FOR GOODNESS SAKE

Sound product safety and keen innovation drive healthy early growth curve for hardworking

Riverside Natural Foods plants Story on page 14

Sound product safety and keen innovation drive healthy early growth curve for hardworking

Riverside Natural Foods plants Story on page 14

To discuss exhibitor & sponsor options, contact: Stephen Dean | Tel: 416-510-5198

sdean@canadianpackaging.com

Leading packaging suppliers under one roof at the same time – ONE DAY ONLY! Network, discuss, and exchange ideas so you can drive your business forward!

Meet some of the most innovative suppliers of the best new packaging materials, containers, machines and automation options in:

• Package Design

• Packaging Automation

• Package Decoration & Coding

MAY 2016 VOLUME 69, NO. 5

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph (416) 510-5228 AJoseph@canadianpackaging.com

ART DIRECTOR

Kathy Smith • (416) 442-5600 x 3215 ksmith@annexbizmedia.com

PRODUCTION MANAGER Barb Vowles • (416) 510-5103 BVowles@annexbizmedia.com

CIRCULATION MANAGER

Barbara Adelt • (416)-442-5600 x3546 badelt@annexbizmedia.com

VICE PRESIDENT Tim Dimopoulos • tdimopoulos@annexbizmedia.com

PRESIDENT & CEO Mike Fredericks

ANNEX BUSINESS MEDIA

80 Valleybrook Drive, North York, ON, M3B 2S9; Tel: (416) 510-5198; Fax (416) 510-5140.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

e-mail: rthava@annexbizmedia.com

Tel: (416) 442-5600 ext 3555

Fax: (416) 510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE): Canada $74.50 per year, USA $130.95 US per year, Outside Canada $149.00 US per year, Single Copy Canada $10.00, Outside Canada $27.10. From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

ANNEX PRIVACY OFFICER

privay@annexbizmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2016 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without

its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

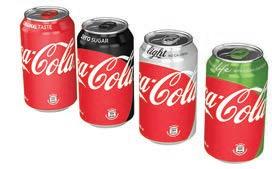

There’s no such thing as being too big to fail in modern business these days, and for firms like The Coca-Cola Company, failure is not an option.

Happily for the Atlantaheadquartered soft-drink colossus, the company has never really had to live through a near-death experience—the disastrous New Coke experiment in the 1990s notwithstanding—that put its very existence at serious risk throughout its glorious 130year history.

Thanks to the unrivaled global consumer following and loyalty to its core Coca-Cola master brand, the beverage producer has come through many economic downturns and recessions relatively unscathed, always ready to “add life,” to “make it real,” or “teach the world to sing” through one catchy advertising slogan or another to remain the world’s go-to soft-drink.

long-term picture of eternal growth and prosperity that were once taken for granted as a divine right. In that light, the company’s newly-launched “One Brand” global marketing strategy has an undeniable ring of urgency that reveals a certain level of concern and dissatisfaction with the existing marketplace status quo

To shake things up, Coca-Cola recently announced the launch of new graphics that use one visual identity system featuring Coca-Cola Red as a unifying color across the trademark, whereby the signature Red Disk emblem will migrate across the carefully vetted and selected sub-brand colors of the Coca-Cola brand family: black for Zero; silver for Light/Diet; and green for Life

The problem for Coke these days, though, is that the world is no longer turning to soft-drinks to quench its thirst as much as it used to, resulting in stubborn and steady erosion of the brand’s market share in some of its critical markets. Despite remaining the bestselling soda brand in the U.S., for example, Coke saw its volume dropping by a full percentage point in 2015, according to the Beverage Digest magazine, with Diet Coke volume drop by an alarming 5.6 per cent.

While not catastrophic declines in themselves, given the current trends towards healthier food and beverage options across the western world and beyond, these are not the numbers suggesting a

As Coca-Cola’s chief marketing officer Marcos de Quinto correctly points out: “Packaging is our most visible and valuable asset [and] Coca-Cola Red Disc has become a signature element of the brand, synonymous with great taste, uplift and refreshment.

“By applying it to our packaging in such a bold way, we are taking the next step towards full adoption of the ‘One Brand’ strategy, uniting the Coca-Cola family under one visual identity and making it even easier for consumers to choose their Coca-Cola with or without calories, with or without caffeine.”

Rolling out in global markets later this year and through 2017, this significant packaging makeover may or may not save the day for Coca-Cola with the same aplomb and stellar success of the years past, but at the very least, it’s undeniably the right place to start.

By Andrew Joseph Southern Ontario ice cream manufacturer leverages smooth production flow and formidable packaging capabilities to foster strong brand loyalty and customer satisfaction.

27 KALEIDESCOPE OF COLORS By Andrew Joseph Gum and candy producer hits the packaging sweet-spot with automatic bagging machinery and high-speed pouching capabilities. 32

ON FLEXIBLES A roundup of new technologies, systems and equipment for innovative flexible packaging applications.

34

A final reminder why you should be attending our annual Top 50 Packaging Ideas Expo tabletop trade show next month.

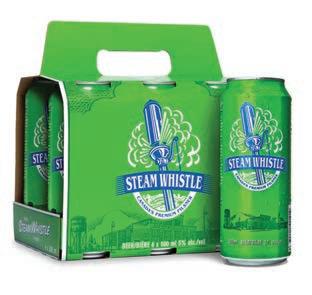

In Canada, the arrival of spring is always fondly greeted by the country’s beermakers as a warmup for the annual summertime ‘Beer Wars,’ and Toronto’s leading craft-brewer Steam Whistle Brewing is already showing all signs of being battle-ready with a new multipack of its flagship Steam Whistle Pilsner brand.

Launched across Ontario last month at select grocery stores and at The Beer Store retail locations, the company’s one and only brand is now available in a convenient six-pack of 500-ml tall cans inserted inside a stronger and sturdier beer-case featuring a built-in carrying handle for enhanced consumer convenience and portability.

“Nothing’s better than sitting back and cracking open a refreshing Pilsner after a hard day’s work,” says Steam Whistle co-founder Cam Heaps.

“We’ve had 500-ml can singles and 24-packs of our large cans available for years, but the launch of the new six-pack format means a convenient new carton is available for Ontario beer drinkers just in time for summer,” says Heaps, noting that cans now account for nearly 40 per cent of all Canadian-made beer sold in the province.

Designed primarily with portability in mind, the new custom can carrier—produced by Jones Packaging Inc. in London, Ont.—was inspired by the

company’s original suitcase-style design first used to package six-packs of 355-ml Steam Whistle Pilsner brand bottles.

Featuring a sturdy handle and endpanels for enhanced stability and balance, the new pack has also been upgraded to a 26-point wet-strength paperboard from the 24-point board used for the glass bottle six-packs, according to Steam Whistle’s director of purchasing Chris Johnston.

“We had two priorities when developing the packaging for the new 500ml six-pack: to keep our signature suitcase handle, which requires an intricate series of folds; and to maintain the overbuilt, premium packaging experience expected by our customers,” Johnston says.

“The end result is a stable package ready to be carried home by thirsty consumers, and one that is also easy to bring along to your next cottage getaway, golf trip, patio hangout or camping adventure.”

In addition to upgrading the beer suitcase, Steam Whistle has also enhanced the cans’ seal integrity

with an innovative double-seaming technique that makes the seal act like a miniature air-tight keg—keeping unwanted oxygen at bay.

As Steam Whistle’s assistant brewmaster Colin Banting explains, “Cans are impervious to oxygen and light, which are two of beer’s worst enemies.

“The double-seam used to seal the can provides an effective barrier to the ingress of oxygen, which can cause premature staling,” Banting says, “while the can’s aluminum body prevents exposure to light, thereby reducing the likelihood of the beer becoming light-struck or acquiring a ‘skunky’ taste.”

Big on convenience but woefully short on marketing sizzle and packaging excitement, instant coffee has steadily seen its share of the otherwise healthy Canadian coffee market erode over the years.

According to a 2013 study by the Coffee Association of Canada (CAC ), traditional instant cof-

It may seem odd that one of the world’s largest and oldest peanut processors has not had a brand of peanut butter it could call its own in Canada for over a century.

But good things come to those who wait and, according to Planters Canada, the wait was well worth it.

fee accounted for only nine per cent of total coffee sales in Canada that year, despite coffee being the country’s dominant beverage of choice after only tap water.

But according to prominent global coffee distributor Coffee Globe LLC, bushing off instant coffee

whole new level.

Launched across Canada last month in resealable one-kilogram plastic jars, the new Planters brand of Smooth and Crunchy peanut butter features the iconic Mr. Planters mascot on the large wraparound blue and red (Crunchy) decorative product labels in distinctive splendid regalia—consisting of a walking cane, a classy top hat and a monocle—that dates back exactly 100 years to its first rendering, initially created for an art competition.

With no transfats or cholesterol, the Planters brand peanut butter is proclaimed to be “the best-tasting peanut butter on Canadian grocery store shelves,” according to Planters, a division of The Kraft Heinz Company

“Quite simply, it the better-tasting peanut butter,” says Planters Canada vice-president of sales and marketing Don Lock.

