What makes a tough job easy is a machine that is simple to operate and simple to maintain. The Snorkel 660SJ mid-size telescopic boom lift is packed with operator benefits like all-proportional hydraulics and removable tri-entry platform. As the largest model in the family, this boom lift can lift up to 600 lbs. (272kg) up to a maximum working height of 72 ft. (22.1m) with a 6 ft. 6 in. (2.0m) jib boom for unparalleled precision.

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

(800) 265-2827 or (519) 429-3966 Fax: (519) 429-3094

READER SERVICE

Print and digital subscription inquiries or changes, please contact Shawn Arul, Audience Development Manager

Tel: (416) 510-5181 Fax: (416) 510-6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR I Patrick Flannery pflannery@annexbusinessmedia.com (226) 931-0545

BRAND SALES MANAGER I Robert Elias relias@annexbusinessmedia.com

ASSOCIATE EDITOR I Alex Mackenzie amackenzie@annexbusinessmedia.com (416) 510-6809

ACCOUNT COORDINATOR I Barb Comer bcomer@annexbusinessmedia.com (519) 429-5171

ACCOUNT COORDINATOR I Barb Comer bcomer@annexbusinessmedia.com (519) 429-5171

MEDIA DESIGNER I Curtis Martin

MEDIA DESIGNER I Alison Keba

GROUP PUBLISHER I Danielle Labrie dlabrie@annexbusinessmedia.com (226) 931-0375

GROUP PUBLISHER I Danielle Labrie dlabrie@annexbusinessmedia.com (226) 931-0375

6

COO I Scott Jamieson sjamieson@annexbusinessmeda.com

COO I Scott Jamieson sjamieson@annexbusinessmeda.com

Publication Mail Agreement #40065710.

Publication Mail Agreement #40065710.

Printed in Canada ISSN 0383-7920

Printed in Canada ISSN 0383-7920

Subscription Rates

Subscription Rates

Canada- 1 Year $45.00 + tax U.S.A. - 1 Year $102.50 (CDN)

Canada- 1 Year $45.00 + tax U.S.A. - 1 Year $102.50 (CDN)

4

6

Occasionally, Canadian Rental Service will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Occasionally, Canadian Rental Service will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Time to raise awareness of the other pandemic.

INDUSTRY NEWS

Nor-Val buys West Equipment...fuel distributors merge...new lead for JLG telehandlers...

12 WHISTLING PAST THE BONEYARD

Boneyard Event Services has trade shows in the blood.

Privacy@annexbusinessmedia.com Tel: 800-668-2374

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request.

All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request.

16 BUILD YOUR OWN BOARD

18

MECHANICAL PROBLEMS

Serving the Canadian rental industry for 45 years.

Serving the Canadian rental industry for 44 years.

A corporate coach recommends building a board of directors... not for your company, but for yourself.

Training organizations across the country are scrambling to fill the demand for heavy equipment mechanics. 12

10

EVENTOLOGY

22 AT YOUR SERVICE

26 FUEL TANK FEATURES

Here’s what to look for when choosing the right fuel tanks for your fleet.

23 WHAT WENT HONG

www.canadianrentalservice.com

www.canadianrentalservice.com

Where few dare to go: inside the mind of a bride. by Michelle Nicol

Leadership in your organization and your market. by Russ Dantu

A look at fire codes and how to stay in compliance. by James Hong

Opioid addiction is a bigger problem than I thought.

by Patrick Flannery

According to the Ontario Construction Consortium, 30 percent of Ontario’s 2,500 deaths from opioid overdose in 2020 were construction workers. That’s 30 percent of all the deaths, including all other job descriptions. While rental store staff are not construction workers, a lot of them were in the past and the demographic profiles are very similar. So I think the statistic is relevant to our business as well. Which means there’s a special problem with opioid use and abuse that afflicts the people we work with and serve.

Thirty percent of Ontario’s 2,500 deaths from opioid addiction were construction workers.

My attention was drawn to this issue by a news item in our last issue announcing online courses by the Canadian Centre for Occupational Health and Safety educating employers and workers about opioid abuse –how to identify it, how to raise the issue, how to respond, how to treat overdose and how to get help. The courses only cost $20 and take about 45 minutes to complete...no excuse really not to take one. The issue came to the forefront again recently with the Ontario government’s proposed Working for Workers bill that would mandate naloxone kits at all jobsites. Clearly, this is a problem we need to be paying some attention to.

It’s not hard to see how people in physical industries like construction and our adjacent industry run into trouble with these drugs. Injuries are common just due to the nature of the work, and painkillers get prescribed. I remember being surprised when opioids were approved for general use outside hospitals in

the late ‘90s, but convinced by the reports that they could be used without causing addiction as long as they weren’t abused. Apparently, a lot of doctors were convinced, too, and soon it seemed like OxyContin was just about everywhere.

In retrospect, it was pretty naive to expect these drugs could become widespread in society without abuse. I remember a friend of mine in high school who was hospitalized for Crohn’s disease and had to be put on morphine to manage the severe pain it causes. Even with the hospital controlling his doses, he ended up becoming dependant on the drug and had to do a stint in rehab before he could go home. According to the American National Institute of Biotechnology Information, consumption of opiods in the U.S. rose from about 47,000 kilograms in 2000 to over 165,000 kilograms in 2012. Opioids had already been legal to prescribe for several years before that, so either there was a four-fold increase in the number of people experiencing pain, or something else was going on. I suspect that something was a growth in popularity of opioids as a recreational drug, adding to the numbers of addicts who became hooked through medical use.

Whatever the cause, today we are confronted with what the OCC calls “the other pandemic.” I know it is an issue we have all seen in our workplaces. Over the next months, I’m going to be getting a conversation going about this issue in these pages, online and in the CounterTalks podcast. In the meantime, it might be a good idea to take advantage of resources from CCOHS or similar organizations to learn how to effectively address and mitigate this problem in your workforce. CRS

Two of Ontario’s largest family-owned fuel and lubricant distributors have finalized an agreement that welcomes Dowler-Karn to McDougall Energy. This acquisition closed at the end of February. This unique opportunity allowed McDougall Energy to acquire what it calls one of the best familyowned and managed petroleum businesses in Canada, which will add significant scale to its business in southwestern Ontario. McDougall Energy and Dowler-Karn are proud to be third-generation, family-owned, Canadian businesses with similar origins and values. With over 150 years of combined industry experience, McDougall Energy and Dowler-Karn have established strong reputations as reliable and customer-focused service providers in the communities they operate within. Dowler-Karn is a family-owned fuels, propane and lubricants distributor, supplying products to customers across Ontario. They are pioneers in propane distribution and storage facility construction. With over 78 years in business, Dowler-Karn services over 18,000 residential, agricultural, commercial and industrial customers from eight fuel, propane, and lubricant plants and nine 24-hour fuel access centres across southwestern Ontario. Through this acquisition, Dowler-Karn will continue to operate under its family name and management as a division of McDougall Energy. Customers will continue to be serviced by the company’s team in the regions they operate within.

“The acquisition of Dowler-Karn brings two 70-plus-year-old family businesses together,” said Darren McDougall, president of McDougall Energy. “This unique opportunity allows us to acquire one of the best family-owned and managed petroleum businesses in Canada and will add significant scale to our business in southwestern Ontario. It is an honour and a privilege to welcome the Karn family, and the entire Dowler-Karn team, to McDougall Energy.”

Established in 1949, McDougall Energy is a third-generation, familyowned Canadian business headquartered in Sault Ste. Marie, Ont. As one of the largest and most diversified 100-percent family-owned fuel and lubricant marketers and distributors in Canada, McDougall Energy has local offices across Ontario and team members in western Canada. Family values and community-mindedness remain essential to its success and guide business decisions. Each local office is staffed by team members who live and work in the communities they operate within. McDougall Energy is committed to continuing to build and maintain strong customer relationships in new and existing markets.

