Upscale meat processor re nes vacuum skin-forming techniques to boost product shelf-life and presentation

Upscale meat processor re nes vacuum skin-forming techniques to boost product shelf-life and presentation

Story on page 13

Page 20

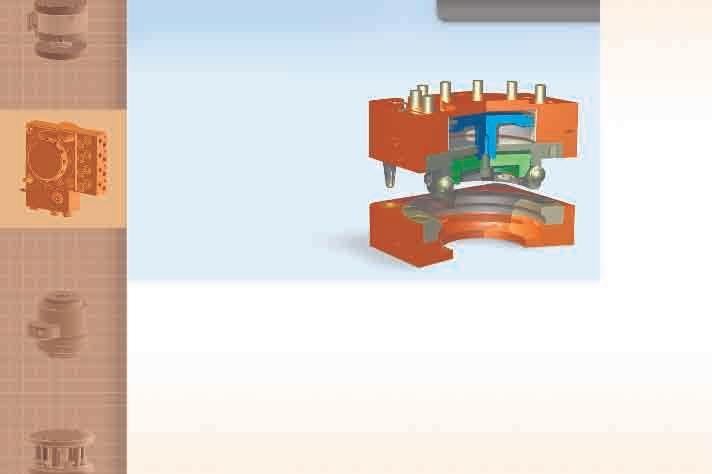

Flexible to the core –Highly Scalable Valve Technology MPA-L

• High quality valves can be individually combined or extended at any time.

• Conversions made quickly and easily.

• Polymer sub-bases reduce weight, important for dynamic robotic applications.

• Flexible wiring options from cage clamp terminals to the most common fieldbus networks.

• Aluminum endplates offer robust and secure mounting.

Looking for a supplier who can help you achieve an “A” on your report card?

We offer:

A team of design experts to provide you with innovative packaging designs and solutions to your packaging challenges, using state-of-the-art design software coupled with computerized sample making capabilities.

A design team available to assist you in choosing packaging that minimizes product/package ratio, maximizes cube use, and optimizes transportation of your product.

An integrated, environmentally friendly, corrugated company.

Corrugated containers made from 100% recycled containerboard manufactured at our two mills in Scarborough, a simple way to maximize the recycled content of your package.

We can help you sustain and increase your business with your customers!

Make us your corrugated supplier and we will help you make the grade! Service Driven!TM

“Responsive to your needs”

FEBRUARY 2012 VOLUME 65, NO. 2

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227

GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph • (416) 510-5228

AJoseph@canadianpackaging.com

ART DIRECTOR

Stewart Thomas • (416) 442-5600 x3212

SThomas@bizinfogroup.ca

ADVERTISING SALES

Munira Khan • (416) 510-5199

MKhan@canadianpackaging.com

PRODUCTION MANAGER

Kim Collins • (416) 510-6779

KCollins@bizinfogroup.ca

CIRCULATION MANAGER

Diane Rakoff • (416) 510-5216 DRakoff@bizinfogroup.ca

EDITORIAL DIRECTOR

Lisa Wichmann • (416) 442-5600 x5101 LWichmann@canadianmanufacturing.com

EXECUTIVE PUBLISHER

Tim Dimopoulos • (416) 510-5100 TDimopoulos@bizinfogroup.ca

BIG MAGAZINES LP

Vice-President of Canadian Publishing • Alex Papanou President of Business Information Group • Bruce Creighton

HOW TO REACH US: Canadian Packaging, established 1947, is published monthly by

(416) 442-5600; Fax (416) 510-5140.

EDITORIAL AND ADVERTISING OFFICES: 80 Valleybrook Drive, North York, ON, M3B 2S9; Tel: (416) 442-5600; Fax (416) 510-5140.

SUBSCRIBER SERVICES: To subscribe, renew your subscription or to change your address or information, contact us at 416-442-5600 or 1-800-387-0273 ext. 3258.

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE): Canada $72.95 per year, Outside Canada $118.95 US per year, Single Copy

Every generation has to deal with the everpresent challenging task of facing up to the future, and rightfully so. But with the world population now well over the mind-boggling seven-billion threshold—and widely expected to surpass nine billion by 2050—one could make a strong case for that challenge being more pressing at this early stage of the 21st Century than it has ever been before.

On the flipside, every challenge is invariably an opportunity in disguise; the trick for today’s CPG (consumer packaged goods) and other companies is to draw proper conclusions from the current unfolding macro trends and developments in order to shape an appropriate corporate strategy and vision.

While we dare not pretend to be expert, or even remotely gifted, futurists to be an all-knowing authority on what the world economy will look like even a couple of years down the road—never mind a decade or two from now—part of the beauty of this gig is the opportunity to listen to brilliant, knowledgeable people for whom identifying incoming macroeconomic paradigm shifts and epic changes are their bread-and-butter.

People like Richard Spear, San Antonio, Tex.based corporate vice-president for world-renowned global business consultants Frost & Sullivan, who single-handedly brought down the house with his expertly-delivered, awe-inspiring, and highly illuminating closing remarks at the end of Schneider Electric’s two-day Machines NOW conference held in Orlando, Fla., last November. (See Picture)

According to Spear, the rest of the first half of the 21st Century will be shaped by several profound so-called “megatrends”—defined as “global, sustained, and macroeconomic forces of development that impact business, economy, society, cultures and personal lives to define our future world and its increasing pace of change”—that companies, governments and other key institutions will ignore at their peril:

• Urbanization worldwide driving the accelerated development of mega-cites (population over eight million), mega-

publisher.

DISCLAIMER: This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking speci c advice from quali ed engineering professionals. Canadian Packaging

regions (over 15 million) and mega-corridors (think Boston-Washington or Windsor-Quebec City) to shape the convergence of “smart city technologies” in the core industries such as energy infrastructure, information technology, and automation/building control, according to Spear.

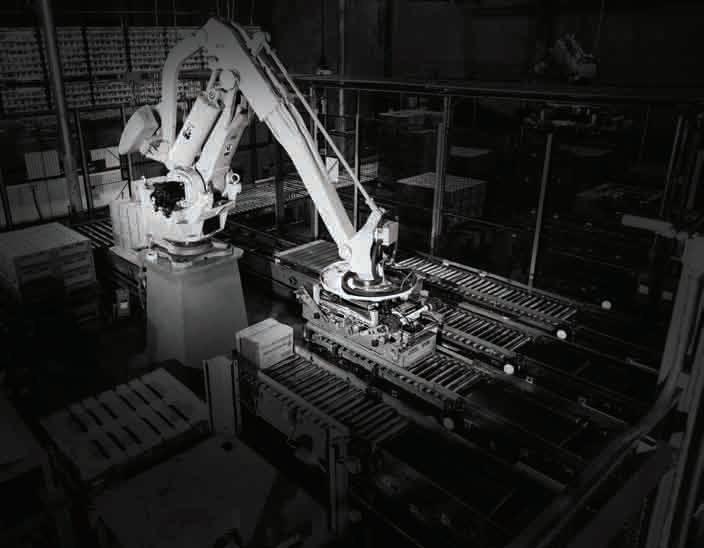

• Future Robotics. “Robotics are here to stay,” Spear declared, predicting an “incredible increase” in the development and deployment of next-generation consumer robotics that will take on the role of “pets, companions, waiters, nannies and someone to do your household chores.” On the industrial side, Spear says robots will become an omnipresent feature in space exploration, military and healthcare sectors by utilizing artificial intelligence and predictive analytical tools.

• Virtual World. “By 2020, three-dimensional simulated environments will be used to enhance both consumer and business activity, profoundly changing the way we interact with users and data,” Spear predicted. “Virtual shopping will allow consumers to try products without leaving their homes, while virtual surgeries will allow doctors to train for new types of procedures just like airplane pilots train in flight simulators today.”

• Emerging Economies. While there is no understating China’s role in today’s global economy, Spear said, “it will be important to keep an eye on places like Vietnam, Turkey, and parts of southern Europe and Africa that could be well be the next major game-changers.”

• Infrastructure Development. According to Spear, the estimated $300 billion being spent by Russia to turn its famed Trans-Siberian railway into a high-speed line is just a tiny sample of the massive, trillion-dollar future projects that will cover everything from new water desalination and power-generation plants to launching an estimated 920 new satellites into space in the next decade.

Hold on tight, dear reader, we have takeoff!

