that shares the vast amount of knowledge Genie has gained in five decades of serving the industry,” says Karen Stash, senior director of global product management and marketing for Terex AWP. In addition to providing educational content, Genie Aerial Pros is designed with the ability for customers and key stakeholders to participate in the site. Each page gives viewers the opportunity to interact with company and industry experts by commenting on posts, asking questions, requesting more information or sharing their experiences.

WORKING-AT-HEIGHTS GRACE PERIOD RUNNING OUT

Since April 1, 2015, Ontario employers have been obligated to ensure that workers complete a working-at-heights training program that has been approved by the province and delivered by an approved training provider before they can work at heights. The training requirement is for workers on construction projects who use any of the following methods of fall protection: travel restraint systems, fall restricting systems, fall arrest systems, safety nets, work belts or safety belts. There was a twoyear transition period for workers who, prior to April 1, 2015, met the fall protection training requirements set out in subsection 26.2(1) of the Construction Projects Regulation. Sections 26.1 to 26.9 apply where a worker may be exposed to any of the following hazards:

• Falling more than three metres

• Falling more than 1.2 metres, if the work area is used as a path for a wheelbarrow or similar equipment

• Falling into operating machinery

• Falling into water or another liquid

• Falling into or onto a hazardous substance or object

• Falling through an opening on a work surface

These workers will have until April 1, 2017 to complete an approved working-at-heights training program. The training requirements are in the Occupational Health and Safety Awareness and Training Regulation, and are in addition to training requirements under the Construction Regulation. Rental stores may wish to make their homeowner customers aware that they can be affected by the regulations as well. Depending on the circumstances, homeowners may be considered constructors and subject to obligations under the Occupational Health and Safety Act if they hire multiple contractors to work at the same time. It is in a homeowner’s best interest to make sure workers at their home are safe. This can be as simple as asking contractors if their workers have been trained, and how they plan to keep workers safe on site, before signing a contract. In the case of projects where workers will be at heights, such as repairing a roof, homeowners should ask contractors if their workers have been trained to do the work safely.

COMING EVENTS

2016

Aug. 17

ALQ Golf Tournament Montreal, Que. associationlocation.ca

Aug. 18

CRA Manitoba Golf Tournament Winnipeg, Man. 8 crarental.org

April 22 - 23

Expo Grands Travaux Montreal, Que. 8 masterpromotions.ca

June 15 - 17

Canada’s Farm Progress Show Regina, Sask. 8 myfarmshow.com

Sept. 13

CRA Ontario Golf Tournament Guelph, Ont. 8 craontario.org

Sept. 23

CRA B.C. Golf Tournament Langley, B.C. 8 crarental.org

2017

Jan. 10 - 12

Landscape Ontario Congress Toronto, Ont. 8 locongress.com

Feb. 26 - March 1

The Rental Show Orlando, Fla. 8 therentalshow.com

March 7 - 11

Conexpo-Con/Agg Las Vegas, Nev. 8 conexpoconagg.com

Canadian Rental Service editor Patrick Flannery and L.B. White national sales manager Gary Webb teamed up to show the flag for the Canadian rental industry at a Blue Jays baseball game in Dunedin, Fla., in March.

CRA PRESIDENT’S MESSAGE

SUMMER STUDENT SAFETY

by TIM RANSON, CRA PRESIDENT

Get off on the right foot safety-wise with new hires.

Spring is officially here, and we are once again considering adding high school students to the payroll for casual summer work. Many rental operators have developed the next generation of rental professionals by introducing them to the business as a summer student. This practice has been successfully implemented with many businesses in previous years.

Pre-planning is necessary to have success with hiring any new staff. I recommend you establish a rigorous and consistent orientation. This not only provides structure, but ensures all workers learn the same important safety and operation rules. By following pre-set onboarding steps, such as filling out hiring paperwork and reviewing safety information, we also ensure introductions are completed before the worker is permitted into the yard or shop environment.

Tim Ranson is Environment, Health and Safety manager at Finning (Canada) / The Cat Rental Store in Edmonton, Alta. He has worked in the rental industry for more than 20 years. Tim sat on the ARA Trade Show Committee and the ARA Risk Management Committee and helped start its Professional Driver Improvement Program. He was also a speaker/panelist over the past three years at the ARA Rental Show learning sessions.

In our branches, we use the first two days as an opportunity to ease new employees into the culture of the business and provide them with the safety training essential to daily activities such as movement of equipment and hand signals. We issue Personal Protective Equipment (PPE) necessary in our shop, yards and on customer sites. We also use these first few days to introduce the new employee to all the staff, assign a specific team member as a mentor and finally, to provide instruction on the scope of work they will be assigned in the next few weeks.