“Deciding to sell Dowler-Karn was a very difficult decision, but choosing to sell it to McDougall Energy was not,” said David Karn, president of Dowler-Karn. “After all, they are a third-generation familyowned and operated business, built on similar values as Dowler-Karn, which makes this a perfect fit. The talents and strengths of our teams will position our combined organization in a trajectory of continued success for years to come.”

No service interruptions are anticipated during this transition. DowlerKarn staff members, including members of the Karn family, will remain with the business and continue to operate its facilities on a day-to-day basis. Dowler-Karn customers are encouraged to contact their local office or service representative if they have any questions or for more information.

Nor-Val Rentals in Armstrong, B.C., has acquired West Kelowna, B.C.,-based West Equipment Rentals. The three locations of West Equipment Rentals will be branded as Nor-Val Rentals and will continue to serve the South Okanagan Valley.

“We are excited to welcome West Equipment Rentals to our team and to expand our operations into the South Okanagan,” said Jim Clipperton, Nor-Val Rentals owner. “We will be merging their West Kelowna operations into our existing store in Westbank on Louie Drive and will continue to serve customers out of their Penticton and Oliver locations with the same great service and quality equipment that Nor-Val is known for throughout the rest of the valley. We look forward to getting to know the South Okanagan communities better and to continue our legacy of strong dedicated support of charities and organizations in those areas.”

Nor-Val Rentals was established in 1994 and is an equipment rental and solutions provider to construction, agriculture, industrial and homeowner markets. With its acquisition of the West Equipment Rentals locations, Nor-Val Rentals now operates six locations. West Equipment Rentals was established in 1987 to offer equipment rentals in addition to new and used equipment sales.

Construction machines are estimated to generate around 400 megatonnes of carbon dioxide emissions per year, according to a recent report by IDTechEx, which is around 1.1 percent of global CO2 emissions. Decarbonization of non-road mobile machines will therefore be an important factor in efforts to limit global climate change. With an increasing number of countries around the world committing to a net-zero carbon future, the construction industry is facing growing scrutiny of its greenhouse gas emissions, the report said. Leading construction machine OEMs and suppliers are already recognizing that powertrain electrification is set to become a key zero-emission technology for construction machines. Many of the largest engine suppliers such as Cummins, Deutz and Volvo Penta are investing in electromobility research, and several OEMs have already launched battery-electric construction machines as commercial products, including Volvo CE, JCB, and Komatsu. The starting point for most OEMs will be smaller compact machines, whose duty-cycle requirements are relatively light, meaning the daily workday energy and power requirement can be met with a practical size of lithium-ion battery, electric motors and a well-defined charging strategy. In recognition of the potential for electrification in this segment, Volvo Construction Equipment has already committed to moving its entire range of compact wheel loaders and compact excavators to electric powertrains, completely stopping its development of new diesel models. Other OEMs will follow this lead, the report predicts. As excavators over 10 tonnes are responsible for around 46 percent of the total CO2 emissions by construction vehicles, it is crucial that zero-emission solutions are developed for large machines. The arduous duty cycles of these heavy-duty vehicles mean those over 20-tonnes need more than 300 kilowatt-hours of energy to deliver a full eight-hour workday. Projects in Norway and the Netherlands have already investigated solutions such as battery swapping and cable operation to meet the duty cycle demand. In China, construction machine OEMs XCMG, LiuGong, and SinoMach have all opted for large battery systems with rapid dual-gun DC fast charging (up to 300 kilowatts). Critical to the deployment of electric machines will be the total cost of ownership. There is a premium on electric machines over diesel, primarily related to the cost of the large battery packs. IDTechEx analysis in the report suggests that the extra cost of an electric mini-excavator could be modest enough that diesel fuel savings and reduced maintenance could largely offset the additional premium, but, for larger machines, the extra cost of electrification likely remains prohibitive and OEMs will need significant regulatory and financial support to promote uptake. While greenhouse gas emission reduction is key, there are other important drivers for machine electrification, most notably health and safety issues around diesel engine operation on construction sites. The construction industry in the UK is responsible for the largest annual number of occupational cancer cases, with around eight percent of these directly related to diesel engine exhaust emissions. Construction is also a high-risk industry for noise-related ill health. Electric machines are significantly quieter offering the potential for improved communication, safety and productivity on-site, while reducing the inconvenience of noise pollution for the surrounding area. The elimination of toxic exhaust emissions could improve air quality on jobsites and in the surrounding vicinity, greatly improving the work environment for construction workers. Given the necessity for zero-emission construction machines, IDTechEx forecasts that in 2042 the global electric construction machine market will be worth $105 billion.

April 13 -14

Atlantic Heavy Equipment Show Moncton, N.B. ahes.ca

April 29 - 30

Expos Grands Travaux Saint-Hyacinthe, Que. expograndstravaux.ca

June 21 - 23

Canada’s Farm Show Regina, Sask. canadasfarmshow.com

Sept. 27-28

Canadian Rental Mart Mississauga, Ont. canadianrentalmart.com

Sept. 28

IPAF Innovate Chicago, Ill. ipaf.org

Oct. 24 - 30 Bauma Munich, Germany bauma.de

2023

Feb. 12-15

The ARA Show Orlando, Fla. ararental.org

March 14 - 18

Conexpo-ConAgg Las Vegas, Nev. conexpoconagg.com

Correction

In our March issue cover story, “A Golden Era,” Cooper Equipment Rentals CEO, Doug Dougherty’s, name was misspelled. Canadian Rental Service regrets the error.

Ottawa-based Robertson RentAll has opened a new location in the Findlay Creek area to keep up with demand in the south-central part of the city. The facility is an 11,000-square-foot existing building located in a heavy industrial business park. It will support 15 staff and act as a central hub between the company’s other two branches in Ottawa, being located exactly 30 minutes’ drive from each. The goal according to Robertson is to centralize its growing fleet of aerial work platforms, forklifts, scaffolding and fencing, as well as provide much-needed work space for the heavy equipment mechanic team. The main customer base in the area is general contractors, landscapers and homeowners.

“We are excited to expand our reach in Ottawa and to provide our customers with three convenient locations,” co-owner Cameron Robertson said. “The new location plays a key role in the future growth of our company allowing us to expand our customer base, equipment fleet and team of employees.”

Aquajet, a hydrodemolition machine manufacturer, has hired James Brown as its service and application specialist for North America. Brown provides service and support for Aquajet customers throughout the United States and Canada. His role includes commissioning new equipment and providing operational and maintenance training. He also provides troubleshooting and repair services for Aquajet equipment, including Aqua Cutter robots, Ergo Systems, Ecosilence high-pressure pumps and EcoClear water treatment systems.

“As a former hydrodemolition operator himself, James brings a deep understanding of the equipment, how it works and the kinds of challenges our customers experience on jobsites,” said Keith Armishaw, Aquajet’s business development manager for North America. “We believe our customers will greatly benefit from his knowledge of the industry, his passion for hydrodemolition and his enthusiasm for helping contractors learn how to maximize the performance of their Aquajet equipment.”

Brown started his career at a commercial lighting company where he traveled around the U.S. installing wiring for lighting and electrical applications. Due to a long-time interest in hydrodemolition technology, he then pursued a position as a hydrodemolition robot operator. As he learned the ins and outs of the business, he became interested in the manufacturing side and applied at Aquajet to help build understanding of hydrodemolition equipment and showcase all it can do.

“Hydrodemolition is the way of the future and I’m proud to be a part of this revolution as the application continues to grow,” said Brown. “I enjoy taking customers from ground zero to getting them up to speed and creating experienced hydrodemolition specialists.”

Brown lives in southern Indiana with his wife and children.

