Plastic packaging producer a true poster child for Circular Economy Story on page 14

The Boxxer Kartnr™ automatic carton forming machine is engineered to vertically form chip board cartons.

Compact in design, the Boxxer Kartnr™ includes a heavy duty steel frame, PLC, color touch screen, interlocked safety doors and easy to adjust product change over.

Available in three models:

new Videojet 1860 Continuous Inkjet Printer

1. True predictability

Industry-first ink build-up sensor provides true predictability and warnings of possibly degrading print quality, even before a fault occurs.

True IP rating

Optional IP66 rating for entire cabinet and hygienic design following industry guidelines; easier integration with slanted printhead design. 4. True scalability

Workflow modules help to customize the printer to perform the exact need required. It is easy to adapt the printer with new capabilities and functionalities, and to meet growing demands. 2. True remote services*

Multiple access options (Ethernet™, WiFi) and secure VPN communication meet highest standards in the industry as part of VideojetConnect™ Remote Service, and help to improve machine uptime and customer experience.

* Subject to availability in your country

NO. 5

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

ASSISTANT EDITOR

Alanna Fairey • (416) 510-5228 afairey@canadianpackaging.com

MEDIA DESIGNER

Brooke Shaw • (519) 428-3471 bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer • (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

CIRCULATION MANAGER

Anita Madden • (416) 442-5600 x3596 AMadden@annexbusinessmedia.com

VICE PRESIDENT

Tim Dimopoulos • tdimopoulos@annexbusinessmedia.com

PRESIDENT & CEO Mike Fredericks

ANNEX BUSINESS MEDIA

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

e-mail: rthava@annexbusinessmedia.com

Tel: 416-442-5600 ext. 3555

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year, USA $138.00 US per year, Outside Canada $156.50 US per year, Single Copy Canada $10.00, Outside Canada $27.10. From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted

Reaping what you sow can be a very joyless experience, and there is little joy among Canada’s recycling operators today, who have seen the market prices for virtually all of their recycled materials—including the high-prized aluminum waste—collapse at alarming double-digit rates or worse in recent months.

With market demand in a freefall and massive bales of recycled packaging waste piling up outside the recycling plants’ sorting lines, many of Canada’s well-intended municipal recycling programs are in jeopardy of outright collapse without massive government bailouts or subsidies, which would be a tragic shame in light of all the investment and public education efforts in selling the virtues of recycling to Canadian consumers over the last few decades.

While it’s true that China’s decision to ban shipments of recycled material from Canada from entering the country has played a large role in creating the current predicament, why on earth did we think that dumping our garbage halfway across the globe was a good idea to begin with?

While recycling is an effective and noble sustainability strategy, when you consider the cost of fuel required to ship recycled materials to the Far East, such a practice seems a lot less sustainable when assessed from the full LCA (life-cycle analysis) perspective.

Naturally, no one wants to see the Canadian recycling infrastructure collapse outright, but maybe the time has come to re-evaluate just how much Canadians can truly depend on our Blue Box curbside recycling programs alone to make a significant difference in the long term?

And more to the point, are we actually doing recycling in a way that will be compatible with the so-called Circular Economy model that so many nations and have pledge allegiance to in recent years?

According to a recent report from global chemical industries group Chemsec ( The International Chemical Secretariat), “A Circular Economy represents a golden opportunity to combine corporate sustainability with profits, but it is obstructed by weak chemicals legislations in every part of the world.”

Titled The Missing Piece: Chemicals in Circular Economy, the study will not make comfortable reading for many companies and organizations who thought they had all the angles covered with the traditional 3R’s of reuse, reduce and recycle.

“Recycling markets can only be sustainable if they can assure that recycled materials do not contain toxic substances,” the report states. “Willingness to support the development of nontoxic material cycles will thus not only protect human health and the environment, but will also enhance the quality of secondary raw materials and boost recycling markets.

“Unfortunately, there is a trend to focus more on recycling targets than on eliminating hazardous chemicals,” the Chemsec study points out, “but recycling targets should never be achieved at the expense of human health and the environment.”

As the report pointedly asserts, “Recycling should never be viewed as a low-cost solution.

“It might sound contradictory, but setting identical, strict rules for recycled materials will help them compete with virgin materials,” the report concludes.

“It is a fact that regulation drives innovation, and recycling is no exception.”

Quebec

Why

tray-sealing equipment to enhance product

and boost output levels.

Our exclusive preview of the PACKEX Toronto 2019 exhibition next month.

how the Factory of the Future is today’s reality.

New unit dose packaging solution offers breakthrough consumer convenience and ease-of-use.

Packaging automation integrator shifts its strategic focus to

edgling recreational cannabis industry.

Automatic top-loading packaging machinery a big boost for popular Japanese beverage.

Industrial robotics cement their critical importance in the packaging industry as key productivity and automation enablers.

It takes a lot of flair and foresight to stand out in one of the dairy industry’s most crowded product categories, but for Verannes, Que.-based Maison Riviera, staying on top of consumer trends is an indelible part of the company’s culture of continuous product innovation.

With vegan foods starting to show signs of fast-growing market acceptance across the county, the privately-owned dairy processor has just launched a vegan alternative to traditional milk-based yogurts with a “decadent, yet healthy and nutritious” line of Vegan Delight yogurts made with coconut milk.

nutritionally complete dairy alternative that meets their specific dietary needs, while preventing nutritional deficiencies,” Valiquette states.

According to food industry observers and peaking numbers of Google searches, consumer interest in veganism has never been higher in Canada than today.

A 2018 study conducted by Dalhousie University estimates that 7.1 per cent of Canadians are vegetarians and 2.3 per cent are vegans.

Available in three tantalizing flavors—including pineapple and coconut; raspberry and blackcurrant; and mango and passion fruit—Vegan Delight is now retailing at high-end and specialty grocery stores throughout Ontario, British Columbia and western Canada.

Packaged in 500-gram plastic tubs decorated with fanciful IML (in-mold label) packaging graphics developed by Caroline Reumont Design in Montreal, the Vegan Delight product line was created to satisfy consumers with lactose or gluten intolerances, nut allergies, vegans, vegetarians, flexitarians and ordinary consumers wishing to adopt ethical eating habits, according to Maison Riviera.

“Riviera is meeting the needs of Canadians who don’t have access to as many alternatives as in Europe or the United States,” explains the company’s general director Martin Valiquette.

“We’re pleased to expand the vegan options available in our grocery stores with a new high-quality product that has the texture and taste to rival any classic yogurt,” says Valiquette, adding the company adds to expand the line with more flavors and packaging sizes later this spring.

“It’s our goal to be a part of this current ethical shift by offering vegans a

Notably, American vegan alternatives to dairy products held 25 per cent of the market share in the U.S. in 2016, according to the study, and are expected to increase to 40 per cent in 2019.

Globally, the market share for vegan cheese products is expected to grow 7.6 per cent annually through 2024.

As Valiquette points out, growing trends in specialty diets confirm that consumers are looking for alternatives in order to change their eating habits and reduce consumption of meat and animal byproducts—firmly believing that doing so is better for one’s health, as well as the environment.

Says Valiquette: “Our new dairy-free product meets the growing needs of those interested in plant-based foods who currently have limited options available to them.”

Made from real coconut milk and sustainably-grown, perfectly ripened fresh fruit and berries, Vegan Delight is dairy-free, gluten-free product offering rich, creamy and velvety in texture that makes it a delightful dessert or snack on its own, or as versatile and nutritious addition to any recipe or smoothie beverage.

Free of artificial colors, flavors, stevia, aspartame or any other artificial sweeteners, making it ideal for all ages, Vegan Delight also contains no nuts, making it suitable for consumers with nut allergies.

Complete motion control solutions - from Mechatronics, Conveyance, Assembly Handling, and Tightening Systems, to Linear and Electric Drives and Controls Technology

Rely on Bosch Rexroth, the world leader in drive and motion control technologies that power today’s most advanced manufacturing systems. You can rely on our local manufacturing, applications engineering, and commissioning expertise as well as our complete local support services.

