AT CLOSE RANGE

Upstart meat processor nails hole-in-one with top-class thermoform packaging machine

Story on page 14

Upstart meat processor nails hole-in-one with top-class thermoform packaging machine

Story on page 14

Discover new ways to keep your bottling lines moving while making your business more sustainable. System Plast® conveyor components will help you achieve your sustainability targets. Interested in reducing the use of water, elimination of slippery floors, reduced energy consumption, less downtime and less waste?

Ask our specialists for specific recommendations for your plant. You can start now reducing the natural resources we consume!

* Actual numbers depend on line size and circumstances

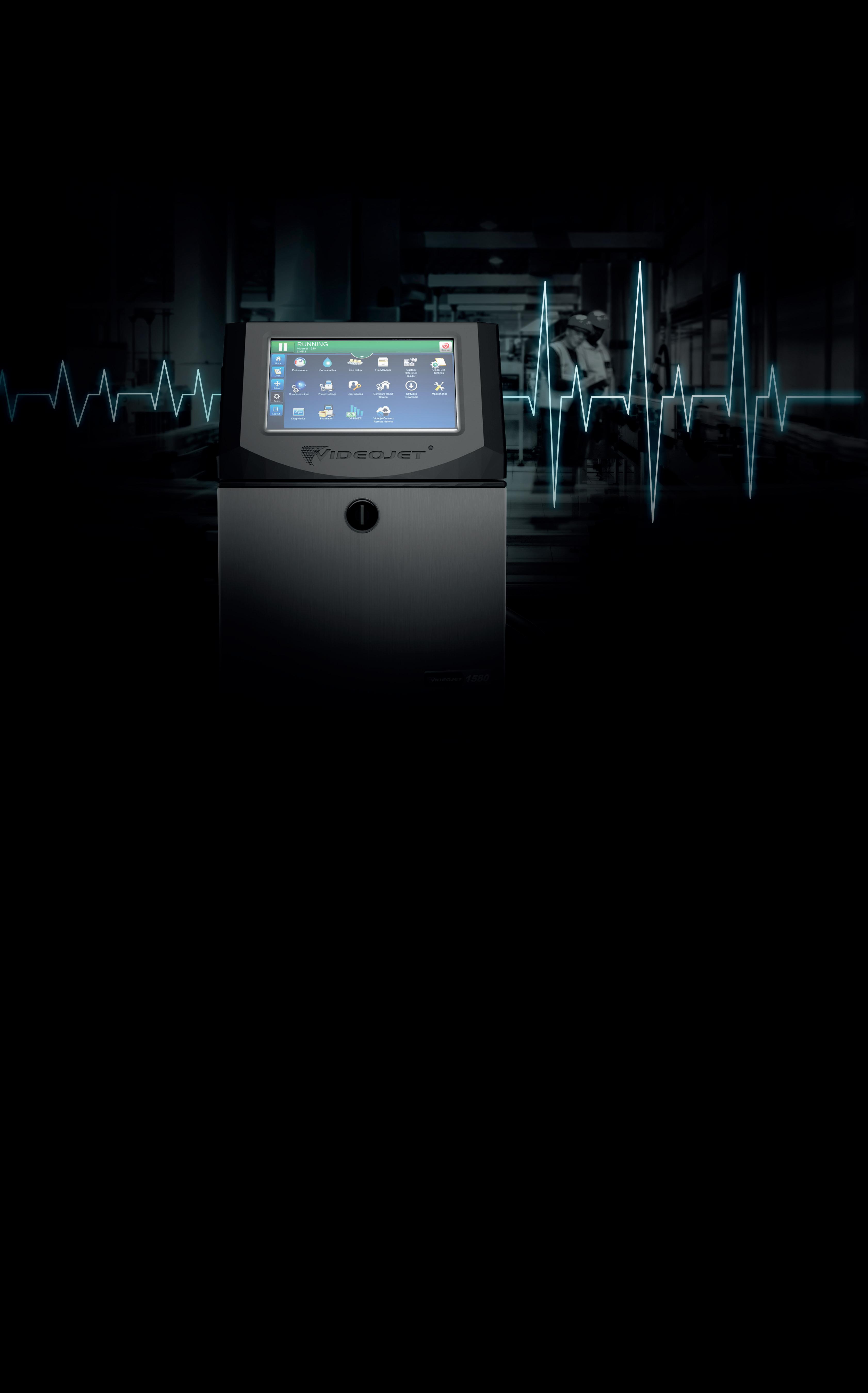

Backed by more than 40 years of continuous inkjet expertise, the latest Videojet CIJ printer is designed for uptime peace of mind and errorproof operation. The 1580 features the SIMPLICiTY™ user interface, CleanFlow™ technology, Dynamic Calibration, SmartCell™ components and optional VideojetConnect™ Remote Service to drive significant printer improvements through everyday operations.

Technical Support

Before and after sales support includes same-day parts shipment, rapid-response service, applications assistance, engineering, installation, and operator training.

Demonstration + Testing

Test the latest inspection equipment at Heat and Control’s demonstration centers.

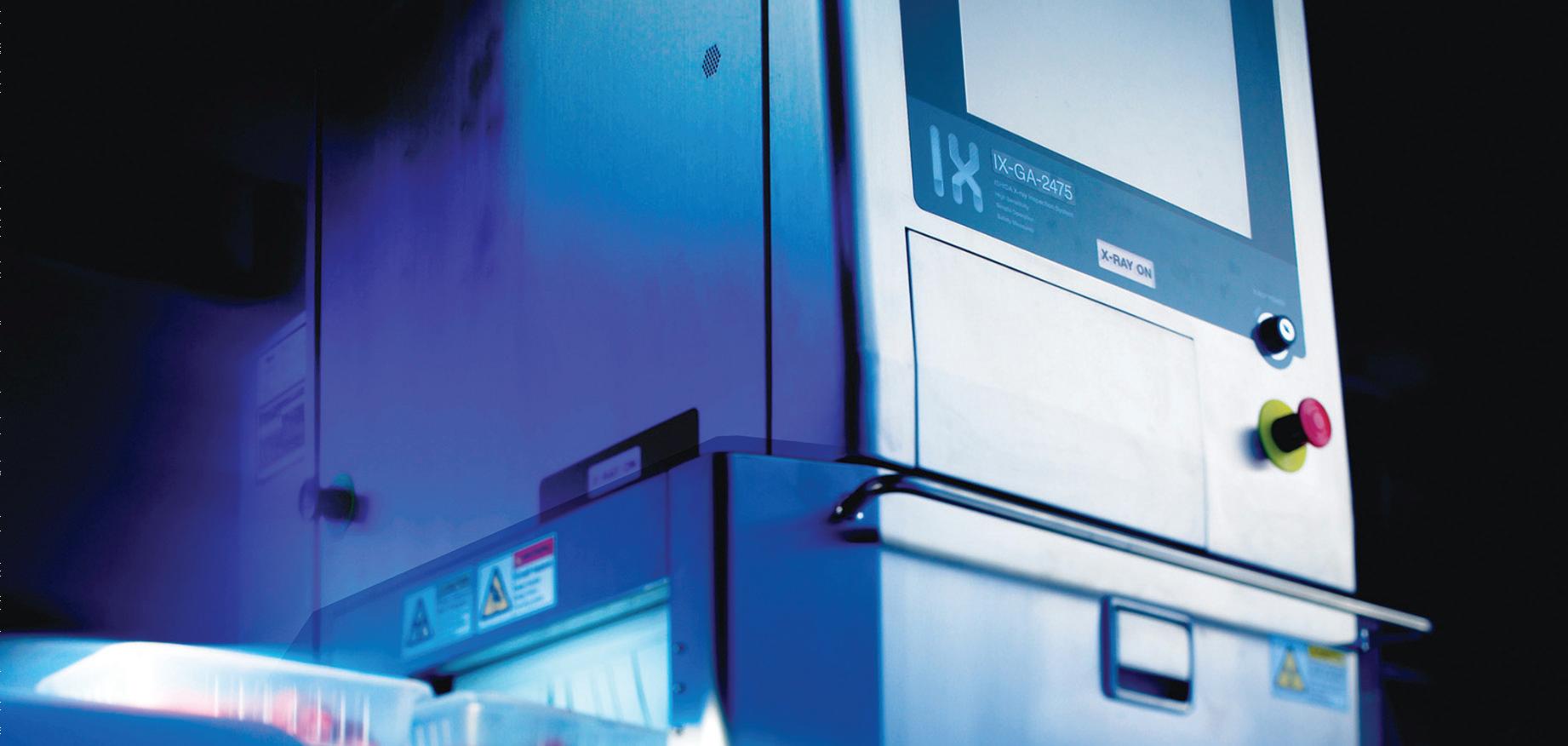

Heat and Control® offers a complete line of metal detectors, checkweighers, and X-ray inspection systems for pharmaceutical and food products from the leading manufacturers: Ishida and CEIA®

CEIA Metal Detection

The world’s largest manufacturer of metal detectors, with more than 90,000 units installed. Systems include THS/MS21 for food products, with optional USDA-certi ed construction (e.g., dairy, meats, poultry) and PH21-Series for pharmaceutical products (e.g., pills, tablets, capsules); both deliver unparalleled accuracy and sensitivity to all metals and provide high throughput rate.

