Ryson makes a full line of spiral conveyors that can satisfy most vertical conveying needs. Ryson Spirals need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Unit Load Spirals convey cases, totes and packaged goods smoothly on our slat style belts and are available in 8 standard slat widths ranging from 5”to 26”.

Mass Flow Spirals handle full and empty bottles, cans and jars in mass up to 2000 units per minute. Available in 4 different slat widths ranging from 10” to 20”.

Narrow Trak Spirals are new super compact spiral conveyors designed to handle your smaller loads and can run at speeds in excess of 200 fpm. They can be configured for end or side tranfer, with products being conveyed in a single file or in a continuous mass flow.

Visit Ryson Booth N-5528

High Capacity Spirals are in response to our customers need to go higher and handle more weight. The load capacity is 75 lbs. per linear foot of conveyor with speeds up to 200 FPM.

Multiple Entry Spirals The Multiple Entry Spirals allow loads to enter the spirals from several different elevations. A new high speed induction conveyor provides controlled spiral entry.

Quality and service come first at Ryson. We are the number one spiral manufacturer in the USA. For application assistance or more information, give us a call or visit www.ryson.com

OCTOBER 2016 VOLUME 69, NO. 10

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph (416) 510-5228 AJoseph@canadianpackaging.com

ART DIRECTOR

Katerina Maevska • (905) 713-4389 kmaevska@annexweb.com

PRODUCTION MANAGER

Barb Vowles • (416) 510-5103 BVowles@annexbizmedia.com

CIRCULATION MANAGER

Anita Madden • (416) 442-5600 x3596 AMadden@annexbizmedia.com

VICE PRESIDENT

Tim Dimopoulos • tdimopoulos@annexbizmedia.com

PRESIDENT & CEO Mike Fredericks

ANNEX BUSINESS MEDIA

80 Valleybrook Drive, North York, ON, M3B 2S9; Tel: (416) 510-5198; Fax (416) 510-5140.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

e-mail: rthava@annexbizmedia.com

Tel: (416) 442-5600 ext 3555

Fax: (416) 510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE): Canada $74.50 per year, USA $130.95 US per year, Outside Canada $149.00 US per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

ANNEX PRIVACY OFFICER

privacy@annexbizmedia.com Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2016 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

For all the bad press that the meat industry and its products, especially red meat, have been subjected to in recent years from a wide range of critical interest groups and even the health community, the idea of a meatless future is still by and large a utopian fallacy, and amen to that dear brothers and sisters!

To paraphrase an old truism, if God really wanted us all to be vegetarian, he would not have made animals taste this good.

That said, having the benefit of an assured market demand for its products does not excuse the global meat industry of its CSR (corporate social responsibility) obligations and shifting consumers tastes and preferences that manifest themselves in increasing calls for tighter regulation to make the meat sector a more humane, safer, cleaner and eco -friendlier business.

Naturally, packaging has a key role to play in all this, which is why the U.S.-based Sealed Air Corporation, producer of the famed Cryovac brand of meat packaging materials and solutions, deserves due praise for doing the industry a big favor with its annual Power of Meat study, whose sound methodology and thoughtful analysis help meat processors stay abreast of the many important unfolding and upcoming changes in the marketplace for the good of their bottom line, their employees and the consumer public.

Now in its 11th year, the 2016 Power of Meat study provides a largely upbeat assessment of the North American meat markets by making it clear that the industry remains a key source of daily nourishment for the vast majority of North American consumers.

“Nearly eight in 10 shoppers believe a balanced diet is essential to good health [and] an even greater number of shoppers (82 per cent) believe meat and poultry are valuable sources of protein and other nutrients for a

balanced diet,” the report notes. “This belief reflects the growing popularity of protein, which has experienced seven-percent growth in sales.”

As rosy as that all sounds, a closer look reveals that much of that sales growth had been driven by higher meat prices, rather than volume, with beef sales recording a 6.1-percent sales increase despite experiencing a 4.1-percent decline in volume sales.

While this imbalance is less pronounced in other meat categories, the overall trend of paying more for less should be viewed with a certain amount of caution on the meat industry’s behalf, as continuously taking consumers for granted rarely results in a happy ending.

As the Power of Meat study points out, “High inflation for some protein varieties has caused the shoppers to change how they shop—whether by type of meat and poultry, volume or channel and indicates continued caution or many consumers following the economic downturn.

“Over the course of 2015, 60 per cent of shoppers made changes to what, where, when and how they purchase meat and poultry,” the report states.

“The lion’s share of shoppers who made changes (60 per cent) spent the same amount but purchased fewer or different items.

“This group was followed by shoppers who spent less money (25 per cent) and those who chose to increase spending (15 per cent).”

While such numbers are not reason to panic, a cautious consumer in a fragile economy is a factor that cannot be blissfully ignored—not when you’re talking about 25 per cent of the customer base.

Like it or not, affordability is a big part of the modern consumer’s mindset these days, and the sooner our leading meat processors, distributors and retailers address this elephant in the room, the happier they will be in the long run.

thermoform packaging machinery to keep up with robust growth in the foodservice marketplace. Cover photography by Naomi Hiltz

3 UPFRONT By George Guidoni

4-8 NEWSPACK Packaging news round-up.

9 FIRST GLANCE New solutions for packaging applications.

10 ECO-PACK NOW All the latest news on packaging sustainability.

11 imPACt A monthly insight from PAC, Packaging Consortium

12 NOTES & QUOTES

industry briefs & updates

13 EVENTS Upcoming industry functions.

52 CHECKOUT By Julie Saunders Joe Public speaks out on packaging hits and misses.

George Guidoni

23 THREE TIMES THE CHARM By George Guidoni

An inspired packaging redesign prompts Ontario craft brewer to invest into new canning line capacity to meet surging market demand.

30 THE RIGHT PATH TO GROWTH By George Guidoni

Canadian-based flexible packaging group enjoying quick growth in the U.S. markets with thoughtful integration of newly-acquired business assets.

35-50 PRESHOW REPORT

Our extensive preview of next month’s PACK EXPO International 2016 packaging technologies and innovations exhibition in Chicago, Nov. 6-9, 2016.

36 ADVANCING ROBOTICS

The robots’ relentless rise up the value chain.

39 BOOST YOUR NET WORTH By Maria Ferrante

How the Industrial Internet of Things is shaking up status quo

41 WINDS OF CHANGE IN WINDY CITY

Our sneak preview of PACK EXPO International 2016 show-floor exhibits.

Everybody likes to think they’re different from the rest in one unique way or the other, but pleasing everyone’s individual taste to the max gets tricky when you’re talking about millions of people.

Unless you are Diet Coke, whose extraordinary new One of a Kind marketing campaign seems destined to rewrite the book on what today’s digital printing technology can do for major consumer brands

trying to find a personal connection with their target consumers—one at a time if necessary.

Bottled and canned at six Coca-Cola Ltd. and Coca-Cola Refreshments Canada plants across Canada, the popular no-calories cola beverage has been flying off the shelves since the remarkable packaging redesign project that has resulted in millions of different new vibrant graphic designs appearing on

the 500-ml plastic bottles and 355-ml and 237-ml glass containers of the storied Diet Coke brand, Available across Canada while the supplies last, the limited-edition One of a Kind bottles will not have any repeat designs among them, while the 355-ml and 222-ml cans will use an expansive but limited range of different graphic patterns.

“The ‘One of a Kind’ campaign showcases the great taste of Diet Coke that Canadians know and love in a completely new way,” says Michael Samoszewski, Coca-Cola Ltd.’s vicepresident for the sparkling business unit.

“With millions of designs to choose from, Canadians will have fun finding that one Diet Coke bottle that truly reflects what makes them unique and ‘One of a Kind’.”

To create the unique packaging, Diet Coke worked with global printing systems manufacturer HP Inc. to leverage its innovative HP Indigo digital printing technology developed in Israel, which was the first country to conduct the One of a Kind promotion.

After first creating 36 ‘base’ designs inspired by the bubbles, fizz, taste and spirit of the Diet Coke soft-drink, designers used the HP SmartStream Mosaic hyper-customization software for automatic creations of millions of entirely new graphics as imaginative variations of the base—all printed with the HP Indigo digital oppresses.

During the printing process executed by Perennial Packaging Group, a special algorithm automatically performs a variety of actions—such as zooming and rotating—to alter specific areas of the designs, creating millions of entirely new original graphics.