Our automation solutions drive your manufacturing performance with fast throughput, precision, repeatable efficient motion control for maximum uptime. We’re set to help you achieve smarter, more productive automation solutions for your factory of the future today.

Because the Factory of the Future begins Now. develops Next. and goes Beyond.

Order your free Factory Automation Resource Kit: www.boschrexroth.ca/factoryautokit

For expert advice call 1-855-REXROTH (739-7684) or email us at info@boschrexroth.ca

More famous for the cars and whisky produced there for decades, the southwestern Ontario city of Windsor also happens to be home to Canada’s only rice mill—operated by Dainty Foods since 1967.

Owned by the French food products multinational Marbour since 2015, the company was originally founded in Montreal back in 1882 under the Mount Royal Rice Mills moniker—operating there until its move to Windsor.

Processing about 50,000-tonnes of globally-sourced rice per year, Dainty Foods has a long-enduring affinity with Canadian consumers that traces back to the 1947 launch of its signature rice-in-a-can products that can still be found on shelves of most major Canadian grocery outlets.

Traditionally available in 11 different flavor varieties ranging from Spanish Rice and Pilaf to Roasted Garlic and Olive Oil —the beloved can-in-a-box Dainty brand rice packages were originally created to offer post-war consumers quickmeal components in convenient packages that would allow them to spend less time in the kitchen.

Having developed into a popular go-to consumer favorite, the rice-in-a-can format still offers the same convenience advantages of providing consumers with a generous portion of pre-cooked rice that only takes a few minutes and a bit of liquid to heat up and serve, along with the added benefit of fully-recyclable packaging.

A few weeks ago, the company played up its proudly

Canadian heritage with the launch of the all-new Maple Brown Sugar Pudding kit— requiring only a bit of sugar and milk to prepare a simple and tasty dessert in only eight minutes.

Featuring striking bold packaging box graphics designed by the Montreal office of Pigeon Brands Inc., the 350-gram packs are enough for two to four servings of a delicious and heart-warming rice pudding evoking the friendly sugar shack ambiance and sweet maple syrup taste, according to the company.

Seeking to modernize its classic and instantly recognizable Barbasol shaving cream products, personal-care products group Perio Inc. has partnered with Crown Holdings, Inc. to launch a progressive package design that elevates the brand’s visual and tactile appeal.

Making its global debut on the new seven-ounce can sizes, the project marks the first use of Crown’s debossing technology worldwide—coinciding with the 100th anniversary of the iconic Barbasol brand this year.

The first three-piece aerosol can manufacturer to offer this capability in North America, the proprietary debossing technique imprints the brand’s iconic stripes and logo at varying depths on the can—creating an exterior that helps catch the light and draw consumer attention at point-of-sale.

As an added benefit, the package is easier to grip with wet hands thanks to the three-dimensional texture created by the debossing pattern.

“Our longevity as a brand stems from our ability to modernize with the times without sacrificing our heritage or the relationships we have built with generations of consumers,” says Tim McNamara, vice-president of marketing at Peri Inc. in Dublin, Ohio.

“Partnering with Crown to introduce this new debossing technique is an example of that in action,” McNamara adds, “resulting in a package that modernizes the Barbasol brand and provides our customers with an enhanced shaving experience.”

n Roda Packaging Inc., Montreal-headquartered manufacturer of plastic containers and closures for packaging applications in pharmaceutical, food and other CPG (consumer packaged goods) industries, has completed the acquisition of Rada Ltd., one of Quebec’s leading suppliers of injectionand blowmolded PET (polyethylene terephthalate) and (high-density polyethylene) parts and engineered components, including those made from recycled resins. To operate under the new corporate name of Industries Rada (2019) Inc. going forward, the company’s new management team is headed by president Stéphan Berthiaume and chief financial officer Isabelle Lehoux. “We believe in the intrinsic value of the made-in-Québec business model we offer our clients, and now look to reap the benefits of enhanced production capacity and of technology investments to be made in the months to come,” says Berthiaume. “Furthermore, we are firmly committed to becoming a collaborative lab and high-performance centre for recycled-resin reintegration. By reusing plastics diverted from landfill, we are helping lower greenhouse gas emissions, thereby contributing to the circular economy, local recovery and reuse efforts and, ultimately, a healthier planet for the generations to come.”

n Leading German product inspection and sorting systems manufacturer Sesotec GmbH has completed the move of its Sesotec Canada Ltd. subsidiary to a new larger facility at 275 Hanlon Creek Boulevard, Unit 3, Guelph. Ont., N1C 0A1. Tel. (519) 763-9729. According to Sesotec Canada’s director of sales Doug Pedersen, the company’s former Canadian office in Cambridge, Ont., became to small to cope with its growing business, whereas the new Guelph facility offers ample room for product testing and customer

training, in addition to expanded on-site parts storage. “Sesotec has thousands of systems for contaminant detection and sorting installed around the world, making it one of the leading manufacturers and the only one to offer such a broad and flexible range of products,” Pedersen says. “The new location will allow Sesotec Canada to better meet the needs of the food, plastics and recycling industries with superior technological and application-specific expertise.”

n Mississauga, Ont.based Packaging Products Inc. (PPI) has announced the startup of a new manufacturing line dedicated to production of laminated paper edge protection products—commonly referred to as corner boards, corner posts and edge boards—widely used to protect and unitize goods for safe transport and storage. Started up in 1991, PPI has been supplying the popular CornerTuff and CornerWrap brands of edge-protection products since 1997 as a valueadded reseller—recently deciding to move the production of these products in-house. “The benefit of working directly with clients is that, over time, you get to learn a lot about their needs for a better-quality product, shorter lead-times and customized solutions,” says PPI president Jack Taylor. “We knew we could deliver, but we had to take control of the entire production process to make that happen. Ultimately, it was our commitment to customer service that really drove us to become a manufacturer.”

presses. Under the agreement, Apex and BOBST will work together to promote the REVO brand narrow-web presses outfitted with the patented Apex GTT anilox engraving technology to provide valueadded solution to the Web-fed Division’s customers across North America. “We have a long history of working together in the narrow-web label and packaging industry,” says Todd Blumsack, vice-president of Web-fed business unit of Bobst North America. “The agreement will also work in the direction of promoting each other’s technology through seamless integration of our solutions—adding more value to the relationship with our clients in the American and Canadian printing and converting markets.”

n Roseland, N.J.-based paperboard converting machinery supplier Bobst North America Inc. has appointed anilox manufacturer Apex North America, LLC of Donora, Pa., as the preferred partner for Bobst’s Web-fed Division in the U.S. and Canada, which distributes a comprehensive range of flexible packaging, pre-print and narrow-web

n Leading prepress and color management software systems developer GMG Americas of Hingham, Ma., has appointed Toronto-based Access, an operating unit of Access Group Inc., as an auhthorized dealer for all GMC products across Canada. “We look forward to providing GMG’s full range of color management products throughout Canada,” says Access Group president John Visentin. “We hope to show the value of GMG ColorServer, GMG ColorProof and GMG OpenColor to a wide array of users—from ad agencies to digital, offset and wide-format printers,” says Visentin, also citing the company’s status as an authorized Canadian vendor for Epson color printers. “As an Epson partner, we see tremendous opportunity pairing up Epson SureColor printers with GMG solutions to produce accurate proofs and prototypes.” Tel. 1 (844) 789-5542

- precise, fast, robust, and

With workpiece pallet changeover up to 10 times as fast, Rexroth’s ActiveMover transfer system significantly increases productivity in short cycle applications. When you need to transport products with great speed and precision, the new linear motor transfer system from Rexroth sets new standards of performance. Because the Factory of the Future begins Now. develops Next. and goes Beyond.