Ishida X-ray Inspection

Find foreign objects, including metal, glass, bone, plastic, hard rubber, shell, and stones. Or detect product defects, like cracks, voids, missing items, and improper weights.

Ishida Checkweighers

Verify product weight, count, or missing items with DACS checkweighers. User-friendly controls include advanced data collection and management features.

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

As the gloom and despair wreaked around the world by the COVID-19 pandemic slowly begins to lift, there is no doubt that getting the world’s leading economies back up from life support will become top priority for Ottawa, White House and all other nations whose economic supply chains and social safety nets have never been stretched like they have over the last several weeks of collective worldwide house arrest.

cause-and-effect relationship at play between human and environmental health.

It’s a telling paradox to see how a sudden stop to everyday industrial activity has manifested itself in surprising displays of Mother Nature’s resiliency: smog-free sunny days in Beijing, marine life returning to the clear blue canals of Venice, the Himalayans becoming visible from 200 kilometers away ... it’s like seeing a planet healing itself after a prolonged depletion of its resources and ecosystems.

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

MEDIA DESIGNER

Brooke Shaw • (519) 428-3471 bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer • (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER

Anita Madden • (416) 510-5183 AMadden@annexbusinessmedia.com

VICE PRESIDENT

Tim Dimopoulos • tdimopoulos@annexbusinessmedia.com

COO Scott Jamieson ANNEX BUSINESS MEDIA

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

But it is not their one and only job. For all intents and purposes, any hope of salvaging the world’s annual economic growth from grim reality of lost jobs, productivity and prosperity any time this year or next is pure wishful thinking. The global economy was already sputtering even before global health authorities and national governments came to grips with the destructive nature of the coronavirus outbreak, so getting back to the way things were even at the turn of the decade is simply not in the cards.

Whatever new normal emerges form this tragic calamity, it will never be the normal we once knew and took for granted. And with a magic cure or vaccine still being at the idea stage, at least at press time, we all better get used to it.

The problem with focusing solely on economic recovery is that such tunnel vision will hold back the much-needed efforts to clean up the planet’s environment and the impact of climate change, which we have witnessed over the last year played out in many corners of the globe at unprecedented levels of death and destruction—forest fires, hurricanes, tropical storms, heat waves, you name it.

While there is no evidence of a direct link between the growing incidence of weather-related disasters and the coronavirus outbreak per se, it does not seem beyond reason to speculate about some sort of a

That’s why it is paramount that in our rush to regain the lost economic ground we don’t do it at the expense of putting the pressing environmental issues of the day on the back burner, yet again.

For the packaging industry, that means continuation of the considerable pre-pandemic progress towards the Circular Economy goals and objectives aimed at minimizing the industry’s environmental footprint.

Much has been said in the past about consumers not backing up their green intentions with their purchasing decisions, but as the current lockdown across much of the world shows, consumers can be led to do the right thing in the moment of crisis once they realize the life-and-death gravity of the situation.

The point is to give the consumers the means to make the right choices during the new normal, which means making the more sustainable products and packaging mainstream, rather than alternative options. To do that, governments must show the resolve to see their green promises brought to life in spite of the short-term economic discomforts this may cause. It’s all about leadership and the will to stay the course despite temptations to cut corners for the sake of short-term expediency. Let’s hope we have it in us, for all our sakes.

With the raging COVID-19 epidemic continuing to claim soaring numbers of victims across Canada, and with the province of Quebec recording the highest fatalities, Kingsey Falls, Que.-based forest products group Cascades Inc. wasted no time in stepping up to the frontlines last month to help reverse the deadly tide.

Partnering up with hockey equipment manufacturer Bauer and clothing retailer Tristan , Cascades commenced production of at least one million pre-cut medical visors at the company’s Inopak plant in Drummondville, Que., to help protect the province’s medical and healthcare professionals overwhelmed by the rapid spread of coronavirus throughought Quebec communities.

Cascades is using extruded recycled rolled plastic supplied by Vaudreuil-Dorion, Que.-based plastic recycler NU-B, Inc. to manufacture the visors, with Tristan and Bauer taking care of the final assembly.

Both Tristan and Bauer have retooled some of their manufacturing operations in recent weeks to boost production of various much-needed medical equipment and protective clothing for the province’s medical workers.

“Our company is very pleased to be able to contribute to these promising and important initiatives by providing materials and components,” says Cascades president and chief executive officer Mario Plourde.

“We applaud the organizations launching these projects and want to thank our employees for their remarkable agility and dedication,” says Plourde.

“Other projects have been submitted to Cascades,” he adds, “and the company is assessing the feasibility of supplying materials and production capacity needed for their completion.”

According to Cascades, whose “essential business” exemption has allowed the company to continue operating, any new special orders with not interfere with company’s regular containerboard and tissue product manufacturing activities.

Founded in 1964, Cascades currently employs about 12,000 people at over 90 production sites in North America and Europe, and the company is the country’s leading producer of paper products

made from recycled fiber.

Last month, the company was included in the 50 Top Business Moves for the Planet list—released on the 50th anniversary Earth Day, April 22, 2020, by Earth Day Canada and the Corporate Knights philanthropy group—to recognize Cascades’ pioneering role in the growth of recycling in Canada.

“In the 1950s we could not have foreseen that the simple idea of diverting material from landfills to recovery would go so far,” says company co-founder and executive chairman of the board of directors Alain Lemaire.

“By giving new life to this material, we reduce the pressure on natural resources and minimize waste,” Lemaire adds.

“Even though the idea wasn’t popular at the time, I am very proud that we were true to our values and ideals and continue to honor them today.”

According to Cascades, 83 per cent of the materials used to make its products come from recovered sources.

While tradition dictates that premium quality wine can only be enjoyed from a glass or a bottle, Toronto entrepreneurs Chris Noll and Justin Dumitrescu had vastly different ideas when they ventured to California with the goal of creating a modern winery that would put the same premium quality wine into portable packaging formats like aluminum cans and paperboard boxes.

And starting this month, Canadian wine aficionados will be able to judge for themselves, as the Sheep Black Wine makes its debut in the Canadian markets— excluding Quebec—with the phased launch of the winery’s stel+mar brand of premium California wine, packaged in single-serve 250-ml aluminum cans supplied by Ball Corporation and 500-ml Tetra Pak aseptic beverage cartons.

While the canned wine category has been growing at an average rate of 94.9 per cent in the last few years, the Sheep Black co-founders noticed that most of the cans were used to package fairly low-quality product that serious wine aficionados would generally bypass altogether.

“That’s when the light bulb went off in our heads,” says Dumitrescu. “We didn’t think you needed to sacrifice taste to get convenience, so we went to work putting really, really, really good California wine in cans and boxes.”

According to Sheep Black, the stel+mar brand only uses premium low-sugar, fruitforward California varietals for its flagship product line, which includes:

• a dry classic style Zinfandel (100% Red Zinfandel ) from Lodi, Ca., notes of raspberry, blackberry and cherry;

• a dry but fruit-forward 100% Unoaked Chardonnay from the North Coast region

of California, with flavors of ripe green apple, melon, and hints of caramel;

• a well-balanced Grenache/Syrah Rosé, bursting with notes of ripe nectarine, grapefruit, and strawberry;

• sparkling White and Sparkling Rosé bubbly wines, said to be perfect accompaniments for any festive and/or toasting occasion.

As Dumitrescu relates, Sheep Black recruited the services of an up-and-coming Toronto-based graphic designers Zoca Studio Inc. to create the vivid, attentiongrabbing graphics used to decorate the stel+mar brand’s cans and cartons.

“We desired a modern design concept to accompany our vision for a modern winery,” Dumitrescu told the Canadian Packaging magazine. “The basic idea was ‘wine for a new generation of wine drinkers,’ meaning drinkers who care less about Old World traditions and more about great wine and convenience.

“We enlisted the help of the amazing Jose Garcia at Zoca Design to bring our vision to life,” he says, “and he really hit it out of the park!”

Adds co-founder Noll: “One of the major benefits of cans and boxes is that you can take them anywhere. With stel+mar, really good wine can now go where you go—to the park, to the party, to the dock … all the places traditional bottled wine couldn’t go,” says Noll, also citing the portion control aspect of the brand’s packaging.

“People often open up a bottle of wine and either end up wasting some of it or feel obligated to drink more than they wanted,” Noll explains.

“With stel+mar that problem goes away: you can open one, two, three or more cans if you want more wine.”

leadership performance

Processed deli meats and sausage generally get a bad rap from health experts on the account of their high salt content, among other things, but Quebec-based pork processor Les Viandes du Breton inc. is happy to challenge such assumptions—one slice at a time. Since becoming the first North American pork producer to receive the Certified Humane certification for animal welfare, the familyowned company has become one of the continent’s leading progressive manufacturers of organic processed meats by adopting innovative methods that respect consumer needs, animal welfare and the environment.

These righteous values have been emphatically underscored with last month’s launch of two new duBreton brand gluten-free product lines, retailing in transparent ‘clean label’ packaging designed by the company’s in-house graphics team.

Produced and packaged at the company’s St-Charlesde-Bellechasse plant near Quebec City, the duBreton brand Cooked Ham, Smoked Ham and Black Forest Ham slices are packaged in lightweight 125-gram flexible vacuum-packs outfitted with an innovative sideway Zip-Pak closures for easy resealability of the product.

