More flexible and efficient automation with IndraDrive Mi

With IndraDrive Mi, the intelligent drive system, you relocate the entire drive technology from the control cabinet directly into your machines. That saves space, sharply reduces the wiring costs up to 90% and optimizes your energy balance. Thanks to the integrated motion logic, complex motion sequences can be achieved right at the drive level. The IndraDrive Mi is a fully-equipped automation system, with a wide variety of certified safety functions and multi-protocol interface. Put the intelligence of this system to use in your modular machine concepts as you start your journey into Industry 4.0.

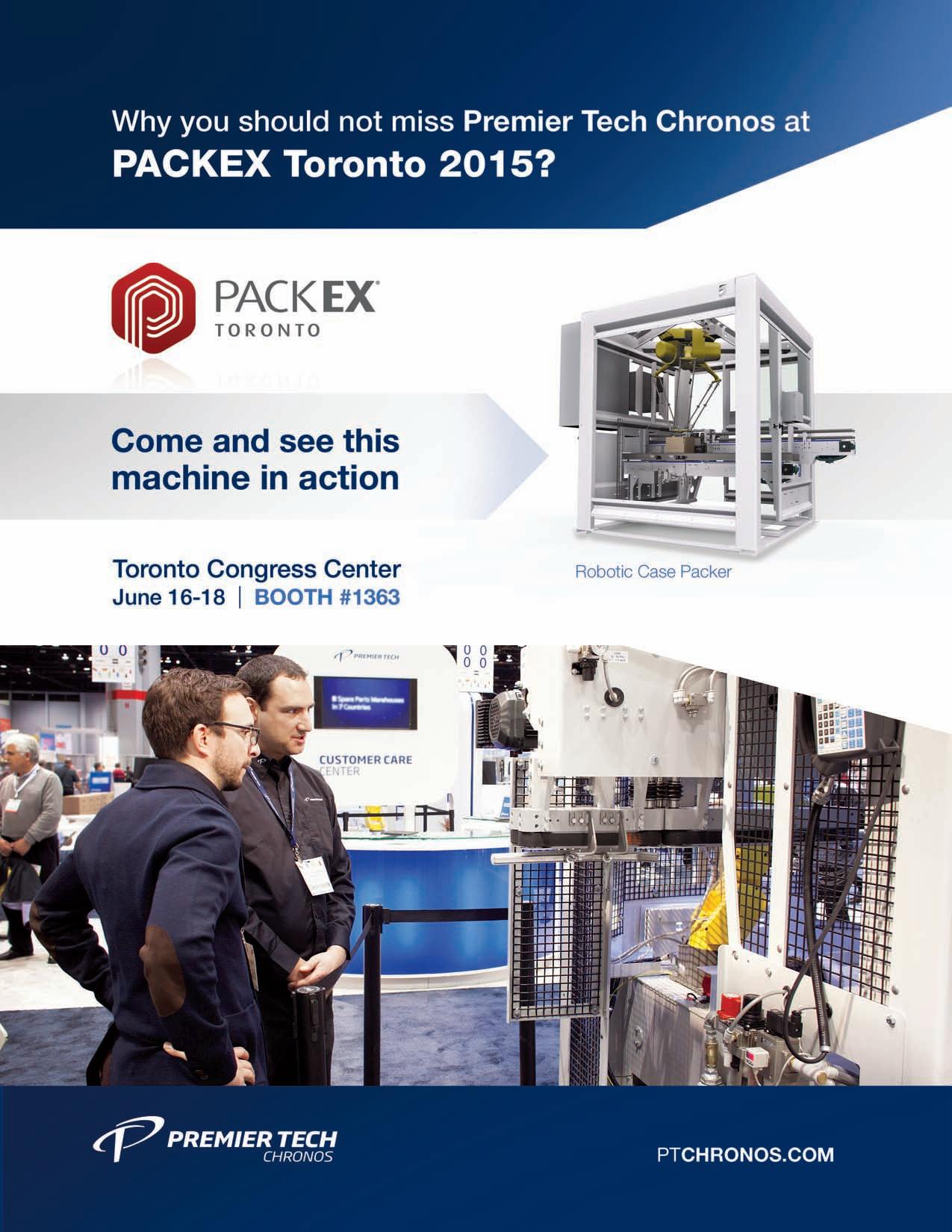

See us in booth 1523 at ATX/Packex Toronto, June 16-18.

With its breakthrough design, the 9550 applies labels directly onto packs without the need for an applicator, while self-adjusting label placement accommodates varying line speeds, throughput and package sizes. Revolutionary Intelligent Motion™ technology targets zero unscheduled downtime as it precisely and automatically controls the entire system.

2015 VOLUME 68, NO. 5

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227

GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph • (416) 510-5228

AJoseph@canadianpackaging.com

ART DIRECTOR

Sheila Wilson • (416) 442-5600 x3593 shwilson@annexnewcom.ca

PRODUCTION MANAGER

Barb Vowles • (416) 510-5103 BVowles@annexnewcom.ca

CIRCULATION MANAGER

Anita Madden • 442-5600 x3596 AMadden@annexnewcom.ca

ANNEX PUBLISHING & PRINTING INC.

Vice-President Annex Business Media East Tim Dimpoloulos tdimopoulos@canadianmanufacturing.com

President & CEO Mike Fredericks mfredericks@annexweb.com

HOW TO REACH US: Canadian Packaging, established 1947, is published monthly by Annex Publishing & Printing Inc.

80 Valleybrook Drive, North York, ON, M3B 2S9; Tel: (416) 510-5198; Fax (416) 510-5140.

EDITORIAL AND ADVERTISING OFFICES:

80 Valleybrook Drive, North York, ON, M3B 2S9; Tel: (416) 442-5600; Fax (416) 510-5140.

SUBSCRIBER SERVICES: To subscribe, renew your subscription or to change your address or information, contact us at 416-442-5600 or 1-800-387-0273 ext. 3555.

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE): Canada $72.95 per year, Outside Canada $118.95 US per year, Single Copy Canada $10.00, Outside Canada $27.10. Canadian Packaging is published 11 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

©Contents of this publication are protected by copyright and must not be reprinted in whole or in part without permission of the publisher.

DISCLAIMER: This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

PRIVACY NOTICE: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Phone: 1-800-668-2374 Fax: 416-442-2191 Email: vmoore@annexnewcom.ca

Mail to: Privacy Office, 80 Valleybrook Drive, North York, ON M3B 2S9

PRINTED IN CANADA

PUBLICATIONS MAIL AGREEMENT NO. 40069240, ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund of the Department of Canadian Heritage for our publishing activities. Canadian Packaging is indexed in the Canadian Magazine Index by Micromedia Limited. Back copies are available in microform from Macromedia Ltd., 158 Pearl St., Toronto, ON M5H 1L3

Of all the bad, really bad words commonly used in the packaging industry, the word ‘waste’ is arguably the closest thing to an F-bomb equivalent there is—in virtually all its forms, meanings and contexts. So it should not come as a surprise to hear that consumers also hate waste in all its iterations—especially when that waste directly costs them in good old hard-earned cash, albeit mostly in pennies at a time.

It’s a lamentable fact of everyday life that far too many consumer product packaging is discarded after use even still containing small amounts, however minute, of perfectly good and usable product that cannot be recovered from its original packaging without resorting to drastic means and measure better-suited to sitcom comedy sketches. Just think of the good old toothpaste: Who can really claim with an open heart that they have used each and every drop before opening up a new one?

But despite the absence of any organized collective lobby voice on consumers’ behalf to the CPG (consumer packaged goods) brand-owners to give this issue their undivided focus and attention there is an awful lot at stake for companies to lose in terms of brand loyalty, respect and recognition once consumers collectively wake up to the reality of this everyday petty scamming, intentional or not.

In fact, it is happening already, according to a recent comprehensive survey of 1,000 U.S. consumers on this very subject conducted by an innovative surface coating technologies startup LiquiGlide Inc. of Cambridge, Mass.

When told how much of their commonly-used everyday products like shampoo, conditioner, toothpaste and body lotion gets thrown away, 89

13 WINNING ATTITUDE By George Guidoni

per cent of respondents said they thought it was “a huge waste” and 57 per cent said they think the manufacturers are “screwing them over.” Using an improvised ‘hate scale’ to determine how much they hate this, consumers actually ranked it less favorably than going to the dentist, doing household chores and paying taxes—trailing only behind the joys of waiting for a cable repairman.

More tellingly, some consumers go to incredible lengths to make sure they get their money’s worth: from the tried-and-true storing of bottles upside down and adding water to cutting containers open, using spatulas, and applying centrifugal force.

“When asked for the ‘craziest way’ they’ve gotten the product out of its packaging, respondents admitted to smashing, heating, stepping on, licking, sucking and biting—all to get those precious few last drops.” How’s that for packaging rage?

Naturally, there would be no reason for LiquiGlide to do a survey like this unless it had a solution in mind and, happily enough, that’s the company’s recently-launched, multi-patented specialty coating that makes the inside of a bottle or other containers just wet and slippery enough to facilitate 100-percent removal of its entire contents, down to the proverbial last drop.

A winner of the Silver Award in the Food Waste Reduction category of this year’s PAC Global Leadership Awards packaging competition, LiquiGlide’s propriety coating—a two-component formulation developed at the Massachusetts Institute of Technology (MIT) —is showing a lot of promise as a potential game-changer for the global CPG industries, along with countless industrial, medical and other applications.

