The new Vivo! Touch is the first intelligent photo-quality label printer, capable of dynamically printing fullcolor labels on-the-fly directly from your production system or other database. The Vivo! Touch prints labels quickly, at up to 5 ips (25 feet per minute).

You can print labels at the touch of your fingers from its touchscreen interface, and even print labels without a computer, in standalone mode. This LED printer uses a unique micro-fine CMYK toner system and proprietary halftone screen to make beautiful labels with accurate color and precise dot placement.

Toll-Free 800-565-2216

QuickLabel.ca/Vivo

QuickLabel’s Xe series of thermal transfer color label printers can print color labels print in real time, ondemand or in batches. Designed to be integrated in-line with an existing packaging system, and to print labels from ERP systems such as SAP. Labels print with unique, product-specific content that varies from label to label such as color codes, barcodes, logos, expiration dates, best-by dates, and other serializing text, prompted fields, and databased information. Programmable host protocol, applicator mode, and “peel off” option. Prints labels and tags at speeds of up to 7 ips.

Toll-Free 800-565-2216

QuickLabel.ca/ Color

Need labels printed fast? Our QuickPrint™ Service will custom-print labels for you using QuickLabel digital label printers. Small quantity printing, fast turnaround, low minimum order, artwork assistance.

Toll-Free 800-565-2216

QuickLabel.ca/QuickPrint

QuickLabel’s Pronto! Barcode Printer Family offers more: built-in Ethernet, built-in web server, and high-speed and high-resolution barcode printer models. Printers come with Lifetime Warranty, QuickSwap™ Loan & Replacement Service, and 24-Hour Technical Support.

Toll-Free 800-565-2216

QuickLabel.ca/Pronto

Want a competitive quote on labels and ribbons? We offer low prices because we’re the manufacturer of our ribbons and barcode labels. We have more color thermal transfer ribbons than anyone in the world, including metallic gold, silver, white, and a rainbow of colors.

Toll-Free 800-565-2216

QuickLabel.ca/Quote

We’ve made history – of label printers that don’t allow you to “print your own color labels” from your production system. We’re introducing an intelligent label printer that allows you to print labels just as you would with a barcode printer – but in full-color, photo-quality:

>> Print labels directly from the touchscreen

>> Print in photo-quality, even at 5 ips

>> Print rolls of die-cut labels in any shape

>> Make more money with easy private labeling

>> Dynamically print color labels on the fly from any database

The Vivo! Touch puts intelligent label printing at your fingertips –from its touchscreen – and gives manufacturers the in-plant label printing flexibility you’ve been waiting for. To schedule an in-person demonstration, go to QuickLabel.ca/demo.

“Responsive to your needs”

Atlantic Packaging bring the innovation to you! Service TMDriven!

Entrust us with your business and let

Atlantic Packaging offers the largest number of facilities and innovation experts to respond to your needs. With 4 Innovation & Design Centres, two state of the art Graphic centres, backed up by a fully equipped testing facility, we are available to help develop new and unique methods for your corrugated packaging.

a novel way to package your product, a better way to protect your items, a new method to market your product, or simply a new way of doing things, we can help you develop ideas and solutions.

Whether it is a unique labour savings idea,

to find that creative idea that will help you attain your packaging goals.

At Atlantic Packaging we like to turn things upside down... inside out... backwards... forwards... and every which way in order

SEPTEMBER 2011

VOLUME 64, NO. 9

EDITOR

George Guidoni • (416) 510-5227

GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph • (416) 510-5228

AJoseph@canadianpackaging.com

ART DIRECTOR

Stewart Thomas • (416) 442-5600 x3212

SThomas@bizinfogroup.ca

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198

SDean@canadianpackaging.com

ADVERTISING SALES

Munira Khan • (416) 510-5199

MKhan@canadianpackaging.com

PRODUCTION MANAGER

Kim Collins • (416) 510-6779

KCollins@bizinfogroup.ca

CIRCULATION MANAGER

Diane Rakoff • (416) 510-5216 DRakoff@bizinfogroup.ca

EDITORIAL DIRECTOR

Lisa Wichmann • (416) 442-5600 x5101 LWichmann@canadianmanufacturing.com BIG MAGAZINES LP

Vice-President of Canadian

Alex Papanou President of Business Information Group • Bruce Creighton

It is somewhat of a conventional wisdom these days, especially in packaging industry circles, to think that the Canadian public is far more attuned to today’s multitude of pressing environmental issues and concerns than our American cousins south of the border.

While there are some elements of truth to this rosy notion, we should not get too smug.

In fact, a recent project sponsored by the global electronics and electrical engineering giant Siemens —ranking 27 major U.S. and Canadian cities on their environmental performance—raises more questions than it answers about how serious Canadian city-dwellers, accounting for 81 per cent of the country’s population, are about minimizing their individual environmental footprints for the greater cause of communal good.

Conducted by the well-respected Economist Intelligence Unit of The Economist magazine, the US and Canada Green City Index carefully scrutinizes the environmental performance of the randomly-selected metropolitan centers using a range of evaluation criteria that includes carbon-dioxide emissions, energy, land use, buildings, transport, water, waste, air and environmental governance to determine its rankings.

On the face of it, the five Canadian cities fare relatively well compared to the U.S., with Vancouver placing in the second spot behind San Francisco and Toronto coming in as the “ninth greenest city” in North America.

With Ottawa ranked in 12th spot, Calgary being 14th on the list and Montreal placing 19th, a casual observer may actually subscribe to the notion of Canadian cities being good examples of progressive environmental stewardship.

Alas, we think that would be a wrong conclusion to draw from a report that actually lowers the bar of expectations right from the outset by deliberately not including any European or AsianPacific cities in its otherwise very informative and enlightening report.

age higher than in Europe or Asia,” says the report.

“Energy is another challenge for many U.S. and Canada index cities,” the report adds. “Electricity use is high even when taking into account the underlying level of economic activity.”

It’s an even more unsettling picture when it comes to water usage, according to the report’s findings.

“[Although] U.S. and Canadian cities have efficient water infrastructure and robust policies regarding water conservation,” the study acknowledges, “nevertheless, their water consumption is twice as high as in other parts of the world.”

But there are bright spots, of course, which should not be overlooked.

Naturally, Vancouver gets most of the praise among the surveyed Canadian cities, ranking first overall in carbon-dioxide emissions and air quality, although it’s hard to shake off the suspicion that the city’s enviable location right on the Pacific Coast may have something to do with it.

“Perhaps even more impressively, Vancouver ranks in the top seven from all categories,” the report points out, “with an exception of environmental governance, where it ranks tenth.”

But that’s far ahead of Toronto, which ranks a lowly 24th in terms of environmental governance—dragging down a fairly decent showing in waste management (fourth place) and several other above-average scores.

For its part, Ottawa ranks third in land use and fifth in transport and carbon dioxide emissions, albeit low scores for environmental governance (again! ), energy and air quality pull down its overall performance closer to the middle of the pack.

While Calgary ranks first of all North American cities for water use, it fails to crack top 10 in any other category, while the highest rankings achieved by Montreal are for air quality (eighth) and carbon-dioxide emissions (10th).

or premium issues, which count as two subscription issues.

©Contents of this publication are protected by copyright and must not be reprinted in whole or in part without permission of the publisher.

DISCLAIMER: This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking speci c advice from quali ed engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its af liates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

PRIVACY NOTICE: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Phone: 1-800-668-2374 Fax: 416-442-2191

Email: privacyof cer@businessinformationgroup.ca

Mail to: Privacy Of ce, 80 Valleybrook Drive, North York, ON M3B 2S9 PRINTED IN CANADA PUBLICATIONS MAIL AGREEMENT NO. 40069240, ISSN 0008-4654

We acknowledge the nancial support of the Government of Canada through the Canada Periodical Fund (CPF) for our publishing activities. Canadian Packaging is indexed in the Canadian Magazine Index by Micromedia Limited. Back copies are available in microform from Macromedia Ltd., 158 Pearl St., Toronto, ON M5H 1L3

In respect to carbon-dioxide emissions, “The emission figures in both the U.S. and Canada are on aver-

So any way you look at the scores, it is hard to make a case for anything better than a middling glass half-full, half-empty scenario, which is arguably far less than ought to be expected from one of the world’s richest societies and most stable economies.

Multinational brand-owners and retailers can finally speak a common language when determining the environmental footprint of their packaging operations—thanks to last month’s long-awaited release of the final draft of the Global Protocol on Packaging Sustainability (GPPS) by the Paris, France-based Consumer Goods Forum international consortium.

Drawing on two years of discussion and pilot projects undertaken by some of the world’s largest CPG (consumer packaged goods) brand-owners, retailers and packaging materials suppliers and producers—including Walmart, Target, Tesco, Kraft Foods, Procter & Gamble, Nestlé and Unilever —the protocol provides a science-based measurement system to complement last year’s release of the forum’s original framework document titled A Global Language for Packaging Sustainability

According to the forum’s main two sponsors— Tesco chief executive Philip Clarke and Unilever chief executive officer Paul Polman—the metrics presented in the protocol will help companies to reduce the environmental impact of their packaging by providing a common language to address a range of business questions about packaging sustainability, either within a company or between business partners.

“One of the strengths of this project is how it has brought together so many companies and organiza-

tions from across our industry to work collectively on developing this common language,” says Polman. “Now we need to put the language to work.

“We are already doing so at Unilever and we are seeing the benefits.”

Adds Clarke: “Tesco is a responsible retailer who understands that packaging is important to its customers.

“We’re working hard with our suppliers to minimize the impact of our packaging on the environment, and having a common language will allow us to have the right conversations with our diverse supply chain,” Clarke explains.

uct shelf-life, cube optimization, ozone depletion and community investment.

Most of the metrics discussed in the protocol are comprehensively supported by examples of their usage and explanation of the methodologies and statistical analysis tools used to measure their impact on specific packaging designs and concepts. (See Graphic)

“We can then work with suppliers to reduce the environmental impact of packaging while making sure it still does the essential job it needs to do to protect the products we sell.”