Made without any nitrates and offering 20-percent protein content per slice, the packaged hams are put through a rigorous HPP (high-pressure pasteurizing) process—whereby the finished packages are inserted inside a special HPP vessel that uses water to generate high levels of isostatic pressure to sterilize package contents prolong their shelf-life, without affecting the taste or texture of the meat inside.

For their part, the new duBreton brand of pork sausages—offered in Mild Italian, Hot Italian and Toulouse flavor varieties in both rustic and organic versions—are made with simple ingredients and without any filling agents such as breadcrumbs or flour.

Produced and vacuum-packed at a duBreton plant in Rivière-du-Loup, the premium-quality sausages are made only with shoulder muscles, according to the company, without adding any meat fillers or byproducts.

n Cincinnati, Ohio-headquartered packaging machinery manufacturing group ProMach has completed the acquisition of PharmaWorks, Inc., a prominent supplier of blister packaging technology for the pharmaceutical, consumer goods, and contract packaging industries. Founded in 2001 in Odessa, Fla., PharmaWorks employs about 100 people to manufacture a broad range of thermoforming solutions for the creation of blister-packs—from semi-automated thermoformers to fully automated systems capable of speeds up to 600 packages per minute—along with all the auxiliary feeding, transferring, collating, cartoning, and vision/inspection systems. In addition, PharmaWorks provides complete blister line integration services for customers needing turnkey blister packaging lines, complete with validation documentation. Says ProMach president and chief executive officer Mark Anderson: “The pharmaceutical industry has been a strong growth engine for ProMach over the last five years, beginning with our acquisition of NJM in 2016 and continuing with the addition of WLS in 2017 and now PharmaWorks in 2020. With market research forecasting continued strong growth in the pharmaceutical sector over the next few years, blister-packs are a key part of that growth story—driven by consumer convenience and safety, particularly with regulations around serialization.”

n Keystone Folding Box Co. Newark, N.J.-based supplier of paperboard secondary packaging solutions for the pharmaceutical and healthcare industries, has completed installation of additional die-cutting and gluing machinery that will expand its capacity for vial and syringe packaging by 25 per cent. According to the company, fast-growing demand in the biologics and vaccines market segments for the packaging of pre-filled syringes, autoinjector pens, vials and ampoules has prompted the investment, which will also enable it to offer significantly shorter lead-times. “With injectable products made of glass or rigid plastic, protection is paramount,” says Keystone Folding Box director of marketing and business development Ward Smith. “Secondary packaging must be designed and produced with the right materials to protect pre-filled syringes, auto-injectors, vials and ampoules as they travel through the supply chain.”

n Legacy Pharmaceutical Packaging, LLC, St. Louis, Mo.-based contract packager serving the global pharmaceutical industry with bottling, blistering, pouching, unit-of-use, compliance and secondary packaging services, has purchased three high-speed blistering and cartoning lines with serialization and aggregation capabilities from McKesson RxPak ’s production facility in Memphis, Tenn. The infrastructure acquisition nearly doubles Legacy’s total blister production capacity, according to the company, which now stands at a half-billion packs per year. In a separate equipment investment, Legacy has also announced plans to install an additional new highspeed bottling line this summer, bringing its bottling capacity to about 600 million units per year. Additionally, the company recently incorporated two new pouching machines to help

meet growing demand for tablet and capsule filling applications. “This infrastructure investment is a natural evolution of the expansion plans Legacy adopted several years ago, starting with a 100,000-square-foot expansion in 2017 that added both production capabilities and warehousing capacity to provide a total of 300,000 square feet,” says Legacy’s chief executive officer David Spence. “Considering both recent growth, and that we anticipate more U.S.-based production moving forward, this was the right time to continue in a way that makes Legacy an even more versatile, dynamic and turnkey packaging partner.”

The new PTF series machine from Premier Tech Systems and Automation is a fully-automatic openmouth bagger designed for quick and precise dosing of powders with up to +/-25-gram accuracy for minimal product giveaway. The machine’s innovative bottom-up filling system avoids product free-falling as the vertical auger automatically fills the bag from bottom to top, keeping dust emissions to a minimum. The filling is done in two distinct steps—coarse filling followed by top top-up fine filling—to achieve rapid and accurate target weights at speeds of up to 20 bags per minute. The platform was also designed in accordance with all standards for the handling of explosive powders, according to the company, with the flexibility to accommodate many different bag sizes up to 55-kilogram weight capacity.

Premier Tech Systems and Automation

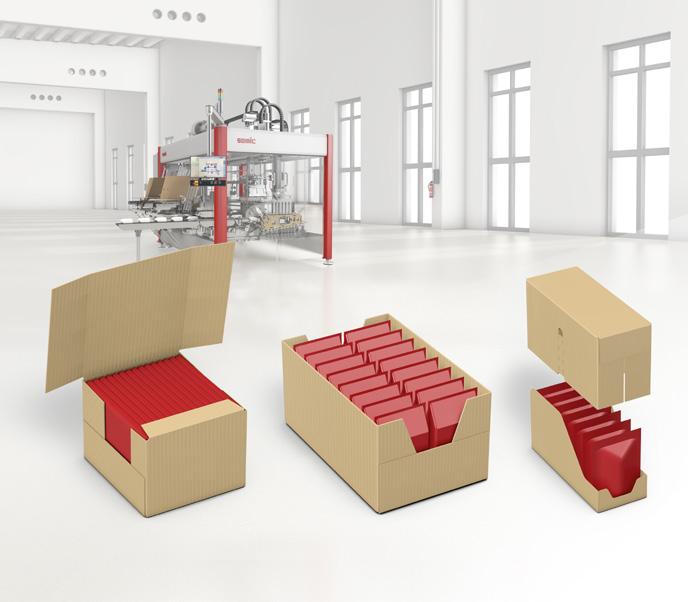

Designed for medium to high outputs in secondary packaging cartoning applications, the new SOMIC 424 DT machine from Somic America Inc. can collate up to 600 products per minute, with a cartoning capacity up to 30 packaging units per minute, depending on the product. Designed to ensure gentle product handling, the machine’s proprietary tool-less, quick-change technology ensures rapid format changes to accommodate products to be packaged either flat or upright, in a single or double row, into two-component carton packaging—tray and lid—that can go right onto the shelf at the retail pointof-sale.

The new VMEF/VHEF directional control valves from Festo literally puts precision actuation at the user’s fingertips, or even just a pinky, as a single finger can be used to activate these valves via a trigger mechanism. Based on touch actuation with minimal force—with no energy to convert, no long cables or additional response time—the valves are designed to perform functions that directly result in a follow-up action: like clamping or closing safety doors (if manually actuated); or acting as a signal generator (if mechanically actuated). The actuated stem switches the valve and triggers that next step in the process. For manual actuation, the VHEF offers a choice of triggers—a finger, handle or toggle lever or a pushbutton—while VMEF offers a stem, roller-lever or one-way rollerlevel actuation. These ergonomic manual/mechanical valve series have a robust metal housing and are capable of withstanding sudden, significant force to allow for occasional rough treatment.

Festo Inc.

Omron Automation Americas has launched a next-generation software package developed to simplify the management of mobile robot fleets. Called FLOW Core (Fleet Operations Workspace Core), the software offers a user-focused design that simplifies integration, charge management functionality to increase flexibility and efficiency, intelligent fleet management, and other advanced capabilities that provide operators with seamless robot control for all activities, including fleet ob -

servation, job assignment, and mapping.

Omron Automation Americas

Designed for easy and intuitive programming of ABB’s popular singlearm YuMi collaborative robots, the company’s new Wizard Easy programming software is built on the concept of Blockly, an open-source visual coding method that presents programming language or code as interlocking blocks. By using this simplified approach, Wizard Easy allows users to simply drag and drop these functions on the FlexPendant device, see the results immediately, and adjust the robot’s actions within seconds. Featuring essential robot functions such as Move, Pick and Vacuum to cover a wide range of tasks typically performed by robot, the software also provides functions for error handling—allowing novice programmers to take care of errors such as collisions. Available as a preinstalled application on the FlexPendant device for all new single-arm YuMi robots, the Wizard Easy programming software is available for free to existing YuMi customers in the form of a free add-in that can be installed via RobotStudio to the FlexPendant device.

ABB Robotics

Designed to ensure safe product conveying without the risk of static electricity discharge, the new tribo-polymer xirodur F182 from igus is specifically engineered to pro -

vide users of xiros polymer ball transfer units to move sensitive or heavy product loads of up to 50 kilograms in all directions. Designed to facilitate smooth product transfer and requiring no lubrication, the durable abrasionresistant xirodur F182 features special composition that dissipates any static charge by the ball transfer unit, making sure that the puncture voltages are not discharged on to transported goods or employees. igus, inc.