If and when it really catches on won’t, it’s come a moment too soon for consumers and industry alike.

Progressive Quebec produce grower puts itself on solid growth path ahead with cutting-edge product innovation, a high-energy workforce, and world-class packaging skillset and competencies. Cover photography by Pierre Longtin

3 UPFRONT By George Guidoni

4-5 NEWSPACK

Packaging news round-up.

6 NOTES & QUOTES

Industry briefs and company updates.

8 FIRST GLANCE

New technologies and solutions for packaging applications.

10 ECO-PACK

All about packaging sustainability.

11 imPACt

Monthly insight from PAC, Packaging Consortium

50 EVENTS

Upcoming industry functions.

50 PEOPLE Career moves in the packaging world.

51 ANNOUNCEMENTS

Company and marketplace updates.

52 CHECKOUT By Sarah Harper

Joe Public speaks out on packaging hits and misses.

20 CULTURAL EVOLUTION By Andrew Joseph

Retired food industry veteran sets up oneof-a-kind home business venture to offer Canadian consumers a taste of high-end deli luxury and indulgence with unparalleled product authenticity and elegant packaging presentation.

25 FULL IMAGE PROFILE

Image-based code readers really earn their keep at Kraft Canada’s high-speed sauce packaging lines.

29 BLUEPRINT FOR SUCCESS By Andrew Joseph

An Ontario machine-builder startup off to a flying start with a new type of caseformer that aims to redefine the role of secondary packaging equipment in fastmoving food production environments.

49 FROM START TO FINISH By Del Williams

Foil-sealing technology helps food startups get a leg up.

Our preview of next month’s PACKEX Toronto 2015 national packaging exhibition begins on page 33

Although it is undoubtedly one of the world’s favorite tourist destination, you don’t have to actually go to Italy to taste some of that country’s most celebrated beverage experiences— t hanks to Canada’s leading water products bottler Nestlé Waters Canada (NWC)

Launched at leading retailers and upscale restaurants across Canada earlier this spring, the new Sanpellegrino Melograno e Aranciata (Pomegranate Orange) drink—containing 10-percent orange and six-percent pomegranate juice from concentrate—features a unique European flavor profile and is made with only high-purity can syrup, according to the Puslinch, Ont.-headquartered NWC, rather than the commonly-used corn syrup.

“Made with the juices of delicious oranges and

pomegranate, Sanpellegrino Sparkling Fruit Beverages Pomegranate Orange has a strong aroma of pomegranate combined with a delicate taste of orange to create a fresh tartness and a finish tending toward sweetness,” says NWC marketing manager for international brands Jennifer Semley-Robert.

Marketed as a nonalcoholic adult sparkling alternative to cocktails, the 330- ml cans of the new flavor—each boasting its on individual foil seal wrapped around the can’s lid for extra hygiene, the moderately sweet drink is made with all-natural ingredients and bursting with small carbonated bubbles to create an intensaly refreshing taste.

According to NWC, the Sanpellegrino Sparkling Fruit Beverages family was relaunched in 2009 fol-

lowing a significant reformulation aimed at making the beverage sodium-free and to boost its overall juice content.

“With the pure pleasure that comes from drinking them, Sanpellegrino Sparkling Fruit Beverages afford consumers everything they want in a beverage product and represent a great example of how our company is giving consumers what they want in increasingly novel, healthy and environmentally sustainable ways,” Semley-Robert states.

Joining a growing upscale global beverage brand also comprising the Aranciata (Sicilian orange), Aranciata Rossa (blood orange), Clementina (Clementine orange), Limonata (lemon), Melograno e Aranciata (pomegranate orange) and Pompelmo ( grapefruit), the new Melograno e Aranciata can be purchased from grocer across Canada in shrinkwrapped six-packs, or as single-serving cans at fine dining establishments.

“Each of the beverages boasts a revitalizing flavors that truly embraces the bubbly, breezy, care-free lifestyle of Italy,” says Semley-Robert, crediting the origin and quality of the fruits used in their production for their strong mass appeal worldwide. In addition to using the famed, centuries-old S.Pellegrino

Sparkling Natural Mineral Water as the main ing redient, the Sparkling Fruit Beverages are also uniquely distinct in the marketplace due to their special pasteurization and flavoring processes, according to the Stamford, Conn.-headquartered brand-owner Nestlé Waters North America

• Pasteurization. A heating process for food and beverage that guarantees an optimal preservation of the product and makes the addition of preservatives unnecessary, pasteurization was first used by Sanpellegrino in 1932—at the time acknowledged as a revolutionary advance—in combination with the old Italian tradition “spremuta,” or literally-squeezed juice.

• F lavoring. The process uses the old-school Italian traditional recipe, whereby the concentrated is kept at low temperature until the orange paste is kneaded with concentrated orange oil.

“The only additional ingredients are essential oils, which are strictly natural and extracted from fruit, to add a unique fragrance that recreates for the sensory experience of holding a ripe, freshly picked piece of fruit.

“The balance between the bubbles of the naturally occurring (non-synthetic), delicate CO2 gas bubbles and the flavor of real juices gives the beverages their unmistakable taste,” says NWC.

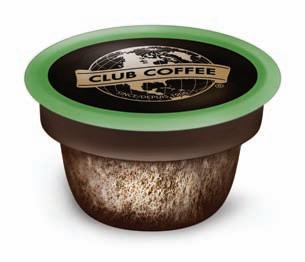

Widely scorned and vilified by environmentalists as one of the worst packaging waste excesses of the modern age, the much-maligned single-serve coffee pods may finally be on their way to green redemption—thanks to promising efforts by the venerable Toronto coffee roaster Club Coffee to develop a fully compostable coffee capsule with minimal carbon footprint.

Launched to rave reviews art last month’s SCAA 2015 annual exposition of the Specialty Coffee Association of America (SCAA), the company’s new PürPod100 pods were conceived and designed to bypass the inherent recycling difficulties involved in the collection and materials separation of the conventional platbased coffee pods by being made from renewable, bio-based materials that are 100-percent compostable and can be completely digested by bacteria inside industrial composting facilities.

“The amount of used single-serve pods sent to landfills last year could have circled the earth 11 times—an unacceptable amount,” says Club Coffee’s chief executive officer John Pigott.

“We now have the most viable solution available to address that issue—a pod that will be certified as 100-percent compostable and can be converted to useful compost.

“As a large manufacturer and distributor of packaged coffee, we have a responsibility to our customers, and to society, to reduce the environmental impact of our activities,” says Pigott.

According to Club Coffee, the new pod is currently undergoing a rigorous testing process to meet U.S. and international standards and certifications required by municipal and commercial compost manufacturers, with the certification process expected to be completed in the coming months.

Developed in partnership with international experts and scientists at the University of Guelph in southwestern Ontario, the the PürPod100 pods should be available in the United States market later this fall with the purchase of Kauai Coffee, Chock full o’Nuts, Hills Bros. Coffee, Copper Moon, Boyd’s Coffee and Paramount Coffee brands.

According to Club Coffee, the PürPod100 pods—featuring a ring made from coffee chaff, the skin of the bean that comes off during the roasting process—is compatible with most Keurig home brewing systems, including the new Keurig 2.0 brewers.

While the company’s name may be new to Canadian users of metal detection equipment, the newly-formed Sesotec Canada Ltd. business in Cambridge, Ont., is anyhthing but a newcomer to the product inspection field.

Previously operating under the banner of S+S Separating and Sorting Technology, the recently-renamed Sesotec GmbH in fact boasts over 30 years of experience in manufacturing and servicing a broad range of metal detection, X-Ray inspection, magnetic separation, and sorting systems widely used by the food, plastics and recycling industries across North America and worldwide.

According to Sesotec Canada’s director of sales for the food business Doug Pedersen, last month’s launch of a Canadian subsidiary is its Germany parent company’s acknowledgment of Canada as an important strategic end-user market for food production, plastics processing and recycling operations, which are all core segments for Sesotec.

“For the past 30 years, Sesotec has worked with clients in a wide range of industries to develop practical and cost-effective solutions to product inspection, metal detection and contaminant removal problems using innovative and reliable technology,” says Pedersen.

“With many thousands of metal detection and separation systems installed worldwide, Sesotec is one of the leading manufacturers, and the only one with such a wide and flexible product range,” says Pedersen, noting Sesotec also operates subsidiary companies in the U.S., U.K,, Singapore, China, India, France and Italy.

“Using its extensive technical resources, both at the main facility and in subsidiary companies, Sesotec engineers can evaluate even the most difficult applications and provide our customers with realistic performance estimates.” Tel. (519) 621-6586.

Krones helps Steam Whistle do one thing really, really well – package Canada’s premium pilsner

Steam Whistle Pilsner offers the style and flavour of the great pilsners of Europe, yet is brewed fresh locally at their independent, Canadian brewery. Crafted under the watchful eye of the Czech-born Master Brewer, this golden-coloured Bohemian pilsner is made using only four all-natural ingredients, a distinctive recipe, traditional methods, and a whole lot of passion.

How is this brewmaster know-how and brewery freshness retained until it reaches you? With the assistance of Krones’ TFS filter, Lavatec bottle washer, VOC can filler, and Modulfill bottle filler. All this ensures quality through zero-bacteria control, minimum oxygen pickup and accurate fill heights. Just some of the measures that Steam Whistle takes to be the worthy reward at the end of your day.