“Our approach is simple: We put more peanuts in our peanut butter to create a premium spread that will take your sandwiches, snacks and baking to a

“In fact, our peanut butter is so good that you’ll be tempted to forego the bread or crackers and simply grab a spoon and eat it straight from the jar,” says Lock, citing the long-enduring popularity of peanut butter in Canada, where it’s been a food staple at countless Canadian households for generations.

According to the most recent consumers surveys:

• Eighty-one percent of Canadian consumers believe peanut butter is nutritious and high in protein, and 80 per cent believe that peanut butter also provides a quick energy boost;

• Al most 40 per cent consistently enjoy peanut butter regularly in their diets (i.e. multiple times per week);

• Ei ghty-one per cent feel peanut butter makes a good snack for children, and 82 per cent feel the same for adults;

• Wh ile the most common way to enjoy peanut butter is still on toast, bread or baked goods, 31 per cent of Canadian consumers admit to dipping right into the peanut butter jar with bread, sliced apples, celery, bread sticks, a spoon, etc.

as an irrelevant yesteryear product is highly premature.

Based in Florida, the company says it enjoyed great success in the U.S. with last summer’s launch of the upscale, gourmetquality Egoiste brand of instant coffee imported from Germany, where instant coffee is a popular mainstream beverage staple.

Making its Canadian debut at the SIAL Canada 2016 food industry trade show in Montreal last month, the brand’s core Egoiste Café Noir flavor variety—made with a blend of highland and lowland Kenyan Arabica beans and freeze-dried through a secretive proprietary process—is expected to hit the Canadian store-shelves later this year in a national rollout, according to Coffee Globe.

“We are thrilled to expand our reach to include all of North America,” says Coffee Globe vice-president of sales Tim Bush. “We know many Canadians have a great affinity for high-quality coffee, and we are excited to be setting the new standard for quality in instant coffee.”

Resembling a bottle of premium men’s cologne, the brand’s 100-gram octagonal-shaped, highlyrigid black plastic jars and tight-fitting lids are decorated with a classy dark-grey shared label, with white font lettering and splashes of metallic finishes helping create elegant packaging presentation and a boldly confident shelf presence, according to Bush.

“We look forward to showing our new Canadian customers that gourmet instant coffee is not an oxymoron and that our products will truly live up to their taste and quality expectations.”

Each 100-gram jar provides about 60 servings, which are made in less than 10 seconds with one or two teaspoons and a cup of hot filtered water.

For now, Canadian consumers can purchase the product online by going to: www.egoistecafe.co

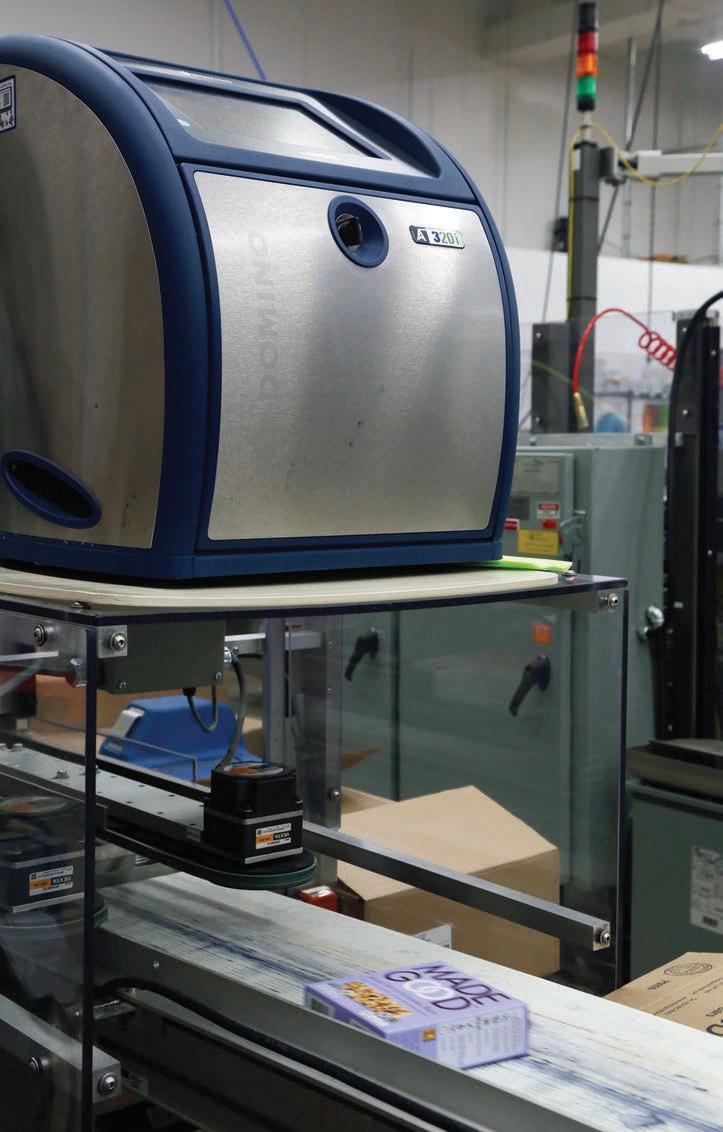

Since 1978 , Domino has evolved to offer a comprehensive portfolio of end-to-end coding solutions designed specifically to meet compliance and productivity requirements. But our advantages don’t stop with our remarkable products. We work hard every day to ensure our service is just as exceptional as our products.

At Domino, our people constantly do more to provide you with a true difference in printing.

The difference is in our people. The difference is in our printing.

Domino. Do more.

n Leading flexible packaging products group Bemis Company, Inc. of Oshkosh, Wis., has picked up two 2016 Flexible Packaging Achievement Awards of the Flexible Packaging Association (FPA), including:

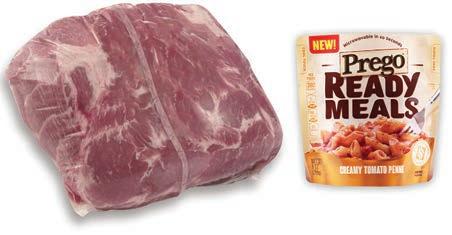

• The Best in Show award for the self-venting pouch produced for Campbell Company’s Prego Ready Meals brand of portable meals, which can be microwaved in 60 seconds to provide consumers with a convenient meal that can be enjoyed straight from the bowlshaped pouch. According to Bemis, the pouch’s unique controlled venting design ensures even heating of the entire contents with no ‘cold spots,’ with the added convenience of eliminating the need to tear open the pouch prior to heating.

• A Silver award in the competition’s Technical Innovation category for the foodservice package utilizing the company’s Curwood FlowTite shrink rollstock film. Used to package large cuts of fresh meat by leading U.S. meat processor Smithfield Foods, the hermetic-

ally-sealed packaging enabled Smithfield to realize several process efficiencies compared over the previous packaging method, including a 50-percent reduction in manual labor and a notable gain in processing throughput from 32 to 35 bags per minute.

n Leading bagging systems and equipment manufacturer Automated Packaging Systems of Streetsboro, Ohio, has completed the acquisition of Ergocon Solutions, a prominent manufacturer of automated textile inspection and packaging systems for industrial laundry applications that include bar, shop, utility and microfiber towels, washcloths, pillow slips, gloves, mops and other textile-based cleaning supplies. “We have worked closely with Ergocon and its customers, providing state-ofthe-art baggers and pre-formed bags for the overall solution,” says Automated Packaging Systems president Cliff Brehm. “With this acquisition, we

Ill., and a sales and design office in Bentonville, Ark., along with owning a minority interest in the Five Star Sheets sheet feeder consortium in New Carlisle, Indiana. “This acquisition brings new capability in point-of-purchase displays and digital print capability that complements our current print offering,” says Billy Medof, president of GP Corrugated. “We are excited to welcome them to the GP Corrugated team and look forward to enhancing the solutions we bring to our customers.”

n Transilwrap Company, Inc., Franklin Park, Ill.-headquartered manufacturer, converter and distributor of specialty film products used in healthcare, packaging, point-of purchase, display advertising and industrial markets, reached an agreement to acquire the Specialty Films business of The Dow Chemical Company. Targeted to close by the end of the second quarter of 2016 pending regulatory approvals, the acquisition would see Transilwrap take ownership of two manufacturing facilities in Hebron, Ohio, and Drusenheim, France, specializing in the production of SARANEXT, PROCITET, OPTICITET and other established brands of value-added specialty films widely used in packaging, medical and industrial markets worldwide. “Dow’s film technologies, market focus and geographic presence support accelerated growth and global expansion in Transilwrap’s strategic market segments such as healthcare and packaging,” says Transilwrap president and chief executive officer Andy Brewer. “Dow’s specialty films business is well regarded in the industry for strong technical expertise and globally recognized brands associated with quality, reliability and leadership, and we look forward to working with their existing management team to drive new business opportunities forward.”

see an opportunity to expand our product line to meet the unique needs of the professionally laundry market in North America and internationally. Ergocon’s unique experience in the textile laundry market, combined with Automated Packaging’s strong engineering and service teams, will give customers a textile packaging system with unique production efficiencies and fast return on invest-

Atlanta, Ga.-headquartered pulp and paper Georgia Pacific LLC has significantly beefed up its corrugated operations last month with the acquisiExcel Displays and Packaging, awardwinning manufacturer of corrugated point-ofpurchase displays, highgraphic retail packaging, in-store signage and industrial packaging products. Employing about 120 people, Excel operates a stat-of-the-art converting plant in Aurora,

n La Crosse, Wis.-based product labeling manufacturer and converter Inland has completed the acquisition of Valley Label, a flexographic printer of flexible packaging and shrinksleeve, pressuresensitive and rollfed labels, employing 35 people at a 48,400-square-foot plant in Neenah, Wis.