Configurable for any collaborative robot application with any major robot brand, the new vacuum-operated piCOBOT end-of-arm-tool (EOAT) from Piab offers users a generic electrical interface as well as several options for mechanical mounting plate dimensions in accordance with the ISO 9409-1 standard— thereby enabling it to be configured to work with any collaborative robot and smaller industrial robots. With Piab’s user-friendly online configuration tool, customers can choose between a generic electrical interface—including a standard cable or one specified by Universal Robots—or from various different mechanical interfaces to configure tools that precisely meet their specific requirements and/or applications. Featuring Piab’s proprietary and highly efficient COAX vacuum technology, piCOBOT comprises a vacuum pump unit and a gripper unit fitted with suction cups selected from Piab’s extensive range of suction cups, enabing customers to tailor their own cobot solutions with true plug-and-play versatility. Piab

Engineered for use on the new HP Indigo 35K digital press for foldingcarton printing, the new-generation TRESU iCoat II coating technology is a high-end, single-pass coating solution capable of applying spot, partial or full surface coating immediately after the printing stage across a broad range of substrates. Featuring superior registration and tight tolerances, the new fully integrated inline coating solution is designed on a flexible modular platform, which can be updated with further modules and functionalities at

any time in order to accommodate future changes in brand-owners’ printing operations or changes arising from short-run seasonal fluctuations.

CLOSING TIME

The new Dara SYXE-OR aseptic filling and closing machine for vials and bottles from NJM Packaging —a division of ProMach —features direct drive servo-motion controls, a starwheel-driven design, compact footprint, precise operation, quick changeover, modular configuration, and a wide variety of options to enable each system to be customized to handle the exact products, containers and closures to satisfy each customer’s specific needs. The servodriven, rotary, intermittent-motion Dara SYX-E-OR fills liquid or powder products in vials or bottles made from glass, plastic or metal, with dose volumes from 0.1-ml to one liter. The quick-changeover system can be equipped with stainless-steel or ceramic rotary piston pumps to achieve +/-0.5-percent accuracy; with peristaltic pumps to achieve +/-1.0-percent accuracy; or with a powder doser to achieve +/-2.0-percent accuracy. The robust and versatile system can close the containers with snap-on caps, screw-caps, childproof caps, aluminum caps, stoppers, spray/dosing pumps and droppers, whereby the caps and droppers are fed automatically by vibrating feeders made of AISI-316L stainless steel. A pick-andplace station places the caps and droppers onto bottles sequentially using a vacuum, while the closing station is equipped with a servo head to handle even the most difficult screw closures. The closing torque can be managed either electronically or magnetically, and the system can be built as a single-head system—to run at production speeds of up to 100 units per minute—or as a dual-head system featuring two filling, two plugging and two

closing stations to handle throughputs of up to 183 units per hour.

NJM Packaging (Div. of ProMach)

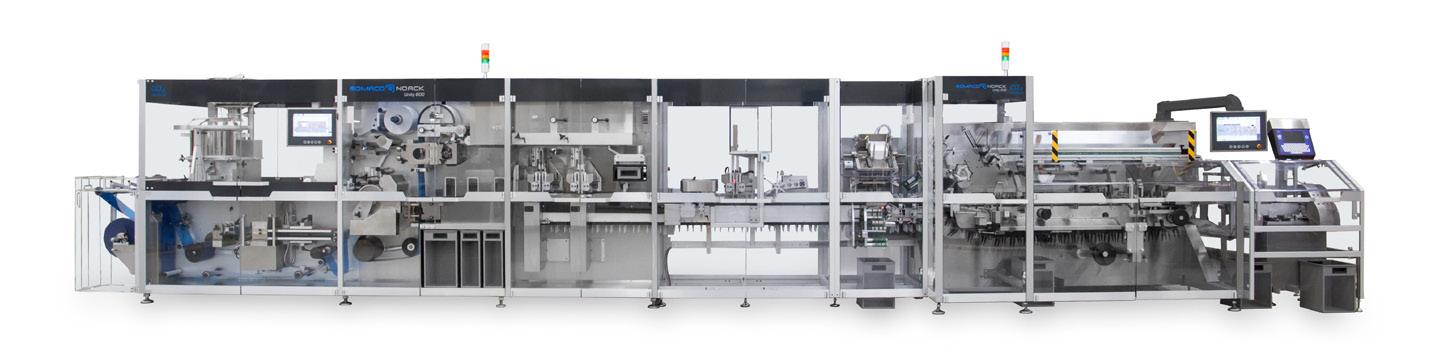

Designed to process blister packaging formats arranged crosswise to the running direction, the new Unity 600 blister packaging line from Romaco Noack is a high-speed monobloc machine capable of reaching speed of up to 600 blisters and 400 cartons per minute. Consisting of a blister ma-

chine with rotary sealing and a continuous-motion cartoner, the compact and flexible system can be configured with a wide range of various feeding units, and it can also be easily integrated with different Romaco cartoners, track-and-trace and end-of-line-packaging solutions. Offering reproducible parameters, lightweight format

parts and simple settings to speed up format and product changes via the machine’s operator-friendly HIM (human-machine interface), the Unity 600 blister packaging machine can also be shipped with RFID (radio fequency identification)-assisted user identification, according to the company. Romaco Noack

and I’m a member

of

Toronto-based TerraCycle Canada is continuing to build up its credentials as the country’s leading recycling pioneer with a new program designed to recycle the MEGA brand construction toy brand manufactured venerable toymaker Mattel

Launched last month across Canada, the Blocks and Bricks Recycling Program encourages consumers to send in used MEGA Bloks, MEGA Construx and other non-electronic MEGA brand toys to be recycled at no charge.

After consumers sign up for the program online at www.terracycle.com/blocks-and-bricks, they can mail in their used MEGA pieces using a pre-paid shipping label that can be printed at home.

Once collected, the blocks and bricks will be cleaned, melted into hard plastic and remolded to make new products such as playgrounds, picnic tables and park benches, to name a few.

“MEGA is giving builders of all ages a unique opportunity to divert waste from landfills,” says TerraCycle founder and chief executive officer Tom Szaky, adding the Blocks and Bricks Recycling Program is open to any individual, school, office or

For Swedish flexible packaging pioneer Ecolean AB, capturing the imagination of Russian consumers with its distinct, lightweight flexible beverage and liquid food packaging has been a challenging but rewarding endeavor that was fittingly celebrated with the opening of a first collection and recycling point for Ecolean packages in Moscow last month.

Located at the Zelenaya Tochka waste collection point at the Flacon Design Factory complex in Moscow—once home to a 150-year-old glass factory—the new recycling depot is part of Ecolean’s agreement with leading local waste diversion group EcoLine Group, which serves about two million residents and 7,500 business located in the city’s central and northern districts.

Under the agreement, all Ecolean packages collected at Zelenaya Tochka (Green Point in Russian) is sent to the Tver Secondary Polymer Plant—about 160 kilometers from Moscow—for recycling, after which they are used to manufacture new products such as stationery, plastic furniture, polymeric sand pavers, and housewares.

“Our packages weigh about 50 to 60 per cent less than many conventional packaging concepts,” says Sergey Sirotin, managing director of Ecolean Russia & CIS.

“This significantly reduces environmental impacts during the entire life-cycle of the packages, including transportation, storage, use and disposal.

“To join forces with EcoLine and to offer yet another recycling opportunity is absolutely fantastic,’ Sirotin states, “and we are committed to continue to develop new ways of reducing waste and to increase recycling.”

Adds EcoLine’s deputy chief executive officer Elena Vishnyakova: “EcoLine Group’s strategy is aimed at reducing waste by collecting and recycling as many packages as possible.

“So we are glad to see a growing number of packaging producers participating in collecting and recycling activities of their packages, because without their participation this process is impossible,” says Vishnyakova, adding that EcoLine annually collects and transports more than 700,000 tonnes of refuse that is then sorted at the company’s various plants.

“The collection point at Flacon has become an important test site for collaboration with a number of sustainability-minded packaging producers like Ecolean.”

community organization.

Says Szaky: “By collecting and recycling items that are typically not recyclable through municipal programs, consumers are given the opportunity to think twice about what is recyclable and what is truly trash.”

For its part, Mattel says its partnership with Terra Cycle is a timely extension of the company’s own sustainability program that most recently culminated in the launch of a new line of building products made from plant-based materials.

“Our plant-based blocks were the first step towards creating a more sustainable future and we are excited to continue the momentum, as we believe that with every step, together we can make an impact,” says MEGA brand’s senior vice-president Bisma Ansari.

“By teaming up with TerraCycle, we are providing builders a more sustainable option to dispose of their well-loved toys and the ability to recycle our toys for free,” Ansari states.

“We are very proud to continue our commitment towards a greener planet, one block at a time, as we build a brighter tomorrow together.”

With global consumption of plastic beverage bottles forecast to reach half-trillion containers per year by 2021, worldwide efforts to recycle waste PET (polyethylene terephthalate) plastic are often undermined by the limited range of end-use possibilities that recycled PET (rPET) materials offer.

For all the efforts by the bottle-making industry to ramp up its reuse of transparent plastic bottles, there is still an enormous amount of colored PET left over due to the lack of commercially viable afterlife applications.