JLG Industries has announced Daliborka (Dali) Ribeiro as its director of product management for JLG and SkyTrak telehandlers, including the company’s latest rotating and agricultural models. In this role, Ribeiro will lead the multi-generation product plan and drive the direction and implementation of its telehandler go-to-market strategy.

“JLG has a well-established position in the telehandler market,” says Ribeiro. “It’s an honour to represent two market-leading brands like JLG and SkyTrak and to have the opportunity to talk directly with customers about the current product line and future enhancements. Feedback from the field spurs our process of customer-inspired innovation.”

JLG has recently diversified its telehandler portfolio to meet the growing demand for these highly versatile machines. These new models support applications across the agricultural and landscape industries, as well as work in highly congested urban areas and in specialty applications where higher capacity and greater height are required.

“Our team is passionate about understanding jobsite challenges to develop solutions that drive tangible value for owners and operators. It’s an exciting time to step into my new product management role and I am looking forward to applying my aftermarket experience and developing a full lifecycle strategy for the telehandler product line,” concludes Ribeiro.

EquipmentWatch is a trusted source for heavy equipment data and intelligence, producing leading database information products for the construction equipment industry. It is a world leader in heavy construction research and serves more than 15,000 professional, high-volume users of construction and lift-truck data. Find more heavy equipment intelligence at equipmentwatch.com.

The Cross-Canada Rate Report is provided to Canadian Rental Service as a free service to the Canadian rental industry. Rate data shown are national averages generated by quarterly surveys of 505 Canadian rental companies. Rates shown are reported list rates and may not reflect the actual changes to any particular customer. For in-depth analysis, subscribe to CounterTalks at canadianrentalservice.com or through your favourite podcasting service. Number of

by Michelle Nicol, CERP

On Sept. 25 last year, one-and-a-half years of hard work and planning for my own wedding paid off, and I married the love of my life!

Being in the event industry for as long as I have, I knew I would be planning my own wedding and I was excited at the opportunity to be able to work with so many of my amazing colleagues in the event industry. Along the way, I learned many things from an end-user’s point of view, and with this personal insight I am now able to offer a unique and personalized service to my customers.

We all assume when a couple approaches us to quote their wedding, they are solely looking for the most inexpensive quote, right? Wrong! There were so many factors that went into deciding who I wanted to be part of one of the biggest days of my life that went beyond the buck. To me, it was most important to work with companies that were reliable, punctual, quick to reply, clearly valued my business, seemed well connected and were able to make recommendations. It was also important to find companies that took time with me without rushing and were able to show their experience with photos, reviews and suggestions. With so many things coming and going while planning your own wedding, it is such a joy to be able to work with an experienced and professional vendor whom you can fully trust to deliver what you agreed upon. This is so much more important than just cost and it is up to the vendor to make this known to the client. The saying, “You get what you pay for,” reigns true.

One of the main things I learned from a customer point of view is how each vendor made me feel. Did they take the time to go through the details with me, or did they just assume that I knew them already? Did they go above and beyond and make suggestions, and did they have my event’s best interests in mind, or where they just looking to close the sale? Each vendor we selected treated me like a person and as if my event was their top priority. This is how we should be treating each

client, big or small. Word-of-mouth is a huge source of free advertising that we do not want to lose out on, and brides are happy to share their experiences in event groups, Facebook pages and review sources if you give them this personalized experience.

The caterer we selected knew I was vegetarian and at our tasting prepared separate meals for us to try. After the ceremony and photos, my new husband and I took some time to ourselves and we were pleasantly surprised to find the caterer had saved us a few of our delicious appetizers to nibble on before dinner. It’s these little details that are so important and often forgotten about. What little things can you offer to your client that will make a lasting impression and make you stand apart from the rest? Do you follow up with your clients after their event? There is nothing more special than a handwritten note or quick email asking how everything went. This is also a great time to ask for photos that you can share on social media.

Lastly, one of the best decisions we made for our wedding was to hire a day-of coordinator. I knew that I did not want to be working on my wedding day and if I did not have someone there to oversee the entire day, I would be. This is something I am going to suggest to all my clients going forward. For a small fee, the peace of mind the coordinator provided was priceless. I was able to fully enjoy the day and not worry about any issues, late deliveries or problems. Being able to recommend these types of services to your client will show your experience, professionalism and that you have their best interests in mind.

This also offers you an opportunity to foster relationships with other vendors to refer clients. This could be for caterers, DJs, entertainment, transportation, hotels, venues, florists, decor companies and so much more. The more we can offer our clients, the happier our clients will be.

And happy client equals happy business! CRS

Michelle Nicol is account manager and festival specialist at Higgins Event Rentals

“

It took perseverance, effort and lots of long days,” says Kevin LeGallais, of building his business Boneyard Event Services in Mississauga, Ont. in the early days.

by TREENA HEIN

“I was motivated because I saw a need to provide a better and more personal level of service to the industry. I relied on word of mouth and relationships and even to this day, extending relationships, being involved and looking for mutual connections are the main ways we find new business. Do a good job and do it at a fair price and people will tell their friends.”

Boneyard has worked to excel in the planning and execution of events through efficient communication, flexible offerings and friendly, professional staff. “Our training initiatives emphasize courtesy, helpfulness and responsiveness,” says LeGallais. “Shows can be stressful and overwhelming for many and we do everything we can to make the experience easy and hassle-free. A current project we are creating is a training resource package for new exhibitors looking to learn the ins and outs of face-to-face marketing.”

Boneyard services southwestern Ontario from Ottawa to Niagara Falls and over to Stratford and London with services ranging from installation/dismantling and rental of drape booths, hard wall system booths, aisle/booth carpeting, branded tents, logistics, graphic production, floor planning, poster boards and both standard and specialty furniture like benches and picnic tables. To deal with COVID, they now have

on hand over 100 tabletop plexiglass guards, clear vinyl drapes and hand sanitizer dispenser stands for rent.

Shipping of equipment to smaller shows is done via company vehicles and rented trucks, with tractor trailers contracted for the larger shows. There are plans to build on their logistics services, and they have increased warehousing space from 10,000 square feet to 15,000.

LeGallais got his start in the trade show industry in 1991. “I often call myself the accidental exhibitionist,” he says. “I was at Carleton University studying economics and got a parttime job for a local, family-run show services company. I guess I just had a knack for what it was about and I was a sucker for the long hours and dynamic nature of the job. It really is a different job every day and it keeps you on your toes to think your way through a problem and to understand the similarities of the craziness.”

After nine years in Ottawa, LeGallais went to GES to oversee their freight operations in Toronto. “I got the opportunity to switch sides of the industry and took a newly developed job for a UK-based show production company as their operations manager for the Toronto Home

Show Group,” he remembers. “It gave me event management experience, to which my years as a supplier helped immensely. In 2006 I went out as an independent contractor overseeing trade and consumer show management. But as much as it was challenging and dynamic, I missed the intensity of being part of dozens of events a year in multiple industries. I had a friend and colleague starting up a company to produce his own events and was looking for a show services company. It was the gasoline on the fire I was starting to light. I agreed to service his events and the rest as they say is history.”

LeGallais describes his building his business as “bootstrapping it from the start.” “It’s probably the hardest way to start up but one that provides the greatest learning lessons,” he points out. “Like most rental companies, we fund everything up front and hope to get our money back eventually. We started slow as it takes time to get the opportunity to quote on events. I supplemented the rental side by event management contracts. Luckily I had lots of relationships in the industry and they helped me get to the decision makers. I also joined lots of chambers and associations that held annual events and we were able to get them to use us eventually.”