The detailed document provides a wide spectrum of different measuring metrics— broadly grouped into environmental (attribute and life-cycle), economic and social indicator categories covering nearly 50 different criteria used to measure the full environmental footprint of packaging products from concept to end-of-life disposal, ranging from weight optimization and recycled content to prod-

According to the forum’s steering team co-chair Roger Zellner of Kraft Foods, the protocol incorporates many of the packaging sustainability guidelines developed by the European Organization for Packaging and the Environment (EUROPEN) with ECR Europe, along with and similar work on metrics for packaging developed by the Sustainable Packaging Coalition (SPC) in the U.S.

Says Zellner: “Our global collaboration has been a truly unique achievement, and now many diverse players have a common language and measurement tools for decision-making.”

The Global Protocol on Packaging Sustainability is available free of charge from the project website: www.globalpackaging.mycgforum.com

Leading Canadian forest products manufacturer Cascades Inc. says it is pleased with the efficiency and environmental improvements achieved at the Breaky Fibres mill operation of the company’s Cascades Specialty Products Group in the wake of a $3.7-million capital upgrade program launched at the Breakeyville, Que.-based facility last year.

According to Cascades president and chief executive officer Alain Lemaire, who visited the mill earlier this month to officially inaugurate the strategic investment, the upgrades already carried out at the mill will significantly enhance its product quality, while also protecting jobs.

“This investment shows our commitment to

maintaining our competitive edge in a down economy and a challenging market situation,” Lemaire said. “We believe that innovation is the key to our company’s growth.”

Started up in 1985, the Breakeyville plant specializes in the production of recycled deinked kraft pulp mainly used to manufacture the company’s fine papers, such as the Rolland Enviro100 product range. Since the modernization program began last year, the newly-expanded mill has been significantly upgradeD with the installation of a new flotation cell, several washers and thickeners, a disperser and a clarifier, as well the addition of several other major pieces of production machinery from other

Cascades manufacturing operations.

According to Cascades Specialty Group chief executive officer Luc Langevin, the quality of pulp produced at the mill has already vastly improved.

“We consider this to be a very significant benefit, especially as the quality of raw materials—the wastepaper to be recycled —is declining more and more,” says Langevin, citing a 50-percent reduction in the amount of visible dirt and glue residue in the deinked pulp, along with a slight improvement in whiteness.

“We believe this investment will allow us to remain competitive by continuing to offer highquality recycled products,” he adds.

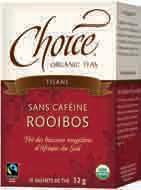

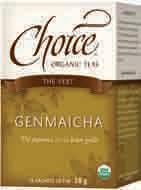

Canadian tea-lovers have long enjoyed a broad variety of choice when buying their favorite hot beverage, and now that choice has been extended to include 100-pecent organic and Free Trade-certified teas thanks to a recent launch of fully-bilingual packaging by the Seattle, Wash.-based Granum, Inc.

Originally launched in 1989 as North America’s first exclusively organic line of tea products, the company’s Choice Organic Teas line has grown over the years to comprise more than 75 different varieties of teas and herbal infusions available in teabags, tea-pyramids and loose-leaf formats—gradually winning over consumers on both sides of the Canada-U.S. border.

According to the company, the brand’s sales soared to new heights in 2000 when it became the first North American tea product line in the U.S. to become fully Free Trade-certified—finding a new responsive audience among socially-responsible and aware consumers in both countries.

But while it was widely available throughout the U.S., its original English-only product labeling had limited the brand’s distribution in Canada to a relative handful of specialty food shops and naturalfood outlets for whom a simple placement of stickers with dedicated bilingual packaging onto the folding-carton packaging was sufficient to satisfy the bare minimal requirements for marketing the products in Canada.

“It was not pretty, but it was acceptable for the existing customers in Canada,” recalls the brand’s head of sales and marketing AnneMarie Phillips.

But as the brand’s popularity continued to grow in this country, it hooked up with the Vancouver, B.C.-based branding specialists Fluid Communications Ltd. to make some of its more popular bestselling product fully-compliant with all the Canadian bilingual requirements.

“Replacing the stickered product with dedicated bilingual packaging has opened the door for Choice Organic Teas to offer the product to larger mainstream chains such as Safeway, thereby significantly expanding the company’s distribution,” says Phillips, adding most of the main elements of updated packaging were designed by the company’s inhouse creative department.

Since about mid-summer, the repackaged Choice Organic tea products—including Premium Japanese Green, Earl Grey, English Breakfast, Classic Black, Peppermint, Decaffeinated Earl Grey, Jasmine Green, Chamomile, Genmaicha and Rooibos tea blends—have been retailing throughout Canada at select Safeway and Whole Foods Market outlets, according to Phillips, along with a growing number of larger independent natural-foods shops.

“Our Choice Organic Teas line

has long enjoyed a growing popularity in Canada because of our high-quality, greattasting teas and our firm commitment to environmental and social responsibility,” Phillips states.

“Canadian shoppers are very sophisticated and health-conscious, so it was an easy decision to deepen our commitment to our Canadian customers.

“With our updated and new bilingual packaging, we will be better positioned to reach even more Canadians across the country,” she adds.

“We are really looking forward to expanding our distribution right across Canada.”

Outsmart Your Challenges: At Intelligrated, smart means meeting unique material handling challenges with proven technology tailored for your application. With the right combination of hardware, software, people and processes, Intelligrated keeps you ahead of the competition. Solving customer challenges. That’s the Intelligrated way.

Integrity. Committed. Innovative. Smart. The Intelligrated Way.

The new VB-Series Vacuum Lifter-Tilter from Anver Corporation is an electric hoist-based vacuum lifter combined with a pneumatically-powered 90-degree tilter to help reorient coiled products. Featuring an articulating handle with fully integrated controls and a vacuum gauge, this ergonomic liftertilter enables one person to pick up and load coiled products onto all types of assembly and packaging equipment—eliminating all manual bending, lifting and twisting. Employing a remote power station to ensure high continuous flow throughout operation, the Lifter-Tilter is offered in 250- and 500-pound capacities and with a wide assortment of suction pads and vacuum pad attachments, which can be custom-made by Anver to match specific load requirements.

Anver Corporation 401

The new H-400/H-600 Series thermal-transfer product identification and barcode label printers from Tharo Systems, Inc.—available in 203or 300-dpi (dots per inch) print resolution—feature a durable, all-metal construction with a cast aluminum center wall for added strength, with the large media window allowing operators easy viewing and monitoring of supplies. Standard features

include a high-speed USB 2.0 interface for super-fast data transfer, and a real-time clock for time- and date-stamping of labels with a wired Ethernet adapter, along with the standard Stripper Sensor that can be used for either strip-and-peel or tear-off applications. All printers are shipped with a free copy of the company’s EASYLABEL Start software for custom designing and printing labels, with all the label formats easily downloaded directly into the printers’ flash memory without using a PC device.

Tharo Systems, Inc. 402

The new AR-200 Series robotic case-packer from Premier Tech Systems is designed as a high-performance solution for automated packing of bags, bottles, cases, cans, bundles, etc. into boxes or any other rigid container, according to the company, with its robotic motion eliminating the need for flap holders. Featuring integrated machine vision technology that enables it to pick up different kinds of products in mutipick mode and randomly-oriented items before packing them into cases or other rigid containers, the system can use one or two robots, depending on application requirements, and is offered in standard version or custom-designed to the end-users’ precise application requirements.

Premier Tech Systems 403

Made from 100-percent recycled materials, the new Flexicomb flexible packaging from the Industrial Packaging Sector of Cascades Specialty Products Group is designed to provide an economical and eco-friendly alternative to conventional protective packaging materials, according to the company. Easily adapted to conform to

irregular shapes by employing patented FiberSmart technology, also available with a cohesive coating option, the new packaging effectively eliminates the risk of damage during shipping and handling of fragile and delicate products, while the new ThermaFresh protective packaging—jointly developed with Trans Industrial Packaging Ltd.—provides an innovative replacement alternative to traditional containers used for packaging fresh fish. Made of water-resistant corrugated paperboard, metallized paper film and paperboard honeycomb cells, the ThermaFresh packaging offers numerous performance advantages over traditional shipping containers, according to the company, including significant savings in shipping and product damage-related costs.