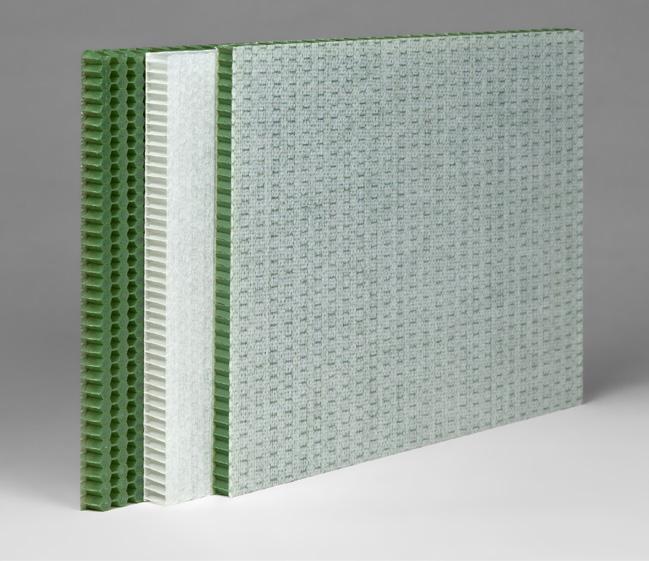

To address this imbalance, Belgian plasticS processor EconCore has developed a new method to incorporate large amounts of rPET materials into the company’s proprietary ThermHex plastic honeycomb materials that can be used to make reusable plastic containers, pallets, layer pads, dividers, protection panels, advertising boards and other industrial and transportation packaging solutions.

According to EconCore, the sandwich-panel design of the ThermHex honeycomb material provides a number of performance advantages over conventional corrugated plastic boards and PP cup-shaped (bubble) panels, including bidirectional performance; enhanced rigidity at a lower weight; flexural strength and compression strength at a lower weight; cost-savings due to lower material and energy use, as well as the fast continuous process used to make the material; Having spent two years to two years to develop and commercialize the rPET honeycomb production process boasting at least 95-percent PCR (post-consumer recycled) content , EconCore says the lightweight material offers a highly effective eco-alternative for lowering the overall greenhouse emissions incurred during production and transportation supply chain stages.

Says EconCore technical manager Wouter Winant: “When you consider the global problem of plastic waste and the urgent need to take better care of the environment, using a honeycomb core based on recycled PET could, without a doubt, be a sustainable solution for markets of large volume production, including automotive, general ground transportation, packaging and furniture.”

As Winant relates, the rPET honeycomb material also offers manufacturers car interiors a high-performance eco-friendly material to build components such as luggage compartment floor; spare wheel covers; door panels and inserts; seat back stiffeners and compartment dividers; cabin floor and underfloor systems.

We’re here to help.

As the world is facing turbulent and unprecedented times, we know that you are confronted with rapidly evolving challenges within your business. We want to assure you WestRock is ready and able to help you navigate these changes. Whether you need redesigned packaging structures or automation for greater efficiency, we can help you get your product to market on time and at speed.

Thank you to the front line workers and all essential services during the COVID-19 pandemic. Our hearts go out to the families who have lost loved ones. PAC is committed to keeping you connected but safe while providing value to support your business and goals.

Our mission GROW your business. DEVELOP your career. PROTECT our planet.

- Continue to bring you valuable virtual opportunities until we can safely meet in-person again - July 1st - PAC Global Leadership Awards launch - offering you an opportunity to showcase your packaging innovations on the world stage - September 1st - Stay Connected Webinar Wednesdays fall launch - offering you access to quality educational content wherever you are

We are actively seeking sponsorship for webinars and other virtual events, giving you an opportunity to partner with us and showcase your brand to our valued community. Please reach out to Jim Downham for further information jdd@leaderlinx.com

We are proud to continue to serve you during this time. Our hope is that together all of us will come through this crisis stronger and better connected.

Sincerely,

James D. Downham President & CEO

Former golf pro prospect exchanges one set of links for another with successful start-up of a meat snack business tailored to suit today’s healthy eating trends

BY GEORGE GUIDONI, EDITOR

It’s a long way to the top in the highly competitive market for processed deli meats. But for Brandon Markiw, 32-year-old founder and chief executive officer of Road Range Meat Co. in Leduc, Alta., patience and winning mentality are two of many requirements for success that the youthful entrepreneur has already mastered to a tee over the years of playing competitive golf during his university years.

Having picked up the game at an early age, among many other sporting pursuits, the Edmonton native focused on improving his golf through his early teenage years—ultimately becoming good enough to earn himself a golf scholarship at the Ohio State University south of the border.

Upon returning to Canada after a couple of years, Markiw enrolled at the University of British Columbia (UBC) in Vancouver to finish his business degree and also earn a major in finance and urban land economics.

Although admittedly tempted to try his hand at professional golfing, Markiw ultimately decided to put has competitive instincts to use in the business world—specifically in the ready-to-eat meat products that were a important part of his daily diet during his formative years.

Growing up in a household proud of its Ukrainian roots and heritage, Markiw naturally had plenty of opportunities to sample

Range Road Meat Co. founder and chief executive officer Brandon Markiw (background right) operates his company out of a leased 6,000-square-foot production facility housed inside the Food Processing Development Centre in Leduc, Alta., which provides promising local food industry entrepreneurs with a wide range of shared services, equipment and expertise to help them achieve commercial success.

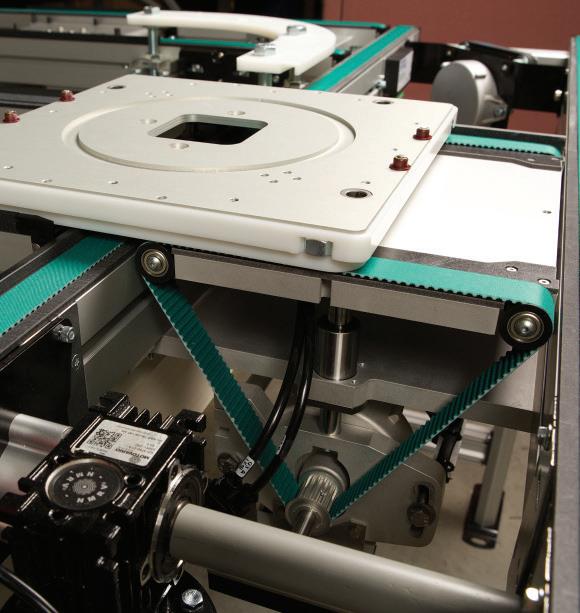

Range Road Meats packages all its vacuum-packed sausages and meat sticks on the Multivac R 085 entry-level thermoforming machine that company president Brandon Markiw purchased right from the demonstration floor of Multivac Canada’s regional office just north of Vancouver in Richmond, B.C.

many types of authentic European-inspired recipes for sausage, cold cuts and other traditional Old World meat staples that he still regularly enjoys as part of his daily diet.

“Although I’ve never really had any direct experience in manufacturing, I’ve always been a big product guy, a big brand guy brand guy, and a big food guy,” says Markiw, who launched Range Road Meat in November of 2016.

“And having always appreciated the manufacturing industry in general, all these things combined into a sort of a ‘Perfect Storm’ of ideas that inspired me to explore this product category of ready-to-eat meat products.

“It’s the sort of food that was typically put on our dinner plates at home on a pretty frequent basis by our parents,” he recalls, “and as I accelerated my athletic pursuits I became even more aware of the nutritional benefits of such products in supporting my active physical lifestyle.”

But the more he became knowledgeable about the process and the business of the read-to-eat meats product category, the more he became convinced of an existing market void for premium-quality deli meats that were big on flavor, short on artificial ingredients and additives, and were also primarily locally-sourced.

“As I became more conscious of the importance of making the right purchasing decisions and nutritional choices to my physical needs, I became increasingly aware of a big gap in this category, whereby I just couldn’t find many existing products that really satisfied my meats.

“That’s why I always felt like there was an opportunity to make a real impact in the space,” Markiw told the Canadian Packaging magazine in a recent interview.

To get his business idea off the ground, Markiw contacted the Food Processing Development Centre in Leduc, a modern, fully-equipped pilot plant and product development laboratory facility operated by

the Food and Bio Processing Branch of the provincial Alberta Agriculture and Forestry (AF) ministry.

Staffed with experienced food scientists, engineers and technologists, the facility provides a wealth of services designed to “strengthen and expand the capability of food processors to meet the challenges of the marketplace through application of new technology and the development of new or improved products and processes,” according to the Centre’s website.

The Centre’s on-site Agrivalue Processing Business Incubator—a multi-tenant CFIA-approved facility set up to enable new food processors to scale-up and commercialize new products for both domestic and international markets—provides a vast range of services and equipment to help these start-ups succeed, including:

• Product development;

• Technical consultations;

• Concept analysis and development;

• Prototype design and demonstration;

• Product packaging technology;

• Regulatory requirements and labeling assistance;

• Quality control/quality assurance specifications.

Critically for Road Range Meat, the Incubator also houses a well-equipped pilot plant consisting of four spate processing areas— meat, wet process, dry process and fine particulate—that can be shared by the Centre’s tenants to fine-tune their product development, including access to a complete forming, batter/breading, frying, cooking, baking and freezing line that can be arranged in any required sequence.

For Markiw, the access to these services, equipment and expertise has been instrumental in enabling Road Range Meat to hit the ground running.

“We approached the Centre with a wish-list of what we wanted to accomplish with out product, namely to offer an all-natural, locally-sourced, high-quality product with unique flavor profiles, and after doing some early R&D work, we decided to lease one of the Incubator’s eight tenant suites starting in August of 2017,”

Markiw recalls.

In the two-and-a-half years since setting up shop at the Incubator, Road Range has developed 26 new products that, according to Markiw, currently retail at nearly 350 grocery outlets across western Canada.