Our new wide belt conveyors allow you to create space efficient layouts and predictable production flows. The system is designed for the transportation of large individual items or large flows of smaller products. Find out more about the new wide belt conveyors and how you can use them to get the most value out of your production. Contact us today at info.ca@flexlink.com or give us a call at (905) 639-6878.

Improving on something as naturally perfect as water is no easy task, but that hardly ever stops the folks at the Puslinch, Ont.-headquartered Nestlé Waters Canada (NWC) to keep doing just that through various packaging enhancements aimed at providing Canadian consumers with healthier and more environmentally-friendly beverage options.

Earlier this month, the company has expanded its popular Nestlé Pure Life Sparkling Carbonated Natural Spring Water brand with addition of the new Sparkling Mandarin Orange flavor—adding to the existing selection of the original, lime- and lemon-flavored beverages boasting zero-calorie, zero-sugar formulations.

“Our new Sparkling Mandarin Orange features a fresh, light and natural flavor of mandarins and oranges, and it is a refreshing and flavorful beverage accompaniment for day, evening and meal occasions,” says NWC marketing manager for domestic brands Carol Guier.

“With no added sweeteners, no calories and a level of carbonation that tingles in the mouth, the Nestlé Pure Life Sparkling Carbonated Natural Spring Water family is an affordable, healthy alternative to sugared beverages—allowing consumers to stay properly hydrated, while affording them an exciting overall experience.”

Each of the brand’s four flavors is distributed across Canada by leading retailers in 100-percent recyclable 500-ml single serve and one-liter multiserve PET (polyethylene terephthalate) bottles.

Also last month, NWC has reintroduced its oncepopular, single-serve 591-ml plastic containers for the company’s market-leading Nestlé Pure Life and Montclair natural spring water brands to support its growing presence in the convenience store and foodservice market segments, according to the company.

Weighing just 13.1 grams on average, these bottles contain 18 per cent less plastic than their 591ml predecessors—discontinued in 2008—with the Montclair bottle containing at least 50-percent recycled plastic content, according to NWC, which

sources the decorative container labels for its Puslinch operations from the Rochester, N.Y.-based Hammer Packaging, with Fort Dearborn Packaging supplying the labels to NWC’s West Coast bottling operations in Hope, B.C.

“With about 30 per cent of Canadians drinking bottled water regularly, reducing the amount of plastic in our bottles is one of the best ways to reduce our carbon footprint,” says NWC group marketing manager Tracey Peake, adding the company regularly communicates the importance of recycling to Canadian consumers on its product labels and product cases, along through advertising and via its website.

“Consumers can further reduce the carbon footprint of the bottle by 25 per cent by simply dropping it into a recycling bin,” says Peake, adding that an estimated 70 per cent of all plastic beverage containers sold in Canada last year were diverted from landfill through recycling, according to the provincial environment stewards.

An active participant in funding Canada’s municipal recycling infrastructure across the country—designed to also collect glass, paper and aluminum—NWC and its industry partners were in fact responsible for the launch of Canada’s first public spaces recycling program in Quebec in 2008, says Peake, followed by introduction of a similar program and Manitoba in 2010 and completion of successful pilot programs in British Columbia, Nova Scotia and Ontario.

Good things come in threes for Lyle Small, founder of a thriving specialty inks and coatings company which pioneered and commercialized the use of temperature- and light-sensitive inks now commonly turning up on containers of beer, soft-drinks and a growing range of other consumer packaged goods as an effective, value-added packaging feature to differentiate these products from competition.

Recently selected as 2011 Entrepreneur of the Year by the Colorado Springs Regional Economic Development Corporation, Small founded Chromatic Technologies Inc. (CTI) in Ithaca, N.Y., soon after his 1993 graduation from Cornell University—where he developed temperaturesensitive inks in his dormitory room—moving the upstart business three years later to Colorado Springs, Co.

By 2007, CTI was supplying its temperaturesensitive ink to nearby brewing giant Coors as part of the beermaker’s breakthrough marketing cam-

paign—using famed slogan ‘When the Mountains Turn Blue, It’s As Cold as the Rockies!’—with color-changing beverage cans boasting the innovative ‘metal decoration’ finish applied during a fast-paced, high-speed manufacturing and packaging environment.

With subsequent development and commercialization of light-sensitive photochromatic inks, CTI briskly continued to expand its client base in both the U.S. and Canada—today including global corporate heavyweights such as Anheuser-Busch, Coca-Cola, Duracell, Monster Energy and Pizza Hut —as well as moving into the fast-growing security and anti-counterfeiting applications. Complimenting Small as “a focused visionary with a proven aptitude for innovation and adopting ideas into a meaningful advancement of technology” in its 2011 tribute, the Colorado Springs Regional Economic Development Corporation had previously selected Small as its Inventor of the Year award recipient and 2009, while honoring CTI as its Manufacturing Company of the Year in 2010.

Leading material handling and logistics equipment manufacturer and integrator Intelligrated has officially broken ground on construction of the company’s new, 108,000-square-foot headquarters building in Mason, Ohio, which will house over 450 people by its scheduled October 2012 completion. According to the company, which plans to house its newly-expanded engineering, customer service and R&D staffing and testing facilities at the new location, an incetives package worth about US$15 million in tax credits from local and state governments played a key role in getting the project off the ground. “Today’s groundbreaking is a milestone in Intelligrated’s ongoing growth as one of the most technologically-advanced players in the

material handling industry,” said chief executive officer Chris Cole. “The new building will help us continue to expand our footprint, grow our technical staff and create advanced productivity solutions ... [and] we appreciate the incentives from the state of Ohio and the city of Mason which help support our expansion.”

Bellwyck Packaging Solutions, Torontobased manufacturer and converter of pharmaceutical and specialty high-end folding cartons for cosmetic and luxury goods applications, has completed the acquisition of Ace Packaging Limited—a well-established supplier of OTC (over-thecounter) and prescription pharmaceuticals and HBA (health-and-beauty) products operating out of a 30,000-sqaure-foot facility in Toronto—from Dallas, Tex.-headquartered private equity group Generational Equity. “The acquisition of Ace is a great addition to Bellwyck, which will enable us to offer the current Bellwyck and Ace customer a broader suite of products and services and continue to expand our ‘one-stop fulfillment’ concept,” says Bellwyck’s chief executive office Jeff Sziklai.

New York City-headquartered private capital investment firm CI Capital Partners LLC has acquired the assets of the diversified Canadian packaging products conglomerate IntraPac Group for an undisclosed amount. Headquartered in Toronto, IntraPac employs over 750 people at eight production facilities in Canada, the U.S. and Costa Rica to serve the North and Central American customers in the pharmaceutical, food-and-beverage, household and industrial chemicals sectors, with its broad product portfolio including personal-care and amenity bottles, single and double-walled jars, injection-molded caps and closures, laminate tubes, tin tubes, deodorant stick canisters, and many other types of specialty rigid plastic packaging.

has been a great historical partner for us and we wanted to tighten and align that relationship even further,” says Fluke president Barbara Hulit, adding that current Martel president Tom Fatur will continue to head the Derry plant as part of the Fluke Calibration business unit.

Life sciences and industrial products group 3M Company of St. Paul, Minn., has reached a definitive agreement to acquire the Office and Consumer Products (OCP) business of the Pasadena, Ca.headquartered labeling products and technologies manufacturer Avery Dennison Corporation for US$550 million in cash. With estimated 2011 revenues of US$765 million, OCP is one of the world’s leading suppliers of printable media and related products, with vast expertise in pressure-sensitive labeling materials and technologies used to make retail and brand packaging, as well as various organization and identification products for offices and consumers. “The sale of our OCP business to 3M presents the best opportunity to maximize its value for Avery Dennison’s shareholders, and it highly complements 3M’s global portfolio,” says Avery Dennison president Dean Scarborough, adding the transaction is expected to be completed in the second half of 2012 pending regulatory approvals.

SATO Holdings Corporation, Tokyo, Japanheadquartered barcode printing, labeling and RFID (radio frequency identification) technologies group, has completed the acquisition of Argox Information Co. Ltd., manufacturer of barcode printers and scanners, portable terminals, thermaltransfer and direct-thermal label printers based in Taipei, Taiwan.