Spiroflow Holdings, Inc., Monroe, N.C.headquartered manufacturer of automated material handling systems for bulk products, has completed the acquisition of Food Control Solutions, Inc., a prominent systems integrator and industrial automation technologies supplier for the food and dairy industries headquartered in North Olmsted, Ohio. “This acquisition will allow us to provide complete end-to-end automated process solutions to our customers,” says Spiroflow Holdings co-chairman

Jeffrey Dudas, noting Food Control’s recognized systems integrator status for the Allen-Bradley automation and process control technologies manufactured by leading automation supplier Rockwell Automation, as well as a certified Wonderware systems integrator. “The combined strength of our teams permits us the powerful ability to expand our reach into our respective customer bases and provide a complete range of products and services that no other supplier can offer,” Dudas adds.

Transcontinental Capri, the flexible packaging business unit of Vaughan, Ont.-headquartered TC Transcontinental Packaging based in Clinton, Mo., has achieved the Safe Quality Food (SQF) Level 3 certification for food safety assurance for both of its production plants, making them formally compliant with the Global Food Safety Initiative (GFSI) requirements established by the Safe Quality Food Institute. Primar -

ily involved in the manufacture of flexible plastic packaging for cheese, yogurt and other dairy products, Capri facilities underwent a rigorous certification process comprising desk audits, physical audits and reviews—conducted and confirmed by the National Sanitation Foundation (NSF) to implement robust and documented food safety control mechanisms designed to provide consumers an assurance of safety all the way through the food supply chain. “I am really proud of our people at Transcontinental Capri and their hard work to provide consumers with a quality product that is very safe,” says Brian Reid, president of the Printing and Packaging sector of TC Transcontinental. “The SQF Level 3 certification confirms to employees, suppliers, customers and the industry that food packaging safety will always be essential to TC Transcontinental.”

Leading flexible packaging products group Bemis Company, Inc. has picked up a Gold Award in the packaging excellence category and a Silver Award in the sustainability category of the annual Flexible Packaging Achievement Awards competition of the Flexible Packaging Association (FPA) for the McCormick Skillet Sauce flexible pouch the company produced for leading spice and seasonings manufacturer McCormick & Company. Designed as a light weight alternative to the traditional bottles and jars used in the skillet sauce category, the new pouch’s design (see picture) facilitates a clean pour of the sauce and also lets the consumer connect with a unique and appealing shape, with the easy-tear-open ‘cap’ ensuring mess-free product use, with no scissors required. “We’re honored to be recognized along with our customer for a breakthrough concept to the market,” says Bemis director of marketing Don Schnabel. “We strive every day to better understand our customer’s businesses and challenges, as well as collaborating to position their products for even greater success.”

Columbia/Okura LLC, Vancouver, Wash.-based manufacturer of automated, robotics-based pal letizing equipment, has formed a strategic alliance with Fischbein Americas, Statesville, N.C.-based supplier of bag closing and packaging technologies, aimed at providing single-source, endto-end, fully-automated bag packaging solutions to North American customers. “Our two companies have worked together for well over a decade, and this formalization of our strong working relationship into a strategic alliance was the next logical step in our evolution,” says Columbia/Okura president Brian Hutton. “This strategic collaboration allows both companies to provide our mutual customers with best-of-breed equipment and truly optimized, integrated line performance with intelligent software communications.”

Showcasing over $2,000,000 of finished packaging machinery inventory, the Paxiom System Center is the perfect environment for testing your product on one of our many packaging solutions.

After years of development, QC Industries has launched a new range of HydroClean Sanitary conveyors featuring modular construction that enables them to be quickly disassembled without using any tools for quick and easy cleaning. According to the company, the modular design incorporates

an innovative configuration of pull-pins, sides and guides that can slide off in one piece, as well as stand brackets that can be simply flipped down and out of the way. After this, the tail end can then be flipped up to relieve tension on the belt, allowing operators to remove the belt, drive and tail for indepth cleaning. The HydroClean Sanitary conveyors are built on a 304 stainless-steel frame to NSF (National Sanitation Foundation) standards to minimize the risk of bacteria growth, with the sanitary design further enhanced via a self-draining frame, flat horizontal surfaces, no exposed threads, and hex-head fasteners with sealed ball bearings.

QC Industries 402

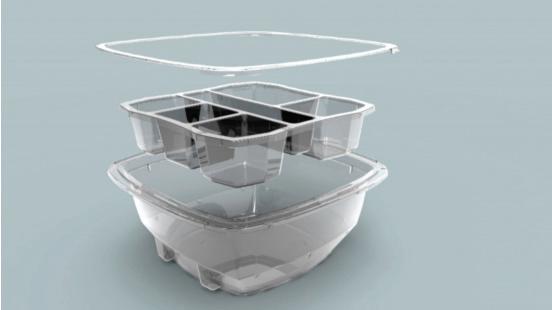

Milliken & Company’s recently-launched Millad NXTM 8000 additive has been selected by leading plastic products and systems manufacturer Milacron LLC to create the new range of clear polypropylene Klear Can brand containers—developed as a more user-friendly and higher-performance alternative to the traditional metal food cans. Said to be 40 to 50 per cent lighter than metal cans of equivalent volume size, the stackable Klear Can containers feature two layers of ultra clear polypropylene (PP ) resin clarified with Milliken’s advanced Millad NXTM 8000 additives to produce optical clarity comparable to that of glass-like polymers such

as polycarbonate, crystal polystyrene and acrylics. The end resilt is a fresher, cleaner and brighter look for containers that that of conventional PP-based applications for greater retail shelf impact. Featuring the same easy-open and traditional lids as metal cans, the Klear Cans allow brand-owners to differentiate their products at the point of purchase, while enabling consumers to clearly see the quality and freshness of fruit, vegetables and other foods through the clear container walls. Formulated to enable the containers to maintain up to two-year product shelf-life, the BPA (bisphenol-A) -free Millad NXTM 8000 additive can also be used for a diverse range of other packaging applications such as sportsdrink bottles, thermoformed cups and clamshells, detergent bottles and closures, food packaging and storage containers.

Milliken & Company

Milacron LLC

403

404

The newly-commercialized SURPASS HPs667AB polyethylene resin developed by NOVA Chemicals Corporation is a high-density polyethylene (HDPE ) designed for cast film, extrusion coating, extrusion lamination, and some barrier molding applications. Boasting innovative molecular architecture that enables it to achieve up to 50-percent moisture and oxygen barrier improvement over conventional technology, according to the company, the resin also features superior stiffness to facilitate notable layer or lamination reductions. According to Nova, this enables both packaging converters and brandowners to improve the sustainability and shelf-life performance of packaged foods in a wide range of applications such as dry foods, snacks, packaged liquids, and various dairy products.

NOVA Chemicals Corporation

sion is a fully-automatic printer and verifier of product-specific labels commonly used in the food industry. The system combines a printing module with a high-resolution camera and a reject system for faulty labels, with the printing module containing a thermal-transfer printer to apply high-contrast ink to every label with superior precision to clearly communicate the use-by date, provenance, list of ingredients, allergens and other required product information to the customers. A high-resolution camera then checks the printed lables m for quality factors such as legibility and completeness—allowing producers to determine any deviations from the specified quality. Processing a multitude of different label formats and automatically adjusting itself to changing line speeds, the system effectively prevents incorrect or illegible labels from getting in circulation, according to the company.

Mettler Toledo CI-Vision 407

405

Capable of printing and checking up to 500 labels per minute, the new high-speed Label Check Station (LCS) system from Mettler Toledo CI-Vi-

Effective July 1, 2015, Paul Cooke has been appointed Regional President Americas and President & CEO of Bosch Rexroth Corporation U.S. Mr. Cooke will continue as Senior Vice President Sales within the Business Unit Industrial Applications at the headquarters in Lohr, Germany until the end of June 2015.

Paul Cooke joined Bosch Rexroth in 1982 and has served in positions of senior leadership at Bosch Rexroth in the United Kingdom and Germany, most recently as Senior Vice President Sales and Industry Sector Management for Machinery and Engineering. Cooke has over 30 years of experience in both Industrial Technology and General Management. He received his Bachelor with Honors Degree in Mechanical Engineering from The University of Newcastle upon Tyne, England.

Berend Bracht, who is currently Regional President Americas and President & CEO of Bosch Rexroth Corporation U.S. is resigning from the organization for personal reasons. “We thank Mr. Bracht for his high level of commitment in the many years of service to Bosch Rexroth. We wish him all the best for the future,” said Dr. Karl Tragl, the chairman of the executive board of Bosch Rexroth. Bracht was appointed to his current role in 2006.

Designed to inspect tablets and capsules that are gravity-fed from the tablet press, the new Xtreme Pharmaceutical metal detectors from Eriez offer a high-performance solution for removing minute pieces of ferrous, nonferrous and stainless-steel contaminants from the packaging and production process to meet stringent FDA (U.S. Food and Drug Administration) requirements, while easily accommodating spacerestricted areas within tablet and encapsulation rooms. Featuring an adjustable stainless-steel support stand with casters, the highly-sensitive and robust Xtreme Pharmaceutical metal detectors are equipped with adjustable sensing heads and easyto-clean chutes for optimal user-friendliness, flexibility and convenience, according to the company.