About half of those products are retailed under the company’s own brand label, with the rest being copacked for other manufacturing clients in the meat processing business.

“It all started with a pilot project for 30 Save-on Food stores in Alberta,” Markiw reveals, “and it just took off from there.”

Nowadays, the company has the daily capacity to process up to 5,000 kilograms of meat, mostly pork, employing from 10 to 14 production line operators to turn out high-quality sausage meat treats such as Premium Classic Sausage, Premium Texas Chili Sau-

sage and Premium Italian Herb Sausage, along with pepperoni-styled snacks like Spicy Pick Up Sticks and Original Pick Up Sticks

To ensure premium-qaulity product, the company makes extensive use of Handtmann PLVH 228 sausage line manufactured in Germany by Albert Handtmann Maschinenfabrik GmbH & Co. KG

The high-performance machine provides vary fast casing change times, especially for natural casings, along with perfect positioning of the linked sausages straight or curved, with the linking position exactly on the hanging unit’s hook—regardless of weight, length and loops—with hook spacing of five millimeters.

The Handtmann PLVH 228 operates a continuous filling process, enhanced with the highly dynamic linking, to ensure high-accuracy portioning to within one gram, along with uniform lengths for each por-

tion.

To ensure perfect smoky finish, Range Road has also invested into a highly advanced and versatile FESSMANN Eco.Line smoke generator—also made in Germany by FESSMANN GmbH und Co. KG. featuring variable smoke intensities to permit a diverse range smoke aromas and color nuances.

As Range Road’s website proudly proclaims: “We combine our lean meat with natural spices that possess superior flavor and potency, and we use a natural smoking process to create all Range Road products.

“Our unique preparation and grinding method allows us to develop a product that is very lean compared with other sausage offerings, while still possessing the desirable attributes of a product with much higher fat content.

“This gives the product a versatility in the ways it

can be served: It is equally satisfying cold, sliced on a tray, heated on the grill or in a pan, or in one of your favourite dishes.

“The freshest, highest-quality ingredients will always produce the best tasting outcome, plain and simple.”

This approach has already enabled Range Road Meat to line up some key co-packing and privatelabel accounts, according to Markiw, who credits the hard work of the company’s 20-person field sales team of “Range Roadies” crossing western Canada to conduct in-store product tastings and demonstrations, as well as pursuing new business opportunities.

“We focus most of our sales and marketing efforts primarily on in-store demos,” Markiw states.

“It is really important for us to have the face-to-face interaction with consumers at the stores to allow them to sample our products, while we tell them about our

product, our brand, or history, philosophy and so on.

“We found it to be a very effective marketing strategy for us.”

While the current COVID-19 epidemic is sadly making this strategy impossible to implement in the immediate perceivable future, Markiw believes that the company’s attractive and elegant product packaging will help to fill that gap to some extent.

With all of its branded products tightly vacuumsealed in high-barrier plastic film processed on the robust, made-in-Germany Multivac R 085 thermoform packaging machine, Road Range Meat’s coiled sausage products, packed in single-link 300-gram portions, and meat sticks, laid out in rows of 10 stick per 250-gram pack, achieve impressive shelf-life performance of up to 74 days, according to Markiw.

“It is a critical piece of equipment for us,” states

Markiw, who purchased his Multivac R 085 right off the demonstration floor at Multivac Canada’s branch office in Richmond, B.C., after thorough consultations with the local Multivac field service technician Dave Grootelaar.

“This machine represents one of the biggest capital investments we have made so far,” says Markiw, also citing the installation of a state-of-the-art smokehouse, and high-performance grinder and mixer.

Running the Multivac at robust throughput speeds of up to 1,260 packages per hour, Markiw says he is highly impressed by the machine’s flexibility to produce a broad variety of packages; accommodate quick format changes; perform complete oxygen purge for each package during the wrapping stages; and to create durable high-integrity seals to protect and preserve the products inside, even without any gas-flushing.

Moreover, Markiw says he is impressed with the quality of the plastic film supplied to him by Multivac on a regular basis, with a flexible delivery schedule to accommodate his production needs.

“Multivac is pretty much a one-stop-shop for our primary packaging needs,” says Markiw, while praising the company’s superior customer support performance.

“In the two years we’ve been running this machine we only had one day of downtime,” he recalls, “which was traced to a broken housing on one of the linear bearings inside the machine’s sealing station.

“This resulted in some of the packages coming out of machine looking crumpled,” he continues, “but after we got in touch with Multivac and described the problem, they had it all figured out in no time, and I had a replacement part delivered to us the very next day, straight from Multivac’s North American headquarters in Kansas City.”

Says Markiw:“It is a very good machine supported by an exceptionally good team.

“For me, the big feature of this Multivac machine is the HMI (human-machine interface) terminal, which I find visually appealing, thoughtfully laid out and, operating a Windows-based program, quite easy to navigate,” he points out.

“Although it is a pretty sophisticated piece of equipment with lots of moving parts and air and water connections, I found it very easy to train operators to use this machine via the HMI.

“From an operator’s standpoint, user-friendliness doesn’t get much better than this.

“And while think I have enough technical aptitude to handle any minor problems on the machine,” Markiw notes, “the Research Centre has a very competent onsite maintenance team that really knows all the nuances and ins-and-outs of Multivac machinery inside out.

“But like I said, we’ve not really had a major critical issue with the machine resulting in any significant

downtime to speak of.”

As for the brand packaging part of the equation, Range Road Meat uses pre-printed wraparound paperboard sleeves—supplied by Casepak Manufacturing Ltd. of Richmond, B.C.—to draw the consumer’s attention and curiosity.

Manually wrapped around the thermoformed packages around the middle of the pack, the decorative sleeves are color-coded by product and feature simple, clearly legible lettering and “clean label” product information listing the product’s all-natural ingredients, along with the pertinent gluten-free, no MSG, and no artificial ingredients product claims.

Originally designed by Vancouver-based creative studio Glasfurd & Walker, the trapezoidal-shaped sleeves also feature printed cooking instructions on the inside of the panels.

According to Markiw, the sleeve’s graphic simplicity works well to reinforce the product’s all-natural composition, while providing a commanding visual presence and effective shelf impact.

As he relates, having professional, attractive high-end packaging is “critical” for the marketing of the company’s premium-priced products.

“For better or worse, you can have the greatest product in the world, but if it’s not branded in an attractive way that jumps out at the consumer, it may be a wasted effort,” Markiw opines.

“It is important for your branding and packaging to convey the message of the product to your target audience,” he says, “and our message is that our product is high-quality, local, premium, approachable and affordable.

“I certainly think that packaging oftentimes gets overlooked,” Markiw states, “and I think many companies are doing themselves a disservice, unfortunately, by neglecting their packaging.

“For new products coming into the market with

low levels of brand recognition, using packaging to create a brand identity that is aesthetically attractive to consumers is extremely important in terms of making that brand grow into a household name.”

For Markiw, making Road Range Meat a household name is a labor of love that provides him with priceless sense of professional gratification and fulfillment, along with well-earned pride in generating additional economic spinoffs in his native province.

“All our pork comes from an old family farm located about 150 kilometers from Leduc,” he says, “and we have also worked with a local garlic grower for 18 months to get their food safety accreditations up to snuff to supply a federally-inspected facility,” he says.

As for future product development, Markiw says he is excited by a recently-formed partnership with the nearby Cree First Nation to produce and market a new line of Pansawan dry bison meat snacks using traditional North American aboriginal cooking techniques.

“It’s something that closely resembles the jerky experience,” he says, “but it’s done in a traditional way without any seasonings, additives or sugars.

“We see this as an opportunity to introduce traditional First Nations cuisine to the mainstream consumers, and thereby connecting the two cultures closer though a shared traditional food experience.”

Markiw adds he is also keeping his eyes close on the rapid growth of plant-based alternative meat products in the marketplace, as well as the equally promising emergence of cultured lab-made meats that are often cited as the future of meat production.

“This is a really exciting industry to be in,” Markiw remarks, “and we are fortunate to have access to the valuable resources that the Food Processing Development Centre provides.

“If we were to build an equivalent free-standing facility comparable to what we have at the Centre, we would need somewhere between 20,000 and 25,000 square feet of production space to house all the equipment,” Markiw explains.

“But having access to many shared common facilities enables us to operate our own independent process—including grinding, mixing, stuffing, slicing, cooking and packaging—in our own space of about 6,000 square feet.

“I’m proud of the fact that we already employs nearly 40 people less than three years after start-up,” he states.

“There’s been a fair bit of blood sweat and tears along the way,” Markiw acknowledges, “but that’s just the nature of any start-up business.

“You kind of throw yourself into the fire and try to do all you can to navigate whatever obstacles come your way to come out the other side,” says Markiw, adding he has recently resumed his life-long love affair with golf by joining a local amateur circuit.

“It’s a great way to keep my competitive juices going,” he quips,“and you really need to have that to succeed in this exciting, but highly challenging, product category.”

As consumers around the world navigate life while social distancing, e-commerce is becoming the new normal for many shoppers.

In January, Statista published key figures on retail e-commerce sales in the United States, projecting that online retail sales of physical goods will reach close to US$600 billion in 2024 from US$365.2 billion in 2019.