He also used a lot of subcontractors, freelancers and a small crew of part time labourers to get the ball rolling. He notes, however, that it’s tough to staff an event company at the best of times due to the infrequency and efforts needed. “At the beginning we did a lot of home shows and smaller community events,” he says. “They were the low-hanging fruit we needed to build our reputation as a service-oriented partner. Our portfolio of these types of events grew over the next few years. Eventually we started getting small conferences and trade shows and now we have a healthy mix of consumer and trade events. Today we still service many of the events that we started with but also large trade shows in multiple cities.” Competition hasn’t really changed much, he says. There have always been five other main competitors for Boneyard.

Equipment was stored in the back of the event venue run by the aforementioned colleague, and it was a big help

financially but also came with a whole lot of handling. LeGallais built his own storage and shipping crates (not too pretty, he says, but they got the job done) and some are still in use today. (And if you’re wondering, the name Boneyard Event Services is a reference to the “boneyard,” the storage area on a show floor for the show services company and exhibitors. LeGallais is starting to transition the name to BES for a few different reasons, but he says “we know our roots will always be in the Boneyard.”)

With regards to equipment, there hasn’t been a big change in product range over the years, but LeGallais notes that as his company has grown, he’s definitely had to invest in more of it – more colour options and more professional options to service the trade industry versus the consumer events. For example, they re-designed the standard poster board setup to make them more suitable to smaller venues as well as being able to use them in closer proximity.

Before COVID, he had four full-time and about 20 part-time/casual staff, and when the pandemic hit, LeGallais had actually been poised to add two more full-time people due to being named the official show services company at the Western Fairgrounds in London, Ont. While it’s hard to recruit and retain, he’s connected with those who have show life in the blood like he does. “The best retention strategy is ensuring staff have what they need when they need it, making sure they feel appreciated and fostering a solid work-hard, play-hard philosophy,” LeGallais says. “Teamwork gets everyone through those long days and nights. When we find good staff, we always ask if they have any friends or siblings that are available to add to our roster.”

LeGallais and his team are constantly talking to industry contacts to build a consensus of what the future will hold in terms of safe and cost-effective event solutions. They predict staffing will be tough across the industry.

For his part, LeGallais may make some acquisitions. “And we continue to look to add unique options for rental,”

he says. “The iPad kiosks we designed and promoted are a good example of that. They help our clients collect survey data in a professional way that also creates a sponsorship option to generate additional revenue. We’ve also acquired a large amount of equipment that we can use to design and install customized exhibits, which is an area we intend to market in aggressively as events return.”

LeGallais feels very confident in his future and that of the company, as well as in the return to live events. “The pandemic has caused us to rethink what we do and how we do it,” he says. “There will be new baselines that event producers will be looking for in their service providers and we feel that we’ll be able to meet those needs for them. I think between some generic growth, strategic partnerships, revised internal processes and some acquisition/expansion opportunities, we are in a good place.”

COVID has been devastating for the live events industry and both LeGallais and his wife picked up part time work where they could. Government support eventually came and although it helped, it didn’t cover everything. But they are optimistic about 2022. “There are lots of positive conversations beginning to happen throughout the industry and the fall 2021 saw some shows return,” says LeGallais. “And reports of a rebound in 2022 are all over the media. But much of this is out of our control and as much as we are planning every day and hopeful to be out on the show floors again, we know we may need to adapt some plans for the short term.”

“I think future opportunities for events lie in a hybrid event model, but not so much the virtual/in-person type,” he says. “Rather, there will be indoor/ outdoor models. People need to gather in person. That’s where business happens and where relationships and memories are made. We think there’s good opportunity to expand our products and services to events that lend themselves to having an outdoor component.” CRS

Find Boneyard online at bes.show, on Instagram at Life_in_the_boneyard and on Twitter @Boneyardbanter.

Here’s how to assemble a trusted circle of advisors to help you succeed.

We all have an inner circle of trusted friends, those we rely on for advice when life throws us a curveball, but have you considered a formalized personal board of directors for your career development?

by CRYSTAL HYDE

Senior professionals in any field often realize how much they owe to the people who helped

them

get their start, and are eager to play the same role with newcomers. People are often surprised by how willing they are to contribute their time and advice.

A personal board can act as a sounding board, offering distinct expertise to take your career to the next level.

Your board members serve different purposes and have distinct expertise, but consistently these members need one key ingredient: trust. The people you trust to be completely selfless in their guidance and advice with a single focus on helping you to meet your goals are the ideal candidates to make up your board.

A simple exercise to determine your board

members is to write a list of trusted professionals in your network, noting their area of strength beside their names. Then write down your career goals to assess what resources you may require to support your efforts. Once you have identified the subject matter expertise you need, you can then start to slot in board members identifying any gaps.

While certain members will remain consistent, your board may change depending on the goal you are moving towards and adding

members with specific expertise to contribute to more of their knowledge to achieve your next milestone. What if you need a financial expert and don’t have one in your immediate pool of contacts? Network, ask your existing board members for recommendations, as others for referrals and then identify the best fit to contribute to your career journey.

At this point, a common question becomes, “Why would someone join my board of directors and donate their time?” This is a general question I get from career starters about networking with more senior professionals, and my answer is consistent: anyone further along in their career recognizes the value of the many contributors to their journey and often welcome the opportunity to pay it forward by giving someone else a helping hand. This rule does not apply to everyone, but you’ll be surprised by how many people openly and willingly share their expertise to assist others in their careers. Well-developed expertise is a gift to be shared, and those confident enough to know that share enthusiastically.

Now that you have identified your board of directors formally or informally

at your discretion and want to activate it, how do you do that? To make the most of the resources available to you, it’s vital to be a receiver, meaning your goal is to provide plenty of air time for the member to share their knowledge, ask open-ended questions and listen, take notes and not dismiss a single idea of how you extract the most information to consider.

Listening to advice does not mean you need to take it or even apply it. Instead, consider it, layer over the nuance of your particular circumstances and goals and make the best-informed decision for you. If you do not take the lead in the process and filter accordingly, this is where people can get lost chasing their tail and by changing direction with every piece of advice. The belief that respecting the recommendation is to follow it is honourable, though it leaves you rudderless when navigating towards a goal. You have to be the captain of your ship, and taking this approach of listening, considering, and adjusting to customize your strategy is a critical lesson in leadership. No one should lead your career journey but you. You are the head of your board that you have contributed to your career goals.

To get the most out of this esteemed group, you need to compose thoughtful, open-ended questions. For example, “I want to buy out my partner in the next three years; what should I do now to prepare myself?” “How would you approach raising rates?” “What are some things you had to overcome to get to where you are?” “What do you suggest to improve my writing?”. By preparing clear and direct questions before engaging with each member, you can ensure you are making the best use of their time.

The most respectful approach to your members is to prepare before speaking with them, acknowledge the importance of their time and don’t take too much. Engaging with members for shorter increments of time and more frequently can keep your guidance current, relevant and adjusted to real-time developments in your progress. CRS

Crystal Hyde is a certified professional coach in Waterloo, Ont., and founder of Propel Leadership Coaching, specializing in communications consulting and leadership coaching. She can be reached at crystal@propelleadership.ca.

Brandt has an extensive lineup of John Deere skid steers available to round out your fleet and make this your most profitable season ever.

With exceptional pushing power and breakout force, Deere skid steers deliver the tractive effort and leverage to dig into any task.

Bigger fuel capacity, high-quality components, and superior stability ensure you can do more with less effort, every day.

Easy serviceability and low-maintenance requirements let you keep working longer, so you can keep up to your tightest deadlines.

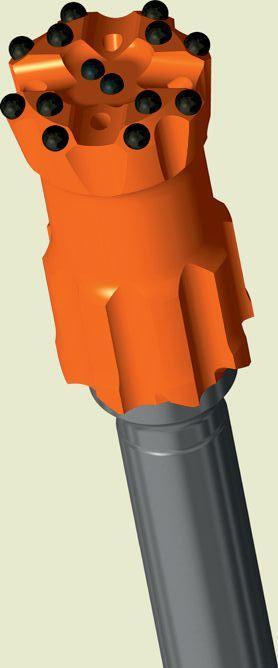

Rental shops looking to hire heavy equipment mechanics may need to adjust their approach as well as their salaries.