Says Samoszewski: “We are always looking for new and innovative technologies make our packaging interesting and engaging to Canadians.

“The ‘One of a Kind’ program is about connecting with Canadians who not only love the great taste of Diet Coke, but who see their unique personal style reflected in one of the millions of available designs, made possible with HP’s innovative SmartStream Mosaic software,” Samoszewski says.

Since its rollout last month, the One of a Kind campaign has been heavily supported by a fully-integrated marketing program including a 30-second television spot, and 30- and 15-second digital and social media ads featuring top Canadian female tennis player Genie Bouchard, depicted her battling a tennis ball machine to create her very own One of a Kind bottle design, which will feature on only 200 selected bottles.

For a company that produces only one product, albeit in ever-growing volumes, Toronto-based craft brewer Steam Whistle Brewing seems to have an uncanny knack for making its bottles and canned beer feel new all over again—thanks to some truly memorable keepsake giftware used to promote its flagship Steam Whistle Pilsner brand in the marketplace.

And true to form, last month’s release of the company’s new customdesigned Retro Lunch Box gift-pack

across Ontario at LCBO (Liquor Control Board of Ontario) retail outlets—a colorful embossed tin reminiscent of the 1950s construction worker lunch–boxes—will have the company’s long-time fans talking for a while this fall.

Built to last, the Retro Lunch Box has a chrome plated handle and sturdy front clasp and hinges borrowing from yesteryear’s popular toolbox designs, with just enough space inside to accommodate a six-pack of the

Wayne Bryant rejoins Reiser Canada as Vice President of Sales

Wayne Bryant has rejoined Reiser Canada as their Vice President of Sales. In his new role, Mr. Bryant will lead Reiser’s Canada sales team and be responsible for the continued sales growth of Reiser Canada.

“Wayne is the consummate salesperson and his customer-first philosophy and management style are a perfect fit for Reiser,” says Roger Reiser, President and CEO of Robert Reiser & Co., Inc.

Mr. Bryant has broad knowledge of the Canadian food equipment industry, having focused much of his career in sales and sales management within that industry. For the past ten years, he served as Country Manager for CFS Canada and more recently as Director of Sales at Multivac Canada. Prior to that, Bryant held various roles at both Reiser Canada and Reiser UK.

company’s signature-green 473-ml cans of Steam Whistle Pilsner

“Built to last, it reminds one of the tackle boxes and tool boxes like the ones our granddads used,” says Steam Whistle’s marketing coordinator Holly Postlethwaite.

“It’s shareable, portable, collectible and, best of all, drink-able.

“Inspired by the idea of the classic boxed lunches of the 1950s and how they satisfied the appetite of honest, hardworking folks, Steam Whistle wanted to bring that satisfaction back to be shared with friends, co-workers and family,” Postlethwaite explains.

According to Steam Whistle, the company’s in-house designer Ashley Brown worked with 39 different initial design concept before settling on the final lunch-box design, which was manufactured in limited quantities by Ottawa-based giftware supplier 2ii Inc.

Says Brown: “It was critical to design a lunch box that could stand the test of time and stay iconic for years to come.

“Since most of Steam Whistle’s designs are inspired by retro-aesthetic, it seemed a natural starting point to draw some inspiration from tin lunch boxes dating back to the 1950s,” Brown recalls.

“I found immense inspiration in the shape of the lunch box: it alone offered that retro flare we desired.

“We all can imagine construction workers pausing for a moment to enjoy their lunch with fellow co-workers. It was a simple pleasure.

“One of the goals with the Retro Lunch Box was to capture this very feeling and idea,” Brown continues. “There was no need to over-complicate the graphics: my role was to ensure the graphics complimented the shape and didn’t work against it.

“By using a similar shape to the 1950s era, it reminds us of a simpler time when lunch was the reward for hard work.

“Hopefully our customers can enjoy our beer in the same way with a relaxing setting and good company.”

To accommodate the distribution of the hefty lunch-box six-packs to the LCBO outlets, Steam Whistle’s longtime packaging partner Packaging Technology Inc. (PTI) of Concord, Ont., designed the high-strength ‘Mother Tray” and Lunch Box Wrap for shipping and displaying the Retro Lunch Boxes on the shelf-level, as well as supplying a structured insert between the boxes made of BC-flute corrugated partition.

According to LCBO, the Retro Lunch Box has already been a runaway hit with the Canadian consumers.

“We have had a number of very successful special packs over the years from Steam Whistle, but none have taken off like the Retro Lunch Box,” says LCBO’s acting category manager for beer and cider Mark Wilson.

“It has lots of consumer appeal, and is also a great fit with Steam Whistle’s brand positioning,” Wilson states.

Adds Steam Whistle’s director of sales and marketing Bromlyn Bethune: “The Retro Lunch Box is resonating with consumers: in fact, we’re blown away by the response.

“We sold 80 per cent of the inventory within the first two weeks and our social feeds are flooded with people sharing images and praise.

“We’re grateful for the reception, and as we stay committed to producing one beer Canadians can be proud of, we will continue to push the boundaries in creativity combining Canada’s Pilsner with that touch of nostalgia and fun that our customers love.”

Getting their kids to eat enough veggies has long been a parental challenge of the highest order, but thanks to some groundbreaking product innovation from leading Canadian dairy product group Ultima Foods, Inc., busy parents can make sure they do their part by adding one of several new IÖGO Nanö brand yogurts into their lunch-box on their way on the way to school.

Launched a few weeks ago just in time for the annual backto-school season, the newly-expanded IÖGO Nanö range of popular, kid-friendly yogurts now comprises several tasty and nutritious flavors combining freshly-made mixtures of fruits and vegetables in a variety of engaging, colorful and vibrant singe-serve packaged designed by the Mississauga, Ont.-based branding specialists Davis Design.

Offered in a choice of drinkable

bottles, foil-lidded cups, stand-up spouted pouches and squeezable tubes, the new IÖGO Nanö flavors now include inspired original fruit-and-veggie blends such as banana/ squash, blueberry/beet, peach/carrot and applecherry/beet, along with several fruit-only flavors.

Says IÖGO brand marketing director Eliane Ouimet, “On top of adding vegetables for the first time ever, we also felt it was important to keep convenient packaging to continue offering truly kid-friendly products to our consumers, especially with our squeezable pouches.

“Also as offered in our current nanö line, we are well known for the cap we designed for children to able to drink from spill-proof cups,” Ouimet states. “It’s very practical for parents as the cap is resealable and spill-proof— ensuring kids can enjoy their nanö anywhere without making a mess.

While winning high-profile international hockey competitions has long been second nature for Canada’s top male and female hockey players, this dominance has not always translated into the world of luxury distilled spirits—at least until the recentlyheld 2016 Wine & Spirits Wholesalers of America Spirits Tasting Competition in Las Vegas, Ont. Distilled and bottled in Kelowna by Orchard City Distilling Co. at the heart of British Columbia’s famed Okanagan Valley, the ultra-premium High Stick Vodka —packaged in 750ml hand-blown glass hockey stick— managed a rare hat-trick by winning a Double Gold and being named the Best of Show vodka at the annual event—beating out 53 other worldcall vodkas evaluated by the event’s judging panel.

women’s teams consistently reaching the top of the podium in the Winter Olympics,” says High Stick Vodka president Illarion Shulakewych.

“We are proud to have achieved the same distinction with High Stick Vodka, a premium vodka proudly made with premium Canadian ingredients.”

Shulakewych says the High Stick Vodka recipe uses only the finest local grains and the purest artesian mountain water, along with a distillation process using an 18 bubble plate copper still to filter out all the impurities all impurities are filtered out and create the highest quality spirit.

“On the international stage, Canadians have gotten used to a double gold in hockey with the men’s and

“A Canadian bar shelf is incomplete without High Stick Vodka as the centerpiece it deserve to be,” says Shulakewych, adding he expects most people who purchase the premiumpriced product are not likely to open it, preferring to keep it around as a keepsake and a conversation piece.

Ten years after receiving the first distillery license awarded in Ontario in about a century, London, Ont.based Black Fly Beverage Company is bringing innovation to the largest spirit category in Canada with the launch of bob’s SUPER SMOOTH vodka brand—a premium whey vodka that delivers what it promises — a super smooth, silky and remarkably

drinkable vodka with a remarkably smooth and silky profile that rivals many brands in terms of quality at a highly competitive price-point.

