Polypropylene made in Canada, ready for the world.

Heartland operates out of a major industrial hub in Alberta, Canada. Being located in one of the top propane producing regions in the world is a real asset. Having abundant local supply of feedstock and access to polymer-grade propylene helps us serve customers, wherever they are, more reliably.

made better

polypropylene

FROM THE ARCHIVES

The April 1988 issue of Canadian Plastics reported on a new indoor street hockey rink in Welland, Ont., with a playing surface made from linear low-density polyethylene (LLDPE). Intended as a less costly alternative to ice hockey, the rink was composed of hundreds of foot-square LLDPE sections fitted together, in black, white, and yellow to allow marking off without the need for paint. “They have a textured surface to prevent slipping, although a player who takes a tumble is unlikely to be seriously injured,” our story noted. The idea was developed by two entrepreneurs from Niagara Falls, Ont., and the squares were molded by an injection molder in Stoney Creek, Ont. A second rink was being planned for St. Catharines, Ont.

Number of the month: 133*

*Number of countries represented by attendees at NPE2024. (See pg. 6)

cover story

10 ROBOTS & AUTOMATION: Forearmed

4 Editor’s View: New report should be required reading for INC

5 Ideas & Innovations:

Bioplastic shotgun wads make firearms more eco-friendly

6 News:

• NPE2024 draws over 50,000

• Gracious Living investing $9.8 million in Kentucky expansion

• Integrity Tool sells injection molding division

• Supplier News and People

20 Technology Showcase

21 Advertising Index

22 Technical Tips: Choosing the right rotational mold and moldmaker

Robots are a godsend for many plastics processors, but like any piece of machinery, they only work until they don’t. Implementing a preventive maintenance program that pays attention to key operational aspects will keep your robots running smoothly.

features

13 DRYERS: A very dry forecast

Dryers were a big part of technology introductions from some companies at NPE2024, with new models offering a range of features, from faster cycles to lower dewpoint values to artificial intelligence.

18 MATERIALS: Coming to North America

Having made its name in the Indo-Pacific region, Bralco Advanced Materials is now offering its EMI shielding thermoplastic polymers to molders of automotive, aerospace, and electronics parts in Canada and the U.S.

New report should be required reading for INC

The subjects of Canada and plastics manufacturing were linked together before the eyes of the world in April, although not in a way that’s likely to bode well for our industry.

The United Nations’ Intergovernmental Negotiating Committee’s fourth meeting (INC-4) on plastic pollution wrapped up in Ottawa on April 30. Featuring 2,500 delegates from 170 member nations, the weeklong talks were expected to deliver a timeline for severely curtailing global plastic production, but this didn’t happen, due to significant differences among delegates over how – or even whether – to limit plastic manufacturing. For this, credit is due to plastics companies and major petrochemicalproducing nations that pointed out the social and economic risks of production caps. Some delegates also raised procedural objections that made it tough to make progress, including – wait for it –concern about “insufficient” human rights language, described as key to a “legitimate, equitable, and effective” plastics treaty.

Substantive differences also remain in other areas, such as whether the treaty should create lists of plastics applications that are problematic for recycling or lists of potentially toxic chemicals of concern within plastics that can then be phased out.

For our industry, these hurdles are the good news. The bad news is, the delegates did produce an advanced draft text of the final instrument and agreement on work to continue, all to facilitate what INC-4 spokespeople call “a just transition” to a world with a lot less plastic in it. The fifth and final round of talks, INC-5, is scheduled for Nov. 25 to Dec. 1 in Busan, South Korea – just in time to give our industry a lump of coal in our

collective Christmas stocking if they agree on a legally binding treaty.

Overlooked by many during the INC-4 hype was a report on plastic production caps that came out just before the meeting, and which exposed the foolishness of much of the whole enterprise.

The detailed study from Oxford Economics was commissioned by the International Council of Chemical Associations (ICCA) and shows conclusively that limiting global plastic production will have serious and unintended negative impacts. The first will be on the global economy by shifting consumer demand to more expensive alternative products and thereby pushing up prices of plastic goods – cost increases that will hit the poorest people the hardest. “Since poorer regions of the world spend significantly more on plastics as a share of their overall consumption, it can be expected that households in these regions would suffer disproportionately from this inflationary shock,” the report said.

Second, the study said, capping plastic manufacturing and switching towards alternative materials – excluding recycled plastics – also carries the risk of unintended environmental consequences. “Broadly speaking, these risks are due to the fact that plastics are lighter than potential commercial alternatives,” the report said. “For example, swapping plastic for other materials may result in increases in food waste and heavier vehicles, in food packaging and automotive applications, respectively.”

By timing the release of the study to coincide with INC-4, ICCA officials said, they hoped to carry the message to diplomats that a production cap will have widereaching and damaging consequences on society. I guess we’ll know by the end of the INC-5 talks if the message was received and understood.

Mark Stephen, editor mstephen@canplastics.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal

Tel: 416-510-5113

Fax: 416-510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR M ark Stephen 416-510-5110 mstephen@canplastics.com

ASSOCIATE PUBLISHER Stephen Kranabetter C: 416-561-5362 W: 416-510-6791 skranabetter@annexbusinessmedia.com

MEDIA DESIGNER Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT COORDINATOR Melissa Gates 416-510-5217 mgates@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Serina Dingeldein 416-510-5124 sdingeldein@annexbusinessmedia.com

GROUP PUBLISHER/VP SALES Martin McAnulty mmcanulty@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PRINTED IN CANADA ISSN 008-4778 (Print) ISSN 1923-3671 (Online)

Publication Mail Agreement #40065710

2024 SUBSCRIPTION RATES

5 issues Canadian Plastics, plus Dec. 2024 Buyers’ Guide: CANADA: Single copy $12.00 plus applicable taxes

1 Year $79.05 plus applicable taxes

2 Years $125.97 plus applicable taxes USA: $179.52 (CAD) / year FOREIGN: $205.02 (CAD) / year

Occasionally, Canadian Plastics will mail information on behalf of industry related groups whose products and services we believe could be of interest to you. If you prefer not to receive this information, please contact our audience development department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com • Tel: 800-668-2374

No part of the editorial content of this publication can be reprinted without the publisher’s written permission ©2024 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

MEMBER: Magazines Canada, Canadian Plastics Industry Association.

Bioplastic shotgun wads make firearms more eco-friendly

When even the firearms industry starts going green, you know the messaging about environmentalism is getting through.