Fluke Corporation, Mississauga, Ont.based manufacturer of portable electronic test and measurement technologies, has completed the acquisition of Martel Electronics Corporation. Based in Derry, N.H., Martel is a well-known manufacturer of electronic test tools, handheld and bench calibrators, process instruments, process indicators and power supplies, which has worked closely with Fluke since 1996 in joint development of a wide range of process tools and calibration instruments. “Martel

H.B. Fuller Company, St. Paul, Minn.headquartered manufacturer of packaging, assembly and other industrial adhesives, has reached a definitive agreement to acquire the global industrial adhesives and synthetic polymers business of the Forbo Group, a Swiss-owned industrial conglomerate operating global flooring, bonding and power transmission systems businesses. According to H.B. Fuller, which expects the transaction to close in March 2012 pending regulatory approvals, Forbo’s industrial adhesive business is widely considered to be a top supplier in several markets where H.B. Fuller does not currently operate, including VAE polymers, automotive interiors and engineered textiles with reactive hot-melts.

St. Louis, Mo.-headquartered rigid packaging products group TricorBraun has acquired the assets of Santa Rosa, Ca.-based glassmaker Trilogy Glass and Packaging, Inc., which will now operates as part of a TricorBraun division specifically serving the wine industries, with estimated annual revenues of about US$120 million. According to TricorBraun, the acquisition makes it the largest North American-based supplier of wine packaging, while also boosting its logistics capabilities with a recently-opened new distribution center in Fairfield, Ca., outfitted with a US$2-million repacking system designed to automatically transfer wine bottles from eight-foot-high stacks of pallets to individual wineries’ custom, 12-bottle cartons. “Bringing Trilogy Glass and Packaging into the fold was an easy decision, as both companies operate from a ‘customer first’ perspective and have very similar cultures,” says TricorBraun’s chief executive officer Keith Strope.

The new Versa Warehouse control from Thermo Fisher Scientific is an inline scale control for demanding distribution and warehouse environments designed to obtain extremely accurate weight data without compromising robust line speeds of more than 500 feet per minute, according to the company. Employing unique algorithms designed for variable package dimensions and weight, the new software dramatically increases accuracy when weighing all sorts of packages with variable attributes, while being capable of weighing each package more than 100 times as it travels across the scale. Well-suited for line speeds up to 100 packages per minute, the control’s upgraded software also offers advanced calibration and diagnostics capabilities, along with a built-in oscilloscope to display waveforms on the control panel—enabling the operator to see a visual representation of the weight on a color touchscreen with a user-friendly interface. Boasting a rugged design to ensure optimal reliability and maintenance-free operation, as well as overload protection up to 1,000 pounds, the Versa Warehouse inline scale control can provide accurate measurement for a variety of package types—corrugated cases, padded mailers, envelopes, totes, etc.—of up to 110 pounds.

Thermo Fisher Scienti c Inc.

free design with no place for food to hide—the VLT Decentral Drive FCD 302 and the VLT AutomationDrive FC 302, the VLT FlexConcept can significantly lower the total costs of ownership by reducing the costs of stocking, storing and maintaining spare parts, according to the manufacturer.

Davis Controls Ltd. 403

401

A new modular wide-belt plastic belt conveyor system from FlexLink—designed to provide an efficient solution for the transportation of large individual items and flows of smaller products—offers full advantages of optimal design modularity for easy assembly and modifications to adapt quickly to virtually any production requirement. According to the company, every part of the conveyor system— from the smallest component to horizontal plain bends and fully-functioning conveyor modules—is standardized for easy engineering, simple maintenance and a trouble-free operation. Available as a series of selected components, modules, or a complete system offering a choice of 322-, 424- and 626-mm widths—the system can easily handle cartons, bundles, bags and other large individual items requiring the stable support of a wide chain, as well as allowing for large flows of smaller products at a brisk conveyor speed of 40 meters per minute.

Designed to ensure maximum productivity, minimal changeover times and streamlined maintenance procedures, the PrimoWeigher combination scales from CombiScale LLC feature an openframe design to facilitate easy access to all components, and it can be stripped to its core in minutes for fast-and-easy cleaning, further enhanced by tool-less buckets, chutes, pans, and center hopper. Unlike conventional four-post hoppers, the center hopper conveniently pivots out of the way to facilitate both cleaning and product changeover, and it is easily height-adjusted for different products with the removal of just one pin. The PrimoWeigher design virtually eliminates product spiraling with individual chutes positioned directly beneath each head, while NEMA 4X-rated panel housing core electronics is located remotely from the scale to eliminate the risk of moisture infiltration during washdowns.

CombiScale LLC 404

FlexLink Systems Canada Inc.

402

The new VLT FlexConcept Drive from Danfoss available from Davis Controls Ltd.—is designed as a unified and optimized drive solution specifically engineered to satisfy the efficiency, flexibility and reliability demands of the food-and-beverage and packaging industries, according to the company, and which is equally well-suited for centralized or decentralized application in dry, wet or aseptic-critical areas. Consisting of the VLT OneGearDrive —featuring a smooth, crevice-

The POPLOK trayformer from Eagle Packaging Machinery is a self-locking tray erector that erects corrugated trays without using any glue to produce virtually any type of self-locking trays, including the onetuck, two-tuck, multitack and the more intricate displays increasingly required by Club Stores and other large retailers. The machine’s versatile design enables it to erect multiple size trays on the same machine to run large or small trays, with or without a lid, and POPLOK is equipped with various handy quick-changeover features that allow for the tray sizes to be adjusted in a matter of minutes. The trayformer’s heavyduty construction includes sealed ball bearings and self-cleaning tracks in the blank transfer section to ensure clean, quiet, maintenance-free operation, while its efficient use of vacuum technology for tray extraction, top-sheet feed for positive tray control through the machine, and a high-capacity lift-table hopper that provide user with reliable durability, low maintenance requirements, and reduced cost of ownership, according to the company.

Eagle Packaging Machinery LLC 405

A new separator/stacking module developed for the A-B-C Packaging Machine Corporation‘s Model 108 bulk depalletizers allows packagers to their reduce corrugated waste by reusing their depalletizing tier sheets and picture frames. In operation, the system automatically stacks the tier sheets and top picture frames on pallets in separate hoppers for easy removal by forklift once the stacks are filled, with the palletloads then returned to the bottle suppliers for reuse. The module has a compact footprint to allow installation where the floorspace is limited or as an addition to an existing depalletizing system, with the tier sheets and picture frames securely transferred by an automated pneumatic gripper system.

A-B-C Packaging Machine Corporation

406

Manufactured by National Bulk Equipment, Inc. (NBE), the NBE 3-A , USDA -, FDA - and BISSC -compliant bulk bag filling systems are engineered, fabricated, and constructed to speed inspections, simplify integration, and ensure qualification for startup into food processing and packaging operations. These NBE sanitary bulk bag filling systems include features such as 32 Ra surface finishes to simplify cleaning; tool-less, demountable assemblies to speed inspection; 3-A compliant components to aid in sanitary standards conformance; HEPA air filtration for sanitary bag inflation; and a structural framework leak test system to facilitate clean-in-place (CIP) procedures, as well as offering NTEP-certified weigh devices to assure certified weight accuracy to +/-0.01 per cent to a 4,500-pound bag weight.

National Bulk Equipment, Inc.

407

Designed to ensure minimal film waste, Pack 301 IN inverted flowwrapper from Bosch Packaging Technology has a modular film backstand that can be located in various positions relative to the infeed and wrapper—resulting in less waste, fewer rejects and enhanced package appearance, according to the company. Well-suited for the packaging of soft products, mutipacks and other products that are difficult to handle using a traditional upright flowwrap design, the Pack 301 IN gently transports the product by carrying it on top of the film from the former through the cutting head—minimizing jams and ensuring superior package appearance. With the machine’s finwheel assembly easily raised or lowered to accommodate products of different heights and achieve short changeovers, the Pack 301 IN can easily integrate with a variety of infeeds such as flighted, lug-less, trough-style and belt feeders.

Bosch Packaging Technology

408

Protective packaging products heavyweight Sealed Air Corporation of Saddle Brook, N.J., is significantly accelerating its efforts in largescale commercialization of sustainable packaging alternatives by hooking up with bioplastics pioneer Ecovative Design LLC to speed up the production, sales and distribution of Evocative’s highly-promising new EcoCradle Mushroom packaging made from agricultural byproducts and mycelium, commonly referred to as “mushroom roots.”

Founded in 2007 at the Rensselaer Polytechnic Institute in Troy, N.Y., Ecovative specializes in adapting living systems to create novel biomaterials and products—many of which have already been successfully adapted by some leading Fortune 500 companies for products that went on to win prestigious international packaging awards, including the DuPont Packaging Innovation Diamond Award, the Greener Package Innovator of the Year award, and the Popular Science magazine’s Best of What’s New award.