Often the young worker will have a restricted driver’s license. I would urge you to check with your insurance company prior to permitting this worker to operate your company vehicles. Also, remember to restrict them from operating any other mobile equipment for safety and insurance purposes.

New hires must be assigned to a mentor within the branch. This mentor needs to be a senior worker with competence in the scope of work required by the young worker. The mentor must be patient and able to instruct the new worker in all aspects of the yard and the shop. Safety and well-being of all staff is the most important priority for both the mentor and the new worker. The mentor and the student should be in constant communication. I suggest a pre-job discussion of the scope of work with periodic breaks to review, providing constant supervisor access while the work is in progress. In our business, the student is not to be left unsupervised when working.

It is critically important to explain all hazardous activities and components, and to develop in your staff awareness of being able to stop work if they are unsure of how to proceed safely or if dangerous conditions exist. This is an occupational health and safety requirement in all jurisdictions in Canada, often referred to as “the right to refuse dangerous work.” Your discussion with new staff provides an opportunity to re-think a task to reduce or to remove the hazards before resuming the task.

The mentor is responsible to ensure the student worker is involved in your job hazard analysis process and is given direction and supervision on the assigned tasks for each day.

While the student is in the employment of the rental company, they are expected to follow all rules and policies. Demonstrating the rules by explaining the reasons why, and leading by example will help ensure the student worker clearly understands this responsibility. CRS

Thom

1-800-665-8990 ext. 7313

thom.proch@westernfgis.ca

1-800-665-8990 ext. 7215

nolan.friesen@westernfgis.ca

Progressive discipline

The chances are good that you regularly crunch the numbers and eliminate profit.

by Deryk Coward

You know that your employees are critical to the success of your organization. Productive, happy employees will make your business more successful. The manner in which you discipline your employees can have very important productivity-related and legal ramifications.

Progressive discipline is the appropriate process to use in order to effectively deal with sub-standard job performance. Most sub-standard job performance issues do not entitle an employer to automatically terminate the employment relationship. They could, however, warrant some form of discipline.

Progressive discipline calls for the discipline meted out to an employee to increase in severity with each and every failure to live up to expectations. Each instance should be formally recorded on an employee’s file. Over time, once an employee has been disciplined on multiple occasions and it’s clear that their behavior is unacceptable and they have failed to correct the problem, the prospect of being able to legally terminate that employee increases.

There are two primary reasons why progressive discipline should be followed. It will allow your employee to understand that their behavior is not up to expectations and will communicate to the affected employee that they should modify that behavior. It will also support you legally from a lawsuit involving an affected employee.

In order to be able to effectively engage in progressive discipline, it is important that the expectations of your employees have been clearly and concisely outlined. If your employees do not know the standards to which they are being held it would be unfair to discipline them for failing to meet those unknown standards. In a perfect world, the expectations for your employees should be codified in a written employment contract. If you don’t have employment contracts, you can nonetheless communicate acceptable

standards through company policy and other written means.

Examples of things which could attract the need for progressive discipline include but certainly are not limited to proper business attire, swearing and other abusive behaviour, lateness and absenteeism, renting company equipment for personal use and safety issues.

An example would be an employee who is habitually late by 15 or 30 minutes on a regular basis. Let’s say that you like this employee and that he/she is fine in other respects, but the fact that they are always running late is something that has troubled you for a long time. It would be inappropriate for you to terminate their employment abruptly after never having said anything to them. Rather, you should clearly spell out the expectations of your organization for punctuality and give a verbal warning the first time the employee arrives late. Suspend the employee for a very short period of time, the next time it happens, then suspend the employee for a slightly longer period of time if it happens again. Ultimately, if the situation does not improve, you may be able to legally terminate the subject employee.

Generally, the discipline should correspond to the seriousness of the issue. The level of discipline warranted for tardiness would be less than, say, a breach of your company safety policy.

All steps taken with respect to progressive discipline should be recorded in the employee’s personnel file. The affected employee should know why they have been disciplined, and should be given a clear way to improve their behavior, correct the issue and thereby avoid future discipline. Nothing in this article is intended as legal advice, as every situation is different. Since labour laws vary from province to province, it’s important that you consult with a lawyer in your jurisdiction who practices labour and employment law. CRS

SMART STYLE

Listening to the customer and working with partners is key to this Clinton, Ont., success story

On the NJS website, owner Nancy Snell describes her business as “a speciality linen and decor rental company where relationships, listening to, and fulfilling the needs and wants of the customer go hand-in-hand with quality fabrics, fashionable concepts and imaginative vision.”

by TREENA HEIN

Right: Snell was pleasantly surprised to win both the President’s Image Award and the tabletop design competition at this years’ CRA Ontario banquet. Considering the spectacular designs NJS executes, she should not have been.

