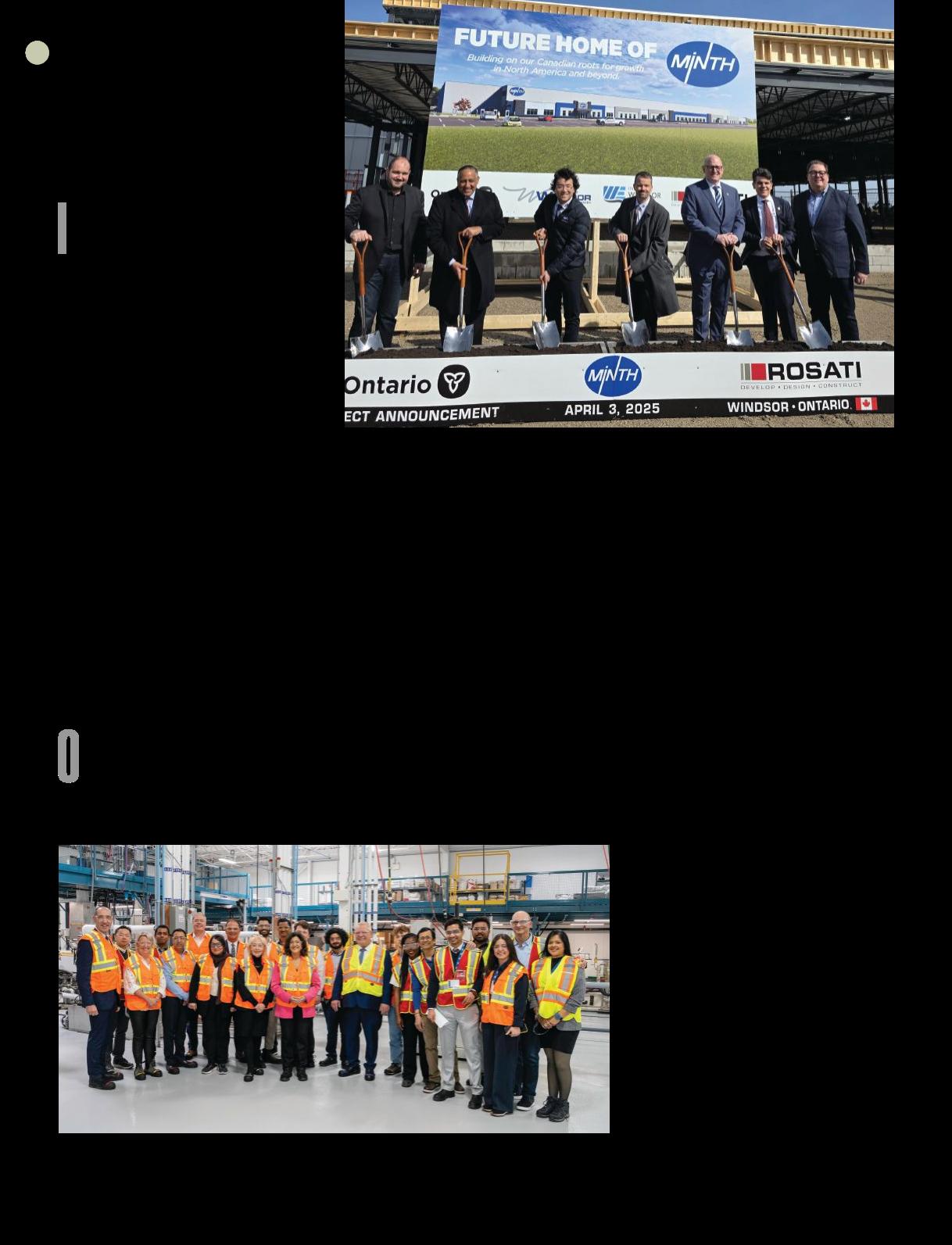

: r Ylokhmf ne rnld ne L Yqjcnl

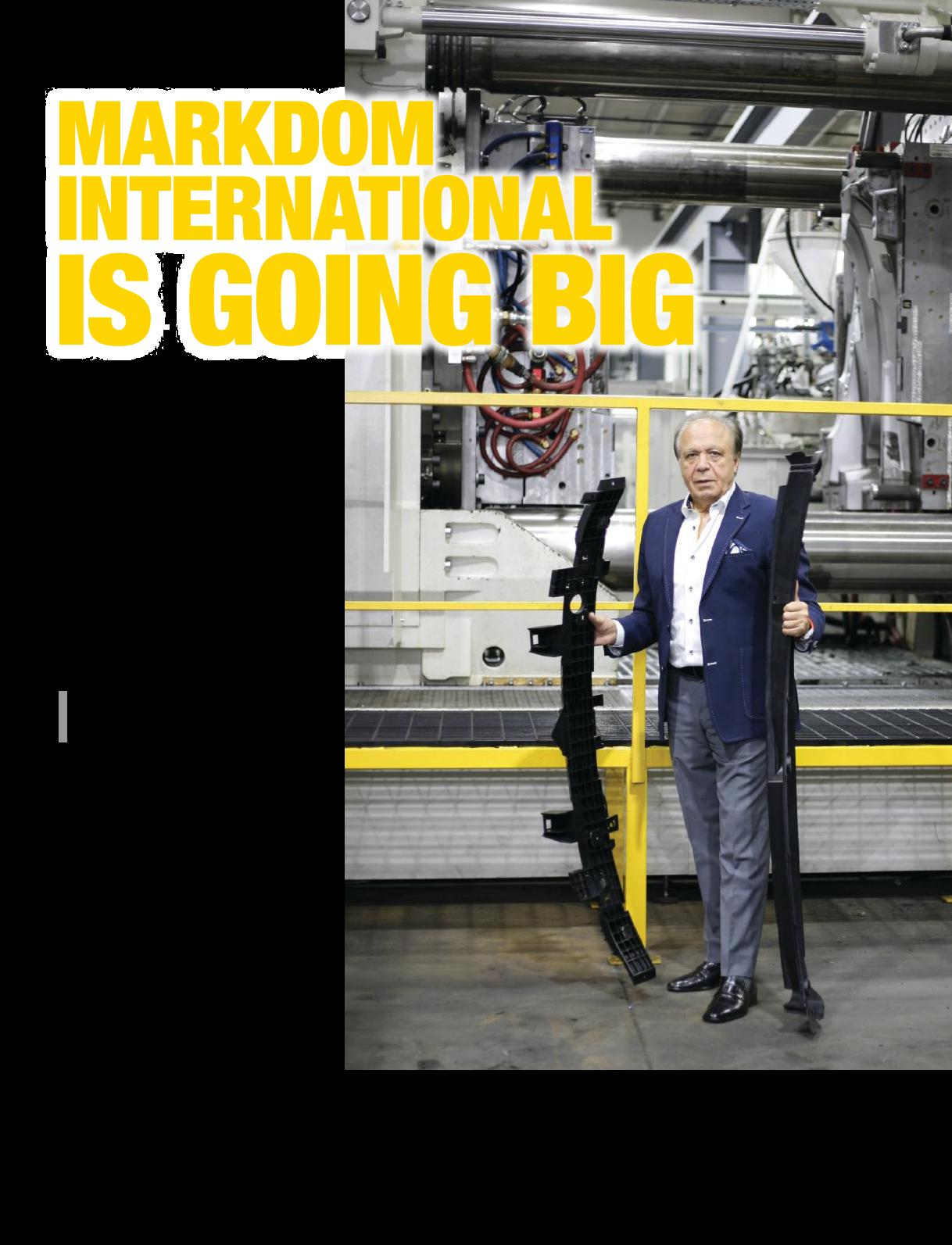

HmsdqmYshnmYk r Ytsn bnlonmdms r- Eqnl sno sn ans snl9 Y eY rbhY rtoonq s aq Ybjds* dkdb sqhbYk lnctkd aq Ybjds r* eY rbhY fthcd aq Ybjds r* Ymc Y khbdmrd okYsd aq Ybjds-