Eriez 408

Made from a proprietary low-friction polymer engineered for dry, high-speed conveying on bottling and packaging lines, the dry-running System Plast NG Evo conveyor chain and belt from Regal Power Transmission Solutions is claimed to exceed all the previous benchmarks established by the original NG material in terms of delivering higher breaking load, greater elasticity, lower coefficient of friction, much greater abrasion resistance, and significantly reduced energy consumption and noise levels. When used with companion Nolu-S wear strips and guides—made with a specialty resin with a solid lubricant that dramatically reduces the coefficient of friction—an average high-speed conveyor line in an average facility can achieve up to 30-percent reduction in energy consumption, according to the company. Regal Power Transmission Solutions 409

ENSURE PRODUCT SAFETY, BRAND PROTECTION AND TRACEABILITY

PREVENT PRODUCT RECALLS AND wASTE

ENSURE YOUR h Yg IENE STANDARDS ARE m ET BY wAS h IN g IT DO wN w IT h OUT RIS k IN g ANY DA mAgE (IP66)

ThE NE w 9400 SERIES INkjET PRINTER DESIgNED TO mANAgE YOUR OVERALL EqUIPmENT EFFECTIVENESS (OEE)

If improving the EFFICIENCY of your production is one of your priorities, the new 9450 coder was engineered for you. The new Markem-Imaje 9450 is designed to be fully available, keep up with your line speed and secure each of your products with the right code!

Take step towards efficiency call 800-267-5108 Visit us at www.markem-imaje.com/9450

Although edible seaweed has been consumed as part of a regular diet in some cultures for centuries, it may be a little while before products like the Ocean’s Halo Seaweed Chips catch on in North America’s mainstream consumer markets in a really big way.

But when they do, their eco-minded brandowner—San Francisco, Ca.-based New Frontier Foods Inc.—will already be one step ahead of the game on the sustainability front, having selected bio-based NatureFlex flexible packaging material to retail its highly innovative product.

Manufactured from wood pulp by the U.K.based Innovia Films, Inc., the certified compostable NatureFlex materials are engineered to ensure superior barriers to oxygen and moisture, according to the company, which worked with leading Canadian packaging converter Genpak LLC to produce the high-quality stand-up pouches used to pack the brand’s five different flavor varieties. (See Picture)

Says Ocean’s Halo co-founder Robert Mock: “We were introduced to the compostable packaging alternative NatureFlex by Genpak, which is a leading food packing company with manufacturing locations in both the U.S. and Canada.

“Over the past two years, we have built a great partnership with Genpak to bring our products to market with not only high-quality material, but also with a like-minded approach to the environment,” Mock relates.

Made from sustainably-grown seaweed and other natural ingredients, the Ocean’s Halo Seaweed Chips brand is produced in five gluten-free flavors— Chili Lime, Sea Salt , Korean BBQ , Hot & Spicy and Texas BBQ —that require optimal shelflife protection to guard against moisture vapor in order to maintain the crunchiness of each chip.

“Our challenge was to develop a structure that

It doesn’t take a great leap in logic to draw a link between respect for the environment and concern for animal welfare, with Canadian pet-food upstart Open Farm Inc. happily underscoring that connection with a progressive packaging waste collection and recycling program for the 4.5-pound multiwall bags used to pack the Toronto company’s premiumquality brand of dog-food.

Claimed to be Canada’s first dog-food brand made exclusively from “ethically raised and sourced” meat and fish products, Open Food has partnered up with waste recycling and upcycling specialists TerraCycle Canada Inc. to enable green-minded dog-owners to not only prevent the packaging from reaching landfill for free, but actually help direct it for use in the manufacture of many useful new products—ranging from park benches to food and water bowls.

Under the program, consumers who purchase Open Farm dog-food from any participating retailer can join the Open Farm Brigade program online at terracycle.ca, and after amassing at least two pounds worth of empty Open Farm bags, they can download and print a free shipping label from the TerraCycle website and call a nearby UPS office for a free next-day pickup.

The package is then sent to a warehouse in Toronto to be weighed, sorted, recycled, and eventually used to make various new products, including dog leashes. (See Pictures)

“We’re delighted that Open Farm has come on-board as the first pet-food brand to recycle their packaging waste with TerraCycle Canada,” says Tom Szaky, Canadian-raised founder of the Trenton, N.J.-headquartered TerraCycle. “This is an important first step for a sector in which 95 per cent of pet-food packaging is thrown in the garbage.”

According to Open Farm, all its products are made from grain-free recipes using a select set of premium proteins, fruit and veggies that are raised naturally and responsibly in line with recognized industry standards.

“As an animal lover and ethical eater myself, I feel it’s important to work only with farmers who raise their animals in accordance with strict ethical and humane standards,” states company co-founder Jacqueline Prehogan. “When we learned that almost all pet-food packaging was nonrecyclable, we had to find a solution, which is why we partnered with TerraCycle.”

provides excellent barrier properties and works well on the packaging equipment,” recalls Genpak’s development manager Bill Reilly.

“Oceans Halo, Innovia and Genpak worked closely together to develop this functional and completely compostable structure,” Reilly says, adding each flavor in the brand is distinguished by its respective bag’s unique color.

According to Mock, the seaweed chips were formulated to not only taste good enough to be put into the snack-aisle, but also be nutritious enough to retail in the grocers’ fresh-produce aisles.

“Organic, baked, great-tasting, and packed with vitamins and minerals, these chips are completely free of GMOs, transfats, MSG and artificial ingredients,” says Mock, adding the chips are already retailing in select U.S. geographic markets by progressive grocers like Whole Foods Market, Sprouts, Safeway and Central Market

Says Ocean’s Halo co-founder Mike Shim: “When we were faced with packaging choices, we were 100-percent committed to compostable bags because it’s the right thing to do.

“Health and sustainability is one of our core pledges to our customers,” Shim states, “and compostable bags are an integral part of that pledge.”

If a happy cat is a sure sign of a happy owner, as an old Chinese proverb has it, there is plenty of happiness to go all around with Nestlé Purina PetCare’s recent launch of the highly innovative Pro Plan Renew brand of premium, natural clumping cat litter.

Made entirely from a mixture of corncob and cedar without using any artificial fragrances, the lightweight, virtually dust-free litter—offered in Unscented and Balsam Wood Scent formulations at over 1,200 PetStore retail outlets across North America— is packaged in fully-recycled and 100-percent recyclable containers made from molded pulp fiber derived primarily from OCC (old corrugated case) materials. Designed and manufactured by the Oakland, Ca.headquartered Ecologic Brands, Inc., the six- and 10.5-pound containers are produced using made via a proprietary combination of heat and pressure that make the jugs strong enough to hold the litter, while maintaining effective moisture resistance to ensure the product inside remains dry throughout its use.

Completely recyclable in most communities via local municipal recycling streams, as well as the special recycling bins located at most PetStore locations, the containers are topped with friction-fitted caps that are also made from recycled pulp fibers, with zero plastic content. (See Pictures)

“Many consumers are on a journey to improve their impact on the environment, and so is Purina,” says Nestlé Purina PetCare’s sustainability manager Diane Herndon. “The Pro Plan Renew litter is an exciting step in our journey, combining the benefits of a corncob and cedar litter with recycled and recyclable packaging for a totally new product experience that eco-minded cat-owners can really appreciate.”

Adds Ecologic Brands’ Canadian-born founder Julie Corbett: “Ultimately, the Purina Pro Plan Renew jug delivers a packaging solution that goes beyond addressing one component of sustainability, and instead looks to revolutionize the packaging industry by addressing the entire life-cycle of the package.”

Founded in 2008, Ecologic Brands has produced over five million fullyrecyclable paper bottles, jugs and other rigid containers in various shapes and size since 2010, with the company’s client base now comprising 20 well-known CPG (consumer packaged goods) industry brand-owners.

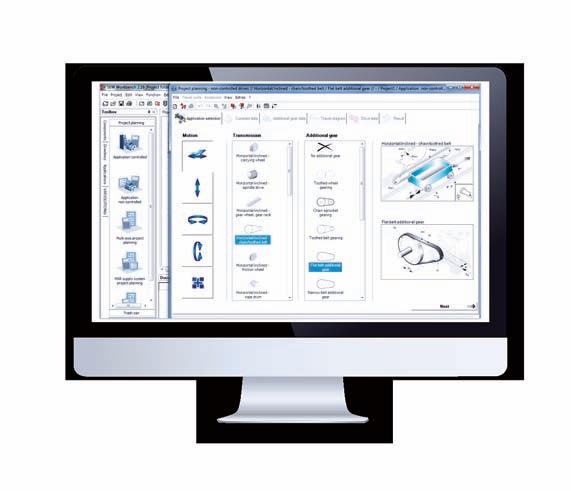

Clients want someone who really understands their project and will help them get to the finish line - cost-effectively, on time, and delivering on their expectations.

Plan Automation does just that, offering clients a comprehensive project management approach from start to finish.

• Processing Design & Engineering Support

• Food Safety Inspection

• Packaging Automation

Your project is our project.

We don’t require a contract or any commitment - we will invest our skills, time and research.

With over 175 combined years of industry experience, we will help you find the best processing, food safety inspection and general automation solutions by dedicating our extensive resources to guarantee results.