Cascades Specialty Products Group 404

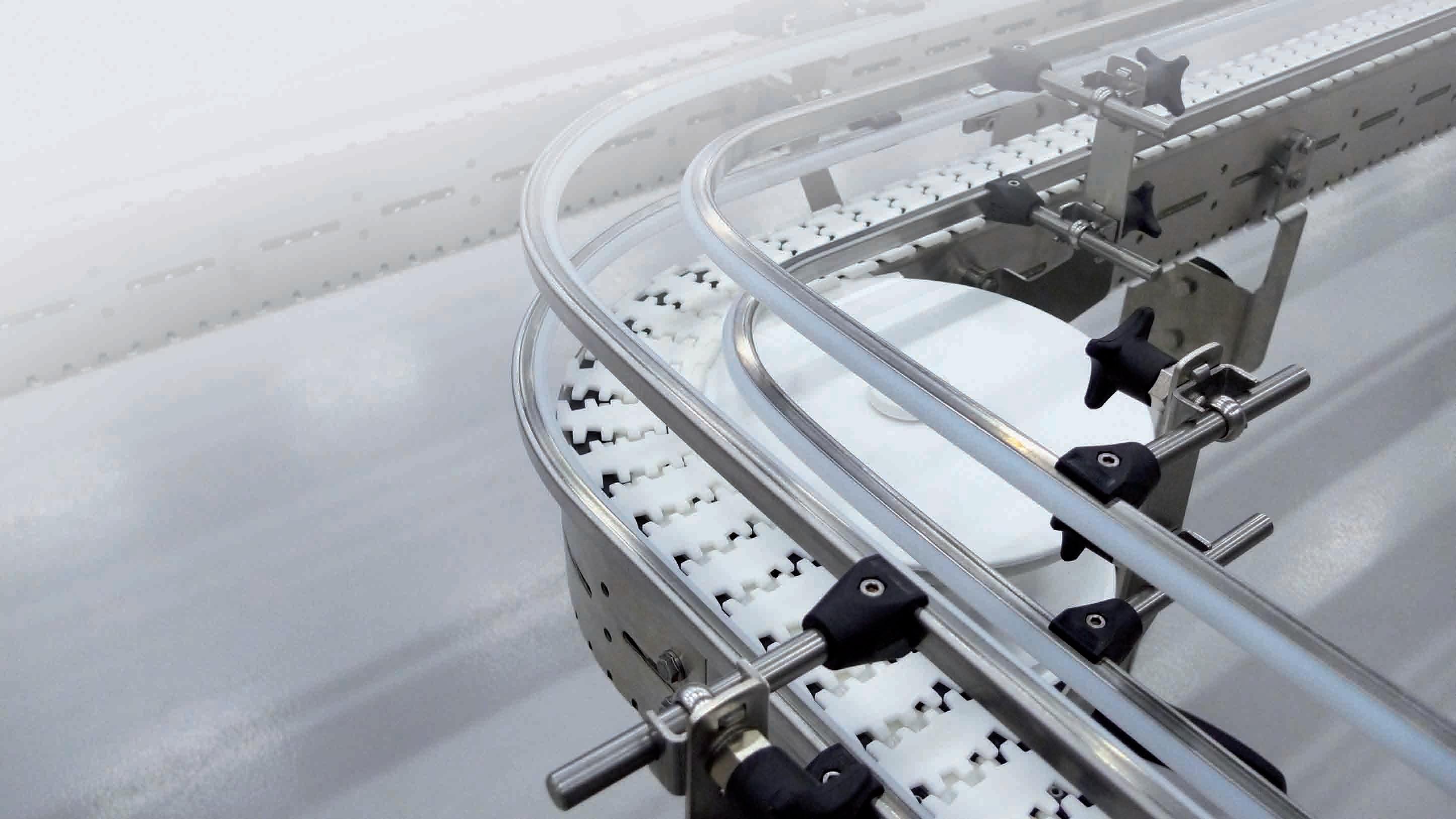

The new DynaClean conveyor system from Dynamic Conveyor Corporation are designed as flexible, reconfigurable alternatives to traditional stainless-steel, fixed-length conveying systems in food, pharmaceutical and other applications with stringent cleanliness and sanitation requirements, according to the company. Designed for quick-and-easy cleaning and sanitation and constructed from corrosion-resistant, nontoxic, non-absorbent and temperature-resistant materials, the DynaClean conveyors are custom-built to meet all the pertinent NSF, FDA, USDA and BISCC standards, and they can be easily reconfigured to include horizontal and multiple angle options such as 30-, 45- and 90-degree turns and inclines.

Dynamic Conveyor Corporation 405

The new VS Series shrinkwrappers from Douglas Machine Inc. are designed to provide an economical, small-footprint shrinkwrap solution by interfacing with existing tray-packers—including the Douglas’ Invex and Axiom tray-packing systems—to achieve throughput speeds up to 40 trays per minute. Incorporating single film roll technology to eliminate the costly maintenance problems associated with conventional cutting and sealing technologies, the system boasts the company’s proprietary heat-tunnel technology to ensure minimal graphic distortion and a tighter, more durable wrap for optimal product presentation and protection.

The new four-lane, multiaxis Digitronic Packaging Machinery, Inc. ensure high-accuracy filling of drink mixes, cocoa, soup mixes, coffee and other powders into rigid containers—incorporates a common hopper with a dual infeed flow, according to the company, while the addition of extra delivery lanes will enable packagers to achieve significant productivity gains in high-output production environments. Incorporating a special drawer-slide feature to facilitate the filling head’s easy removal from the conveyor for quick access to tooling and simplified changeover, cleaning and maintenance functions, the Series Digitronic auger filler is controlled via an intuitive touchscreen operator interface with user-friendly graphics and pop-up menus— enabling operators to make adjustments while the filling is in progress for optimal production flexibility.

Spee-Dee Packaging Machinery, Inc. 407

Designed for high-volume packaging lines, the new partition opener/inserter from the Packaging Machine Corporation tions into two cases simultaneously via servo-powered handling devices—incorporating servo-driven operation to blend the partition indexing/opening and inserting into one harmonious action

ing panels, thereby ensuring smooth insertion into the waiting case or tray.

A-B-C Packaging Machine Corporation 408

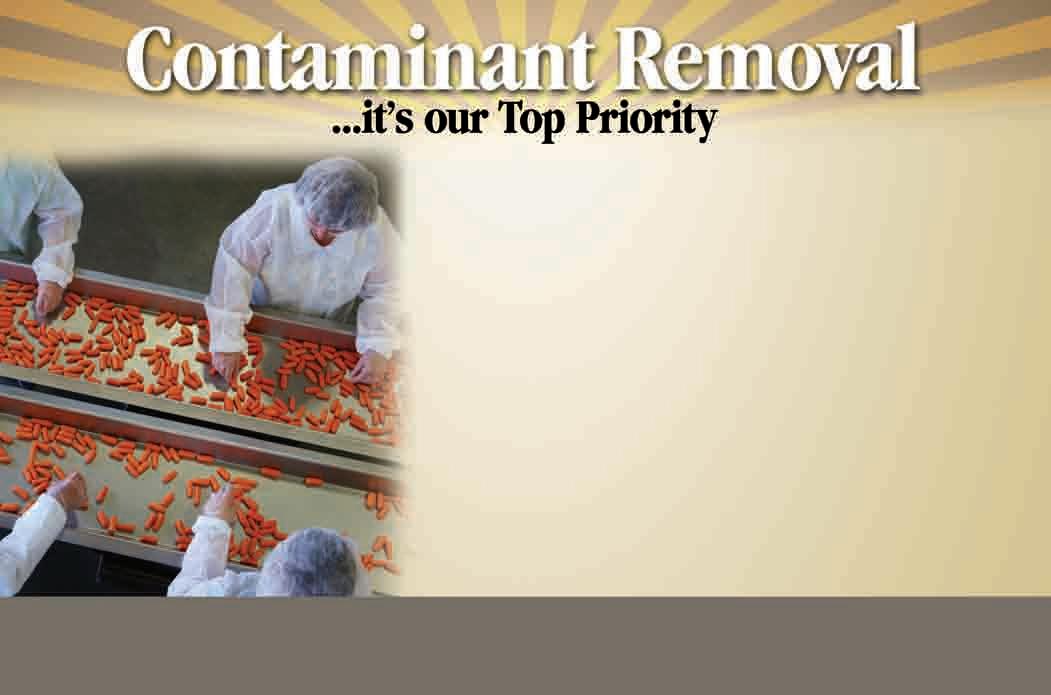

S+S Inspection Inc. completely redesigned its RAYCON X-ray product inspection system utilizing the latest low-energy X-ray source and sophisticated image processing software to identify metallic and nonmetallic contamination, flavor clumps, and missing components at rates of up to 600 items per minute, accord-ing to the company, making it ideal for a multitude of endof-line and in-process inspection of a wide range of packaged products, particularly in the food industry.

S+S Inspection Inc. 409

able operation and easy maintenance, the mechan-

ical trayformer from Eagle Packaging Machinery LLC can run a diverse variety of tray types—including stan- dard end-slot, side-slot and clamshell, with or without a lid—at speeds of up to 40 trays per minute. The machine’s built-in, quick size-changeover system ensures fast product changeovers, as well as a hopper option to enable nonstop production. Equipped with an Omron PLC (programable logic controller), a Nordson adhesive applicating system, and a color touchscreen interface for user-friendly adjustment of glue patterns and full access to all the machine functions—the Vassyo comes in a heavy-duty, welded steel frame to protect key performance features such sealed ball bearings in the blank transfer section with self-cleaning tracks, and venturi vacuum technology for smooth tray extraction from the hopper.

Eagle Packaging Machinery LLC 412

Our new generation of stainless steel conveyors are robust, modular and clean. Delivering high throughput, flexibility and gentle product handling that will boost your production e ciency.

And with over 700 employees worldwide and operations in more than 60 countries, you’re never far away from a FlexLink o ce. Contact us today at info.ca@flexlink.com or give us a call at +1-888-748-8677.

If eating cereal is the healthy breakfast option it is often touted to be by nutritional experts, then the recent launch of the Sally’s brand of cereals at 234 Walmart Canada stores across Canada last month could also be a welcome boost to the health of the country’s growing environmental movement— thanks to the brand’s partnership arrangement with TerraCycle Canada for the collection of its product packaging around the country.

The innovative program—modeled after TerraCycle’s similar arrangements with leading consumer goods manufacturers such as Kraft Foods, PepsiCo, Kimberly-Clark , SC Johnson, Nestlé and L’Oréal —aims to create 650 so-called Sally’s Cereal Bag Brigades in schools, charities and communities across Canada as collection sites for post-consumer Sally’s cereal bags to prevent them from ending up in landfills.

Instead, the collected cereal bags will be “upcycled” by TerraCycle to be turned into useful materials for manufacturing new consumer products such as tote bags, lunch-boxes, matting, fencing, outdoor furniture, waste and recycling bins, plastic lumber, and various kitchen and bathroom accessories, among others.

transfat-free cereals—containing no artificial flavors, saturated fat, hydrogenated oils, or high-fructose corn syrup—already have a smaller environmental footprint than most other cereal brands in the market because they are only packaged in bags, rather than in the bag-in-box formats that consume considerably more packaging materials.

The company’s arrangement with TerraCycle, whereby the designated school or charity will receive a two-cent contribution from Malt-OMeal and TerraCycle for each collected Sally’s cereal bag, will further lessen the environmental impact of the company’s manufacturing operations.