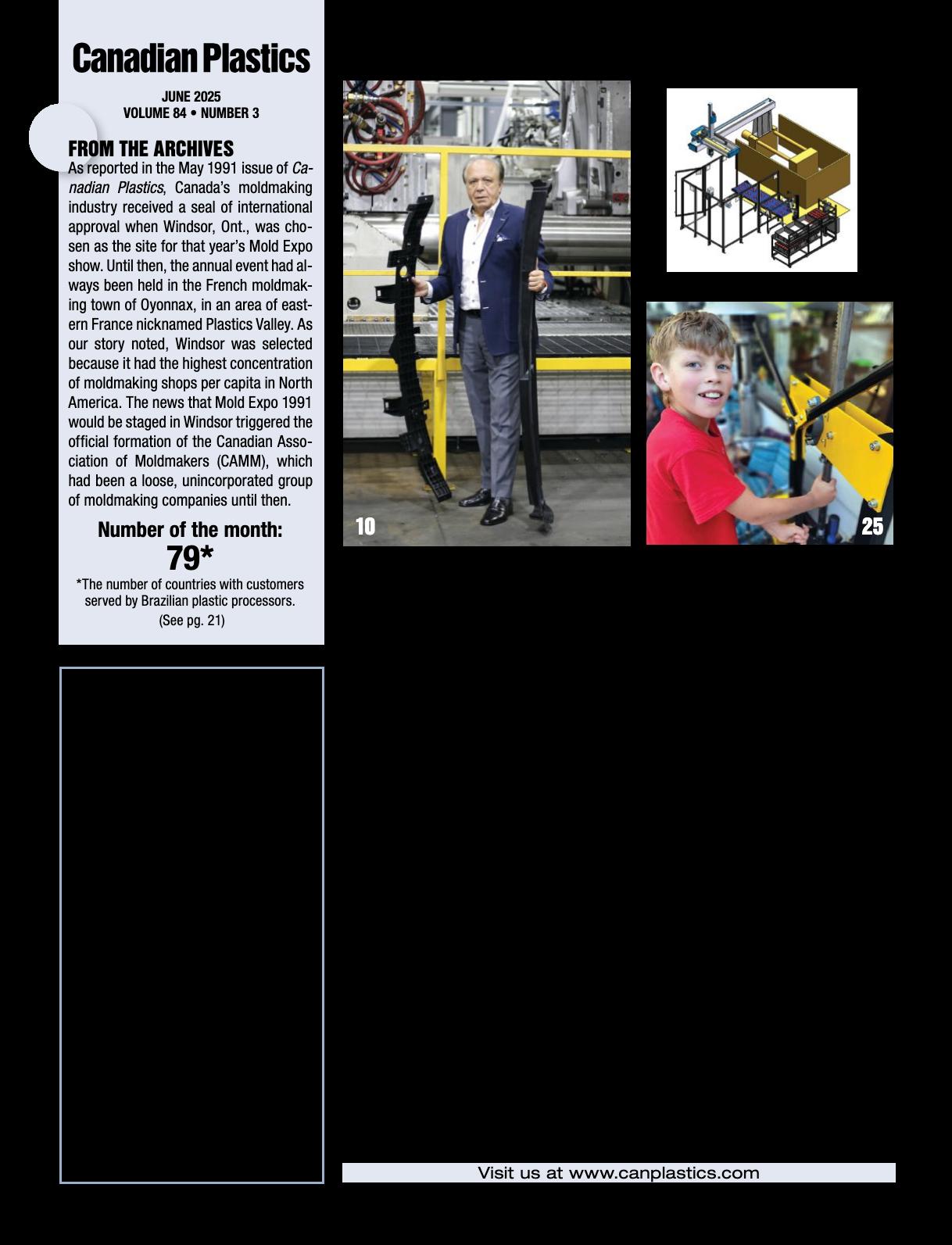

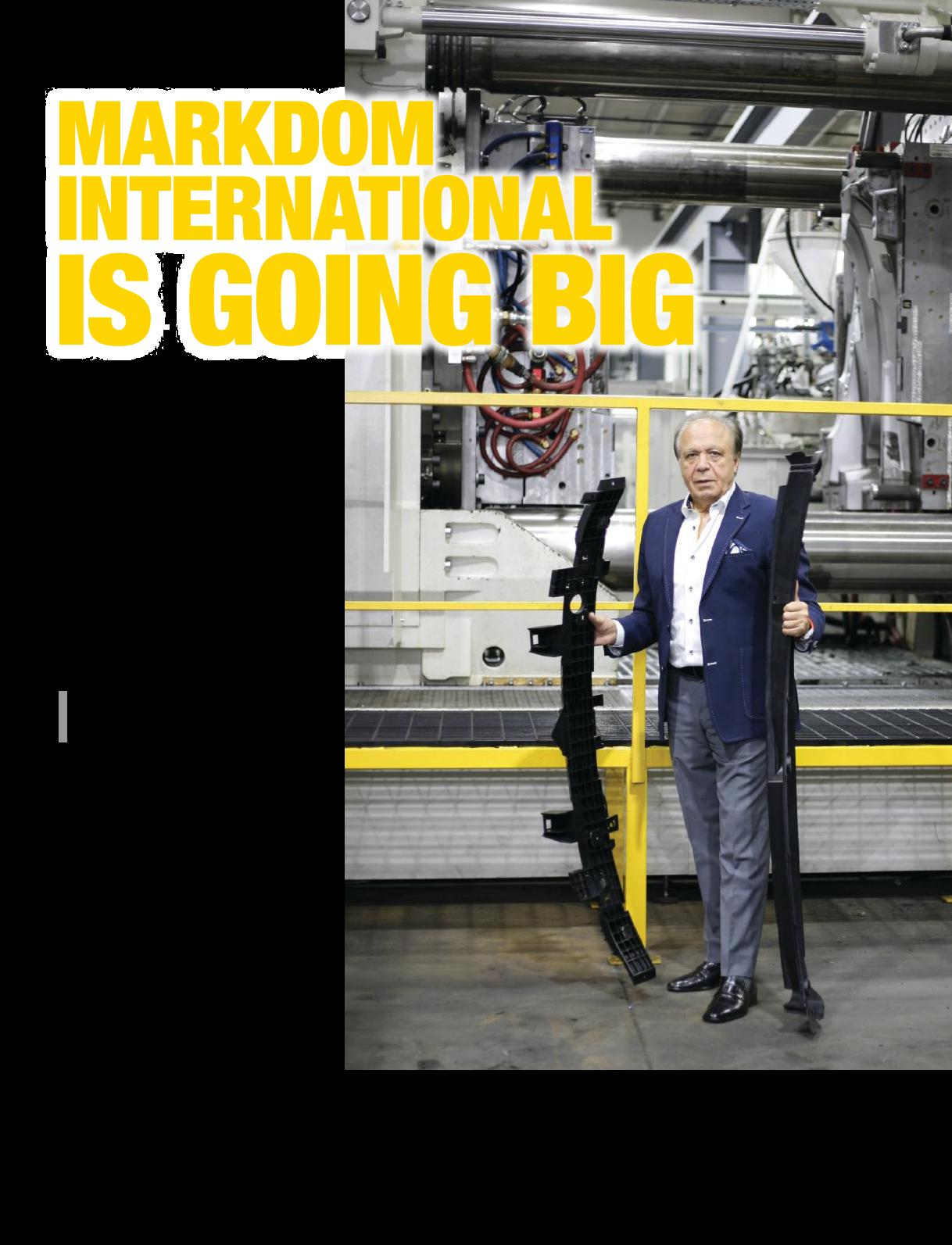

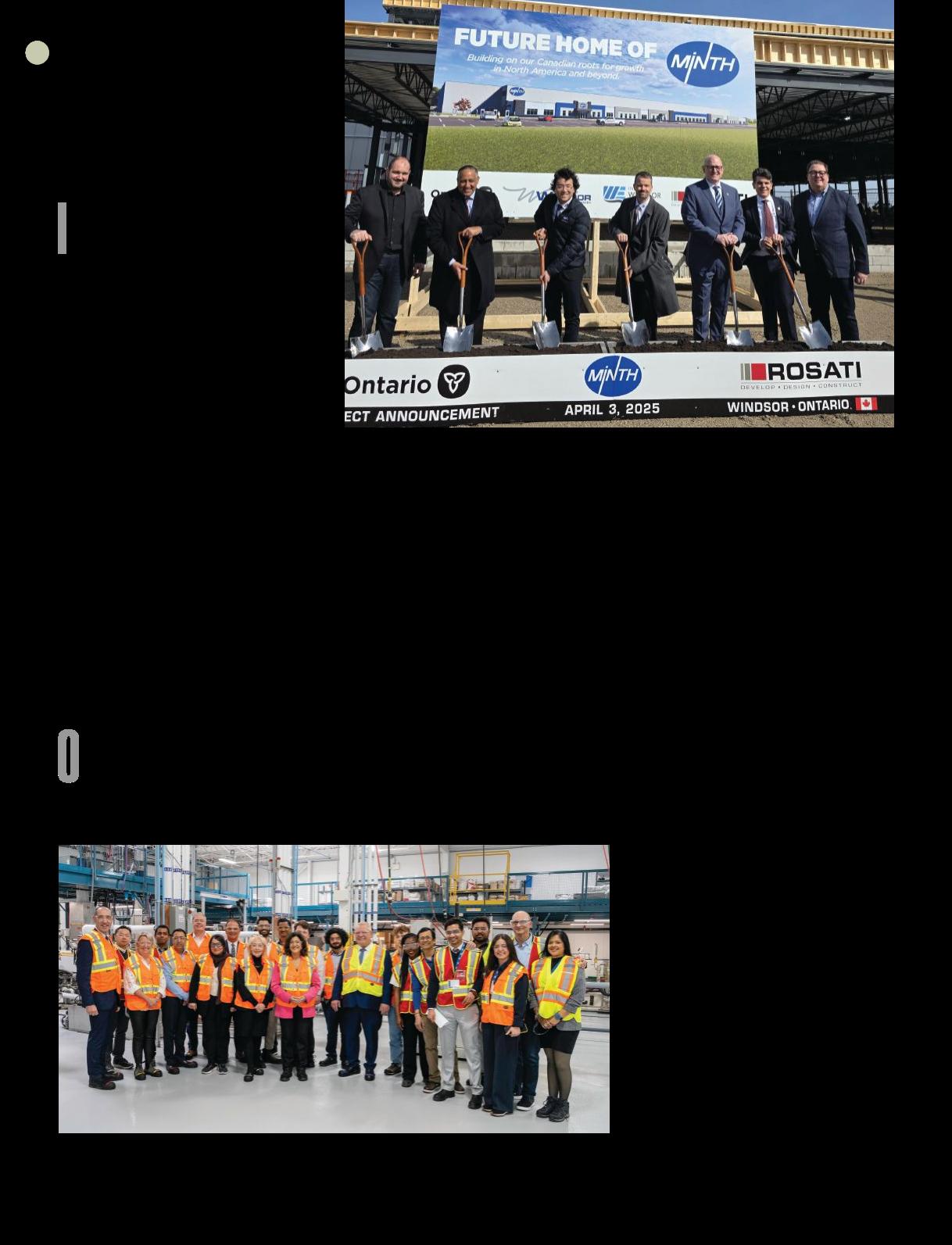

Today, Ma rkdom has approximately 500 skilled workers and has more than tripled its annual revenue. The company has also expanded its manufacturing space from 160,000 to over 500,000 square feet spread out over four state-of-the-art manufacturing facilities – in Toronto; in Monter rey and Irapuato, Mexico; and in the company’s first U S facility, in Charlotte, Mich., where it’s leasing a 100,000-squarefoot building in an industrial park and expects to begin production later this year on parts for the automotive and consumer goods industries.

Ma rkdom’s adva nced in-house capabilities encompass single- a nd two -shot mold i ng, ut i l i z i ng nea rly 10 0 presses with capacities up to 3, 0 0 0 tons T hese soph isticated processes enable the production of complex, h igh-p er for ma nce auto components such as a i r in let systems, fa n sh rouds, a nd active g r ille system f ra mes. T he compa ny’s ma nufact u ring ser vices include injection molding, i nser t mold i ng, se c ond-shot mold i ng, va lve-gate molding, heat sta k ing, overmolding, sub -assembly, a nd on-site injection mold design a nd const r uction

Markdom has now fir mly established itself within the Nor th American automotive supply chain, deliver ing precision, tight-tolerance pa r ts “We’re expanding our por tfolio to include automa kers like General Motors, Stellantis, Ford, Tesla, and other inter national automa kers,” said Dr. Changize Sadr, Markdom’s president of engineering and chief technology officer The company’s manufacturing facilit ies a r e c er t i f ie d u nd er t he I AT F 16949:2016 Automotive Quality Management System which is the global technical specification and quality management st a nda rd for t he auto i ndust r y and hold ISO 140 01 cer tification “As a result, we’ve consistently received t he General Motors Supplier Quality Excellence Award over multiple years,” Sadr said

And beyond automotive, Markdom is actively diversifying into sectors such as c on su m e r go o d s, ele ct r on ics, fo o d, a n d m e d ic a l m a r ket s. “ C u r r e nt ly, ou r busi ness is even ly spl it bet we en aut omot ive a nd c on su m e r/i ndu st r ia l

par ts,” Sadr explained “We’re experiencing rapid growth in the industrial segment, manufacturing large components like air conditioner bases that requi re lighter weight and integrated designs ”

Ma rkdom’s leader sh ip t ea m p ossesses sig n i f ica nt exp e r ienc e i n aut omot ive pa r t s ma nu fact u r i ng, wit h i nd ividu a ls having worked with indust r y gia nts such as A BC Plastics, Ma r tin rea I nter nationa l I nc., Ma g na I nt e r na t ion a l I nc., a nd Dayco. “Collectively, we have nea rly a cent u r y of exp er ience at some of t he world’s leading auto pa r ts ma nufact u rer s, wh ich ha s b e en i nst r u ment a l i n developing ou r st rategy to elevate Ma rkdom in both automotive a nd other indust r ia l ma rkets,” Sad r sa id.