“Ecovative is extremely excited to be partnering with Sealed Air to bring EcoCradle packaging to a worldwide audience,” says Evocative’s chief executive officer Eben Bayer, describing EcoCradle Mushroom as a cost-effective, homecompostable protective packaging made entirely from renewable, non-food agricultural materials.

“Over the last five years, we have established ourselves a leader in sustainable, cost-effective biomaterials, and so we are thrilled to combine this with Sealed Air’s global sales network, strong packaging design capabilities, and world-class supply chain,” Bayer relates.

“Together we are furthering our vision and broadening our impact, providing an innovative and effective alternative to petrochemical-based packaging at a much larger scale.”

Widely renowned in global packaging circles as inventor of the original BubbleWrap protective cushioning, Sealed Air’s annual revenues of US$7.6 billion, a workforce of more than 26,000

employees serving customers in 175 countries, and strong R&D (research-and-development) commitment embodied by some 35 dedicated Packaging Design and Development Centers, operated by the company’s Protective Packaging business unit, make it ideally-positioned to take EcoCradle Mushroom packaging to the next level, according to Ryan Flanagan, president of Sealed Air’s Protective Packaging division.

“We are very excited by the prospects of working with Ecovative,” Flanagan states.

“This entrepreneurial team has created a fundamental new material technology, using the unique properties of mycelium, to provide new solutions to packaging, as well as other, applications.

“Ecovative has been able to use its science to manipulate material properties by varying density, strength, texture and appearance to meet different performance needs of a variety of customer applications,” adds Flanagan, “and coupling Ecovative’s technology with Sealed Air’s packaging knowledge and infrastructure will allow us to accelerate this innovation to meet our customers’ needs.”

Being your own harshest critic may not be everyone’s idea of a good time, but when you set your standards as high as The Coca-Cola Company has in terms of its sustainability targets, a little self-criticism may be in order from time to time.

And according to the Atlanta, Ga.-headquartered soft-drink giant’s eighth annual Sustainability Report released earlier this month, the company’s environmental performance to date merits a self-declared B+ grade, based on its first use of the disclosure and reporting requirements of the Global Reporting Initiative (GRI) metrics in the 2010/11 report, which is available online in its entirety at www.thecoca-colacompany.com/ sustainabilityreport

“Sustainability has been core to our business

strategy for nearly 125 years,” says Coca-Cola’s chief sustainability officer Beatriz Perez. “After receiving feedback from a variety of stakeholders, we decided to make some significant changes to our sustainability reporting efforts.

“In addition to increasing transparency within the content, we have taken a digital approach to make the report more user-friendly and accessible on a variety of mobile devices,” Perez adds. “As we continue to strengthen our sustainability efforts, we also will innovate the means by which we share our progress.”

According to Coke, reporting against the new GRI G3.1 key performance indicators in the areas of economic, environmental and social performance originally led it to give itself a B grade,

• Increase the flexibility of your robots by adding the ability to use more than one end-effector in an application.

• Production line tooling changed in seconds for maximum flexibility.

• Change tools in seconds for maintenance and repair.

• Increase operator safety by changing tools automatically.

• Million-cycle tested for reliability.

but a following third-party verification resulted in a slight upwards revision to an overall B+ ranking.

Some of the key performance highlights from the company’s 2010/2011 Sustainability Report —providing an in-depth review on the sustainability efforts of Coca-Cola and its nearly 300 bottling partners—include:

• Growing worldwide use of the company’s breakthrough PlantBottle containers (see picture), which replacs 100-percent petroleumbased PET (polyethylene terephthalate) plastic with PET plastic that contains up to 30-percent plant-based material content.

“In 2010, we distributed 2.5 billion PlantBottle packages in 10 major markets, saving more than 60,000 barrels of oil and sequestering the equivalent of nearly 30,000 metric tons of carbon-dioxide from our PET plastic bottles,” the report states. “By the end of 2011, PlantBottle packaging was available in 20 markets, and nearly 10 billion PlantBottle packages had been shipped to date.”

• Improved water efficiency performance for eight consecutive year by “reducing the average amount of water required to produce each beverage serving,” according to the report.

“As of the end of 2010, we had achieved 93-percent alignment, and by the end of 2011 we estimate 96-percent alignment with our stringent standards.”

• A two-percent reduction in global carbon emissions in 2010, despite growing production volumes.

Packaging sustainability is ultimately a team sport, in which the most memorable goals usually tend to be scored through committed teamwork, as renowned German high-end appliance manufacturer Miele recently demonstrated with its groundbreaking use of a new, jointly developed process and film technology used to protect the company’s high-end washing machines.

Developed through a collaborative project between the Wilmington, Del.-headquartered DuPont Packaging & Industrial Polymers, German-based packaging equipment manufacturer Zappe Verpackungsmaschinen, and specialty films producer jura-plast of Reichenschwand, Germany, the new-generation skin film has recently been put to use at Miele’s assembly plant in Warendorf to prevent high-gloss, thermoplastic bezel surfaces of the washing machines from getting scratched as they make their way through the fully-automated assembly line to retail and, ultimately, to the end-user’s home.

So far, the tailored skin packaging process has been credited with helping significantly reduce rejects and associated raw material waste, while the material’s use of DuPont’s hightransparency Surlyn packaging polymers is said to offer considerable energy savings in the film’s manufacture, compared to converting polyethylene,

Both the skin-film itself and its production residue can be recycled in the polyethylene wastestream, according to jura-plast’s managing director Jürgen Müller.

“The development of this film has resolved two issues,” he explains. “The special formulation of the base layer made from Surlyn ensures that there is no formation of air bubbles between the component surface and the film, which would otherwise spoil the high-quality appearance of the bezel.

“Moreover, thanks to its combination with a modified adhesive resin from DuPont, adhesion between the component and the film is sufficiently high for the fully-assembled washing machine door, weighing around five kilograms, to be transported using vacuum grippers.

“Yet the consumer is still able to easily peel off the film without leaving any residue behind.”

Ulrich Zappe, managing director of the family-owned Zappe Verpackungsmaschinen, credits Surlyn’s exceptional thermoforming properties for helping make the project—originally using traditional polyethylene as base ingredient—such a resounding success.

“Thanks to its chemical structure, Surlyn remains very melt-stable and tough even when heated,” he explains. “This is particularly important for three-dimensional components, as it enables very high draw ratios without the risk of the film tearing at the edges.

“It was only by switching to Surlyn that we could deliver the high process reliability required by Miele,” states Zappe, whose company manufactures high-quality shrinktunnels, skin-packaging machines and thermoforming equipment.

Says Zappe: “This time-, material- and energysaving technology is highly suitable for the protection of almost all three-dimensional molded parts with susceptible surfaces—regardless of the substrate material.”

Applied using a modi ed skin- lm process, the combination of a highl-transparency base lm derived from Surlyn and a specially-tailored adhesive resin, both from DuPont, provides reliable protection for susceptible components from their assembly right through to their rst use by consumers.

Back in the day

Since 1950 the packaging community has been connecting through their favourite watering hole – PAC. Over the decades it has been the go-to place for thousands of industry folks to meet and greet, embellish fish stories and exchange packaging ideas. To most it had been to network and a fraternity was formed. Small, medium and large companies of all shapes and sizes were welcome. People actually met face to face. They had no other choice if transactions were to occur.

Sales people were schmoozing buyers, engineers looking for new widgets, while entrepreneurs were on the prowl for the next big deal. Often deals were made on the back of a napkin during the two hour martini lunch or in the golf cart on the back nine. Many lifelong friendships were created. Those were the good old days and PAC was the place Where Everyone Knows Your Name

Letterpress still existed; gravure was a primary process while offset was rapidly growing but with crews of five. Steve Jobs hadn’t created the MAC and you had to use a dime for the pay phone. Tens of thousands attended trade shows. Technology breakthroughs were UPC codes and strippers were lithographers found in the graphics house.

PAC was founded on the premise of advancing the packaging movement in Canada. Packaging was a relevant and important element of business. Millions of dollars were spent on raw materials, packaging containers, packaging machinery and ancillary services. PAC gave the community a voice at the table. Packaging shows, technical seminars and national conferences, packaging competitions, golf tournaments and government relations described the value proposition.

Gen Y Era

Jump to today and relationship building and communication has drastically changed. People no longer have time to socialize and business is done promptly in thirty minute sound bites. Many corporations do not allow their employees to fraternize with their supplier. Lunches, hockey games and the golf course are strictly verboten.