As we exit the pandemic, there’s a new level of concern about the supply of skilled labour. And few professions are as demanding of knowledge and expertise as the heavy equipment mechanic trade.

by TREENA HEIN

RIGHT: Heavy equipment and small engine mechanics are in high demand across Canada, with more severe shortages coming as older mechanics retire. It may be time for rental stores to invest in training less experienced workers.

A rental outlet where labour isn’t a constant concern is becoming a rarity. Nowadays, it’s tough to recruit for most positions, but filling the role of heavy equipment mechanic or small equipment mechanic may be the toughest of all.

“We always need mechanics,” says Matt Abell, director of recruiting at Talon Recruiting in Ottawa, which specializes in servicing all heavy industry sectors across Canada and the United States. “It’s so bad in certain geographic markets that we don’t take on new business. All the major rental chains in Toronto, for example, are hiring heavy equipment mechanics on a constant basis.”

According to a recent RBC report, Canada will face a shortage of at least 10,000 people in the Red Seal trades in the next five years. This number grows by a whopping 10 times when you include the provincially regulated trades. The shortage of industrial mechanics, among other trades such as welders, will be most severe. In terms of recruitment, Abell has some tips to share. He notes that despite desperately needing mechanics, some rental company owners or managers are not keen to hire mechanics who may lack experience. Abell urges them to re-think this sentiment and work with new hires on any further training

that might be needed.

As well, Abell explains current salary rates may be a sticking point, as they could lead to discord within the company’s team of mechanics.

“Your mechanic or mechanics that you may have had for years are making X dollars an hour, and the new mechanic will start at the same rate,” he says. “That can upset older employees, but the fact is that you’re going to have to pay more for new hires because everyone is paying more. You may have to bump everyone up. Mechanics in the past haven’t tended to be a group that’s constantly looking for a better salary, as is the case in other sectors. That’s not true today.”

Recruitment aside, training mechanics is also an important piece of the puzzle. To understand how training programs across the country are keeping up, here’s the view from several provinces.

Heavy equipment programs have been in high demand for more than a decade

at NAIT (the Northern Alberta Institute of Technology) in Edmonton, Alta.

“We are at our capacity limit and expansion is critical,” says James Hallett, chair of NAIT’s heavy equipment programs, and Scott Sinclair, department head of transportation programs. “The Heavy Equipment Technician (HET) program just underwent a massive upgrade to their training spaces, and we are continuing to make advancements with training aids and tooling.

All HET labs and shops underwent a major renovation during summer 2021, including facility upgrades to support power requirements of the latest, most advanced training aids, paint, flooring, air handling, tooling and some large equipment. We also hired additional instructors in summer 2021.”

Throughout Canada, mechanic training is apprenticeship-based. Hallet and Sinclair explain “one of the largest challenges with the apprenticeship system is not having the resources in place to allow for timely curriculum updates.

Trades are only reviewed every five to seven years for content accuracy and in fast-changing trades such as HET, this often leaves the curriculum outdated.”

NAIT also offers the outdoor power equipment technician program, which teaches small engine mechanics, enabling students to repair a variety of machines, from turf and compaction equipment to lift platforms.

At the BC Institute of Technology (BCIT), the heavy equipment mechanic program has been at capacity for more than 15 years.

“This is an in-demand trade,” says Bruce Thompson, interim associate dean of motive power. “There’s always a shortage of heavy equipment mechanics now and there will be in the future.” British Columbia’s Industry Training Authority is looking to add 176 additional seats to the program starting in 2024 and continuing for four years, and BCIT is hoping to offer half or more of those seats.

In Ontario, the Ministry of Labour, Training and Skills Development

According to the federal Job Bank website, these are the employment requirements typically needed to become a heavy equipment mechanic:

• Completion of secondary school.

• Completion of a three- to five-year apprenticeship program or combination of over four years of work experience in the trade and some high school, college or industry courses in heavy equipment repair is usually required to be eligible for trade certification.

• Heavy-duty equipment technician trade certification is compulsory in Quebec and Alberta and available, but voluntary, in all other provinces and the territories.

• Agricultural equipment technician trade certification is available, but voluntary, in Newfoundland and Labrador, Nova Scotia, Prince Edward Island, New Brunswick, Ontario, Manitoba, Saskatchewan, Alberta and British Columbia.

• Red Seal endorsement is also available to qualified heavy duty equipment technicians and agricultural equipment technicians upon successful completion of the interprovincial Red Seal examination.

The message needs to get to young people that the heavy mechanic trade pays well and is interesting.

reports that seats in the heavy equipment mechanics program have not been filled in the last five years. In 2016/17 and 2017/18, there were about 166 seats available with about 20 empty each of those years. For 2020/21, the trend continued with 179 of 270 filled. There is good news, however, in the work world in Ontario. In 2021, there were 15,700 heavy equipment mechanics employed in Ontario, an increase of nearly 20 per cent compared to 2019. Looking forward to 2025, employment growth for heavy equipment mechanics in the province is expected to range between 11 and 12 per cent.

The trend in the program fulfillment for small engine technician in Ontario was similar. From 2016/17 to 2020/21, seats grew from 43 to 64 with enrollment trending towards capacity. Employment for this type of mechanics is expected to grow by about 13.5 per cent every year to 2025.

• Check bulldozers, cranes, graders and other heavy construction, agricultural, logging and mining equipment for proper performance and inspect equipment to detect faults and malfunctions

• Diagnose faults or malfunctions using computerized and other testing equipment to determine extent of repair required

• Adjust equipment and repair or replace defective parts, components or systems, using hand and power tools

• Test repaired equipment for proper performance and to ensure that work meets manufacturers’ specifications

• Clean, lubricate and perform other routine maintenance work on equipment

• Service attachments and working tools such as harvesting and tillage equipment, blades, ploughs, winches and side booms

• May perform repair work on heavy trucks

• May attach components and adjust new farm equipment.

• Heavy-duty mechanics may specialize in specific types of machinery such as combines or tracked vehicles, or in engine overhaul, power shift transmissions, fuel injection, hydraulics or electronics.

To increase interest in mechanics and other trades, the Ontario government recently updated how trades are delivered and promoted in the province. The government states that for more than a decade, the provincial skilled trades and apprenticeship system has been complex, difficult to navigate and confusing as delivery was shared between the government and the former Ontario College of Trades. New legislation enabled the creation of Skilled Trades Ontario, a new Crown agency which, at maturity, will lead the promotion and marketing of trades in the province, develop the latest training and curriculum standards and provide a one-window experience for clients for such services as registration, credentials issuance and exam administration.

The focus will be on “breaking the stigma associated with skilled trades,” to attract more youth, simplify the system and encouraging employer participation.

“By 2025, one in five jobs in Ontario will be in the trades,” says Minister of Labour, Training and Skills Development Monte McNaughton. “We want more apprentices, and we need to simplify the apprenticeship system. If we’re going to recruit people into the trades, reform is needed.”

McNaughton points to the former timeframe for apprentice registration under the Ontario College of Trades was 60 days. This timeframe is expected to be reduced to 12 days.

“We’re also moving to create a digital

portal for tracking of hours and so on,” he says.

In addition, Canada needs to attract more underrepresented groups, such as women and new Canadians, to become mechanics or other types of tradespeople.

“Canada is falling short of its goal to bring in 3,000 skilled tradespeople

Governments are introducing programs across the country to attract and train the mechanics of the future.

annually through immigration, admitting 2,365 such newcomers in 2022 through the Federal Skilled Trades Program,” states the RBC report.