A key comp onent of t h is st r at eg y, Sad r continued, is a clea r pla n for revenue g row th. “Ou r goa l has been to g row revenue f rom $35 m illion in 2021 to over $20 0 m illion in a n nua l booked revenue by the end of 2027,” Sad r sa id. “We at t r ibute ou r success so fa r to quick a nd agile de cision-ma k i ng t hat leads to u n ique, h igh-tech solutions to cha llenges faced by major automa kers – solutions not provided by la rger competitors ”

T he compa ny helps to foster its spi r it of in novation – a nd to keep its sk illset well-honed – by encou raging a ll employees to cont r ibute ideas “My backg round in resea rch a nd development [ R&D] has taught me the va lue of involving ever yone in the in novation process,” Sad r sa id “We welcome suggestions f rom a ll ou r employees on how to improve ou r product s ” Ma rkdom a lso t aps i nto you ng ta lent whenever possible by employing co - op st udents f rom loca l engineer ing schools “We a lso collaborate with severa l Onta r io un iversities a nd colleges on R&D projects,” Sad r sa id. “For elect r ic veh icle pa r ts li ke bat ter y t rays, for exa mple – ideas that have g rabbed the public imagination – un iversities a re ver y keen on becom ing involved in the development a nd testing work ”

HMCTR S QW 3 ,. ? MC AD WNMC

St ayi ng a head of tech nologica l adva nce-

R bdmdr eqnl L Yqjcnl HmsdqmYshnmYk r rgno eknnq- S gd bnloYmx ne edq r rdq uhbdr sgYs hmbktcd hmidb shnm lnkchmf* hmrdq s lnkchmf* rdbnmc rgns lnkc hmf* Ymc hm gntrd lnkc cdrhfm Ymc bnmr sqtb shnm-

ments, Ma rkdom has a lso i nteg rate d Industr y 4.0 practices and is progressing towa rds t he successor te ch nolog y of Industr y 5 0, which adds a human-centric focus, sustainability, and a circular economy to the mix. “Our web-based program ma nagement syst em of fer s rea l-t i me i n sig ht s i nt o ou r p r o duc t ion p r ocesses,” Sad r expla i ned. “We’ve i ntegrated our scheduling system with a propr iet a r y M R P [mater ia l re qu i rements planning] system and utilize predictive analytics to extend equipment life and fore cast ma i ntena nce ne eds, ensu r i ng f u l ly opt i m i z e d m a nu fa ct u r i ng processes.” Additionally, all critical infor mation – including cor respondence, document at ion, t i mel i nes, a nd t asks – is accessible th rough Markdom’s web-based Advanced Product Quality Planning system, enabling team members to review and update project statuses a round the clock This transparency also extends to customers upon request

I n t he end, t he reboot of Ma rkdom u nd e r it s new, but ve r y exp e r ienc e d, leadersh ip t ea m has b e en wi ld ly successf ul so fa r at expa nd i ng t he company’s p r e s e n c e b eyo n d To r o nt o a n d b eyond t he aut omot ive s e c t or, t r a n sfor m i ng t he f i r m i n fou r shor t yea r s f rom a relat ively sma l l player i n Ca nad a’s auto pa r ts sector i nto a for m id able force for automot ive a nd i ndust r ia l products t h roughout Nor t h A mer ica. “T he ma rkets for automot ive, i ndust r ia l, a nd consu mer goods a re a l l rapid ly evolvi ng, a n d we’r e a lway s i n n ova t i n g i n response,” Sad r sa id “We’ve cha nged a lot i n order to get to where we a re tod ay, a nd ou r pla n is to cont i nue to evolve i n order to ser vice bot h old a nd new customers ” B O J

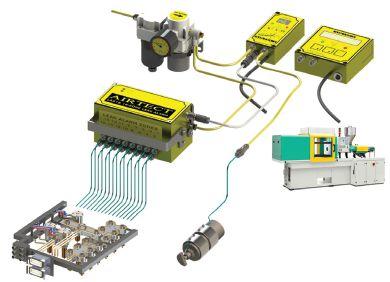

Ohbjhmf sgd qhfgs rnktshnm enq xntq mddcr hr Y bqhshbYk oYqs ne trhmf hmctrsqhYk YtsnlY shnm* Ymc sghr nesdm

ldYmr bgnnrhmf adsvddm sqYchshnmYk qnansr Ymc mdvdq bnkkYanqY shud qnansrGdqd r vgY s sn jddo hm lhmc-

Ax LZqj Rsdogdm’ dchsnq

Rhe debate about whether to automate plastics ma nufact u r ing pla nts is over, a nd automation won. T he factor ies of today have robots a lmost ever ywhere to plug labou r gaps, boost productivity a nd t h r oug hput, a nd i mp r ove p r o duc t ion qua lit y.

So with that debate over, the indust r y is a l ready on to the next one: choosing the r ight type of automation for a pa r ticula r job A big pa r t of th is new discussion has t raditiona l indust r ia l robots on the one side, a nd a new type of mechan ized helper on the other: collaborative robots, n ick na med cobots W h ile both ca n increase eff iciency, productivity, a nd sa fety in a plastics pla nt, thei r distinct cha r a ct er ist ics a nd appl icat ions m a ke

e n a rios Cobots a re designed to be mechan ized tea m mates, work ing sa fely a longside hu m a ns i n a sha re d work spa c e. Robots, on the other ha nd, ta ke on those t asks t hat a re rep etitive, ha za rdous or requi re exceptiona l precision a nd /or h igh speeds, of ten work ing independently of hu m a n i nt e r ve nt io n M a k i ng wel lin for med decisions about wh ich automation type best f its you r specif ic needs a nd ci rcumst a nces is one of t he most impor ta nt a processor will ma ke. A nd the evidence suggests they don’t a lways choose wisely “A lot of plastics molders don’t seem to k now exactly where cobots f it in the ma nufact u r ing space, a nd th is leads them to ta ke the wrong approach:

buying a cobot a nd then t r ying to f ig u re out on thei r own where to use it,” sa id A. J. Za mba n i n i, d i re ctor of sa les a nd ma rketing for Ca nada a nd the U. S. with Sepro Nor th A mer ica

T he r ight approach is to understa nd robots a nd cobots distinct cha racter istics, the OEMs a nd vendors say, a nd the d i f ferenc es – i nclud i ng st reng t hs a nd wea k nesses – between them in key a reas such as integ ration, ease of use, cost, a nd how they f it into a work envi ron ment

T he pr ima r y difference between indust r ia l robots a nd cobots is huma n involvement – the for mer a re designed to replace huma n employees a nd must operate in a

R s Yq sto bnans lYjdq B nans r Hmb-* Y rhr sdq bnloYmx ne O qnbn L Ybghmdq x* hr s Yqfdshmf Y q Ymfd ne hmctr sqhdr* hmbktchmf okY r shbr-

s epa r at e work spa c e, wh i le t he lat t er assist workers a nd ca n sa fely complete tasks a longside them. Traditiona l robots a re typica lly la rger, heavier, more powerf ul, have a g reater ra nge of motion, a nd – cr ucia lly – ca n ha ndle heav y payloads. T he specif ic payload capacity depends on the robot type – either SCA R A, a r ticulated, or Ca r tesia n – a nd on the weight thei r wr ists ca n suppor t, but heav y- duty models a re capable of lif ting over 1, 0 0 0 k i log r a m s ( kg) W h ich is why t hey rema in the k ings of indust r ia l automation “Ca r tesia n robots, in pa r ticula r, a re still ver y well-suited for most injection molding applications a nd a re prefer red to ot her indust r ia l robots due to t hei r speed a nd overa ll foot pr int,” sa id Jason L ong, vice president of sa les with Wit tma n n USA.

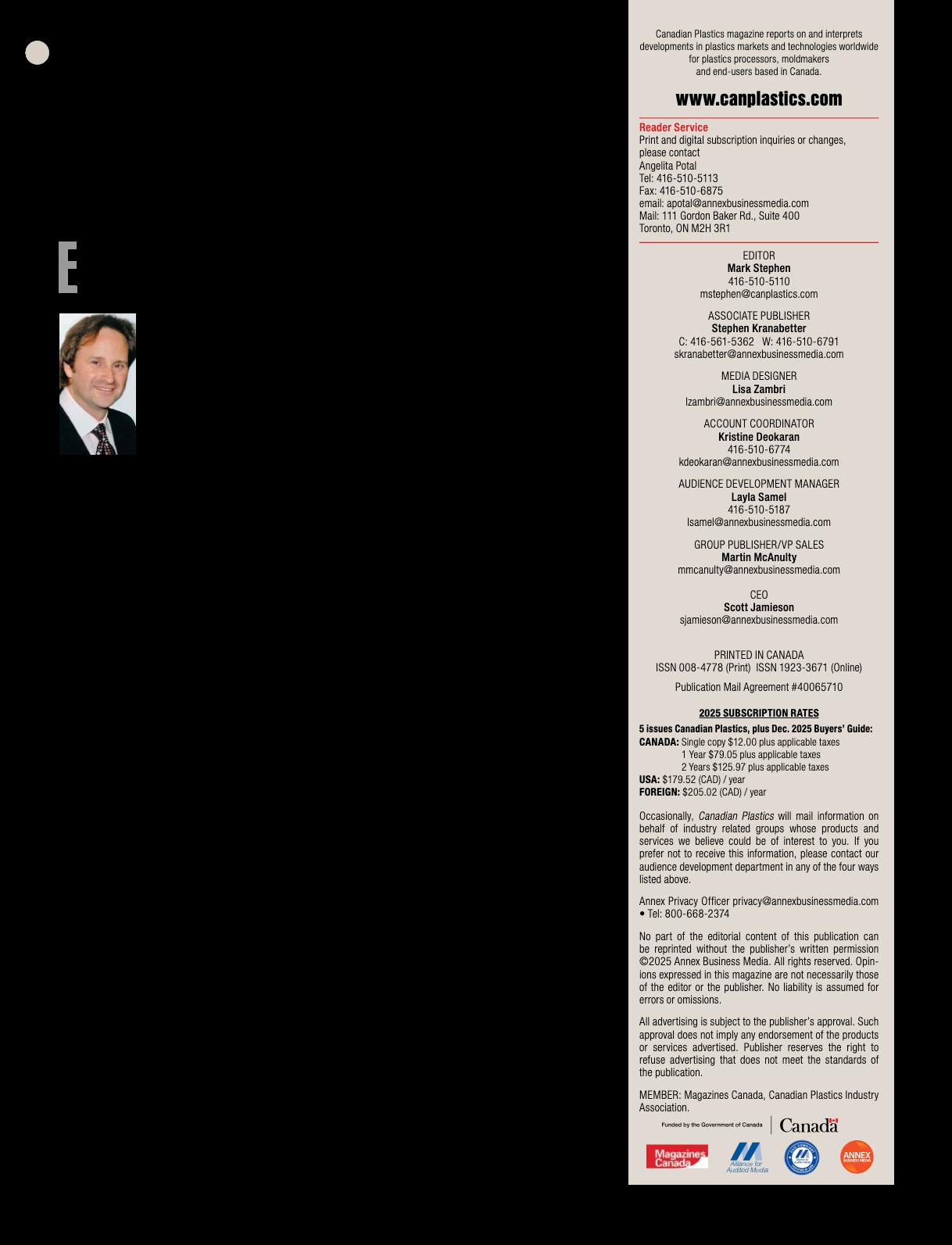

Cobots, in cont rast, have lower payload capabilities due to thei r design for sa fe huma n interaction a nd typica lly ha ndle payloads of f ive kg or less – a lthough some models a re being beefed up in th is rega rd. Fa nuc’s CR X-25i A cobot offers a 30 kg payload capacit y with f ull wr ist a r t icu lat ion, for exa mple, a nd its CR35i B cobot has a 50 kg payload capacit y. But questions rema in “Even with a cobot that ca n lif t 20 kg or more, the question is, ca n it do it 2 4/7/365? ” sa id Joh n McCor m ick, president of P roco Mach iner y a nd its new sta nd-a lone sister com-

pa ny Cobots I nc , wh ich McCor m ick founded ea rlier th is yea r to design a nd supply cobots for a ra nge of indust r ies, including plastics “T he cobot’s tooling has its own weight as well, wh ich adds to the payload a nd to the mecha n ica l st ress,” McCor m ick continued.