Communication is left to the Blackberry or IPhone, exchanges on Facebook or LinkedIn, or in tweets of 140 characters or less. Webster defines tweeting as “a chirping note”. We have become a bunch of chirpers. Many have a hard stop on their meeting so that they can dial in to their next webcast; in between they may send off several BBMs or tweets. We live in a world of instant gratification.

All graphics are digitized and strippers are obsolete (certain clubs excluded of course). QR codes are the new bar codes and smart phones the scanning devices. Printing presses are manned by one computer trained operator and flexography and digital are the fastest growing processes. Private label has become retailers’ primary product and CPGers spend as much time on recovering discarded packaging as getting products to market. Everyone is more sustainable than the next guy. Extended producer responsibility is the force de jour. Food safety is an important topic throughout the supply chain.

Today the packaging community is defined in terms of $ billions. The marketplace is North America and often with global reach. Retailers are more powerful than ever. Walmart, McDonalds and Tim Horton’s didn’t exist in 1950 but are members of the PAC today. Many long term industry folks work for the same company but the name has changed three times and is now owned by private equity. Many have not avoided being right-sized.

But this is what hasn’t changed: PAC is more relevant today than in yesteryear. PAC remains the conduit that brings everyone together to talk about packaging and its respective issues. Our core values are now defined as Sustainability, PAC NEXT, PACed, PACsecure and Networking. And of course PAC is on LinkedIn, on Facebook and chirping, uh excuse me … tweeting. It’s still the go-to place Where Everyone Knows Your Name. They just might not know your face. Join the PAC today.

D

President & CEO, PAC

“Harlund Industries has been a member of PAC since 1987. Why? Its primary asset is the end-to-end supply chain of PAC membership. No one brings the entire packaging community together like PAC. As a member I get discounts for space at PACEX Toronto. It is up to me to make the sale but PAC creates the forum to facilitate the relationship building. As a small business owner I need all the help I can get and PAC is a great broker.”

“Our membership in PAC has been extremely helpful in new business development and brand awareness. We value our association with PAC so much that we have sponsored many of their events over the years, such as their annual golf tournaments and various education seminars.”

McGregor, President b2 Retail Solutions

“Innovolve has been a very satisfied PAC member since 2008. During that time, the Association has provided significant opportunities for connecting with sustainability innovators along the packaging value chain. Whether it’s the biennial national conference, the summer golf tournament, or any number of the creative initiatives such as the Green Den or PACNEXT, PAC consistently delivers value such that non-renewal is not an option.”

JOSEPH,

Sometimes a fresh new start is what a company needs to rediscover its market mojo—even if that means starting totally from scratch.

For Henryville, Que.-based Viandes VP Meats, that rejuvenation process could not have commenced under more troubling and disastrous circumstances—namely a devastating fire that completely destroyed what was at the time a spanking-new, state-of-the-art, 45,000-square-foot production plant, freshly certified as a federal facility by the Canadian Food Inspection Agency (CFIA) to enable the company to expand its markets outside of Quebec to other Canadian provinces.

“At that time we were only able to sell our products within the Province of Quebec due to our [former] facility’s certification,” company president Guy Paquette told Canadian Packaging in a recent interview, referring to the company’s original, 10,000-square-foot production plant that was already running at full capacity, offering virtually no room to grow for a business that clearly had its sights on expanding its marketing reach in a major way.

Originally founded in 1985 by four Paquette brothers—Guy, Robert, Jacques and Mario—the upstart company was in many ways the siblings’ way of paying tribute to their father: a self-employed professional butcher who eventually expanded his craft into a successful grocery store enterprise.

With business going briskly over the years, the company relocated a couple of times to accommodate growing volumes, making a fateful decision to construct a brand new building from which it could proficiently serve the entire Canadian market and beyond.

“Since we wanted to expand across Canada, we

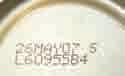

simply had no choice but to construct ourselves a new facility that would allow us to not only increase our capacity, but also our market base and reach,” Paquette relates, recalling the massive fire on May 7, 2009, which gutted the entire facility just prior to its official opening.

“We were lucky that no production had begun at the facility at that time, and that no staff were inside,” states Paquette.

“The only thing we could do after getting over the shock was to start building again.”

And much along the lines of the mythical phoenix rising from the ashes, build again they did—constructing a brand new greenfield, $16-million facility over about 10 months to restart the company’s production in late 2010, according to Paquette.

Currently employing 85 full-time people, the

82,000-square-foot, fully HACCP (Hazard Analysis Critical Control Points) -certified building is not only an impressive physical structure—housing elaborate processing equipment used to turn over 30,000 kilograms of meat per week into a broad range of valueadded beef, pork, chicken and veal products—but it is also a showcase of environmental manufacturing sustainability, according to Paquette.

“When the fire completely destroyed our plant, we didn’t want to simply rebuild—we wanted to redesign it and make it into an environmentally-friendly facility that everyone could be proud of,” states Paquette, complimenting the phenomenal architectural work turned in by Michel Pérusse Architecte during the design and construction stages.

“We tried to examine every detail of the building to see if we could improve the quality of the workplace while simultaneously bolster the building’s energy performance.”

One of the key features of the VP Meats facility is its new Eco Chill ammonia and glycol-based refrigeration unit—manufactured by Torontobased CIMCO Refrigeration a division of Toromont Industries Ltd. of Concord. Ont.— that not only helps with the quick freezing of the products, but also aids in the lowering of energy consumption within the facility by collecting and recycling the heated energy from the refrigeration

Continues on page 14

unit, and then reusing it to warm the flooring on the loading docks and the employee terrace.

“This new heat recovery system is able to reduce our energy dependence by some 2.5 million kilowatt-hours per year,” notes Paquette, adding that by using ammonia and glycol, the Eco Chill system completely eliminates the need to use freon, a gas known to be harmful to the ozone layer.

The building is managed by 760 energy control points and uses a water recovery system that helps VP Meats save thousands of gallons of water per year, according to Paquette, reasoning that a production plant that provides for a cleaner environment profile also naturally provides for a cleaner and healthier environment for manufacturing the company’s products.

Now generating annual sales of over $10 million, the new plant currently operates one shift over a five-days-a-week schedule, the company is considering adding a second line to keep up with the production demands, as well as for an impending launch of a new, ready-to-eat meals project VP Meats has planned for the near future.

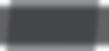

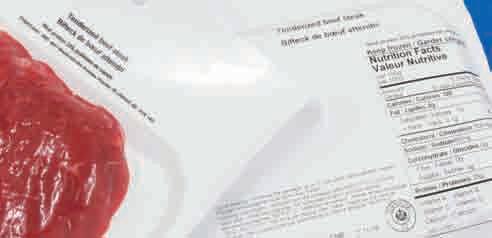

Boasting six processing lines and eight packaging lines—three skin-pack; two thermoskin-pack; and one each of thermoforming, vacuum-sealing and MAP (Modified Atmosphere Packaging)—the new VP Meats facility was installed with what Paquette calls “the newest and best equipment in an effort to not only provide a better workplace for our employees, but to also provide a safer product in a better quality package for our customers.”

Paquette says that 90 per cent of VP Meats’ output is currently sold via its own flagship Delectables brand at the company’s Viandes VP Meats shop, with the balance of production co-packed for clients throughout Canada, the U.S., Central America, the Caribbean, Mexico and Russia.

Naturally, product safety takes paramount priority at the VP Meats plant, which took care to reduce the chances of any accidental product crosscontamination by separating its chicken production area from the other meats production lines, as well as adding a high-performance air filtration system to remove dust and smells from within the facility, and then thoroughly filtering it to eliminate foul

The Multivac R 275 CD thermoformer is used to create DARFRESH vacuum-skin packaging. (Inset ) VP Meats uses the Labelstar PLUS software system from Carl Valentin to produce its own graphic label designs.

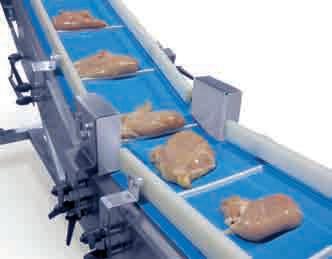

A Greydon complete line printing system, including a S-107/128 Series printer (right ) produces a nished package (above) with application of nutritional data, production codes, cooking instructions, product name and other product information.

odors from escaping out the building’s exterior.