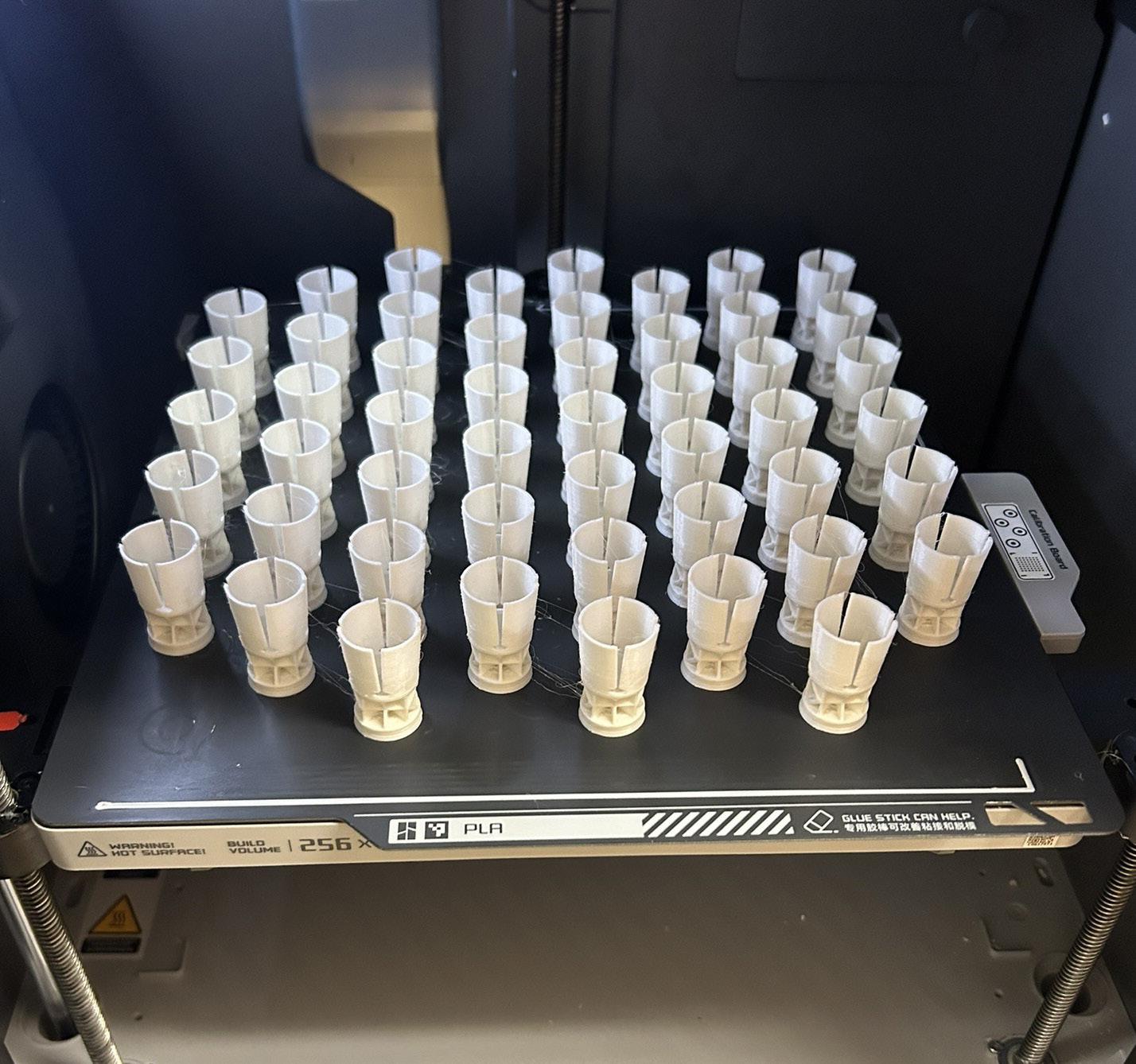

Beyond Plastic, a Commerce, Calif.based developer of sustainable polymers based on polyhydroxyalkanoate (PHA) technology, is working with manufacturing partner Eco Shot LLC, headquartered in Carbondale, Colo., to bring biodegradable shotgun wads to market.

With Beyond Plastic’s 100 per cent biodegradable PHA 3D print filament, Eco Shot says it has successfully conducted rapid prototyping and created a design and production process for eco-friendly shotgun wads.

For the uninitiated, the “wad” is a critical component of a shotgun shell that keeps the shot together but separate from the powder, creating a tighter, safer shot pattern and a more consistent discharge. Until the 1970s, shotgun wads were made of paper or cardboard, but during that decade manufacturers switched to plastic – typically either polyethylene or polypropylene – to lower manufacturing costs and increase ease of production. The

problem is, because the wad is discharged with the shot and travels quite a distance before separating, and is often shot over water, hunters don’t consider them to be retrievable, leading to a buildup of wad litter in freshwater and estuarine waters, as well as on hunting reserves – plastic wads have been reported as a common debris item collected during cleanups of beaches and landscapes, and have been found in the stomachs of fish, foraging birds, and other wildlife.

The PHA biodegradable wads are designed to offer a sustainable solution to mitigate these concerns. Derived from renewable resources such as plant oils, PHA decomposes naturally, minimizing environmental harm and reducing the accumulation of plastic waste.

“The PHA biodegradable shotgun wads, designed by Eco Shot, are made to tackle the problem at the source,” said Beyond Plastic’s chief technology officer Fred Pinczuk. “After each wad is discharged, it will naturally biodegrade into the soil in a matter of months, as opposed to traditional plastic that lasts for hundreds of years.”

The new biodegradable shotgun wads can replace traditional wads typically made from polyethylene or polypropylene that contribute to plastic pollution.

There’s no doubt the problem to be solved is a big one: According to the Virginia Institute of Marine Science, worldwide production of shotgun wads has been estimated to be about 15 billion wads every year for the last 50 years, with each wad equalling the same amount of plastic as two grocery bags. But the PHA biodegradable wads are certainly a step in the right direction. “With Beyond Plastic’s PHA filament, we’re able to conduct rapid prototyping for our designs, which allows us to increase our offerings and meet the needs of a broader range of hunting activities,” said Eco Shot founder Andrew Thomas. CPL

Partnership Announcement

NPE2024 draws over 50,000

After a six-year hiatus, the recent NPE trade show drew more than 50,000 attendees.

While the final attendance figures haven’t been released as of press time, the show had exceeded 50,000 registrants by May 7, its second day of operation. NPE2024 ran from May 6-10 at the Orange County Convention Center (OCCC) in Orlando, Fla.

The triennial trade show – which was cancelled in 2021 due to the COVID-19 pandemic – is the largest plastics trade show in the Americas, and featured over 2,300 exhibitors within more than 1.1 million net square feet of exhibit space in 2024.

The 2018 edition of the show had a total of 56,034 attendees.

According to the Plastics Industry Association, which organizes the show, more than 15,000 international registrants made NPE2024 the most international edition in the show’s history. Representatives from 133 countries – or 68.2 per cent of nations worldwide – attended, representing a 9.9 per cent increase of countries compared to NPE2018. The show also drew young and first-time attendees. Sixty-three per cent of the attendees were first-time visitors to NPE, and 30 per cent of overall attendees were under the age of 40.

“The show seemed well-attended overall, but compared to 2018 I believe attendance was down, due in part to the present economy, Chinaplas happening the week before, and the Automate 2024 show in Chicago happening during the same week as NPE,” said Mike Hicks, director of sales with Diemould Service Co. (Canada) Ltd. (DMS), a mold component supplier in Oldcastle, Ont., and an exhibitor in the South Hall. “We right-sized our booth from NPE2018 and it turned out to be the right size for this show.”

The show had a substantial Canadian presence, both exhibitors and attendees. “It was wonderful to have some of our Canadian suppliers stop by our booth to discuss how Canada can be at the forefront of sustainability initiatives around keeping waste plastic out of the environment,” said Domenic Di Mondo, president of Brantford, Ont.-based clean technology developer GreenMantra Technologies.

Heartland Polymers – one of North America’s newest entrants to the polypropylene (PP) market – was a first-time exhibitor at the show. “NPE2024 was important for us because you only get to be a new entrant once, and we were excited to bring our team together and debut the brand in one location where the entire industry comes together,” said Yonas Kebede, the Calgary-based company’s PP sales and marketing director. “Overall, it was a well-run event, and our team made some great connections.”

NPE2027 is scheduled for May 3-7, 2027, at the OCCC. “NPE is still the must-do/must-attend show for the plastics industry in North America and DMS plans to exhibit at the 2027 show,” Mike Hicks said. CPL

Scenes from NPE2024 (top to bottom): Lining up for parts at the Arburg booth; networking; and Canadian exhibitors Cap-Thin Molds, StackTeck Systems, and K+G Machinery Works Ltd.

Gracious Living investing $9.8 million in Kentucky expansion

Canadian processor Gracious Living Corp. (GL), which manufactures products for storage, laundry, patios, garages, pets, and recreation, is investing US$9.8 million to expand its operations in Morgantown, Ky.

The Morgantown facility consists of a 160,000-squarefoot plant on a 12-acre lot about 95 kilometers north of metropolitan Nashville, Tenn.

GL will expand its operations to manufacture patio furniture, storage containers, and shelving, according to an April 9 news release from Kentucky Gov. Andy Beshear. It also plans to add about 50 new employees.

The project is expected to be completed by the end of 2025.

“We eagerly anticipate the opportunity to expand in a state with hard-working citizens and a supportive government stance on economic growth,” said Charles Kida, GL’s vice president of finance. “The Morgantown site offers an ideal location due to its strategic position for distribution. We look forward to establishing our first presence in the U.S. through this expansion initiative.”

Founded in 1980, GL had operated out of two facilities in Vaughan and Mississauga, Ont., until buying the Morgantown site. CPL

Next Generation of Injection Molding Machines

DMS buys grinding specialist Border Steel, appoints new sales rep

Diemould Service Co. (Canada ) Ltd. (DMS), a mold component supplier in Oldcastle, Ont., has acquired Border Steel Ltd., a Windsor, Ont.-based manufacturing and service company that’s been in operation since 1962.

The financial terms of the purchase have not been disclosed.

In a March 27 news release, DMS officials said the deal brings DMS’s own expertise along with Border Steel’s to offer a range of services to their North American customer base. They added that customers will benefit from Blanchard grinding and flame-cutting services, along with access to a wide selection of tool steel plates.

Under DMS ownership, both companies will continue to operate as separate entities while working together. On the heels of the purchase, DMS and Border Steel have appointed Cara Owen as the sales representative for both companies in Michigan, and for Border Steel in southwestern Ontario.

Border Steel says it runs Canada’s largest Blanchard grinder, allowing the firm to process more parts at once and to quickly fulfill large grinding orders.

Cara Owen

Photo

Sonny Morneault named president of Wittmann USA

David Preusse, president of Torrington, Conn.-based processing machinery maker Wittmann USA, has stepped down and passed the reins to Sonny Morneault, the company’s vice president of sales.