“Now we can take our commitment to sustainability one step further by partnering with TerraCycle to reduce our packaging waste by creating a second life for used Sally’s cereal bags,” Fisher says.

Founded in 2001 by a Toronto native and university dropout Tom Szaky, the Trenton, N.J.-based TerraCycle, Inc. estimates to have collected over two billion pieces of pre- and post-consumer packaging—ranging from drink pouches and chip bags to candy wrappers and diaper packaging—since the 2007 launch of its fund-raising Brigades, directly donating nearly $2 million to various schools and non-profit organizations through the program.

According to the brand’s manufacturer MaltO-Meal Company of Minneapolis, Minn., the Sally’s brand of all-natural, cholesterol- and

Aseptik, Canadian Packaging Buyer‘s Guide, 133 x 200 mm, CC-en24-AZ098 07/11

“Sally’s is committed to producing high-quality cereals in a way that minimizes environmental impacts and sustains natural resources for the future,” says Malt-O-Meal spokesperson Linda Fisher, adding the company also actively supports renewable energy by purchasing wind energy credits to offset 100 per cent of the electricity consumed in the production of its cereals.

Introduced to Canada in 2009, the Brigades program has since been extended to the U.K., Mexico, Brazil, France, Germany and several other countries in continental Europe, along with parts of the Middle East.

For all the packaging material substitution and innovation of recent years, glass is still class when it comes to the packaging of upscale

brands in many food, beverage, fragrance and cosmetics markets, as well as offering a pre-eminently sustainable packaging option thanks to the material’s inherent recyclability.

“Nothing communicates purity, quality and value to consumers like a well-designed glass package,” says Lynn Bragg, president of the Alexandria, Va.-based Glass Packaging Institute (GPI), whose annual Clear Choice Awards competition was founded back in 1989 to celebrate the multitude of performance and aesthetics advantages enabled by the use of glass in North America’s consumer packaging industry.

Announced earlier this month, this year’s Clear Choice Awards winners—judged on the basis of innovation (in container form and product category), package design (including container, label and closure), and shelf impact—include:

• Beer: Boulevard Brewing Co. for Tank No. 7 Farmhouse Ale

• Wine: Jackson Family Wines for Freemark Abbey 125th Anniversary Blend

• Food: Kensington & Sons LLC for Sir Kensington’s Gourmet Scooping Ketchup

• Carbonated Beverage: H-E-B for H-E-B Dr. B

• Non-Carbonated Beverage: Kyäni, Inc. for Kyäni Sunrise

• Organic Food or Beverage: TruBee Honey for TruBee Honey

• Distilled Spirits: Finlandia Vodka Worldwide Ltd. for Finlandia Vodka

• Flavored Alcoholic Beverage: American Vintage Beverage Co. for Calypso Bay Spritz

• Cosmetics or Fragrances: Oscar de la Renta for Espirit D’Oscar

• Conversion Recognition: Traders Point Creamery for Traders Point Creamery Cottage Cheese

“These winning package designs demonstrate that glass continues to be the ‘clear choice’ for consumers who want a package that complements today’s healthy and environmentally-conscious lifestyles,” says Bragg.

Affecting positive change on a global scale is a remarkable achievement for any business, and it’s even more remarkable for a company that’s only been around for 10 years—such as the pioneering bioplastics manufacturer NatureWorks LLC of Minnetonka, Minn.

As the world’s first commercial-scale producer of plastics made from renewable plant-based resources, NatureWorks has made a tremendous contribution to the cause of packaging sustainability over the years with the development of its Ingeo brand of commercially-available biopolymers derived from corn starch, which in recent years have been widely adopted by leading global consumer goods manufacturers, retailers and foodservice operators to produce a broad array of packaging products with extremely low carbon footprint—compared to the conventional petroleum-based plastics.

In recognition of those efforts, the United Nations Office for Partnerships and the Foundation for Social Change have recently short-listed NatureWorks as one of the finalist nominees for the coveted Leader of Change award—to be handed out at next month’s annual Global Conference for Social Change: Turning Social Responsibility into Business Opportunity event in New York City.

“We have nominated NatureWorks as a 2011

While packaging sustainability is often thought of as a fairly new movement limited mostly to rich industrialized nations, a new study from market researchers The Freedonia Group, Inc. of Cleveland, Ohio, predicts the global demand for green packaging products to rise by 5.7 per cent annually in coming years to reach US$212 billion by 2015, with the world’s emerging economies playing a key role in that growth.

“Overall, some of the fastest growth will be seen in Asia, specifically in India, China and Indonesia,” says The Freedonia Group report, which groups green packaging into three broad categories to encompass recycledcontent, reusable and degradable packaging products.

“Other developing countries such as Russia, Turkey, Brazil and Mexico are also expected to see healthy gains,” the report states.

While recycled-content packaging will remain by far the largest type of green packaging throughout the forecast period and beyond, according to the World Green Packaging study, its growth rates will be held back by the maturity of key recyclable packaging products such as metal cans and glass containers.

“Gains in recycled-content packaging will be supported by increased collection activity and processing capacity, coupled with greater use of recycled-content packaging by firms seeking to demonstrate environmental responsibility and differentiate their products,” the report notes.

Leader of Change because the organization embodies a compelling sustainability proof point,” says Louise Guido, chief executive officer of the New York-headquartered Foundation for Social Change.

“NatureWorks is not a long-standing, conventional company that decided to ‘go green’—this is a company actually founded, just 10 years ago, on the simple principle of selling sustainable performance products, giving contemporary industry a new way to do business, and offering today’s consumer a new choice,” Guido explains.

“And this early bet on environmental performance is clearly paying off.”

The prestigious nomination for the award— recognizing visionary executives of companies, financial institutions, and advocacy groups that have demonstrated an exemplary commitment to the pursuit of sustainability by embedding environmental and social performance in the organizations’ competitive strategy—has capped NatureWorks’ highly successful Ingeo Earth Month celebration this past summer.

Inspired by the United Nations Earth Day, the month-long event involved taking the company’s Ingeo Innovation Galleries showcase of low-carbon consumer product innovation to three locations in the U.S.—New York, Minneapolis and Boulder, Colo.—as well as to the international

“Demand for reusable packaging will be boosted by an acceleration in global manufacturing activity,” the report adds, “and degradable packaging will continue to see the fastest advances in demand, but will only account for approximately one per cent of the overall green packaging market through 2015.”

Accounting for 23 per cent of global sales of green packaging in 2010, the U.S. will continue to remain the

interpack and Chinaplas exhibitions, in Germany and China respectively.

Supported by major leading global ‘ambassador’ brands and retailers—including Bioserie, CocaCola, Danone, Earth’s Best, Electrolux, Elements Naturals, Frito-Lay, Henkel, Shiseido, Stonyfield, Target and Walmart —the seventh annual roadshow was the most successful one yet, according to NatureWorks president Marc Verbruggen.

“We created real interest and awareness around innovative and sustainable product innovation and have gathered the support of a number of leading organizations in the field, including LOHAS, Climate Action and European Bioplastics,” states Verbruggen, relating broad interest generated by the display of hundreds of everyday consumer product made with Ingeo fibers, ranging from plastic beverage cups to iPhone covers.

“Naturally, we are very honored by the nomination as a 2011 Leader of Change as well,” says Verbruggen.

largest single national green packaging market in the world “by a wide margin,” says the report, which also identifies Germany and Japan as large but “generally mature markets” with relatively slow demand growth.

Access the Global Packaging Network Accéder au réseau mondial de l’emballag e

Poultry processor breaks out of the box with packaging line automation and one-piece corrugated cartons

BY ANDREW JOSEPH, FEATURES EDITOR PHOTOGRAPHY BY COLE GARSIDE

Claiming perfection is not a mere idle boast for folks at Perfect Poultry Inc., but rather a daily pursuit of operational and packaging excellence that has enabled the Torontobased chicken processor to spread its wings at a very impressive pace despite some early turbulence and setbacks.

And if breaking into the highly-competitive business right at the peak of the Avian Flu epidemic back in 2004 may have seemed like a slight case of irrational exuberance at the time of a nationwide shortage of edible birds, it seems more like a stroke of genius today in light of the upstart’s steady rise through the industry ranks, especially in the challenging economic climate of the last few years.

“Hey, everybody’s gotta eat, even during these tough economic times,” says company co-owner and president Danny Rother, who founded the further processing operation jointly with his old pal Ian Segal, who oversees sales and purchasing.

“Once the Avian Flu crisis was over and we were able to ensure a steady supply of poultry, our business has grown steadily every year since,” Segal told Canadian Packaging on a recent visit to the

company’s 23,000-square-foot production facility in the city’s north end.

Employing 65 people to process and package fresh chicken drums, thighs, wings and breasts for major grocery chains across Canada, the company is perfectly content to focus on the further processing segment of the business, according to Rother, rather than developing its own consumer brands.

“We don’t have our own brands, and it was a conscious decision,” explains Rother. “We knew from the start that the poultry market is a very tough one, with many popular, respected and big-name companies involved, so we thought it might be a better business if we became a further processor, who also did the packaging on-site.

“What we do is ensure that we cut up the chickens into whatever cuts the customer’s order calls for,” he adds, “while ensuring we only supply the best chicken out there, which has been processed in a perfectly safe and clean environment.”

To back up that premise, the Perfect Poultry plant became a HACCP (Hazard Analysis Critical Control Points) -certified facility almost right from the outset, according to Segal.

“Being HACCP-certified lets our customers

Holding this year’s PAC Sustainability Competition Award trophy in his hands, Perfect Poultry co-owner Ian Segal is anked (from left ) by Roger Keeley, director of marketing for Atlantic Packaging Products; Perfect Poultry co-owner Danny Rother; and Atlantic Packaging sales representative Ken Fleming.

know that along with providing a high-quality product, we are also very serious about providing a safe product for the consumer,” says Segal, pointing out that cutting corners or doing just a bare minimum to get by is just not part of the company’s hardworking culture and philosophy.