In Canada, revenue from online sales will climb from US$25.4 billion to US$33.3 billion. At this time, it is difficult to know for certain the full impact COVID-19 and related safety measures will have on consumer behavior.

When Canadian Packaging initiated this Q&A with Brian Techter, director of packaging design and engineering at integrated communication services group R.R. Donnelley (RRD) in Chicago, coronavirus was not yet a global pandemic.

However, in the spirit of seeing the forest through the trees—and providing readers with the insight necessary to help their companies endure, Techter sheds some light on ways that brands can secure and retain

consumer loyalty when the only points of engagement available are some screen time and packaging.

What are some of the biggest e-commerce trends we can expect to see through the remainder of 2020? Subscription services continue to be extremely popular. Whether it’s personal care brands such as Dollar Shave Club and Harry’s Razors, pet product supplier Chewy, or meal delivery kits such as Blue Apron, this category continues to grow.

The subscription service model is not only a convenient way for consumers to try new products and refill necessities, it also enables brands to leverage subscribers’ digital activity to inform the contents. For example, some brands enable subscribers to select the type of products they’d like to receive while others may take hints from customer product views online.

And of course, internet searches are also a key indicator for product interest. However, the ‘gift box’ presentation doesn’t have to be limited to just subscription services. Companies can offer products in well-appointed brand experience kits to reward loyal

customers or offer a premium unboxing experience. Product customization and personalization also represent a significant trend. By offering these services, brands can better understand consumer preferences. Customization and personalization also provide a special and unique experience for the customer.

In one example, Oreo’s ‘design your own package promotion’ allowed consumers to add their personal touches to a package of cookies. Activities that allow shoppers to exercise a little creativity and make a product theirs go a long way to strengthen the connection between individuals and a brand.

What has been the biggest imact of this trend on product packaging?

The one really big trend that stands to accelerate is the development of specific e-commerce packaging SKUs (stock-keeping units).

We’re all accustomed to seeing the Amazon box on our doorstep. However, we’re increasingly seeing packaging that is better designed for shipping. Less and less, we receive a brown corrugated Amazon box, inside of which is a smaller box, maybe some dun-

Bian Techter, Director, Packaging Design and Engineering, R.R. Donnelley

nage or airbags, and finally, the primary package containing your product.

Increasingly, brands are rightsizing, redesigning and reinforcing packaging to minimize space and material while resisting damage from other, heavier items. This approach enables packaging and supply chain professionals to greatly reduce waste—and subsequently costs— while addressing consumer concerns about the environmental impact of so much packaging material winding up in a landfill.

We also continue to see Ships In Own Container (SIOC) packaging. Since Amazon put into place initiatives to minimize handling at its distribution centers, more brands have adopted this shipping container style package, which also reduces shipping costs.

It feels like everyone nowadays is more conscientious about sustainability. How can brands better respond to consumer concerns about the environment and the impact of discarded packaging? Specifying the right package design for the application can go a long way in saving material. RRD enables brands to manage two types of SKUs. As more brands adopt an omnichannel business model, the immediate tendency can be to just ship the packaging designed for shelf allocation at a brick-and-mortar retailer.

However, that sizing, design and even material gauge may not work for e-commerce. This approach can lead to greater waste, and hence unnecessary costs. However, managing both a traditional retail and e-commerce SKU offers the best of both worlds. Other brands may opt for “omnichannel” packaging that strikes the perfect marriage of attributes to perform in traditional retail spaces as well as along the e-commerce supply chain. It is a balance of the additional complexity of multiple packaging SKUs versus cost and performance, and in this example cost and performance trump the additional complexity.

On the material front, we are also seeing brands opt out of some petrol-based substrates like foams. Some companies adopt plant plastics, and among fragile products molded pulp is a growing alternative. Importantly, any sustainable alternative must adequately protect the product. There is nothing more wasteful than eco-friendly packaging that under-

performs, arrives damaged, disappoints the consumer, gets thrown away or, even worse, is shipped back to the brand and then thrown away. That’s why brands should work with suppliers they can trust to provide guidance on design and material specification.

Why should businesses go digital and how can brands really benefit from digitized engagement?

Eventually, the world will have an answer to COVID-19 and we’ll see life return to “normal.” I’m sure when that day comes, people will be eager to get out of their homes and back, safely, into stores.

However, many communities in the U.S. and Canada are still adhering to stay-at-home orders. Others may be required to follow social distancing restrictions, and some may just be exercising a lot of caution when out and about. The virus will likely have reverberations for years to come. For the foreseeable future, however, it’s fueling more e-commerce activity. Companies that can manufacture at this time must make the most of the e-tail channels available to them.

The good news is that e-commerce provides excellent opportunities for personalization, customization, and customer engagement, so consumers can better know the brands they love and brands can better serve consumers.

ooking for a machine that can handle the high-speed demands of your industrial environment while delivering secure packages across each cycle?

Address labor concerns and produce a high-quality, visually-appealing product on a machine that is extremely robust and reliable, with incredible fl exibility. Package after package, time after time. Trave ® tray sealers from G. Mondini allow you to perform fast changeovers, switching between various packaging formats on a machine built with stainless steel to put your mind at ease when it comes to sanitation concerns. Our tray sealers are available with Allen Bradley ® controls from Rockwell Automation, so you know you’re getting equipment that is at the forefront of digital transformation and smart, connected machines. Contact Harpak-ULMA Packaging today to learn more about these industry-standard machines!

Direct digital can printing technology to lay the groundwork for mass product customization in the global beverage industries

With shifts in attitude towards the way we package products, an increasing need for creative and customizable solutions, and relentless pressure to react quickly to market trends and demands, the beverage industry is experiencing significant changes.

As a result, forward-thinking companies are introducing cutting-edge technology that meets these changing needs in a way that could reshape the way we market, package and consume beverages.

Based in the famed English university town of Cambridge, Tonejet Limited offers a shining example of the seismic changes to come.

We sat recently sat down with the down with the company’s chief executive officer, Rob Day, to drink it all in.

Can you tell us a bit about the Tonejet journey to date?

Tonejet Ltd began as a technology project within TTP Group, one of Europe’s leading technology and product development companies, before becoming a wholly-owned independent subsidiary some years ago.

Working out of our cutting-edge production facility, we now manufacture the Cyclone system almost entirely in-house. We produce printheads in our own clean rooms, carry out system assembly, full testing and commissioning all on-site.

We consider the business very self-sufficient and vertically integrated, ensuring tighter quality control and a better flow and management of information across the supply chain, which is vital in such a specialized field.

While our operations are currently U.K.-based, at least half of the demand for our products is generated from the United States.

Since the company was established, what’s changed in the beverage packaging sector? How would you describe the industry today?

The commercial reality of the industry in 2019 is large manufacturers using technology, and not least digital printing technology, to convert a small number of base products into myriad variants in response to customer orders,

and fulfilling those orders within hours or days. You cannot do that if your product packaging has to be produced using printing plates and labels.

Of course, the same technology that enables global brands to do this can be used by innovative start-ups who rarely manufacture anything in runs longer than a few tens of thousands.

Craft beer is a perfect example. In the U.S. overall beer sales are flat, but the US$27-billion craft beer market is seeing annual growth closer to 10 per cent.

That’s around 7,000 breweries, all wanting to make seasonal specials and short runs for sports or cultural events in addition to their core products, which are themselves niche and low-volume.

And it’s not just beer: new beverage categories like hard seltzers are seeing 200-percent growth, as a younger demographic looks for low-alcohol, relatively healthy drinks that are also sugar-free.

With plastic packaging being demonized because of its environmental impact, water is increasingly being packaged in 100-percent recyclable, lightweight aluminium cans, along with wine many new and coffee products. Wine and coffee are also growing categories.

So how does the Cyclone compare with traditional technologies and meet the challenges of this changing market?

Brands who want to buy printed cans from can makers have a number of issues to deal with, including large volumes. This tends to be a major stumbling block for smaller craft brewers, who will need to work through, and pay, an intermediary distributor.

Additionally, traditional can printing requires the

Day, Chief Executive Officer, Tonejet Limited

production of printing plates which cost thousands of dollars and take months to procure, leading to a minimum order volume of around 100,000 units. This leaves larger brands suffering from a lack of agility and procurement delays, while the smaller, independent brands would struggle to even get started.

This is where Tonejet fits in—our customers are specialists providing services to smaller breweries and larger brands wanting to run promotional specials, create limited edition beverages, or use unique barcodes for track-and-trace purposes.

What level of market opportunity do you believe this technology represents to the market/customers?

It’s an enormous opportunity. The Cyclone cuts short-run packaging costs compared to labels or sleeves by around two-thirds.

The real value of digital, however, is in the new functionality and supply chain dynamic it enables. Mass-customized products are in their infancy, but have been so successful that they will become the norm once supply chains are remodelled to fit this new way of doing things.

Sales increase and premium pricing is achievable when packaging is targeted at specific consumer niches who will really identify with the product. Then there is the brand activation that is possible through web or social media-driven promotional messaging, perhaps triggered by a unique VR (virtual reality) or other code on a pack.

The list goes on—we are just entering the age of mass-customized product.

Do you feel that the opportunities and advantages delivered by the Tonejet Cyclone are fully recognized by

designers and brand-owners?

Designers and brand-owners are only just getting a feel for all the possibilities that targeted digital packaging can bring with it.