Unlike traditional vodka that is made from potatoes, grain, or corn, bob’s SUPER SMOOTH whey vodka contains no grain, lactose and or gluten, while its unique triple-distilled, charcoal-filtered process virtu-

ally eliminate any “burn” when enjoyed on its own.

“To craft bob’s SUPER SMOOTH, we take the highest quality distillate and blend it with Ontario spring water drawn from a source that Canadian Geographic calls ‘the purest spring water on the planet’,” explains Black Fly co-founder Rob Kelly.

“The result is remarkably smooth vodka that can be enjoyed neat, on the rocks, or rocking’ your favorite mix.”

Initially sold across Ontario at the provincially-owned LCBO (Liquor Control Board of Ontario) retail stores, the 750-ml PET (polyethylene terephthalate) plastic bottles feature a unique three-dimensional “Hang Smooth’ hand signal created with state-of-the-art body scanning technology developed by Pickering, Ont.-based decorative printing specialists E3 Systems Ltd.

“Our non-breakable PET bottle is tailored to address the preferences of today’s consumers looking for lightweight, safe-to-handle, eco-packaging that is highly recyclable, offering multiple end-uses for the recycled material,” says Black Fly co-founder Cathy Siskind-Kelly.

“We are committed to bringing to market ultra-premium products at price points that offer tremendous value, which is a win-win for our consumers, and we bob’s SUPER SMOOTH with this mission in mind.”

Designed as a simple way to eliminate the risk of leaks in packaging or components, the new LEAK-MASTER EASY system from WITT-Gasetechnik uses a straightforward water bath method, whereby the test sample is placed in a water-filled chamber and compressed air is used to evacuate the air space above the water level. At leakage points, the resulting vacuum causes air or filling gas to escape and bubble up to the top of the chamber in a clearly visible way. Available in five different models—with chamber volumes ranging from five to 55 gallons—the LEAK-MASTER EASY is available in five variants—making it possible to detect even the smallest of leaks in packaged food items, electronic goods, pharmaceutical products, bubble wrap and PET plastic bottles. Providing an easy way to see not only whether the product is leaking but also where the leak is, the LEAK-MASTER EASY is offered with an optional touchscreenoperated electronic control module which makes it possible to record, save and transmit all of the test results.

WITT-Gasetechnik

401

Designed for reliably securing of 40x48inch pallet loads of packaged goods and for accommodating double-stacked pallets, the new StakCap system from ORBIS Corporation is designed to provide a stable top cover for container loads to maintain uniform weight distribution when stored or transported. The top cap’s low-profile design allows for a high nesting ratio to create more floorspace on plant, storage and trailer floors, according to the company, while enabling the use of more varied pallet and tote combinations to minimize the risk of collapsed loads during shipping and storage.

can handle all thermoformable grades of PET, OPS, HIPS, PLA, PP, and PVC plastic films, according to the company, with its 800x570-mm forming cavity capable of forming up to 150-mm above and below the sheet line. With powerful 75-ton cutting force of the form ing and cutting stations, the GN800 features a standard oven that is four times the index length of the forming area, with the additional space between

the forming and cutting stations providing extra cooling time when running heavier-gauge materials or PP plastics. Handling sheet width of up to 880-mm, the machine can run sheet thicknesses ranging from 0.25-mm to 1.5-mm—using high-efficiency Solar heaters, and cut-in-place capabilities, and independent top and bottom servo plug-in drives to achieve better material distribution.

ORBIS Corporation 402

Designed for a broad range of food, medical, and industrial packaging applications, the new high-speed GN800 form/cut/stack thermoformer from GN Thermoforming Equipment

GN Thermoforming Equipment 403

Contiform AseptBloc, Canadian Packaging, 200x273 mm, CC-en31-AZ0?? 09/16

Sustainability always works better as a team game, and for leading German aseptic packaging producer SIG Combibloc, it’s game on.

As of the end of August, all of the aseptic cartons supplied by SIG Combibloc to its customers worldwide can be fully-validated as eco-friendly packaging by labeling them with the internationally-recognized FSC (Forest Stewardship Council) logo—meaning that all the

wood fibers used in their construction are sourced from responsibly-managed forests, as defined by FSC’s strict criteria.

“As one of the leading manufacturers of carton packs for foods and beverages, safeguarding the planet’s forests is a key corporate goal for us,” says SIG Combibloc’s chief executive officer Rolf Stangl.

“Hand-in-hand with that goes our commitment to ensuring that the cardboard we use for our carton packs comes 100-percent from certified sources.”

FSC has recently developed a new version of its logo, featuring the ‘Forests are Forever’ slogan, to help brands better connect with consumers an emotional level.

According to the company, its internally-developed Corporate Compass metrics are applied throughout the procurement of all materials, products and services used in its manufacturing operations, and its commitment to using the recently-updated FSC logo (see above) is another step forward in its long-time collaboration with the certification authority.

In fact, SIG Combibloc was one of the first packaging manufacturers to have all its all its production sites worldwide certified in accordance with the FSC’s criteria for a continuous product chain-of-custody (CoC), thus providing undisputable documentary evidence of its high environmental standards.

As FSC International director general Kim Carstensen explains, “Food and beverage manufacturers can make important contributions to saving the environment and safeguarding social interests in the forest by working with FSC, while also securing a crucial competitive advantage for themselves.

As a pioneer in smart automation technologies, Schneider Electric makes it easier for you to offer your customers better connected machines. Our future-ready machine solutions intelligently connect people, devices, machines, and data to simplify machine design and boost business efficiency. Both today and tomorrow. How you can benefit from digitization and the IIoT Download our FREE white paper to learn more today!

“Manufacturers and retailers can demonstrate their environmental and social commitment by offering FSCcertified products.

According to FSC’s new eco-labeling guidelines, each food and beverage manufacturer can make its own decision on displaying the FSC label visibly on the carton pack to position itself as an environmentally responsible company.

To give manufacturers enough scope to integrate the FSC label into their respective packaging designs, SIG Combibloc encourages its customers to position the FSC label on one of the four fully printable display surfaces of the carton packs, as well as onto the socalled ‘lateral ears’ of the cartons or on the carton base.

According to SIG Combibloc, “This solution is an effective option, for small-size carton packs with limited space.”

• 2406 Members

• 4000+ Database Contacts

• 1539 LinkedIn; 1383 Twitter; 210 Facebook followers

• 37 Newsletters

• 31 Educational Days

• 26 Project Meetings

UBM – PACKEX Toronto & PACEX Montreal 25% Discount on floor space for PAC Members only

PAC Global Leadership Awards showcasing innovative products, celebrated with Package Design partners Exclusive 25% Discount for entries for PAC Members

PAC Canadian Leadership Awards showcasing members innovation, celebrated and featured at PACKEX Toronto 25% Discount for entries for PAC Members only

• Members discounts 25% - 50% off

• 15 Webinars

• 15 Plant Tours

• 12 Social Networking

• 6 Conferences

• 5 Seminars

• 2 Galas

PAC TO THE FUTURE Conference 25 Speakers, 200+ Attendees

Discounts on Innovation Reports UK’s packaging innovation specialist

IFS PACsecure – 110 packaging manufacturers certified, 7 countries, and long term agreement with partners IFS

Graphics Canada – intelliPACK hosting a 2 day workshop and pavillion April 6 – 8, 2017. 25% Discount on workshop/floorspace PAC Members only A SMART PACKAGING Innovation Accelerator Partnership with CPEIA

Designed for packaging manufacturers Reduce risk, reduce cost

Insuring Canada’s packaging industry

Saving members $ thru recovery solutions, Innovation Gateway, and customized solutions for the toughest challenges

Food Waste thru advanced technical packaging solutions and creating industry awareness

Pilz Automation Safety Canada, has announced that Andreas Sobotta has accepted the position of CEO & General Manager of the Canadian operation. He is an experienced professional with many years in the electrical and controls world and has held various leadership roles at Davis Controls, Festo, Siemens, Phoenix Contact and most recently Hammond Manufacturing.

“I am very excited to join such an innovative company which spends over 20% of their global sales in R&D. The Canadian team is very enthusiastic and I look forward to growing with them”, Sobotta says.

n Calgary, Alta.-headquartered plastic resins producer NOVA Chemicals Corporation has announced the completion of its PE1 Expansion project—a third gas phase reactor at the company’s production site in Joffre, about 20 kilometers northeast of Red Deer. (See Picture) According to the company, a wholly-owned subsidiary the International

Multivac Canada Inc., Brampton ON - one of the leading providers worldwide of packaging solutions for food products of all types, life science and healthcare products as well as industrial items, is pleased to announce the appointment of Paul Marsden to Director of Sales.