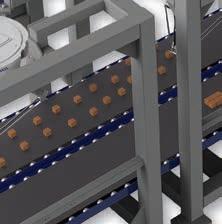

Aimed at companies in the food, beverage, chemical and pharmaceutical industries, Xeikon’s new digital printing solution for exible pouches was developed to provide a fast turnaround for companies with signi cant numbers of SKUs (stock-keeping units) and short lead-times. According to the company, Xeikon’s dry toner technology has many advantages that include exceptionally high print quality of exible substrates, along with reduced startup costs; virtually no changeover downtime; and the ability to print variable data information in both single and full-color at high processing speeds to allow for true JIT (just-in-time) production, versioning and last-minute adaptations on the y. Xeikon

Dynamic Conveyor Corporation has announced the availability of a new cable E-Stop accessory option for the company’s DynaCon range of modular conveyors— provide the ability to quickly stop the conveyor from running in an emergency situation to o er optimal protection along the entire length of the conveyor. According to the company, the cable can be run on one or both sides of the conveyor, and is compatible with all the popular DynaCon

and

Z-conveyors, at conveyors and angle conveyors. Dynamic Conveyor Corporation

Designed for secure holding of slimmer and sleeker cans becoming popular across many segments of the beverage industry, the new WaveGrip Sleek six-pack carriers from WaveGrip are designed to provide signi cant packaging material savings and environmental advantages compared to standard six-pack rings, rigid plastic handles, and traditional cardboard carriers. Measuring just 117x117-mm, the WaveGrip Sleek six-pack carriers can be applied across the range of WaveGrip applicators, which are easily integrated by WaveGrip’s OEM partners into production lines by brewers and beverage manufacturers to provide highly secure and reliable collating of cans to meet the rigorous standards of busy retail environments.

WaveGrip

Designed to provide more exibility in designing controls architecture, the Device Integration IO-Link family of IO-Link masters from Ballu BNI00E1 (Ethernet/IP) and BNI00AZ (Pro net)—feature four Type A IO-Link ports and four Type B IO-Link ports, each with up to 2A of output per channel to meet a wider range of requirements. Ac-

cording to the company, new Device Integration IOLink master o ers M12 T-coded power connections capable of up to 12A of power, while boasting 9A of galvanically isolated output power with up to 2A per port on Type B ports to drive high amperage devices such as pneumatic or hydraulic valves. Moreover, the enhanced webserver capabilities on-board the master enable remote con guring, parameterizing and monitoring IO-Link devices with IODD les without the need for additional software, according to the company.

Balluff

Emerson Automation Solutions has announced the expansion of its product portfolio to include new programmable logic controllers (PLCs) to enable more comprehensive manufacturing control and production optimization. Acquired as part of Emerson’s acquisition of General Electric Co.’s Intelligent Platforms group, the new PLCs will enable Emerson to provide more end-to-end automation solutions to its existing process control market, as well as expand into the rapidly growing hybrid and discrete markets, as well in industries where PLCs are sometimes preferred or required for faster response and machine control. According to Emerson, the expanded automation and control portfolio will enable more operational performance and e ciency for the company’s enduser customers in life sciences, metals and mining, power and water, food and beverage, and packaging industries, which often blend process and discrete machine control to manufacture and deliver nished products.

Emerson Automation Solutions

automation with IndraDrive Mi With IndraDrive Mi, the intelligent drive system, you relocate the entire drive technology from the control cabinet directly into your machines. That saves space, sharply reduces the wiring costs up to 90% and optimizes your energy balance. Thanks to the integrated motion logic, complex motion sequences can be achieved right at the drive level. Put the intelligence of this system to use in your modular machine concepts as you start your journey into Industry 4.0. Because the Factory of the Future begins Now. develops Next. and goes Beyond.

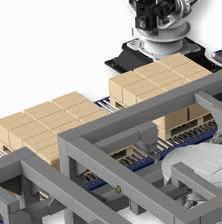

The new RPX-SW series of modular robotic palletizers from Brenton, integrated with an Orion automatic stretchwrapper, o er small to mid-sized companies a cost-e ective solution to advance rom manual to automated palletizing. The RPX-SW series, o er four palletizer con gurations—including two with automated pallet handling modules—that require minimal oorspace, while o ering throughput rates of up to 14 cases per minute. According to Brenton, a division

of ProMach, the modular system can be delivered in as little as 10 weeks and installed in a matter of hours, with its quick-connect/disconnect features allowing for the RPX-SW robotic cells to be easily disassembled, moved, and redeployed as needs change. Each RPX-SW palletizer comes standard with two pre-programmed pack patterns, with ne pack patterns are easily entered via the workcells’ touchscreen HMI (human-machine interface) terminals.

Brenton (Div. of ProMach)

The new automated Pharma ll NB-1, Series II neck bander from Deitz Co. features a special print registration option that allows tamper-evident shrinkbands to be applied to bottles with long necks without compromising

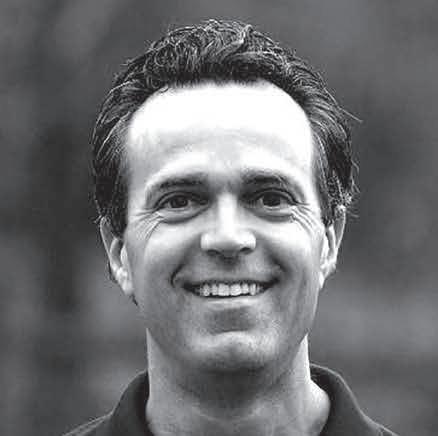

“I’m Mike McCann and I’m part of the Reiser team of Packaging Specialists who work with customers to improve the packaging of their products. I can help you every step of the way –from evaluating your product, your customer, and your goals to assessing your various packaging machine options. With decades of experience, I can help you select the very best packaging solution for your specific application. Are you ready to produce a better package? Let me show you how.”

Watch Mike’s video

company logos, text or other branding set around the neck and cap. Engineered with the company’s proprietary photoelectric sensor and software system, the neck banding machine cuts the shrinkbands precisely in register with the printed graphics for consistent, repeatable accuracy at speeds up to 100 bottles per minute. Ideal for packaging wine, beer, liquor, soda, oil, sauce, dressing, and a variety of foods, beverages, cosmetics, and nutritional products, the NB-1 with print registration accommodates all heat-shrinkable banding applied on glass and plastic bottles with caps ranging from 14- mm to 76-mm diameter on round, oval, and tapered necks with bar top, cork and other neck nishes.

Deitz Co.

Proco Machinery Inc., has introduced an innovative lay- at packing technology which allows blowmolders to pack plastic bottles on their sides—as opposed to placing them with necks up or down—by making optimal use of collaborative robot automation systems from Universal Robots. According to the company, Proco’s new Lay Flat Tooling innovation helps blowmolders and brand-owners maximize product capacity for a given container. The company has developed two sets of tooling for two di erent applications—one for straight neck-to-neck packaging in the box and another for o set neck orientation from row to row—potentially allowing a blowmolder of bottles to pack 270 bottles in a box instead of 250, resulting in maximized capacity and big savings on freight cost. In addition, Proco Machinery has developed several di erent options for packing bottles inside a box including a patent-pending end-of-arm Tooling speci cally designed for PET (polyethylene terephthalate) plastic bottle applications.

Proco Machinery Inc.

Good packaging ideas have a habit of making their way around the world whatever the distance, as an Australian strawberry producer has recently found out with an award-winning compostable packaging solution developed by Canadian packaging producer CKF, Inc.

Selected as winner of this year’s Award of Excellence of the Australian Packaging and Processing Machinery Association (APPMA) in the Customer Collaboration category, the new homecompostable packages for the Fresh Berry brand of strawberries use CKF’s proprietary EarthCycle brand of thermoformed molded-pulp packaging heat-sealed on high-performance tray-sealing machinery supplied by Proseal Autralia Pty Ltd.

Intended as a replacement for traditional plastic clamshells often used to package fresh berries, the recyclable and home-compostable EarthCycle punnets have enabled the grower to reduce its use of plastic packaging for this product by 95 per cent, while providing various line efficiencies and better product shelf-life.

“It was Proseal Australia who introduced us to the top-seal concept, and throughout our dealings with them we have found them highly professional and flexible,” says Jenny Briggs of Fresh Berry.