This description rings true. When asked about what’s most rewarding about running her business, Snell answers without hesitation. “The collaboration that we are able to do on a weekly basis,” she says. “Teaming up with other local businesses, photographers, tent companies, florists, venues, DJ’s, event planners – knowing who you’re working with and their strengths gives us a huge advantage when planning with a client,” she says. “It’s the lasting friendships we have come to make with other business owners in the industry, our customers, their families and our community.” In mid-April, NJS again hosted their annual “Vendor Blender” event, where other

event business owners in the region are invited to what Snell calls “a night of food, drink and catching up. It’s so great to see so many other small business owners in one place.” NJS was started 19 years ago in 1997 from Snell’s family farm. “I had started doing graphic design and web design, then opened an online store for wedding accessories in 1999,” she recalls. The rental business started over a five-day period, with a single inquiry kicking everything off. “I had a call on a Tuesday for wine glasses, and I said we were thinking of adding these to our inventory,” she remembers. “The next call was Wednesday for white linen table cloths and

www.skyjack.com

wine glasses, and I said I was working on it. I started to do my research and when a third call came on Friday, I had a supplier for linen sub-rentals, and had costing to purchase wine glasses. I made arrangements with a local restaurant to use their commercial dishwasher after hours to wash the wine glasses. And that’s how NJS started into the rental industry.”

Snell says there’s always been com-

petition, but that she “just made it a priority to offer unique products and services. I really just listened to the customers and what they were looking for or were having issues finding.” It worked. In the first year, NJS did 40 weddings – mostly renting linens, wine glasses and backdrops. “The following year we added chair covers, dishes, cutlery,” Snell says. “The following year, we had more styles of

glasses and centerpieces. I remember we had seven events one weekend and I thought I was going to lose my mind. I had one part-time staff at the time.”

As anyone can imagine, space (even though the business was in separate buildings) was running out, and NJS was also hitting the wall in terms of electricity capacity, water, natural gas and internet speed. After 13 years, in spring 2010, Snell built a 5,000-square-foot showroom and warehouse in the industrial park in Clinton. She’s never looked back. Her daughter Laura started with the business in 2011 and last year, NJS had seven full time employees during peak times.

“Our business has grown nicely in the shoulder seasons,” Snell notes. “The fall is huge for us now. Our full swing season goes from May thru October. November and December are slower and a time to organize and do physical inventory counting. January, February and March is all about consultation and planning for upcoming events and attending trade shows and whoosh, we are back at April again with our annual Vendor Blender evening and then a two-day open house for our current customers and general public.”

INVENTORY AND TRENDS

To say NJS has a rather large selection of fabric napkins, table cloths, chair covers and more would be an understatement. The fabrics range from solids to prints, from simple and elegant to contemporary. The company is also known for its outstanding backdrops.

To keep up with the current trend of rustic weddings, NJS had custom harvest tables and benches made in 2014.

“We’ve also purchased Chiavari chairs in champagne gold and mahogany, for more elegant settings,” Snell says.

“We’ve added speciality serving pieces, platters, larger wine glasses, and for 2016, 72-inch round tables and dark wood folding chairs.” Snell never buys something she “thinks” customers will want, but keeps careful track of what people ask for. “The first inquiry is logged, and the second inquiry is our signal that we need to source it,” she says. “By the time the third inquiry happens, we have a costing, availability

/JCBNA @JCBNA JCBNA |

JCB’s Range of Rental-Tough Equipment. When it comes to choosing what brand of equipment to put in your rental fleet JCB knows it’s all about rental utilization rates and the ROI it drives to your bottom line. That’s why we offer a full range of equipment purposebuilt for rental, all of which boast JCB’s superior No DPF Tier 4 Final engine solution.

No DPF means no regeneration and one less part to replace and maintain over the equipment’s lifecycle. Add to that No DEF in 74hp and under models and you’ve got a complete package that minimizes maintenance to maximize profit.

Learn more about how to put your best fleet forward at JCBNA.com.

and rental pricing ready.”

While DIY weddings were very popular two and three years ago, Snell says last year NJS saw a very strong trend to full event setup and teardown. “Brides don’t want their wedding party to be setting tables Saturday morning,” she explains. “They want to enjoy their weekend and are willing to pay to have someone else handle it.”

NJS will do events within a 1.5-hour drive, from Sarnia, Bayfield and Kincardine to Mildmay and Waterloo.