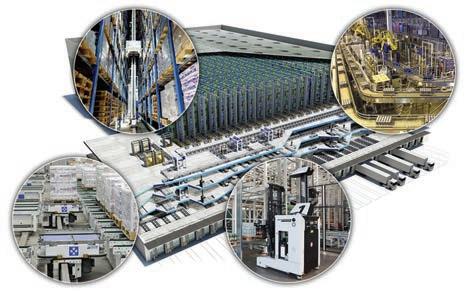

n German beverage filling and packaging technlologies group Krones AG has acquired a 60-percent owneship stake in System Logistics S.p.A., a globally-operating provider of logistics, material handling and warehousing technologies based in northern Italy. Employing about 250 people and generating annual revenues of nearly $150 million, System Logistics manufactures a broad range of automated storage and retrieval systems (AS/RS), automated guided vehicles (AGVs), order-picking systems and coveyors, along with related software. According to Krones, “By acquiring a majority holding in System Logistics, Krones is enhancing its competencies in the field of intralogistics—particularly in terms of automated order-picking systems—and taking a major step forward in covering the important material and data flows along the entire value creation chain of our customers.”

A new tear-resistant, woven polypropylene bag with a stable, square base from the Consumer Goods Packaging Division of Mondi in North America is designed to ensure secure packaging for a broad range of powders and granular materials, including grass seed, fertilizer, cat litter, laundry detergent, flour, sugar and rice. Called the WPP (woven polypropylene) Box Bag, it presents significant benefits of a multilayer woven polypropylene structure that offers high durability and product protection throughout the packaging life-cycle. The WPP bag’s square base and box-style design allow for upright positioning on pallets and inside shipping containers, and the WPP package can also stand upright right on the store-shelves for

maximum promotional impact. Offering a large surface area for brand messaging, the WPP can be printed in up to 10 colors using rotogravure or high-definition flexographic processes, while allowing for matte finishes to be applied to the bag’s printed areas—thereby adding visual depth and producing an appealing contrast with the packaging’s glossier images. Easily converted to be equipped with an integrated die-cut handle or a label handle for convenient carrying and easy pouring of the contgents, the innovative WPP bag is available in sizes ranging from 16 to 40 inches (400-mm to 1,000mm) in height and 10 to 18 inches (250-mm to 450mm) in width.

Mondi in North America

401

Designed for the product inspection/ detection requirements of food processors handling larger product and case profiles, the new NextGuard C500 X-ray detection system from Thermo Fisher Scientific Inc. features an enlarged aperture that is 35 per cent wider and 50 per cent taller than previous NextGuard series models, according to the company, making it well-suited to inspect a broad range of larger-sized products and cases. As with all NextGuard systems, the C500 model uses a wide X-Ray beam and an arc-shaped detector designed to eliminate blind spots in the inspection tunnel, and it is said to be well-suited for the inspection of cases with multiple components, such as cartons or flexible bags, as well as large individual packages or boxes. Moreover, the C500 can be configured for up to eight lanes of simultaneous inspection— making it more cost-effective than purchasing and maintaining several smaller-aperture, single-lane systems.

Thermo Fisher Scientific 402

The new Contour Series M-60 Multiwrapper from Douglas Machine Inc. features an automatic film splicer to allow operators to stage clear or printed film while the machine is running, while automatically performing all the required splicing to deliver highly precise print registration. Designed for high performance and reliability, the Contour Series M-60 Multiwrapper machine can run single-, dual- or triple-stream bundles of PET (polyethylene terephthalate) water bottles at various cycle speeds—up to 60 per minute—to match the filler rate.

Douglas Machine Inc. 403

Designed to provide highly reliable high-speed label and package inspection, the new model V2622 Flex-Lite vision solution from Mettler Toledo CI-Vision provides manufacturers with a flexible means of implementing a machine vision-based label and labeling control program using modular extended components to inspect labels for barcodes, allergy information, expiration dates, and lot and batch numbers. Easily integrated into most existing production lines, they can also conduct high-speed inspections for package integrity—including presence

and proper placement of labels, caps or other packaging elements—while its IP65 dust- and splashproof components make it suitable for a range of food-and-beverage applications. The basic V2622 ssytem includes a smart camera, a patch panel—used as a connecting element into an existing control

panel—and configuration software, with any additional modular components easily installed to suit changing production line needs. According to the company, the V2622 system’s smart cameras employ unique resolution, lenses and lighting for different inspections, thereby eliminating the need for camera adjustment during product changeovers to optimize production run efficiencies, with on-board LED indicators visually displaying camera status and I/O signals for simplified set-up and troubleshooting.

Mettler Toledo CI-Vision 404

New from Bosch Rexroth AG, the company’s second-generation electromechanical cylinder (EMC) has been designed to expand the possibilities for utilizing compact drive units, according to the company. Boasting a distinctive hygienic design and IP65-rated protection class, the new EMC cylinders a particularly well-suited for heavy-duty applications requiring frequent clean-

ing cycles, such as those in the food industry, with optional force sensor allowing for use of decentralized process controls without a higher-level control system. With a multitude of available options to help ensure long and reliable service life even when operating in demanding environments, the powerful new EMC offers a highly efficient and cost-effective alternative to pneumatic linear drive systems, according to Bosch Rexroth.

Bosch Rexroth Canada Corp. 405

The new top-loading Sigpack TTMP pharma cartoner from Bosch Packaging Technology has been designed specifically for reliable, safe and secure packaging of ampoules, vials, syringes, pens and other types of medical devices used in the pharmaceutical industry. Offering full benefits of simple and safe changeover concept, high process safety, and a broad format and product flexibility enabled by its modular design, the machine layout can be easily adjusted to different product infeeds to achieve output levels of anywhere between 30 and 200 carton per minute to handle both small and large production batches, complemented by a wide range of product

infeed solutions and gripper technologies to ensure smooth and gentle handling and packaging of sensitive products such as vials, ampoules, syringes and injection pens.

Bosch Packaging Technology 406

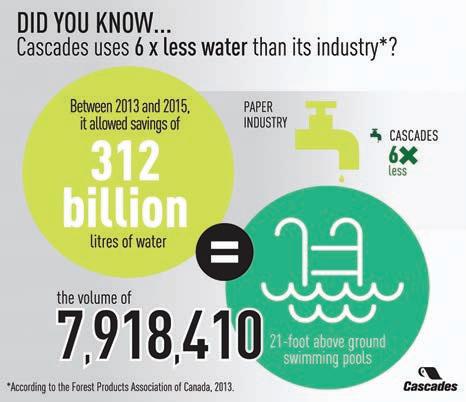

The only thing more gratifying than meeting ambitious goals is exceeding them, and for Canada’s leading forest product group Cascades Inc., staying ahead of its self-defined water conservation targets is an exceptionally satisfying achievement.

According to the Kingsey Falls, Que.-headquartered Cascades, the company significantly exceeded its 2015 targets for water consumption identified in its publicly unveiled corporate Sustainable Development Plan for the 2013-2015 period.

Under that plan, the company’s objective was to decrease wastewater output of its plants to 10.6 cubic meters of water per tonne of products.

But by implementing several process improvements in its manufacturing operations, Cascades reduced its output to 9.9 cubic meters per tonne—six times less than the average amount for the Canadian pulp and paper industry cited by the Forest Products Association of Canada (See Infographic)

“By choosing to manufacture many products from recycled materials we not only save trees, we also save a large amount of water during the manufacturing process,” says Cascades president and chief

executive officer Mario Plourde.

“And even though we already consume less water than the industry average, we will spare no effort in continuing to improve our performance,” he states.

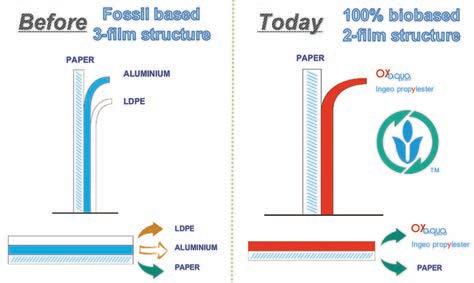

While using renewable packaging for fresh food products is rarely headline news nowadays, extending its use to processed foods with longer shelf-life requirements could be the start of a whole new exciting chapter in flexible packaging.

And thanks to a four-year joint research effort the Minnetonka, Minn.-based renewable plastic polymers pioneer NatureWorks LLC and Italian coatings specialists Metalvuoto, that new chapter may already be unfolding with the introduction of a new generation of high-barrier Ingeo -based flexible substrates designed specifically to keep processed foods fresh on store shelves longer.

The beauty of the new substrates, according to Metalvuoto, is that the coated layer of this new film essential ly replaces the need for a two-layer film structure when combined with a layer of paper—resulting in considerable material savings and uncompromised shelf-life performance.