Preusse is moving into a part-time business development position with the firm, filling a role focused on developing new business and markets.

Morneault has been Wittmann USA’s vice president of sales since 2015. He joined Wittmann in 2007 and has held a variety of sales and leadership roles since.

Jason Long will replace Morneault as vice president of sales. Long joined Wittmann in 2006, and has been national sales manager for Wittmann USA’s robots and automation division since 2017. CPL

PEOPLE

Integrity Tool sells injection molding division

Integrity Injection Molding (IMM), the molding division of Oldcastle, Ont.based moldmaker Integrity Tool & Mold Inc., has been sold to Rochester, N.Y.-based automotive and consumer parts molder Century Mold Co. Inc., for an undisclosed amount.

In an April 11 news release, Century Mold officials said the purchase strength-

SUPPLIER NEWS

ens its capabilities in high-tonnage presses “in response to rising North America demand for these capabilities.”

The deal includes Pulaski, Tenn.based IMM’s 75,000-square-foot facility, with up to 3,000-ton press capacity.

Integrity Tool & Mold expanded into injection molding in 2019 with the launch of IMM. CPL

– Nylon 6/6 maker Ascend Performance Materials, based in Houston, has appointed Overland Park, Kan.-based PolySource LLC as a North American distributor for its full portfolio of engineered nylon materials, including the Vydyne, Starflam, HiDura, and ReDefyne polyamide product lines, which are designed for automotive, electrical and electronic, healthcare and consumer, and industrial applications.

– South Korea-based injection molding machine maker LS Mtron has appointed FM Mécanique, located in Sainte-Anne-des-Plaines, Que., and headed by Jocelyn Fournier, as its sales agent for Quebec and Eastern Canada.

– Sweden-based recycling equipment maker Rapid Granulator AB has appointed Ottawa, Ont.-based Leap Green Polymers as its sales agent for Ontario, Manitoba, Saskatchewan, Alberta, and British Columbia.

– Wilmington, Del.-based materials firm Chemours Co. has named Denise Dignam as president and CEO.

– McHenry, Ill.-based specialty colour and additives supplier Chroma Color Corp. has named Joe Herres as CEO.

– Pawcatuck, Conn.-based extrusion and converting technology maker Davis-Standard LLC has appointed Brian Anderson as chief procurement officer.

– Midland, Mich.-based chemical supplier Dow Inc. has appointed Brendy Lange as president of its performance materials and coatings division.

– Lebanon, Ore.-based extruder maker Entek International LLC has named Joel McBride as sales account manager for its wear parts division.

– Extreme Coatings, a St. Petersburg, Fla.-based supplier of wear resistant coating solutions, has named Steve Jackson as

director of sales for North America for its plastics division.

– Extrusion tooling maker Guill Tool & Engineering Co., headquartered in West Warwick, R.I., has named Rob Peters as general manager.

– Houston-based Neutrex Inc., the manufacturer of Purgex purging compounds, has named John Haag as president and CEO.

– Italy-based auxiliary equipment maker Piovan SpA has appointed John Erkert as regional CEO of its North American operations, headquartered in Cranberry Township, Pa.

– Chemical supplier Wacker Chemical Corp., based in Adrian, Mich., has named Christoph Kowitz as president and CEO.

– Cranston, R.I.-based robotic automation maker Yushin America Inc. has named Michael Greenhalgh as president.

Denise Dignam Joe Herres Brian Anderson

Joel McBride Steve Jackson Rob Peters John Haag John Erkert

Christoph Kowitz Michael Greenhalgh

Brendy Lange

Sonny Morneault.

Photo Credit: Wittmann USA

FOREARMED

Robots are a godsend for many plastics processors, but like any piece of machinery, they only work until they don’t. Implementing a preventive maintenance program that pays attention to key operational aspects will keep your robots running smoothly.

By Mark Stephen, editor

Plastics manufacturing has always had a strong focus on innovation and improvement, which is why it has come such a long way since its inception. And nowhere more so than with robotic automation. The integration of a range of industrial robots – 3-axis Cartesian beam, 6-axis articulated-arm, Scara, top-entry, side-entry, high-speed, and collaborative – has been totally transformative: with their mechanical precision, they operate at a pace and consistency that human operators just can’t match. Which is a good thing for the humans: The incorporation of robots in handling dangerous and repetitive tasks has dramatically improved workplace safety, resulting in fewer injuries, reduced labour costs, and enhanced operational capacity, all of which helps molders stay competitive.

Since robots often represent a significant investment for all businesses, you’d think that performing preventive maintenance, buttressed by repairs and periodic upgrades, would be the obvious strategy to ensure the longevity of these systems. But it can be hard to keep this fact in sight, given that processors are under tremendous demands to meet customer delivery

dates, and preventive maintenance doesn’t obviously contribute to this goal. “When companies invest in robots, they often believe that the more the equipment is running, the greater the return on investment,” said Tim Lavigne, business unit manager with Absolute Robot. “So, there’s pressure within an organization to keep the robots running, sometimes non-stop, at companies that have 24/7 operations.”

But don’t be fooled: There’s a direct and proven correlation between conducting regular preventive maintenance and robots that operate smoothly and efficiently, and when this maintenance is neglected, big problems can arise with the robot’s mechanical and electrical components, leading to downtime, lost production, and a shorter lifespan for the equipment.

KNOW YOUR ROBOT

One of the keys to keeping robots in good condition involves understanding that some types are prone to more – and/or different – wear and tear than others, which can affect the frequency of maintenance. “High-speed robots perform the most cycles of all robot types, so component

wear can be an issue; and they also carry lighter payloads, so they have smaller, more complex drive types,” said Jason Long, vice president of sales with Wittmann USA. “All of this means a shorter preventive maintenance schedule compared to other robots.” And high-speed robots can also be at risk of colliding with other machinery on the shop floor, with bad consequences. “The faster a robot is moving, the more catastrophic the collision is going to be, so processors should pay attention to how to eliminate these accidents,” said Dale Arndt, director of engineering with Fanuc Canada.

Most 3-axis robots use belts or rack-andpinion drives and linear bearings. “The belt drives on 3-axis units all require different types of maintenance, depending on the drive type,” said Jason Long. Since rackand-pinion robots are supposed to operate very quietly and with a smooth motion, some OEMs say, take note if there is any hesitation or jerking during operation, which can indicate damage to the drive system or some foreign object lodged in it.

And 6-axis robots, meanwhile, typically have complicated end-of-arm tooling (EOAT) for deflashing or deburring that

poses unique maintenance challenges. “A lot of the wires, cables, and hoses that run down the robot arm to the EOAT experience regular twisting and bending,” Dale Arndt said. “Even if these are high-flexrated they can still wear and eventually fail, so the processor should watch them carefully and install a new set if they know what the failure rate is.”

In other ways, virtually all robot types, from sprue pickers to sophisticated multiaxis robots, require inspection of the same areas. “Across the board, items that you want to keep an eye on are lubricants, motors, drives, and any rails and bearings – anything that facilitates and powers movement or bears the brunt of movement,” said Tim Lavigne. The obvious caveat here is that it’s beneficial to have employees who are trained in maintenance, since it can be difficult to schedule visits from service technicians. Some OEMs offer operating training on topics that include maintenance.

EYES AND EARS

One thing that can get in the way of preventive maintenance at the very outset is accessibility. “The height of most robots means that maintenance technicians don’t easily see what’s happening from ground level,” Lavigne said. “It’s literally a case of out of sight, out of mind, until the robot stops running.” The solution, some OEMs say, is to make sure that maintenance technicians have either a scissor lift or ladder to give access to the top of the robot.

The simple act of watching a robot in action can actually play an outsized part in keeping it in good condition, which means being aware of the robot’s normal appearance. “Generally, up to 90 per cent of a preventive maintenance check is visual,” Lavigne said. “This is an easy activity, but it’s also one of the most overlooked.” According to some OEMs, all robots require visual inspection of linear rails for adequate greasing (and if the robot is being operated in a dusty environment, clean the rails frequently); of the robot and surrounding areas for grease leaks; of filters to maintain clear airflow; of the inside of electrical cabinets for loose wires and debris; and of belts for looseness, tears or cuts. When it comes to

the control panel interface board, some OEMs suggest checking the relays and fuses that protect the robot from short circuits. “We recommend replacing these yearly to avoid unexpected failure,” said Richard LaChance, service sales manager for North America with Sepro America.

And watch the operation of the molding machine too. Usually, most robots are installed on the platen of the molding machine, and when the machine is running on a fast cycle, vibrations from the press can be transmitted to the robot, with damaging results. So, make sure the mold movements are properly adjusted to limit the amount of jerking or vibration.