“We joke it’s anywhere with gas stations,” Snell says. “Fifteen years ago, you had to have the vehicles full for Sunday rental pickups as no gas stations opened on Sunday before 10 a.m. We were caught a few times.”

In terms of business challenges over the years, Snell says, looking back, she would have purchased rental software sooner. “I went 12 years planning events from modified computer worksheets I created, but there was no correlation to our physical inventory, so I spent nights poring over the coming event worksheets. The best part of that was you knew your inventory like the back of your hand, and the events in detail. But as the events got more detailed and larger it was becoming more difficult to keep the level of accuracy. I spent the money on the software and would never be without it.”

NJS was honoured recently with the Ontario Canadian Rental Association President’s Image and Innovation Award

CAPTURE A LARGER MARKET

Rent more months per year

WHY MERLO?

Best R.O.I. and retained value in the industry

Can rent at higher price

Less maintenance (intervals of 500 hrs vs 250 hrs)

for Party and Event Rental at the CRA banquet. “When Mike Maltby called to tell us that,” she remembers, “I had to ask him to repeat himself. I honestly didn’t know if we had a chance – and we were so focused on consultations and meetings with our 2016 couples and getting prepped for the ARA Show – that I had actually kind of forgotten about it. Until just before we headed to Atlanta and the email came through. I kept thinking it was a misprint! My staff wanted to compete in the table top design competition, so they organized their design, teamed up with a local florist and if we didn’t win the table top design competition that night at the banquet as well! What a bonus night it was for sure!” CRS

Unique and creative touches are everywhere in the NJS showroom. Snell says their busy season now runs right through the summer from May to October.

TOUGHEST MEMBER ON THE JOB SITE.

The SVL Series sets a new standard in comfort for any comparable sized track loader. With Kubota’s own diesel engine, standard air and heating, and outstanding bucket breakout force (7961 lbs*), the SVL Series will be the toughest and most dependable member on the job site.

*SVL95-2s model only | kubota.ca |

railway cars transporting dangerous goods, carry shipping documents, have training and safety marks.”

Regulations on the movement of dangerous goods can vary by jurisdiction across the country but generally require accurate classification, appropriate means of containment, and correct marking, labeling and documentation. In Canada, federal legislation currently prohibits the transportation of certain high-risk dangerous goods unless an Emergency Response Assistance Plan (ERAP) has been submitted and approved. The plan outlines how specialized emergency response personnel will react to an accident and their overall capacity to respond. As dangerous goods are likely to remain a significant portion of the overall freight moved across the country, there is a recognized need to further enhance the monitoring of these shipments. For instance, in June of 2014 Transport Canada amended the TDG regulations to clarify the criteria for displaying safety marks: now safety marks are required to be displayed on trucks, rail cars and bulk containers used to

transport dangerous goods, identifying the type of goods and the nature of the risk posed.

What does all this mean to rental

and find violations may summon the offender to court for a justice of the peace to apply the suitable fine or they may issue a ticket which is usually $490 each with three commercial

“The Propane Training Institute (PTI) currently has over 30 propane related course offerings.”

operators? “First, it’s a myth that dangerous goods are exempt when empty,” cautions Dubee. “Dangerous goods are just as dangerous empty as when full. The only time they are exempt (from TDG regulations) is if they have been cleaned and purged so there is no evidence of dangerous goods present or they are new tanks never filled.” In Ontario, the penalties for breaking the rules range from zero to $50,000 for a first offence and up to $100,000 for a second offence or six months in prison. MTO constables who stop

vehicle operators’ registration (CVOR) points attached (licence suspensions are issued upon receiving four, six, nine or 15 demerit points depending upon the class of licence). Usually, both the driver and carrier owner/ operator are ticketed.

Asked what red flags prompt MTO inspections and police traffic stops, Dubee replies that, “We typically do random checks, however the main triggers are faded or poor condition placards, and insecure loads. It’s also common that most charges

Marin Robin CRS may

written to a company and drivers are those who haven’t taken adequate dangerous goods training.” He urges taking a course from a qualified instructor who can answer questions specific to the dangerous goods you are transporting. “I believe training is the most important part so that you know about how to transport the goods safely and in compliance.”

One of Canada`s top providers of in-depth, hands-on education in the proper handling of propane is the Propane Training Institute PTI), a division of the Canadian Propane Association (CPA), offering programs available in English and French to assist the liquid propane gas industry and customers in meeting their LPG technical training needs. “We`re not just trainers, we’re also stakeholders in the propane industry,” states Gerald Thompson, PTI’s Calgary-based senior director of learning and development.