“While it is true that we are always looking to streamline our production line in order to save time and money, we have absolutely no interest in cutting corners in any which way,” asserts Segal. “What makes this company a successful one is our competitive nature, our ongoing quest for efficiency, and our ability to always look after our customers’ needs by going that extra mile for them.

“We often have short turn-around times on orders, where a customer will call us up and tell us they need a certain product now,” he says, “and we always manage to get it done for when they need it.”

Although Perfect Poultry operates on an eighthours-a-day, five-days-a-week basis, overtime and extra shift are not a rare occurrence at the Perfect Poultry plant, according to Segal.

“We work until the job is done,” he proclaims.

Continues on page 14

“We don’t stop until the orders are filled.

“I think it’s our work ethic and attention to detail that has helped spur Perfect Poultry to its current level of success,” he reasons, “and since our worth ethic isn’t going to change, we expect we will continue to remain a successful and growing company.”

That also means making continuous process improvements in all of the plant’s operations, says Segal, citing a recent project focused on automating the plant’s secondary packaging operation— namely the placing of trays filled with fresh chicken cuts into the corrugated shipping cartons.

“Up until recently, we had five employees hand-

building cartons for us,” Rother recalls.

“It was a very time-consuming chore, and while it was working, it was not going to allow us to progress to the next level of production efficiency.”

To automate the process, Perfect Poultry sought advice from the Toronto-based corrugated packaging products manufacturer Atlantic Packaging Products Ltd., a long-established supplier of corrugated secondary packaging solutions for the food-and-beverage industries operating 20 manufacturing, warehousing and distribution facilities across Canada.

“We were very excited about working with Perfect Poultry to improve their packaging operations,” says Atlantic Packaging’s corporate director of marketing Roger Keeley.

“Before we became involved, Perfect Poultry had a two-piece carton and an assembly line, with a lot of people manning it, that just wasn’t as efficient as it could be.

“So we had our sales consultant Ken Fleming come in and take a look at the cartons they were using,” Keeley recounts, “and he discovered that if Perfect Poultry decided to utilize a one-piece, diecut carton, then Atlantic Packaging could help them save on materials and improve their throughput.”

Designed by Atlantic Packaging, the new onepiece boxes were not only engineered to help the plant save time and money, according to Keeley, but also to maintain optimal product protection and presentation.

As evidenced by the Silver Award won at this year’s PAC Sustainability Competition Awards of PAC–The Packaging Association this past spring, the new one-piece boxes more than merely fulfilled the plant’s expectations.

“This design enabled Perfect Poultry to go from a traditional two-piece poultry box to a one-piece carton with great success,” says Fleming. “Instead of hand-erecting thousands of units per day with four to five people, this customer went to a twoman crew operating a carton erector.”

Made from 100-percent recycled fibers and utilizing C-Flute liner for better stacking capabilities, the new one-pice, die-cut boxes combine impressive features such as hinged lids, vent holes and easy-lock closures to provide an optimal secondary packaging solution for Perfect Poultry’s requirements, according to Fleming.

Moreover, the one-piece boxes proved to be a perfect match for the new high-speed POPLOK case-erector—manufactured by the Miami, Fla.-based Eagle Packaging Group LLC and supplied via the Burlington, Ont.-based systems integrator Kraken Automation — which was installed at the plant in February of 2001.

Designed to run virtually any type of self-locking tray with or without a lid, from two-sided tucks to fivesided tucks, the new case-erector provided “a no-problem, hasslefree operation right from box one,” according to Rother.

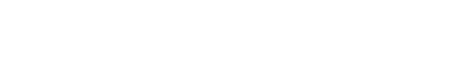

Controlled with an Omron PLC (programmable logic controller) and equipped with a color touchscreen HMI (human-machine interface) for user-friendly operation, the POPLOK machine employs standard Venturi vacuum technology for quick and gentle handling of the cartons’ flaps, with its interlocked safety doors helping ensure

a completely safe working environment for the machine operators.

Other equipment utilized at Perfect Poultry includes: a Bizerba weigher; a DLS tunnel metal detection unit from S+S Inspection Inc. (powered by a Boston Gear motor manufactured by Altra Industrial Motion, Inc.); an Alpha 86 WS model labeler from Weber Packaging Solutions, Inc.; two high-speed Galaxy traywrappers from ULMA Packaging; a Corr-Vac vacuum sealer manufactured by M-Tek, Inc.; and an S8 C2 model small-character inkjet coder from Markem-Imaje

“Becoming better automated has been very helpful for us,” says Rother, adding the company is currently in the process of installing a second production line at the facility to respond to growing production volumes.

“Not only has it allowed us to work with a better

corrugated package and a tray-erector that saves us time and makes us more efficient,” he sums up, “but we also feel confident that we will be able to service our customers more efficiently.

“It all seems perfect to me.”

Would you rather have promises or proof?

Their inkjet coders: many claims are just talk

you

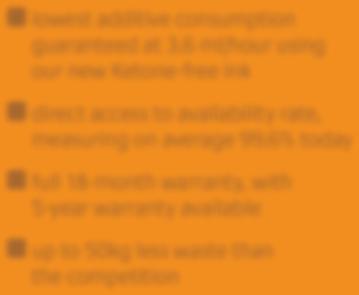

The new 9232 CIJ will change your perceptions of marking and coding, with benefits that lower your total costs over time:

lowest additive consumption guaranteed at 3.6 ml/hour using our new Ketone-free ink direct access to availability rate, measuring on average 99.6% today

full 18-month warranty, with 5-year warranty available up to 50kg less waste than the competition

Unlike other inkjets, our 9232 gives you built-in tools to prove our commitments in real time on the production line, not just talk.

That’s why we are:

ANDREW JOSEPH,

There’s nothing quite like having your cake and eating it, but it would certainly be a stretch to suggest that life is just one breezy cakewalk for folks working at the 45,000-squarefoot The Original Cakerie Ltd. production facility in Delta, B.C.

Not when you’re running flat-out, 24-hours-aday, six-days-a-week to produce over 150 SKUs (stock-keeping units) of high-quality cakes, dessert bars and other such sweet decadent creations sold across North America by leading supermarket chains like Costco, Kroger, New Albertsons and Save On Foods & More, along with specialty frozen-food stores such as M+M Meat Shops

Founded on the Vancouver Island in 1979 by Doug McFetridge and Kent Norris, the company has come a long way since its humble early days of operating out of a tiny 400-square-foot bakery— today ranking as the largest privately-owned dessert manufacturer in Canada, according to special products manager Ray McFetridge.

“In fact, The Original Cakerie is a leading manufacturer of European-style frozen-sheet cake desserts in both Canada and the U.S.,” McFetridge told Canadian Packaging in a recent interview, explaining the company’s relative anonymity that seems to belie its prominent marketplace status.

“It’s very true that many consumers have probably eaten one of our cakes, but have absolutely no idea who The Original Cakerie is because there is no company brand as such,” McFetridge relates.

“What we do is create cakes for our retail customers who resell them to consumers at their own shops.”

It’s a formula that has worked sweet wonders for The Original Cakerie, which had undergone numerous expansions at its British Columbia operations, according to McFetridge, while recently opening up a brand new $40-million, 140,000-square-

foot production facility in London, Ont., to improve its service capabilities for the eastern Canada and U.S. customers.

McFetridge relates that all of the company’s desserts are made using only pure all-natural products—with no artificial flavors or coloring—in accordance with strict, European-style focus on craftsmanship and quality to produce exceptionally upscale, gourmet-quality desserts such as:

• Tall 12- and 16-inch layer cakes made in cut or uncut half-sheet formats;

• Moist single layer dessert cakes, including the best-selling Triple Chocolate Fudge, Maple Chocolate Mania, Vanilla Caramel Swirl and Country Carrot recipes;

• Single-sheet dessert bars, including the popular Nanaimo Bars and Lemonburst Macaroons;

• The tiger-striped Triple Chocolate Chunk Brownie, produced in uncut sheet format.

Relentless emphasis on product and process innovation provide The Original Cakerie with a key competitive edge in the marketplace, asserts McFetridge, citing the company’s innovative combination and variety packs that combine four different single-sheet dessert bars and/or single-layer cakes in one convenient package.

“The Original Cakerie continually pioneers new ideas and directions to develop innovative new products to meet the present and future needs of our customers and their customers—the consumers,” McFetridge proclaims.

“And what allows us to provide our customers with the best quality and value possible is our commitment to ongoing research-and-development, coupled with our dedication to using the best production technology we can finds,” he adds.

A fine example of money being placed back into the company is its recent purchase of four new 3320 model laser coders manufactured by Videojet Technologies Inc. to mark important information on the corrugated cartons used to package the finished desert products, one per box.

opportunity arose in 2010 for us to update out coders here at our BC facility, I jumped at the chance to add a Videojet 3320 laser coder.”

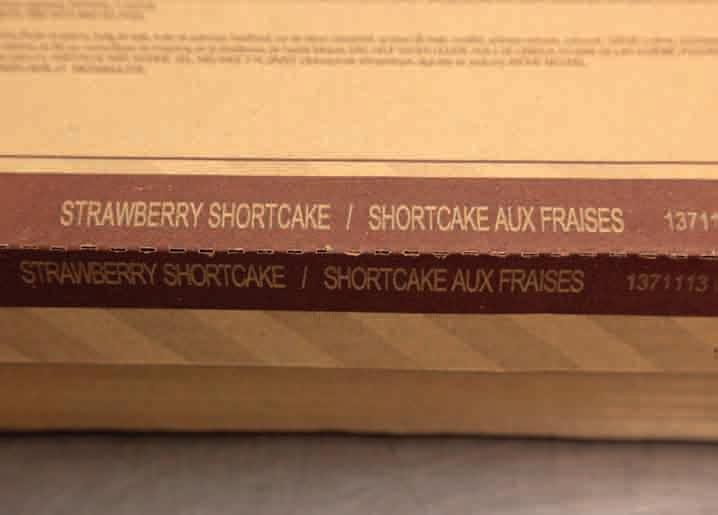

The Original Cakerie uses the Videojet 3320 laser coders to mark a fair bit of information—between 100 and 120 characters, including the product’s name in both English and French, the date code detailing when and where it was produced, and Kosher data—applying the coded message to two sides of the product’s corrugated package.