I ndeed, payload is a cr itica l dividing line between robots a nd cobots, some OEMs say. “T he equation we follow at Fa nuc is, if a customer wa nts the automation to move a ny th ing heavier tha n 50 kg at a fast speed, that r ules out using a cobot,” sa id Da le A r ndt, di rector of engineer ing a nd integ ration with Fa nuc Ca nad a. “G oi ng b eyond t hat payload r isks inju r ing someone when the cobot stops moving, a nd just d ropping a la rge pa r t could cause inju r y, so it wouldn’t be sa fe to sha re the workspace. For ma ny indust r ia l applications, these sma ll payloa d s a r en’t enoug h, wh ich d ict at es using a n indust r ia l robot.”

A nother t radema rk of t raditiona l robots is speed H igh-speed plastic automation ca n ach ieve impressive production rates, with some systems producing hund reds or even thousa nds of pa r ts per m inute, with cycle times as shor t as two seconds or even less. A nd h ig h-sp e e d rob ot s keep get ting faster. Wit tma n n’s Son ic 108, for exa mple, is the latest in its Son ic

line of h igh-speed robots. Optim ized for h igh-speed pa r ts remova l in packaging a nd pick-a nd-pla c e ap pl ic a t ion s, t h e Son ic 108 is designed for cycle ti mes below fou r seconds, wit h i n /out ti mes kept under 0 9 seconds

Cobots ca n’t compete in th is rega rd Because they’re designed to work sa fely a longside huma ns, thei r speed typica lly ra nges between 250 a nd 1, 0 0 0 m illimeters p er second, wh ich is slower t ha n t raditiona l indust r ia l robots operating in sa fety cages – a lthough cobots ca n operate at h igher speeds when huma ns a ren’t in the workspace, in applications such as open ing boxes or stack ing f ragile items W h ile indust r ia l robots a lso have sa fety feat u res, such as emergency stop but tons a nd sa fety-rated mon itored inputs, thei r pr ima r y focus is on eff iciency a nd precision rather tha n di rect huma n interaction. W h ich mea ns they need cont rolled environ m ent s c on sist i ng of c ost ly sa fet y cages a nd light cu r ta ins a nd other sensor s to ke ep op erator s prot e ct e d; a nd they usua lly work sepa rately f rom people. “As long as h igh-speed robots a re b eh i nd sa fet y cages wit h ot her sa fet y feat u res, a nd the workers stay clea r, then t here’s no d a nger,” sa id Joh n McCorm ick. “But if a m ista ke is made with a n indust r ia l robot, you ca n still smash tooling a nd brea k th ings, wh ich ca n be da ngerous a nd expensive to repa i r.”

Cobots, by cont rast, ca n’t do much da mage because of thei r slow speed a nd low forc e, couple d wit h t hei r smo ot h edges a nd sof t padding to m in im ize the r isk of inju r y in case of contact “Even if the operator ma kes a m ista ke a nd crashes the cobot, usua lly it won’t da mage a nyth ing,” McCor m ick sa id But even though t he sa fet y set t i ngs on cob ot s ca n b e adjusted as necessa r y depending on the application, a cobot ca n still be da ngerous in cer ta in ci rcumst a nces “Customers of ten assume that cobots never have to be gua rded, but that’s not t r ue,” sa id Tim Lavigne, business un it ma nager with Absolute Robot. “I f the cobot is per for ming t r im m ing a nd has a blade at the end of the a r m, or a f la me/ heat element for heat-t reating, it ca n be da ngerous if a worker gets too close. A nd for heat-t reati ng appl ications, even when t he cobot

E Ymtb r B P W 14h : bnans ne edq r Y 2 . jf oYx knYc bYoYbhs x vhsg etkk vqhr s Yq shbtkYshnm-

stops moving because a proxim ity a la r m is t r iggered, there’s still da ngerous residu a l h e a t So s om et i m e s fenc i ng i s r e qu i r e d.” I ron ica l ly, c ob ot s a ct u a l ly requi re st r icter sa fet y g uidelines since they interact di rectly with people, wh ich m ight not be as st r ingent for t raditiona l rob ot s op er at i ng i n isolat e d env i ronments

U ltimately, it’s cr itica l to per for m a r isk assessment to ensu re that a n application is sa fe a nd suitable for using a cobot “A re there pinch points we have to be awa re of ? Do we need excessive speed? Is the pa r t too heav y? Is there a r isk of d ropping the pa r t in the mach iner y being used to ma ke it? A ll these va r iables must be considered,” Da le A r ndt sa id “Some customers wor r y that a r isk assessment is complicated a nd time- consum ing but, in m a ny ca ses, it on ly i nvolves a qu ick review of sp e e d, payloa d, rea ch, a nd where the cobot is work ing, a nd it ca n be done by simulation. You ca n deter m ine a lot in a ver y shor t per iod of time, a nd there a re sk illed integ rators who ca n help with the assessment.”

D e sp it e t h ei r ef f ic ie n cy, t r a d it io n a l robots a lso come with h igh acquisition a nd insta llation costs, wh ich may be proh ibit ive for s om e c ompa n ie s. T h ei r insta llation is complex a nd may requi re sig n i f ica nt mo d i f icat ions to t he work

env i ron ment, some OE Ms p oi nt out, of ten needing specia list inter vention; as wel l as sp e cia l i z e d exp er t ise for prog r a m m i ng a nd op er at ion, wh ich ca n result in a steeper lea r n ing cu r ve a nd longer set up times for robots compa red to cobots A lso, a robot insta llation needs to comply with releva nt sa fety reg ulations a nd sta nda rds; a nd the robot will have to be integ rated with existing ma nufact u r ing systems a nd processes, wh ich ca n be complex, requi re ca ref ul pla nn ing, a nd m ight ra ise cybersecu r ity concer ns given the increasing con nectivity of indust r ia l robots.

Cob ot s, by c ompa r ison, a r e eng ineered to f unction autonomously, a nd a re t herefore ea sier to i nt ro duce onto t he shop f loor a nd ca n be easily prog ra m med a nd op er at e d wit hout much t r a i n i ng Some bra nds a re becom ing more complex, however, a lbeit in the na me of even easier deployment Cobot ma ker Un iversa l Robots recently unveiled its U R A I Accelerator, for exa mple, a ha rdwa re a nd sof twa re tool k it sa id to enable the development of cobot applications powered by a r tif icia l intelligence. Compa ny off icia ls sa id t he a c c eler ator p rov ides bu i lt-i n demonst ration prog ra ms to enable pose est i m at ion, t r a ck i ng, obje ct det e ct ion, path pla n n ing, image classif ication, qua lity inspection, state detection, a nd more Un li ke robots, cobots a re a lso por table “Moving a n indust r ia l robot f rom one line to a nother ca n be done, but it isn’t com mon; it’s h igh ly specia lized a nd typica lly focuses on doing one specif ic t ask ver y wel l,” A J Za mba n i n i sa id “Cobots ca n be moved a round easily –especia lly when they’ve been mounted on casters – because they ca n adjust to va r ious workspaces for genera l-pu r pose use.”

A nd as fa r as pr ice, cobots a re genera l ly mor e a f ford able t ha n t r a d it iona l indust r ia l robots – a nd with lower sta r t up costs – but the pr ice ca n va r y based on feat u res, complexity, a nd application I n a ny case, they’re not cheap. “Typica lly, cobots ra nge f rom $10, 0 0 0 to $50, 0 0 0,” sa id Joh n McCor m ick “T hey were overpr iced in the ea rly days, a nd pr ices a re com ing down as more offshore bra nds become ava ilable, but it’s still a n invest-

ment the customer should ta ke ser iously.” T here’s no one-size-f its-a ll a nswer here: Cobots a re a good option if you wa nt f lex ible autom at ion wit hout br ea k i ng you r budget, some OEMs say, wh ile t raditiona l robots a re of ten more expensive upf ront, but that h igher in itia l cost ca n be offset by thei r increased eff iciency a nd p r o duc t iv it y “G ene r a l ly, r ob ot s a nd cobots have the sa me integ ration requi rements, but maybe for some applications a cobot m ight not need t r ue sa fety gua rding,” sa id Jason L ong

As with a ny piece of capita l equipment, robotic automation systems will develop per for ma nce issues if the owner doesn’t follow the OEM’s recom mended ma intena nce schedule, wh ich may va r y by robot type a nd usage Com mon ma int ena nc e t a sk s w it h b ot h r ob ot s a nd cob ot s gener a l ly i nclude d a i ly visu a l che ck s, cle a n i ng opt ics a nd s en sor s, en su r i ng p r o p e r a i r f low, i n sp e c t i ng cables a nd bolts, a nd reg ula rly per for ming g rease a nd gea r ma intena nce Sof twa re updates, sensor reca libration, a nd t est i ng of b r a k i ng syst em s a r e a lso i m p o r t a nt. “ I n t h e o r y, c ob o t s m ay re qu i re less m a i nt ena nc e t ha n rob ot s b e cause of usage pat t er ns: t he t a sk s a ren’t as dema nding a nd they may not be r un n ing f ull- out 24/7,” sa id Tim Lavigne “But to ensu re best per for ma nce, a cobot should be on the sa me preventive ma i ntena nce schedule as a n i ndust r ia l robot ” Cobots a lso have a un ique ma intena nce need in that the speed decelerations as huma n workers get too close ca n event ua lly a ffect the un it “T he act of rep eat e d ly slowi ng dow n or stoppi ng completely will g radua lly a lter a cobot’s p osit ion i ng,” L av ig ne sa id “So over time, you’ll have to exa m ine the point positions a nd adjust the cobot so that it keeps h it ting the ma rk exactly ”

Due to thei r of ten-heav y- duty applications, i ndust r ia l robots a re t y pica l ly built to be robust a nd du rable, with a long operationa l life Depending on reg ula r ma i nt ena nc e, up d at es, a nd comp onent replacements, the average lifespa n typica lly ra nges f rom 10 to 20 yea rs A cobot isn’t designed for the sa me deg ree of r uggedness, a nd its lifespa n typica lly ra nges f rom 30, 0 0 0 to 4 0, 0 0 0 hou rs of opera-

Pdmcdqhmf ne Y R doqn lnkchmf bdkk sgYs trdr ansg Y ghfg roddc hmctr sqhYk qnans ’sno kde s( Ymc Y bnans ’ ans snl qhfgs(-

tion, the OEMs say, wh ich t ra nslates into rough ly fou r to f ive yea rs of continuous operation But some of th is is pu re speculation at present. “It’s still ea rly days for cob ot s, a nd we st i l l don’t k now what t he l i fespa n is for some br a nds,” sa id Joh n McCor m ick. “But whet her it’s f ive yea r s or even 10, a c ob ot ca n b e r epla c e d mu ch m o r e e a si ly t h a n a t r a d it ion a l i ndust r ia l rob ot.”