Pilz, with their Head Office near Stuttgart/Germany, is a global leader of safety automation and offers safety automation products and solutions, as well as safety services like risk assessments, plant assessments and CE markings.

Tom will be responsible for developing solutions for customers’ automation needs beginning from conception through the sale and implementation.

Tom has previously held several positions where he was responsible for project management and engineering of Automated Systems.

Tom can be reached at: 774-504-0218 or thomasmurphy@harpak-ulma.com

Harpak-ULMA would like to welcome Martin Merker, their newest Regional Sales Manager for Western Canada. Martin is based in Ontario. His territory will consist of the provinces of Alberta, Saskatchewan, Manitoba and Ontario. Martin is no stranger to the packaging industry. He has extensive experience in sales and project management working for several large packaging companies.

Martin is looking forward to working with the Western Canadian customers to solve their packaging challenges!

Petroleum Investment Company (IPIC) of the Emirate of Abu Dhabi, United Arab Emirates—the new reactor is designed to produce approximately one billion pounds of LLDPE (linear low density polyethylene) annually. Most of the new capacity will be used to produce the company’s NOVAPOL to meet growing demand for flexible film products such as food packaging, heavyduty sacks and collation shrinkwrap films.

“Our expansion of the Joffre site with the addition of a third gas phase LLDPE reactor is a key component of our growth strategy to support growing polyethylene demand,” says NOVA Chemicals’ senior vice-president for the polyethylene business Chris Bezaire, adding that the new reactor will boost the Joffre site’s total annual production capacity for polyethylene resins to approximately 3.5 billion pounds by the end of this year. “As we collaborate with our customers, we are excited to bring updated technology to drive better resins, structures and applications,” says Bezaire, noting the NOVAPOL butene LLDPE resins already enjoy good industry reputation for their “excellent balance of physical properties, product uniformity and consistency, and best-in-class gel performance.”

n Guelph, Ont.-based food safety certification authority NSF-GFTC —formerly known as the Guelph Food Technology Centre (GFTC) —has officially changed its name to NSF International, reflecting a change ownership structure following its 2013 acquisition by NSF International of Ann Arbor, Mich. As part of that name change, the organization has also completed its move to a new, 20,000-square-foot facility near the University of Guelph campus, which will house its eLearning capabilities along with its well-established food packaging, labeling, and product and process development services.

“NSF International was pleased to have merged with NSF-GFTC and its members three years ago, and our role has been to continue to fortify the Canadian market by investing in our staff and infrastructure for our clients,” said Kevan Lawlor, president and chief executive officer of NSF International.

“NSF International’s Canadian clients also have access to a growing global organization dedicated to food safety and quality to protect human health,” says Lawlor, citing a wide range of services NSF provides to more than 1,500 Canadian businesses and over 7,000 global food safety professionals.

Oct. 17-19

Tuscon, Az.: 2016 MHI Annual Conference, material handling, logistics and supply chain forum by MHI. At Hilton El Conquistador. To register, go to: www.mhi.org/conference

Oct. 18-19

Malmö, Sweden: Top Packaging Summit, international conference by Packbridge. At Quality View Hotel in Hyllie. To register, go to: www.toppackagingsummit.com

Oct. 20

Chicago: ABCs of IML: A Basic Course, training seminar on im-mold labeling and in-mold decorating technologies by InMold Decorating Association (IMDA). At DoubleTree Hotel & Conference Center Chicago North Shore. To register, go to www.imdassociation.com

Oct. 21-23

Huntsville, Ont.: The Meating Place 2016, biennial conference of the Ontario Independent Meat Processors (OIMP). At Deerhurst Resort. Contact OIMP at (519) 763-4558.

Oct. 19-26

Düsseldorf, Germany: K 2016, international trade fair for the global plastics and rubber industries by Messe Düsseldorf GmbH. At Messe Düsseldorf Fairgrounds. Contact Messe Düsseldorf (Canada) at (416) 598-1524.

Nov. 1

Toronto: How Green is your Customer?, conference by the Paper & Paperboard Packaging Environmental Council (PPEC). At the Islington Golf Club. Contact PPEC at (905) 458-8807; or via email ppec@ppec-paper.com

Nov. 6-9

Chicago: PACK EXPO International 2016, international packaging technologies exhibition by PMMI-The Association for Packaging and Processing Technologies. Concurrently with Pharma EXPO 2016 pharmaceutical and packaging conference and trade show by ISPE (International Society for Pharmaceutical Engineering). Both at McCormick Place. To register, go to: www.packexpo.com

Nov. 14-15

Amsterdam, The Netherlands: AIPIA World Congress and Exhibition on active and intelligent packaging, by Active & Intelligent Packaging Industry Association (AIPIA). At Mövenpick Hotel Amsterdam. More information at www. aipa.info

Nov. 14-17

Paris, France: ALL4PACK Paris,

global marketplace for packaging, processing, printing and handling by Comexposium Group. At Paris Nord Villepinte. To register, go to: www.all4pack.com

Nov. 15-17

Vienna, Austria: Multilayer Packaging Films 2016, conference by Applied Market Information Ltd. (AMI). At Austrian Trend Hotel Savoyen. To register, go to: www.amiplastics.com

Nov. 29-30

Berlin, Germany: European Bioplastics Conference, by European Bioplastics. At Steigenberger Hotel. To register, go to: www.europeanbioplastics.org

Nov. 30 – Dec. 1

Montreal: Advanced Design & Manufacturing (ADM) Expo, multishow event by UBM comprising PACKEX Montreal, Expoplast, Automation Technology Expo

(ATX), Design & Manufacturing and Powder & Bulk Solids (PBHS). All at Palais des congrès de Montréal. To register, go to: www.admmontreal.com

Dec. 5-7

Nairobi, Kenya: East Afripack 2016, regional processing, packaging and converting technologies exhibition by Ipack-Ima Spa. At the Kenyatta International Conference Center. To register, go to: www.ipackima.it

Dry application? Why buy more checkweigher than you need? That’s the premise behind the new Thermo Scientific™ Versa Flex checkweigher. It has the precision and performance our Versa platform is known for, but with the right features for checkweighing dry food products.

More choice in checkweighers. Another example of how we’re bringing you the answers you need, simply packaged

us at Pack Expo 2016, Booth S-2130

out more at thermofisher.com/VersaFlex

Whether you are labelling cartons at a distribution centre or adding variable information labels to your clamshells, Weber has a label printer-applicator to fit your production line. Weber’s systems are modular so that they can be built to print and apply labels to tops, bottoms, sides, around corners, into recessed areas, and just about any other place you need your labels attached.

And you can print your variable data labels with a wide range of print engines from 203 to 600 dpi at up to 12” per second. Connections to external devices are easy with the numerous I/O’s and the unit’s controller can be remotely operated via a 15’ umbilical cord. The entire system can be monitored using your favourite web browser.

Weber’s Model 530 0 Series label printer-applicator is built to operate 24 hours a day, 7 days a week, and can be configured for standard tamp- blow print-apply, or air -blow, direct -tamp, corner - wrap, split-tamp, two label twin -tamp, swing -tamp and many other configurations.

Weber’s Model 430 0 Series is a more economical version built to operate 16 hours per day and 6 days per week. Available in tamp -blow and swing - tamp variations, the Model 4300 has most of the abilities of the 5300 Series, with a few less features.

Busy Ontario meat processor steadily winning the relentless race against time with cutting-edge, top-quality thermoform packaging technology

BY ANDREW JOSEPH, FEATURES EDITOR

BY NAOMI HILTZ

Back in 2008, Canadian Packaging magazine first visited up-and-coming meats processor

The Elite Meat Company, to see how its facility upgrades and capital investments had helped it grow its foodservice business.

A s of 2016, the Federally-inspected meat and poultry processor has seen its sales continue to rise with more consumers craving its high-quality pea meal bacon, select meat cuts, ground beef, diced beef, breakfast and BBQ sausage offerings, among many other products.

The success has prompted the company to once again expand its facility and add more top-notch equipment via capital investments, and evaluate opportunities now presenting themselves in other Canadian and American markets.