June 16-18 | Booth# 1176

Produce grower channels positive energy and upbeat attitude to strengthen its market growth through continuous product and packaging innovation

BY GEORGE GUIDONI, EDITOR PHOTOS BY PIERRE LONGTIN

As intangible as they may be, it is sometimes hard to overstate the importance of positive thinking and an upbeat attitude in helping a company achieve and surpass its goals and targets—even in one of the most competitive markets out there.

Even more so when that positivity and self-confidence have been honestly earned through good old hard work and keen business smarts, as the Sherrington, Que.-based vegetables processor Veg Pro International Inc. has done year after years since its 1998 startup.

Nowadays ranking as one of Canada’s largest vegetable growers by tonnage, the family-owned business has grown in proverbial leaps and bounds virtually right from the outset, according to the

company’s vice-president of operations Anthony Fantin.

As one of a group of local investors—led by Gerry Van Winden and four family farm operators—behind the launch of what has evolved into one of Quebec’s most remarkable home-grown business success stories, Fantin in many ways personifies the competitive, self-assured ‘can do’ mindset that has continuously steered Veg Pro to greater heights on a consistent basis.

With a solid track record in the fresh produce wholesale industry, the opportunity to be part of a professionally promising and rewarding entrepreneurial journey was just too good to pass up, according to Fantin, who studied industrial relations at Laval University prior to entering the food business.

To this day, it’s a career decision that the fluently trilingual (English, French and Italian) Montreal

Retailing in four different flavor varieties in fresh produce sections of major grocery outlets across Quebec and Ontario, the Asian Stir Fry kits boast colorful branding graphics designed by the Effet Boomerang marketing agency. native has never had to regret or rethink even for a millisecond.

“There is a lot to be said in favor of working for

a family-owned business operating under a set of traditional family values in a real teamwork environment,” Fantin told the Canadian Packaging magazine in a recent interview.

“We take a lot of pride in what we have achieved so far but the best part is that we strongly feel the best is still to come,” says Fantin, fondly recalling the early days of operating out of a tiny 8,000-square-foot plant on the outskirts of Sherrington, a close-knit southern Quebec rural community of less than 2,000 residents.

But whatever Sherrington itself may lack in terms

of population size and scale, according to Fantin, is more than aptly compensated by the region’s favorable climatic conditions, high-quality soil for growing the company’s core vegetable products (lettuce, spinach, celery, carrots, onions, shallots, etc.) and strategic proximity to the company’s primary geographic markets.

“Being located in the most southern part of Quebec, with its own little warmer microclimate that is very favorable for growing lots of the veggie crops that are most important for our operations, is definitely a source of advantage for our company,” Fantin relates.

“The rich dark soil in these parts is very similar to the type of soil you would purchase from a gardening products center to pot your plants in your home garden, and the location couldn’t be better,” he points out.

“Being located about 35 kilometers south of Montreal and only 15 kilometers north of the U.S. border enables us to export our products as far down south as Maryland.

“The proximity to our key markets is a really important factor for us,” says Fantin, adding the company distributes its flagship Fresh Attitude retail line of salad kits, along with its private-label of-

ferings, right up to the western reaches of Ontario and throughout the Maritimes provinces out east.

“Most of our customers serviced by our processing plants are basically within the range of overnight delivery,” Fantin relates.

“We don’t leave much to chance when we put our product on the truck—most of it gets delivered to customers within one to 14 hours at the most.”

As a highly skilled and knowledgeable grower operating over 7,000 acres of prime farmland in the region, the company’s high degree of integration—from harvesting right through value-added processing and packaging—also plays a key role in maintaining a competitive cost structure, according to Fantin.

“We grow about 90 per cent of all produce that goes into our processing facilities,” says Fantin, also accounting for the output of the company’s nearby carrot-and-onion packing facility, as well as significant acreage of farmland owned by the company in sunny Florida, where it also operates a packing plant in Belle Glade.

Says Fantin: “Being our own grower means we always know exactly what the product is, what conditions it was grown in, how much water was applied, how much fertilizer was used, and all those factors that enable us to predict our products’ shelf-life with very good accuracy.

“It’s not really exact science, but we are generally very good at ensuring at least 10-day shelf-life for our customers’ DC (distribution center) operations,” says Fantin, relating that many of the products tested in-house have demonstrated extended shelf-life potential of up to 14 to 16 days.

“Being integrated like this also enables us to manage the whole process better in order to remain cost-competitive in a highly competitive marketplace that has a lot of big companies fighting fiercely for market share all the time,” says Fantin, citing the likes of Dole, Del Monte, Chiquita and other multinational food giants that Veg Pro competes with on day-to-day basis.

“We really are a small company compared to those Big Boys,” he notes.

But be that as it may, it is a much bigger company than it was not all that long ago.

Employing roughly 800 people throughout all of its farming, processing and office operations, the company’s central 80,000-square-foot value-added processing facility in Sherrington—started up in 2007 and last expanded about two-and-a-half years ago—is currently gearing up for another major plant expansion this fall that will see it double in physical size and footprint, Fantin relates.

Already employing 450 people on an aroundthe-clock, three-shift schedule—two production shifts and one daily sanitation shift in between— the plant already houses 11 high-volume, highspeed production lines to keep up with healthy demand for its products from both consumers and retail customers alike.

“We are looking at adding another five our six lines once the new plant addition is complete later in the year,” says Fantin, describing Veg Pro’s outstanding growth track record over the years.

“We have experienced growth rates ranging from 20 to 40 per cent every years since we started,” says Fantin, stressing the importance of the company’s continuous investment in new processing and packaging technologies for helping drive that growth.

“I don’t want to use the words ‘state-of-the-art’ because it’s such an often-overused term nowadays,” he says, “but all our production lines are operated with modern, late-model machinery and equipment, with a fair bit of automation on some of the lines, that enables our staff to obtain very good productivity performance levels.

“And even though our production costs are fairly competitive, we’re always looking at ways to better ourselves,” says Fantin, adding the company’s internal department of continuous improvement is

Veg Pro International’s vice-president of operations Anthony Fantin is one of the thriving Quebec company’s original co-founders and shareholders.

a key driver of its whole-hearted commitment to manufacturing and customer service excellence.

Boasting all the pertinent, fully-validated GFSI (Global Food Safety Initiative) and HACCP (Hazard Analysis and Critical Control Points) certifications for food safety and quality, the busy facility is a committed GMP (Good Manufacturing Practices) devotee, Fantin confides, with plenty of built-in process flexibility to adjust to changing production volumes and demand with minimal process disruption or downtime.

“Above all, we are fortunate to have very good and dedicated employees working for us,” Fantin proclaims.

“Dealing with a highly perishable product naturally dictates a need for a vary fast-paced work environment, and we are lucky to have a lot of young people employed throughout the organization—

from field to plants to key office positions—who bring high levels of energy and enthusiasm, working in sync with all other staff towards achieving the same common goals.”

All these attributes and competencies will be leveraged to maximum potential in the coming months, according to Fantin, as Veg Pro follows up on the recent launch of the company’s highly innovative Fresh Attitude Asian-Style Stir Fry kits—introduced with much fanfare at major grocery retailers last November across Quebec and Ontario.

Currently comprising four popular recipe choices—including General Tao, Teriyaki, Thai and Sweet and Sour—the fresh, never-frozen kits containing an assortment of Asian-style veggie mixes, noodles or rice, and authentically-made sauces and

toppings are packaged in patent-pending, multicompartment microwavable bowls that incorporate a unique steaming process to cook all of the kits’ ingredients to the optimal serving temperature.

“I don’t want to sound pretentious, but it only seems fair to say that we have founded a whole new mini product category with our Stir Fry kits,” Fantin states, praising the company’s hardworking R&D (research-and-development) department, led by R&D manager Luc Van Winden, for creating “a real winner.”

Says Fantin: “Most stir-fry kits out in the market simply cannot be microwaved, whereas our speciallyengineered plastic bowls hold the steam very well to offer consumers a great meal solution for consuming a healthy serving of fresh-grown steamed vegetables with a very appealing taste profile.

“I actually hope that our competitors follow suit

and offer consumers similar products in order to grow this whole new category segment,” says Fantin, citing “rave reviews and feedback” from food critics, self-proclaimed consumer ‘foodies,’ retailers and foodservice customers alike.

“We have seen the sales of the new Stir Fry kits grow steadily from week to week ever since the November launch,” confides Fantin.

While the initial sales numbers have not been skyrocketing at the same breathtaking pace as when Veg Pro first launched its Fresh Attitude salad kits, “We are very confident about this product’s growth potential,” he states.

“The big difference is that launching our salad kits was basically all about giving consumers an additional choice to all the other salad kits already out there in the marketplace,” he explains. “All we really did was enter a segment that was already there.

“With these Stir Fry kits, we are talking about a totally new product that nobody even though about doing the way that we have done it—making it microwavable and so consumer-friendly to prepare and enjoy in mere minutes.

“Not only is this a whole new offering that requires a whole new habit of purchasing this sort of product,” he extols, “but the fact that it is such a high-quality product, with a taste profile that appeals to so many people, makes us thing that this is a product that can really take off in the marketplace.

“Maybe launching it in November was not the best time to do it strategically, and perhaps we could have waited until April or May to get a better initial growth curve,” he reflects, “but being first to mar -

ket is also important in terms of the bigger picture.”