READ THE LABEL

The following information is now required on a shipping document for the transportation of propane/ Liquified Petroleum Gas (LPG), also referred to as simply propane or butane.

• The name and address of the place of business in Canada of the consignor

• The date the shipping document or an electronic copy of it was prepared or was first given to a carrier

• The description of each of the dangerous goods, in the following order: the UN number, the shipping name and the description of the substance immediately after the shipping name unless it is already part of it

• For dangerous goods that are subject to special provision 16, the dangerous substance that predominantly contributes to the hazard or hazards posed by the dangerous goods

• For a liquefied petroleum gas that has not been odorized, the words “not odorized” or “not odorized” or the equivalent in French

• The primary class, which may be shown as a number only or “class”

• The quantity of propane/LPG and the unit of measure used to express the quantity

• For propane/LPG in one or more small means of containment that require a label to be displayed on them in accordance with Part 4 of the TDG Regulations, the number of small means of containment for each shipping name

• The words “24-hour number” or “Numéro 24 heures,” or an abbreviation of these words, followed by a telephone number, including the area code, at which the consignor can be reached immediately for technical information about the propane/LPG in transport, without breaking the telephone connection made by the caller.

“Compliance is of paramount importance when it comes to propane safety.”

According to Thompson, who enjoys the growing relationship his organization is nurturing with its rental company members and customers, PTI’s Transportation of Dangerous Goods – Propane /LPG Specific course has been newly updated with input from propane industry members as well as Transport Canada. “If you make the grade,” he notes, “you will receive a wallet certificate good for three years.” PTI courses are designed to provide basic instruction on the safe handling of propane and propane-powered equipment and satisfy federal and provincial training requirements. Most PTI courses are designed to be delivered in one day or less. Some courses are also available with self-study materials to reduce the amount of in-class time for the student. The final written exam take less than one hour to complete.

Although there is no set check list for rental operators to follow when transporting dangerous goods on Ontario highways, Dubee suggests that a good general rule of thumb includes: ensuring load security, using only trained employees to handle dangerous goods, making certain shipments are correctly documented, and that safety marks (labels and placards) are clearly visible. “These are necessary because everyone wants to protect the environment and persons on the highway,” he says.

With over 400 members, the Canadian Propane Association (CPA) is the national voice of the Canadian propane industry, a multi-billion dollar industry that impacts the livelihood of tens of thousands of Canadians.

The Propane Training Institute (PTI) is the training division of the Canadian Propane Association, and is dedicated to offering state of the art training programs to assist the LP gas industry and customers in meeting their LP gas technical training needs. PTI courses are designed to provide basic instruction on the safe handling of propane and propane-powered equipment and satisfy federal and provincial training requirements.

The Propane Training Institute (PTI) currently has over 30 propane related course offerings, covering over 150 learning objectives. PTI courses are designed to address specific jobrelated topics so that employees can take the propane training that is appropriate for them. Most PTI courses are designed to be delivered in one day or less. Some courses are also available with self-study materials to reduce the amount of in-class time for the student reducing time away from work.

PTI’s recently updated its 100-03 course. Transportation of Dangerous Goods – Propane/LPG Specific is designed for individuals who offer propane for transport, who transport propane or direct others to either transport or offer for transport propane and other LPG’s that fall under the UN Dangerous Goods number 1075 or 1978. The student may attend an instructor-led training course or, upon the direction of a PTI certified trainer, study the course manual and attend a specialized review session and demonstration of correct procedures by a PTI certified trainer. In either case, the certification requirements must be achieved in order to successfully complete the course.

Regulatory authorities recognize PTI courses across Canada and PTI certifies over 30,000 students annually on the safe handling of propane. A full list of PTI training courses can be found on the Canadian Propane Association website. CRS

AERIAL EQUIP MENT SHOWCASE

STORED POWER SYSTEM

jlg.com

JLG’s new non-powered vertical lifts – the EcoLift 50 and EcoLift 70 – are allnew, low-level access lifts designed to be virtually maintenance-free, thanks to a patented stored power lift/ lower system that requires no batteries, hydraulics, oil, or controls. Extremely easy to operate and environmentally friendly, the lifts provide working heights of 11 and 13 feet respectively by simply turning a handle to move the lift up or down. The lifts’ lightweight design makes it easy to push them around a job site. They are rated for 330 pounds, leaving room for materials and tools to boost productivity. And, because there are no hydraulics or motors involved, both of the ecofriendly lifts operate quietly,

making them a preferred piece of equipment for finish work on construction sites or even as maintenance access equipment in schools, hospitals and other institutions. Measuring just under 28 inches in width, the lifts easily roll through standard doorways on caster wheels and maneuver around all areas of a facility. Made of construction-grade materials, the rental-ready lifts offer unlimited lift cycles and can be used 24/7, contributing to a low total cost of ownership.