And just as importantly, use your ears – operators or technicians performing preventive maintenance inspections should be familiar with a robot’s normal sounds and listen for anything unusual. In general, robots have a normal clicking sound made by the motion of links in the track that carries the motor cables and vacuum hoses, and these motions should be smooth and quiet. Anything else – such as squeaking or knocking sounds – can indicate trouble, some OEMs say.

Beyond what you can see and hear, the lubricants inside the robot need to be monitored carefully. “Lubricants are very complex today, with many different types, and using the wrong lubricant in the wrong place can lead to catastrophic failure,” said Dale Arndt. “And lubricants also have a fairly quick breakdown, which can cause

rapid failure of the robot. This is why some shops prefer to subcontract the lubricant replacement to a specialist.” For in-house changing of lubricant, always refer to the robot manual for the appropriate lubrication of metal components, some OEMs say, and remember that rack-and-pinion systems have automatic lubrication from a reservoir, which needs to be replaced every year.

A final wrinkle is that sometimes a robot fails for reasons that have nothing to do with the original components. “Sometimes the problem is with a vison camera that someone put on the robot, or a sensor or cable that was added by an integrator, that the OEM knows nothing about,” Arndt said. “These added components may require additional maintenance beyond what the OEM recommends.”

THE BIG THREE

A simple, effective preventive maintenance program consists of three key steps. First, establish a schedule for conducting maintenance and a log for recording the performance dates. “This schedule may have to be adjusted based on the molding environment,” Tim Lavigne said. “For example, when running ABS [acrylonitrile butadiene styrene], which is a dusty and conductive material, cleaning the robot is required more frequently.”

Second, conduct regular visual inspections for damaged components, as outlined above. And third, establish a list of

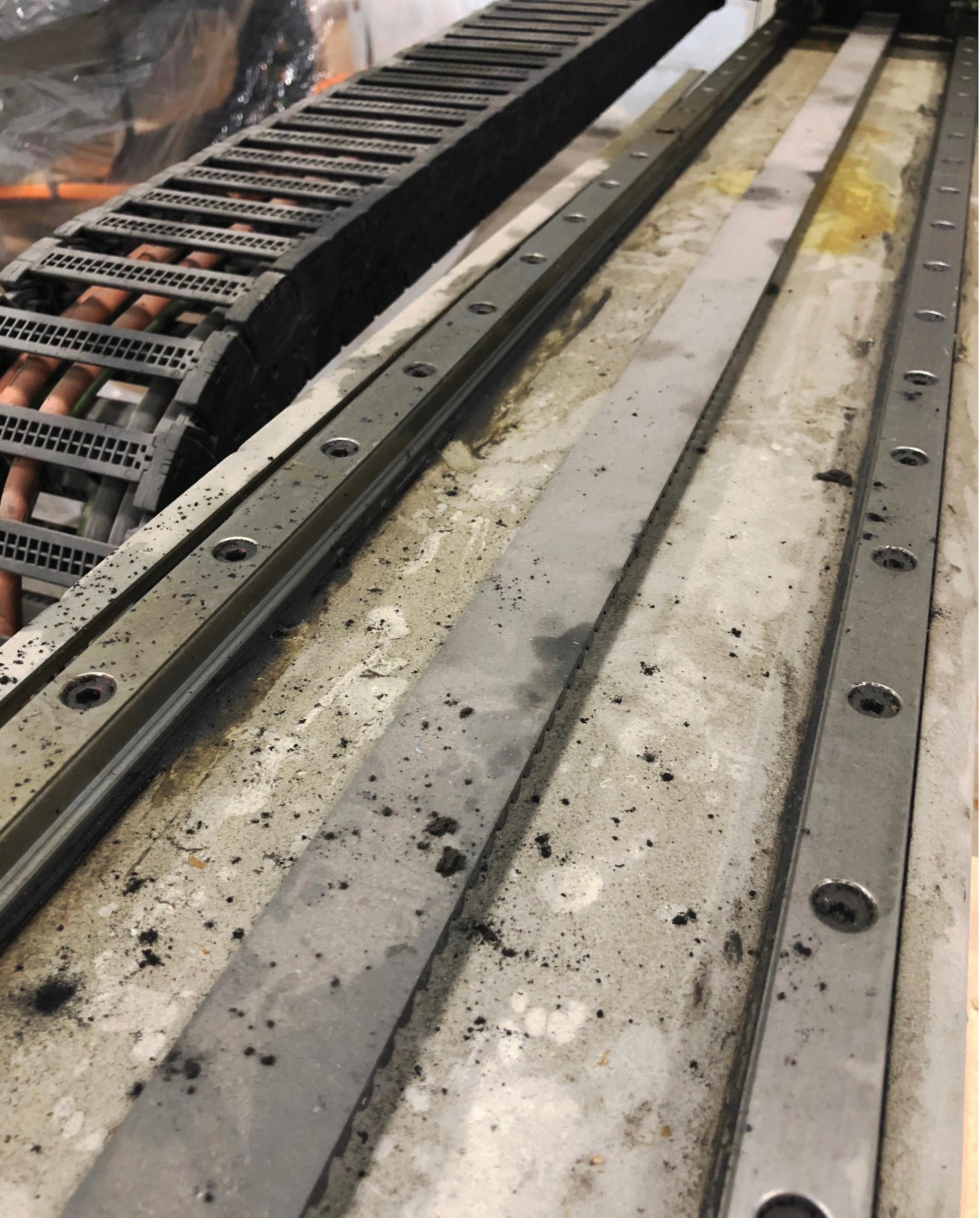

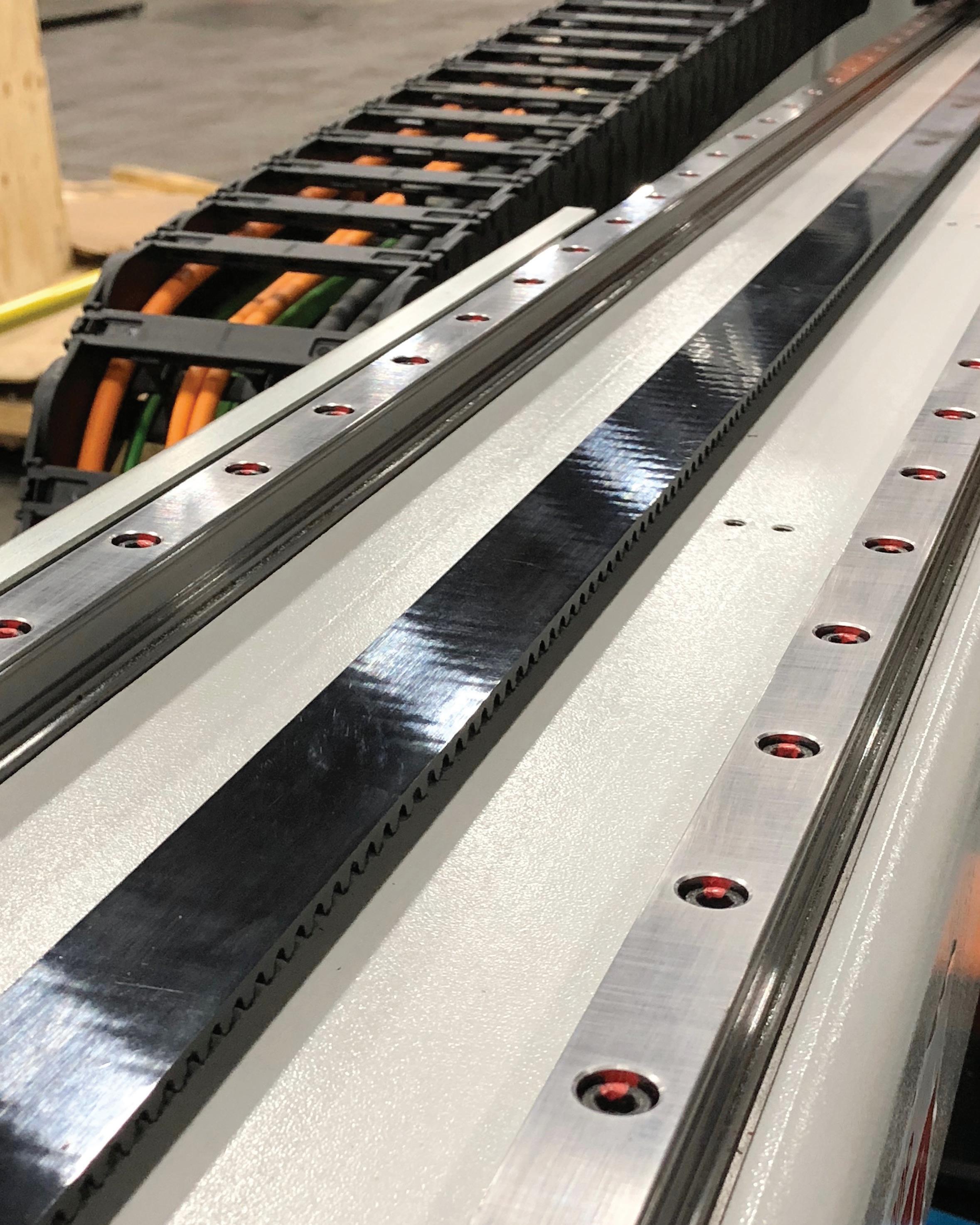

Debris on X-axis rails can cause damage to the underside of the robot arm or friction that can slow down the cycle time (left); a clean X-axis rail.

wear components that need regular replacement and record the dates of installation for each one. “Once you identify your high-wear parts, spares should be kept in stock,” Lavigne said. The good news is that supply chain issues caused by the COVID-19 pandemic have generally been overcome. “The supply chain has been normalized again and there are no real backlog issues anymore with parts needed for robotic automation,” said Jason Long. But remember: When replacing parts, be sure the new part meets OEM specifications. “Sometimes it doesn’t, since lower cost suppliers of similar components often don’t fully understand the application that each component is used for,” Long continued.