“They provide incredible backup support with training and servicing to ensure their equipment is always working effectively and efficiently.”

According to Proseal, the top-seal packs also offer a number of performance benefits over clamshells, including extending the shelf-life of products, reducing overpacking, eliminating spillage, providing effective tamper-evidence, and reducing storage and

transportation costs.

The combination of these many benefits can deliver a ROI (returnon-investment) of less than two years, according to Proseal.

As Briggs relates, “We find the application of top seals for our strawberry punnets quick, clean and simple.

“The seal is non-resealable, thereby ensuring tamper-evidence is easily identified, Briggs states.

“Using top sealing-film has significantly reduced our plastic usage and storage requirements compared with conventional clam-shell packaging.”

Another advantage of the punnets developed by CFK and Proseal is that they mirror the common footprint of PET (polyethylene terephthalate) plastic punnets—meaning there is no need for companies to invest in additional tooling.

“This allows them to make a smooth transition to compostable packs without any downtime,” says Proseal Australia’s general manager Scott Templeton, adding that the highly flexible Proseal tray-sealer is a highly flexible system that can handle different pack sizes with fast changeovers using quick interchangeable tooling and easy-to-change pre-printed films.

“Proseal has always been at the forefront of innovation in tray-sealing developments, Templeton states.

“Equally important to us are the close and longterm working partnerships that we seek to establish with both our customers and suppliers,” he adds.

“This award ideally encapsulates both these elements, and I thank Fresh Berry and CFK for their hard work and commitment in ensuring the success of such a ground-breaking project.

While the demand for sustainable packaging solutions continues to increase across many global markets, most consumes still expect the same levels of functionality and userfriendliness for their favorite foods.

With that in mind, leading Polish ice-cream producer Bracia Koral is setting the pace in its segment with the introduction of packages that can be reused almost immediately once the product is consumed.

Now used to package the Cream Nut and Chocolate and Mamusia (Mummy’s) Cheesecake flavors of the company’s new Flavours of Childhood range, the 450-ml PET (polyethylene terephthalate) plastic jars manufactured by RPC PET Power in The Netherlands, the upscale jars offer full benefits of light weigh and impact resistance to ensure safe handling, while ensuring “excellent clarity to showcase the delicious ice-cream,” according to RPC.

Moreover, their practical design makes them reusable for many different purposes, RPC states, further increasing their appeal among consumers.

“We don’t want our empty packs to go immediately in the waste bin, but instead offer a useful second life as a household, workshop or toy container,” says Piotr Gasiorowski, Koral’s sales and marketing director.

According to Gasiorowski, “We selected the jars from RPC PET Power because they best meet our needs, and because the company provides excellent sales service.”

Imagine a factory floor that can adapt to new tasks at any time, with minimal effort –Welcome to the Factory of the Future!

Whether you require precise positioning with minimum cycle times, fast changeover for small-size batches or flexible adaptation to changes in production, Bosch Rexroth’s i4.0-ready technologies for electric automation, assembly and handling can increase your productivity while reducing engineering time and costs. Because the Factory of the Future begins Now. develops Next. and goes Beyond.

Our conventional polypropylene can be used for everything from hot-fill to cold storage and is easy to recycle with a longer shelf life.

Same quality and durability, less everything else. We created a durable material that’s lighter in every sense; On scale, on cost, and on the planet.

We’re A Smart Plant. Discover how we do things differently.

Same packaging, no waste. Our compostable materials are made from renewable and sustainable resources to provide a 1 year shelf life and durability you can depend on.

For over 25 years, the goal at E. Hofmann Plastics Inc. has been to do better. We do this by doing things differently. We never settle. We’re always exploring new technologies and seeking out innovative solutions to better serve our clients. Contact us for more information about our full range of products.

REUSE, RECYCLE & REUSE concepts will be shared at this one-day professional conference. Join us for an opportunity to engage, learn and develop your own disruptor mindset to put to use in your own organization and professional growth. KEYNOTE SPEAKER:

Ken McGuire Research Fellow

Cedric Dsouza Chief Technology Officer AeroFlexx

Tom Szaky under the LOOP initiative has amassed a blue-chip roster of companies, to pilot a new system of high-quality packaging that can be returned and refilled again and again. Loop partners include Procter & Gamble, Nestlé, PepsiCo, Unilever, Mars, Clorox, Coca-Cola, Mondelēz, Danone and a dozen or so smaller brands. Loop brings back the old ‘milkman model,’ where products are delivered to your door at the same time empties are picked up, washed, refilled and readied for delivery to another customer.

John Layman, PhD R&D Section Head

Ontario

as key competitive advantage to propel market share growth to the next level

BY GEORGE GUIDONI, EDITOR

PHOTOS BY NAOMI HILTZ

Seeking adversity for its own sake is not something most businesses willingly choose to engage in. But when adversity is thrust upon you, being able to turn it into an opportunity is a classic hallmark of business acumen and leadership.

And for the much-derided and criticized global plastic packaging industry, companies like the Orangeville, Ont.-based E. Hofmann Plastics Inc. offer plenty of inspiration and incentive to accelerate its carbon footprint reduction e orts—not only for the industry’s sake, but for the greater well-being of modern consumer society at large.

“We consider ourselves to be carbon-footprint busters,” states company president and chief executive o cer Paul Kalia.

“We are the disruptor in an industry that badly needs disruption to remain a viable global business that o ers practical and sustainable solutions for the packaging of food and other everyday consumer goods and commodities.”

Founded back in the 1980s by Austrian-born entrepreneur Ernst Hofmann, the privately-owned company started out as a manufacturer of largeformat plastic pails used primarily for transporting and storage of liquid and powder foodstu s, industrial chemical, building materials and other such bulk commodities.

While lling this relatively narrow market niche provided a fairly safe and steady way to earn a living for the rm’s original four co-owners right through the turn of the century, the onset of global economy and o shore competition made it imperative for Hofmann to expand its horizons through product diversi cation and value-added manufacturing to remain relevant, according to Kalia.

Soon after completing the company’s move to the current manufacturing facility in Orangeville from its initial location in Brampton, Ont., in 2006, Kalia

Hofmann Plastics president and chief executive of cer Paul Kalia shows off the compostable single-serve coffee pods developed by his company as a practical environmentally-friendly solution to the conventional plastic coffee capsules that have attracted widespread criticism and consumer backlash for being exceptionally difcult to recycle in many municipal waste diversion programs.

took over the sole ownership of Hofmann Plastics a couple of years later, while initiating a far-reaching transformation of the company’s strategic direction and modus operandi.

In addition to completely overhauling the refurbishing the newly-purchased Orangeville facility that once housed a manufacturer of tractor-trailers, the company invested in new production machinery and in-house R&D (research-and-development) capabilities in order to shift the company’s focus to value-added manufacturing, technological innovation and packaging sustainability.

Just over 10 years since the start of that transformation, Hofmann Plastics appears to be hitting its stride in spectacular leaps and bounds.

Currently housing 20 injection-molding machines, 11 high-performance thermoforming lines, three extrusion lines with capabilities of up to seven layers and ve inline industrial printers, the 180,000-square-foot facility is nowadays a yearround 24/7 manufacturing operation employing over 150 people to produce a diverse and growing range of plastic packaging products for customers in the food, construction and chemical industries across North America.

“We ship our products virtually anywhere within a 1,000-mile radius of our plant,” says Kalia, “with U.S. becoming a very important export market for us.”

Industrial plastic pails still account for about a half of the company’s total production output, but the entire product range has been upgraded exponentially with incorporation of new value-added features and size options.

Produced on the plant’s high-performance injection-molding machines, the tamper-evident round pails range from one-quart to 4.5-gallon volume capacity and o er a choice of plastic or metal handles, as well as seven di erent varieties of ex spouts for the lids, which are supplied with or without gaskets as per customer specs.

A primary supplier of retail ve gallon buckets, Hofmann also produces a variety of food-grade pails and buckets for transporting bulk quantities of olive oil, margarine, mayonnaise and other foodstu s, along with several sizes of yogurt containers—all available with upscale decorating options that include dry o set printing (up to six colors) and IML (in-mold labeling).