“Educators, employers and policymakers will need to address chronic problems in the trades pipeline, tap into underused pools of talent and address a widening digital skills gap amid rapid technological advances in the workplace.”

In Ontario, McNaughton says the government is providing “further incentives for employers to take on apprentices, such as an additional $17,000 to taken on an apprentice from an under-represented group.”

RBC also recommends the federal and provincial governments increase funding to promote the trades in primary and secondary schools and incorporate exposure to trades into school curricula. CRS

by Russ Dantu

We are living in precarious times right now. A country divided by what has happened due to COVID and the way our provincial and federal governments have handled things. Truckers blocking ports to the U.S., closing downtown Ottawa to voice their concern and try to get their point across. Rallies in front of parliament buildings in each and every province. I won’t pick a side here, as I’d alienate at least half of you…and I like having friends! What I will say though is that what we are seeing on the news every night is sometimes similar to what can happen at work when tough and possibly unpopular decisions have to be made. When this happens it’s our time as leaders to shine or fail miserably. Below are my 10 attributes of a great leader.

1. Leads by example. When things get tough, a great leader doesn’t hide. She gets in the trenches alongside her employees to get things done!

2. Has an open door policy. Make sure your employees can come and talk to you about work or personal issues when needed. If you do not like playing Dr. Phil, you can simply connect them with the right people to help them with personal issues.

3. Is courageous. Good leaders make tough decisions when needed. It is not always the popular choice to make a tough decision, but, folks, it is not a popularity contest. You are a leader for a reason.

4. Is honest. Trust and integrity are the cornerstones of any good leader. Always do the right thing. Always be honest. There will be times when you are sworn to secrecy so you have to be creative with answering questions without compromising your integrity. If you ever break that trust, it will be hard to win your employees back.

5. Is fair. Treat each of your employees fairly. Being fair means having the same standards for everyone. It means equal pay for equal work; no favoritism for your friends; and eliminating sexist or racist double standards.

6. Is caring. It is important to be supportive, understanding and caring when you are a

leader. This does not mean being weak. It means showing compassion towards other human beings. Learning more about your employee’s personal lives will deepen your relationship with them. Some will argue that they are there to work for you and you should not get involved outside of work. This is old-school mentality. Definitely get to know your employees better.

7. Is competent. How many times have you spoken with the person in charge and wondered, “How the heck did they get to be the boss?” If you are promoting from within, make sure they are the right person for the job. Train them adequately to equip them for all facets of their job.

8. Knows how to delegate. This is so important. If you think you need to have your fingers in everything for it to be done properly, you will either burn out or start making mistakes and alienate your staff. Trust and empower your employees to get the work done.

9. Is forward thinking. Daily decisions are made thinking about the future and where you wish to be down the road. Staying focused on your vision and goals is key.

10. Is inspiring. The ability to rally your team during busy times or when morale is low will help keep a positive atmosphere. When we inspire, we draw out the best in people. It is contagious!

I have many more attributes of being a great leader that I will share in the next newsletter. When we lead effectively, we create a more effective team which leads to a better workplace culture and happier customers. It all starts from the top. Are you a good leader?

Take care of yourselves, your employees and your customers! CRS

Russ Dantu is a 30-year veteran of the rental industry and has been delivering workshops, seminars and keynotes on customer service for over 15 years. Visit russdantu.com.

Understanding regulations outlined by NFPA and WHMIS could help prevent catastrophe on the jobsite.

by James Hong

There are two essential codes covering both hazardous material codes and fire protection standards and regulations: NFPA and WHMIS. The National Fire Protection Association (NFPA) is a non-profit organization devoted to eliminating death, injury, property and economic loss due to fire, electrical and related hazards. The Workplace Hazardous Materials Information System (WHMIS) is a system that provides information for the safe use of hazardous materials used in Canadian workplaces.

You can access the 747-page 2021 NFPA 1 Fire Code documentation at nfpa.org. The National Fire Code of Canada 2015, published by the National Research Council of Canada, can be accessed at nrc.canada.ca. Once you navigate to the webpage, there is a robust search engine for finding the codes you need.

So why is it important to learn to access the fire codes? The short answer is that, in my experience, companies do not include how to access fire codes online in their training. They expect to hire job supervisors who already have that knowledge. The reality is many supervisors do not have this knowledge and may fail to install risk assessment-based preventive measures as a result.

The second set of codes – WHMIS – regulates information provided by means of product labels, material safety data sheets (MSDS) and worker education programs. WHMIS was created as a response to worker’s rights to understand what hazardous materials and chemicals are present in their workplace. The goal is to bring awareness to workers regarding the health ramifications of handling toxic materials and the safety measures for the prevention of injuries, illness and death. All three participating parties, government, industry and labour, developed the system to be in the best interest of everyone involved. WHMIS became law in 1988.

When a product is considered a controlled product, suppliers must label and provide an MSDS for that product. Employers must

implement WHMIS education in their training, as well. It’s also mandatory to do a full audit of all hazardous materials on-site, and ensure the products are labelled and a data sheet is attached. Workers are required to take WHMIS training, follow the safety recommendations for those products and to advise if a product does not have a proper datasheet or readable label. This must all be repeated whenever a new toxic substance is brought onsite and when a new or additional job component requires risk assessment.

I’ve found that one of the best sources for obtaining MSDS material safety data sheets, without having to subscribe, is published by Health Care B.C., which can be searched by product name, manufacturer or product code. The results will provide the full safety data details which can be printed and attached to the product. The SDS search engine can be found at sds.healthcarebc.ca/search. When the product is selected, the result defines whether it is WHMIS-exempt. You may also obtain the SDS safety data sheet from the manufacturer and several other SDS search engines. PubChem has a searchable data source that uses many multiple SDS sources to search for chemical information about products.

Most of the time, it will only be necessary to use the product code input for the MSDS search. Please remember that if a product is controlled by the WHMIS system it must have a MSDS material safety data sheet, without exception. I’ve been on countless job sites and have never seen a MSDS on any product before I gave instruction to do so. Your health and jobsite risks, combined with the lack of required labelling and MSDS, can end in a very regrettable scenario.

Let’s keep our eyes open with a mind for self protection and worksite safety.

Be safe. Be well. CRS

James Hong is an OHS consultant and writer for the construction industry.

A knowledgeable rental store can help generate more than just power.

The equipment rental industry is growing. More contractors than ever are looking to rental as an affordable solution to meet temporary power requirements.

by Michael Frey, rental operations manager for Finning Canada

The increase in market activity and capital investment, combined with supply chain constraints, is positioning rentals as a viable option for contractors looking to meet equipment needs.

By offering customers the right solutions for the job — including equipment, maintenance, service and support — stores are better prepared to meet this growing demand.

Helping customers keep their job sites powered-up and running is not an easy task. It involves a deep understanding of the business and power needs – from sizing, voltage and transport, to fuel, maintenance and repair requirements. By supporting a customer’s business needs, rental operations can help improve

a customers’ profitability and productivity while guaranteeing future success for their own rental operation.

Choosing the right rental dealer is an important part of a contractor’s success. For contractors that have a short-term power need, the most cost-effective solution is often rental.

Helping customers power their jobsites requires a significant understanding of the business.

Even when it comes to long-term temporary power, contractors may need to rent to fill the gap while waiting for new equipment to arrive. When a rental dealer is engaged from the beginning of a project, they can be prepared to provide end-to-end support and offer solutions that work for each application.

As well, a store can support customers by understanding the job, type of equipment required and any service, delivery or technology needs. As a dealer you can help the customer select the exact generator size needed, assessing load and fuel consumption to ensure it runs effectively and efficiently. This is especially important with Tier 4 engines, as sizing is critical for optimum performance. Working with contractors on a solid rental strategy can also help them manage equipment while keeping costs down, by allowing contractors to get a

replacement for a generator that’s out of service or help to meet an increase in demand. This also helps the customer minimize the associated risks of new purchase costs.