Since starting the Ajax, Ont.-based business back in 1995—after growing up in the business working

with their parents in the industry—company president Dan Milanovic and his brother and vicepresident Sasha Milanovic, alongside director of sales Peter Daly have worked extremely hard to triple their business over the past 10 years by selling their Elite brand of products throughout the Canadian foodservice industry.

“We actually process more than just peameal bacon,” notes Dan Milanovic to Canadian Packaging magazine during a recent visit to the now 28,000 square foot facility with 54 employees, upgraded in 2015 by an additional 10,000-square feet and more automation.

The facility is recognized as HACCP (Hazard Analysis Critical Control Points) and SQF Level IIcertified and is a Canadian federally-inspected facility.

“Approximately 50 percent of our production is beef, 45 percent pork, which includes peameal bacon and breakfast sausages, with the remaining five percent taken up by processing veal, lamb and poultry consisting of chicken and turkey,” explains Milanovic, adding that Elite Meat produces some 335 SKUs (stock-keeping units) in total.

A long with peameal bacon, the company provides custom processing and packaging of fresh and frozen pork, beef, lamb and poultry for the retail, foodservice and further processing industry.

Meat products are delivered and procesed to the facility daily, though the pork cuts destined for the production of pea meal bacon require a special 48hour minimum immersion in proprietary brine, created in 1972 by the Milanovic brothers’ father, who continues to play an active role at Elite Meat.

W hile some may compliment the company’s growth, Milanovic says the growth strategy has been more of a tortoise than a hare plan.

He says that as a family business, his parents instilled a philosophy of having to work hard and smart to achieve objectives and goals.

“While there are businesses who subscribe to the adage of jumping in with both feet for the sake of increased volume, we have always taken a more strategic approach,” explains Milanovic.

“We carefully evaluate the pros and cons of all opportunities and decide if, in both the short- and long-term, will benefit or hurt our business.

“It is vital to minimize risk through thorough evaluation of every growth opportunity.”

E lite Meat last expanded its facility in 2015, effectively doubling its production output—triple of what it was back in 2008.

Despite the considerable growth, the company considers itself to be methodical in the way it prepares for change, with Milanovic citing how it decides whether to accept new customers, researching whether or not the sudden influx of a large customer could upset the flow of the rest of its production schedule and output to other customers.

“Keeping our customers happy—from the smallest to the largest—is of paramount importance to not only myself, but to all of our employees,” relates Milanovic. “It’s a matter of pride in ourselves and respect for all our customers,”

It’s the same thoughtful process the company utilized when it came time last year to make a capital investment purchase of a third packaging machine—the iSeries thermoformer from the Canadian operations of Swiss-based VC999.

E lite Meat and VC999 have been working together since 2002, when the meat processor first purchased a single-chamber automatic vacuum seal machine and shrink tank, later adding a doublechamber vacuum seal machine.

A fter the large facility upgrade in 2006 also expanded Elite Meat’s processing, cooling and freezing potential, it added a state-of-the-art Rollstock RS320 thermoformer from VC999.

“It’s not simply a matter of us choosing VC999 and their machines because we are used to them,”

explains Milanovic. “They had to earn each and every one of our purchases.”

The decision to invest in an iSeries thermoformer was born not only for the need to expand the Elite Meat production capacity and capabilities, but also with an eye to expand into new markets and channels.

“We have continued to do very well in the foodservice channel,” relates Milanovic, adding that his company continues to receive queries and encouragement from consumers and retailers who

seek their products out, particularly Elite peameal bacon.

“When we examined our interest in the retail segment, we knew we would have to increase our packaging capability which meant changes and additions to the packaging equipment,” says Milanovic.

He stresses, however, that his company is not involved in the retail market segment at this time, nor does it have any plans to do so—just that it wants the capability to do so should the objectives change.

Even then, despite already owning and continuing to operate a VC999 vacuum chamber machine and RS320 thermoformer, Milanovic says that when it came time to purchase another thermoformer, they wanted to look at all their options.

He says they met with all the major thermoforming machine manufacturers at a recent PACK EXPO tradeshow in Las Vegas, each of whom set up tours for Milanovic to visit non-competitive meat processors to get a first-hand look at their particular equipment in operation, as well as an opportunity to talk with the operators of the equipment to get their personal feedback.

“It wasn’t a quick decision for us,” notes Milanovic. “We met everyone, we talked and asked questions and after several months with all our facts in front of us, we made our decision.

“The number one thing I took away from meeting the machine operators, was the ease-of-operation of the iSeries thermoformer machine,” Milanovic explains.

“The praise I heard about the iSeries gave me even more confidence in VC999.

“I do think that a very important factor in running one’s machinery is for you to have a great working relationship with your supplier,” Milanovic offers, “and with VC999, we certainly do.”

For Elite Meat, Milanovic says he was also impressed with the back-up features, noting that the iSeries is connected to the internet meaning VC999 can perform a machine diagnostic from its North

It’s not a box. It’s a billboard. Canadian corrugated is a billboard for your brand. It’s tried, tested and new.

American headquarters in Kansas city or anywhere in the world, for that matter.

“There’s also a camera provided with a waterproof case that can be plugged in to remotely visually show VC999 any issues which, along with the direct access link to the internet, can help them get the machine up and running—downtime doesn’t profit anybody,” says Milanovic.

“While I really did give all the thermoforming equipment manufacturers a fair and even look, the capabilities of the VC999 iSeries played into our decision.

He says that the flexibility of the iSeries line was also a huge factor for the company.

“If we want to pursue the retail channel, we want equipment that will offer the packaging options we will need.”

Noting that Elite Meats packs pork tenderloin, pork backribs, buckeyes, sausages and peameal bacon on the new iSeries, exactly as it did on the RS series, “now we can run the products through it much faster, knowing that it also provides a better seal giving the products a longer shelf-life,” says Milanovic.

VC999 calls the iSeries the most innovative, intelligent, interconnected and integrated machine on the market, and features a full range of machines with frame lengths from 7.2 meters up to 12 meters with web widths from 320mm up to 720mm.

According to VC999 Canada vice-president Remi Boudot, “Because the iSeries machine possessed such a wide range of machine frame and width,

we were able to design the ideal package for them that would allow Elite Meat to use the least possible amount of plastic film and still be large enough to accommodate the diversity of the product they are producing—as meat products are not always processed equally in size of shape.”

Boudot says the iSeries thermoformers can work at speeds of 16 to 18 cycles per minute contingent on the application.

“Depending on the customer, the iSeries thermoformer can be sized to match –up to the customer production requirements, as well as the loading process,” says Boudot. “Manuallyloaded machines are often limited in speed owing to the human factor, but for others, we can apply a robotics package to load product to maximize package line efficiency.”

The mechanical design of the iSeries is constructed with solid-frame stainless steel, with removable panels, and an incline surface with a smooth finish that makes it easy to clean and maintain.

There is also a completely new and innovative two-stage high-pressure LLP die lift system that provides power and precision while developing 15 tons of closing pressure with its intensifier technology, that provides customers like Elite Meat with excellent forming and sealing results across the board, regardless of what product it packs.

Boudot says the Milanovic brothers were looking for a thermoform machine that had better speed than the one they had purchased in 2008—one that also possessed superior seal technology to reduce the number of rework packaging.

A nother bonus is the iSeries’ ability to easily switch between thin plastic film and thicker rigid film without the necessity of die adjustments.

According to Boudot, the iSeries was designed with the operator in mind.

“Not only does it feature quick and easy access to all areas including the highend vacuum valves, it also has swing-out pneumatics, is grease-free and requires low maintenance,” relates Boudot.

“Also, the servo-driven thermoformer is industrial PC computer-controlled with remote access control also available, with a 1GB speed transmission throughout the machine which provides overall better control, faster service through the internet connections and better security.”

Some of the other equipment used at the Elite Meat facility, includes:

• three IQ3 metal detection units from Loma;

• a Videojet Technologies Dataflex Plus industrial thermal transfer printing system;

• plastic film for the iSeries thermoformer provided by VC999’s XtraPlast division;

• Ross brand meat press from Reiser;

• t wo fast and easy-to-use Handtmann inline grinders/sausage stuffers;

• corrugated shipping containers converted by Coyle Packaging Group and Goldrich Printpak

• block grinders from Butcher Boy, and Weiler brand mixer/grinders from Provisur

Technologies

Regarding the chief difference between retail and foodservice for himself and Elite Meat, Milanovic says that “if we are confronted with a logistics challenge for one of our foodservice distributors, we can work with them to delay delivery for a day or two.”