To facilitate the process, some OEMs offer a variety of maintenance service contracts. Sepro, for example, offers its “Maintenance Pack” contract, which provides an annual preventive maintenance visit by a Sepro technician on all or part of a customer’s robot fleet, changing various consumables such as grease, batteries, filters, and – if necessary – belts; and also, its “SeproMax Full Maintenance” contract. “The SeproMax contract is a oneyear extension of the original warranty coverage and has four services: preventive maintenance by a Sepro technician, replacement of all the robot’s consumables, free troubleshooting, and the oneyear warranty extension that includes parts and labour,” said Richard LaChance.

INSIDE INFORMATION

Beyond following a preventive maintenance program, there are operational tips that some OEMs recommend for reducing component wear. A big one applies to owners of high-speed robots: If you can slow the robot down, do so. “If you can either run the robot at full speed for four hours or half speed for eight hours, choose eight hours at half speed, because it creates a lot less wear on the components,” said Dale Arndt. “There’s no need to run a high-speed robot at its fastest speed if it isn’t necessary.” Using industry standard features like Eco modes can help here. “These features allow the robot to monitor its speed, energy usage, and other things to make sure it isn’t working too hard or too fast,” Jason Long said.

Also, make sure the robot being used isn’t undersized for the application. “If a robot has a set payload, it’s best practice to ensure the tooling is around 80 per cent of that payload,” Long continued. “And don’t forget to follow this guideline when repurposing a robot for applications it wasn’t originally bought for.”

Other wear-saving tips involve people making better choices. “For example, the operator should know not to just hit the e-stop button to stop a work cell, which is very hard on the equipment,” Long said. “Most robotic automation has proper ways to be stopped and restarted that avoids unnecessary mechanical stress.”

SHAPE OF THINGS TO COME

Traditional preventive maintenance that relies on a set schedule based on the number of cycles and operating hours only goes so far, however. It can fix a problem and prolong the life of a robot, but it can’t predict a problem that will happen in the future. Which is where the newly developing field of predictive maintenance comes in. Using data collected from the robotic component itself and leveraging advanced algorithms to assess the robot’s status in real time, predictive maintenance can foresee when a specific maintenance activity should be performed and provide direction on how to resolve the issue.

Preventive maintenance is the past and present of robot upkeep, some OEMs say, and predictive maintenance is the future – so for now, the best solution is to com-

bine the two whenever possible. “Predictive maintenance is a great thing, and if molders are looking at new robotic machinery, it’s worth looking at solutions that can give you a predictive answer,” said Dale Arndt. “Fanuc offers software that does predictive-type analysis of the maintenance situation, but operators performing routine maintenance focused on cleaning, lubrication, and correcting any issues detected during inspections still play the biggest part in preventing unplanned downtime, and maybe always will.”

In the end, most robots will break down because of wear and tear, but a good preventive maintenance program can prevent this from happening for several years. And in a market that increasingly demands both cost efficiency and highquality products, buying that extra time might make all the difference. CPL

RESOURCE LIST

Absolute Robot Inc.(Worcester, Mass.); www.absoluterobot.com; 508-792-4305

CFM Robotique (Sherbrooke, Que.); www.cfmrobotique.com; 819-846-1797

PJS Sales and Consulting (Surrey, B.C.); www.pjssalesandconsulting.info; 778-896-1485

Fanuc Canada Ltd. (Mississauga, Ont.); www.fanucamerica.com; 905-812-2300

Sepro Canada (Montreal); www.sepro-group.ca; 514-515-9349

Wittmann Battenfeld Canada Inc. (Richmond Hill, Ont.); www.wittmann-group.com; 888-466-8266

A dirty air filter (left) and a clean air filter.

Photo

A VERY DRY FORECAST

Dryers were a big part of technology introductions from some companies at NPE2024, with new models offering a range of features, from faster cycles to lower dewpoint values to artificial intelligence.

By Mark Stephen, editor

Overstating the importance for molders of dehumidifying or drying plastics in the processing phase verges on the impossible. Plastic resins, particularly hygroscopic ones like nylon, polyethylene terephthalate (PET), and polycarbonate, have a natural tendency to absorb moisture from the environment – and even when they appear dry on the outside,

these and other materials can be loaded with moisture on the inside. If not controlled, this moisture can cause surface imperfections such as splaying, silver streaks, or delamination on parts.

Which is where dryers come in. Resin drying prior to processing maintains the performance characteristics of your resin and ultimately your parts.

And it’s never more important than during the summer, when the hot, humid weather really puts a strain on both the regeneration and process.

And speaking of hot and humid, the NPE2024 show wrapped up recently after a sweaty week in Orlando, Fla., and new dryers were a big part of auxiliaries introduced by some of the exhibitors. Here’s a look at some of the new offerings, just in time to help you beat the summer processing heat.

ALL ABOUT REGENERATION

Advanced Blending Solutions (ABS) has now made the formerly optional Regeneration Power Saver mode a standard feature on its 14 desiccant dryer models. Known by the prefix “TD” followed by a number signifying capacity, the 14 dryers have capacities ranging from 25 to 2,000 pounds per hour. Benefits of the Regeneration Power Saver include faster cycles that save time, money, and energy, ABS officials said. The Regeneration Power Saver feature shuts down the heater the moment the exhaust temperature of a bed

Moretto’s X COMB mini dryers in action.

being regenerated reaches a specified temperature. And while, as we’ve just noted, dryers tend to be most advantageous during the summer months, this feature is especially beneficial in the winter, ABS officials continued, when the standard regeneration cycle is too long and wasteful.

AEC’s new line of desiccant wheel dryers is designed to provide high-performance moisture removal and has adjustable process airflow that prevents resin overdrying and reduces energy consumption. Available in three configurations –ADP, ADW, and ADC – the AD series is a direct replacement for AEC’s earlier NGX and RDX dryers. The new dryers are said to be well-suited for most beside-the-press drying applications and small central drying systems, and are available with throughputs ranging from 50 to 2,500 pounds per hour. Options include an internal dewpoint sensor, level sensor, take-off boxes, and integration with Industry 4.0 equipment. For precision control, the AD series also utilizes a high-resolution HMI touchscreen and proprietary PLC. Key drying data is visible on a single screen: drying temperature, dewpoint, material throughput, and total energy consumption.

The new ResinWorks with Optimizer, an optional artificial intelligence (AI) feature for Conair Group’s ResinWorks centralized multi-hopper drying system, is designed to automatically keep processready resins at the right temperatures and varied throughputs, while preventing over-

drying and saving money on energy costs. The Optimizer starts with the same conditions as a manual operator would: a required resin delivery temperature and predicted throughput of each resin through each hopper. In operation, the Optimizer monitors overall airflow, first ensuring that only active hoppers are served. Then, its AI-driven logic optimizes airflow through each active hopper based on changes in mass flow and temperature. Once material at the bottom of the hopper achieves the proper temperature, the Optimizer logic holds it steady, while incrementally adjusting airflow through the rest of the hopper to match the actual processing rates, incoming material condition, and material drying requirements. Not only can its AI-driven logic efficiently dial back and rebalance airflows for unused hoppers or reduce airflows for less-than-full hoppers, Conair officials said, but it can also boost airflows — and alert operators — when process resin rises unexpectedly. And the ResinWorks with Optimizer has demonstrated energy savings of 10 to 40 per cent in virtually every situation, they added.