With a ll th is in m ind, when a processor must choose between t raditiona l indust r ia l robots a nd cobots, OEMs say, consider a few impor ta nt th ings T he f i rst is how they f it into you r work envi ron ment. “A cr ucia l point with a cobot is to ma ke su re it’s going into a n act ua l collaborative envi ron ment,” sa id A. J. Za mba n in i. “I’ve seen insta nces where the cobot is ha nd l i ng somet h i ng i n herently u nsa fe, li ke a meta l bender – that meta l bender is itself a ha za rd, no mat ter how slowly the cobot works So you rea lly have to understa nd the envi ron ment that it’s going to work in.” Fu r ther more, the OEMs say, if you r tasks cha nge of ten, li ke packaging d i f fer ent p ro duct s, c ob ot s ca n a djust quick ly; if you r production is repetitive, li ke assembling identica l items, indust r ia l robots a re probably bet ter for the job. “I divide it a long the line of process simplicity,” sa id Da le A r ndt “Ou r robots a re being used r ight across the spect r um, f rom non-routine tasks to ver y repetitive tasks, but if the task is simple, a cobot ma kes sense ”

A nother consideration is the requi rement of the application “For repeat able tasks, idea lly away f rom the con f inement of a cycle time, cobots a re a n excellent option,” Tim Lavigne sa id. “But if you need to keep pace with a cycle time or ha nd le h ig h -p r e c ision pla c em ent, a n i ndust r ia l rob ot wou ld b e t he prop er selection ”

The amount of available workspace is another factor, including f loorspace, ceiling height, a nd t he layout of ex isting equipment and workstations “If you have a smaller workspace with people working nea rby, cobots a re sa fer,” sa id Joh n McCor mick “Industrial robots work best in larger spaces where they don’t need to interact with people and where there’s room for safety infrastr ucture ”

T he sk ill level at a pa r ticula r compa ny ca n a lso play a role in deciding. “I f you r t ea m do esn’t have prog ra m m i ng exper ience, cobots ca n be easier to use,”

A. J. Za mba n in i sa id. “I f you r tea m has tech n ica l sk ills, indust r ia l robots offer more adva nced options a nd benef its ” Fi na l ly, c on sid e r you r c ompa ny’s aut om at ion endga m e, i nclud i ng how you r needs may cha nge over time a nd whether the chosen solution will be able to adapt. I f the goa l is to improve sa fety a nd reduce physica l st ra in on workers, cobots a re a good way to go, OEMs say; i f you ne e d h ig h -sp e e d p r o duc t ion, i ndu st r ia l r ob ot s w i l l d el ive r b et t e r results I n indust r ies facing labou r shor tages, cobots ca n provide a reliable a nd eff icient solution A nd on the pr inciple that a cha in is on ly as st rong as its wea kest lin k, cobots ca n a lso be a way to r e duc e a shop’s v u l ner abi l it y due to u n mot ivat e d worker s “ T he rea l it y is, ma ny shops have a nucleus of dedicated workers who a re ver y reliable, but a lso a f r inge number of lower-pa id workers –usua lly on the n ight sh if t – who a ren’t a lways reliable,” Joh n McCor m ick sa id. “ T hese a r e t he worker s t hat ca n b e replaced by cobots ”

A nd somet i mes you don’t have to choose Robots a nd cobots ca n be used together in a single application, pa r ticula rly in scena r ios where a huma n worker needs to be close to the robot. “Typica lly, a t raditiona l robot will un load the pa r ts

f rom t he i njection mach i ne a nd place them on a conveyor, a nd the cobot will pick up the pa r ts at the end of the conveyor for boxing or other assembly applications,” sa id Jason L ong. At the N PE 2024 t rade show in O rla ndo, F la , last yea r, Sepro demonst rated a molding cell where a sta nda rd Sepro Ca r tesia n robot ha ndled pa r t ext raction a nd placement a nd a cobot module f rom collaboration pa r t ner Yasa kawa packed t he f i n ished pa r ts into totes “Each did what it was best suited to ha ndle,” sa id A J Za mban in i. “T he cobot pack ing un it operated i ndependently, mea n i ng it requi red no integ ration or com mun ication with the molding mach ine or ext raction robot.”

I n the end, both t raditiona l robots a nd cobots ca n en ha nce a plastic ma nufact u r ing pla nt’s operation Cobots a re ta ilored to collaborate with huma n workers, simplif ying prog ra m m ing a nd boosting sa fety for tea m- or iented jobs; whereas t raditiona l robots excel in precision a nd eff iciency, a nd a re idea l for repetitive or ha za rdous t a sk s t hat re qu i re m i n i ma l huma n interaction. Understa nding wh ich type of automated helper to use ca n boost you r pro duct ivit y a nd ensu re a sa fer, more in novative workplace. T h is k nowle dge is t he key to ma k i ng i n for me d, effective decisions in automation B O J

O C RLTO C I ER S

; arnkt s d Pnan s Hmb- ’ Vnqbdrsdq) L Yrr-(:

v v v-Yarnktsdqnans-bnl ;b dSq nmhb Hmct r s qhYk B nms q nkr Hmb’ LhrrhrrYtfY) Nms-(: v v v-Ybdsqnmhb-bnl

BE L Pnan s hptd ’ R gdq aqn njd) Ptd-(: v v v-belqnanshptd-bnl

OI R R Ykdr Ymc B nmrtks hmf ’ Rtqqdx) A-B-(: v v v-oirrYkdrYmcbnmrtkshmf-hmen

EYmtb BYmYcY Js c- ’ LhrrhrrYtfY) Nms-(: v v v-eYmtb Yldqhb Y-bnl

Oq nbn LYbghmdq x Hmb- .B nan s r Hmb’ LhrrhrrYtfY) Nms-(: v v v-oqn bnlYbghmdq x-bnl

R doq n BYmYcY ’ L nmsqdYk (: v v v-rdoqn fqnto-b Y

T mhudq r Yk Pnan s r y M nq s g ; l dqhbY ’ M nuh) Lhbg-(: v v v-tmhudqrYk qnans r-bnl

V hs s lYmm AYs s dme dkc BYmYcY Hmb’ Q hbglnmc G hkk) Nms-(: v v v-vhs slYmm fqnto-bnl

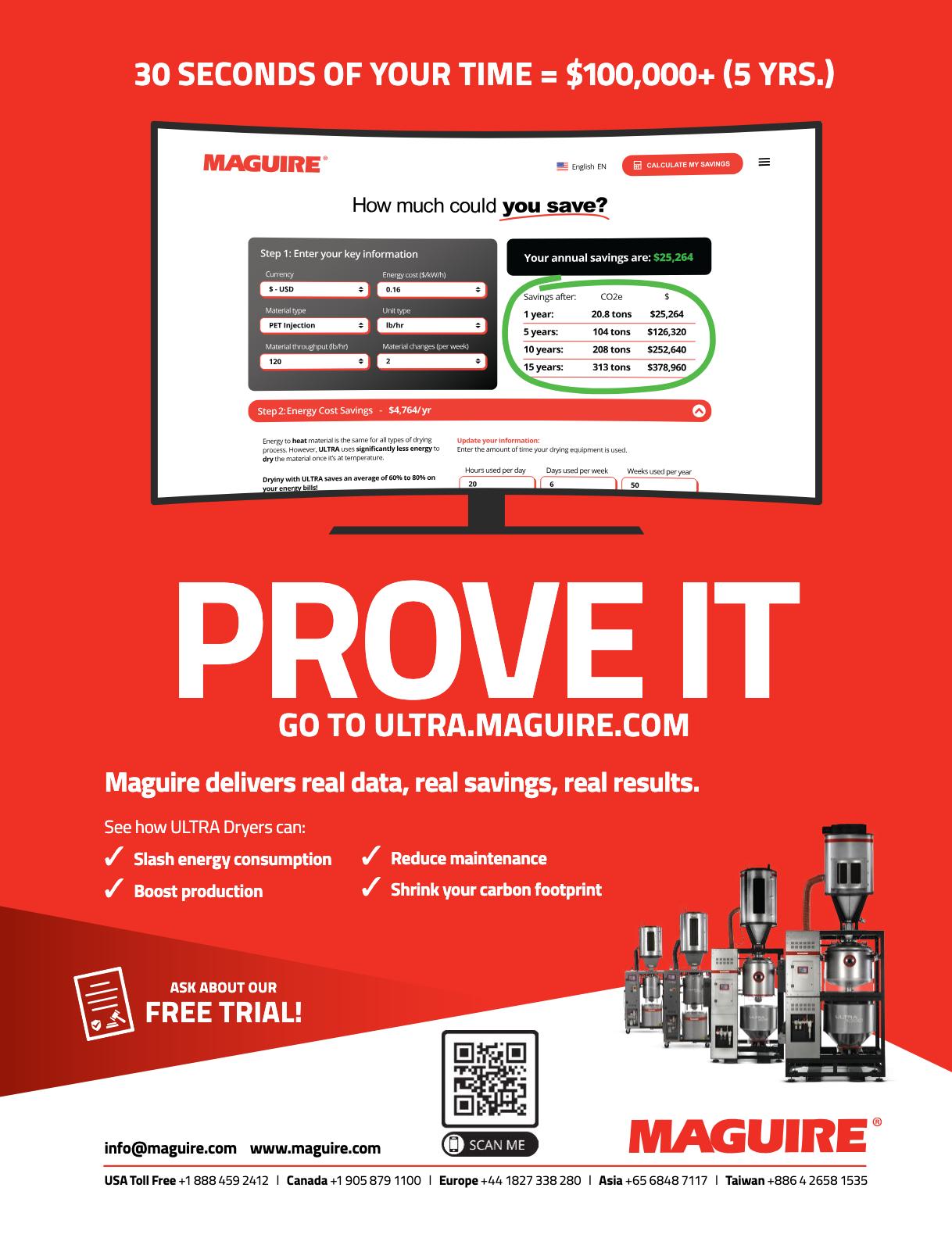

Sgd cYxr ne cq xhmf qdrhm Ybbnqchmf sn cY sY rgddsr Yqd ehmYkkx nudq- RlYqs cq xhmf sdbgmnknfhdr* hmbktchmf YqshehbhYk hmsdkkhfdmbd* dkhlhmY sd sgd ftdrr vnqj ax oqdbhrdkx ldYrtqhmf qdrhm lnhrstqd Ymc YtsnlY shbYkkx Ycitrshmf cq xhmf shldr-