Reliable power is crucial for productivity and when a generator goes down one of the biggest challenges is having the parts and technicians available for repairs. To set themselves apart from the competition, dealers need to provide on-site service and offer agreements that cover maintenance and support from trained technicians.

By understanding a customer’s unique business needs, dealers can establish a relationship with the customer and keep them coming back. The customer benefits by having a knowledgeable rental dealer with well-maintained equipment, reliable service and access to maintenance and repairs with parts that are stocked and ready for delivery.

When a contractor owns a piece of equipment and it breaks down, they’re responsible for costs and scheduling the repair, which can often take days or weeks and result in significant downtime. With rental, service for breakdowns is included with no cost to the customer. Rental machines are also now equipped with GPS technology, which can track hours and other important data, so the dealer knows when the equipment requires maintenance, providing added peace of mind.

Flexible rental agreements allow contractors to get the right gen erator for the project, no matter the size or length of the job. If

The RotoRake from Reist Industries is a hydraulically driven power rake with features such as the dual motor design, 25° angle and 28° tilt, and bi-directional motor. With features like that, you can rest assured that the RotoRake will give you a quality result.

the scope of the job and power requirements change, dealers can negotiate exchanges for properly sized equipment. When dealers have a broad rental inventory, it gives customers assurance they will have access to the equipment they need, when they need it.

Availability and utilization are key factors for contractors who have varying daily, weekly and monthly equipment needs. This is where rental can help. Having the right equipment available at the right time and the right price helps companies balance workflow, giving them the ability to scale up or down as needed.

Power is critical to almost every construction and event site. When it comes to rental power, there is no one-size fits-all solution. Generator down-time can be devastating to the productivity of an operation, or the success of an event. Finding the right rental partner who can support power needs while understanding the demands of the project is crucial for success. As a dealer, you should be up to date on the latest equipment and technology and have effective processes for serving customers that go beyond simply providing equipment.

The right rental company should offer the latest equipment that is safety compliant, well-maintained and can provide an immediate solution for repairs and maintenance at a fair cost.

A rental store should be a one-stop-shop for temporary power solutions. When a dealer develops a reputation for exceptional service and support, it will set them apart from the competition, which is a win-win for both the rental deal

Sby KEN STEURY

Fuel storage tanks, on the other hand, aren’t traditionally thought of as a rapidly changing product. However, more manufacturers are realizing the necessity of designing fuel storage solutions for the modern business, with features such as cloud-based remote fuel monitoring and global transportation approvals.

Diesel — the source of roughly 98 percent of energy consumed at the average jobsite — is a universal expense for operators. And, as the construction industry changes and companies become more competitive globally, profit margins will continue to shrink for businesses that don’t find new and efficient ways to manage assets, including fuel storage.

Today, on-site tanks can simplify fuel management for rental centres and their customers. To make the most of a fuel tank purchase, there are a number of factors to consider, such as the benefits of fuel monitoring, cleaning and maintenance costs, tank transportation, theft prevention and more.

Determining the ideal solution starts with knowing how much fuel is being used and how mobile the fuel supply must be. After all, having an on-site fuel supply only saves time and money if it provides an adequate supply where and when it is needed. Transportation options can range from

certified lifting lugs for handling with a crane to DOTapproved trailers. The most easily transported options are smaller trailer mounted tanks typically holding between 200 and 1,000 gallons that are ideal for delivering fuel to remote sites. Some of the more important items to look for when buying a trailer-mounted tank include a sturdy trailer engineered to withstand the dynamic forces of the moving liquid while navigating rough, unpaved roads at jobsites. Tanks designed to comply with worldwide approvals, including UL, ULC, UN DOT and Transport Canada, are usually the most rugged and well-designed, as they are required to pass the rigorous testing and certification dictated by the various approval bodies.

Keep in mind, however, that just because a tank is approved, does not necessarily mean it’s the safest option. A lower centre of gravity, for example, will make the tank less susceptible to tipping during transport. And for full-fuel transport, internal baffle plates prevent fuel surging to keep the vehicle stable. In most locations, tanks without baffles must be emptied and often cleaned prior to transport, which can require a third-party environmental company.

If the job requires a larger tank of 1,000 gallons or more, consider how it will be moved around a jobsite. Round tanks often require a crane or loader to move. Most cube tanks can also be moved this way but, for added versatility, many also incorporate forklift pockets. Having more options can come in handy when equipment operators are busy or if certain equipment isn’t on the jobsite.

Environmental regulations must also be considered and ground contamination is a major concern for on-site fuel tanks. While all tanks should meet basic environmental standards, round tanks — the traditional go-to storage option — come with the added expense of owning and cleaning secondary containment pans. The average bill for cleaning a containment pan is about $150, which can add up quickly in areas that require pans be cleaned on a regular basis or after it rains. An increasingly common feature on new tanks, particularly cube tanks, is double-walled 110-percent weatherproof containment. This eliminates the need for a secondary basin and can result in significant savings over the life of a tank.

To meet the specific needs of different construction sites, it’s important to evaluate which features have the potential to increase value for a given operation. Tanks with multiple in- and out-ports, for example, allow the tank to serve as an auxiliary fuel supply while still being able to fuel trucks and other equipment. This can drastically extend runtimes for generators and light towers, as well as reduce the risk of running them dry.

For jobs at remote locations, the benefits of remote tracking technology can pay dividends. Remote fuel tracking helps operations monitor and manage supplies from anywhere via the cloud. For those with multiple projects at different sites, this can make it easy to stay on top of fuel supplies and know when a delivery is necessary.

Having tanks with secure access to fittings and dispensing equipment can also prevent unauthorized access and deter fuel theft. While many rely on regular padlocks, these are easy to cut and do little to deter thieves. Investing in more secure cabinets that position locks to be inaccessible to bolt cutters will better keep thieves at bay. While these security features will likely bump up the initial tank price, preventing a single theft of 50 gallons — roughly the capacity of a diesel pickup — may be enough to offset the difference.

Another location-specific consideration is the tank’s power supply. For mobile tanks and tanks at remote sites, adding options such as battery power storage and solar panels can help ensure that the tank will always have the necessary power to run the pumps. And for locations with space limitations, and for storage in rental yards, tanks that can be stacked help to free up space.

No matter the tank or application, it’s important to buy from a trusted manufacturer. Reputable companies understand the importance of long-term customer satisfaction and are more likely to design tanks that are user friendly and will generate

You can’t just stick any tank on a trailer. Look for certification labels to ensure the tank is safe to tow.

higher ROI over the life of the product. Built-in ladders, convenient manhole access doors and a solid warranty, for example, are strong indicators that a manufacturer is not cutting corners. Additionally, double-walled units with removable primary tanks make cleaning much easier. Over time, tanks that are easier to clean and maintain will likely last longer and yield a much higher return.

To extend the life of pumps, meters and other components, look for tanks with enclosed, weatherproof cabinets. This is a common feature on modern cube tanks and will greatly increase the longevity of components compared to tanks with components mounted on the top, where they are exposed to the elements. It is also worth checking whether your tank partner can supply the tank fully fitted with all the ancillary parts including pumps, placards and filters so that when the tank arrives at your site it is ready to rent as soon as it’s offloaded. Additionally, choose a manufacturer that works closely with its customers to help select the ideal tank or fleet for the size and scope of the operation. Some manufacturers will even go as far as partnering with a customer to ensure

Electronics, meters and control panels need to be protected from the elements by waterproof cabinets.

all regulations, from local to state and from EPA to DOT, are met. By providing these services, manufacturers can save customers time and hassle.