VERY COOL (AND DRY) PARTNERSHIP

Auxiliary equipment suppliers Dri-Air Industries and Maguire Products have combined to develop Dri-Air’s second generation of on-demand drying/blending systems for the circular economy, enabling molders to dry virgin material,

Dri-Air Industries and Maguire Products have partnered to develop DriAir’s second generation of ondemand drying/blending systems.

reclaim and redry regrind material, add colourant, and blend these components just prior to conveying to the injection molding machine. Dri-Air’s approach dries materials separately at different temperatures and keeps materials isolated until the blending step, which eliminates the inventory issues and the waste of premixed materials that are no longer needed after the job runs out while keeping materials dry throughout the blending and conveying process. Positioned below the discharge of the drying hoppers is Maguire’s WSB series weigh scale blender. Configured with a touchscreen control, it provides gravimetric accuracy, data reporting and recording, and additional component flexibility. Once the dried components are blended, Dri-Air’s closed-loop, dry-air conveyance system ensures the blended material stays dry and properly blended during conveyance to the process. A small minimum inventory receiver is mounted on the feed throat. The castered blender can easily be removed for ease of cleaning and docked into position for production.

Moretto’s X COMB mini dryer is a compact all-electric dryer specifically designed for engineering resins, and with an “adaptive” feature designed to ensure a very gentle and consistent polymer treatment with dewpoint levels up to -52°C or -61°F. The LCD touchscreen is a standard built-in intelligence feature

Novatec’s DryerGenie system enables processors to dry based on material condition, not time.

Photo

that only requires two parameters: the type of material and the throughput. All the other parameters are automatically set. The interaction between the operator and the system is said to be very easy thanks to the graphic user interface. The dryer includes multiple connectivity options such as RS485, Modbus, and USB for data downloading. It also can be connected to MOWIS, Moretto’s proprietary supervision and management soft ware which enables connectivity between different systems, processes, and even facilities. And X COMB is equipped with an assisted lid and safety device which enable operators to carry out inspection and maintenance proce dures safely and easily.

Motan’s Swift series sCompact dry ers come with integrated conveying and are said to be multifunctional and flexi ble. The dryers are available in three versions and equipped with one drying bin sized 80, 150 or 250 litres, and up to three sConvey hopper loaders for con veying to the drying bin and two pro cessing machines. Additionally, the sCompact has a unique feature and can control an additive dosing unit. The dryer is also offered with standard advanced features such as dewpoint con trol and a dry-air conveying function with line purging. Operation is through the integrated seven-inch full-colour touch display. The complete drying bin is fully insulated, made of stainless steel, and has a large access door. The inte grated conveying system in the sCom pact saves space and money, as no addi tional equipment is required.

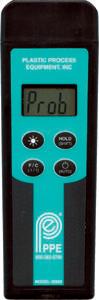

GOODBYE TO GUESSWORK

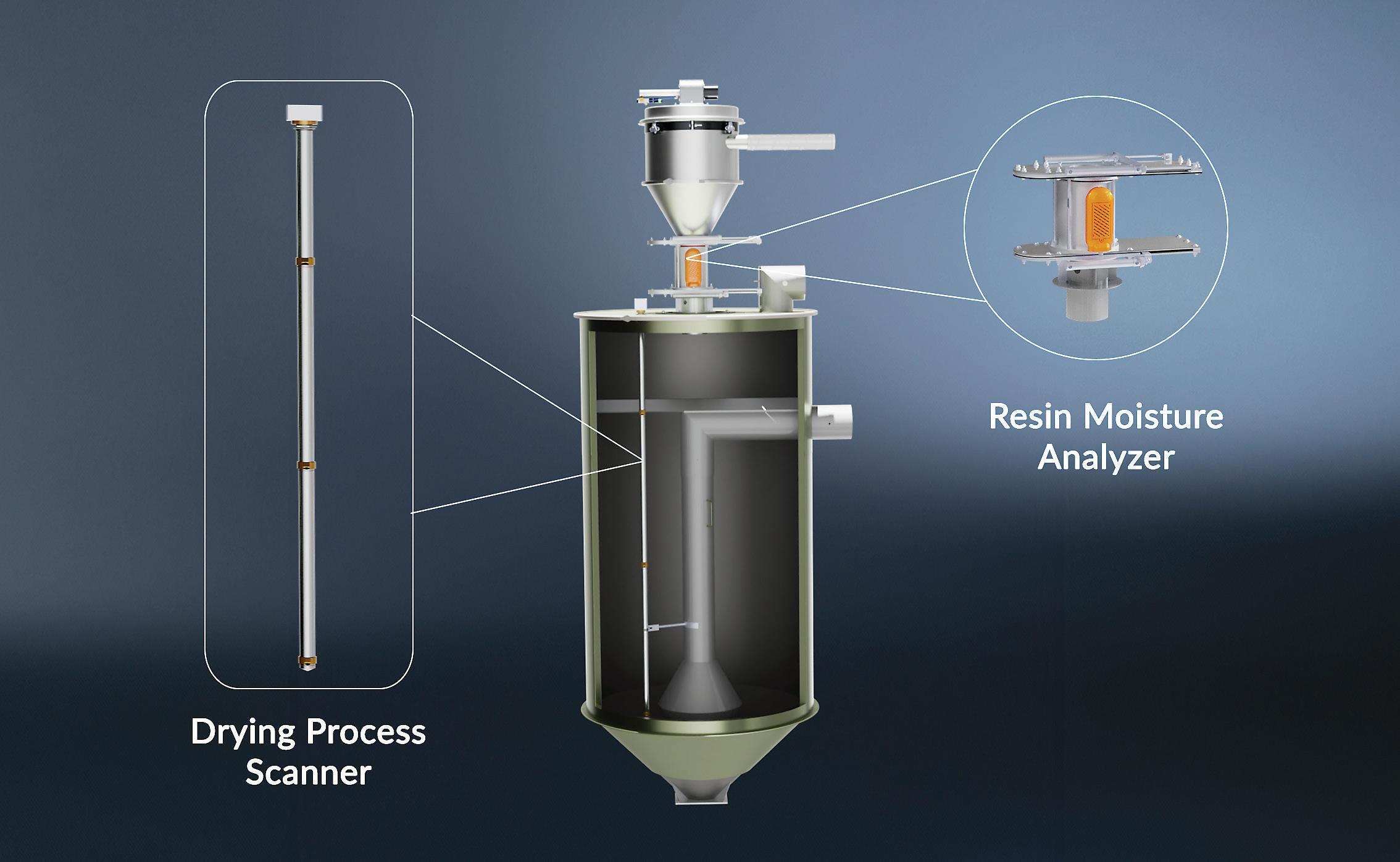

Novatec’s new DryerGenie technology is designed to take the guesswork – and the risks of underdrying or overdrying –out of drying, allowing processors to dry resin based on material condition, not the time recommended by the material supplier. “Until now, processors have had to rely on arbitrary drying times suggested by resin spec sheets, which are based on unknown moisture levels,” said Novatec president Conrad Besse mer. “Given that the moisture content of each batch of resin varies at the time it’s processed, adhering to a generalized set

time leads to significant inefficiencies.”

The DryerGenie features a resin moisture analyzer situated below the receiver and directly above the drying hopper that measures the incoming moisture level of the material and, depending on that reading, suggests the drying time/ residence time based on the dryer/drying hopper used. Inside the hopper, a drying process scanner measures the temperature and intergranular humidity – which

is the moisture released through the drying process – and adjusts as needed to airflow, dewpoint, and temperature. By incorporating real-time, AI-powered resin moisture sensing technology, DryerGenie ensures the resin is properly dried in the shortest time possible and with the least amount of energy consumed. “Each batch of resin is processed to perfection, and the technology can be integrated with many of Novatec’s new

dryers,” Bessemer said.

Piovan’s DPA compressed air dryers for hygroscopic polymers offer running parameters that can be easily loaded from the internal database, and with the use of desiccant cartridges can reach lower dewpoint values of up to -40°C or -40°F. The control manages the airflow in seven increments and adjusts the dryer’s functioning according to the material throughput, which avoids wasting energy and compressed air. Also, DPA dryers can be equipped with the IMD (Intelligent Material Drying) feature, which ensures an optimal management of the drying process, avoiding material overheating and thermal degradation. And thanks to the material database, the control automatically regulates the process condition once the material has been selected and the hourly throughput has been set.

Wittmann’s new Drymax plus is the latest generation of the company’s dual desiccant bed dryers. Key features include Wittmann 4.0 integration and a colour touchscreen display with AmbiLED sta-

tus indication. Wittmann also touted its Drymax central dryers at NPE2024, which are equipped with two desiccant beds and provide continuous high-quality process air. The addition of a premium dewpoint sensor allows for dewpoint-controlled changeover of the desiccant beds, which can reduce the energy consumption of the dryer.