Aside from offering a completely bio-based packaging solution when combined with paper, it offers enough flexibility to be shaped into flat, stand-up or squared-bottom pouches to give brand-owners a range of attractive options to achieve high shelf impact.

As Metalvuoto’s executive director Gianni Costanzo explains, “Until now, the flexible packaging industry has grown up around the use of multimaterial laminates because no one material was able to provide multiple functionality.

“For example, brand-owners often use an aluminum layer for barrier, a PET (polyethylene terephthalate) layer for external aesthetics, and an internal PE (polypropylene) layer for heat-sealability.

“Now, we have used the Metalvuoto Oxaqua coating technology with an Ingeo base film to replace two layers of different materials with one layer that simultaneously provides excellent barrier and heat-sealability,” Costanzo relates, noting the bio-coated film enables a two-layer pouch to

Developed by NatureWorks, the Ingeo polymers derived from corn starch have been used to make fresh-produce packaging for years.

match the performance attributes of threelayer pouches.

Brand-named Ingeo Propylester, the new film is said to provide significantly better oxygen barrier than the commonly used metallized BOPP (biaxially oriented polypropylene), while its good seal strength eliminates the need for an additional sealant layer— resulting in a less complex packaging structure.

“This introduction comes in response to strong interest from the flexible packaging market in packaging simplification, with brands looking to move from complex multilayer laminates to simpler packaging solutions,” says Costanzo, adding Ingeo Propylester is well-suited for food packaging in both horizontal and vertical FFS (form-fill-seal) applications.

“It has demonstrated good processing ability in testing on most pouchmaking machines,” says Costanzo, citing throughput rates of 30 to 40 pouches per minute.

Says Costanzo: “We expect strong interest from the market in two-layer structures in which the Ingeo film and Oxaqua biocoating technology are combined with paper to provide a fully bio-based performance package at a cost-competitive price point with the current three-layer structures.”

“We are now seeing the major benefits of our good practices not only with regard to the environment, but also with our finances, as saving water results in significant cost reductions,” Plourde adds.

Over the past few years, Cascades’ Environment Department has worked closely with the company’s plants to identify areas for improvement in an effort to reduce water consumption.

“Our teams have used their ingenuity to reuse water as much as possible in a closed circuit process to minimize our fresh water usage,” says vice-president of environment Léon Marineau, describing the achieved reductions as “colossal progress.”

Says Marineau: “In 2005, Cascades plants consumed an average of 23.9 cubic meters of water per tonne of products, [but] 10 years later they are using 2.5 times less water.”

Cascades says the estimated 312 billion liters saved between 2013 and 2015 is enough to fill eight million above-ground swimming pools.

Eating on-the-go is a fact of daily life for many busy professionals who just don’t have the time for a proper balanced meal at lunch, but a new ready-to-serve potato dish from French company Parmentine offers a healthy, tasty and supremely convenient alternative to traditional sandwiches, with the added benefit of fully-recyclable packaging components.

Already a popular items at supermarkets across France and Germany, with U.K. soon to follow, the 250-gram cups of pre-washed small potatoes come with a 25-gram serving of dipping sauce and a plastic fork built right into the cup’s lidding—requiring just a few minutes in a microwave to enjoy a satisfying and nutritious dish.

Developed by Austrian-based Greiner Packaging, the sopackage consists of a thermoformed PP (polyAPET (Amorphous Polyethylene Terephthalate) lidding, and a snug cardboard decorative wrap that also reduces the heat from contact with the hot potatoes inside, thus enabling consumption of contents straight from the cup.

“The innovative combination of cardboard and plastic is making our K3 cups very popular with brand-owners and consumers,” says Kenneth Boldog, sales director for Greiner Group’s K Europe division.

“The cups not only look and feel good,” Boldog says, “they also appeal to environmentally-conscious consumers because of the reduced use of plastic.

“These advantages really helped to tipped the scale for Parmentine when they were selecting packaging for this new product line.”

Alexander Manu

Dave Rodgerson

John Scott

David Luttenberger

Laura Studwell

Jeff Davis

Stephen Kaufman

September 28 & 29, 2016 Niagara Falls, Canada

September 27, Golf at Legends on the Niagara

Ken Brooks

Sept. 28 Sept. 29

Starting from Scratch: The Future as a Choice

Customer Expectations in 2025

Perspective: The Consumer Sets a New Dynamic In Retail Food

Packaging Solutions for the Next Generation

Packaging for the Future: Vision 2025

Retail Channel Strategy

The Future Opportunity in Current Packaging Tensions

What Does Circular Packaging Look Like in 2025; and Can We Get There?

Disrupting Single Serve Coffee using Compostable Packaging

MRF 2025Zero waste may be in sight?

An Introduction to intelliPACK: A Collaboration for Smart Solutions

Redesigning the Future with Renewable Packaging

What will the Circular Economy look like in 2025: Industry and Government Perspectives

The Story Behind Larger, More Global Consolidation

Visit www.pac.ca/2016-conference.html

May 17-20

Mexico City: EXPO PACK México 2016, packaging technologies and materials exhibition by PMMIThe Association for Packaging and Processing Technologies. At Centro Banamex. To register, go to: www.packexpo.com

May 18

Mississauga, Ont.: Just One Package Innovation Challenge, packaging design competition by PAC, Packaging Consortium. To register, contact Lindsay Ogle via email logle@pac.ca, or go to www.pac.ca

May 23-25

Indianapolis, Ind.: ANTEC 2016, international plastics technical conference of the Society of Plastics Engineers (SPE). At JW Marriott Indianapolis. To register, go to: www.antec.ws

May 31 - June 10

Düsseldorf, Germany: drupa 2016, global trade fair for print and crossmedia technologies and solutions by Messe Düsseldorf GmbH. At Messe Düsseldorf Fairgrounds. Contact Messe Düsseldorf (Canada) at (416) 598-1524.

June 7

Mississauga, Ont.: Top 50 Packaging Ideas Expo, table- top exhibition and networking event by the Canadian Packaging magazine. At Mississauga Convention Centre. Contact Stephen Dean at (416) 510-5198; or go to: www.top50packagingideas. com

June 9-10

Amsterdam, The Netherlands: Sustainable Foods Summit Europe, eco-labeling and food waste prevention conference by Organic Monitor. At Mövenpick Hotel Amsterdam City Centre. To register, go to: www.sustainablefoodssummit. com

June 13-16

Buenos Aires, Argentina: Argenplás 2016, international plastics exhibition by the Argentine Chamber of Plastic Industry (CAIP). At Centro Costa Salguero. To register, go to: www.argenplas.com.ar

June 15-16

Paris, France: Pack & Gift, promotional and merchandising packaging exhibition by IDICE. At Paris Porte de Versailles. To register, go to: www.packandgift.com

June 21-24

Munich, Germany: Automatica 2016, international robotics and automation technolgies exhibition by Messe München GmbH. At the Messe München Trade Fair Center. To register, go to: www.automatica-muenchen. com

June 23

Toronto: The Business of Water: Canadian Water Summit 2016, by PAC, Packaging Consortium. At Hilton Toronto. Contact Lisa Abraham via email registration@watersummit.ca; or go to: www.watersummit.ca

Sept. 13-15

Chicago: Labelexpo Americas 2016, labeling technologies exhibition by Tarsus Group Ltd. At Donald E. Stephens Convention Center. To register, go to: www.labelexpo-americas.com

Sept. 28-29

Niagara Falls, Ont.: PAC to the Future: Packaging in 2025, conference by PAC , Packaging Consortium. At Hilton Niagara Falls. Register at: www.pac.ca

Oct. 13

Toronto: Ontario Craft Brewers Conference & Suppliers Marketplace 2016, by Ontario Craft Brewers (OCB). At Allstream Centre at the Exhibition Place. Contact Christine Mulkins at (647) 242-3686; or via email pr@ontariocraftbrewers.com

Nov. 6-9

Chicago: PACK EXPO International 2016, international packaging technologies exhibition by PMMI-The Association for Packaging and Processing Technologies. Concurrently with Pharma EXPO 2016 pharmaceutical and packaging conference and trade show by ISPE (International Society for Pharmaceutical Engineering). Both at the McCormick Place. To register, please go to: www.packexpo.com

Reiser packaging expertise and Repak technology are the powerful combination you need to produce a superior form/fill/seal package.

■ The Repak form/fill/seal packaging machine is a rugged, high-speed racehorse capable of the industry’s fastest speeds.

■ Produces the highest quality packages with reliable seals that virtually eliminate leakers and returns.

■ Features rapid air forming to allow the use of thinner, less expensive films while maintaining package integrity.

■ Uses two 4-point lifting systems in both the forming and sealing stations to generate up to five metric tons of closing pressure for uniform forming and higher quality seals.

■ Hygienic design and stainless steel construction for superior sanitation. Test the Repak for yourself – contact us to arrange a demonstration at our Reiser Customer Center.