And it’s not just that the coding is now consistent and clear, but according to Videojet, the bakery has even cited one-year savings of $30,000 compared to the printing method it previously used.

McFetridge says that as the bakery redesigned its packaging to better accommodate all of the data it wanted on the packaging, it also decided to maintain a small footprint for inkjet marking.

“This allowed us to use either inkjet or laser marking on the same package,” explains McFetridge. “This also meant that the transition to laser coders was quite easy for us.”

McFetridge says The Original Cakerie first purchased three 3320 model laser coders two years ago at its London plant.

“I recognized that it is a very cost-effective piece of equipment that was able to consistently produce a quality image for us,” notes McFetridge, who was instrumental in overseeing the equipment purchase and production flow of the London plant during its initial set-up and deployment.

“As such, when the

Known as the fastest laser coder in its class, Videojet notes that its 3320 coder creates consistent, crisp marking even on high-speed production lines, and can easily work with any type of permanent marking requirements consisting of variable data onto virtually any type of substrate, such as corrugated, glass, rubber, labels and plastic.

Specifically designed for reliability and minimal operating costs—there are no conventional consumable costs for inks, compressed air or solvents, and it has an air-cooling system to prolong its laser tube life—the Videojet 3320 laser coder provides the user with thousands of hours of virtually maintenance-free operation offering standard linear and 2D bar codes, expiration dates, batch and lot codes, serial numbers, symbols, and manufacturer names and logos up to 1,300 characters per second.

Housed within IP-54 -rated stainless steel, the coder is easy to operate, offering control via a handheld device or by an on-line external method such as a PLC (programmable logic controller), PC or a host computer with Ethernet, USB or RS232/422, and it employs easy-to-use Windows-based SmartGraph software that also provides multiple

password-protected security.

And while The Original Cakerie utilizes the coder on a more linear production line, the 3320 has been designed to fit into crowded or tight spaces, capable of performing a 0-degree straight output or a 90-degree laser output, where the application head can be detached and positioned for intricate marking jobs.

“We have been very happy with the quality of output from our Videojet coders,” says McFetridge.

“There’s no ink consumables, it provides a nice clean copy that is better than what we previously had with ink, and we received some great help from Videojet with the startup, as well as their ongoing service.”

McFetridge credits the bakery’s dedication to constantly updating its technology for enabling it to maximize its automation technologies to not only save on time and money, but also to provide a better product, citing the addition of a custom-

designed flash freezing spiral conveyance system that ensures consistency and freshness in all its desserts.

McFetridge is also keen to applaud the dedication and work ethic of the company’s employees, many of whom have been with The Original Cakerie for over 15 years.

“Our success is attributed to incredibly delicious desserts made by exceptionally committed employees and on-going research into creating products our customers want,” says McFetridge.

“Our employees are our greatest strength.”

He adds that customers can also rely on The Original Cakerie’s dedication to quality control, as it follows the Good Manufacturing Practices protocol, is HACCP (Hazard Analysis Critical Control Point)compliant, and is moving toward being certified by the BRC Global Standards for food safety by the end of this year.

With all of the company’s high-end produc-

tion line equipment and innovative product recipes and employees, McFetridge says the bakery will always continue to raise the bar in delivering innovative products for its large customer base without sacrificing the company’s core values.

“There are many companies that try to imitate us and our products,” sums up McFetridge, “but the ‘Original’ is still the best.”

For More Information:

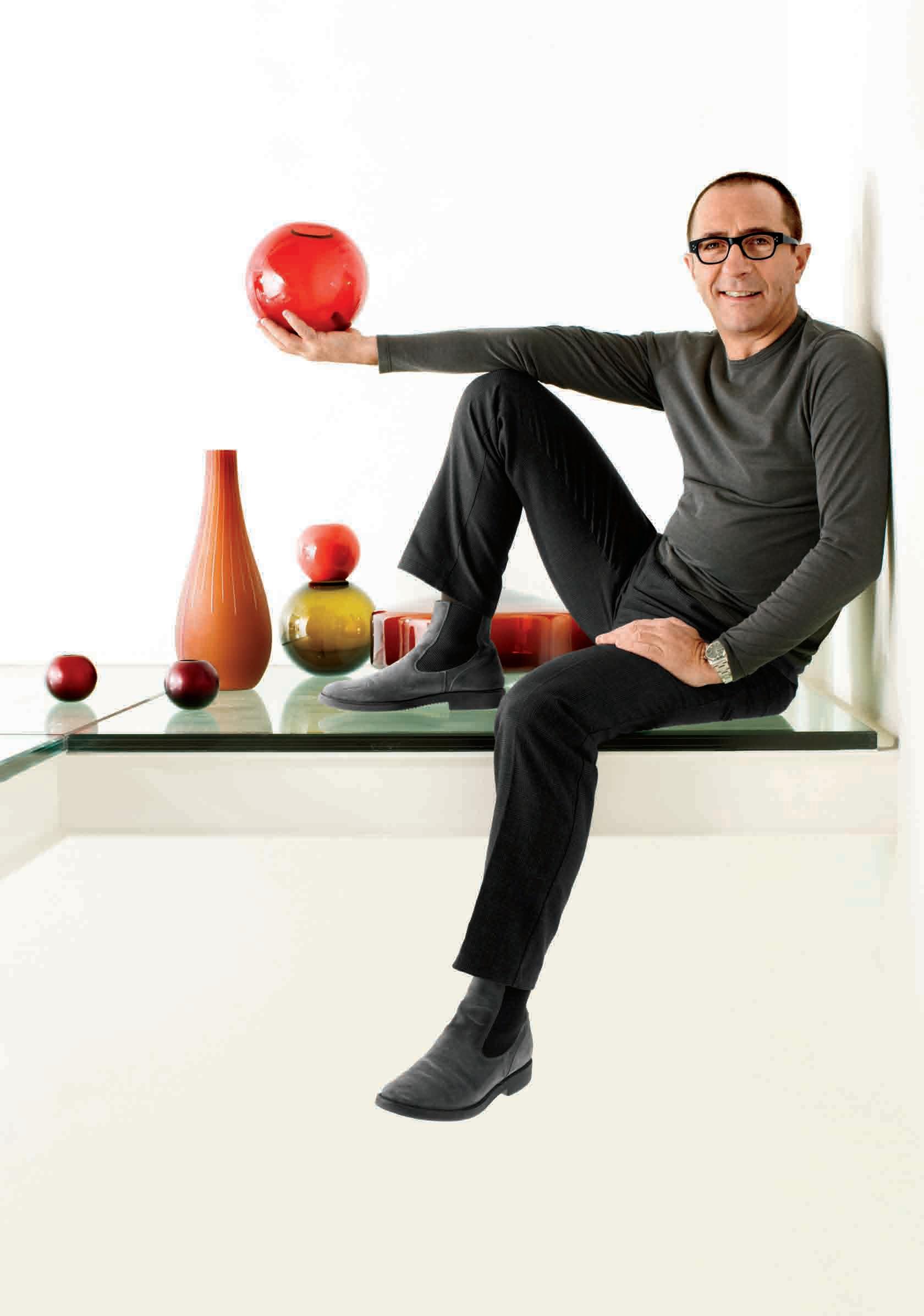

makers of beautiful, versatile, charismatic glass packaging

GlassIsLife.com

DESIGNERS KNOW GLASS IS MAGIC. Francesco Lucchese designs all kinds of things, but he has a particular soft spot for the fiery, glowing quality of glass. “It’s beautiful,” he says. “The way it catches light, the forms you can make, the way it feels in your hand…there’s something eternal about glass.”

ANDREW JOSEPH, FEATURES EDITOR

PHOTOS BY COLE GARSIDE

Keeping things pure and simple seems to come naturally for Carole-Ann Hayes, president of a fast-growing Ontario producer of high-quality soups, sauces and preserves made exclusively from locally-grown fruits and vegetables under the expert guidance from one of the country‘s best-known celebrity chefs.

Since starting up in 2009 under The Great Ontario Food Company banner—better known as Ontario’s Own after the filing of a formal ‘doing business as’ request—the Toronto-headquartered company has quickly acquired a knack and growing industry reputation for its ability to source locallyproduced food ingredients captured at the peak of their freshness to develop a mouthwatering array of soup mixes, stocks, purées, chilis and other wholesome creations with an unmistakable ‘home-made’ taste and texture profile.

“We did not want to call them ‘home-made,’ because we think this is now a much-abused term,” says Hayes. “We prefer to call them ‘lovingly prepared’ instead.

“That’s why we decided to use one of Canada’s top chefs, if not the top chef, to work with us on our plan to support Ontario’s family farms and local economies by offering foods that are grown close to home.”

Along with marketing specialist Hillary Graham, Hayes recruited Dan Donovan—a renowned chef who had recently worked as the executive sous chef at the Royal Ontario Museum in Toronto—as the company’s product developer.

According to Hayes, the fact that Donovan had learned the art of cooking as an apprentice to the world-famous celebrity chef and restaurateur Jamie Kennedy, who also happens to be a vocal supporter

Co-packer Sabatini’s Gourmet Foods helps procure only the best vegetables from select local farms for the Ontario’s Own brand of soups.

of using locally-grown and produced food products, made him a natural fit for the company’s ambitious plans and vision.

“The first thing we did was contact Jaime Kennedy to help us create the recipes,” recalls Hayes. “We were excited to work with Jamie since he was championing a cause we could really sink our teeth into, and he knows how to create authentic but simple dishes, which in some cases would be considered comfort food.”