LOW-EMISSION SOLUTION

genielift.com

In response to growing worldwide demand for high performance, low emissions aerial work platforms, Terex AWP has introduced a new fuel-

GET AGGRESSIVE!

electric Genie Z-boom lift. The new articulating Genie Z-60/37FE boom offers operators two machines in one package for indoor and outdoor applications, while providing lower cost of operation and cleaner performance. Driven by high-efficiency AC motors, this new fuel-efficient model combines the benefits of advanced diesel power, fourwheel drive performance and the cleaner, quieter efficiency of compact, low weight electric-powered booms. The new boom lift provides the choice of two modes of operation: “full-electric,” which means full-day, emissions-free performance on a single charge, or “hybrid” mode, which provides more than a week of run time with a single tank of diesel – an excellent solution for jobsite conditions that demand higher performance and productivity. In hybrid mode, the machine uses its environmentally friendly 24-horsepower Tier 4/ Stage IIIB Final engine-powered generator to maintain the battery state of charge or to supplement the battery power to get a boost in machine performance. To keep productivity high and maintenance costs low, its engine-powered generator constantly monitors the battery state, keeping them topped off for maximum run time, then automatically shutting off to minimize fuel consumption. For extreme usage conditions or after heavy full-electric operation, the hybrid power system can provide a bulk charge within approximately four hours. The hybrid system can also provide power directly to the four-wheel AC drive motors, allowing the system

to combine the power of the diesel driven generator and the 48V DC battery pack, maximizing performance when climbing hills and taking on the most rugged terrain.

PERFECT FOR TIGHT SPACES

skyjack.com

along with exceptional drive and duty cycle performance. Two versions of the SJ30 series is available, the SJ30 ARJE articulating rotating jib electric boom, and the SJ30 AJE articulating jib electric boom. Drive from an AC electric source means that activities like loading and unloading trailers is easy, and increased duty cycles maximize the amount of work possible from a fully charged machine. Perfect for tight spaces, both models come in it at just 47 inches wide and feature a working height of 35.6 feet, up-andover clearance of 13.1 feet, a 60-inch inside turning radius, 35 per cent gradeability to make navigating jobsites easy, a maximum weight capacity of 500 pounds and a wind rating of 28 miles per hour. A lot of manufacturing and warehouse facilities have narrow and confined spaces that require up-and over access. With its narrow dimensions and zero tailswing, the SJ30 is ideally

With the new 30SG all hydraulic stump grinder from Barreto.

over delicate floors and get onto green concrete sooner. They also provide an exceptional working area, with platforms that are 25 inches wide by 60 inches long and 30-inch slide out extensions for increased platform length. The lifts can accommodate two people at a time and hold up to 670 pounds, so users can place tools and materials like drywall and ductwork on the platform and reduce the number of trips up and down on a project. The extensions have

a maximum capacity of 250 pounds. Custom Equipment uses state-of-theart technology to test its designs before building all of its lifts, including the HB-1430. This testing process allows the company to use a high-grade of steel, and because it is stronger, less material is required and the lifts weigh less than competitive machines. In addition, the process identifies stress points, allowing those areas to be reinforced without adding a lot of unnecessary weight.

STEP LADDER REPLACEMENT

scissordeck.com

Remarkably stable, safety orange powder-coated Stack Decks replace step ladders with a step-through handrail for a safe work area and safe approach to the top of work areas. Frames may be assembled laying flat or stacked on each other. Handrails are attached and accessed by ladder. Each Stack Deck stage folds flat and easily opens, bolts and pins to next stage. The base stage includes locking wheels with outrigger stanchions which open easily for a sturdy, wide footprint.The two-part folding four-way wrap-around handrail further compacts with spring buttoncontrolled telescoping posts. The ladder is a Type 1, 250-pound rated, adjustable, two-piece extension with easily removed pinned deck connections to either end of the deck. The two-stage, 250-pound single-worker model has a 20- by 24-inch deck and a telescoping frame to further compact and allow for height adjustment. There is plenty of room for one worker to reach past 15 feet.

The two- and three-stage 500-pound capacity model is outfitted with a 36- by 30-inch deck to allow for one or two workers, with reach past 20 feet. Tool tray and deck padding options are available.