An innovative nutrition bar startup off to a flying start with an exciting new brand of healthy snacking options and optimal food safety and quality control capabilities

BY GEORGE GUIDONI, EDITOR PHOTOS BY NAOMI HILTZ

If good things in life come in small packages, it’s safe to say that the good folks at Riverside Natural Foods Ltd. have that formula down pat with their one-of-a-kind MadeGood brand of allergen-free granola bars and bite-sized snacks packing a healthy dose of vegetable-derived nutrients and a unique taste profile appealing to both kids and their health-conscious parents alike.

Developed and launched in 2014 under the guidance of company founder and president Nima Fotovat, a well-known personality in Canada’s highly competitive marketplace for granola and cereal bars, the upstart MadeGood product family has enjoyed remarkable market success in its early going so far—leading to a significant influx of new staff and high-performance production and packaging machinery at the company’s tidy, BRC (British Retail Consortium) -certified facility just northwest of Toronto in Concord, Ont.

Situated in a suburban industrial park just across the company’s slightly bigger and newer 24,000-squarefoot sister plant specializing in private-label production of store-brand cereal bars for retail customers across North America, the original Riverside facility is a 100-percent nut-free and allergen-free operation whose relatively small size belies its unique industry status.

“As small as it may seem, this is actually the biggest allergen-free production facility in Canada making branded products,” says vice-president of operations Justin Fluit, a professional chemical engineer who joined the company about a year ago after several years in the management consulting business.

“Aside from that distinction, the product we make here is a completely organic, non-GMO (genetically modified organism), gluten-free product that poses many ingredient challenges to manufacture in commercial volumes,” Fluit told Canadian Packaging on a recent visit to the lively, spanking-clean operation that’s doing its best to keep up with soaring demand, both at home and abroad, for the MadeGood products.

As Fluit explains, “There is only one supplier of gluten-free organic oats in Canada, and maybe three or four in the U.S., so the big cereal manufacturers out there could not do what we do here even if they wanted to because they would not be able to secure the supply of raw materials they would need to make it on a large-enough scale to do it profitably.

“What we’re doing here at Riverside is making good-tasting, healthy food that is completely allergen-free,” says Fluit, citing the product’s innovative formulation and cooking process that completely avoids the use of eight common allergens that include peanuts, tree nuts, wheat, dairy, eggs, soy and sesame, along with fish and shellfish.

Instead, the MadeGood recipe makes extensive use of blended vegetable powder—derived from spinach, broccoli, carrots, tomatoes, beets and shitake mushrooms—to deliver the nutritional equivalent of one full serving of vegetables in every pack of MadeGood Organic Granola Bars and ball-shaped MadeGood Granola Minis snacks, thereby providing about 20 per cent of the required daily intakes of Vitamins A, B1, B6, C, D and E

“It’s the kind of product that moms feel good about giving their kids for lunch—being nutritious, organic, school-safe, allergy-free and, above all, tasting good,” Fluit points out.

“It’s the next best thing to having an actual apple.

“It has a unique soft-crunch texture, and consumers also like the unique, bite-sized ball shape of our Minis snacks, which can be enjoyed on their own or added as a topping to milk or yogurt for a more complete meal solution,” Fluit explains, noting that leading domestic airline Air Canada has recently added the MadeGood Granola Minis to its on-board menu selection.

“It has certainly given us some good market exposure and traction,” says Fluit, crediting company founder Fotovat for coming up with the idea of ballshaped granola snacks.

It’s certainly an idea that has found quick international recognition, Fluit reveals, noting that the company currently export about half of its MadeGood brand output to diverse overseas markets, including Japan, Australia, Chile, Holland, U.K., Dubai, Singapore and Hong Kong, among others.

“We are now focusing our marketing efforts on the U.S. markets to take advantage of the low Canadian dollar,” Fluit says, relating that leading organic foods retailer Whole Food Market Inc. is preparing to roll out the MadeGood brand nationally in the U.S. later this year.

“We have already had some regional success with

Installed by Shawpak Systems, the model X33 X-Ray product inspection systems from MettlerToledo Safeline provide optimal quality assurance for products manufactured at the Riverside Natural Foods plants with 100-percent high-speed inline inspection of packaged products to detect minute traces of metal, stone, shell or seed fragments, or any other foreign objects.

Whole Foods in the New York and New Jersey markets,” Fluit points out, “but to be retailed across the U.S. in more than 370 stores will definitely be a big step up for us.”

To keep up with buoyant demand growth, Riverside Natural Foods had to make sizable additions to its workforce since startup, according to Fluit.

“There were only six people working here when the company began operations in 2013,” he states, “which grew to 15 people in 2014, and to about 50 people right now.

“We could well have up to 70 people working at our two plants by the end of this year,” Fluit says. “It really is a terrific job creation story.”

Retailing cross Canada at most leading grocery chains and independent outlets, the MadeGood brand is currently offered in 15 dif ferent retail SKUs (stockkeeping units) and in several tasty flavor varieties, ranging from Chocolate Banana and Apple and Cinnamon to Mixed Berry and Chocolate Chip

According to Fluit, the brand’s main target audience consists of “higher-income, well-educated professional moms that put a lot of effort to look after what their kids eat, but don’t have a lot of time to do it regularly.

“There’s a significant clash between what moms want their kids to eat—apples and carrots and broccoli—and what the kids want to eat, and this is where our product comes in,” Fluit explains.

Not surprisingly, the upscale MadeGood brand products are one of the more expensive cereal bars around at most grocery outlets, Fluit acknowledges, but the price premium is well justified by its “nutrient-dense” formulation and a highly enjoyable snacking experience for the kids.

founder Nima Fotovat holds up a couple of MadeGood brand granola bars, packaged in foil-lined wrappers supplied by Alpha Poly Packaging

, inspected by one of several model X33 X-Ray detection systems installed by Shawpak Systems.

Offering one-year shelf-life—achieved with inline application of MAP (modified-atmosphere packaging) gas-flushing just prior to packaging—the MadeGood nutrition bars are packaged five bars to a box, while the Minis are packaged in four 24-gram pouches to a box, with Toronto-based paperboard converter Accurate Rolal Co. Ltd. supplying the decorative folding-cartons for both product varieties, with each flavor distinctly differentiated by its unique primary color dominating the box.

“The kids really go for the bright yellow, pink

and blue colors of our boxes,” says Fluit, while also crediting Brampton, Ont.-based flexible packaging converter Alpha Poly Packaging Solutions for supplying the high-quality, foil-lined rollstock wrapping film used to pack the individual granola bars. Operating a one-shift schedule for now, the allergen-free facility plant currently produces about 150,000 granola bars and 100,000 packs of Mini snacks per week, according to Fluit, using a broad range of high-quality equipment and machinery supplied by local packaging machinery distributor and integrator CAM Packaging Systems of Aurora, Ont.

In addition to CAM-manufactured VFFS (vertical from/fill/seal) baggers, a rotary eight-station pre-made bagging system, bucket conveyors, combination scales, multihead weighers, turntables and linear conveyors, CAM Packaging also supplied both Riverside plants with AFA Systems manual end-load cartoners; Mach 1 stretchwrappers; Advantage Machinery shrinkwrapping tunnels, case-tapers and conveyors; Dorner gravity conveyors; and an assortment of horizontal flowwrapping equipment manufactured by Campbell Wrapper Corporation, Tecno Pack spa and PFM Group

All told, the aforementioned equipment forms the core of two bar production lines and two VFFS bagging lines at the allergen-free plant, along with the three wrapping lines and one VFFS bagging line re

cently installed at the new

Says CAM Packaging president Gareth Kennedy: “Riverside Foods is a great customer and a terrific family-owned company success story with a fantastic new product.

“I have worked with the Fotovat family for many years, and much more so since they have started up Riverside Natural Foods,” Kennedy adds.

“We are proud to have them as a loyal customer and are very grateful for their business.”

The MadeGood product starts out in a large mixing bin that blends all the pre-measured ingredients together into a consistent mixture, which is then passed through a series of forming rollers to emerge as continuous slabs of product.

The slabs are then precision-cut into individual bars, which are swiftly wrapped into individual wrappers and placed into the folding cartons.

From there, the cartons are packed into the RSC (regular slotted case) corrugated shipping boxes, which are then tape-sealed and placed onto pallets for shipment.

Along the way, the individual packages are coded by one of several Domino, Videojet and MarkemImaje product coding and marking systems placed strategically along the production lines.

“We use a combination of inkjet, laser and thermal-transfer coding systems to take care of all our product identification and traceability requirements: a bit of everything,” Fluit remarks.

“All in all, it’s a fairly manual process at the moment; not very highly automated just yet,” Fluit acknowledges.

“That’s one of the growing pains of starting a new business: you start out being fairly manual so you can be flexible and agile,” he expands, “but that will

only take you so far.

Beckhoff Automation’s HMI (human-machine interface) control panels and automation devices and components (inset) are a common feature on the production and packaging equipment recently installed at both Riverside Natural Foods production facilities in Concord to help the company automate many of its production processes.

company’s ability to ensure optimal product safety and quality control for its customers.

“These systems are invaluable for us in terms of detecting any foreign materials, such as metal or stones and pebbles, of greater than two millimeters,” Fluit says.

“Ensuring food safety is a major CPP (critical control point) for us, and these X-Ray units have worked out very well for us so far.

“So we are now investing quite extensively to automate our whole bar manufacturing process,” notes Fluit, “and CAM Packaging has been of great help to getting us there.”