For all that, Kalia is even more excited about the company’s fast-growing food container business, which is now starting to pay o in a big way for all the extensive R&D investment carried out by Hofmann Plastics over the last 10 years.

“We are well on our way of becoming industry leaders in polypropylene thermoforming in less than 10 years of installing our rst thermoforming line,” Kalia states, citing the more recent installation of an advanced co-extrusion line machinery at the plant to spur further thermoforming innovation.

“In the past, resin manufacturers would do their own R&D and then tell processors like us what we would be able to do with it on our end,” Kalia recalls.

“That’s why we decided to invest into our own in-house lab, hire our own PhDs to spearhead our R&D e orts, and partnered up with many local universities to take this company to the next level,” Kalia explains.

“Our test lab is a good as any other lab in the word,” he extols, “while having in-house R&D capabilities has made us a full-service packaging company

The 180,000-square-foot Hofmann Plastics production facility in Orangeville is an around-the-clock 24/7 operation housing an extensive array of advanced injection-molding, thermoforming and co-extrusion machinery to produce a wide variety of packaging products, ranging from heavy-duty plastic pails use to package bulk-liquids and powder products to tiny portion cups and coffee capsules for leading food-and-beverage producers and foodservice operators.

with world-class injection-molding, co-extrusion and thermoforming capabilities.”

As Kalia relates, the installation of new co-extrusion equipment has given the company formidable new competencies in the development of new value-added plastic food packaging products—such as deli containers, case-ready trays and single-serve co ee pods—incorporating breakthrough sustainability advantages, superior shelf-life properties and robust antimicrobial protection.

“We made a big push in thermoforming in the last four years,” he explains, “and in the last couple of years some of those things are really starting to bear fruit.

“The co-extrusion line is responsible for bringing to life many innovations developed by our internal R&D team by allowing us to formulate many di erent types of polymers to achieve di erent attributes,” Kalia elaborates.

“Although it’s just a standard co-extrusion line, we have done a fair bit of modications on it in terms of making it robotically-operated and completely computer-controlled.”

According to Kalia, the past year has been the most productive one in the company’s history in terms of launching new innovative packaging products ready for large commercial-scale use—all o ering notable sustainability advantages.

For example, the company’s polypropylene case-ready meat trays incorporate a special foaming formulation that makes them 30 per cent lighter than conventional PP trays, according to Kalia.

Made with EVOH (ethylene vinyl alcohol copolymer) barrier co-extrusion to provide maximum product freshness and shelf-life, the fully-recyclable, microwave-safe trays are designed to withstand the rigors of automated packaging lines and distribution networks with easy de-nesting and simpli ed automated loading, while o ering higher temperature tolerance the conventional PP trays.

Available in a broad variety of sizes and depths to suit an expanded gamut of beef, sh, pork, deli-meats and produce packaging applications, the lightweight trays are treated with Hofmann’s proprietary antimicrobial technology that kills harmful microbes such as salmonella and listeria on contact.

Even more impressively, the company has also developed a fully-compostable case-ready trays made from renewable plant-based resins and biomass.

“We are really excited to o er our compostable case-ready meat trays that are made from a renewable and sustainable resources without compromising on the packaging performance,” Kalia states.

“Everything we have used to make these trays is certi ed as compostable material, he says, “and our compostable plastic has an oxygen transmission rate that is twice as e ective as conventional packaging.”

While packaging sustainability has become one of the company’s core guiding principles in new product development, Kalia says the plastic industry has to play a more active role in educating its customers and consumers about the signi cant di erences between various approaches to packaging sustainability.

“In addition to reducing the carbon footprint by making our containers signi cantly lighter, we also focus on recyclability and compostability to meet our customers’ needs for sustainable packaging options,” he says.

“If there are some things that should not be recyclable, like dirty trays containing product residue, then we will strive to make that packaging compostable, so that eventually it biodegrades completely.

“Not everything should be recyclable and not everything should be compostable,” Kalia states, “but sustainability in one form or another should always be an option.

“That’s what makes us di erent from many other plastic packaging producers out there—industry disruptors, if you will.”

This disruption is ttingly encapsulated in the development of the company’s compostable single-serve co ee pods earlier this year, along with compostable portion cups for sauces, dips, hummus and other single-serve products.

Kalia says the main reason that leading co ee producers have been largely unable to develop a fully sustainable option for single-serve co ee that can overcome widespread public criticism of co ee pods as being inherently harmful to the environment is it focused exclusively on the recyclability of used co ee capsules, without exploring other options.

By making the Keurig-compatible cups from fully biodegradable materials, the Ho mann capsules can be safely disposed of for good in industrial composting facilities without leaving a trace, he points out, while also not requiring the consumers to perform the various cleaning and separation steps required to make used plastic capsules to recycling-ready for all the di erent municipal wastestreams.

“People buy single-serve co ee capsules for the convenience,” Kalia points out, “so it’s unrealistic to expect these people to spend time separating all the di erent

components after use to make those pods recyclable—there’s no convenience in that.

“With our compostable cups, the pod is ready for composting right after you’ve made your co ee—no need to remove anything,” says Kalia, noting that the compostable pods provide the same one-year shelf-life for the co ee as the conventional plastic pods.

“These compostable K-cups let consumers enjoy consistently fresh of co ee guilt-free, being made from both industrial and natural compostable materials,” he says.

“Our unique process of blending biomass and these materials creates a rigid and e ective capsule that is substantially more environmentally-friendly than any other packaging solution available in today’s market,” says Kalia, adding the company invested millions of dollars into the development of these biodegradable pods.

“We have made tremendous strides to be ahead of the industry when it comes to developing products that reduce our impact on the environment,” Kalia states.

“To that end, we will be working even more closely with municipalities, waste companies and our customer partners across North America to move the needle even further in this area.”

Looking forward, Kalia says he is con dent that the plastics industry will be able to address many of the environment-related issues facing it.

Says Kalia: “The way we consume food today would be very dramatic if it weren’t for some important plastic packaging innovations over the last 20 years.

“From extending shelf-life to limiting portion size, the industry has always found ways to help improve the consumers’ relationship with food,” he states, “and it will continue to do so by keeping up-to-date with consumer trends to en able proper direction for future R&D and new innovative packaging solutions.”

Emerson delivers an unparalleled breadth of products, technical expertise, and global services to the packaging market. Our extensive portfolio of brands including –ASCO™ and AVENTICS™ – will help you achieve Top Quartile business performance with the industry’s top technologies.

Your path to improved performance starts with Emerson.

Au P’tit Marché plant director Daniel Trottier strikes a proud pose alongside the ReePack ReeMatic150 tray sealer recently installed at Au P’tit Marché’s Boucherville production facility as part of their continuous efforts to improve how they do production.

BY ALANNA FAIREY, ASSISTANT EDITOR

No business understands the convenience that comes from delicious ready-to-eat meals better than family-owned Au P’tit Marché Traiteur Inc., a privately held food manufacturing company based out in the suburb of Boucherville, Que.

A member-company of Aliments du Québec, Au P’tit Marché was founded back in 2003 in a di erent location and focused solely on prepared frozen meals.

When the company saw an increase in demand for spaghetti sauce in 2005, Au P’tit Marché broadened their product selections to include fresh products such as their ready-to-eat varieties, frozen soups and pies, as well as an assortment of pasta sauces.

Having moved to their current Boucherville location in 2014, the 10,000-squarefoot facility houses 20 employees working one shift ve days a week, which may increase to two production shifts as the business continues to grow.

“Au P’tit Marché started growing quickly,” says plant director Daniel Trottier.

“We went from a $100,000 worth of revenue to about $2.5 million in a matter of about six years.”

Even though Trottier joined the Au P’tit Marché team about ve years ago, he

came to the plant with over 30 years experience and noticed quickly that the facility’s choice to use shrinkwrapping as the method to package their products were dated and tedious.