Adds Hayes: “Jamie has an iconic status with local farmers because while he always creates great meals and it is always done with an eye towards supporting the local farmers, which is something that we strive to do with Ontario’s Own to make it unique in the marketplace.”

At the moment, Ontario’s Own is using Jamie Kennedy recipes for marketing three of its popular product lines: Chicken Noodle Soup, using Rowe Farms -supplied chicken; and Sauce Bolognese and Chili con Carne , with both products using tomatoes supplied by the Thomas Utopia farms.

Other products currently marketed under the Ontario’s Own brand label include:

• Tomato Soup, using tomatoes grown in the province’s southwestern-based Essex County;

• Roast Carrot Soup, using carrots grown at Carron Farms;

• Butternut Squash Soup, using southwestern Ontario butternut squash;

• Vegetarian Chili, using Persal Farms black turtle beans;

• Chicken Stock, using Rowe Farms chickens;

• Vegetable Stock, using Soiled Reputation Farm vegetables;

• Tomato Sauce, featuring tomatoes from Kerr Farms;

• Peach Puree, using Cherry Lane venture peaches;

• Pear Puree, using Andrewes Farm bartlett pears;

• Organic Pear Puree, using Filsinger’s Organic Foods & Orchards’ organic orchard pears. While Hayes says the company’s ultimate goal is to have all of its raw produce grown in Ontario one day, she points out that all Ontario’s Own

brand products already contain at least 98 per cent Ontario-sourced ingredients by weight.

To actually manufacture its products on a commercial scale, the company recruited the services of wellestablished nearby contract food manufacturer and co-packer Sabatini’s Gourmet Foods—a familyowned, 40-employee operation in northern Toronto that co-packs about 300 SKUs (stock-keeping units) of many popular private-label and brand-name food products, including soups, pasta dishes, dips, sauces, and various ethnic-cuisine offerings.

Hayes says Sabatini’s was highly recommended to her by several referrals as reliable, quality-driven third-party manufacturer and co-packer, with a wealth of experience in helping new food products find a place on store-shelves of major supermarkets and independent retailers.

“I am happy to tell everyone that Sabatini’s is my co-packer, although in truth I really like to think of them as my partner in this venture,” Hayes remarks, adding she is also appreciative of Sabatini’s increasingly helpful role in the actual sourcing and purchasing process.

“Ontario’s Own came to us in the summer of 2009,” recalls company president Umberto Sabatini. “And while they provided us with the recipes and the shopping list of which farmers to buy the ingredients from, it wasn’t long after that I took over dealing with the farmers directly.”

Founded by his father Giorgio back in 1975, the company has always managed to maintain unwavering commitment to high-quality produc-

tion methods and keen focus on combining prepared convenience foods with fresh ingredients and authentic taste by utilizing advanced packaging techniques and technologies, according to Sabatini.

“When we first opened our doors in 1975 we were operating out of a 3,500-square-foot room, but despite the small size of the operation we were completely dedicated to bringing forth a highquality product with a taste that would bring the customer back for more,” Sabatini told Canadian Packaging on a recent visit to the company’s Safe Quality Food (SQF) -certified facility, recently expanded to 16,000 square feet to accommodate the growing business, which also includes production of Sabatini’s own branded products.

Sabatini credits the company’s relatively early embrace of MAP (modified atmosphere packaging) methods and technologies to extend product shelf-life for giving it a strong competitive edge in the co-packing business, and Hayes wholeheartedly agrees.

“Although our products contain no preservatives, the way that they use our recipes to make the food and package it provides an unopened jar with— depending on the product—a shelf-life anywhere from three months for the soups and up to two years for the purée products,” says Hayes.

While most of the products made and co-packed at the plant are packaged in plastic trays, Sabatini’s also utilizes various types of pouches, aluminum trays and glass jars, with the latter being the packaging of choice for Ontario’s Own products.

“We like the glass jar look,” Haye states, com-

Continues on page 22

With Cognex, every read is an easy read.

Patented IDMax® technology allows Cognex readers to successfully read codes that other readers cannot. Regardless of code quality, size, marking method or material, we can read it!

1DMaxTM is our best-in-class reading tool optimized for omnidirectional barcode reading and can handle extreme variations to achieve unsurpassed read rates. Cognex 2DMaxTM technology helped trigger the adoption of 2D Data Matrix and QR coding in many industries.

Combined with the best performing hardware available, in both handheld and fixed reader formats, any code can be read quickly and reliably.

Which makes using Cognex an easy choice.

To find out more, download the “10 Reasons to Choose Image-based ID Readers” guide from www.wecanreadit.com

Continued

plimenting the high quality-finish of 725-gram glass jars made by leading packaging glassmaker Owens-Illinois, Inc. (O-I) and supplied to the Sabatini’s plant by Richards Packaging Inc. along with the lidding.

“It presents a more traditional look to our products, one that actually looks like it comes from a farmer rather than a big conglomerate,” says Hayes, while lauding the inherent recyclability and other sustainability virtues of glass packaging in general.

To give the jars a matching complimentary look, Hayes turned to the services of Toronto-based branding services specialists Watt International Inc. to create an attractive label that would help capture consumer attention at the shelf level, while conveying the branding theme of food being carefully grown, picked, preserved and delivered in traditional ways—from farmers right to the consumer.

“When Ontario’s Own first approached us, I knew this was a project we wanted to be involved with,” recalls Watt’s executive vice-president of creative and client services Randy Redford.

“And after our initial meeting, I decided to take on the project myself,” says Redford, who played a key role in developing the brand name, logo and packaging concepts in time for the products’ May 2009 launch.

“The white label has simple black lettering combined with bold color photography of the main ingredients, while still presenting the consumer with a large amount of viewing space to see the product inside the glass jar.

“It is very sharp-looking; it really stand out on the shelf to grab the consumer’s eye,” Sabatini states.

He’s not the only one to think so.

At the recent national PAC Leadership Awards competition of PAC-The Packaging Association earlier this year, the Ontario’s Own brand pulled off a remarkable double feat— being selected as a Gold Winner in the New Product Launch segment of the Brand Marketing Category and as winner of the prestigious Best-of-Show PAC Packaging Award, earning special praise for the product’s positioning as a socially- and environmentally-conscious quality brand.

The Sabatini’s plant employs a PL-521 horizontal wraparound automatic labeling machine—manufactured by the Taiwan-based Pack Leader Machinery Inc.—to dress up clear glass jars after filling with the award-winning labels, which are flexographically printed by Burlington, Ont.based Techmark Labels on a Scout model narrow-web press manufactured by Mark Andy, Inc.

While Ontario’s Own is still a very young brand, Hayes says she’s pleased with the fact that it now retails in the province of Ontario from as far west as London to Whitelake in the east through select Loblaw and Metro supermarket locations, while becoming a much sought-after product at many smaller specialty grocers such as Pusateri’s Fine Foods, Pusateri Fruit Market , Longo’s, Remark Fresh Markets , Nature’s Emporium , Garden Basket , Michael-Angelo’s Gourmet Foods, McEwan Foods, Organic Garage, Multiple Organics , The Sweet Potato, Green Earth Organics , Harvest Wagon , The Big Carrot , Summerhill Market , The Health Shoppe, The Village Grocer, Vincenzo’s and Castlegarth

According to Redford, the package labeling created by Watt aims to relate the brand’s position as a product that would support local Ontario farmers; provide Ontario families with better choices; leave the smallest environmental footprint possible; and contribute to the financial fortunes of local farmers, processors, distributors, retailers and restaurants.

“I really like how our labels feature the name of the farm that produced the main product ingredient,” says Hayes.

Adds Sabatini: “All of us at Sabatini’s really love the labeling.

“It really does make you think of a fresh farmer’s product,” he says.

“Despite having two renowned chefs creating recipes, the Ontario’s Own brand really isn’t just about the recipe for us,” states Hayes.

“The product source, and how you make the product and package it are equally important to us,” she concludes. “And Since Sabatini’s helps us do all that—dealing with the farmers, sourcing our jars, manufacturing the product and applying the labels—we could not be happier about having them as our co-packer of choice.”

Canadian family-owned and operated carton manufacturer

Ingersoll Paper Box believes excellent customer service and top-line equipment have allowed it to grow into a well-established and highly successful foldingcarton company.

BY ANDREW JOSEPH, FEATURES EDITOR PHOTOGRAPHY BY COLE GARSIDE

he paperboard manufacturing industry has always been a keenly competitive sector made up of ambitious companies playing with razor-thin margins—requiring meticulous attention to detail and ever-changing customer expectations to ensure long-term success—especially in these challenging economic times.

Fortunately for the family-owned Ingersoll Paper Box Co., Limited of Ingersoll, Ont., such harsh realities of life are nothing new.

Since starting out back in 1922 under the Ingersoll Cone and Box banner as a niche producer of icecream cones and boxes, the company has managed to keep earning its special place in the Canadian foldingcarton industry for nearly 90 years through unwavering commitment to top-class customer service, high product quality, and a long-nurtured competence in short-run production, according to the company’s managing director Sarah Skinner, the granddaughter of company founder Robert Skinner.

“We currently manufacture and sell only folding cartons,” says Skinner, explaining that the original ice-cream box business was sold off in the 1930s.

“But in January of 2011 we began manufacturing our own corrugated boxes for our own shipping purposes, and we plan on developing that into a separate business in 2012,” Skinner told Canadian Packaging on a recent visit to the 85,000-squarefoot facility employing 70 people to produce a diverse array of straightline boxes such as reverse tuck, straight tuck and universal bottom; automatic bottoms also known as crashlock; four- and six-corner boxes; and blister cards.

In addition, Ingersoll offers a comprehensive

array of services such as computer-aided design (CAD), printing, embossing, folding and die-cutting, relates Skinner, to serve a diverse customer base in the automotive, food, healthcare and pharmaceutical industries—offering flexible production runs from as small as a few thousand pieces to multiple millions of cartons.