ADVANCED DIAGNOSTICS

haulotte-usa.com

The versatile new Haulotte Optimum 1931 works non-stop to deliver maximum productivity, easy maintenance and safe working conditions at all times. The 1931 operates with great precision in the tightest and most congested work sites, thanks to its asynchronous motor design (AC-motors).

The unit navigates smoothly while elevating or driving, contributing to the operator’s on-the-job

comfort and confidence. The Optimum 1931 AC features a platform height of 18 feet, 11 inches, a lift capacity of 500 pounds and a turning radius of four feet, 11 inches. This 24-volt electric AC-powered scissor lift features active pothole protection for increased safety, and two swing-out trays for easy accessibility to batteries and electric and hydraulic components. The machine is outfitted with onboard diagnostic tool – Haulotte’s ActivScreen – for superior troubleshooting capabilities. It provides operators with key information such as alarms, battery charge levels, and maintenance alerts as well the ability to calibrate the machine when required. Information is capable of being displayed in six languages. With a

BUS

drive speed of 2.8 miles per hour, optimal productivity is always achieved. Other features include nonmarking tires and a battery level indicator on both the upper and lower control boxes. A well-positioned counterweight at the rear of the chassis increases the robustness of the machine. This counterweight acts as a bumper when accidental contact occurs, or as a skid-resistant step plate in addition to a storage area for charging and power-to-the basket cables and plugs.