According to plant manager Alain Daigneault:

“The new facility exceeds current CFIA standards.

“It features a cutting edge computerized tracking system for products in case a product recall happens; it has a cooking room that meets the highest standards in hygiene; and we have even made sure that the water we used during the manufacture of our products is treated and filtered via an ultraviolet (UV) ozone-coal process,” Daigneault explains.

As a company specializing in providing controlled portion cuts of its beef, chicken, pork and veal products to grocery stores, supermarkets and the hotel and restaurant segments, VP Meats has always required precise portioning of its products and safe, reliable packaging.

After the portioned meat cuts go through all the stages on one of the eight packaging lines, the meat packages are conveyed to the plant’s freezing system via an inhouse-designed vertical conveyance system powered by eight SEW-Eurodrive motors.

The plant’s new freezing unit can handle between 8,000 and 10,000 kilograms of meat per hour, Daigneault relates, which is moved along the two spiral conveyors and five quick-freeze blast freezers that cool the products to the appropriate temperature within 15 minutes to avoid crystallization between the meats and the package.

“Ultimately, the goal behind great packaging like this is to ensure the vitamins and nutrients are sealed and not lost during the packaging process,” explains Daigneault. “And our new cooling system is cooler than cool!”

Designed and built in Canada by Busch Vacuum Technics, the VP Meats plant’s new central vacuum system employs five high-efficiency vacuum pumps located remotely off the production line floor in a configuration that provides many key benefits, including:

• Higher productivity, because the machines can run at faster speeds as additional vacuum capacity is installed;

• System fail-safe in case of pump failure, as production is reduced but does not stop.

• Heat load reduction to enable considerable energy savings in the refrigeration system.

• Lower maintenance costs, thanks to pumps not being exposed to daily washdown. Because the pumps are now kept remotely in a warmer room there is less internal condensation, according to Daigneault, adding that the purchase of the expansion module allows for any pump to be shut down for service without interrupting production by having the other pumps pick up the temporary slack.

• Reduced noise levels on the shop floor, thanks to the pumps being centralized in a separate room.

• More floorspace in the production area and improved layout efficiency. Says Robert Laforest, national sales and marketing manager at the Boisbriand (Montreal) office of Busch: “The innovative meat-processing plants are always on the lookout for ways to increase production line efficiency.

“Utilizing the correct vacuum generation system not only improves their cost-effectiveness, but also provides for a better all-around package,” says Laforest, adding that removing all

Continues on page 16

Repak horizontal form-fill-seal packaging machines from Reiser offer the best sealing integrity in the industry. Only Repak machines are constructed with two 4-point lifting stations, which can generate up to five metric tons of closing pressure for reliable sealing and more uniform forming. No matter how complicated your package, Repak will produce it perfectly. For more information, contact Reiser today at (905) 631-6611

vacuum generators from the packaging room effectively eliminates the risk of potential cross-contamination of the food products through oil aerosols.

“An added bonus is that for standard maintenance or repair work, employees do not need to enter the packaging area, enabling the room to maintain its hygienic conditions,” says Laforest, noting that the R 5 series vacuum pumps developed by Busch have become the global standard used by food vacuum packaging machines.

Originally developed by company founder Dr. Ing Karl Busch back in the 1960s, Busch vacuum systems have over the years evolved into the bestof-breed vacuum technology of choice for meat processing operations.

Because VP meats utilizes eight high-speed vacuum packaging machines, Busch advised the installation of a combination of both rough and fine vacuum systems for the facility.

According to Busch, individual packaging chambers of the various vacuum packaging machinery are pumped down in two stages to allow it to run at maximum cycle frequencies.

Utilizing a fully-automatic centralized vacuum system, Laforest says, activates individual vacuum modules whenever a greater vacuum is required. Conversely, it can switch off individual vacuum modules should a less powerful vacuum be required.

A failsafe in the system also allows for a reserve pump to be automatically activated should a vacuum pump fail at any station, allowing the rest of the vacuum generating system to continue working for all the packaging machines.

With regards to maintenance, the centralized Busch vacuum system was designed to be modular, meaning that when an individual vacuum segment is taken off-line for maintenance, a reserve unit

automatically kicks in.

“It means that maintenance can be carried out here in the upper floor where the vacuum system is housed without any affect to the production line,” exclaims Daigneault, adding that because of fewer running hours, the individual rotary vane vacuum pumps are subjected to less force relative to individual units, thereby extending the maintenance intervals.

Daigneault was also quite high on the company’s Greydon, Inc. printer systems on the production lines.

“Our marketing philosophy was for us to move forwards to create the nicest CFIA-approvable retail package of vacuum packed meat portions with improved visuals on the front side while still being able to conform with the new regulations of providing product information on the back without having to utilize too much of a paper label that might hide the packaged meat portion,” explains Daigneault. “Greydon helped us achieve that goal.”

Greydon installed three complete line systems, including six S-107/128 Series printers, three labelers, three Advance Trax and three complete bracket systems.

Greydon was also asked to design and manufacture a complete printing system to allow VP Meats to produce a finished package for the fresh deli meats products, including all of the governmentrequired data such as the product description, contents, nutritional facts, production codes, expiry dates, and a scannable barcode for 200 SKUs (stock-keeping units).

According to Greydon vice-president John Rochon, “In order to achieve these goals, we needed to mount the printers to the back of the packaging machines.”

Each of the six S-107/128 Series traversing thermal transfer printers can print a five-inch pro-

grammable message across the width of the web.

In addition to a cross-web labeler, each of the three printing lines uses an Advance Trax unit that employ a series of gears and rollers to move the web independently from the packaging machine during the dwell cycle to enable an additional second row of printing.

Rochon explains that on each line, the first thermal-transfer S-107/128 Series print: the ingredients, nutritional facts, lot and expiry date, and the barcode directly onto the outside of the bottom of the film web.

The cross-web labeler then adds a generic label on the top side of the bottom web. The second thermal transfer unit then prints the product description onto the top of the label to provide a finished product.

“VP Meats can print over 200 different product labels with one bottom web film and one generic label to eliminate the need for any expensive preprinted films and labels,” says Rochon. “It also helps reduce the long lead times.”

Daigneault concurs: “It was also key for us that VP Meats be able to print directly onto both sides of the package and/or be able to print on a header label and apply it positioned perfectly onto the package header.

“It is all controlled within the system’s memory for each of our 270 different SKUs.”

The Greydon systems utilized by VP Meats employ the Labelstar PLUS graphic label design software, designed by Carl Valentin GmbH , which allows processors to easily create and modify their packages as needed.

Another challenge for VP Meats was that the Greydon systems had to be fitted to the new packaging machines like the Multivac R 275 CD, a Reiser Repak RE 20/6, and to the existing Reiser DixiePak DP-50E skin packaging machine.

“We didn’t realize at first that our list of require-

ments for these systems was so sophisticated, but we were fortunate to have knowledgeable Greydon specialists in Montreal who came up with a solution that not only met our project requirements,” explains Daigenault. “Greydon was also able to offer added features such as bottom film registration control; web shifting to accommodate all of our rollstock machines dividers; film dusting with static control; one-color fully programmable surface side printing of the package including logos, nutritional facts, ingredients; and whatever else we need or want, like one-color registered printing on the header side of the film and/or the label with a registered label applicator.”

Daigenault says that when he and his colleagues had an opportunity to travel to Germany to see and operate a Multivac thermoform packaging machine, they walked away thinking it was perfect for their needs.

The visit led to a purchase of a Multivac R 275 CD thermoformer which VP Meats uses to create the DARFRESH vacuum skin packaging process utilizing DARFRESH films manufactured by Sealed-Air’s Cryovac division.

The new DARFRESH process utilizes special top and bottom films that, when applied via the R 275 CD thermoformer, create a vacuum skin that surrounds and seals the product to not only provide the consumer with a true shape and a visual of the product’s texture, but it also provides a longer shelf-life with a highly durable cover.

The R 275 CD thermoformer works by evacuating the air from the chamber that causes the top film to move to absorb heat and to form a dome. After a gentle airflow is introduced, the top film relaxes so that it can flow over the product to the bottom film or tray, as in the case of VP Meats.

When the dome opens and the top web contracts, it provides a skin-tight barrier that follows the product’s contours. Finally, the top and bottom films are then heat-sealed to each other by the Multivac thermoformer right up to the product’s edges to ensure a safe and hygienically-sealed pack.

The stainless-steel Multivac R 275 CD has been designed specifically to work at medium- to high- volume vacuum processes.