“Our North American customer base has been built around the concept of service,” states Skinner. “We give the ultimate in customer service, but we also demand the same from all of our suppliers.

“Being a smaller-sized company without a lot of hierarchy and bureaucratic red tape, we have the ability to make the quick decisions and the skill to provide the customer with whatever they require and when they require it,” says Skinner, adding that superior customer service is vital in an industry where there is always someone willing to promise to do a job cheaper.

Says Skinner: “If you know what you are doing and can do it right every time, one-time customers quickly become return customers, as we know that this type of service capability goes a long way in making us who we are.”

Asked to explain the company’s impressive longevity, Skinner is quick to give credit to her dedicated employees.

“They really are a great bunch of people,” she states. “We have a large number of long-term employees who all take their job very seriously: We all have the same goals when we come to work, and we all want to make sure that the customers receive exactly what they are asking for and more.”

Naturally, maintaining those exceptional services and constantly improving the quality of the final product requires continual investment in advanced boxmaking and converting technologies, and Skinner

Continued from page 23

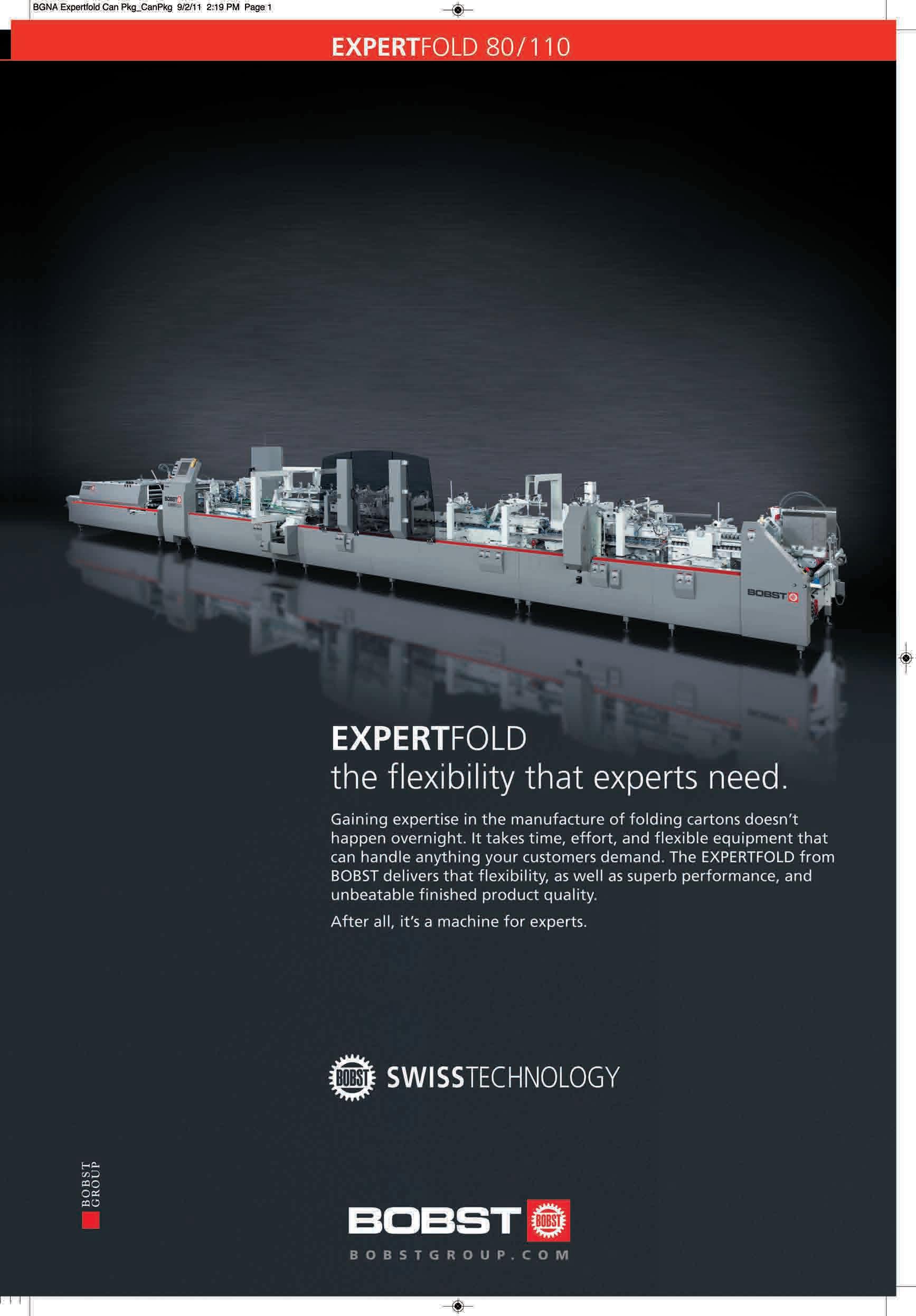

has no hesitation in procuring new machines and technologies from bing-name industry leaders such as the Bobst Group, headquartered in Switzerland.

Just this past May, the Ingersoll Paper Box plant installed a new Bobst Experfold 110 A-2 highspeed folder-gluer that Skinner says replaced some older antiquated equipment, while significantly increasing throughput capacity.

Because the plant already had two other Bobst gluers operating in the same department, there was a minimal learning curve and production slowdown due to the arrival of new equipment.

“The Experfold was set up and running by Bobst within a week, and our guys on the shop-floor had no problems learning the new features of this machine,” Skinner recalls.

“The Bobst trainers really know what they are doing, and they were very easy to get along with.”

To optimize the new folder-gluer’s performance, the company also purchased a Bobst Handypack GT semi-automatic collection table for collecting and packing cartons, along with a VCX Gluing and Quality Assurance glue system option from Valco Melton —ensuring optimal quality control for the glue patterns and application of the Resicol X-697 Blue adhesives supplied by Halltech Inc.

“The machine has notably reduced our initial set-up times, while allowing us to run at a significantly faster speed,” Skinner reveals.

“We know that customers are always going to request shorter and shorter turnaround times, and using the Expertfold allows ourselves the time we need to meet their demands.”

One of the new folder-gluer’s more exciting capabilities, according to Skinner, is its unique Bobst AccuBraille application system for generating onpackage information that can be read by the visuallychallenged consumers, along with a special Braille verification system that is claimed to the only one of its kind currently operating in North America.

To create the Braille messaging on the cartons, a metal band with raised nodules is added to the Expertfold to apply pressure to the metal band as each paperboard carton passes by.

According to Skinner, it is easy to set up and it provides reliable, cost-effective Braille dot definition over the entire length of the run.

After each carton has the Braille messaging applied to it, a Valco Melton CaptorT system uses high-speed CCD (charged-coupled device) camera technology and custom lighting to produce over 10,000 images per second of the carton area.

Utilizing sophisticated image analysis algorithms, the system’s software evaluates the entire image and identifies any specific failures such as a faulty carton, incorrect Braille, or insufficient adhesive.

In addition, Valco Melton’s OT-120 control package is a touchscreen data entry system that uses simple pictograms and market-specific program symbols for very fast set-up and changeover on the Experfold machine, according to Skinner.

“I would say that purchasing the new Bobst Experfold with the inline Braille application and verification system has been our latest and biggest innovation to date,” states Skinner, saying several of the company’s important pharmaceutical clients have provided glowing feedback on the high-quality Braille codes produced with the new technology.

“The old way of applying Braille to packaging has been completely revamped with the Expertfold foldergluer,” Skinner extols. “Until we purchased this system, we had been performing this function via one of our Bobst die-cutters.

“But because of the high tooling costs involved in applying Braille that way, we were looking for an alternative solution, and we were happy to discover that Bobst still had the right solution for us.”

Some of the other notable features incorporated into the Expertfold folder-gluer include a Schneider Electric power and control panel, Baumüller servo motors, and Festo pneumatic components.

Other key production equipment employed at the Ingersoll Paper Box includes:

• a Bobst HandyPack Alpina 110 folder-gluer;

• a Bobst Media 100 II gluer;

• two Bobst SP 102-SE die-cutters;

• a SP 102-E Autoplatine automatic flatbed die-cutter;

• two manroland 700 printing presses;

• two 3M-Matic case-sealing systems from 3M Company;

• a Phoenix Innotech stretchwrapper;

• a Marsh PatrionPlus large-character inkjet printers from Videojet Technologies Inc.;

• a Mx12 ink formulation and dispensing system manufactured by GFI Innovations, Inc. and maintained by Sun Chemical via Sun’s GFI ink dispensing program, with Ingersoll being the first sheetfed printer to sign up to the program, according to Skinner.

“Back then a rush order was a rush order just as it is today, and being first-to-market was no less important then than it is now,” she asserts.

Says Skinner: “As much as business has changed over time, I think the demands in 1922 compared to those in the 21st century would all be relative to the time.

“Our reputation as a trusted supplier, and our business itself, has grown directly as the result of the success of our customers’ own success in their markets,” she concludes. “We know, just as they did back in 1922, that our customers depend on us to do the job right and do it right on time—and that’s something that we are always determined to do very well, whatever it takes.”

Bionics-based automation technologies promise a wealth of new possibilities for future manufacturing and packaging line ef ciencies

BY ANDREAS SOBOTTA

For today’s manufacturers, being competitive globally means we have to think differently from the way we used to—we need to really start thinking outside the proverbial box.

Unfortunately, what we still see a lot from our customers is the same old obsession with immediate savings. They typically come to us and say, “Here is my process. Can you sell me this part that I have been using for the last 20 years, for a lower price?”

This is the wrong approach because when it comes to providing successful automation, we are not talking about products—we are talking about technology.

That is the mindset we hold dear at Festo AG & Co. KG in Esslingen, Germany, a privatelyowned company that has amassed sales of well over $3 billion since it was founded in 1925.

Today the company has 58 national headquarters supporting 180 countries, with more than one million square feet of production space worldwide.

Continues on page 28