In retail, Milanovic points out, “the packaging is more specialized.”

The equipment must be dependable and fullyoperational to ensure delivery deadlines are not missed.

“With our iSeries, we can process two to three

times more loins a week, if needed,” explains Milanovic. “Thanks to an efficient packaging line, we can increase production output from the boning line by adding more skilled workers.”

He says that by increasing the amount of trimming produced on the boning line, he has also increased the sausage production capacity.

“It’s a chain reaction,” smiles Milanovic. “Because of that one new piece of equipment, we now have the capacity to substantially grow our entire business.

“In addition, we are better equipped when we receive a large order on a tight timeline, as we have the line time, the skills and the equipment to meet

our customers’ expectations.”

E lite Meat company director of sales Peter Daly recalls starting at the company 10 years ago, sitting down with the Milanovic’s to strategize how they would maximize and grow with the equipment they had.

“It was determined that only after we had fully exploited our capacity that we would then physically expand our operations and invest money in new equipment,” notes Daly. “It’s a plan that has worked well for us.”

He says that it was also important for Elite Meat to maintain its focus on the foodservice industry and to not branch out into retail for the sake of potential low margin volume growth.

“We saw some large and small processors close after becoming too heavily committed within the retail segment.

“ Retail can really hurt the inexperienced.”

B oth Daly and Milanovic agree that maintaining its focus in foodservice has been key through these past years of growth.

D aly says that by being selective and strategic about the market segments targeted and new products chosen to introduce, Elite Meat has positioned itself to be recognized by the trade as a quality processor, which is now known for high value, competitively-priced meat products.

“We have been asked by multiple retailers to package our peameal bacon for their stores,” Milanovic says, “but the challenge is top try and meet their price-point expectations and hence, margin.

“To date, these opportunities, although tempting, could threaten the valuable brand equity that we have worked hard to create over the past 40 years.

“ We’re not a low-cost meat company. We process highend, quality meat products at a reasonable price.”

By not compromising the brand quality and pricing all products fairly to all customers, we believe that our customers and those consumers who know our product are confident that we will not compromise our quality,” Milanovic notes.

“Our respected position in the market, for instance, as the Number 1 selling brand of peameal bacon in food service across Canada, reinforces that position for all our products and our name.”

W hile Elite Meat is now confident that it has the packing equipment in hand should it decide to

take on the retail market, Milanovic says that the strategy for growth also includes plans to enter the foodservice market in the U.S.

Explains Milanovic: “ Just like our very effective foodservice sales broker, Magnum Food Industry, that we have here in Canada, we are currently looking for a company equally as trustworthy to represent our foodservice meat products in the United States.”

M ilanovic is very pleased with the performance of the VC999 iSeries , as well as the flexibility options it affords Elite Meats.

“ The iSeries from VC999 does more than simply package our meats in a clean and efficient manner that gives every package a high-quality look to match the high-quality meat inside.

“ Thanks to the option of gasflushing, we could pack directly into semi-rigid trays and create reclosable packaging,” sums up Milanovic.

“T his new high tech thermoformer can help make our packaging even better than it was in the past—the sky’s the limit.

“It’s great to have additional options for growth.”

Ontario craft brewer catches lightning in a can with classy packaging redesign and a smooth canning line startup

BY GEORGE GUIDONI, EDITOR

PHOTOS BY COLE GARSIDE

If good things come to those who wait, then Cameron’s Brewing Company provides a compelling example of why patience is a blessed virtue in Canada’s fast-growing craft beer business.

Founded 19 years ago by Cameron Howe in Mississauga, Ont., the privately-owned microbrewer is hardly a newcomer to the burgeoning craft beer market—having been honored with well over 140 prestigious awards for its craft-brewed recipes over the years at dozens of international beer industry competitions.

But after six years of fine-tuning its brewing competencies at its current digs in Oakville, Ont., under the watchful eye of current co-owner and president Bill Coleman, the company has really come into its own this year as a serious player with a fresh packaging redesign of its core product portfolio and installation of a brand new canning line to fuel a spectacular sales surge across Ontario.

“Our sales have grown by 300 per cent since we launched the new cans earlier this year,” Coleman told Canadian Packaging on a recent visit to the company’s fully-owned, 30,000-square-foot facility that offers plenty of extra room and capacity for what is expected to be a vastly accelerated growth curve for Cameron’s three core flagship brands in coming years.

With the province of Ontario finally relaxing its long-time ban on retail beer sales outside the traditional LCBO (Liquor Control Board of Ontario) and The Beer Store outlets by letting select grocery chains and independents to sell limited quantities of beer to consumers while they do their regular grocery shopping, Coleman is highly upbeat about the company’s future growth prospects and opportunities.

“Our main beer brands have remained unchanged because we

always produced a great beer,” says Coleman, “but our new packaging is a real game-changer for our overall branding strategy.”

With cans now accounting for over half of all beer sales across Canada, Coleman says that switching the main Cameron’s brands from bottles to cans was always in the cards, but not before the company had the perfectly updated designs to launch into a marketplace already brimming with a growing variety of eye-catching product labeling and packaging savvy.

To achieve the desired high-impact shelf presence, Cameron’s hooked up with Toronto-based boutique graphic design agency Cactus Design, giving it full creative license for a radical rebranding of its mainstay Captain’s Log Lager, Ambear Red Ale and Cosmic Cream Ale varieties, along with several seasonal products.

Based on the overwhelmingly positive market response to the new can packaging—now retailing province-wide in 65 per cent of the 600-plus LCBO locations and at 45 mainstream Ontario grocery stores operated by leading food retailers Sobey’s, Loblaw’s and Longo’s, along with family-owned Pino’s and La Mantina’s—choosing Cactus to handle the rebranding project seems a brilliant masterstroke.

In fact, Cactus Design principal Ian Fleming credits his team’s personal familiarity with Cameron’s beer as one of key factors behind the highly imaginative and inspired graphic redesign touching on all the main graphic elements and talking points.

“Being craft beer fanatics who have always admired Cameron’s delicious craft beers, the opportunity to update the brand icon and the packaging was a very exciting and interesting project for our agency,” Fleming recalls.

“Although the Cameron’s brand

line’s

had been around for nearly 20 years, it had not been updated since its launch in 1997,” says Fleming, saying the outdated original packaging had “extremely weak shelf presence” that was just not connecting with LCBO or The Beer Store customers.

This shelf presence deficit became especially pronounced in recent years as LCBO adjusted its retail strategy to place greater emphasis on individual can sales.

With craft brewers quickly embracing that change with a flood of new canned products, the task of making Cameron’s brands stand out on the crowded shelves was a considerable creative challenge, Fleming acknowledges.

“As the Ontario-made craft beer category has exploded in the past five years, with many new brands coming into the market, packaging has become a very important factor in how consumers feel and engage with craft beer brands,” he explains.

“Most consumers do not have a deep knowledge of craft beer,” Fleming reasons, “so when they go to the Beer Store or LCBO they are often choosing a section of craft beers to try based on the packaging.

“With the female shoppers increasingly assuming the role of primary purchasers for the family in the important new grocery channels as well,” he points out, “creating packaging with a distinct and interesting shelf presence that tells a story about the beer and your brand is crucial.”

To pull this feat off for Cameron’s, the Cactus team first went about updating the brand’s original ‘Barley Man’ logo, now depicting a stylized bearded farmer carrying oversized barley sheaves tucked under his arm.

(See pictures above)

“The challenge was to update the brand icon while still maintaining its history and heritage,” Fleming explains, noting that in addition to being a key packaging graphic, it’s also the main marketing emblem

appearing on Cameron’s branded apparel, glassware, coasters and other promotional items.

“The new Barley Man is very distinct, dynamic and modernlooking,” says Fleming, “helping the brand stay fresh and relevant.”

As for the rest of the cans’ packaging real estate, Cactus decided to deploy an array of classic Canadiana imagery—mountains, black bear, lighthouse, sailboats and pine-trees— to lend a unique voice to each of the three core brands.

“The can designs are modern representations of classic Canadian imagery, places and stories,” he explains.

“We were very careful to take a unique direction that would be visually interesting and distinct on the shelf, while maintaining a style that didn’t alienate our long-time customers, but was more likely to attract new ones.