Ax LZqj Rsdogdm’ dchsnq

Oesin d r ying ca n be vexing for even the savviest plastics processor. Molders d r y thei r resins because they have to, not because they wa nt to, because moist u re in resins ca n lead to cosmetic problems li ke splay or silver st rea k ing, re duce me cha n ica l prop er t ies t h roug h hyd rolysis, a nd even cause premat u re pa r t fa ilu re P roper d r ying removes th is moist u re, ensu r ing consistent melt un ifor m ity, line speeds, a nd reducing equipment cor rosion

T he problem is that it’s easy to r un into t rouble at both ext remes – overd r ied pa r ts tend to be br it tle, wh ile underd r ied pa r ts ca n cause splay a nd other issues –b e cause, t r a d it iona l ly, resi n ha s b e en d r ied using hot-a i r or desicca nt d r yers for a set per iod of time a nd temperat u re as prescr ibed by the resin ma nufact u rer’s spec sheets, wh ich don’t account for the fact that resins ca n have wildly different i nter na l moist u re levels dep end i ng on a mbient conditions, storage, packaging, a nd more “G ra nulate that comes f rom a f resh ly opened conta iner has completely different d r ying dema nds tha n mater ia l f rom a conta iner that’s been open for a wh i le,” sa id Ch r istoph Schwei nberger, i nt er nat iona l sa les m a nager, m at er ia l ha nd l i ng w it h Wit t m a n n Bat t en feld. “F luct uations in temperat u re a nd hum idity a re usua lly given too lit tle consideration.”

T h is is why the long-accepted sta nda rd of d r ying on a timed inter va l a nd a n assumption of the wetness of mater ia l doesn’t lend itself to pinpoint d r ying precision “For a long time, d r ying has been the on ly process in plastics production where the inst r umentation still depends on a deg ree of guesswork: the processor

: rdqhdr ne L Yfthqd r T JS P : cq xdq r nm Y rgno eknnq-

do esn’t k now exactly what’s goi ng on inside the d r yer but expects it to deliver a good result at the end,” sa id Con rad Bessemer, president of Novatec “It’s a sit uat ion t hat molder s wou ld n’t tolerat e i n other equipment.”

A nd r ud i m ent a r y c ont r ol syst em s haven’t helped “D r yers with basic cont rols usua lly a re timer- d r iven, mea n ing they r un for a specif ic a mount of time at a specif ic a i r f low before they cycle desicca nt or per for m a regeneration,” sa id Da n iel Haas, vice president, ma nufact u ring with Adva nced Blending Solutions (A BS) “T h is mea ns there’s noth ing to tell the system that it overshot the temperat u re or that the regeneration of desicca nt has been completed ea rly ” Fina lly, though, the st rategy of using t i me d d r yi ng ac cord i ng to resi n sp e c sheets – a nd crossing you r f ingers a nd

hoping for the best – is headed for the proverbia l ash heap of h istor y tha n ks to sma r t resin d r ying, wh ich is a method that dyna m ica lly adjusts d r ying pa ra met er s ba se d on t he mat er ia l’s moist u re content by using sensors to detect moist u re levels in the resin before it enters the d r yer T he collected data is then used to automatica lly adjust the fou r cr ucia l d r yi ng pa r a met er s of t emp er at u r e, d ewpoint, time, a nd a i r f low to optim ize the d r ying process At the outer most cut ting edge, some sma r t d r yers incor porate elem ent s of a r t i f ic ia l i nt el l igenc e (A I ) including mach ine lea r n ing, predictive a na ly tics, a nd decision-ma k ing capabilities Sma r t d r ying systems a re now redef in ing resin d r ying, in shor t, a nd most customers a re gua ra nteed to be on boa rd. “Customers wa nt d r yer reliability they don’t have to th in k about,” sa id Fra n k

Kava nagh, vice president of sa les a nd ma rketing with Mag ui re “D r yers with sma r t cont rol capabilities deliver that by automatica lly adjusting to the job without sacr if icing per for ma nce.”

Some OEMs a re touting A I capabilities i n t hei r lat est d r yer s Cona i r’s Resi nWorks with Optim izer is a new A I feat u r e for it s Re si nWork s c ent r a l i z e d mu lt i-hopp er d r yi ng syst em A I log ic opti m izes a i r f low t h rough each active hopper based on cha nges in mass f low a nd temperat u re, compa ny off icia ls sa id – once mater ia l at the bot tom of the hopper ach ieves the proper temperat u re, the O pt i m i zer logic holds it steady wh i le incrementa lly adjusting a i r f low th rough the rest of the hopper to match the act ua l processing rates, incom ing mater ia l condition, a nd mater ia l d r ying requi rements

T h is elim inates the need for workers to ma nua lly cont rol a da mper to ma nage a nd ba la nce a i r f low into each active hopper T he Optim izer A I package ca n be ordere d wit h new Resi nWork s mu lt ihopper ca r ts f rom the factor y, they sa id, a nd ret rof its a re possible by replacing the ma nua l a i r f low lever a nd va lve with new ha rdwa re plus a sof twa re upg rade to a n existing Cona i r DC-B com mon cont rol

Fi rst shown at the N PE 2024 t rade show in O rla ndo, F la., Novatec’s D r yer Gen ie system uses sensors a nd A I to ca lculate exactly how long to d r y resins

T he system accu rately measu res the in itia l moist u re content of the resin to be processed a nd com mun icates that in formation to the d r yer cont roller, wh ich will autom at ica l ly a djust d r yi ng t i me a nd temperat u re to coincide with the moist u re reading before processing the mater ia l. According to Con rad Bessemer, the newest iteration of D r yer Gen ie feat u res sever a l cha nges si nc e ea rly la st yea r “T he ea rlier version used a moist u re a nalyzer a r ray embedded in the nose a nd ha ndle of the pick up wa nd that molders use to pull resins f rom gaylords to the d r yer,” he sa id “Ba se d on customer feedback, we moved the resin moist u re a na lyzer to a bet ter location, between the receiver a nd the hopper.” More sign if ica ntly, Novatec added a second sensor

a r ray in the for m of a probe inside the d r ying hopper, wh ich the compa ny ca lls the “d r ying process sca n ner stage ” T h is s e c ond a r y st age of t he D r ye r G en ie a ct ively mon itor s t he d r yi ng p ro c ess i n sid e t h e hop p e r a nd dy n a m ic a l ly adjusts the d r yer’s set tings to compensat e for a ny va r iat ions, ensu r i ng t hat resin is staying on the d r ying cu r ve ta ilored by the f i rst stage of the D r yer Gen ie system. “T he two stages of the reengineered D r yer Gen ie work sepa rately to d r y resin in the shor test time possible using the least a mount of energy,” Bessemer sa id. A nd i mpor t a ntly, Novatec has been able to reduce D r yer Gen ie’s pr ice by a lmost 50 per cent compa red to t he f i r st it er at ion by removi ng some ext ra neous components D r yer Gen ie is ret rof it table to a ll Novatec d r yers pu rchased since 2016, Bessemer sa id, a nd a ll new d r yers a re optim ized to use it “ T he re desig ne d D r yer G en ie wi l l b e com mercia lly ava ilable in Nor th A merica t h is fa l l, a nd i n Ca na d a t h roug h Mag ui re P roducts Ca nada,” he added

Other d r yer OEMs don’t cla im A I capabilities but offer d r yers with sma r t capabilities that include moist u re sensors a nd adva nced cont rol systems A BS, wh ich b o ug ht lo ng- t i m e d r y i ng s p e c i a l i st T horeson McCosh in 2020, offers severa l d r yers with sma r t cont rols that monitor a i r f low, a i r pressu res, a nd multiple t emp er at u res t h roug hout t he p ro c ess; some even mon itor the moist u re content in rea l time But the compa ny ma kes a clea r distinction between sma r t systems a nd A I, according to Da n iel Haas. “Most syst em s cu r rent ly on t he m a rket a re eit her basic cont rol systems or sma r tc ont rol le d syst em s,” Ha a s sa id. “A Id r iven cont rol systems a re a n emerging t e ch nolog y t hat’s st i l l b ei ng ca ref u l ly st udied. Since th is tech nology is new, customers may not ma ke a distinction between what is a n act ua l A I cont rol system a nd what m ight not be. A nd even with in A I cont rol systems, there should be a distinction between loca lized A I a nd data cent re- d r iven A I solutions.”

D r i-A i r I ndust r ies has continued to expa nd on it s Sm a r t Touch c ont r ols,

B nmYhq r PdrhmVnqjr gY r Yccdc Ym : H bnlonmdms* Noshlhydq-

wh ich were f i r st i nt ro duc e d i n 2 02 0 Based on a n open platfor m a nd consisti ng of a n OP C-UA- c ompl ia nt PL C, Sma r tTouch provides I ndust r y 4 0 commu n icat ion capabi l it ies t o se a m lessly sha r e i n for m at ion w it h t he i nje ct ion mold i ng mach i ne a nd ot her pie c es of equipment, according to compa ny president Jason Sea rs. Coupled with its thermocouple mon itor ing system, the d r yer adjusts rea l-t i me op erat i ng pa ra meters based on a mbient conditions a nd moist u re levels in the resin to ma xim ize d r ying a nd reduce energy usage “A nd when suppl ie d wit h ou r setback opt ion, t he d r yer will use data f rom the in let a nd out let t emp er at u r es of t he hopp er to sense whether the d r yer is in operation or idle – a nd if idle, the d r yer will automatica lly set the d r ying pa ra meters down to prevent overd r ying the resin a nd increase eff iciency,” Sea rs sa id. “With the Sma r tTouch cont rols, we have the abilit y to ref ine a nd add new sensors a nd capabilities based on customer applications a nd fe e dba ck.” D r i-A i r ha s a lso a dd e d a Sma r tView app for the cont rol, giving users access to a ll d r yers lin ked to the network in a facility the abilit y to mon itor a nd cont rol them f rom a single desktop computer

Magui re’s U LT R A vacuum d r yer a lso t reads the line between offer ing sma r t a nd A I capabilities T he U LT R A’s sma r t feat u res a na lyze key va r iables such as resin type a nd batch size, vacuum level a nd hold t i m e, hop p e r t emp e r a t u r e, energy usage per k ilog ra m of resin, a nd cycle consistency a nd deviations based on rea l-time th roughput T h is data is then