“When I came here, pretty much everything was done by hand and the problem with that is that everything is obviously done one-by- one and it takes times,” Trottier told Canadian Packaging in a recent interview.

“From the minute I started to work here, I said that the only way to improve and increase our sales and business is to get machines to help, which would not happen if we kept on doing it by hand.

“Basically, it would be like going back in time where

companies like us could hire 50 people to do the job of three, but now we need three to do the job of 50.”

This realization commenced Trottier’s search for the perfect machine for the Au P’tit Marché facility.

Trottier began canvassing for machines by shopping around at di erent trade show events and conferences in Montreal and Toronto, as well as scouring the Internet.

Trottier shares that he also talked to friends and people he knew who worked in the food industry and did di erent types of business that could point him in the direction of di erent machines and di erent companies.

As a self-proclaimed “tough cookie” with a disdain

for failure, Trottier needed a guarantee that he was being shown machines that were going to bene t Au P’tit Marché in the long run.

“If the machines I buy causes me to either have downtime or have problems with it, I can be a not so fun guy to be around,” Trottier says with a laugh.

“I needed to make sure that all of the products were there and that it was going to help our business get ahead.”

When Trottier rst met Eric Williamson the president of Stock Packaging Canada Inc., a leading supplier of rigid trays and containers, exible packaging lms, pouches and machinery, at last year’s SIAL Montreal show, everything fell into place.

“We sat down with him and discussed our need and we were on that aspect extremely well served because the people at Stock are extremely competent,”Trottier recounts.

“There was the feeling that we were getting the right information, and Eric was answering all of our questions, and listening to all of our worries.”

Serving the food and pharmaceutical industries for over 30 years, the focus of Stock Canada’s business is MAP (modi ed atmosphere packaging) solutions, as well as acting as the Canadian dealer for Reepack machines, which include thermopackers and tray-sealers.

“When a client comes to us, they usually quickly realize that they don’t need to go anywhere else for anything else on their project unless there is a speci c need to,” says Williamson.

“We’re able to give them the expertise on everything that they need to make that project work.

During the initial consultation with Williamson and his team, Trottier was looking at a di erent machine that Stock Canada was selling.

After listening to the needs of Au P’tit Marché, Williamson advised against the original machine and in-

stead redirected Trottier to the Reepack ReeMatic150, a single chamber MAP tray sealer with wide conveyor that seals trays in automatic modes.

Branded as the “war horse” machine, the ReeMatic150 has been manufactured and sold since the company’s humble beginnings.

While there have been a number of technological updates and encroachments throughout the years, the ReeMatic150 has remained one of Reepack’s most proven machines, thanks to its noteworthy repute for postulating steadfastness and assiduousness.

“Before this machine, when we would produce fresh products like lasagne or shepherd’s pie, it would take me basically 40 per cent of my working time to get ve-per cent of my revenue, which makes no sense,” Trottier says.

“With the ReeMatic150, I’m now able to get just under 20 per cent of my working time to go get all of this production done and more.

“It allows me to do ten times, if not twenty times, more production and packaging any given day.”

Designed as a plug-and-play machine, there was no fuss when the ReeMatic150 was installed.

“We have machines that are pre-engineered,” Williamson explains.

“At the beginning of a project, customers don’t have a lot of the surprises and problems and tweaking that they’ll need with other kinds of machines, so they can start their project hassle-free.”

Running the ReeMatic150 has also been proven to be a comprehensible experience for Au P’tit Marché facility workers.

When production begins, the operators will place the trays with product on the infeed conveyor and the conveyor brings the trays automatically into the sealing chamber.

When the trays are in the sealing chamber, the operators pull a vacuum to a very speci c set point and gas is reinjected to an incredibly speci c set point and then the product is sealed.

Our pressure sensor with display

Once vacuum-packed, the nished product gets transferred onto an outfeed conveyor, which then moves the trays out of the machine and transfers them onto the downstream equipment.

Since installing the ReeMatic150, Trottier has seen signi cant increase in sales, as well as better quality of the product that comes o the conveyor.

Trottier also discerned that the ReeMatic150’s comprehensible interfaces bene tted his operators who did not speak English as a rst language.

“For some mahines, all of the instructions come on the screen with words and asking you commands in English, but I’ve got workers that don’t speak English

and that can be a problem,” Trottier elucidates.

“The ReeMatic150 is very user-friendly, it’s easy to understand, and it’s easy to change the tooling out of it.”

Not only has the installation of the ReeMatic150 resulted in a completely transformed method of business for Au P’tit Marché, it has also strengthened their professional relationship with Stock Canada.

For his part, Trottier was impressed with Stock Canada’s constant guidance and helpfulness to them before, during and after selecting and installing the ReeMatic150

Stock Canada continues to follow up with Au P’tit Marché and assists them quickly when they run into problems.

“We had an issue at the beginning with one electrical component, and it was xed,” Trottier recounts. “It didn’t take a month, it didn’t take two weeks, it didn’t even take a week––it only took three days.

“Whether it’s sales, after-sale service, or whether its because we now buy containers from Stock as well, they are extremely well-organized.”

Now part of his close-knit network, Stock Canada has become Trottier’s rst choice when he eventually begins to shop for machinery in the future for Au P’tit Marché.

“It becomes a relationship,” Trottier says.

“If you can’t build a relationship with a supplier, I don’t understand why anybody would do business with suppliers that are not interested in doing business with them.

Concludes Trottier: “I’m not going to start fooling around and shopping around if Stock Canada can help me with what I’m looking for.”

Compact and rugged. Convenient with easy-to-read display. Pressure value directly via IO-Link. Comes ready to install. Can be used as pressure sensor or as pressure transmitter. Just one of over 30,000 Balluff products of proven quality. Ask your sales partner or inform yourself online.

s the largest packaging event in Ontario, PACKEX Toronto 2019 exhibition at the Toronto Congress Centre is a natural meeting place for packaging professionals to nd the latest innovations, processes, and techniques that can enhance their projects, including digital printing, exible packaging, adhesives, print-and-apply labelers, blister packaging and automation systems.

Running from June 4–6, 2019, it is also one of ve concurrent industrial trade shows organized under the ADM (Advanced Design & Manufacturing) Toronto 2019 umbrella, also including Automation Technology Expo (ATX), Design & Manufacturing (D&M), PLAST-EX and Powder & Bulk Solids (PBS)

Visitors will revel at the three days of education, networking, and solution-sourcing with approximately 5,500 industry professionals and more than 426 suppliers, really immersing themselves in the industry’s latest innovations.

Expo organizers have prepared a plethora of special on-site activities and events that are both educational and entertaining, while highlighting the continued prosperity and competitiveness of Canada’s ever-growing packaging and manufacturing industries.

Coming back to this year’s show is the well-received Tech Theater, a unique opportunity for guests to meet exhibitors who are showcasing the latest solutions in the advanced design and manufacturing industry. Attendees will have the chance to network with professionals and get opinions on how to diminish tedious production costs, nd automation solutions that develop competence, as well as scrutinize materials and

Bosch Rexroth Canada is bringing the Factory of the Future to the automation industry at PackEx

Featuring an extensive variety of products and demos from its automation, assembly and linear motion technology portfolios, Rexroth experts will be present to answer questions about the Factory of the Future, its impact on the packaging industry and how Rexroth is contributing.

For attendees who would like to learn more, Bosch Rexroth’s I4.0 Specialist, Asvin Parsad will be hosting a presentation called “The Factory of the Future Drives Customer Bene ts” at the Tech Theatre, which is sched-

procedures that help deliver projects faster and more a ordably.

This year, ADM Toronto is excited to introduce the rst annual Startup Stadium, which will highlight 10 startup companies from across Canada.

While this inaugural event will allow visitors to stop by and discover new and emerging products, the Startup Stadium also features an inventive pitch competition as their leading event, which guests will have the chance to watch.

uled to take place the morning of June 5.

Bosch Rexroth will also have demonstrations of the I4.0 Cube and Industry 4.0 Solution showcase demo, which will exhibit the cutting-edge advancements in Industry 4.0 and forward-thinking technology to curious attendees.