In the end, drying tends to be vexing for even the savviest of processors, since overdried parts tend to be brittle, making them prone to breakage, while underdried parts can cause splay and an assortment of other problems. These new technologies can help you hit that sweet, very dry spot in between. CPL

RESOURCE LIST

Advanced Blending Solutions LLC (Wallace, Mich.); www.adv-blend.com; 906-914-4180

AEC (New Berlin, Wis.); www.aecinternet.com; 262-641-8600

Conair Group (Cranberry Township, Pa.); www.conairgroup.com; 724-584-5500

Auxiplast Inc. (Varennes, Que.); www.auxiplast.com; 866-922-2894

Dier International Plastics Inc. (Unionville, Ont.); www.dierinternational.com; 416-219-0509

Turner Group Inc. (Seattle, Wash.); www.turnergroup.net; 206-769-3707

Dri-Air Industries Inc. (East Windsor, Conn.); www.dri-air.com; 860-627-5110

Maguire Products Canada Inc. (Vaughan, Ont.); www.maguire.com; 905-879-1100

Moretto USA Corp. (Jackson Center, Pa.); www.moretto.com; 724-269-7600

Injection Depot Group (Markham, Ont.); www.injectiondepot.ca; 705-627-5456 FM Mécanique (Sainte-Anne-des-Plaines, Que.); www.fmmecanique.com; 514-953-5307

Motan Inc. (Plainwell, Mich.); www.motan-colortronic.com; 800-991-9921

D Cube (Montreal); 514-272-0500

Novatec Inc. (Baltimore, Md.); www.novatec.com; 800-237-8379

Piovan Canada (Mississauga, Ont.); www.piovan.com; 905-629-8822

Wittmann Battenfeld Canada Inc. (Richmond Hill, Ont.); www.wittmann-group.com; 888-466-8266

Register Now

SEPTEMBER 5, 2024

CANADIAN PLASTICS FALL CLASSIC GOLF TOURNAMENT

REGISTER NOW for the Canadian Plastics Fall Classic taking place September 5th, 2024.

Register early to take advantage of the early bird rate and guarantee your spot as we expect to sell out.

After a very successful tournament in 2023, we are returning to Piper’s Heath Golf Club with their award winning links-style golf course. The day will be filled with great networking opportunities, friendly competition, loads of prizes, and lots of great food and beverages.

Address:

5501 Trafalgar Rd, Milton, ON

For sponsorship opportunities, please contact Stephen Kranabetter 416-561-5362

skranabetter@canplastics.com

COMING TO NORTH AMERICA

Having made its name in the Indo-Pacific region, Bralco Advanced Materials is now offering its EMI shielding thermoplastic polymers to molders of automotive, aerospace, and electronics parts in Canada and the U.S.

By Mark Stephen, editor

Woody Allen once said that 80 per cent of success is just showing up. In that vein, a thermoplastic material supplier with a proven track record in the Indo-Pacific region is now hoping to make a big mark with molders in Canada and the U.S. by showing up here.

Bralco Advanced Materials Pte. Ltd., based out of Singapore and India, is a functional materials specialist that designs, develops, and manufactures electromagnetic, electrostatic dissipative, and carbon fibre-reinforced structural composites using advanced ceramic and magnetic materials. For plastics processors involved in the automotive, aerospace, and 5G telecommunications industries – of which there are a great many – the firm offers a range of thermoplastic materials designed to combat one of the great enemies of successful part molding: static electricity that damages electrostaticsensitive devices (ESD) and can even cause accidental ignition of flammable liquids or gases. “Electromagnetic interference, or EMI, happens when an outside source causes noise or interference in an electrical path or circuit,” said Bralco’s founder and CEO Amit Nanavati. “EMI can be generated from various things – such as wireless signals, electronic components, and power lines – and can disrupt the proper functioning of sensitive equipment. For electronic components that go into interconnected devices, EMI poses a big challenge to product performance, with consequences ranging from erroneous readings to permanent damage resulting in excessive equipment downtime and costly repair or total part replacement. Our EMI shielding materials, along with our ESD dissipative coatings, provide the protection that sensitive electronics need.”

FROM AUTOMOTIVE TO EMI

Nanavati – who has a background in international business and material science – founded Bralco in Singapore in 2015, and the company has built a solid reputation working with some of the biggest automakers in India, including Suzuki and Toyota, to reduce part weight and enhance performance with customized functional materials. In 2019, the firm took a big step beyond the auto sector when it signed a memorandum of understanding (MoU) with GE subsidiary GE Additive to develop 3D-printed magnets for applications in the aerospace, electric vehicle, medical, energy, and industrial automation industries. The MoU led Bralco to establish a research and development lab and product innovation centre in Singapore and set the stage for the company to become a service provider for magnetic 3D printing components in the Indo-Pacific region. “We developed and obtained a patent for a process to additively manufacture magnetic materials, and evolved into solving more general EMI part design problems,” Nanavati said. “And this led us into functional thermoplastic materials: We developed an EMI solution that uses ABS [acrylonitrile butadiene styrene] as the base matrix

Bralco’s founder and CEO Amit Nanavati (left) and director of strategic partnerships Emil Radoslav (right) meet with Canada’s Deputy Prime Minister and Finance Minister Chrystia Freeland.

material and reinforced it with different EMI powder fillers to make it more functional for processing. It’s available as filaments for 3D printing and pellets for injection molding, and also offers ESD and fire safety protection for automotive, electronics, aerospace, and other components.”

Staffed by a team with diverse backgrounds in material science, engineering, and technology, Bralco currently offers customized thermoplastic materials for a wide range of electronic applications, including high-temperature thermoplastics for components for the aerospace sector; EMI shielding solutions for electronic, medical, and aerospace parts; and solutions for automotive applications. “All of the properties of our materials are customizable, including elasticity and shore hardness, which is something our competitors don’t offer,” Nanavati said. “This level of customization involves a lot of discussion with the customer up front to learn about what properties they need, and we’re happy to do it.”

Having established a firm foothold in the Indo-Pacific region, Nanavati said, Bralco is ready to expand into North America, and has a careful strategy for doing so. First, the company has put boots on the ground by hiring Emil Radoslav, who’s based in southern Ontario, as its director of strategic partnerships. Second, it has begun attending North American trade shows, beginning with the Detroit Auto Show in September 2023. “Just before that, in June 2023, Amit and I met with some Canadian federal leaders, including Deputy Prime Minister and Finance Minister Chrystia Freeland, to discuss how our materials can be used in Canada’s aerospace, automotive, and 5G telecom industries; and also discussed with them our plans for establishing a technology centre somewhere in Canada,” Radoslav said. “And in February of this year, we met with senior-level defense personnel of the Office of Naval Research, within the United States Department of the Navy, at a meeting organized by the Singapore Space & Technology Ltd. organization.”

Gaskets for enclosures made with Bralco’s EMI shielding thermoplastic polymers.

CANADIAN CONNECTION

Although they’re casting a wide net, Bralco plans to target the auto industry initially, Nanavati said, to build up a North American customer base. “A good entry point for us is working with auto part molders on applications like battery casings,” he explained. “Once we get some traction in North America through automotive, where we can show proven success with components for Toyota and Suzuki, we want to expand into the aerospace components, satellite components, interior components for spacecraft, and defense electronics sectors, where we believe our ability to customize our materials will set us apart.”

And Bralco’s having selected a Canadian as its first representative in North America was no accident. “The U.S. is a bigger market than Canada, obviously, so we expect to do more business in the U.S., but we definitely want to keep Canada in focus,” Nanavati said. “I used to live in Canada, and I really

like the country and I know it well.”

Bralco still does all its product development in Singapore and its industrialscale manufacturing in Ahmedabad, India, and India currently remains its core market. “We have a very good standing in India, with reputable, regular customers, but we’re ready to take the next step, which is expansion into North America,” Nanavati said. “Electronic parts are becoming smaller and denser as far as the location of the chips and other electronic components in interconnected devices, and this proximity creates EMI issues that can hurt product performance. From ESD protection that prevents signal disruption to fire resistance and structural reinforcement, our materials can help ensure that products meet the highest standards of performance and safety.”

For Bralco, then, the plan isn’t just to show up in North America, but to put in the work to become a specialty material supplier of choice.

SIZE REDUCTION

Shredder with new pusher system

Rapid Granulator has made enhancements to its Raptor Duo Shredder with integrated granulator, including a newly designed reinforced pusher system.

The system has upgraded pneumatic cylinders, enabling the operator to increase output, and making the machine adaptable to more applications. The pusher body system now has an increased depth and reinforced side guides for support, to withstand irregular loads.

The system also offers preadjustable knives for optimal sharpness.