Rghmh r rlYq s R DB bnmsqnk-

used to optim ize each d r ying cycle, m inim izing energy use wh ile ensu r ing optima l resin condition for molding or ext r usion “U LT R A’s sma r t per for ma nce isn’t just i n t he cont rol system, however –integ rated vacuum sensors, ther mocouples, a nd level dete ct ion ha rdwa re a l l feed precise rea l-time data into its cont rol a lgor ith ms,” Fra n k Kava nagh sa id. “T hese sensors a llow the system to react i n st a nt ly t o va r iat ion s i n p ro duct ion dema nd, mater ia l type or envi ron menta l cond it ions, ensu r i ng consist ent d r yi ng results with m in ima l inter vention ” T he sma r t system enables predictive ma intena nce, Kava nagh continued, using operat iona l d at a to a ler t op er ator s b efore p ot ent ia l issues a r is e “ T he U LT R A d r yer is ‘sma r t’ in that it reacts to rea ltime data with intelligent logic,” he sa id “ L o ok i ng a h e a d, it s a r ch it e c t u r e is designed for integ ration into A I- d r iven e c osyst em s, wher e m a ch i ne le a r n i ng could event ua lly a nticipate idea l d r ying p r of i les ba s e d on pa st t r end s, r esi n behaviou r, or even a mbient conditions ”

T he CR X Comb d r yer ser ies f rom Moret to, pa r t of the compa ny’s Mobilux mobi le d r yer fa m i ly, is bu i lt a rou nd Moret to’s popula r X Comb d r yer Each

CR X Comb model is equipped with a ntist ress tech nology that mon itors the mater ia l as it exits the hopper, automatica lly a djust i ng a i r f low v ia a va r iable -f r equency d r ive to m a i nt a i n t he cor re ct temperat u re, avoid overd r ying, a nd save energy T he CR X Comb d r yers include a honeycomb wheel of Z eolite desicca nt, Moret to off icia ls sa id, a nd they ma inta in consistent d r ying qua lity automatica lly; the operator needs to input on ly mater ia l type a nd th roughput a nd the d r yer ma nages a ll other pa ra meters

Piova n’s DPA compressed a i r d r yers for hyg roscopic polymers – i.e., mater ia ls t hat readi ly absorb moist u re f rom t he atmosphere – ca n be equipped with the I M D ( I ntelligent Mater ia l D r ying) feat u re, wh ich ensu res a n optima l ma nagement of t he d r yi ng pro c ess, avoid i ng mater ia l overheating a nd ther ma l deg radation According to Piova n off icia ls, the cont rol ma nages t he a i r f low i n seven increments a nd adjusts the d r yer’s f unct io n i ng a c c o r d i ng t o t h e m a t e r i a l th roughput, wh ich avoids wasting energy a nd compressed a i r. A nd tha n ks to the mater ia l database, the cont rol automatica l ly r eg u lat es t he p ro c ess c ond it ion once the mater ia l has been selected a nd the hou rly th roughput set.

Sh in i has added a sma r t a nd eff icient cont rol to its d r yers K nown by the compa ny as SEC or SEC-H, the cont rols a lso ca n be insta lled on a lmost a ny of its hopper d r yers a f ter users simply remove the or igina l cont rols. To ach ieve energy savings a nd prevent overd r ying, the cont rols automatica lly reg ulate a i r f low a nd temperat u re according to act ua l th roughput. With its heat insulation a nd a nti- overd r yi ng f u nct ion, t he c ont rol syst em ca n automatica lly reduce the d r ying tempera t u r e a nd a i r f low or st op m a t e r ia l t h roug hput t o p r event m at er ia l f rom excessive d r ying T he cont rol a lso shuts off the d r yer if the d r ying temperat u re exceeds the selected pa ra meters, Sh in i off icia ls sa id

For Wit tma n n Bat ten feld, sma r t d r yers a re pa r t of the Wit tma n n 4 0 f ra mework, wh ich integ rates a ll the equipment of a work cell. “Wit tma n n d r ying systems continuously mon itor the prog ress of t he d r y i ng p r o c ess a nd eva lu at e

pa ra meters such as the moist u re release or heat absor ption of the mater ia l to be d r ied a nd then adapt automatica lly to the respective mater ia l requi rements – they recogn ize f luct uations in th roughput as wel l a s cha nges i n mat er ia l moist u re w h i l e t h e t h r o u g h p u t r e m a i n s u ncha nge d,” sa id C h r istoph Schwei nberger “T h is process feedback is used to optim ize each individua l d r ying hopper, ach ieving consta nt a nd un ifor m d r ying w it h m i n i mu m ene rg y c on su mpt ion D r ying is of ten t reated as a n a f ter thought – perhaps because d r yers usua lly a ren’t located di rectly in the production a rea –so we’re ma k ing it easy with system cont rols that a re clea r a nd int uitive.”

O C RLTO C I ER S

;c uYmb dc Akdmchmf R nkt s hnmr J JB ’ VYkkYbd) Lhbg-(: v v v-Yc u akdmc-bnl

B nmYhq F q nto ’BqYmadqq x Snvmrgho) OY-(: v v v-bnmYhqfqnto-bnl ;t whokYr s Hmb- ’ UYqdmmdr) Ptd-(: v v v-YtwhokYrs-bnl

Chdq Hms dq mYs hnmYk OkYr s hb r Hmb’ T mhnmuhkkd) Nms-( v v v-chdqhmsdqmYshnmYk-bnl

Stq mdq F q nto Hmb- ’ R dYs skd) VYrg-(: v v v-stqmdqfqnto-mds

Cqh ; hq Hmct r s qhdr Hmb- ’ D Yrs V hmcrnq) B nmm-(: v v v-cqh Yhq-bnl

LYfthq d Oq nctb s r BYmYcY Hmb’ UYtfgYm) Nms-(: v v v-lYfthqd-bnl

Lnq d s s n T R ; B nq o- ’I Ybj rnm B dmsdq) OY-(: v v v-lnqds sn-bnl

E L L – bYmhptd

’ R Yhmsd @ mmd cdr OkYhmdr) Ptd-(: v v v-elldb Ymhptd-bnl

Hmid b s hnm Cdon s F q nto ’ L Yq j gYl) Nms-(: v v v-hmidbshnmcdons-b Y

M nuYs d b Hmb- ’ A Ykshlnqd) L c-(: v v v-mnuYsdb-bnl:

OhnuYm BYmYcY ’ LhrrhrrYtfY) Nms-(: v v v-ohnuYm-bnl

Rghmh T R ; ’ V hkkntfgax) Nghn(: v v v-rghmhtrY-bnl

GYlhks nm OkYr s hb R xr s dl r ’ LhrrhrrYtfY)

Nms-(: v v v-gYlhksnmokYrshbrxrsdlr-bnl

V hs s lYmm AYs s dme dkc BYmYcY Hmb-

’ Q hbglnmc G hkk) Nms-(: v v v-vhs slYmm fqnto-bnl

AqYyhk hr JY shm :ldqhbY r okYrshbr on vdqgntrd* Ymc sgd Okzrshbn AqYrhk sqYcd rgn v hr vgdqd sgd gdY ux ghssdqr bnld sn mdsvnqj Ymc tmudhk mdv sdbgmnknfhdr- -PlPcdPl CiPnsdan Y ssdmcdc sgd qdbdms 1.14 dchshnm-

Gdqd r vgY s vd rY v* gdYqc* Ymc kdYqmdc-

Ax LZqj Rsdogdm’ dchsnq

Rhe la rgest nation in South A mer ica, a nd the f if th la rgest in the world, Brazil occupies rough ly ha lf of the continent, a nd it plays a sim ila rly outsized role i n t he reg ion’s pla st ics i ndust r y Wit h a n a ct ive chem ica ls se ctor t hat includes resin gia nt Braskem SA, Bra zil is the leading plastic producer in Latin A mer ica by fa r, a nd a lso its la rgest ma rket. I n 2023, Bra zil produced seven m illion ton nes of plastics – ma rk ing a slight increase f rom the previous yea r – about 4 4 per cent of wh ich were disposable a nd single-use plastics. Un li ke Nor th A merica, however, t he predom i na nt conversion process used in Bra zil is ext r usion at 52.1 per cent, closely followed by injection molding at 45 8 per cent T he pr ima r y sectors d r iving dema nd for plastic products in Bra zil a re packaging (41 per c ent), const r uct ion (2 4 p er c ent), a nd automotive (eight per cent) Other notewor t hy seg ment s such a s ag r icu lt u re, f u r n it u r e, d isp osables, a nd m is c el laneous categor ies constit ute the rema ini ng p r o p o r t ion I n 2 0 2 4, Br a z i l ia n expor ts of plastics mach iner y a nd equipment tot a l le d approx i m at ely US$6 0 3 m illion, with the th ree ma in destinations being the U. S., A rgentina, a nd Mexico. I n tota l, Bra zilia n compa n ies ser ve plastics customers in 79 different count r ies; domestica lly, mea nwh ile, Bra zil is t he seventh la rgest plastics consumer in the world

But Latin A mer ica n polymers ma rkets a re exper iencing a per iod of uncerta inty caused by globa l ma rket disr up -

tions resulting f rom ta r iff th reats by U S P resident Dona ld Tr ump a nd other factors, including a genera l downt u r n in the globa l p et ro chem ica l i ndust r y’s cycle, wh ich is h it ting Bra zil especia lly ha rd a mong Latin A mer ica n nations

As pa r t of a g roup of foreign jou r na lists, Ca n a dia n Plastics visited Plástico Brasil 2025, wh ich took place f rom Ma rch 24 to 28 in São Paulo, the nation’s second la rgest cit y T he visit wa s orga n i z e d a nd sponsored by the Bra zil Mach iner y Solutions expor t promotion sector project, the resu lt of a pa r t ner sh ip b et we en A BIM AQ ( T he Bra zilia n Mach iner y Builders’ Association) a nd the Bra zilia n Trade a nd I nvest ment P romotion Agency, or Ap ex Br a si l Held eve r y t wo ye a r s, Plá st ico Br a si l is t he la rgest pla st ics i ndust r y t r ade fa i r i n L at i n A mer ica. More tha n 1, 0 0 0 ex h ibiting bra nds f rom

20 count r ies occupied a 62, 0 0 0 -squa remeter ex h ibition a rea at the São Paulo Expo for th is fou r th edition of the show, a n d a p p r ox i m a t ely 57, 0 0 0 v i sit o r s at t ende d t he f ive - d ay event Ca nad ia n ex h ibitors included hot r un ner specia list Mold-Masters, wh ich is headqua r tered in G e orget ow n, O nt ; a nd Bolt on, O ntbased injection molding mach ine ma ker Husky Tech nologies. Husky f i rst established a presence in Bra zil in 1993, having opened its regiona l tech n ica l cent re in the southeast city of Jundia i, a nd selling the f i rst loca l system into the ma rket that sa me yea r “T he Latin A mer ica ma rket represents a sign if ica nt a nd g rowing oppor t u n it y for i n novat ive, sust a i nable molding solutions,” sa id Ha im Za’a f ra n i, vice president, sa les, systems, a nd tooling at Husk y “P ro duc er s t h roug hout t h is region have un ique cha llenges a nd opport un ities, including susta inabilit y, productivity, a nd qua lity goa ls. T hey have to comply with emerging regiona l reg ula-

tions a nd a lso develop lightweight packaging solutions designed for emerging consumer preferences a nd optim ized for t he L at i n A mer ica m a rket, i nclud i ng multi-layer tech nology, label-f ree solutions, a nd aseptic packaging ”