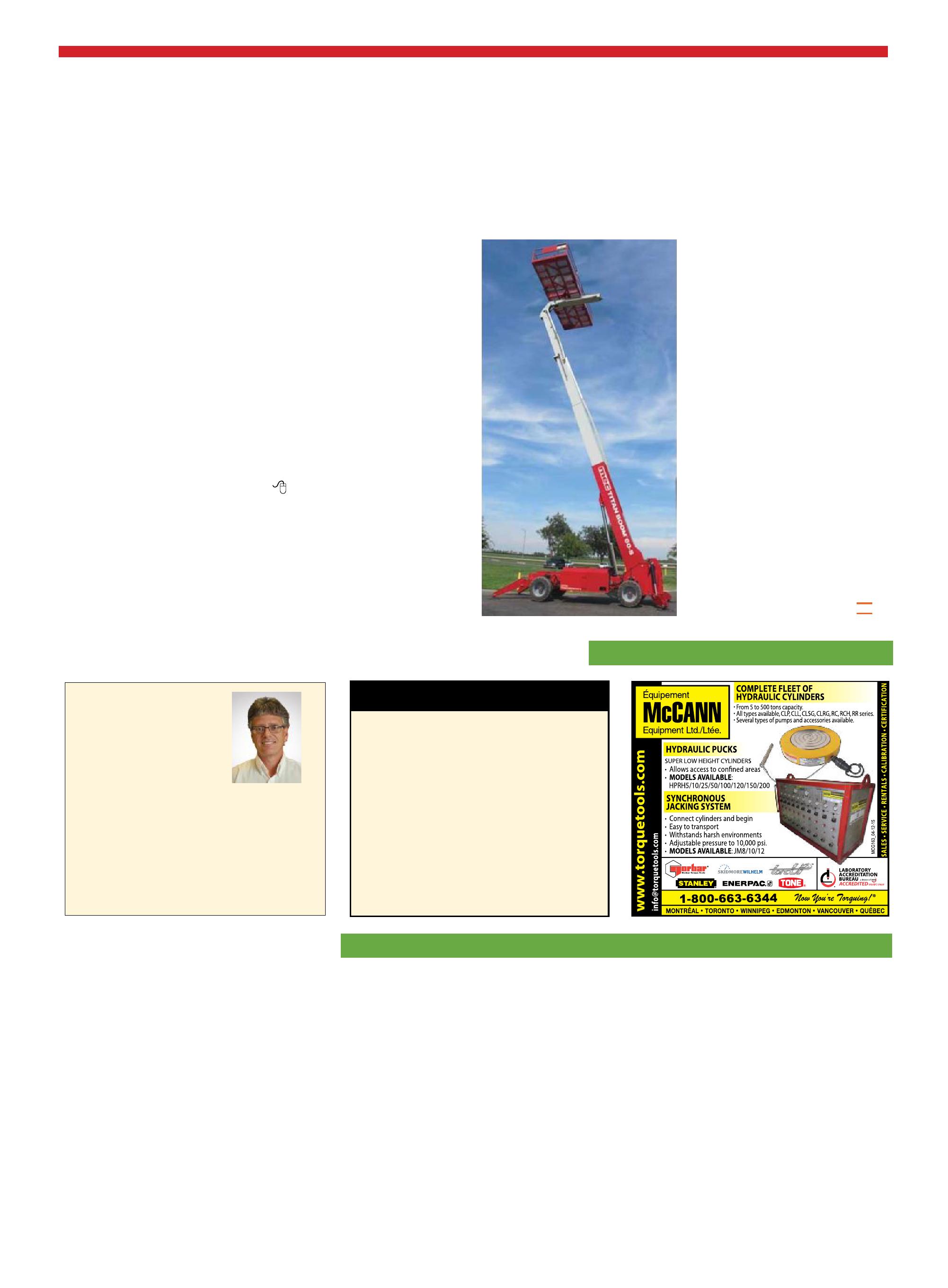

BIG CAPACITY

mecawp.com

The 2016 Titan Boom 60-S from MEC boasts a horizontal reach of 75 feet at 24-foot elevation. Lift capacity is 3,000 pounds. The lift travels at 6.4 kilometers per

hour, maximum, with 40 per cent gradeability. The platform is 60 feet long by 90 inches wide and the boom makes a full lift/extension motion in 75 seconds. The platform rotates 180 degrees,

90 degrees to either side. Powered by a 100 horsepower Kubota V3800T turbo diesel, the whole lift measures 23 feet long by 80 inches high at loading height, with a maximum drive height of 40 feet. Weight is 39,700 pounds and the inside turning radius is 10 feet. The deck includes non-skid metal construction with easy-access side gates and stainless steel wire rope lanyard anchors. The guardrails use a pinless system and AC power is supplied to the platform. Drive and lift controls are fully proportional and the front and rear axels oscillate for superior frame levelling. The 60-S features 18-inch ground clearance, dual front and rear stabilizers, onetouch chassis levelling and a high-torque power package with four-wheel drive. . CRS

905-829-4046 email: info-ontario@marind.ca Branch

SAFETY FIRST AND LAST

Improving training results

Your plan is the key to training success.

by Jeff Thorne

We hear the constant declaration that common sense is required in health and safety but based on current accident statistics, it simply demonstrates that it doesn’t exist. If common sense were a reality, then there would be no need for orientations or training, people would somehow magically know what to do. The evidence shows that even after extensive inductions, orientations, and training, people still don’t know what to do. This is why its important to manage your training and not just provide training randomly.

Safety training is an important and necessary requirement for equipping people with the necessary knowledge, skill, and abilities required to assist the company in achieving their primary goals of reducing the risk of occupational injury and illness. Training is completed as a method of achieving compliance, and assist in supporting the employers due diligence efforts. But in many cases, training is poor.

Poor training happens all the time and it has a direct effect on employee performance and safety. But what are the true impacts? One is employee satisfaction. A happy employee means a smooth running business. If your employees haven’t been properly trained, then they could eventually feel unsatisfied at work, feeling the stress from their job and not performing as well. If there isn’t strong encouragement of communication, this could also lead the employee to remain quiet about their dissatisfaction and could potentially lead to someone leaving the company, making you revisit the hiring process all over again, or continuously getting substandard work.

To avoid these pitfalls, a solid design strategy can help improve your training. A good coursedesign strategy will identify the desired results, exactly what the learner should know and be able to do once the training is completed. Part of a good design strategy will identify evaluation

criteria, the criteria required for the successful completion of the course.

Business guru Stephen Covey wrote a book entitled The Seven Habits of Highly Effective People. Habit number two – begin with the end in mind – is based on imagination: the ability to envision in your mind what you cannot at present see with your eyes. It is based on the principle that all things are created twice. There is a mental (first) creation, and a physical (second) creation. Training is no different. We need to think about desired results, what learners should be able to know, understand and do, by the end of the training. This is the blueprint to ensure we have the correct content that will render our desired training results.

Know your audience. Part of the training strategy involves identifying the different types of learners you may have in order to meet the different learning styles. There is a massive difference between training Generation “X” (1965-1980) and “Generation “Y” (1981-2000). Gen X are self–reliant, resourceful problem solvers that need to see relevancy in the training. Gen Y individuals, the Millenials, “Generation Me,” need to see how technology and digital media will be incorporated. They like group work and structure. When we look at the adult learner and the learning style, the auditory learner likes lecture and needs an opportunity to discuss content. The visual learner likes to see the instructor demonstrate concepts, see visual aids, graphics and the use of white boards or flip charts. The tactile or kinesthetic learner likes the hands-on approach whenever possible and enjoys the opportunity to role-play or act out the situation.

The point here is that training and applying the best strategy takes analysis, thought, and time to get the best results. With a little bit more focus and effort your training results can improve. CRS

Need your parts fast?

two distRIbution centers in ONTARIO and British columbia