Bosch Rexroth will also be introducing guests to their brand-new technology solutions.

For the rst time, attendees will get a glimpse of the ActiveMover transfer system demo, a new linear motor transfer system from Rexroth sets new standards of performance when operators need to transport products with great speed and precision.

In addition, Bosch Rexroth’s VarioFlow plus plastic chain conveyor system will also be on-hand to highlight why it is known as Bosch Rexroth’s easiest to assemble, quietest, most exible and energy-e cient plastic chain conveyor to date.

Bosch Rexroth’s presentation will be about more than just live demonstrations.

They will also be displaying an extensive range of kiosks from its all-encompassing product group portfolio. These attention-grabbing highlights include:

• Rexroth’s selection of linear motion products

The returning Centre Stage will act as the home base for show visitors to receive tips and advice on how to pursue their projects down the development pipeline. Guests will get the opportunity to participate in two days lled with demonstrations and experiences that aim to broaden their perceptions of the industry, as well as deliver insights that are applicable to their everyday work.

For more show information and to register for the PACKEX Toronto 2019 exhibition, please go to: https://admtoronto.com/packex

such as the new Function Module and IMS incremental measuring system, which provides precise measurement.

• ActiveCockpit, the communication program, processes and envisages data in real-time;

• IndraDrive Mi cabinet-free technology that diminishes the machine footprint of packaging and processing machines;

• And nally, Rexroth’s OpenCore Engineering that bridges together the world of IT, creating new levels of engineering tractability.

Booth #1213

There is no better way for Loma Systems to celebrate 50 years of designing, manufacturing and supporting inspection equipment used to identify contaminants and product defects than to do live dem-

onstrations at PackEx

Their high-quality metal detectors, checkweighers and X-Ray inspection systems demonstrate Loma’s commitment to postulating the most cutting-edge technology and delivering consistent quality to the food, packaging and pharmaceutical industries.

Through the live demonstrations, attendees will gain a better understanding on how to comply with, and exceed, product safety standards, weight legislation and retailer codes of practice while maximizing production uptime and enjoying lower lifetime equipment costs.

Booth #1031

A brand spanking new set of global product catalogs by Ballu Canada Inc. is making it easier than ever for customers to access their extensive range of products meant to measure, detect, identify and connect.

The ve-volume set is available in print or as digital ipbooks on the company’s website.

“While many companies have strayed from print catalogs in 2019, Ballu made a conscious choice to create both print and digital versions of its new catalogs to best meet the demands of those in a manufacturing environment,” says Marketing Communications Manager Juli Hale.

“The digital versions o er the bene t of being searchable with quick links to product pages on the website.

“However, we realize that the warehouse oor, where it can be highly bene cial to review product drawings or specs, often has limited or no Internet access and print versions are more useful here.”

Booth #1415

VC999 Canada will be putting the “P” in performance when they showcase their p-Series roll stock thermoformer, known as their most advanced packaging machine yet.

The p-Series comes with interchangeable modular body components, which helps to extend the machine’s life and can also include major line changes and product revisions.

The machine also features stainless construction for excellent washdown exceeding IP69 hygiene standards.

All p-Series machine and safety features are controlled by a PLC HMI (human machine interface) system, which has been praised by customers for its comprehensible and malleable qualities.

The new p-Series opens the door for new possi-

Booth #1221

bilities in product packaging to make rigid & exible, plus Skin,Vacuum, & MAP packaging all in one machine without making any major adjustments.

MD Packaging will have plenty to demonstrate and display at PackEx, including Thermo Fisher Scienti c’s Sentinel Multi-scan metal detector and an interactive lounge with video showcase of their innovative solutions.

After seeing the live demonstrations, attendees will understand why MD Packaging are industry experts when it comes to X-Ray, checkweighing, metal detection, induction sealing, case forming, case packing, labeling, tray forming, palletizing and stretch wrapping.

Having worked alongside some of the most progressive inspection and automation OEM’s in the likes of Pearson Packaging, Inc.Jet, JLS, Thermo Fisher Scienti c, TMI and Universal Labeling, MD Packaging has factory trained technical managers that are ready to help their customers.

Visitors will also learn about the services that MD Packaging provides, which include: parts supply, calibrations, preventative maintenance, certi cations, rentals and emergency rework.

Booth #1565

Reiser Canada Co. will do live demonstrations of their lines of Ross tray seal equipment, Fabbri automatic stretch wrappers, Supervac vacuum chamber packaging machines, and Reiser FFS packaging machines.

Reiser will demonstrate its new Fabbri 75 automatic stretch wrapper, which uses stretch lm to package fresh food products in preformed trays.

The Fabbri 75 can handle a wide range of tray sizes with no changeovers, producing up to 75 packs per minute.

It features a programmable control panel that includes diagnostic software and can be adapted with weighing and labeling equipment.

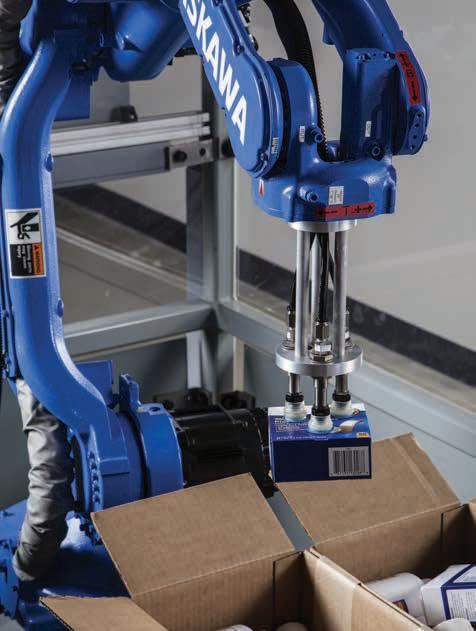

Finally, Reiser will also present its range of JLS robotic packaging solutions for primary and secondary food packaging with a focus on robotic pick and place systems, tray loaders, and case packers.

All lines demonstrated are accessible in various model sizes to meet fundamentally any production requirement.

Booth #1203

The product division of Mettler Toledo will be conducting a number of live demonstrations of a number

of their di erent systems for attendees at PackEx

Accomplished subject-matter experts will be providing visitors with a comprehensive collection of product inspection equipment, which will include checkweighers, metal detectors, vision systems and x-ray inspection systems.

These systems will provide attendees with solutions to guarantee brand protection, identify solid contaminants, ratify component content, examine closures, measure ll levels and verify product weights.

Booth #1521

AstroNova and its company’s two subsidiaries

QuickLabel and TrojanLabel will showcase QuickLabel’s QL-120, TrojanLabel’s T2-C and the brandnew QL-300

QuickLabel’s QL-120 is a eld-proven printer devised for adaptability and steadfastness, and has the capability to print an assortment of labels as narrow as 0.5”, which makes it a superlative choice for third party integration.

As the world’s rst CMYK+White toner-based tabletop label printer, the QL-300 adds a new dimension to label printing with the addition of the white ink-printing feature.

Finally, making an appearance to the show is the T2C, the world’s smallest label press courtesy of TrojanLabel’s. The T2-C has quickly become the preferred choice of printers, due in part to being known as and its compact.

Booth #1159

Squid Ink Manufacturing Inc. announced that its authorized Canadian distributor Dependable Marking Systems would be featuring the Streamline 5 CIJ printing system at next month’s show.

The Streamline 5 was speci cally designed to print superior quality small characters on a variety of substrates, which include but not limited to: porous, nonporous, smooth, textured, curved, and concave.

O ering reliable, yet inexpensive solutions, the Streamline 5 operates with a wireless or wired touchscreen tablet that runs Orion software, which allows operators the choice of controlling their printers on the production oor, or interacting multiple systems from one location.

Attendees will be able to see the Streamline 5 selfcleaning printhead with CleanJet maintenance routine that allows for quick and easy automatic start-up and shut down.

Visitors will understand that when regular upkeep is necessary, components can be substituted out quickly, jettisoning the need to buy expensive lter and pump assemblies or schedule service calls.