As for the critical quality control and product inspection functions, Riverside Natural Foods has it all expertly covered with installation of five highperformance model X33 X-Ray inspection systems from leading product inspection equipment manufacturer Mettler-Toledo Safeline

With three X33 systems in place at the allergenfree plant and two more units in the new satellite facility, Fluit says he is very confident about the

“In fact, they have worked so well that we recently decided to purchase two more X33 units for the new plant,” Fluit revels, “making it seven X-Ray detection systems in total.

“The Mettler-Toledo technology is really world-class, and these systems have been a key part of our business right since we started,” Fluit continues.

“They are very reliable, highly accurate, and very flexible, so that we can use them on bars one day, on Minis the next day, and wherever else they may be needed,” Fluit relates.

They can pick up things like fruit pits and nut shell fragments that conventional metal detectors could not detect, which provides us with a real peace of mind,” he elaborates.

“We certainly don’t want consumers to end up with a chipped tooth because of something getting into our product that should not be there, or have any sort of a negative experience,” he states.

Enquire about our Label Review Service for fresh

Prevent delays and potentially costly reprints by using the Canadian Produce Marketing Association’s label review service. Our members benefit from two free label reviews per year, with additional reviews at only $250 each. CPMA members also have exclusive access to Labelling Guidelines for Shipping and Master Containers of Fresh Produce in the Canadian Marketplace.

“In the overall scheme of things, it’s a fairly reasonable investment with a very quick ROI (return-on-investment) payback,” says Fluit, noting Riverside also uses its X33 X-Ray detectors for the “dual purpose” of checkweighing all the packages to verify their weight accuracy.

“I think we are very unique in using these systems for two functions,” he notes, crediting the systems’ Canadian distributor Shawpak Systems of Oakville, Ont., for enabling Riverside to make optimal use of the robust XRay technology.

“They were extremely helpful in installing the systems, upgrading them with the latest software, running tests for new products, and helping to train our line operators to use them at a reasonable comfort level.

“It’s a fairly complex technology that requires a certain learning curve, but we received good support from Shawpak to get familiarized with it,” says Fluit, noting that the versatile X33 systems can also be set up to inspect bulk ingredient shipments, if required, or to inspect finished products already inserted inside secondary or tertiary packaging.

Such system flexibility and modularity are a perfect fit for the company’s ambitious business plans in the upcoming years, as Fluit confides.

“There are no shortcuts in this business, and if you want to attract bigger customers down the road, you need to show them that you have the best available equipment to ensure that the product you ship to them is as safe as it can be,” Fluit states.

“And naturally, this is also the best way to safeguard the reputation of our brand, which has been so well received in the marketplace already.”

Says Fluit: “We have a lot of young enthusiastic staff, full of energy, who have fully embraced our team culture and the potential to grow with the company, as we continue to pursue exciting opportunities in this fast-growing market segment.

“For us, being part of a movement that is helping to steer the food in-

dustry in a healthier direction gives us a meaningful purpose behind what we do here, which is to provide modern consumers with healthier and more enjoyable food options, without taking any shortcuts when it comes to quality and product safety,” he asserts.

“We want our MadeGood snacks to be a staple in every kid’s lunchbox,” Fluit concludes, “because we honestly believe that this is the best-quality, healthiest and safest lunchbox item out there in the snack business today.”

Please see the online video of Mettler-Toledo Safeline X-Ray system installation at Riverside Natural Foods on Canadian Packaging TV at www.canadianpackaging.com

Unilever’s Canadian ice cream facility blends cutting-edge production and packaging competence with uncompromising food safety to cultivate customer loyalty

BY ANDREW JOSEPH, FEATURES EDITOR

PHOTOS BY NAOMI HILTZ

There’s something about ice cream that tends to bring out the kid in everyone—a mystical fountain of youth that drives Unilever Canada Inc. to continue to supply the Canadian market with a plethora of well-known and much-loved tasty brands of the universally-adored frozen treats, as it continues to operate as one of Canada’s top ice cream manufacturers.

While it is an Anglo-Dutch multinational consumer goods company that owns a multitude of popular brands, it tends not to be overt in waving its corporate flag in the consumer’s face, preferring to let its products do the talking instead. That said, it is one of the world’s leading suppliers of food, home and personalcare products, with sales in over 190 countries and reaching two billion consumers a day, with its global workforce of 169,000 people helping it generate sales of

$80.8-billion in 2015.

Unilever has more than 400 brands commonly found in homes around the world, with its Canadian portfolio including such iconic brand as: Axe, Becel, Ben & Jerry’s, Breyers, Dove, Hellmann’s, Klondike, St. Ives, TRESemmé, and Vaseline

BELOVED BRANDS

“Our 264,000-square-foot ice cream manufacturing and packaging plant is run by over 300 top-notch employees,” Unilever Canada senior operations manager of ice cream Darren Vanbesien told Canadian Packaging during a recent visit to the Simcoe plant.

The state-of-the-art facility produces some of the best-known and top-selling brands in Canada, including:

• the Klondike brand offers delicious frozen treats in a variety of formats and flavors;

MULTIVAC Canada offers comprehensive solutions for film-based packaging. Our service and product portfolio includes an extensive range of MULTIVAC Canada packaging materials to meet special demands and guarantee first-class processing.

Due to the perfect interaction of packaging machine and film, packs of the highest quality are produced with unique efficiency.

• the M agnum line offers a variety of smooth and silky ice cream flavors dipped in Belgian chocolate;

• the super-premium Ben & Jerry’s ice cream has delicious, fun flavors like Half Baked and Jimmy Fallon’s Tonight Dough;

• Breyers offers a family of creamy smooth flavors, including New Breyers Gelato —a trio of textures in every bite;

• and the Popsicle brand, which includes products like Creamsicle , Fudgsicle , and the classic red-white-and blue Firecracker, as well as fun flavors such as Spongebob

http://ca.multivac.com sales@ca.multivac.com

The actual site has long been home to the ice cream business, explains Vanbesien.

“The original building here was operated as a family-run business beginning in 1888, until that family sold the operation to Unilever in 1962,” he recounts.

In 1980, Unilever sold its ice cream business to Beatrice, which ironically sold it back to Unilever in 1994, which in turn acquired Natrel ’s ice cream enterprises in 1995.

After modernizing the Simcoe facility between 1995 and 1997, Unilever began to consolidate all of its Canadian ice cream production business to this southwestern Ontario plant.

Vanbesien says the Simcoe plant is proud to play a part in Unilever’s sweeping global plans to operate as an environmentally responsible manufacturer and brand-owner.

Unilever announced earlier this year that it has advanced a new industry-leading benchmark of sending zero non-hazardous waste to landfill across more than 600 sites in 70 countries, including factories, warehouses, distribution centers and offices.

In January of 2015 after announcing that over 240 factories globally had achieved zero waste by landfill status—including the Simcoe facility—Unilever sought to replicate and achieve a zero waste model across the rest of its businesses.

Based on the Four Rs principles of reducing, reusing; recovering; and recycling, Unilever’s Sustainable Living Plan (USLP) document pledges to:

• Decouple growth from environmental impact;

• Help more than a billion people take action to improve their health and well-being;

• Im prove the livelihood of millions of people by 2020.

To achieve zero landfill status with its extensive recycling program, Unilever Canada will compost or incinerate materials not deemed recyclable, according to Vanbesien.

“Unilever Canada is also the single-largest commercial purchaser of green electricity via renewable energy in Canada,” proclaims Vanbesien, adding that all Unilever Canada facilities are ‘bullfrogpowered’ with 100-percent clean, renewable electricity.

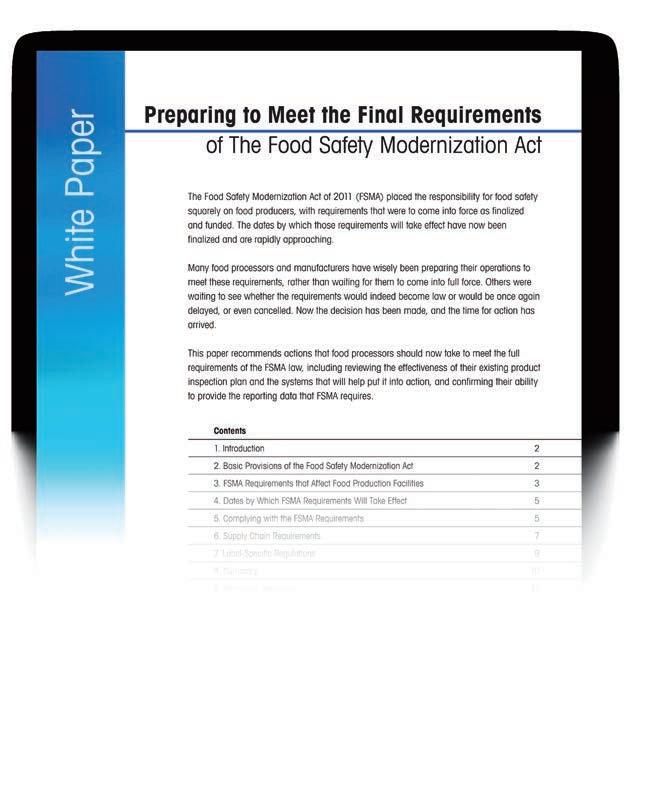

Just like its sister west-end Toronto plant in Rexdale, where Unilever produces the Becel margarine and Hellmann’s mayonnaise brands, the Simcoe facility is certified to the new international FSSC 22000 (Food Safety System Certification) food safety standard of the ISO ( International Standards Organisation).