“We can run the R 275 CD at up to 10 cycles per minute,” says Daigneault, “but since the machine can process six products at a time, it actually packs up to 60 packs a minute.

“That is very fast,” he says, “and is one of the reasons why we have been able to double our production in the past year, and hope to double it again in 2012.”

The R 275 CD thermoformer provides

the user with a smooth, sloping IP 65 hygienic design without recesses, corners or sharp edges to make it easy to do a full washdown to the inside and outside of the machine. It also boasts easily accessible side panels to clean, and sufficient space to allow thorough cleaning of all equipment parts like the chain guide, chain and motors.

And according to Multivac, the R 275 CD, like all of its thermoformers, is certified for numerous international hygienic standards.

Says Daigenault: “We bought the Multivac R 275 CD in 2009 for a variety of reasons, including the hygienic benefits it could offer, and we have not been disappointed.

Meat skewers (right) in skin-packs are packaged via a DixiePak DP-50E thermoformer supplied by Reiser. Cryovac DARFRESH thermoskin packs of minced meat (below) are produced on a Reiser Repak RE20/6 machine.

The plant also employs a Multivac T 350 traysealer, likewise purchased in 2009, to perform MAP for its natural and marinated beef, chicken, pork and veal product packs.

“While the R 275 CD is used heavily for our Delectables brand, we use the T 350 to pack product for our contract packaging customers,” explains Daigneault. “While it generally only runs at about six cycles per minute, it provides the perfect package our customers desire, and keeping the customer happy is always a good thing.”

Another line at VP Meats utilizes the Repak RE20/6 horizontal form/fill and seal packaging machine, purchased in 2009 from Reiser

“Along with that, we have been very happy with its ease-of-operation, and have also been impressed with how quickly it packages our products in a form that is visually appealing to the customer.”

Production-wise, the R 275 CD is simple to operate with a touchscreen control panel that features a data acquisition and storage feature to make repeating package designs quick and easy to setup.

Featuring strong and reliable lifting systems, the R 275 CD offers a maximum cut-off length of 640 millimeters.

Canada, that is used to create vacuum skin-packs and thermoskins.

Constructed from stainless steel, the Repak RE20 utilizes its compact modular design to provide a simple way to perform a full hygienic washdown process to prevent the accumulation of water, cleaners or particulates.

The Repak RE20 uses the rapid air formation process to fully distribute the web throughout the product, with an efficient use of film that can pro-

Continues on page 18

from page 17

vide the user with thinner film applications that can save it some 20 per cent in cost.

Considered to be a small machine, Reiser nonetheless ensured that the Repak RE20 has been constructed in the same exacting manner as the larger machines, utilizing the same reliable die-lift technology, the same strong frame design, and the same operator-friendly interface.

Other important equipment at VP Meats includes the rugged stainless steel Reiser Rotoclaw II frozen meat block breaker that breaks up frozen chunks of meat without damaging the product’s texture, thanks to its low-speed rotor that breaks the block into smaller pieces.

Able to handle frozen blocks up to 9.5-inches-thick and 21-inches-wide, the Rotoclaw II can, depending

The frozen-meat

on the piece sizes, process up to 4,540 kilograms of product per hour without generating a lot of noise.

In adition, Reiser also sold VP Meats its Vemag MMP220 ground meat portioner that automatic-

GC 4200 Wet Ink Printer

• prints in register on multiple rows.

• 100mm x 50mm print area.

GC 225 Wet Ink Printer

• low cost, high quality.

• made of ertylyte which doesn’t corrode and is half the cost of stainless steel.

• rugged washdown performance at half the cost.

Ink Jet Traversing System

ally places ground meat onto paper to convey it to a vertical cutting blade that portions it consistently in a uniform shape and to an accurate weight.

For its part, the newly-purchased Vemag HP20E vacuum filler for sausages uses a positive displacement double-screw pump to quickly and gently provide accurate portion control.

“We have had great service from Reiser,” says Daigneault, noting that Reiser also supplied two Fomaco FGM26 injectors for meat marinating;

• a Seydelmann AE130 meat grinder;

• a pair of tumblers manufactured by Henneken and Amfec;

• a Reiser Repak RE15 form/fill/seal packaging machine.

Another company that has impressed Daigneault is S+S Inspection, a prominent food inspection systems manufacturer, who worked with Bizerba Canada to install nine new metal detection units at the facility.

S 128 Thermal Transfer Printer

• split platen allows for registered print on 2 rows without having to use a second printer.

• all new housing for washdown.

• very economical ribbon use.

• works with all major ink jet brands.

• traversing system moves in the X and Y direction and carries an ink jet printer to print codes on several rows of packages.

Greydon coders are built to be rugged and exible in the harshest washdown food plant conditions.

Parts and service available across Canada. Don’t settle for anything less.

Phone: 717-848-3875

“They provide us with another boost of high-level confidence in knowing that our products are safe,” says Daigneault. “We have nine of them because we trust them to do the job.”

Coming full circle to its roots, VP Meats has set up its own grocery store in nearby Saint-Jean sur-Richelieu as a tip-of-the-hat to the hard work and dedication of their father’s profession.

“While the shop does sell a host of other meat products, it is also an excellent showcase for many of our Delectables products,” sums up Paquette. “And while I am proud of this shop, I am also very pleased with our processing facility that enables us to keep this shop and those of our customers with our great products in great packaging.”

Vivo! Touch Label Printer Intelligent Color Labels at Your Fingertips

Barcode Printers with Lifetime

The new Vivo! Touch is the first intelligent photo-quality label printer, capable of dynamically printing fullcolor labels on-the-fly directly from your production system or other database. The Vivo! Touch prints labels quickly, at up to 5 ips (25 feet per minute).

You can print labels at the touch of your fingers from its touchscreen interface, and even print labels without a computer, in standalone mode. This LED printer uses a unique micro-fine CMYK toner system and proprietary halftone screen to make beautiful labels with accurate color and precise dot placement.

Toll-Free 800-565-2216

QuickLabel.ca/Vivo

QuickLabel’s Xe series of thermal transfer color label printers can print color labels print in real time, ondemand or in batches. Designed to be integrated in-line with an existing packaging system, and to print labels from ERP systems such as SAP. Labels print with unique, product-specific content that varies from label to label such as color codes, barcodes, logos, expiration dates, best-by dates, and other serializing text, prompted fields, and databased information. Programmable host protocol, applicator mode, and “peel off” option. Prints labels and tags at speeds of up to 7 ips.

Toll-Free 800-565-2216

QuickLabel.ca/ Color

Need labels printed fast? Our QuickPrint™ Service will custom-print labels for you using QuickLabel digital label printers. Small quantity printing, fast turnaround, low minimum order, artwork assistance.

Toll-Free 800-565-2216

QuickLabel.ca/QuickPrint

QuickLabel’s Pronto! Barcode Printer Family offers more: built-in Ethernet, built-in web server, and high-speed and high-resolution barcode printer models. Printers come with Lifetime Warranty, QuickSwap™ Loan & Replacement Service, and 24-Hour Technical Support.

Toll-Free 800-565-2216

QuickLabel.ca/Pronto

Want a competitive quote on labels and ribbons? We offer low prices because we’re the manufacturer of our ribbons and barcode labels. We have more color thermal transfer ribbons than anyone in the world, including metallic gold, silver, white, and a rainbow of colors.

Toll-Free 800-565-2216

QuickLabel.ca/Quote

We’ve made history – of label printers that don’t allow you to “print your own color labels” from your production system. We’re introducing an intelligent label printer that allows you to print labels just as you would with a barcode printer – but in full-color, photo-quality:

>> Print labels directly from the touchscreen

>> Print in photo-quality, even at 5 ips

>> Print rolls of die-cut labels in any shape

>> Make more money with easy private labeling

>> Dynamically print color labels on the fly from any database

The Vivo! Touch puts intelligent label printing at your fingertips –from its touchscreen – and gives manufacturers the in-plant label printing flexibility you’ve been waiting for. To schedule an in-person demonstration, go to QuickLabel.ca/demo.

Tony Rabinovitch, Vice-president, Pelmen Foods Ltd.

JOSEPH, FEATURES

When people think about perogies, most Canadians will often think about comfort food as it should be—shapely pieces of soft, yummy cooked dough filled to capacity with cheese or potato stuffing. But they would only be partially correct, according to the folks at Pelmen Foods Ltd., an entrepreneurial, Toronto-based food processor who wants to spread the word that the comfort aspect aside, the growing varieties of different types of perogies available in grocery stores nowadays offer Canadians a whole new breed of authentic, European-style cuisine made from all-natural products.