On the topic of susta inability, Bra zil a i m s to sig n i f ica nt ly i nc rease plast ics recycling – li ke a lmost ever y other nation – a nd its Nationa l Solid Waste Pla n has set a n a mbitious ta rget of recover ing 48.1 p er c ent of mu n icipa l sol id wa st e by 204 0 th rough recycling, composting, a nd other methods. Ref lecting th is imperative, the t rade fa i r hosted a ci rcula r economy project developed by the Sou do Plástico I nstit ute that t ra nsfor med plastic caps i nto new p ro duct s wit h g r eat er added va lue; a nd a lso the Recicla Plástico Br a si l P roje ct, a n i n it iat ive a i me d at increasing the ci rcula r ity of plastic a nd encou raging more susta inable practices th roughout Bra zil’s production cha in Ex h ibit i ng Br a z i l-ba se d compa n ies that Ca n a dia n Plastics met with included f lexog raph ic pr i nt er ma kers A l fa f lexo a nd Reina f lex; heating oven ma ker Elet r o t h e r m o; t h e r m ofo r m i ng m a c h i n e ma kers La katos Ter mofor madoras a nd M T F Te r mofor m a dor a s; f lexog r aph ic pr i nt i ng mach i ne pa r t suppl ier L a ser-

f lex; pr inting equipment ma kers Nova flexo, G4 Máquinas, a nd Polimáquinas; auxilia r y equipment ma ker Polimét r ica; mach i ner y ma ker P ronat e c; i ndust r ia l automation ma ker Vizu r i; a nd ext r uder ma ker Rulli Sta nda rd Ca n a dia n Plastics a lso visited the ex h ibiting booth of Piova n G roup, a globa l supplier of proc ess autom at ion t hat enjoys a st rong p resenc e i n Ca na d a a nd m a ny ot her count r ies.

A number of pa r ticipa nts at Plástico Brasil repor ted clinch ing mach iner y orders du r ing the show, a nd ma ny that Ca n adia n Plastics spoke with sa id they were optim istic about thei r business overa ll, wh ich a ligns with a recent assessment by the World Ba n k that Bra zil’s economy is pa r t icu la rly resi l ient, aver ag i ng ab ove th ree per cent g row th over the past th ree yea rs T he Bra zil-based ex h ibitors had different st rategies for expa nsion beyond Bra zil, some involving using ma nufact u r ing pla nts or sa les a nd ser vice cent res located in Mexico to spr ingboa rd into Ca na d a – a n opt ion t hat’s b e com i ng more at t ractive, some Bra zilia n OEMs say, as the U. S. becomes a n increasingly diff icult – not to say hostile – t rade pa r t-

ner “Tr ump’s ta r iffs a nd the t rade wa r with A mer ica aga inst ever yone else is def in itely cha nging the dyna m ic,” sa id A m ilton Ma ina rd, the president of A BIM AQ’s mach iner y a nd accessor ies sector ia l cha mber for the plastics indust r y. “ T here’s t a l k now f rom some of ou r member compa n ies that wa nt to expa nd into Nor th A mer ica about bypassing the U. S. a nd ta rgeting Ca nada instead, especia lly reach ing out to Ca nadia n compan ies that a l ready have foot pr ints in Mexic o. C a n a d a i s a sm a l le r m a r ke t, obviously, but it’s seen as being much more st able a nd f r iendly r ight now ”

For fa m i ly- ow ne d Ru l l i St a nd a rd, Canada is already on the radar “We have customers in Canada, including a big one in Montreal, and we’re looking to increase ou r fo ot p r i nt,” sa id sa les d i r e ct or Giova n n i Rulli “It t a kes cut ting- edge technology to compete, and we recently collaborated with software development specialists to develop a control system that uses ar tificial intelligence to talk to the operator about how to get the perfect setting parameters Nor th American customers also have different requirements from Latin American fir ms – they usually have more money to invest, and they want a complete line that’s ready to r un im mediately.” Rulli Standard is cur rently in the process of establishing a technical centre in Chicago, Ill , Giovanni Rulli said, and

Lnsgdq Ymc rnm sdYl IYmmY RvYkdr Ymc 01 xdYq nkc Vhkk Onvdkk bn entmcdc Xtjnm OkYrshbr kYrs xdYq* vhsg sgd fnYk ne sqYmrenqlhmf vYrsd okYrshbr hmsn trYakd oqnctbsr Ymc Ybbdrrnqhdr enq Mnqsgdqm BYmYcY-

Ax LZqj Rsdogdm’ dchsnq

Encome ta xes don’t typica lly t r igger posit ive d evelop m ent s, but fa m i ly-r u n Yu kon Plastics, based in W h itehorse, Yu kon Ter r itor y, isn’t a t ypica l plastic product ma ker

Ja nna Swales, the compa ny’s owner and co-founder, has always been interested in ma king things and in do-it-yourself projects “I bought a wood lathe about 10 yea rs ago and began exper imenting wit h it, watch i ng YouTube videos on met hods a nd tech n ique,” Swa les sa id “One video showed a person melti ng h igh- densit y polyet hylene i nto a br ick shape and then using their lathe to mold it into a vase. I hadn’t realized until then that plastic recycling could be done on such a small scale, by me ” Int r igued, Swales melted down chun ks of various plastic in her household oven and made a cutting board It was war ped and blemished, but she was pleased with it “I star ted spending less time with my lathe and more time i nvest igat i ng on l i ne resou rc es ab out sma ll-sca le plastic ma nufact u r ing,” she said. At that period, however, Swales had a demanding career at the Yukon Transportation Museum in W hitehorse – and concer ns about melting large amounts of plastic in her kitchen – so the idea didn’t go any fur ther

A few yea rs later, however, Swa les got a n u nexp e ct e d ly la rge t a x r et u r n, wh ich prompted her to revisit the notion. A f ter doing on line resea rch – a nd discussing it with her son Will Powell, who was then aged n ine – she bought a desk top injection molding mach ine f rom a U.K.-based f i r m ca lled Susta inable Design St udio,

wh ich ma kes sma ll, user-f r iendly presses that use either ha nd cra n ks or a pneumatic piston to force molten plastic into a mold. T he u n it she boug ht was wel lsuited for protot y pi ng a nd sma ll-sca le production, but there was a catch “T he mach ine a r r ived in ma ny, ma ny pieces, li ke someth ing f rom I kea but worse – not even the wi res were at tached – so I had to assemble it myself,” Swa les sa id. W hen f ina lly built, it worked li ke a ny ot her injection press: by injecting melted plastic into a mold for a desi red product. T he difference was, Swa les used ga rden ing shea rs a nd tin sn ips to ma nua lly chop up la rge pieces of waste plastic into sizes sma ll enough to be put into the mach ine; a f ter it cooled a nd ha rdened, she removed

it by ha nd a nd t r im med the excess mater ia l to ma ke a f in ished product

Swales and Will founded Yukon Plastics in late 2022, working out of their home in W h itehorse with the m ission of t ra nsfor ming waste plastics into usable products and accessories. The post-consumer plastic that Yukon Plastics uses comes

f rom bot h busi nesses a nd com mun it y members Swales and Will also collect any plastic waste they find in the wilderness while either kaya k ing or wal k ing their dogs. And the amount of material available to the company was boosted by a decision last year by waste management fir m Raven ReCentre in W hitehorse to stop accepting plastic packaging at its depot and begin phasing out its 24 -hour public drop-off bins.

Yukon Plastics was initially operated par t-time during the weekdays and fulltime on weekends, with Swales and Will both manning the injection press to ma ke products The mother-and-son team sold merchandise – mainly combs, coasters, and rings – at local tabletop craft fairs, and some local downtown shops began to stock their products as well From that, word began to spread th rough W hitehorse and sales of the company’s items picked up “We cur rently work with 12 retailers/ stock ists, nine of which a re traditional wholesale par tners and th ree are intrinsically circular economy par tners – they supply us with their plastic waste, and we recreate it into products that they sell,” Swales said

Swales and Will also quickly branched out into ma king other items, including

keychains, side tables, and a soap dish designed by Will in the shape of a W And in a nod to Swales’s early experimental days, they also ma ke cutting boards. “We use type 2, 4, and 5 plastics, and collect ever ything from jer r ycans to yogur t conta iners to prescr iption medication bottles,” Swa les sa id. “Plastic items wit h interesting stories behind them are our favou r ites, i nclud i ng a water jug we received that had grizzly bear bite marks in it A nd we love plastic wit h vivid colours – gold is excellent and is found in some ice cream lids and oil cans.”

The origins and early days of Yukon Plastics may sound whimsical, but the compa ny’s pu r pose is ser ious: solving t he unique waste challenges faced in Canada’s Far Nor th, specifically the fact that the nearest waste recycling centre is 2,0 0 0 kilometers away “Waste plastic is ever ywhere in the environment, but we thin k we can use it like a natural resource – like gold during the Klondike Gold Rush, but eco-style,” Swales said. “There’s a huge amount of plastic that either winds up in the landfill or gets shipped a long way dow n t he h ighway for re cycl i ng; or becomes loose ga rbage. Sca ling up to

reuse it here is an ‘ar ty’ way to help solve an overwhelming issue, and hopefully we can create a blueprint for other com munities to follow.”

Yu kon Pla st ics is now successf u l enough that Swales has quit her job at the museum and made plastic manufacturing her full-time career, with Will – now aged 12 – pitching in whenever he can “Will still enjoys working the press, but as he’s getting older, he’s becoming more interested in the business development side of things,” Swales com mented And on that business development side, Yukon Plastics recently moved into a small office and manufacturing plant and is preparing to hire a new full-time worker or two. The company has also added th ree more injection presses, a 3D printer filament ma ker, a specialized resin printing setup for inhouse printing of injection molds, and a safer manual sh redder to create feedstock materials Local interest in the company has reache d t he poi nt where Swa les recently held a th ree-day workshop for 50 public school students, from kindergar ten to Grade 9. “They all got involved with ma king products, and each made a plastic ring as a keepsa ke,” Swales said “It gave them a sense of how to become personally involved in plastic recycling.”

Swales and Will have also added an enclosed trailer stocked with a molding machine – dubbed the Mobile Factor y – to the mix “We take it on the road for the double pur pose of showing Yukon communities how our process works, and to watch their plastic waste become beautiful and useful products in real time,” Swales sa id. T he Mobile Factor y a lso a llows Yukon Plastics to double its production capacity from 50 pieces a day – which represents about two kilograms of plastic – to 100 pieces a day. And the firm also wants to star t making larger products, like benches, picnic tables, and building materials. “The only way that a consequential amount of plastic can be removed from the waste dynamic of the Yukon is at the factor y scale, and that’s our next step,” Swales said “We’re in a period of rapid growth, and we hope to keep growing It might sound odd, but we think this is the most exciting type of resou rce ext raction in Nor thern Canada right now ” BOJ

E s T a a r s T l s r T s

5 8 0 2 I B R I C O 1 t 1 2

R f d T n o k c y r G n - / Ro W c d D W h o e n o N k W r s h b r W m c P t a a d o

1 r r d k c n o e ’ F d o l W m u

j , n m k h m d - b n l . i n h m