Booth #1437

A leading provider of packaging solutions used to pack a range of products, Multivac Canada will be taking over at PackEx

Visitors will have an exclusive live demo of a complete Skin Packaging line, beginning with the R126 and R085 Thermoformers along with an L300 Labeller that can be used exibly in di erent locations in production.

Other areas of the booths will showcase the T300 Traysealer, and the TVI GMS520 single cut portioning system.

To further demonstrate their pro ciencies, Multivac will additionally do live demonstrations of their competitive P600 baseline double chamber machine.

Booth #921, booth #1021

Busch Vacuum Technics Inc. will display the R 5 rotary vane vacuum pumps from the company’s RD series vacuum pumps.

Speci cally designed to be used in vacuum packaging machine and fast packaging cycles, the R 5 rotary vane vacuum pumps stand out for its robustness and reliability of operation, thanks to its highly resilient carbon ber vanes.

The R 5 is also highly energy-e cient and sustainable, as it uses 20 per cent less energy consumption, has reduced heat emission, as well as low operating costs.

Booth #1335

Sesotec Canada Ltd. will present the VARICON+ metal detection system, a state-of-the-art system that detects all metal contaminants, such as steel, stainless steel and aluminum.

The VARICON+ Complies with the necessary requirements for metal detectors pursuant to IFS (International Food Standards) and analogous guidelines within the food industry.

Along with a 7” touch display and USB port on the control panel, the VARICON+ also includes a product signal graph that shows the product signals over time and also shows changes in the product signal.

Booth #1445

Sipromac will be showing o their vacuum tabletops, single and double chambers vacuums, as well as thermoforming machines.

Renowned for manufacturing stalwart equipment,

Sipromac offers more than 20 di erent sizes of vacuum packaging machines, and cater to a wide range of clients that range from small butcher shops to a large processing plant.

Sipromac’s brand spanking new 50,000 square-foot factory includes equipment at the cutting edge of technology to help design and ensure a production of superior quality and reliability.

With machines installed in over 70 countries, Sipromac’s packaging solutions ensure freshness and prime shelf life of food products around the globe.

Booth #1635

Next month, Dependable Marking Systems Ltd. will be showing o their HERMES+ print and apply systems.

Constructed for industrial applications and real-time label application, the HERMES+ comes with a precision guide that allows the labels to be applied or blown on the product correctly.

Labels may be applied on the product from all sides.

Also on display will be the HERMES+ C, the rst labeling system to print and apply two-color labels in one operation.

The HERMES+C has been developed and optimized for applications corresponding to the new Classi cation and Labeling Inventory according to GHS

Booth #1437

Weber Packaging Solutions will be displaying their brand new Alpha HSM high-speed label applicator.

The modular Alpha HSM comes in ten di erent versions that can t any labeling application, and can keep up with an impressive line speed of up to 500 feet a minute.

The standard mechanical label unwinder and rewinder can be upgraded to a motorized servo-controlled system for higher speeds.

Application modules for the Alpha HSM include: a xed peeler plate, a swivelling peeler plate, a pneumatic peeler plate, and adjustable peeler plate or a pneumatic applicator.

In addition, the Alpha HSM is IP65 certi ed and its multiple interfaces allow for a number of di erent connections, including HMI display.

Booth #1309

We are Pigeon. For the past four decades we’ve been collaborating with Canada’s biggest and best brands to build their stories from the ground up. We do it by bringing key attributes to light and weaving them throughout the entire brand – from the packaging right through to the entire communications eco-system. At Pigeon, we understand that IDEAS THAT TRAVEL are ideas that ensure your brand’s growth and success in the marketplace.

Predicting the future is risky business at best, but it certainly helps when you’re in the driver’s seat of the future-bound technologies widely expected to be the fundamental building blocks of the next golden age of manufacturing in the industrialized world.

For leading German industrial automation giant Bosch Rexroth AG, the company’s designation as one of the leading forces behind the rapidly advancing Industry 4.0 manufacturing transformation rooted in seamless enterprise-wide date acquisition and realtime machine-to-machine communications is a wellearned badge of honor that accurately re ects its vast expertise in many industrial automation applications, including CPG (consumer packaged goods) production and packaging.

As one of the more prominent industrial technology powerhouses working tirelessly to promote the utilization so-called IIoT (Industrial Internet of Things) networking and connectivity into everyday manufacturing process and equipment operation, the company’s self-styled Factory of the Future (FOTF) doctrine of improving manufacturing productivity by leveraging analytics to optimize equipment uptime and human decision-making is a culmination of three years of intense research and development of Industry 4.0 principles and techniques at many of its own and manufacturing facilities around the world.

To get a better idea of FOTF has to o er to today’s ercely competitive packaging industry, the Canadian Packaging magazine recently reached out to Asvin Parsad, business development manager for Industry 4.0 at Bosch Rexroth Canada, to explain why IIoT is the inescapable new reality for manufacturers in high-cost countries like Canada.

What is the main de ning feature of FOTF that makes it such a transformational development?

Our vision of the FOTF is complete exibility, whereby only the factory walls, the oor and the ceiling will be xed, but everything else will be mobile.

The assembly lines will be modular, and their constituent machines will be moved and reorganized into new lines for new purposes. They will communicate wirelessly with one another with other process functions and with Cloud-based IT systems.

The FOTF will provide full transparency in the digitalized value stream: from procurement to production and right through to the customer.

What prompted Bosch Rexroth to develop the FOTF

business model in the rst place?

Our FOTF vision was a response to what we and our customers (manufacturing plants) were facing as a result of profound changes in customer demands. As consumers, we want our stu cheap, quickly, to provide high quality, and to be customized for our needs, so that we have the exibility to change our minds as taste changes.

That puts a huge pressure on the manufacturing process and the supply chain to balance e ciency, productivity and automation, while coping with shorter product life-cycle, higher product variability, and high quality expectations.

Which industries stand to gain the most from the implementation of Factory of the Future in their operations?

We have implemented elements of this FOTF vision in a broad range of manufacturing industries that include automotive, packaging, food, electronics, mining, forestry, and even the entertainment industry.

We found that the type of industry was less important in determining successful implementation than having the right behavioral pro le and a set of core competencies that needed to be present in the organization.

Success would depend on whether they have a ‘Lean’ mindset and are adaptive to change, critical thinking and digital literacy, with a high value on data security. These set of behaviors would allow the organization to best leverage data to improve their supply chain and embrace new business models that can emerge out of Industry 4.0 principles.

Please explain the relevance of Factory of the Future concept to the packaging sector.

We have had extensive exposure to high-performance packaging machines through our Bosch Packaging division. The common questions we get asked are: ‘How well does my machine actually perform? How do I make inexpensive adjustments in order to optimize productivity, quality and e ciency?’ and ‘How do I get started?’

Packaging machines are complex structures—essentially a ‘Black Box’ that need to be made transparent to see what is going on inside the machine.

To achieve that, we came up with an IoT Gateway hardware/software solution that could read the control commands, motion parameters and peripheral devices.

Some of the controllers were from third parties like Rockwell, Siemens, Beckho , etc., and because we needed to read their parameters too, and we did it using an open industry standard called OPC UA.

The environmental conditions could also a ect the packaging process, so we needed to record additional data like humidity, temperature, vibration and we did it using our Bosch XDK and CISS sensors.

All that data was then pulled into the IoT Gateway, cleaned up, ltered and transported to the analytics engine on the cloud to make sense of it.

The customer was then able to generate a health report of the machine, determine when the drop in performance occurred, and what were the probable causes behind it.

They now had the tools to initiate corrective actions and make adjustments to improve their performance.

How is your FOTF vision di erent from the Industry 4.0 blueprints developed by other automation companies, like the afore-mentioned third-party manufacturers?

The main di erentiation from our peers is that our Industry 4.0 o ering was mainly ‘customer-driven,’ rather than be purely driven by product innovation.

The customers were our own Bosch plants, with speci c problems to solve and we had to develop tools to address these demands.