Known as an old-school Eastern European specialty, perogies are half-circular dumplings of unleavened dough traditionally stuffed with meat, potato, cheese, sauerkraut, spinach or mushrooms, but this highly versatile food can also leave your tastebuds dazzled when made with raspberry,

blueberry, peach, plum or any other fruit filling, as Pelman Foods has in fact done for many years— albeit for a fairly limited audience.

“Pan-fried or boiled, served as an entrée, appetizer, snack or a dessert perogies are a tasty and convenient food to eat,” Pelman Foods vice-president Tony Rabinovitch told Canadian Packaging during a recent visit to his company’s new, 15,000-squarefoot facility near the city’s lakeshore.

Along with perogies, Pelmen also specializes in a dish called pelmeni—hence the company name— which is a traditional Russian staple food of doughwrapped dumplings filled with various meats and spices, which can in fact be eaten hot in its broth or as a cold dish after it has been cooked in water, usually with sour-cream

According to Rabinovitch, who hands-on operates the family-owned food processor, Pelmen Foods employs 15 full-time people to create a total 23 different SKUs (stock-keeping units) of perogies, pelmeni, dumplings, pot stickers, samosas, egg rolls, gyozas, curry puffs and empanadas under its own flagship brand name, as well as for privatelabel sale across North America.

“For private-label concerns, we have a reputation for being flexible and clientoriented,” reveals Rabinovitch.

“We will work closely with our cus-

Pelmen Foods uses an Eagle Pack 240 X-Ray system from Smiths Detection to act as a secondary checkweigher to ensure precise, contaminant-free lls in every bag of product.

tomers and all their stringent requirements with respect to choosing the proper ingredients, formats and packaging—all the while ensuring they get the perfect taste.”

Despite the company’s success making and selling perogies to date, Rabinovitch relates that his family’s involvement in the industry was perhaps due more to luck than to some ingenious business plan or design.

“My father, Jeff, had worked as an electrical engineer for the only bakery in our city of 300,000 people back in Russia, and as such, he learned how to fix all sorts of bakery equipment,” he recalls.

“When we emigrated to Canada back in 1993 and he found himself ‘between employment,’ a family friend who was already making perogies and supplying them to a local deli asked if my father would take over the business for a couple of months, while she took care of some personal interests in Israel,” Rabinovitch recounts.

“So in January of 1995 my father gave her a $300 deposit for a pasta roller, dough mixer and a small freezer chest, and he began making perogies following her recipes to sell to the deli, and because she never came back to claim her business, my father kept on making perogies, with time switching to our own family’s delicious recipes, and then tweaking them based on his own professional expertise and knowledge.”

At that time, Rabinovitch reveals, business was conducted right in the family home—initially a small apartment in Toronto’s north end, followed by a move to a larger rented house in the city, where the family continued to crank out its perogies for its mostly ethnic deli customers.

After a series of similar moves to slightly larger nonresidential premises, in 2010 the company finally decided that taking its business to the next level would require Pelmen Foods to reduce its dependence solely on Russian and other East European-

style deli shops by moving into the mainstream national grocery segment of the food industry.

To execute this new vision, Pelmen transferred its perogies manufacturing business into a new production facility in Toronto’s west end—purchasing all-new, state-of-the-art equipment and creating a new packaging look for the store-shelves to match the high-quality products proudly manufactured by the company.

“Packaging-wise, Pelmen moved away from the traditional look of a clear plastic bag containing the perogies because to me, that is the look everyone already has in the frozen perogies business,” notes Rabinovitch.

“And while that look may still be fine for other perogies manufacturers, we were really looking to grow our business into more mainstream markets— rather than just continue be known as a niche foods manufacturer selling to niche food outlets.”

After making a fairly radical switch to preprinted, nine-color, reclosable plastic bags purchased from a Chinese-based supplier, Rabinovitch did note that while many of its Eastern European constituents seemed naturally resistant to the decidedly more “western” look of the new package, vendors welcomed the new look. And now, having the Pelman brand now sold in high-end fine-food stores like the Toronto-based Pusateri’s Fine Foods, Rabinovitch feels totally vindicated about the packaging makeover.

“There is no way our old packaging could have passed the muster at a store like Pusateri’s or at any of the other larger major grocery store retailers we are dealing with, but now our product is literally flying off the shelves,” Rabinovitch extols.

“It hurts to lose a few long-time customers, but there just seems to be a mentality that perogies have to come in cheap-looking packaging, and we are doing our best to change that perception,” says Rabinovitch, adding that not only is he proud to stand by his product, but that unlike much of his company’s Canadian-based competition, he is not willing to compromise on the quality of his products under any circumstances.

“Pelmen Foods is the only perogies manufacturer in Canada that exclusively uses only fresh products and ingredients,” he proclaims.

“We use fresh potatoes, not flakes, and real cheddar cheese, not powdered cheese, with no artificial flavoring, coloring or preservatives added whatsoever,” Rabinovitch stresses. “When you bite into Pelmen perogies, you are tasting real, authentic, traditional perogies.”

Moreover, Rabinovitch points out that the filling-to-dough ratio of the Pelmen brands at 60 per cent filling versus 40 per cent dough is the opposite of the industry average, thereby commanding a certain price premium.

Sold to both retail and foodservice industries, Pelmen products offer a superior quality, product authenticity and, most importantly, an incredible taste pro-

file, according to Rabinovitch, as well as a perfectly safe-to-eat product.

Everything Pelmen brings to market is screened by both the Canadian Food Inspection Agency (CFIA) inspectors and the HACCP (Hazard Analysis Critical Control Points) protocols, with the company currently working on achieving the Food Safety System Certification 22000 accreditation and the prestigious, internationally-recognized BRC (British Retail Consortium) certification.

“While we are not yet looking at exporting our products outside of North Anerica, the BRC certification has quickly become known as an important food inspection initiative that customers are looking for before they do business with you, and it is also a very important thing to have for our private-label customers,” Rabinovitch explains.

As a part of its product safety focus, when Pelmen created an all-new production line in 2010, it

Continues on page 22

Continued from page 21

purchased a new Eagle Pack 240 X-Ray system, manufactured by Smiths Detection Product Inspection, a Tampa, Fla.-based developer and manufacturer of X-Ray inspection systems that was purchased by the Mettler-Toledo International Inc. group in March of 2011.

Supplied and installed by Smiths Detection’s Canadian distributors Plan Automation of Orangeville, Ont., the Eagle Pack 240 X-Ray was selected by Pelman for its robust detection capabilities that would ensure optimal quality control at the plant by detecting the tiniest contaminants, along with providing high-precision checkweighing capabilities in the same machine.

An option that Pelmen purchased for the Eagle Pack 240 is a Festo Inc. pneumatic rejection system that blows contaminated or incorrectly-weighted packages from the line and into separate bins.

“I chose to purchase an X-Ray detection system primarily because of the technology’s reputation for reliable performance when working in a cold environment,” says Rabinovitch, “but it is also nice to have this X-Ray system act as a secondary checkweigher, so that it can be programmed to reject filled bags of the weight that are not within the set parameters, as well if it detects something

that shouldn’t be inside.”

Capable of high-speed detection of stainless steel, ferrous and non-ferrous metal particles as small as 1.2 mm, as well as glass shards as small as 1.5 mm, the Eagle Pack 240 system was a wise capital investment for the Pelmen plant, says Rabinovitch, citing the system’s multiple inspection capabilities and robust line speeds of up to 300 items per minute, while offering high-speed imaging up to 400 frames per minute.

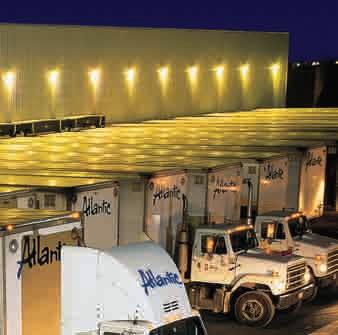

Such capabilities are more than sufficient for the needs of the Pelman Foods plant, whose bagging line fills frozen perogies at an average rate of about 25 bags per minute, after which they are immediately sent to the Eagle Pack 240 X-Ray system for a full inspection, and eventually hand-placed by the dozen into corrugated cartons, manufactured by

Atlantic Packaging Product Ltd., before being stored in a cold room to await same-day shipment to customers.