According to Fantin, the Fresh Attitude Asian Stir Fry kits launch was a culmination of more than a year’s worth of intense product development, testing and market research efforts involving many crossfunctional teams and plenty of creative, collective brainstorming.

“There’s a lot more to it than just creating a recipe,” he states. “Not only do you need to determine the right mix of vegetables and find the right taste profile, there is also the matter of finding the right equipment to pack it, finding the right containers to pack it in the right containers to put it in and, above all, finding a way of making it to reach a retail pricepoint that will not run away consumers at the store level.

“Having done all those things gives us hope that the sales part will fall into place in due time,” Fantin adds, citing the general market trend to eating more vegetables as part of a healthier life-style among the increasingly health-conscious Canadian consumers.

Being well in tune with the Canadian consumers’ growing appetite for healthier food options also makes Veg Pro very sensitive to those consumers’ increasing demand for more environmentallyfriendly manufacturing practices and sustainable packaging. According to Fantin, being a good and green corporate citizen is really second nature to a company that at the end of the day depends on a healthy environment to earn its livelihood.

To that end, Veg Pro only uses the fully-reyclable and widely-recycled virgin PET (polyethylene terephthalate) plastic 142-gram and 312-gram bowls— supplied by Precision Packaging and Par-Pak—to package the lion’s share of its Fresh Attitude brand of lettuce-based Spring Mix, Caesar, Greek, San Marino, Spinach Leaf and other traditional salad

kits, with the microwavable Stir Fry polypropylene bowls also said to be fully-recyclable.

“If we can’t offer packaging made from recycled materials, we’ll make sure offer packaging that is fully recyclable,” Fantin states.

“Internally, we use reusable containers almost exclusively, which enabled us to reduced our waste disposal to the bare minimum, and we also compost all of the product waste from our plants,” he relates.

“Also, being the only veggie processor on the east cost to grow its product on the east coast, combined with our proximity to the markets we serve, helps us maintain a much lower carbon footprint than our competitors, many of whom a reliant on produce grown on the west coast,” adds Fantin.

“So for people worried about carbon footprints and the amount of greenhouse gases emitted in the air to make their food products, we provide a very good eco-friendly option,” Fantin asserts.

“Being environmentally-friendly is something we are naturally very much in sync with; we just prefer not to advertise it as a marketing tool but to do it simply because it is the right thing to do,” he sums up.

“It’s just not our style to be shouting from the rooftops about us recycling everything and composting all our waste,” Fantin concludes. “For us at Veg Pro, it’s just a way of life—simple as that.”

Upgrade to thermoform packaging provides longer

ANDREW JOSEPH, FEATURES EDITOR

BY COLE GARSIDE

These days, when a gentleman reaches the age of financial security and family happiness, the long-awaited downtime is often taken up with a mild array of hobbies and other pursuits that are as far removed from work life stages as possible.

But not so for Frank Abballe, former owner of a well-respected deli meats processing company.

After selling the business a few years ago, Abballe picked up a hobby that he could pursue virtually every single day within the comfort of his own home in Trenton, Ont., if you can really call it a hobby, that is.

As the owner and president of La Cultura Salumi Inc., Abballe runs his extremely high-end Italian deli meats processing facility on the main floor of his own home, with the living quarters set on the second floor.

“It’s all about the passion,” Abballe told Canadian Packaging magazine during a recent visit to the 10,000-square-foot facility, situated on 48 acres almost smack dab in between Montreal in the east and Toronto in the west.

Construction of the dual-purpose plant and home began in 2011, with processing starting up in March of 2012.

“To my knowledge, it’s the only meat plant like this in North America,” explains Abballe, “with the live-work concept.”

Abballe says the plant is monitored on a 24/7 basis, with someone always present at the facility— to watch over the meat curing process.

As Abballe says: “It takes a lot of attention and passion to create the real authentic products we do, and like many such Italian-style delicatessen meat processors, we rely on generational family recipes.

“Our recipes are pretty darn impressive.”

Letting us in on a little secret, Abballe explains that his company name implies the bringing of Italian culture to Canada to make the authentic timetested ‘salumi’—Italian for ‘cold cuts’—recipes.

“The true high-quality Italian meat products have never been processed for export,” states Abballe. “They are only consumed in Italy.

“Products manufactured in Italy for the North American market are really called ‘export products.’

“Real Italian products should be from animals born and raised in Italy, slaughtered in Italy, and dry-cured in Italy.

“That is the very definition of a real authentic Italian products.”

Abballe explains: “Saving you the cost of a plane ticket, La Cultura Salumi can create the absolute very next best thing—a taste of Italy as good as anything you’ve ever had in your mouth before.”

Abballe’s passion for meats is as credible as it comes. Although having come to Canada as a young boy, he says the family’s farm back in Italy called him back repeatedly over the years.

So when he was old enough, Abballe began working alongside what he calls “the Italian masters of air-dried meats” in order to learn and perfect the art and value of hand-selecting each piece of meat, and the benefits of personal attention to detail.

“The secret to La Cultura Salumi is simple, yet difficult to achieve: patience, excellence, quality,” he reveals. “When you taste any of our meats, you’ll understand exactly what I mean.”

The processing facility location was chosen for a quality-related reason as well, notes Abballe.

“The reason we built the plant here on farmland

in the Quinte West area is because we know that when one drycures meat products naturally with lots of air and humidity, you need to have the best quality air possible.

“This is the way such products are crafted in Italy,” relates Abballe.

“No one of any self-respect makes such high quality products in an industrial area,” describing his products as “European meat products that nobody makes here in North America.”

These products include Beef Bresaola, Beef Carpaccio, Horse Bresaola, Turkey Bresaola, and Pork Culatello, all made with high-quality meats from all the animal species mentioned above, including water buffalo farmed in Montreal.

La Cultura Salumi also makes its own sausages—a lean, thickwith-meat Tuscany pork sausage—as well as a delicious yogurt made from water buffalo.

“I source my meats from local farmers and reputable wholesaler’s suppliers,” explains Abballe. “We receive the meat, hand-place salt and applicable spices on it, and then place the whole batch into one of our dry aging rooms.

“It could be weeks or even months,” he acknowledges, “but when the product is ready, we send samples to the laboratory to ensure it is clear of harmful bacteria and then slice and package each product in vacuum bags and store them in our finish cooler prior to shipping to our customers.”

Abballe asserts that no one else makes the kind of products here in North America that La Cultura Salumi makes.

“With our recipes and the supreme quality I demand, no one else comes close. Plus it is difficult for processors to tie up so much time and money to age some of the products for the necessary 14 to 16 months.”

A provincially-licensed plant, La Cultura Salumi supplies its high-grade deli meats to Ontario customers in both the retail and foodservice segments, distributing to Off The Bone Meat Products in Toronto, and selling to high-end restaurants and shops in Toronto such as Bar Isabel, Sanagan’s Meat Locker, Sanremo Bakery, Fiesta Farms, Summerhill Market and other upscale specialty grocers.

According to Abballe, the name of the game is constant improvement.

“Every year since we opened, we have invested in new machinery and equipment to help us create our products in a better way,” notes Abballe. “As well as purchasing processing and packaging

technology, we also have the best of the best for our dry curing pro -

The latest choice piece of equipment to grace La Cultura Salumi was designed and manufactured Multivac, a Germany-headquartered global leader in horizontal thermoform fill-seal packaging equipment.

After contacting its Canadian divMultivac Canada Inc., La Cultura installed a brand new R105 thermoformer earlier this year.

“La Cultura had specific needs and wants for the packaging needs of their premium product. After a thorough assessment and discovery process, we were able to provide the right packaging solution to deliver those needs and wants—an economical, but sophisticated packaging solution for a premium product.”

They knew what they wanted, and what they needed,” explains Multivac Canada key accounts manager Chris Salmon, “and after discussing with Frank what he needed and why, we agreed with his assessment.”

After narrowing down all options to two choices, Salmon says “Multivac won this project simply because we were able to deliver a compact machine with the ability to form packages with both flexible and rigid materials.”

Adds Abballe: “Multivac has an excellent reputation in the processed meats industry and are an acknowledged leader in thermoform package machine design.

“I had already done my own due diligence on Multivac, and I knew that it was a company I could put my trust in.”

Abballe explains he wanted a machine that could create a package that could offer a high-end presentation package that would accurately reflect the quality of the products inside.

“The way the Multivac R105 thermoformer packs our pre-sliced

meats with the addition of different types of MAP (modified atmosphere packaging) gas helped us provide a long product shelf-life and maintain the original quality of my products,” he relates.

Salmon notes that the Multivac R105 thermoformer owned by La Cultura Salumi is actually unique in its design from other R105 models, something it did to cater to the meat processor’s specific requests.

“This R105 is built with special forming inserts containing a rib design,” relates Salmon.

“These ribs actually hold the meat product up and away from the bottom of the package, which allows the MAP to flow under the product.”

He says that because the product La Cultura Salumi produces is dry-cured, this package design was specifically designed to not only protect the product, but also to extend its shelf-life.

“Then there’s that rigid ability of this R105 thermoformer,” mentions Salmon. “When I say it has rigid ability, it means that the operator can run a thicker film through it in order to create a very rigid package—essentially creating a lower web tray that won’t flop around in the consumer’s hand when they pick it up.

“It creates a very rigid package.”