“The cans’ simplistic and colorful graphic style is intended to make them fun and approachable,” he states, “because the Cameron’s brand is inclusive, friendly and approachable.

“You can be a craft beer snob or totally new to craft beer and enjoy our beers just as much.”

Says Fleming: “The Cameron’s team puts so much effort into creating fantastic craft beers, that we had to ensure the packaging communicated innovation and quality, while remaining genuinely authentic to the company and its history.”

According to Coleman and Cameron’s brewmaster Jason Britton, the new cans hit all the high notes spoton with their eye-catching design, which is direct-printed right onto the 473-ml aluminum Tallboy-style cans shipped to the Oakville facility from a Crown Metal Packaging canmaking plant in Batesville, Miss.

“Crown has been supplying us with cans for last the several years,” says Britton, “and we have always been impressed with their high-quality cans

that never give us problems on the line.

“We also love their customer service.”

Shipped to Oakville in bulk in towering palletized loads, the colorful cans are filled on the plant’s all-new canning line—installed in early 2016—designed and integrated into a turnkey system by Palmer Canning Systems, Chicago-based beverage line integrator specializing in craft-brewing equipment installations.

Running at the average throughput speed of 42 cans per minute, the compact system comprises:

• An automatic high-level depalletizer. Stationed directly above the canning line on the main floor, the compact depalletizer sweeps the cans off the pallet layer by layer and rinses the interior of each can via a compact S-shaped rinser.

• A monoblock 12-head counter-pressure filler with a single-head seamer, which purges all the oxygen from the cans prior to filling and quickly applies pull-tab can ends to the top of the precision-filled cans.

• A plastic-belt conveyor, a rinser and a drying station to put finishing touches on each can before they pass through the inkjet date-coder.

• A Domino model A320i continuous inkjet coder used to apply highly legible production date codes to the bottom of passing cans.

For now, all the case-packing and palletizing is done manually, but Britton says the company is currently studying its options in the marketplace with the view of automating its end-of-line packaging operations, once volume demand justifies the expected ROI (return-on-investment).

“After the site preparations were done, it took about two weeks to have the system installed and fine-tuned,” says Britton, “and it was time sell-spent.

“This system has exceeded our expectations as far as commissioning of the line, the installation, and the performance and quality levels,” he states, adding the company also enjoys “great” local technical support it receives from Buxton Mechanical Solutions, Inc., Palmer Canning’s Canadian representatives.

“After doing our canning on a mobile canning machine prior to this installation,” Britton relates, “we are very happy with how successful we have been with the new Palmer system to date.”

The well-maintained Oakville plant currently

FFG gap measurement

• Is unique: exact measurement of printed corrugated boxes

• Checks the gaps formed when the panels are folded

• Is based on a patented method

• Is part of the Baumer hhs Box Monitoring system

A precision landing in flexibility and quality: the new Flowmodul from Schubert.

from Schubert, visit www.schubert-magazine.com

employs 10 full-time production people to turn out a dozen to about 20 different SKUs (stock-keeping units).

“We are only using a third of the building right now for production, with the other half used primarily for storage of cans, boxes and other supplies, so we have plenty of room to grow and add to our capacity as the market dictates,” he says.

“We have set up the brewery much like a LEGO toy set, all positioned to drop in additional fermenting vessels to boost capacity and new packaging equipment to handle that capacity.

“We strongly believe in automation as a future strategy for us, but the level of that automation has to match our production demands at the time, while maintaining our commitment and passion for handcrafted beer.

“We still have to grow a little more to justify the more intensive automation investment,” says Britton, noting the company’s short-term plans aim to quadruple its current output volumes.

“Right now we are experiencing growth in all of our segments,” says Britton, noting that while canning accounts for about 70 per cent of total production, its

draught beer (keg) business is also booming. Adds Coleman: “The great thing about cans is that you can go into the LCBO and pick out a can from one of several Ontario craft beers and virtually travel the province by sampling them.

“Or taste-test other provinces’ beer, the U.S., or the world for that matter: consumers are migrating to cans because they love their convenience and the uniqueness of the product experience they offer.”

While the company’s existing bottling line has been largely underused in recent times, “You never say never in this business,” Britton remarks.

“The market can be cyclical: what’s out of style one day may well be back in style in the future, but at the moment it’s really all about cans for us as a primary focus,” Britton states.

“The growth of our can business has been truly extraordinary, especially since the redesign that has really rejuvenated our brand.”

To keep its market momentum going, Cameron’s is launching a new Brewmaster’s Selection four-pack this month, featuring two cans of the three main brands, along with two new seasonal canned offerings—Black Forest Dark Lager and the Bamberg Castle Smoked Ale.

According to Coleman, the company’s strategy of introducing a new Brewmaster’s Selection four-pack twice a year—packaged in attractive, high-strength folding cartons supplied by the Mississauga-

based Zebra Paper Converters —has been exceptionally well-embraced by craft-beer enthusiasts.

“Our four-packs are always popular because we offer consumers a real choice in a small package,” Coleman remarks, “with our two regular beers and two seasonal beers they may never have had before.”

Both of the seasonal beers in the new Brewmaster’s Selection pack are unique Germaninspired recipes made with the freshest and highest-quality ingredients, Coleman asserts.

“The designs offer a fresh take on a European feel that mixes well with the Canadiana look of the core brands,” he points out.

Because the two seasonal beers are only sold for a limited time from October to February, the Crown-made “silver bullet” cans in which they are packaged are shrinksleeved rather than direct-printed, Coleman explains, due to the short-run print requirements.

“It’s just much more economical,”says Coleman, crediting Toronto-based label manufacturer Tapp

Label Company for supplying the colorful, highquality rollstock shrinksleeves, which are applied onto the cans at a nearby Alliance Packaging plant in Oakville.

“Both Tapp and Alliance are doing a fantastic job for us,” says Coleman, singling out the 12-color Bamberg Castle brand full-body shrinksleeves from Tapp Label for special praise.

For the European-trained brewmaster Britton, the license and freedom to experiment with new flavors and recipes on a regular basis is a priceless perk of the job.

“It’s a very unique and artistic challenge to produce ‘never-before’ beers,with rare and inspiring flavors,” he states. “It really helps us to stay relevant in the marketplace.

“Consumers can always get a beer, but where do they go to find, say, a Scandinavian-style ale brewed with brett and aged in a foeder?

“That’s not as easily available as people may think.

“So as a company, we are always looking for gaps and holes in the marketplace that we can fill with new products, such as our two new German-style seasonals,” says Britton, adding there is really no such thing as too many beers in today’s craft beer market.

“The flavor threshold and the flavor palette are endless, so the more new beer is made by companies that are truly passionate about their beer, the better,” Britton asserts.

“Likewise, the sudden emergence of so many new small brewers is also a good thing for the industry and the consumer public.

“Having a local brewery is like a throwback to having a local butcher, a local baker, a local barber and local candlestick-maker all down the street,” he chuckles. “It is a perfect reflection of today’s ‘buy local’ consumer mindset.”

“The society is changing, and this change is providing us all with an opportunity to show what craft beer is all about.”

Coleman concurs: “In places like Oregon, craft beers account for at least a quarter of all beer sales in the state, whereas in Ontario we’re still at about five or six per cent of the market.

“Even in British Columbia and Alberta, craft beers own 15 per cent of the market,” Coleman points out.

“So when people ask me how long the current growth for Ontario-made craft beers can continue at such a fast pace, I say ‘Forever’.”

As a board member of the Ontario Craft Brewers (OCB) association who is genuinely relishing life in the craft beer business, Coleman devotes a lot of time to helping build up the industry and helping new microbrewers to get up and running.

“This is an industry made up of family-run businesses with an incredible amount of genuine passion for what they do,” he states.

“And personally, I just love the craft beer industry for introducing the general public to all the different and exciting new taste options. “

Just 15 years ago, everything tasted almost the same: the pilsners, the lagers, the IPAs … they all tasted alike, with miniscule differences in taste profile and flavor,” Coleman reflects.

“What craft brewers have done is encourage the consumer to be more experimental and adventurous,” he sums up, “and the consumer is in turn pushing the brewers back to be even more experimental and adventurous themselves.