After a feasibility study was enacted, Unilever adopted the FSSC 220000 as its single worldwide external certification program for all 147 of its global food manufacturing facilities.”

“The FSSC 22000 combines ISO documentation standards with food safety,” explains Vanbesien. “The program is both HACCP (Hazard Analysis Critical Control Points) and food safety-risk-focused.

“It is an intensive food safety program that covers all aspects of food safety from management commitment to critical control points within the HACCP program,” he says.

“It requires extensive monitoring and verification, and it drives responsibility to the point of variance.” says Vanbesien. “The initial certification takes four days, and annual recertification is a two- to three-day procedure.”

Other safety features at the Unilever facility include a foot/shoe washdown upon entering the production area, and Sealed Air Diversey Care equipment and materials for complete facility and equipment washdown.

Incidentally, Vanbesien notes that Unilever actually used to own Diversey Inc., now recognized as a global leader in food safety and security, facility hygiene, and product protection assurance.

Vanbesien says that while food safety is extremely important to Unilever across all aspects of the company, he notes that food quality is just as important.

Descon conveyors are powered by the smooth efficiency of SEWEurodrive motors to help move product through the multiple production lines housed at the Simcoe facility.

“We have 25 employees that comprise a trained panel from which we can choose to participate in our daily taste panels on various ice cream products,” explains Vanbesein.

“Every day, between three to five people will enter our sensory room and audit daily production.

“It’s just one of the ways we ensure our customers are able to consistently enjoy our tasty products.

“In addition, we take consumer feedback very seriously, because we want every experience with our products to be a pleasant and positive one.”

With several production lines for all its chilly products, Unilever purchased and installed a Sartorius Inc. X-Ray machine on its Ben & Jerry line that checks quality and consistency.

Headquartered in Hamburg, Germany and part of the Minebea Group, Sartorius is considered to be one of the leading global manufacturers of precision ball bearings, and machine components and other high-quality precision technologies.

The Sartorius X-Ray inspection system at the Simcoe plant is designed specifically for the food industry, with easy maintenance and cleaning capabilities to go along with what Sartorius calls unrivaled accuracy and reliability.

For the food industry, Sartorius designed the machine to inspect for a wide range of contaminants in many different types of packaging, including glass, bottles, cans, cartons and other rigid containers.

A modular system, Vanbesien found the Sartorius system easy to integrate into the existing conveyor system of the Ben & Jerry production line.

“It’s also quite easy to operate,” acknowledges Vanbesien. “The interface is user-friendly, which makes even the most complex of operations a snap.

“The software that was supplied with the equipment also helps play a key role in our quality control system, with checks via virtual testing and parallel image processing to ensure our product is exactly what we and the consumer expect it to be.

Vanbesien states that “any tub

that does not contain the correct fill, is detected and rejected using a pneumatic system, which is then inspected by our Quality team.”

Unilever Canada also uses three Thermo Scientific X-Ray inspection systems.

“I am extremely pleased with the performance of all our X-Ray machines,” extols Vanbesien. The Thermo Scientific brand of X-Ray equipment is manufactured by Thermo Fisher Scientific,

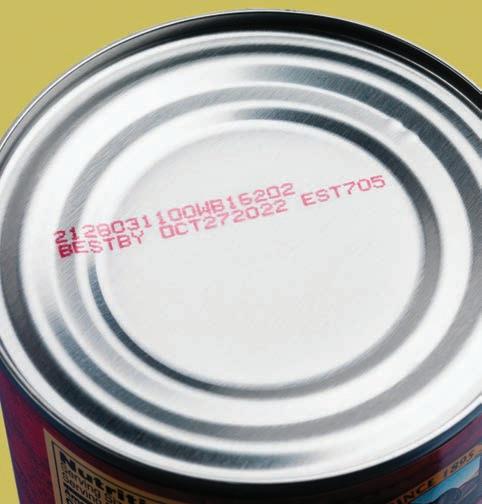

notes Vanbesien, adding that “the Simcoe plant uses Videojet equipment to apply expiration date codes on all cartons prior to sleeving.”

Moving the product along the various production lines are conveyor systems manufactured by Descon Conveyor Systems, a Newmarket, Ont.-based company that has established itself as

Inc., a Waltham, Mass.-headquartered multinational biotechnical product development company catering to research and science technologies.

For lot data and other important product identification applications, Unilever’s Simcoe facility relies on the competencies of Videojet Technologies’ high-performance laser scribing systems.

“It’s a wet working environment, so using the high-quality laser marking systems from Videojet assures us that when we apply all relevant lot code data at this facility, it will reviewable by the consumer at any point in time going forward,” says Vanbesien. “We’re very happy with the performance we receive from the Videojet laser marking systems.

“The laser coders are simply more reliable in this environment than the inkjet coders, and long-term they are cheaper to operate as there are no ink material costs,”

trusted supplier to many major beverage and food manufacturers, including Unilever, Coca-Cola , Molson , Kraft , Pepsi , and Diageo among others.

The Descon conveyors utilize hygienic food-grade SystenPlast belting manufactured by Regal Beloit. Unilever also swears by the performance of its Huhtamaki ice cream filler-capper that Vanbesien says was moved from one of the company’s other

locations to Simcoe.

Other equipment at the Simcoe facility includes:

• ca rton formers and closers designed and built by Imball , a flexible machine that can erect different-sized boxes from flat blanks with either carton lock format or by using hot-melt adhesive;

• Nordson hot-melt adhesive applicating systems for sealing cartons;

• An automatic Edson case-packer;

• Tet ra Pak fruit feeders;

• Five spiral conveyor systems, manufactured by

Ryson, used to elevate product to overhead conveyors because of floorspace constraints.

Says Vanbesien: “They have a very small footprint compared to regular incline conveyor systems.”;

• Wooden shipping pallets supplied by pallet pool operator CHEP Canada ;

• Robotic palletizers manufactured by Lorenz Pan AG, which Vanbesien says “have provided flawless service for the past three years.”;

• Wooden sticks for the Popsicle and Magnum lines are supplied by John Lewis Industries,

a Canadian company that has the largest market share of that product in the world;

• Flexible plastic polywrap film is purchased mainly from Sonoco Flexible Packaging , while tubs are mainly supplied by Double H Plastics

As Vanbesien reiterates, “It’s our dedicated and knowledgeable people making the ice cream that makes us so successful.

“We take pride in being a leader in the ice cream market, and it takes great people and reliable equipment to make it all work.;

Ontario candy and gum manufacturer steps up its production line efficiencies with top-flight equipment designed and built by a Canadian company

BY ANDREW JOSEPH, FEATURES EDITOR

PHOTOS BY NAOMI HILTZ

Human beings have been chewing gum in various forms for the past 100,000 years, and sampling the sweet taste of candy for some 2,600 years.

In contrast, the Toronto-based Oak Leaf Confections Co., has only been manufacturing candy, mints and gum products since 1998, but despite the relative drop in the proverbial bucket timeline, its employees have been doing it correctly right out of the gates.

Nowadays, Oak Leaf Confections, together with its sister company SweetWorks Confections LLC, is part of a much larger conglomerate of candy and

confectionary manufacturers, all organized under the domain of Chocolate Frey AG, Switzerland’s number one manufacturer of chocolate confectionery.

Founded in 1887, the company has long been an industry leader and a major contributor to Switzerland’s well-earned reputation as a country of chocolate experts.

Today, Oak Leaf manufactures a wide variety of confections and chewing gum products under some of the strictest global guidelines for product safety and quality.

The Toronto facility is HACCP (Hazard Analysis Critical Control Points)-certified, BRC ( British Retail Council)-certified, while its products are not only Halal- and Kosher-certified, but are also nut-

and gluten-free.

Oak Leaf general manager Ion Leoveanu told Canadian Packaging magazine during a recent visit to the very busy facility that they are always looking at ways it can work with colors, texture and shine of its products, noting that the business maintains the ability to develop new and exciting colored candy for the market.

While many a company tries to develop a niche, Leoveanu says Oak Leaf is “the best candy finisher in the world, in my opinion.”

While Leoveanu says that the candy manufactured at the Oak Leaf facility appeals to all ages, he adds that the equipment used to manufacture it is all adult, with a nod towards what he considers the best manufacturing processes on the planet.

“Equipment-wise, we are in the process of moving forward to ensure our packaging line equipment matches the high-end quality of our manufacturing processes,” Leoveanu extols.

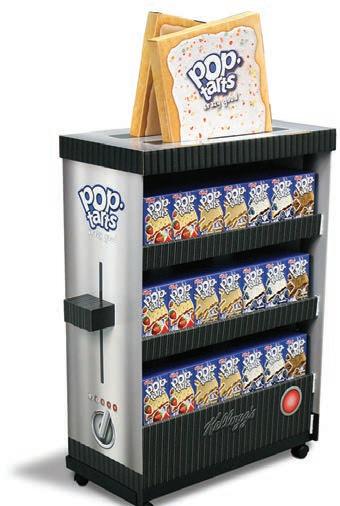

The newest capital investment on the production floor is an all-in-one set-up purchased from WeighPack Systems, a Montreal-headquartered designer and manufacturer of highquality packaging equipment with facilities in Toronto, Las Vegas and Miami.