Big brand campaigns like ‘Share A Coke’, which created a seven-percent increase in sales, are leading the way and flying the flag for digital.

It takes a while for the industry to understand and appreciate that with digital, every single can could be produced with a different image, creating virtually limitless design possibilities.

Every brand owner we’ve met is excited by this prospect and the additional benefits the Tonejet Cyclone offers, and we cannot wait to get more systems on the market to serve them.

How much will environmental responsibility drive adoption of a digitally printed cans compared to bottles? When it comes to bottles, the facts are stark. There are currently less than 10 per cent of plastic bottles being recycled, compared to 50 per cent for aluminium cans, which will continue to increase as household recycling becomes more efficient.

Being 100-percent recyclable also makes cans more environmentally-friendly: in fact, most new beverage cans today are made from recycled aluminium

Cans also stack up well against the heavy and fragile glass bottle, eliminating the need for any secondary packaging materials.

The demand for beverage cans, which has been growing steadily at around three per cent per annum in the last five years, will increase further, as brands continue to switch from both plastic and glass to aluminium.

Is the Tonejet Cyclone commercially available? Can I order one today and how much does it cost?

Beta testing is underway with a customer in Canada, and we also have plans for a second beta to be live at our base in Cambridge in the U.K. later this year, handling short-run can decoration for a large global beverage brand, as well as several smaller local craft brewers.

BY BOB OWENS

Rapid growth presents both a unique opportunity and a substantial challenge for food manufacturers.

This often requires that companies make significant changes to their production lines without missing a beat, as stalled output can represent significant lost earnings.

By investing in the right equipment and streamlining throughput, companies can radically improve efficiency; reduce the amount of time spent fixing problems, and meet new demand as soon as it arises.

Located in Surrey, B.C., Pace Processing is a textbook example of such a company.

Established 18 years ago, this versatile commercial bakery has enjoyed consistent growth from the outset.

Since 2014, that growth had accelerated to double-digit levels, as the company grew into a prominent producer of frozen foods for the North American retail and foodservice industries, including cakes, baked goods, desserts, pizzas, pizza toppings, gluten-free toppings, and many other such products.

To maintain and expand its diverse product portfolio, the company employs about 360 people at six manufacturing plants, with nearly 97,000 square feet of production space in total.

“We have grown substantially in the last several years,” says Pace Processing vice-president of operations Jason Darrah.

“We have done a good job offering a variety of products, from focaccia bread to pepperoni cheese sticks to a cake line, along with starting up glutenfree facilities,” Darrah relates.

“With this increased growth, we recognized the need to automate.”

Automation comes with its own set of challenges, however. Inadequate machinery tends to require more maintenance and troubleshooting, leading to a significant amount of human labor and downtime that can often offset profit margins.

Conversely, systems that properly designed for the application at result in quicker production output, fewer malfunctions and more uptime, yielding improved profits.

“Our primary need was for case erecting, case sealing and tray forming machines that would allow our process lines to operate efficiently,” Darrah recalls.

“In 2014, we were already running several oldermodel case-packers, but because of our growth they were no longer able to handle the output on our lines, and there was also considerable machine servicing required to keep them operational.

“It was then that we began looking for better automation options,” Darrah states.

One of those options was a semi-automatic case

The semi-automatic Bel 150 case taper from Wexxar Bel can seal a wide range of case sizes at speeds up to 30 cases per minute, while facilitating quick case size changes.

taper from Wexxar Bel—a leading manufacturer of machines for automated corrugated container packaging applications located just north of Vancouver in Richmond, B.C.

Founded in 1977 and now operating as a wholly-owned subsidiary of Cincinnati-headquartered packaging machinery group ProMach, Wexxar Bel enjoys a stellar tack record in the global packaging industry, having installed its case formers and case

sealers in nearly 40 different countries to date.

In addition to its own flagship Wexxar equipment brand, the company also offers the Bel line of corrugated box sealers, tapers, and packing systems, as well as the IPAK line of tray and bliss formers, stackers, and sealer systems.

“A team from Wexxar Bel came over and looked at what we were doing for our packaging lines,” recalls Darrah.

The fully-automatic IPAK TF200 tray former can form regular slotted trays in various configurations including four-corner glued trays, one- and twopiece telescoping trays, at speeds of up to 35 trays per minute, handling a wide range of tray sizes used in food processing applications..

“They measured our rooms, evaluated our output, and gave us several different options.

“Our first step was to implement the case sealer, which would provide an economical and effective way to minimize manual labor requirements.”

Specifically, Pace acquired a semi-automatic BEL 150 pressure-sensitive case taper for use on one of its end-of-line packing operations, making good use of the machine’s highly flexible operation that enables it to seal a wide range of case sizes at speeds up to 30 cases per minute, with quick size changeovers.

As Pace continued to expand, it added the BEL 150 machines to all of its processing lines at each of its six manufacturing facilities, Darrah adds.

Soon afterwards, the company began looking at replacing some of its older case formers and packers with more reliable and modern equipment.

After turning to Wexxar Bel for options once again, Pace settled on the Bel 505 semiautomatic case former and pack station for two of its facilities.

The Bel case former and pack station can handle and form a wide range of case sizes and various case types, with a versatile design that allows a high degree of customization.

More importantly, this setup makes product changeovers easy, quick and flexible, thank to the tool-less, quick and simple case size changes and easy access to the change points from both operational sides of the machine.

“The case former and pack station allows us to produce and pack about eight full cases per minute,” says Darrah, adding the two systems were installed in 2018.

“We put these machine in place at out high-throughput pizza topping plants,” Darrah continues.

“In one of these plants we have line changes four or five times a day,” Darrah relates, “so the machine has to be very fast on changeovers, which can be accomplished in under five minutes.”

At these plants, Pace pairs up both the casesealer, and case former and pack station—allowing one operator to form, pack and seal corrugated cases in a single operation.

On one of its lines, Pace has also paired a Bel 505 with a Bel 252 fully-automatic case sealer for extra automation.

In addition to the end-of-line case packing and sealing processes, Pace also desired to

A row of paper-based trays coming out of the IPAK TF2000 tray forming machine and directed towards the processing area, to be filled with cake batter and transferred on to the ovens for cooking.

upgrade its automation for tray forming to support its sheet cake production line. In operation, the paper-based 12x16x2.5-inch trays are put onto baking sheets, cake batter is deposited into the trays, and the trays are then moved into the ovens for baking.

Once baked, the sheet cake may be cut into different shapes and sizes depending on the customers’ requirements, or it may be shipped ‘as is’ in bulk form, in which case the tray acts as the support for the cake when it is moved downstream through the packaging line.

“To automate this tray forming process, we selected the IPAK TF200 fully-automatic tray former, again from Wexxar Bel,” says Darrah.

“We looked at other systems, but the TF200 was definitely more robust for our needs and has a high level of flexibility.

“We can interchange the mandrel on the machine to achieve different depths or tray sizes should we desire in the future,” Darrah explains.

“We were also attracted to the fact that size changes can be performed in less than 10 minutes.”

The IPAK TF200 is capable of forming a wide range of tray sizes, including regular slotted trays in various configurations.

This includes a full range of four-corner glued trays, one- and two-piece telescoping trays, and variations of triangulated-corner and self-locking trays.

The tray former permits diagnostics and advanced programming capabilities to be set up in multiple configurations to suit the needs of the user.

“The machine will continuously operate at speeds of up to 40 trays per minute,” adds Darrah, “but currently we are running it at 50 to 55 percent of the machine’s capability at 22 trays per minute.”

With business growth continuing to gather pace, Darrah says the company is constantly evaluating new possibilities for further automation investment and process improvements.

“Having the automated machinery is just part of the solution,” states Darrah. “We wanted our machines to be userfriendly, so that they are easy to operate.

“And that is exactly what we have achieved with Wexxar machinery,” Darrah sums up.

“Ensuring that the machine operators are trained sufficiently to run the equipment with precision and safety, and with proper maintenance is an integral part of ensuring the company’s production lines run optimally.”

Bob Owens is a freelance writer specializing in industrial and manufacturing processes.

BY USMAN AKRAM

Doubtlessly, package design is one of the essential elements of your product marketing. A good eye-catching design, which connects both physically and psychologically with the consumers, brings higher sales. For consumers, a creative and thoughtful design gives the impression that a brand or business has spent time considering the end-user, which ultimately builds brand image.

Anyone owning a business will agree that standing out in a competitive market is tough, even at the best of times. But that is precisely why it’a mistake to underestimate the power of effective packaging design to distinguish your product in the marketplace. There is a reason why consumer brands that thrive in the long term are the ones who consider package design as a useful marketing tool. With that in mind, here are the top 10 ultimate tips for achieving effective package design to help you take your brand to the next level.

To gain a competitive edge in packaging, you must have a comprehensive plan right from the beginning. Alluring and creative design requires ample time and great attention to detail, and if you precisely know what you want, your package design will show it. Having a clear idea allows you to focus up on the specific goals of your products, such as the type of audience you are targeting. A package designed for kids wouldn’t attract adults, thus having a plan beforehand allows you to make your products captivating enough for the respective audience. Other factors such as what packaging will showcase the type of reaction you want, or if you are trying to stir feelings of nostalgia, should be considered right at the beginning.