As operators scramble to find new ways to decrease their operating expenses, fuel storage tanks — while not front of mind in terms of innovation and technology — should not be overlooked. And as regulations continue to change and the marketplace becomes more competitive, businesses should never ignore an opportunity to trim expenses and work more efficiently than the competition.

Ken Steury leads Western Global’s regional sales team. He has over 20 years of industry experience and has been working closely with Western Global customers for nearly five years. CRS

by Adam Snook

If you’ve been out anywhere lately, you’ve probably noticed that good people are getting harder to find. You go out to a restaurant and it takes twice as long to get your meal as it used to. Only half the registers are open at the grocery stores and it’s actually gotten worse trying to get someone to help you in a big box hardware store. I never thought it was possible for the service level at those stores to get worse, but it has. Why is it so hard to get qualified people who are reliable, responsible, and, most importantly, actually care?

Before COVID ever hit it was a challenge to get the right people on your team. The industry is competitive, wages and benefits were expanding at a much faster pace than your rental rates were. So every time you hired someone new or upped your existing employees’ compensation to match what the other guys were doing, it was straight off your bottom line. When you’re in an industry with this many different skill sets required to operate efficiently, finding the right people at the right price is key. Post COVID, though, the problem has gone to another level.

COVID changed a lot of peoples’ priorities and perspective. An old expression has resurfaced and become the rally cry for what many are calling the Great Resignation: “I work to live, I don’t live to work”. People have decided there’s far more to life than earning a bigger paycheque or the next promotion. Family time is more of a priority than overtime. People are starting to care more about the mission of the business, then the industry the business operates in. This runs counterintuitive to a lot of us, especially in this business. We’re so used to going 100 miles an hour 12 to 14 hours per day that when someone says they don’t want to work 70 hours per week we automatically dismiss them. Unfortunately for us, this is now becoming the norm. We can either adapt, or miss out.

What can you offer an employee or potential employee who is more interested in quality of life then advancing to an upper management position? Here’s what comes to my mind right away:

1. A challenging environment where no two days are ever the same. Variety is the spice of life, and no industry gives you more variety than the rental business.

2. Going home every night, with little need to travel.

3. Competitive wages and benefits. If you can’t offer this, then, honestly, that’s on you. Your rates have been too low for too long and you’ll price yourself out of any good potential employees. This is not a selling feature for people anymore, it’s expected.

4. A team-focused environment. If a rental business is functioning well, it takes a full team of people doing their jobs properly. People take a lot of satisfaction out of being part of a good team. Get matching shirts and pants for everyone. Treat your people like a team, you’d be amazed at the difference in attitude. This also requires getting rid of any non-team players. I know, it’s hard to fire people when you’re already understaffed, but the difference you’ll see when you cut the rotten apple out will make it all worthwhile.

5. Family events like Christmas parties, summer barbeques, whatever you can fit in to the hectic schedule. It’ll make everyone feel closer to your business and less likely to leave over 50 cents per hour.

6. Find a shift structure that works. If you’ve got a group of people who are only interested in eight to 4:30, find a way to make it work. Split shifts, four 10-hour shifts instead of five, eight-hour shifts...be creative.

If you’re thinking of the glory days of 30 resumes for every open position, you’re living in the past. That ship has sailed. This is now the employees market, not the employers. You’re used to selling your business and service to customers everyday, now you’re doing that for employees too. If you don’t like it, I hope you’re planning on working seven days per week, 12 hours per day. I know I’m not. CRS

Adam Snook owns Just Bins, a Regina-based provider of waste disposal solutions.

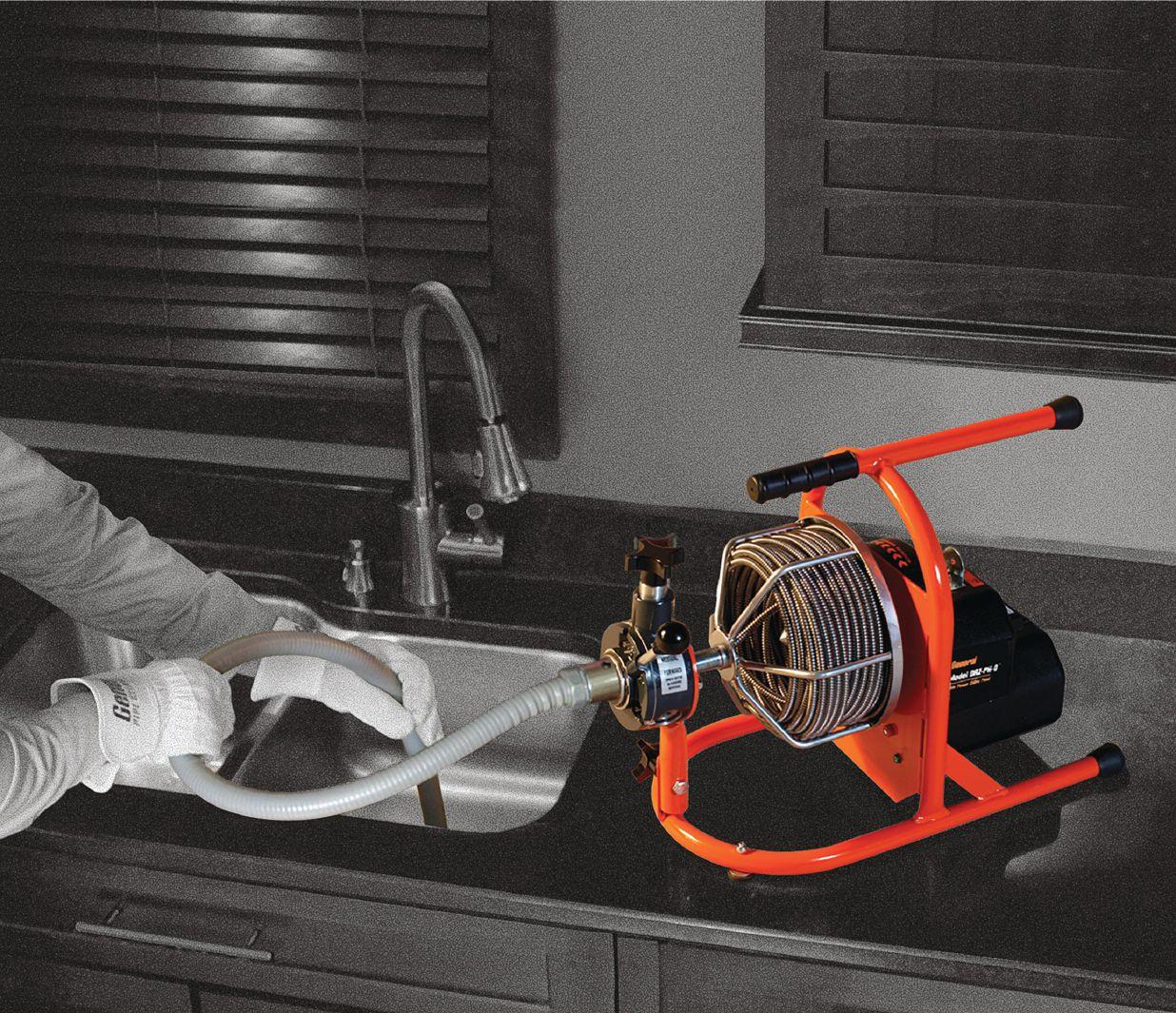

The lightweight, yet powerful Model DRZ-PH-O makes quick work of clogs in sinks, tubs, and laundry drains in 1-¼" to 3" drain lines up to 50 ft. long. The variable speed automatic feed makes the job easier, safer and cleaner, by keeping the operators’ hands off the spinning cable. Flexicore® cable, durable metal frame, and powerful motor make the machine rental tough.

To learn more, call the Drain Brains® at 800-245-6200, or visit www.drainbrain.com/rental