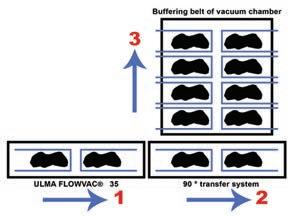

Purchased in December of 2015, the packaging solution includes a WeighPack PrimoCombi multihead weigher that uses a Windows -based Primo 360 software that accurately weighs and dispenses product into a Swifty 3600 bagger which automatically opens, fills and seals premade pouches.

Along with the 14-head PrimoCombi checkweigher and Swifty 3600 bagger, Oak Leaf also purchased an incline infeed conveyor to transport product up into the hopper of the checkweigher.

According to WeighPack territory manager Derek Chandler, Oak Leaf approached them to discuss adding a new stand-up pouch with an option for a reclosable zipper to their already impressive range of products.

“Oak Leaf was looking for a system to automatically weigh and dispense gum and candies in all sizes and shapes into pre-made laminated doystyle pouches with the potential for a zipper closure,” recalls Chandler.

Oak Leaf wanted a system capable of working at high rates of speed with

the ability to adjust to flexible pouch sizes, but Chandler says the full WeighPack system will more than meet the requirements.

“Oak Leaf was very involved in the entire process,” says Chandler, “and I believe they were very impressed with our knowledge of the packaging equipment and industry and commitment to the project’s success.”

After discussing Oak Leaf’s needs, WeighPack suggested the Swifty 3600 bagging machine, with Leoveanu calling it a perfect fit for them based on current production needs—though modular enough for taking things to another level when the time arrives.

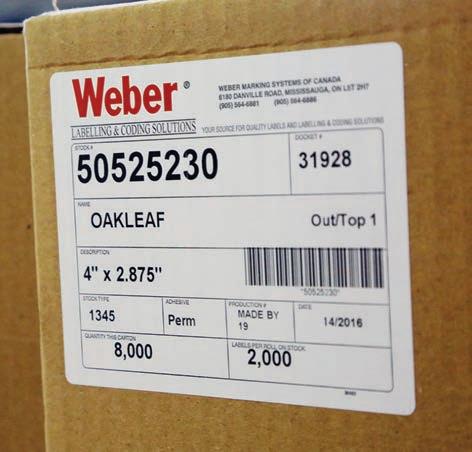

The current set-up on the Swifty 3600 is unique to the system, according to Chandler. “WeighPack integrated a bag magazine to the system and also added a print-andapply label applicator so Oak Leaf is now capable of printing various product labels on-demand—they have many SKUs (stock-keeping units) and wanted to have the ultimate in packaging flexibility.”

Leoveanu says the machine’s modularity was a key factor in their purchasing decision.

“Right now we are using premade pouches, that we place into the magazine of the Swifty 3600,” acknowledges Leoveanu. “However, we will have an option to upgrade the WeighPack’s R2B 3600 to form the pouches itself, then fill and seal.” He says that while the company could indeed have spent more money and bought a larger or faster

packaging system, it’s often better to be more conservative.

Leoveanu says that along with its ability to work with Oak Leaf’s production now and in the future, the small footprint the Swifty 3600 occupies on the limited floorspace available was as important as is its ease-of-operation.

Adds Chandler: “The robust Swifty Bagger is engineered to be easy to service, faster to clean, and reliable.

“The Swifty Bagger can operate on a variety of bag styles, including pillow, stand-up, gusseted and quad bags, with a zipper enclosure or a carry handle.”

Although initial testing of the bagger was only recently completed at the time of Canadian Packaging magazine’s visit to the facility, Leoveanu says they are quite pleased at the speed with which the machine is running.

Filling candy into the Swifty Bagger is the PrimoCombi multi-head weighing system, designed by WeighPack for high performance, speed and accuracy.

According to WeighPack, the PrimoCombi is the first open-frame combination scale with an electrical enclosure that can be conveniently located away from the scale.

“This design eliminates potential washdown hazards as well as provides significant convenience as the electronics can be located at floor level,” explains Chandler.

The PrimoCombi comes standard with single discharge chutes for increased production output, a single hopper assembly which allows the operator to adjust product inflow and rotates out of the way for product changeover and sanitation, as well as an IP-65 digital camera with mounting for total visibility.

As

Please see the online video of Oak Leaf discussing the pluses of their WeighPack Systems packaging solution on Canadian Packaging TV at www.canadianpackaging.com

The PrimoCombi is PC-operated, and comes standard with an intuitive 15-inch color touchscreen with a Windows operating system that is easily configurable to any common ERP/MRP (Enterprise Resource Planning/Material Requirements Planning) system and includes features like Skype, remote access, production reporting, scheduling, customizable languages and much more.

Chandler says the entire WeighPack system was delivered to the Oak Leaf plant in December of last year, and was installed in late January 2016.

“We constantly check in with Leoveanu at Oak Leaf, and so far things are running smoothly,” relates Chandler. “We look forward to a long-lasting partnership with them.”

As for why Leoveanu initially sought out WeighPack, he smiles and simply notes that the equipment manufacturer had a very good reputation for quality versus the price ratio.

“We also learned firsthand that WeighPack’s service level is impeccable,” offers Leoveanu. “We found them to be very helpful, very engaged, very flexible and always willing to work with us.

“WeighPack didn’t just sell a machine; they also offered an excellent aftersales service.

“I found WeighPack to have very competent people with a no nonsense attitude who got right to the heart of the issue,” he enthuses.

“I love that.”

After the installation of the packaging system,

WeighPack ensured that the Oak Leaf employees fully understood how to best operate it for optimum performance for each of their products and packaging options.

“I also liked the fact that WeighPack is a Canadian company with a new office right here in Toronto,” he adds. “I don’t need downtime.

“Having good local support is important,” relates Leoveanu. “For any company interested in making a capital investment—whether small or large—one should always worry about the service afterwards.”

Leoveanu says the finished stand-up pouches look spectacular with accurate product weights constantly being filled.

“The bags we ordered for our products have a clear window to show off the beautiful color of our candy and gum products,” Leoveanu explains.

Summing up, Leoveanu praises the new WeighPack packaging solution saying, “It provides us with excellent packaging options for the present and for the long-term future. We are proud to have a partnership with WeighPack.”

n Wilmington, Del.-headquartered life sciences group DuPont has appointed Randy Stone as president of the company’s Performance Materials business unit.

n Global rigid plastic films group Klöckner Pentaplast, headquartered in Montabaur, Germany, has appointed Brent Jones as chief financial officer and Peter Heinze as chief operating officer.

n Gurnee, Ill.-based product coding and marking systems supplier Domino North America, a wholly-owned subsidiary of the U.K.-headquartered Domino Printing Sciences plc and part of the Brother Industries group of companies, has appointed Michael Barron as sector development manager for medical devices, and David Deagle as sector development manager for food canning.

n Toronto-headquartered specialty labeling and packaging group CCL Industries Inc. has appointed Guenther Birkner as president of the Healthcare & Specialty business at the company’s CCL Label subsidiary, and Peter Fleissner as president of its CCL Design business unit.

n Romaco North America, Hamilton, N.J.- based supplier of processing and packaging equipment for the pharmaceutical industy, has appointed Goran Adolfsson as director of business development.

n Dutch-based conveying systems manufacturer Ammeraal Beltech has appointed Prakash Iyengar as chief executive officer.

n Motion Industries, Birmingham, Ala.-based manufacturer of industrial bearings and a broad range of power transmission and distribution products, has appointed Mark Stoneburner as corporate account vice-president for industry segments.

n Toray Plastics (America), Inc., North Kingstown, R.I.-based manufacturer of polyester, polypropylene, bio-based and metalized films for flexible and rigid packaging applications, has appointed Mark Turano as national sales manager for the company’s Lumirror polyester films division.

n Norcross, Ga.-based food packaging machinery supplier Rovema North America has appointed Ken Place as director of project management.

n Chelsea Becker, strategic project manager for the Forth Smith, Ark.headquartered power distribution technologies manufacturer Baldor Electric Company, has been selected as one of this year’s recipients of the Women in Manufacturing STEP (Science, Technology, Engineering and Production) Ahead Awards of the U.S.-based Manufacturing Institute in the Emerging Leader category, which was created to specifically recognize demonstrated career excellence and leadership among women under 30 years of age who are currently employed in the manufacturing industry.

n PaperWorks Industries, Inc., Bala Cynwyd, Pa.-headquartered producer of paperboard packaging products, has appointed Karl Broderick as vice-president of sales and Peter Jesus as vicepresident of packaging development and support services.

n U.K.-headquartered rigid plastic products manufacturer LINPAC Group, has appointed Helene Roberts as group marketing and innovation director.

n Hartland, Wis.-based conveying systems manufacturer Dorner Mfg. Corp. has appointed Clinton Anderson as industry manager for assembly automation.