Salmon adds that although La Cultura Salumi isn’t looking for a pack-forming machine to break speed records any time soon, he is confident that the economical and compact R105 thermoform

machine will be able to meet and exceed any packing tasks put to it.

“Since La Cultura Salumi usually opts for a thicker film base, we had to fit the R105 with a special knife-cutting assembly to easily slice through it,” says Salmon. “The FS knife punch assembly is able to provide the customer with a rigid package with smooth, rounded corners.”

For Abballe, there’s not one little thing he prefers over the other as far as his R105 is concerned.”

“For me, the Multivac R105 is the total package,” he beams.

“Yes, I love that it can create a consistent highquality pack, but the superior hygienic design of the machine is also extremely important,” he extols.

According to Multivac, the R105 machine provides full wash-down capability—inside and out, with easy-to-access side panels and space for cleaning— allowing the cleaning crew to easily get at all parts of the machine to give it a thorough cleaning.

“With the R105, we have consistently avoided edges and corners in the machines’ construction,” advises Salmon.

“To help avoid build-up of product or cleaning materials, the R105 has smooth slanted surfaces, so that contaminants will not thrive on these machines.”

Inside, Salmon says the whole machine has been fully optimized: from the chain guide and chain design to the lifting mechanisms, mechanical elements, motors, valves and even the cabling.

“In my opinion, no packaging system offers bet-

ter sanitary design than this new generation of Multivac,” Salmon proclaims.

Abballe points out the Multivac R105 is actually very easy to use—with an intuitive control system available in 18 languages—being easy enough for himself to run when his usual operator might be away.

Some of the value-added standard features of the Multivac R105 thermoformer include:

• Durable stainless-steel construction;

• Patented hygienic chain-guide design;

• Industry-leading hygienic design;

• Full IP 65 washdown capability;

• Comprehensive safety systems;

• IPC control system;

• Touchscreen control panel;

• Production data acquisition and storage;

• Cut-off length up to 300-mm;

• State-of-the-art electric lifting system;

• F lexibility in use of materials, cutting systems and formats;

• Easy-access machine frame.

“The Multivac R105 La Cultura Salumi purchased is an excellent small-footprint system that is perfect for the amount of packs they create, with ample additional built-in production capacity should they require it in the future,” says Salmon, explaining that Multivac developed the R105 as a means to bring the benefits of its larger thermoforming systems to the smaller and growing businesses.

With all its film requirements supplied by Winpak, other processing equipment utilized by La Cultura Salumi includes a Sipromac double-chamber vacuumpacking machine and a Bizerba A550 automatic slicer.

“The films from Winpak were actually recommended to us by Chris Salmon,” explains Abballe. “And as an added bonus, the sales representative from Winpak, Mark Bergsma, is fantastic to work with.”

While happy to have his story told in this magazine, “If there’s one thing to regret about a print article on Frank’s La Cultura Salumi meat products, is that the reader is unable to appreciate the fantastic smell of the meats or to taste the mouthwatering goodness,” Salmon sighs.

“However, for consumers unable to make it out to the numerous high-end restaurants in southern Ontario that serve his very high-end meats, or even to the shop at his processing facility, one could now pick up these taste sensations at the grocery store” he says.

Adds Abballe: “I am very happy with the service I have received from Multivac and the equipment they manufacture.

“The R105 thermoforming machine, although very new to our line-up, has performed yeomenlike work with a high level efficiency.

“The packages it creates are worthy of the highquality meats La Cultura Salumi processes,” he sums up, “and I look forward to seeing how far we can work together in the future.”

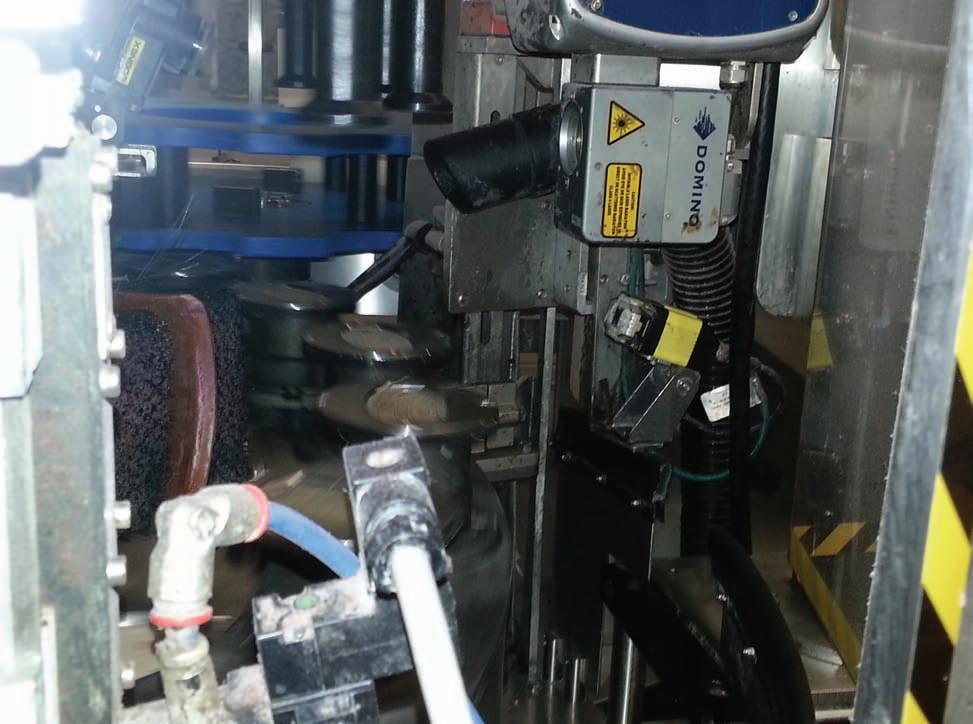

Kraft sauce production line unlocks code-scanning bottlenecks with powerful image-based readers to eliminate product label changeover downtime

Allergen management is playing an increasingly important role in the packaged foods industry, with manufacturers taking greater care to avoid labeling mix-ups that sometimes lead to expensive recalls and potential liability concerns.

Until recently, Kraft Canada Inc. used to address these concerns at its production facility in Saint-Laurent, Que., by scanning each label after it has been attached on the packaging line to ensure that it matches the package contents.

But over time, the laser scanner type ID readers that the facility used on its busy barbecue sauce line—producing 30 different stock-keeping units (SKUs) at rates up to 265 bottles per minute—became increasingly prone to read failures, especially when changing over a new product with the label in a different location.

“Ensuring that each individual package has the correct label is critical because some of the products have ingredients such as mustard and egg that certain customers may be allergic to,” explains the plant’s senior technician Dave Fortin, relating that whenever the line was changed over to produce a new SKU number, the matching labels would be manually loaded into the filling machine.

To guard from instances where machine operator might load the wrong labels, or that a few wrong labels might be accidentally mixed in with the correct batch, Kraft originally used laser-based ID scanners to read the linear code on each label as it passed by and transmit results to the programmable logic controller (PLC) running the machine, which then compared the code to the proper value and eject the package if it was incorrect.

The main limitation of the laser-based scanners is that they are only capable of reading codes located

within a small field of view, whereas the marketdriven nature of label design often results in the codes being positioned in many different spots on the label, depending on each designer’s preference.

“As a result, whenever the labels were changed, the codes may have ended up in a different position from the previous run,” Fortin recalls.

“This required that the position of the laser scanners be adjusted whenever the product line changed to a new SKU number, taking a considerable amount of the technical staff‘s time.”

Yet even when the laser scanners were positioned perfectly, Fortin recounts, they still often failed to read the code—often for reasons that the team could not readily pinpoint.

“My team was frequently called upon to adjust the code readers, which made it difficult for us to fulfill my other responsibilities,” he states.

“Moreover, considerable amount of time was also required on the part of the production team to inspect each of the packages that could not be read by the scanner to make sure it was correct.”

To resolve the persistent problem once and for all,

Fortin contacted local representatives of the wellknown machine-vision and product ID technologies manufacturer Cognex Corporation of Natick, Mass.

“I suggested to Kraft that they consider image-based code reading technology,” says Mike Palmieri, senior technical sales representative for Cadence Automation, a Cognex systems integrator located in Ste-Thérèse, Que.

According to Cognex, the basic idea behind image-based technology is that the reader captures an image and uses a series of algorithms to process the image to make it easier to read.

A typical algorithm will search the entire image for the code and identify the position and orientation of the code for easy reading, while other algorithms work to compensate for any degradations in code quality due to the differences in material types and surfaces.

A key advantage of the image-based approach is that it not only reads the standard linear codes at much higher read rates, according to Cognex, but that it also excels at reading the 2-D (two-dimensional) matrix codes.

Being able to hold and store a much larger volume of data than linear barcodes, these high-density ‘stacked’ codes provide a considerable amount of redundancy that is used for error correction— making the codes readable even when damaged.

For the Kraft line’s application, Palmieri recommended the Cognex DataMan 300 image-based ID reader, whose exceptionally high image resolution also provides for a five-by-five-inch field of view—sufficient enough to capture an image of the entire label with the necessary resolution to read the code, regardless of its position and in spite of any degradation.