Rapid Granulator Inc. (Leetsdale, Pa.); www.rapidgranulator.com; 724-584-5220 DCube (Montreal); www.dcube.ca; 514-272-0500

Leap Green Polymers (Ottawa, Ont.); www.leapgreenpolymers.com; 613-286-4361

INJECTION MOLDING

Fifth generation machine

Absolute Haitian has introduced the fifth generation of its Haitian servo-hydraulic and Zhafir all-electric injection molding machines, with updates related to energy efficiency, performance, and intelligence.

The introduction of an electric screw drive for the screwrotate function as standard on the Generation 5 units with screw diameters up to 120 millimeters reduces overall energy usage by at least 20 per cent and enhances processing stability.

The Generation 5 machines also utilize the newly improved OPC-UA standard KEBA control interface (with intelligent diagnostics and support systems) to apply AI algorithms and sensor technology for enhanced energy management, accuracy, consistency, diagnostics, and support. Absolute Haitian Corp. (Worcester, Mass.); www.absolutehaitian.com; 216-452-1000

Barway Plastic Equipment Inc. (Rivière Beaudette, Que.); www.barway.ca; 450-455-1396

Belplas Inc. (Barrie, Ont.); www.belplas.com; 905-715-6068

Shadow Automation Inc. (Uxbridge, Ont.); 416-464-2070

CONVEYING

Dynamic railcar unloading control

Hamilton Plastic Systems’s new smart railcar unloading control integrates control function for multiple railcar unloading systems, airlocks, directional valves, and silo monitoring all into a single high-definition touchscreen display.

Hamilton’s railcar system automatically calibrates and re-calibrates to an ever-changing system, reducing labour costs, decreasing unloading times, and dramatically changing the amount of material in the system to maximize throughput.

The intuitive display allows authorized users to dynamically view and manage the entire process and make necessary changes on the fly.

The new smart railcar unloading control is also fully compatible with Hamilton’s existing railcar unloading control systems and Meridian 4 control panel. Hamilton Plastic Systems (Mississauga, Ont.); www.hamiltonplasticsystems.com; 905-890-0055

HOT RUNNERS

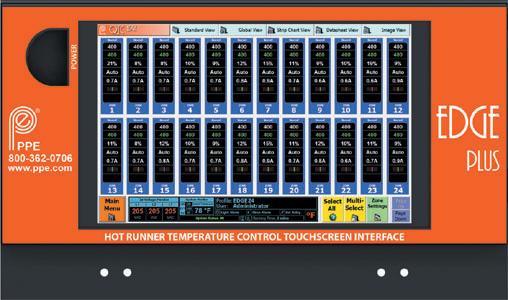

Fast-response controller

The new MCS hot runner control system from PCS Co. uses the latest technology to accelerate temperature and offers controller functions that can be operated safely, even by untrained users.

The machine’s fast control response makes it universally effective for the control of both standard hot runner systems and high-performance applications; and the integrated interfaces are designed to optimize communication between the controller and the injection molding machine, enabling comprehensive support and error detection functions that help reduce costs and downtime.

The standard controller range for the MCS hot runner control system is 6 to 120 zones, and molders can access data and control systems on-site or remotely, as needed.

PCS Co. (Tecumseh, Ont.): www.pcs-company.com; 800-521-0546

Dflex-Mag Inc. (Roxton Falls, Que.); www.dflexmaginc.ca; 514-762-3434

MATERIALS

Processing additive for PLA

Struktol’s TR 041 processing additive, an oleochemical derivative with no metal ions, has been shown to increase the flow of polylactic acid (PLA) by more than two times without reducing mechanical properties, and is an economical option for use in non-food contact packaging applications as well as bioplastic applications utilized in the agricultural and automotive industries.

With a shelf life of two years, the TR 041 material is designed to maximize the wetting to both a polar filler and a non-polar polymer – by wetting both surfaces, it allows a quicker incorporation of additives into the polymer matrix, decreasing mixing times, melt temperatures, and viscosity. Specific viscosity improvements have been seen with high-impact polystyrene. And because the acid value is quite low, the compound can also be used where stearic acid is a problem. Struktol Canada Ltd. (Newmarket, Ont.); www.struktol.com; 416-286-4040

Photo Credit: Gefo/Adobe Stock

Choosing the right rotational mold and moldmaker

By Greg Stout, Blue-Reed LLC

Rotational molding – rotomolding for short – is a specialized field that has a unique set of rules and guidelines to ensure that a product can be successfully rotomolded and achieve all the required specifications. It not only takes experience with the rotomolding process and with the companies who will be manufacturing the product, but also with materials and material flow, tooling, and a strong plastics engineering background to successfully design rotomolded products.

This column will focus on the mold tooling. For some rotomolders, choosing the type of mold and the company to make it is a routine task that doesn’t require any thought. “When we need a mold, we go to ‘Company XYZ’ and get a cast mold; that’s what we’ve always done and it’s the only type of mold we buy.” But that isn’t the best approach, since it doesn’t give any thought to getting the right tool for the job. The fact is, you have to look at price, aesthetics, and function in order to decide on the right mold for the finished product; and when choosing a rotational mold, there are three basic types of production molds available: fabricated, cast aluminum, and CNC-machined.

FABRICATED MOLDS

Fabricated molds are normally less expensive and are made either of aluminum or steel sheet metal. When fabricating with aluminum sheet metal, you have more textures to use than with steel. I used to tell my clients that if they didn’t care what the part looks like, or if it’s something buried in the ground where no one will see it, a sheet metal mold will do. However, there are some fabricated moldmakers that laser-cut the sheet metal and bend and fold the sheets to minimize welding of seams and economize production. These shops make rotational molds that are very high-

tolerance and rival any cast mold in the looks of the parts they produce. But they’re the exception, not the rule. Generally, the decision to get a sheet metal mold is made because it’s cheaper and doesn’t have complicated geometry. And sometimes, just the sheer size of a part calls for a sheet metal mold.

CAST ALUMINUM MOLDS

Next up are cast aluminum molds. These are the types of molds that provide the most flexibility in geometry and textures, and generally hold tighter tolerances than fabricated molds. They’re also the most prevalent of the molds used in rotomolding. The pattern or plug or wooden model that’s used to create the foundry tooling is CNC-cut, so a 3D CAD model is necessary. This means you can’t get the part made that you designed and drew as a sketch on a napkin – you must bring in a designer. And because you’ve hired a designer – as well as a pattern shop, foundry, machine shop, bench department, and assembly department – a cast mold costs more than a fabricated mold. However, the flexibility with geometry and the increase in tolerances make for an excellent part that will come out of the rotational mold. Also, because you’ve hired a designer, you can easily check draft angles, check for undercuts, and can run FEA (Finite Element Analysis) on the part to make sure it’s strong enough for the application and the material selected.

CNC-MACHINED MOLDS

The third type of mold is the machined mold – these are molds machined on a CNC router out of an aluminum billet. This type of rotational mold can be machined to very tight tolerances and has the same advantages as cast aluminum molds. These molds are very popu-

lar in Europe and are gaining more popularity in Canada and the U.S. every year. The size of the final part has some bearing on whether you select this type of mold, but even larger molds can be machined in parts and bolted and/or welded together to form the mold pieces needed. As mentioned, the tolerances are very tight and don’t require either a wooden model or foundry. And the pricing depends on the size and complexity of what must be machined.

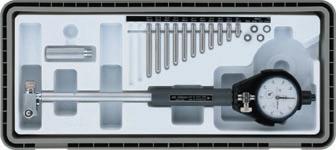

BRINGING IN THE MOLDMAKER

When deciding on a moldmaker, you must know what kind of mold you require, of course, and then determine which shops can manufacture it. I recommend asking around to find out what a particular shop’s reputation is in the industry and then reviewing examples of parts that have come out of their molds. Regardless of which type of mold they make, you’ll want to make sure they have some type of an inspection process. The better moldmakers will have inspection departments that use a Faro arm portable coordinate measuring machine and calipers to check dimensions on the mold and on the wooden model (if one is required), and will be able to generate a report if you request one. Not surprisingly, these are the types of moldmakers you want to deal with: professional, can give examples of their work, can recommend designers and model makers, and – importantly – can give solutions to molding problems that might be encountered before the mold is made. This is what you want to look for. CPL

Greg Stout is the president of Blue-Reed LLC, a rotational molding design consultancy located in Stow, Ohio. For more information, visit www.plasticproductdesign.com, or call 330-322-8707.

Convey. Dry. Load. All In One.

>> Space-saving footprint, sturdy easy-to-move cart.

>> Most popular, most sold dryer in North America.

>> Energy efficient desiccant wheel.

>> Easiest to set-up, easiest to operate touchscreen control.

Get it right, right from the start with Novatec.