“It is a virtuous circle and long may it continue!”

flexible packaging powerhouse finds a perfect pathway to reaching its lofty strategic objectives in the vast U.S. marketplace

BY GEORGE GUIDONI, EDITOR PHOTOS BY RADEK DANIELEWICZ

Everybody enjoys seeing a good business plan come together, especially with the vast amount of money and effort invested by the Montreal-headquartered printing, packaging and media giant TC Transcontinental, which set a goal of becoming one of North America’s leading suppliers of flexible packaging products.

While the plan is still a work in progress, the rapid growth of the recently formed TC Transcontinental Packaging division is absolutely breathtaking in its ambition and scope.

The company already ranks as one of the continent’s top 25 flexible packaging suppliers by revenue.

TC Transcontinental entered the packaging arena in 2014 with the acquisition of U.S.-based Capri Packaging. The second acquisition, Ultra Flex , came a year later and further expanded the packaging division’s capabilities and reach into new vertical markets.

The growth continues with the recent addition of Robbie Flexibles in June of this year, opening up supplemental opportunities in the company’s packaging expansion initiative.

At this pace, there is really no telling just how big a force TC Transcontinental Packaging may become in the North American packaging market, especially considering the company was a virtual non-entity in packaging only three short years ago.

Certainly, TC Transcontinental’s acquisitions represent an exceptionally bold leap forward.

One of the most interesting acquisitions was arguably the addition of

Ultra Flex, which proved beneficially symbiotic to both TC Transcontinental Packaging and Ultra Flex (now known as TC Ultra Flex ).

While TC Transcontinental Packaging benefited by acquiring a company that added firepower to its platforms and leadership in strategic markets, TC Ultra Flex has already been the beneficiary of significant capital investment on the part of TC Transcontinental.

“TC Ultra Flex’s strength lies in directly serving branded consumer products, both national CPG (consumer packaged goods) brands and private-label products for leading retailers,” says vice-president of business development Todd Addison, one of the company’s original co-founders and, by extension, its longestserving employee.

“I think TC Ultra Flex brings to the table a well- established national sales force and the diverse range of markets that we serve and lead.”

Founded in 1974, TC Ultra Flex is a remarkably successful growth story in its own right, with its unique beginnings in flexible packaging for the apparel industry.

It currently employs over 300 people at a state-of-the-art, 220,000-squarefoot facility in New York City’s famed borough of Brooklyn.

As one of the biggest manufacturing employers in the local area, the company has done a stellar job over the years to build and maintain a leading share of the U.S. tobacco, coffee and confectionery markets.

Supporting the growth are high-quality flexible printing and laminations, along with a full gamut of converting capabilities.

We offer a complete range of innovative inkjet, thermal transfer, laser, digital, print & apply systems, software, consumables and services to help you…

Verify code accuracy

Manage any recalls

Assure full compliance

Reduce product rework

Minimize line downtime

With breakthrough technology and state-of-the-art software for any need, Markem-Imaje is redefining what’s possible so you can maximize your production and lead the way in your own market.

1-800-267-5108 www.markem-imaje.com

Operating a busy 24-hours, five-days-a-week schedule with occasional weekend “buffer shifts” to meet seasonal demand swings, the TC Ultra Flex plant supplies a diverse range of high-barrier laminations, printed rollstock and non-foil lidding.

The Brooklyn operation also produces an exceptionally wide variety of bags and pouches including stand-up, quad-seal, three-side-seal and flat-bottom pouches and bags in all shapes and sizes.

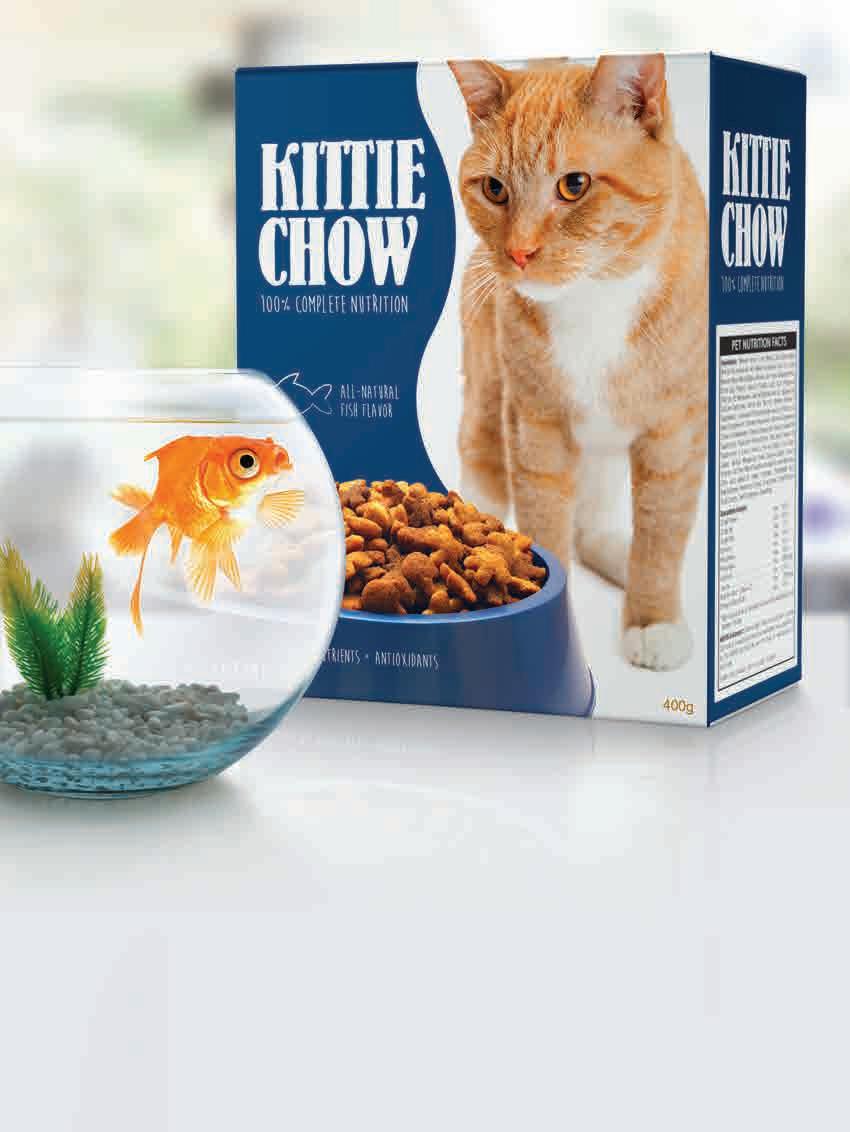

The sizes range from large, 35-pound bags used for bulk dry pet-food to half-pound pouches for products such as pre-cooked rice and very small unique pouches for varied markets across the U.S., Canada and even the Caribbean.

The progressive company continually upgrades its technological capabilities with proactive investment in new production and converting machinery, and, as part of the TC Transcontinental Packaging division, recently completed a multimillion-dollar facility expansion to improve process workflow.

The upgrade also involved adding new cutting edge pouch and bagmaking machinery as well as the highly anticipated arrival of a new multicolor flexographic printing press from Germany.

“To support this expansion and facilitate

efficiency, we installed a new integrated workflow technology system that allows us to easily manage all aspects of production from order input and inventory management, through to shipping and invoicing,” says Addison.

“We added equipment that is the most efficient, yields the highest speeds, maximizes output, minimizes waste and optimizes our equipment utilization.”

“A large part of this recent expansion was moving and upgrading our converting area and opening up an additional bay for a new press,” Addison explains, noting the busy Brooklyn plant now houses multiple state-of-the-art, highdefinition flexo presses and converting lines, along with leading-edge prepress capabilities.

“Our industry is as tough as any other out there,” Addison says, “and to remain competitive we must provide our customers with value.

“We deliver value by providing what our customers need to be responsive and competitive in their markets, which means producing a product that they trust in terms of product integrity, high quality and performance.”

“One key aspect of quality is image reproduction,

with high-definition printing and prepress being key to attaining it,” he adds.

“Having an internal prepress department allows us to be self-sufficient and flexible because we can prepare our own plates,” says Addison, citing the company’s proud track record of quick turnarounds and speed- to-market.

“We are constantly driven by our customers’ needs to produce packaging that is convenient, smarter and more cost-effective than what they already have,” Addison notes, citing a pronounced shift in the pet- food industry from traditional multiwall paper bags to the so-called “polybox” stand-up bags and other similar flexible structures

that enhance consumer convenience and extend product shelf-life.”