“The DataMan 300 also provides built-in Ether -

You’ve set the bar high on your production line, and PACK EXPO Las Vegas is the best place to find suppliers with equally high standards. No other trade show in 2015 will offer so many state-ofthe-art processing and packaging solutions, as well as a program rich in networking and educational opportunities. Make sure to be there.

net connectivity, which makes it easy to communicate with a PLC and plant network at a very affordable pricepoint,” Palmieri says.

The DataMan 300 reader uses an advanced new 1DMax+ algorithm, which incorporates Hotbars technology designed to handle difficult ID code-reading applications on high speed lines.

According to Cognex, the Hotbars technology uses texture to locate barcodes at any orientation to extracts high-resolution 1-D (one-dimensional) signals for decoding, with whereby the Hotbars finder analyzing a raw source image to produce a list of regions where an ID code is likely to reside, along with the orientation and other properties of the code.

Moreover, the DataMan 300 series offers the flexibility of integrated and controllable modular lighting and optics—enabling the user to purchase just one model and then select the appropriate lens to match the required working distance and field of view.

In addition, the controllable, fieldchangeable lighting modules allow the user to create the best possible lighting conditions to ensure optimal read rates, according to Cognex.

Fortin started by replacing a laser scanner with a DataMan 300 ID reader in one of the barcode reading positions on the barbeque sauce line.

From the moment it was installed, Fortin recalls, the image-based reader virtually eliminated read failures, providing 99.9-percent-plus read rates.

Because the line has four spurs requiring a total of four ID readers, Kraft quickly made the decision to replace the three other ID readers on the barbeque line with the DataMan 300 units.

Still delivering the same near-perfect read rate accuracy, while freeing up technical staff from the task of adjust the position of the reader, the company eventually replaced other existing laser scanners on the plant’s three other production lines with the DataMan 300 readers.

Fortin relates that he now easily handles the installation set-up of the DataMan 300 code readers himself, using

the specially-designed pan-and-tilt brackets that he buys with each code reader to mount the scanners into place.

After connecting the reader to a personal computer and adjusting the light and focus on the camera, Fortin connects the reader to a PLC via an Ethernet connection.

The reader’s camera supports all popular PLC communications protocols, while a photodetector in the inspection station provides a signal to the PLC that a bottle is in the station ready for inspection.

The PLC then instructs the ID reader to capture an image and to send it back to the PLC for final verification. If the code does not match the product currently running on the line, the PLC directs an instant transfer of the bottle to a reject conveyor.

“The outstanding performance of the DataMan 300 ID readers now saves the technical team a considerable amount of time, while protecting customers by ensuring the accuracy of our labels,” says

Fortin, adding he can install a DataMan camera by himself in about two hours.

“Over time, the DataMan 300 ID readers have significantly improved the efficiency of all the packaging lines where they have been installed,” Fortin relates.

“In the past, our technical team had to spend a considerable amount of time adjusting ID readers on various packaging lines, while the production staff also had to spend a lot of time dealing with the many bottles with good labels that the laser scanner ID readers were not able to read.

“The new image-based ID readers have solved these problems by providing near-perfect read rates,” Fortin sums up. “Moreover, they are also quite economical to purchase and very easy for us to maintain.”

RockTenn’s precision mandrel-forming technology forms cases around a fixed mandrel, minimizing case-skew and maximizing structural integrity, resulting in cases that outperform standard RSC’s in production efficiency and stacking strength. Meta® Systems’ unique case forming process offers the ultimate in flexibility and enables improved box performance in your production line and distribution system. Why work harder when you don’t have to?

To learn more about our precision mandrel-forming technology, contact RockTenn Automated Packaging Systems at 407.843.1300.

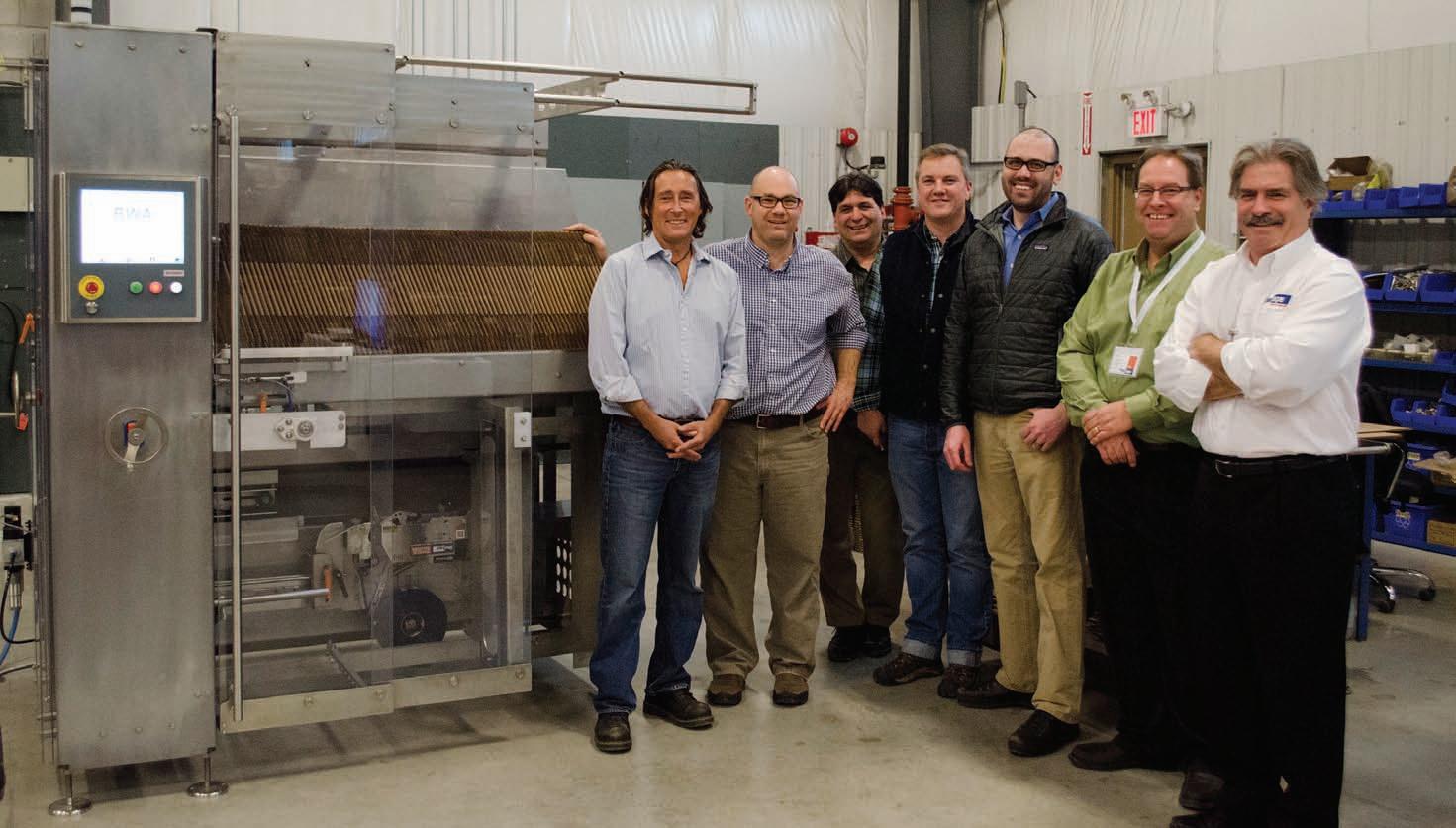

Ontario equipment designer and engineering services provider brings innovative secondary packaging concepts to the consumer goods market

For any group of people contemplating starting up their own business, the main question to ask and answer is the existentialist ‘why’? As in why the proposed business is important or essential in today’s or even tomorrow’s marketplace.

While many would-be business propositions might have a dream that is uniquely their own, for success to occur, the product or service provided must be something that is needed by the prospective customers or consumer.

While some might argue that there are no original ideas left, real entrepreneurs will happily examine a market and determine where a real need is going unfulfilled, and fill it with something the industry and the consumer will both find innovative and helpful to the bottom line.

Frustrated by a perceived lack of innovation within the CPG (consumer packaged goods) sector, one Canadian company recently decided to stop complaining about it and dedicated itself to resolve the issue of what they called an “obvious dearth of forward momentum.”

Called Bluewater Automation, the upstart Canadian design and engineering packaging machine company was founded in December of 2012. Headquartered in Toronto, with multiple regional offices placed throughout both Canada and the

U.S, the new company is wasting no time in making itself known in the packaging industry circles.

“Although there’s no need to reinvent the wheel, there’s nothing wrong with coming up with a way to make the wheel better for all concerned,” company president Jaime Alboim told Canadian Packaging during a recent interview.

“And Bluewater has done just that,” Alboim proclaims, asserting the crew at Bluewater says it can not only talk the talk, but also walk the walk, as well as anyone out there.

Despite its youthful countenance, the company has plenty of experience behind its nameplate, with a roster of highly experienced employees sharing almost 100 years of collective experience specific to the secondary packaging segment of packaging automation.

“Bluewater is actually a few things,” Alboim explains.

“First and foremost we

are a design and engineering company focused on bringing sanitary secondary packaging equipment into the CPG (consumer packaged goods) market.

Says Alboim: “The second part of our business is as a distributor of value-added CI (continuous improvement) solutions for the CPG market.

“Basically, our objective is to help companies identify areas for continuous improvement and

ging ke eps yo urpr odu ct

implement very simple but fast solutions to help with a customer’s workflow issues.”